Modeling and Experimental Validation of the VARTM Process for Thin-Walled Preforms

Abstract

:1. Introduction

2. Model of Resin Infusion in the Deformable Preform

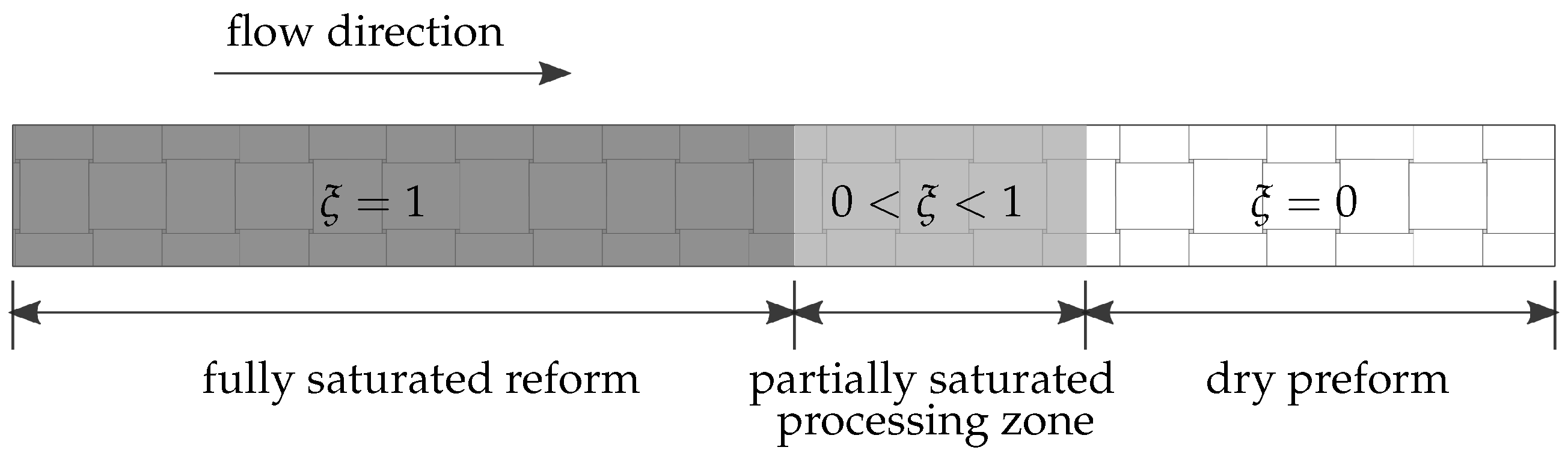

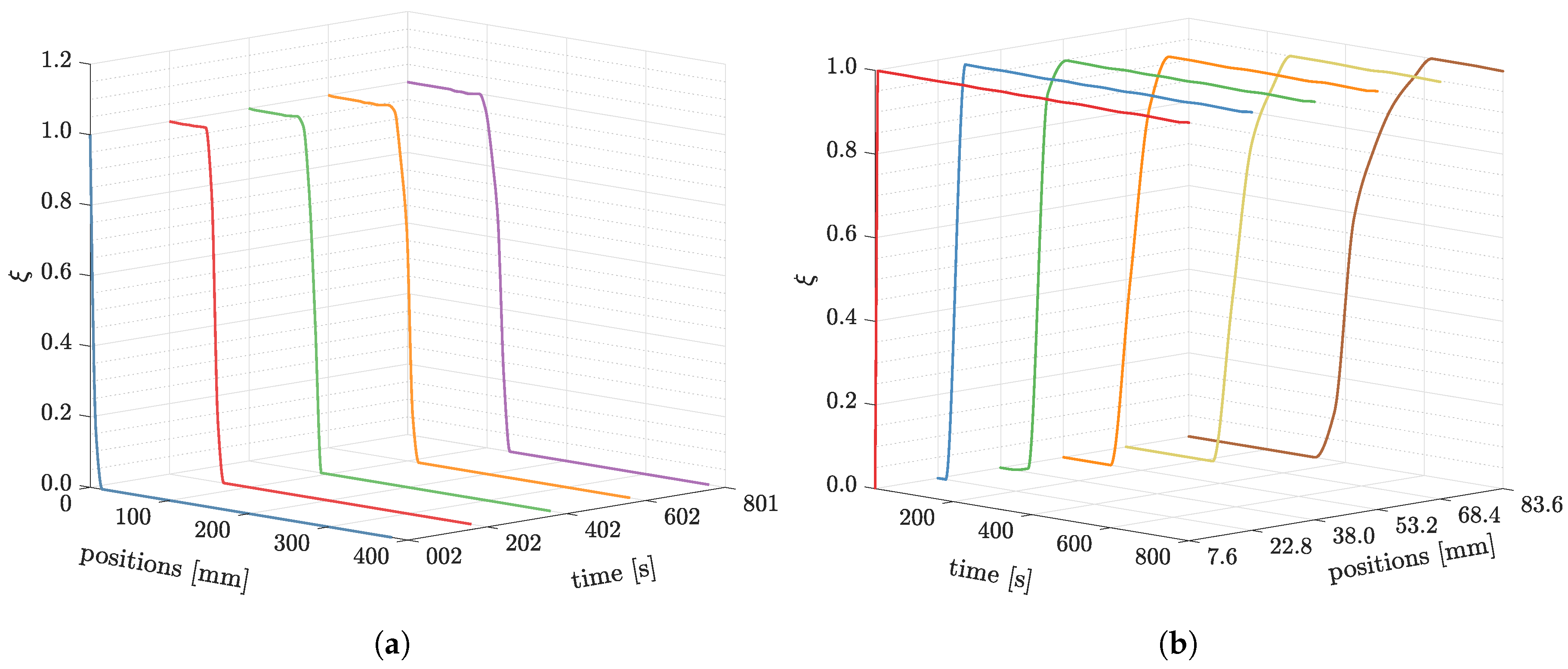

2.1. Saturation Degree

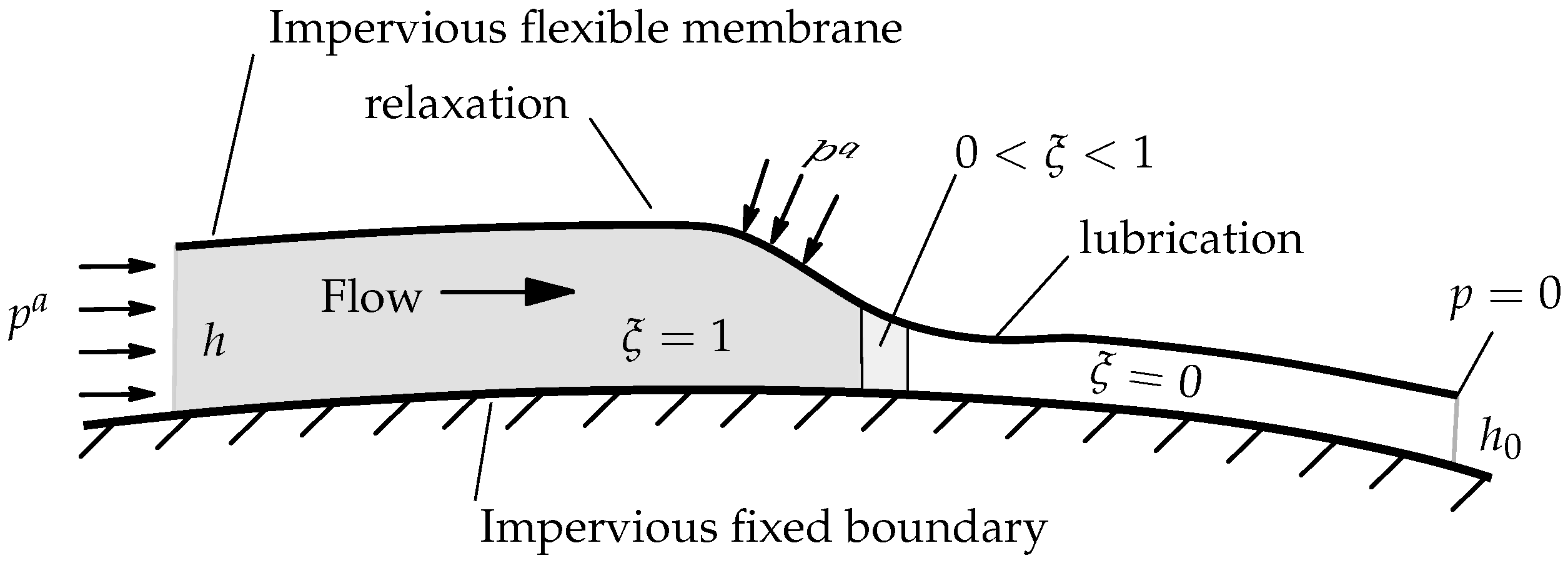

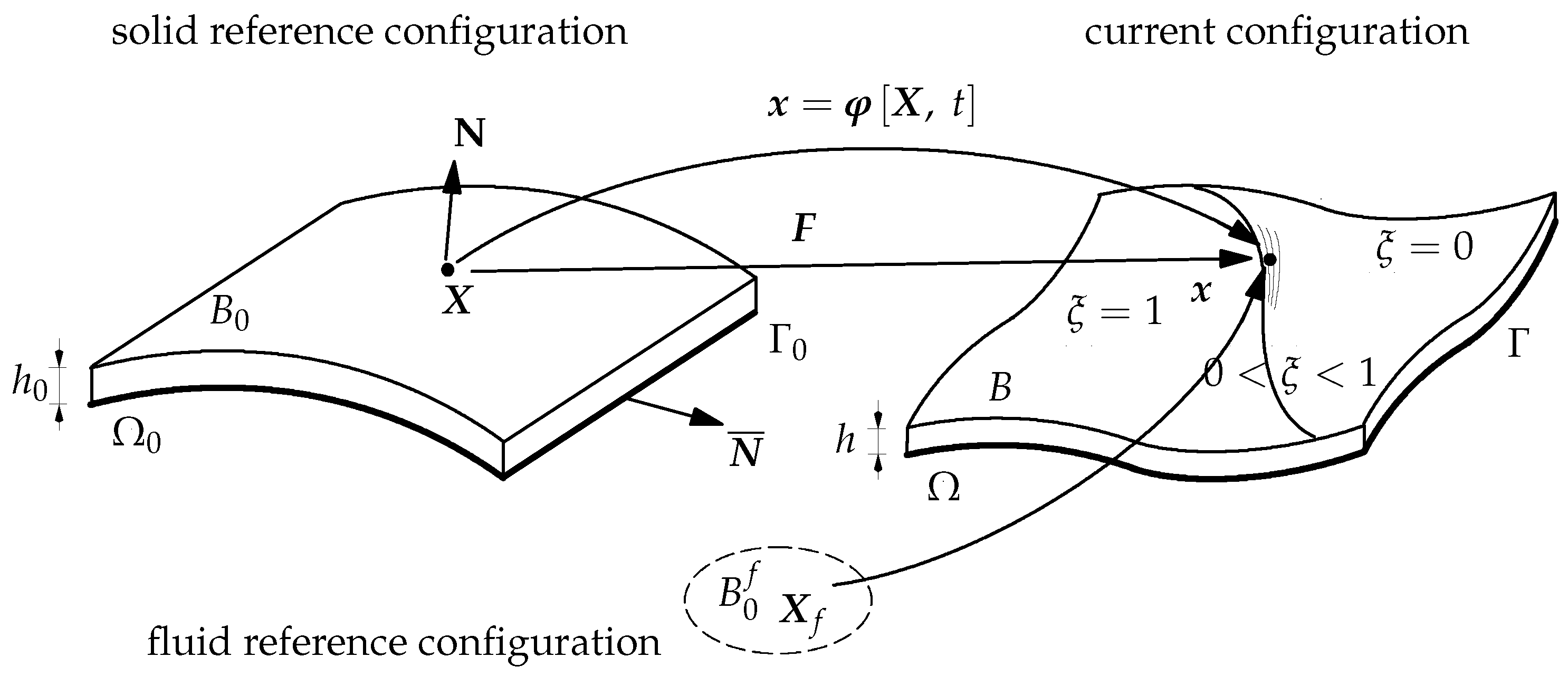

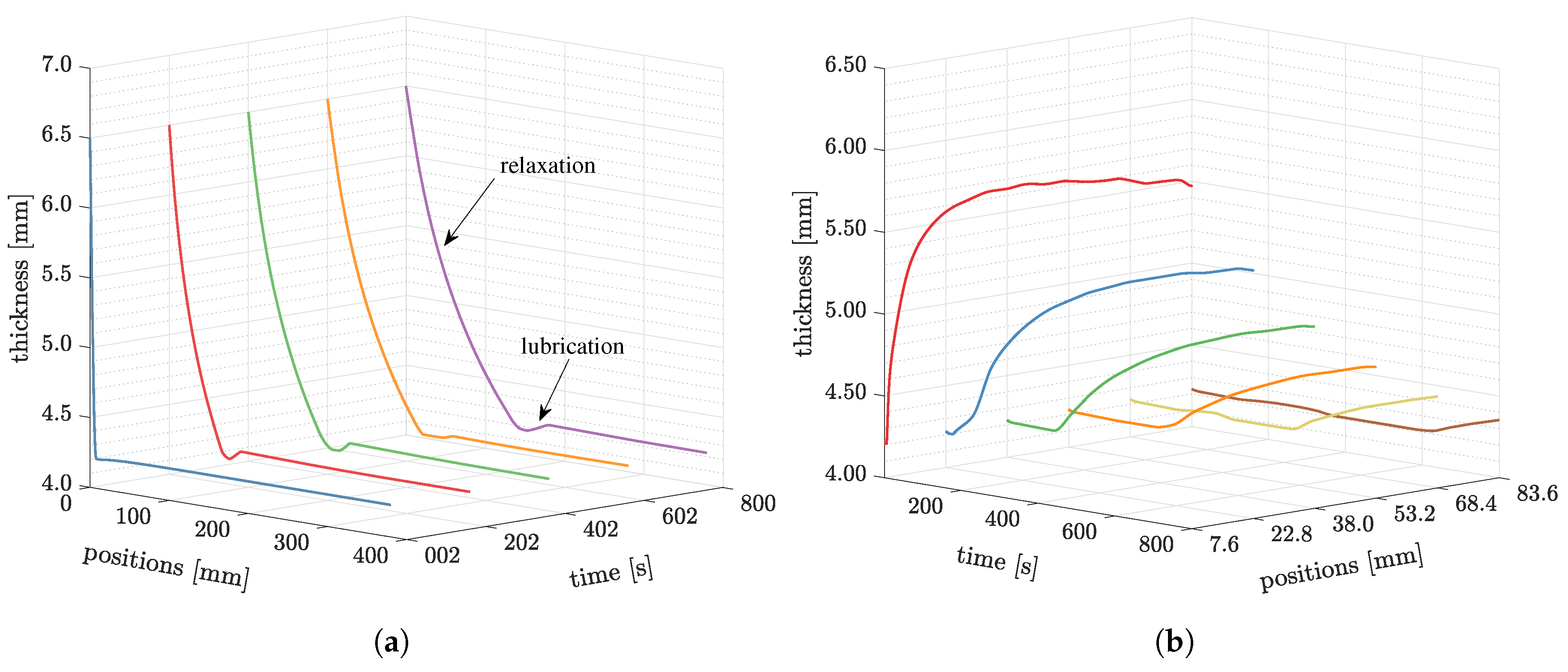

2.2. Kinematics of the (Un-)Saturated Thin-Walled Preform

2.3. In-Plane Darcy Flow

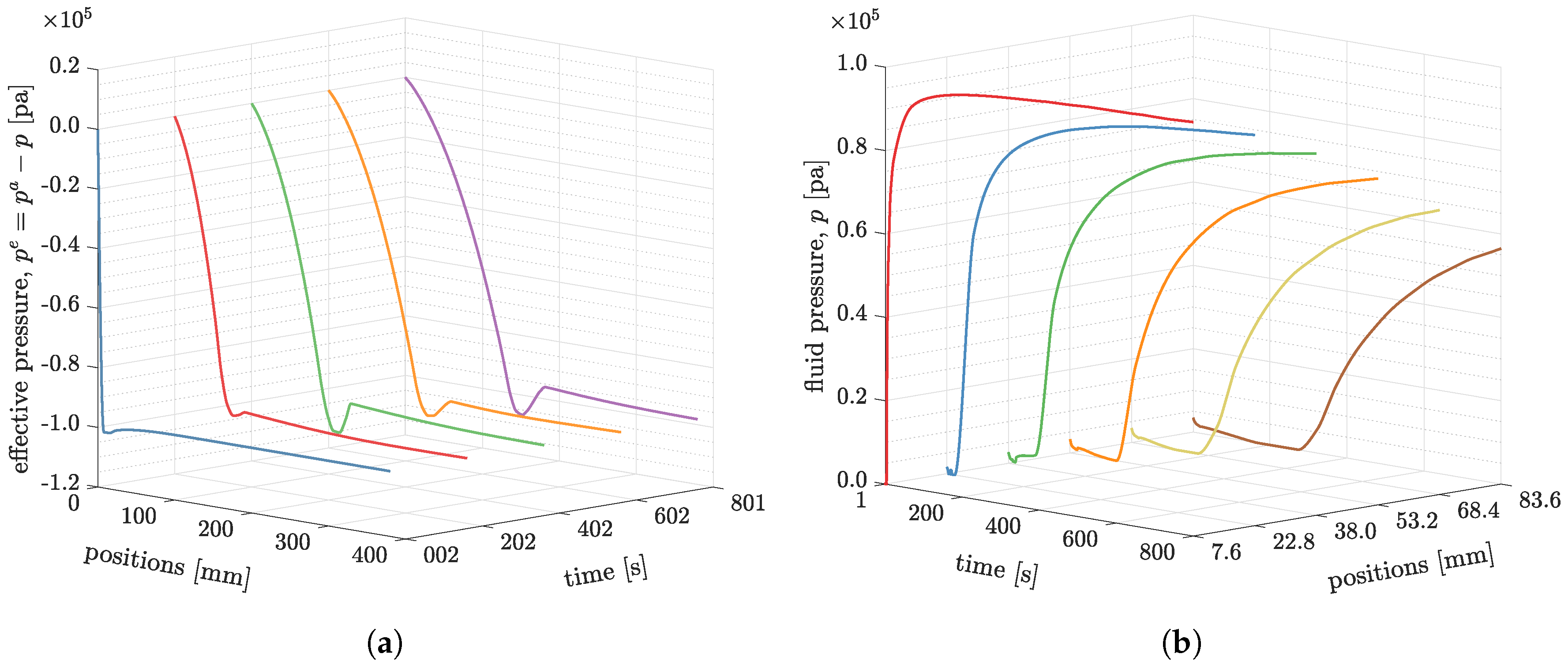

2.4. Constitutive Relations

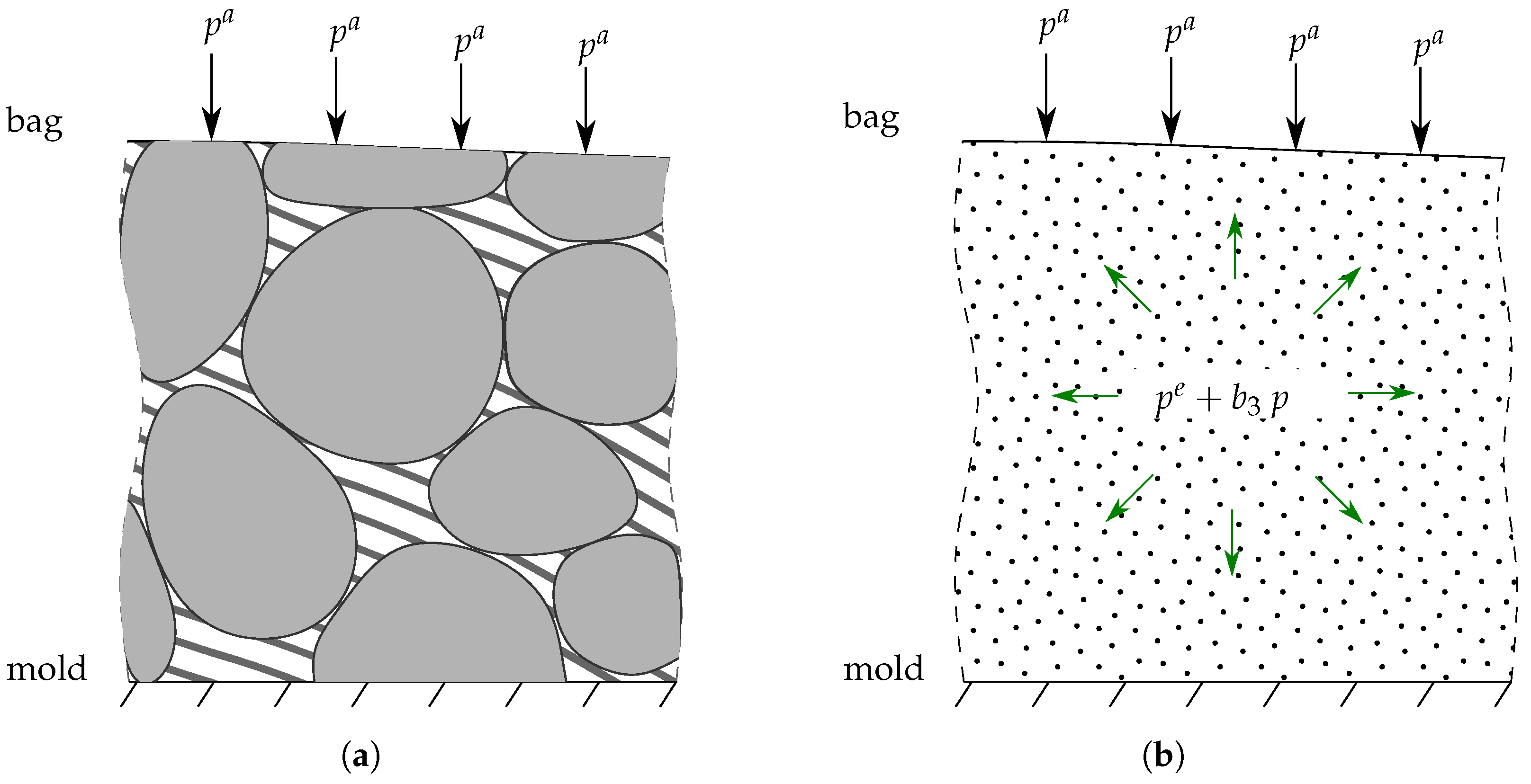

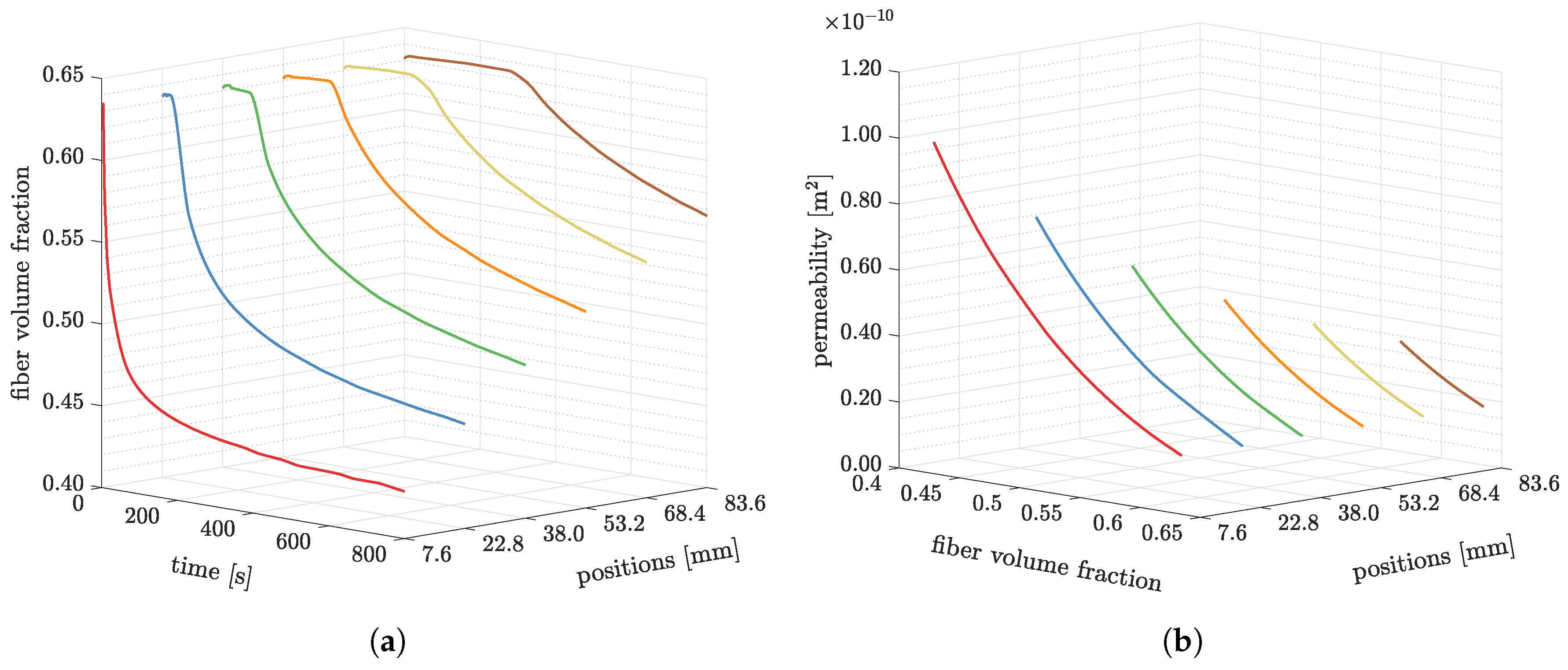

2.4.1. Fiber Preform Compaction

2.4.2. Capillary Pressure and Universal Gas Law

2.4.3. In-Plane Darcy Resin Flow in the Unsaturated Preform

3. Experiments

3.1. Materials

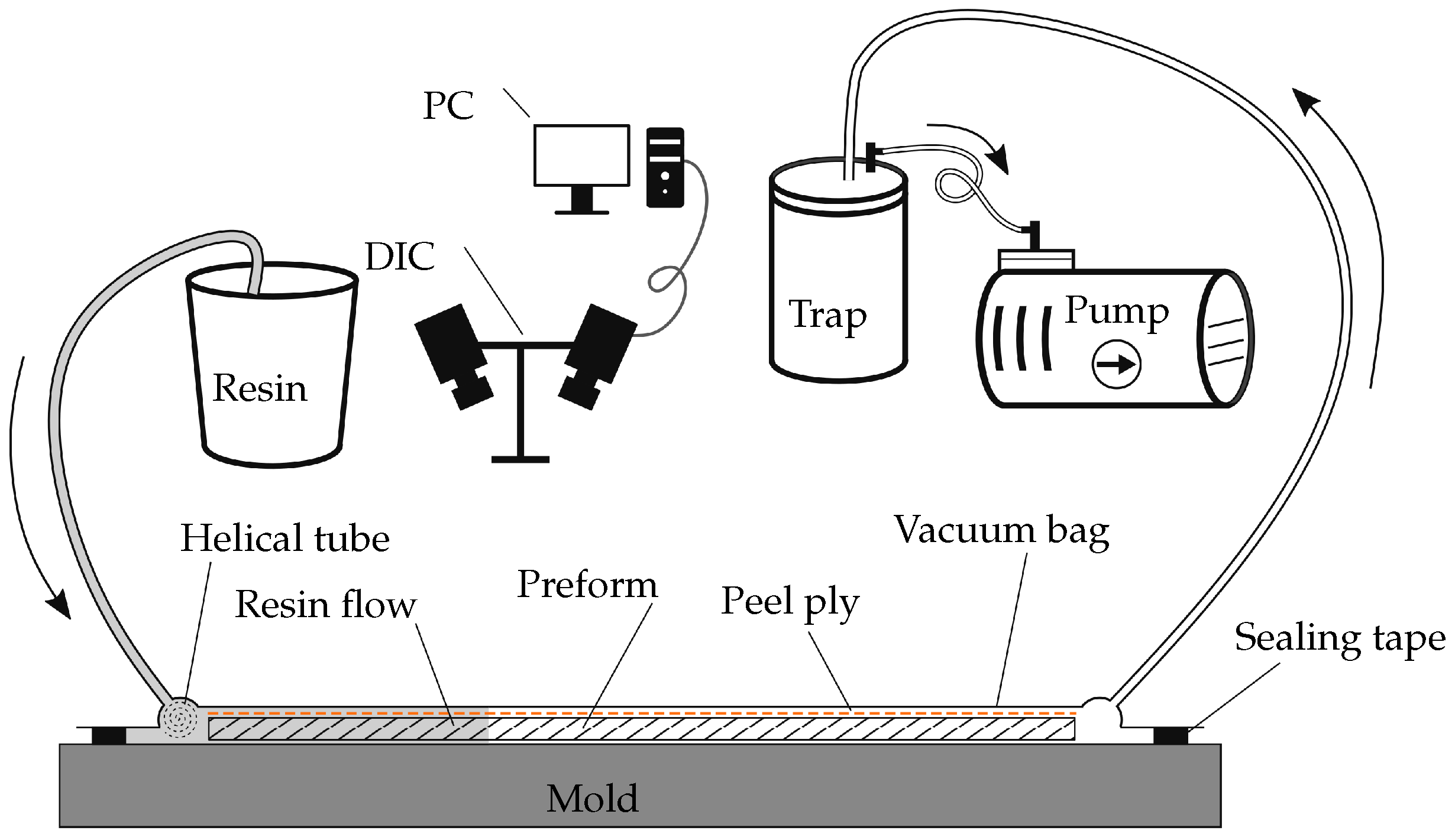

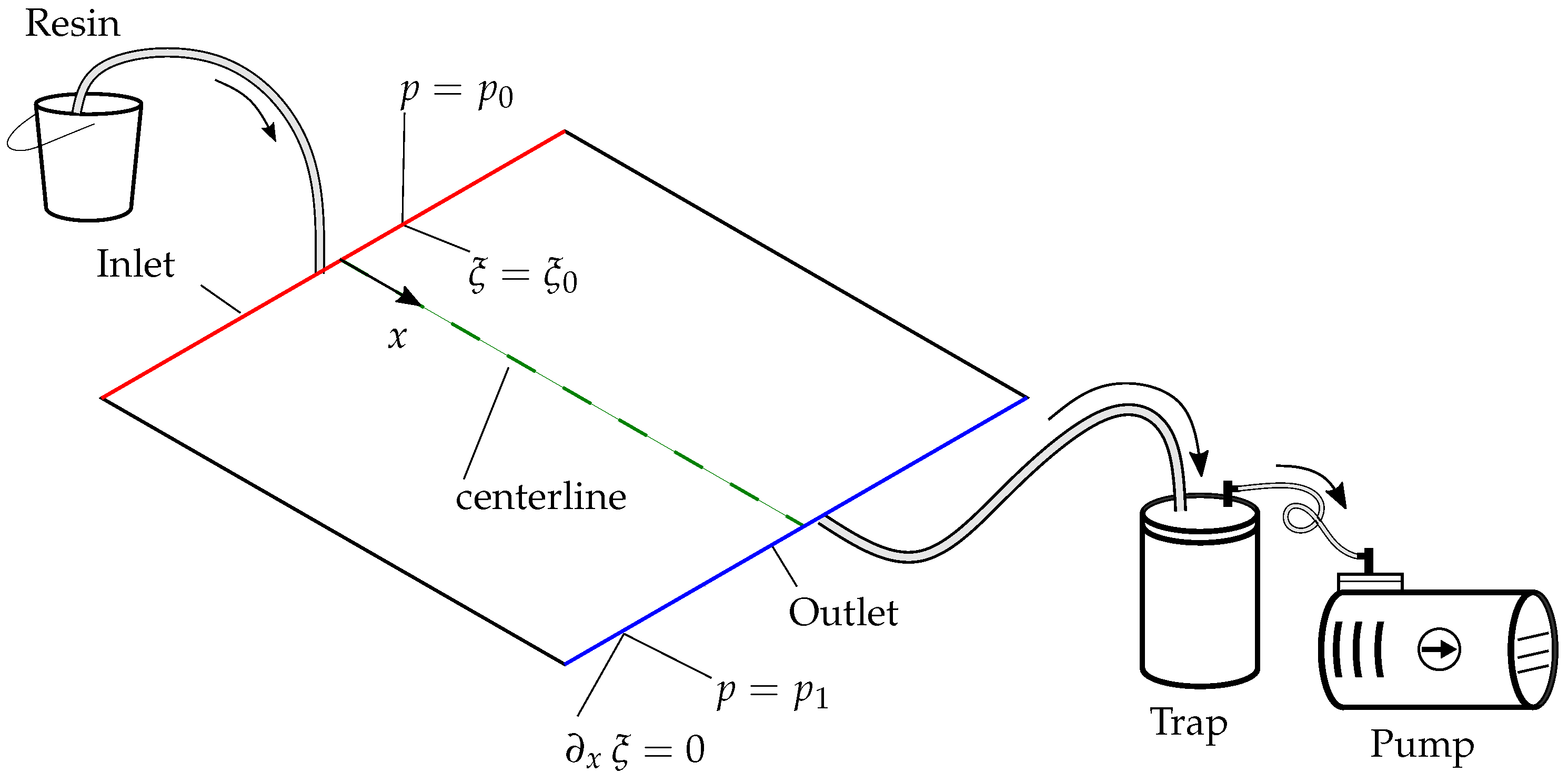

3.2. Experiment Set-Up and Process

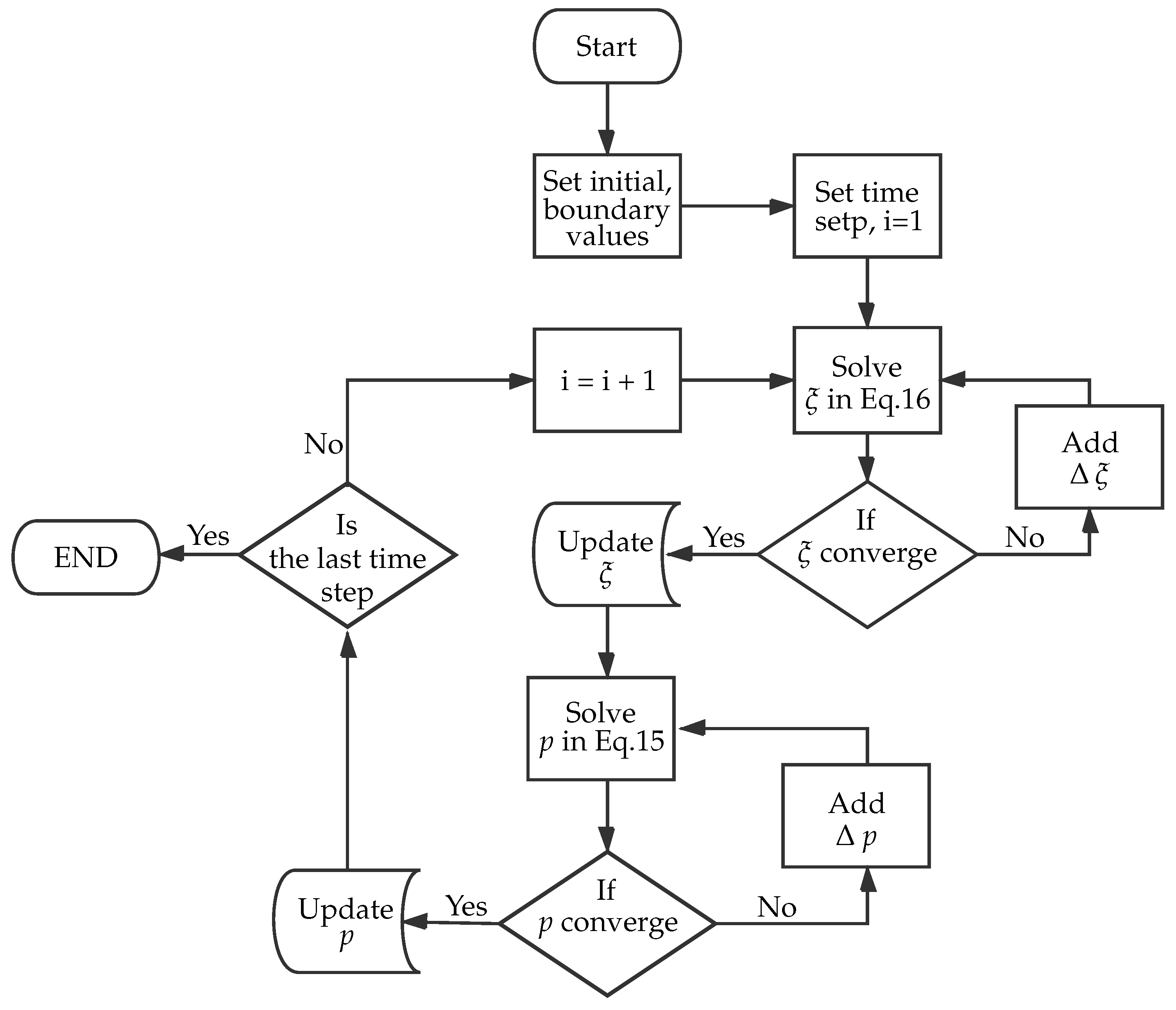

4. Numerical Simulation

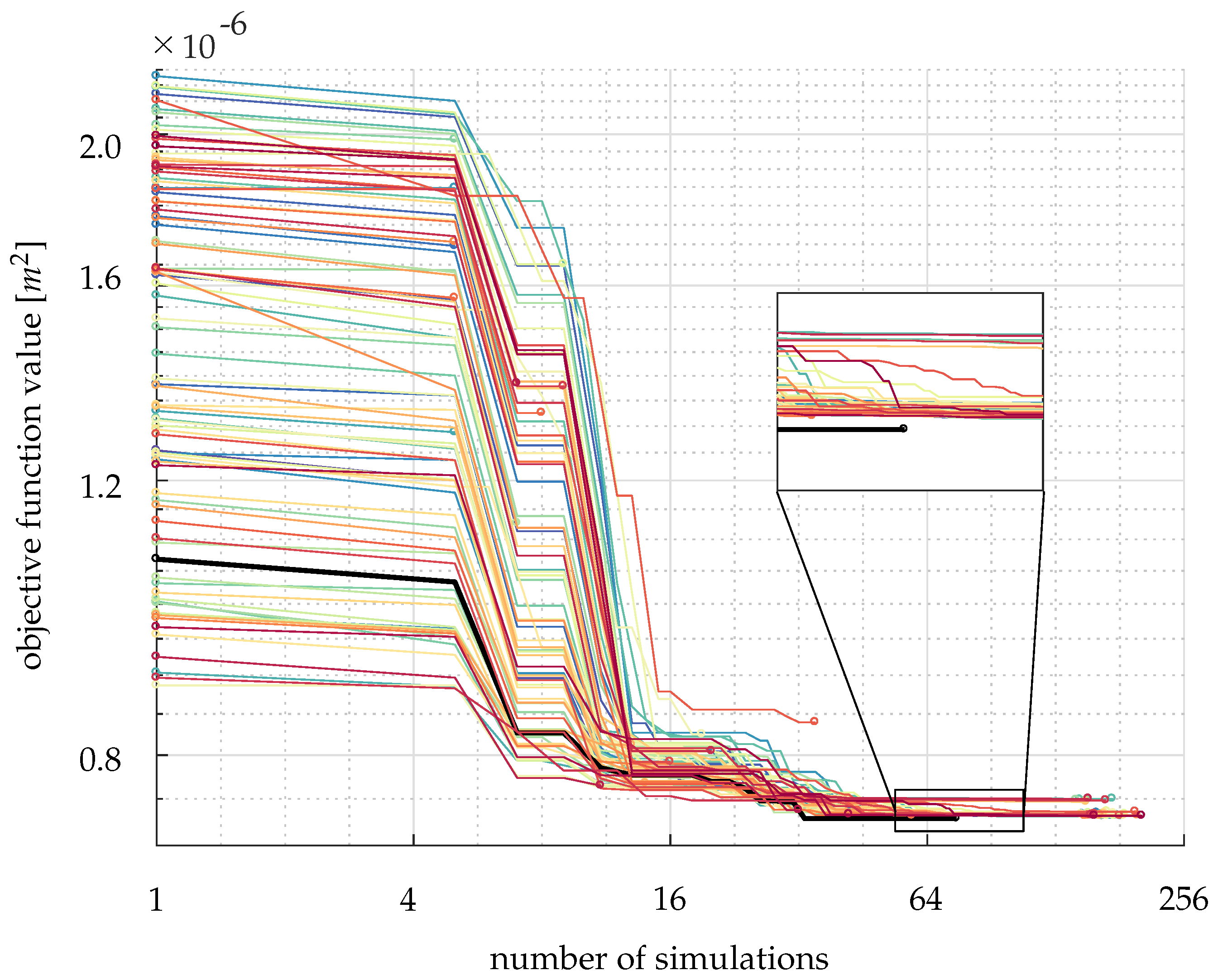

5. Results and Discussion

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Gloria, A.; Maietta, S.; Martorelli, M.; Lanzotti, A.; Watts, D.C.; Ausiello, P. FE analysis of conceptual hybrid composite endodontic post designs in anterior teeth. Dent. Mater. 2018, 34, 1063–1071. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Asp, L.E.; Johansson, M.; Lindbergh, G.; Xu, J.; Zenkert, D. Structural battery composites: A review. Funct. Compos. Struct. 2019, 1, 042001. [Google Scholar] [CrossRef]

- Advani, S.G.; Hsiao, K.T. Manufacturing Techniques for Polymer Matrix Composites (PMCs); Elsevier: Amsterdam, The Netherlands, 2012. [Google Scholar]

- Harshe, R. A Review on Advanced Out-of-Autoclave Composites Processing. J. Indian Inst. Sci. 2015, 95, 207–220. [Google Scholar]

- Park, C.H.; Woo, L. Modeling void formation and unsaturated flow in liquid composite molding processes: A survey and review. J. Reinf. Plast. Compos. 2011, 30, 957–977. [Google Scholar] [CrossRef]

- Lawrence, J.M.; Simacek, P.; Frey, P.; Bhat, P.; Gebauer, T.; Advani, S.G. The Compaction Behavior of Fibrous Preform Materials during the VARTM Infusion. AIP Conf. Proc. 2007, 907, 1039–1045. [Google Scholar] [CrossRef]

- Tackitt, K.D.; Walsh, S.M. Experimental Study of Thickness Gradient Formation in the VARTM Process. Mater. Manuf. Process. 2005, 20, 607–627. [Google Scholar] [CrossRef]

- Vaidya, U.K.; Jadhav, N.C.; Hosur, M.V.; Gillespie, J.W.; Fink, B.K. Assessment of flow and cure monitoring using direct current and alternating current sensing in vacuum-assisted resin transfer molding. Smart Mater. Struct. 2000, 9, 727–736. [Google Scholar] [CrossRef]

- Luthy, T.; Ermanni, P. Flow monitoring in liquid composite molding based on linear direct current sensing technique. Polym. Compos. 2003, 24, 249–262. [Google Scholar] [CrossRef]

- Lekakou, C.; Cook, S.; Deng, Y.; Ang, T.; Reed, G. Optical fibre sensor for monitoring flow and resin curing in composites manufacturing. Compos. Part A Appl. Sci. Manuf. 2006, 37, 934–938. [Google Scholar] [CrossRef]

- Danisman, M.; Tuncol, G.; Kaynar, A.; Sozer, E.M. Monitoring of resin flow in the resin transfer molding (RTM) process using point-voltage sensors. Compos. Sci. Technol. 2007, 67, 367–379. [Google Scholar] [CrossRef]

- Carlone, P.; Palazzo, G.S. Unsaturated and Saturated Flow Front Tracking in Liquid Composite Molding Processes using Dielectric Sensors. Appl. Compos. Mater. 2015, 22, 543–557. [Google Scholar] [CrossRef]

- Hammami, A.; Gebart, B.R. Analysis of the vacuum infusion molding process. Polym. Compos. 2000, 21, 28–40. [Google Scholar] [CrossRef]

- Correia, N.C.; Robitaille, F.; Long, A.C.; Rudd, C.D.; Šimáček, P.; Advani, S.G. Analysis of the vacuum infusion moulding process: I. Analytical formulation. Compos. Part A Appl. Sci. Manuf. 2005, 36, 1645–1656. [Google Scholar] [CrossRef]

- Fracassi, F.T.; Donadon, M.V. Simulation of vacuum assisted resin transfer molding process through dynamic system analysis. J. Compos. Mater. 2018, 52, 3759–3771. [Google Scholar] [CrossRef]

- Pillai, K.M. Modeling the Unsaturated Flow in Liquid Composite Molding Processes: A Review and Some Thoughts. J. Compos. Mater. 2004, 38, 2097–2118. [Google Scholar] [CrossRef]

- Nordlund, M.; Michaud, V. Dynamic saturation curve measurement for resin flow in glass fibre reinforcement. Compos. Part A Appl. Sci. Manuf. 2012, 43, 333–343. [Google Scholar] [CrossRef]

- Michaud, V. A Review of Non-saturated Resin Flow in Liquid Composite Moulding processes. Transp. Porous Media 2016, 115, 581–601. [Google Scholar] [CrossRef]

- Hsiao, K.T.; Mathur, R.; Advani, S.G.; Gillespie, J.W.; Fink, B.K. A Closed Form Solution for Flow During the Vacuum Assisted Resin Transfer Molding Process. J. Manuf. Sci. Eng. 2000, 122, 463. [Google Scholar] [CrossRef]

- Soukane, S.; Trochu, F. Application of the level set method to the simulation of resin transfer molding. Compos. Sci. Technol. 2006, 66, 1067–1080. [Google Scholar] [CrossRef]

- Lawrence, J.M.; Neacsu, V.; Advani, S.G. Modeling the impact of capillary pressure and air entrapment on fiber tow saturation during resin infusion in LCM. Compos. Part A Appl. Sci. Manuf. 2009, 40, 1053–1064. [Google Scholar] [CrossRef]

- Li, M.; Wang, S.; Gu, Y.; Zhang, Z.; Li, Y.; Potter, K. Dynamic capillary impact on longitudinal micro-flow in vacuum assisted impregnation and the unsaturated permeability of inner fiber tows. Compos. Sci. Technol. 2010, 70, 1628–1636. [Google Scholar] [CrossRef]

- García, J.; Gascón, L.; Chinesta, F.; Ruiz, E.; Trochu, F. An efficient solver of the saturation equation in liquid composite molding processes. Int. J. Mater. Form. 2010, 3, 1295–1302. [Google Scholar] [CrossRef] [Green Version]

- Yeager, M.; Hwang, W.R.; Advani, S.G. Prediction of capillary pressure for resin flow between fibers. Compos. Sci. Technol. 2016, 126, 130–138. [Google Scholar] [CrossRef]

- Wu, D.; Larsson, R. Homogenized free surface flow in porous media for wet-out processing. Int. J. Numer. Methods Eng. 2018, 1. [Google Scholar] [CrossRef]

- Andriamananjara, K.; Moulin, N.; Bruchon, J.; Liotier, P.J.; Drapier, S. Numerical modeling of local capillary effects in porous media as a pressure discontinuity acting on the interface of a transient bi-fluid flow. Int. J. Mater. Form. 2018. [Google Scholar] [CrossRef]

- Pillai, K.M.; Advani, S.G. A Model for Unsaturated Flow in Woven Fiber Preforms during Mold Filling in Resin Transfer Molding. J. Compos. Mater. 1998, 32, 1753–1783. [Google Scholar] [CrossRef]

- Dungan, F.D.; Sastry, A.M. Saturated and Unsaturated Polymer Flows: Microphenomena and Modeling. J. Compos. Mater. 2002, 36, 1581–1603. [Google Scholar] [CrossRef]

- Simacek, P.; Advani, S.G. A numerical model to predict fiber tow saturation during liquid composite molding. Compos. Sci. Technol. 2003, 63, 1725–1736. [Google Scholar] [CrossRef]

- Kuentzer, N.; Simacek, P.; Advani, S.G.; Walsh, S. Correlation of void distribution to VARTM manufacturing techniques. Compos. Part A Appl. Sci. Manuf. 2007, 38, 802–813. [Google Scholar] [CrossRef]

- Zhou, F.; Alms, J.; Advani, S.G. A closed form solution for flow in dual scale fibrous porous media under constant injection pressure conditions. Compos. Sci. Technol. 2008, 68, 699–708. [Google Scholar] [CrossRef]

- Tan, H.; Pillai, K.M. Fast liquid composite molding simulation of unsaturated flow in dual-scale fiber mats using the imbibition characteristics of a fabric-based unit cell. Polym. Compos. 2010, 31, 1790–1807. [Google Scholar] [CrossRef]

- Gascón, L.; García, J.A.; LeBel, F.; Ruiz, E.; Trochu, F. Numerical prediction of saturation in dual scale fibrous reinforcements during Liquid Composite Molding. Compos. Part A Appl. Sci. Manuf. 2015, 77, 275–284. [Google Scholar] [CrossRef] [Green Version]

- Tan, H.; Pillai, K.M. Multiscale modeling of unsaturated flow in dual-scale fiber preforms of liquid composite molding I: Isothermal flows. Compos. Part A: Appl. Sci. Manuf. 2012, 43, 1–13. [Google Scholar] [CrossRef]

- Yenilmez, B.; Senan, M.; Murat Sozer, E. Variation of part thickness and compaction pressure in vacuum infusion process. Compos. Sci. Technol. 2009, 69, 1710–1719. [Google Scholar] [CrossRef]

- Arulappan, C.; Duraisamy, A.; Adhikari, D.; Gururaja, S. Investigations on pressure and thickness profiles in carbon fiber-reinforced polymers during vacuum assisted resin transfer molding. J. Reinf. Plast. Compos. 2015, 34, 3–18. [Google Scholar] [CrossRef]

- Yalcinkaya, M.A.; Caglar, B.; Sozer, E.M. Effect of permeability characterization at different boundary and flow conditions on vacuum infusion process modeling. J. Reinf. Plast. Compos. 2017, 36, 491–504. [Google Scholar] [CrossRef]

- George, A.; Hannibal, P.; Morgan, M.; Hoagland, D.; Stapleton, S.E. Compressibility measurement of composite reinforcements for flow simulation of vacuum infusion. Polym. Compos. 2019, 40, 961–973. [Google Scholar] [CrossRef]

- Acheson, J.A.; Simacek, P.; Advani, S.G. The implications of fiber compaction and saturation on fully coupled VARTM simulation. Compos. Part A: Appl. Sci. Manuf. 2004, 35, 159–169. [Google Scholar] [CrossRef]

- Li, J.; Zhang, C.; Liang, R.; Wang, B.; Walsh, S. Modeling and analysis of thickness gradient and variations in vacuum-assisted resin transfer molding process. Polym. Compos. 2008, 29, 473–482. [Google Scholar] [CrossRef]

- Bayldon, J.M.; Daniel, I.M. Flow modeling of the VARTM process including progressive saturation effects. Compos. Part A Appl. Sci. Manuf. 2009, 40, 1044–1052. [Google Scholar] [CrossRef]

- Loudad, R.; Saouab, A.; Beauchene, P.; Agogue, R.; Desjoyeaux, B. Numerical modeling of vacuum-assisted resin transfer molding using multilayer approach. J. Compos. Mater. 2017, 51, 3441–3452. [Google Scholar] [CrossRef]

- Rubino, F.; Carlone, P. A Semi-Analytical Model to Predict Infusion Time and Reinforcement Thickness in VARTM and SCRIMP Processes. Polymers 2019, 11, 20. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Parnas, R.S. Liquid Composite Molding; Carl Hanser Verlag GmbH Co KG: Munich, Germany, 2014. [Google Scholar]

- Modi, D.; Correia, N.; Johnson, M.; Long, A.; Rudd, C.; Robitaille, F. Active control of the vacuum infusion process. Compos. Part A Appl. Sci. Manuf. 2007, 38, 1271–1287. [Google Scholar] [CrossRef]

- Wu, D.; Larsson, R. A Shell Model for Resin Flow and Preform Deformation in Thin-walled Composite Manufacturing Processes. Int. J. Mater. Form. 2019. [Google Scholar] [CrossRef] [Green Version]

- Toll, S. Packing mechanics of fiber reinforcements. Polym. Eng. Sci. 1998, 38, 1337–1350. [Google Scholar] [CrossRef]

- Tran, T.; Binetruy, C.; Comas-Cardona, S.; Abriak, N.E. Microporomechanical behavior of perfectly straight unidirectional fiber assembly: Theoretical and experimental. Compos. Sci. Technol. 2009, 69, 199–206. [Google Scholar] [CrossRef]

- Coussy, O. Poromechanics; John Wiley & Sons: Hoboken, NJ, USA, 2004. [Google Scholar]

- Brooks, R.H.; Corey, A.T. Hydraulic Properties of Porous Media and Their Relation to Drainage Design. Trans. ASAE 1964, 7, 26–28. [Google Scholar] [CrossRef]

- Burdine, N. Relative Permeability Calculations From Pore Size Distribution Data. J. Pet. Technol. 1953, 5, 71–78. [Google Scholar] [CrossRef]

- Lagarias, J.C.; Reeds, J.A.; Wright, M.H.; Wright, P.E. Convergence Properties of the Nelder–Mead Simplex Method in Low Dimensions. SIAM J. Optim. 1998, 9, 112–147. [Google Scholar] [CrossRef] [Green Version]

| Item | Identification | Value |

|---|---|---|

| fabric | longitudinal permeability, | m |

| transverse permeability, | m | |

| fiber volume fraction, | ||

| resin | density, | 930 kg/m |

| viscosity, | Pa · s |

| Parameters | Unit | Identification | Value |

|---|---|---|---|

| [m] | preform thickness | 6.5 | |

| [Pa· s] | gas viscosity | 1.983 | |

| - | capillary pressure constant | 4.5 | |

| [Pa] | entry pressure | ||

| [Pa] | atmospheric pressure | ||

| [kg/mol] | gas molar mass | ||

| R | [J/K· mol] | ideal gas constant | 8.314 |

| T | [K] | absolute temperature | 293 |

| [Pa] | packing stiffness | ||

| m | - | packing law exponent | 6.0 |

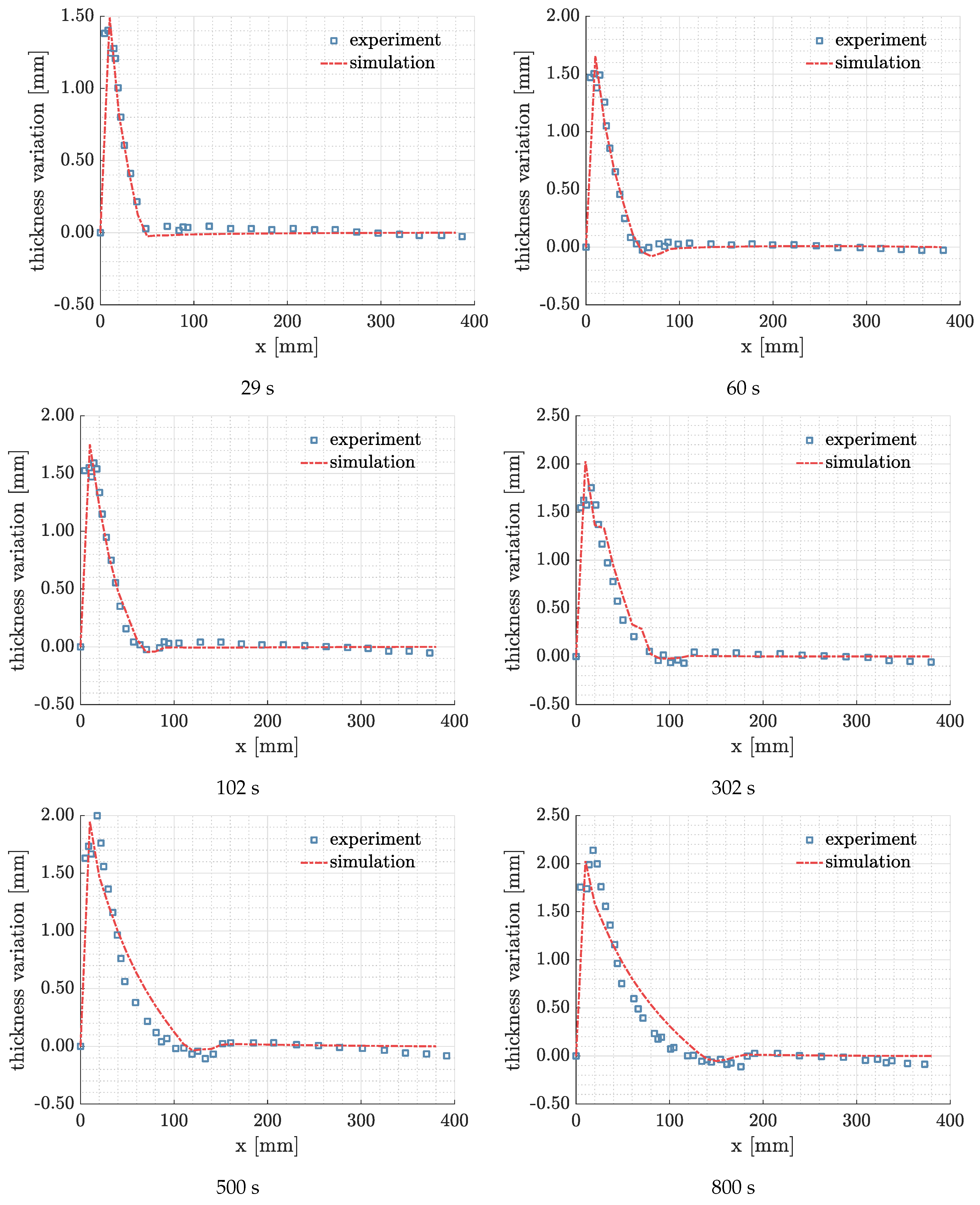

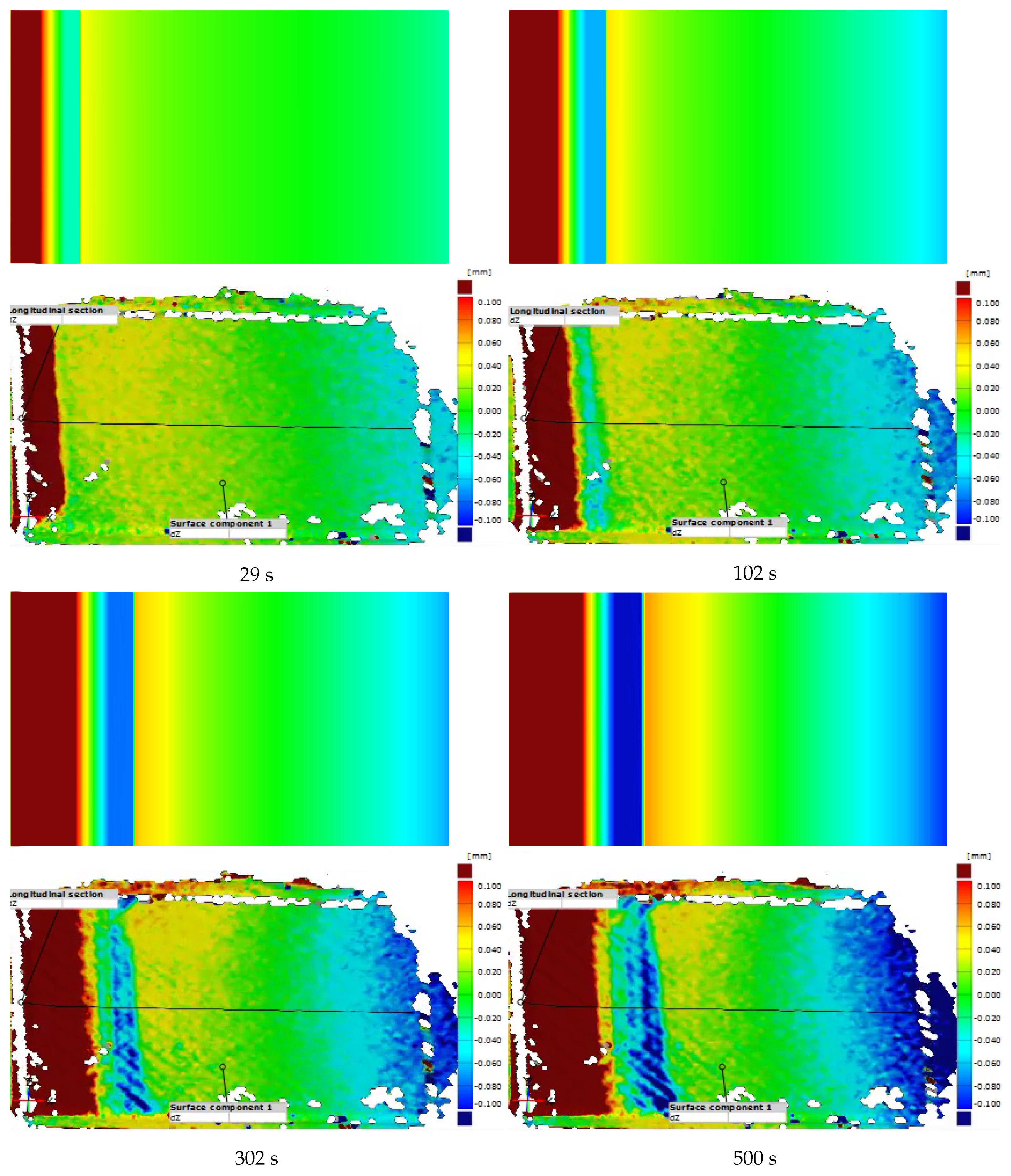

| Time [s] | 29 | 60 | 102 | 302 | 500 | 800 |

|---|---|---|---|---|---|---|

| [%] | 8.81 | 2.91 | 2.01 | 13.42 | 8.91 | 6.89 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, D.; Larsson, R.; Rouhi, M.S. Modeling and Experimental Validation of the VARTM Process for Thin-Walled Preforms. Polymers 2019, 11, 2003. https://doi.org/10.3390/polym11122003

Wu D, Larsson R, Rouhi MS. Modeling and Experimental Validation of the VARTM Process for Thin-Walled Preforms. Polymers. 2019; 11(12):2003. https://doi.org/10.3390/polym11122003

Chicago/Turabian StyleWu, Da, Ragnar Larsson, and Mohammad S. Rouhi. 2019. "Modeling and Experimental Validation of the VARTM Process for Thin-Walled Preforms" Polymers 11, no. 12: 2003. https://doi.org/10.3390/polym11122003

APA StyleWu, D., Larsson, R., & Rouhi, M. S. (2019). Modeling and Experimental Validation of the VARTM Process for Thin-Walled Preforms. Polymers, 11(12), 2003. https://doi.org/10.3390/polym11122003