Improving the Continuous Microcellular Extrusion Foaming Ability with Supercritical CO2 of Thermoplastic Polyether Ester Elastomer through In-Situ Fibrillation of Polytetrafluoroethylene

Abstract

:1. Introduction

2. Experimental Section

2.1. Materials

2.2. Nanocomposite Preparation and Characterization

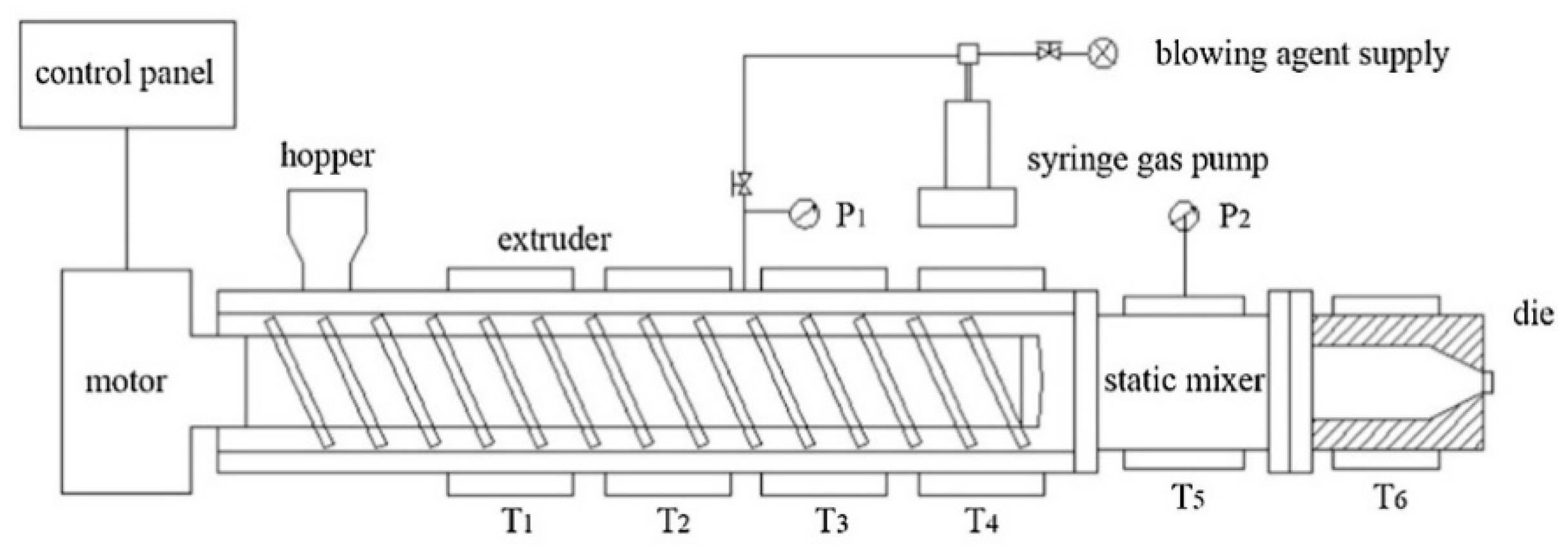

2.3. Extrusion Foaming of TPEE/PTFE Fibril Nanocomposites

2.4. Morphological Characterization of the TPEE/PTFE Nanocomposites

2.5. Rheological Tests

2.6. Thermal Analysis

2.7. Polarized Optical Microscopy (POM) Measurements

2.8. Foam Characterization

3. Results and Discussion

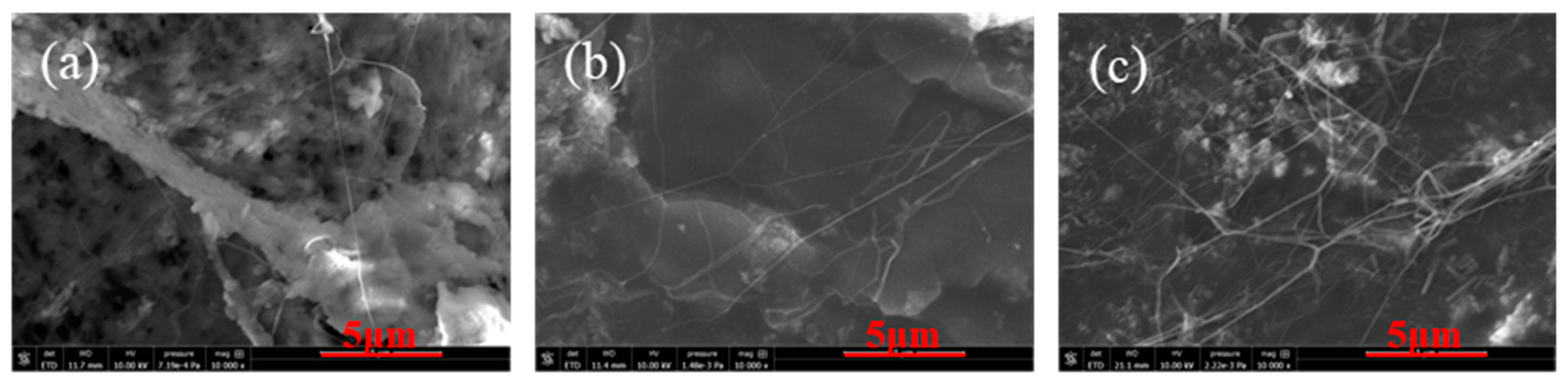

3.1. Morphology of TPEE/PTFE Nanocomposites

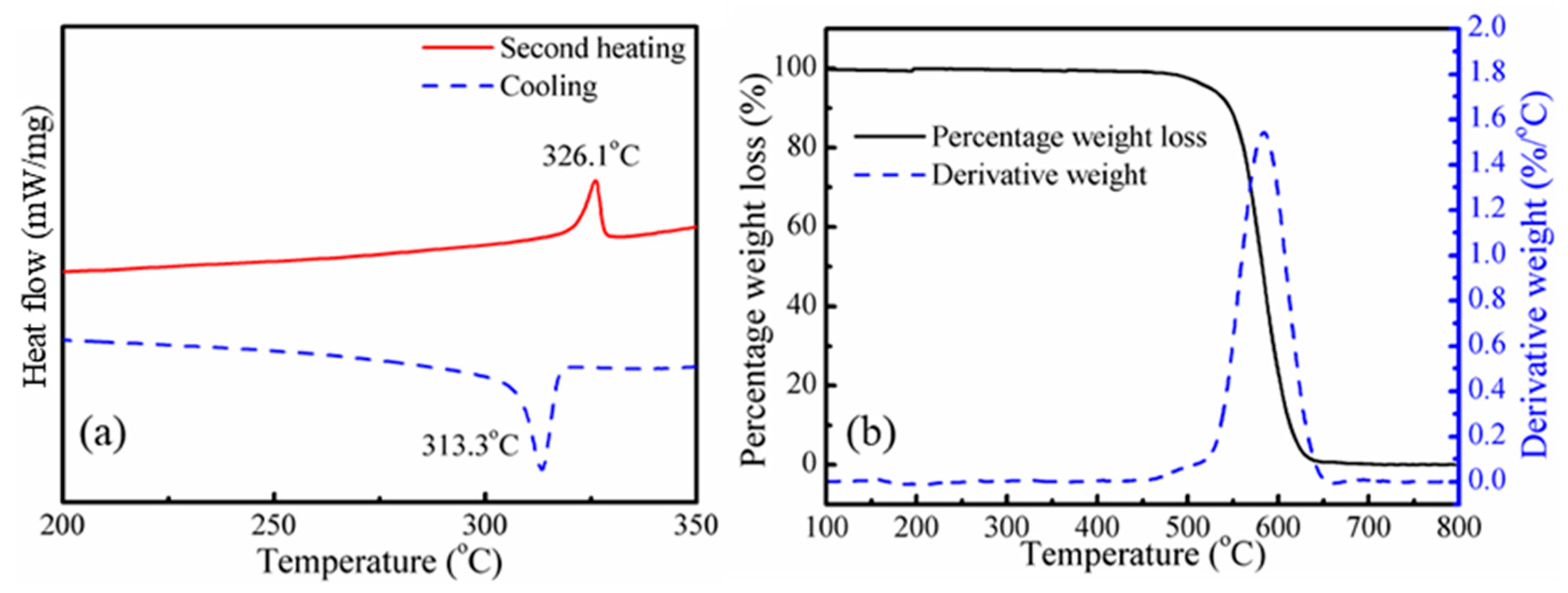

3.2. Thermal Properties of PTFE Fibrils

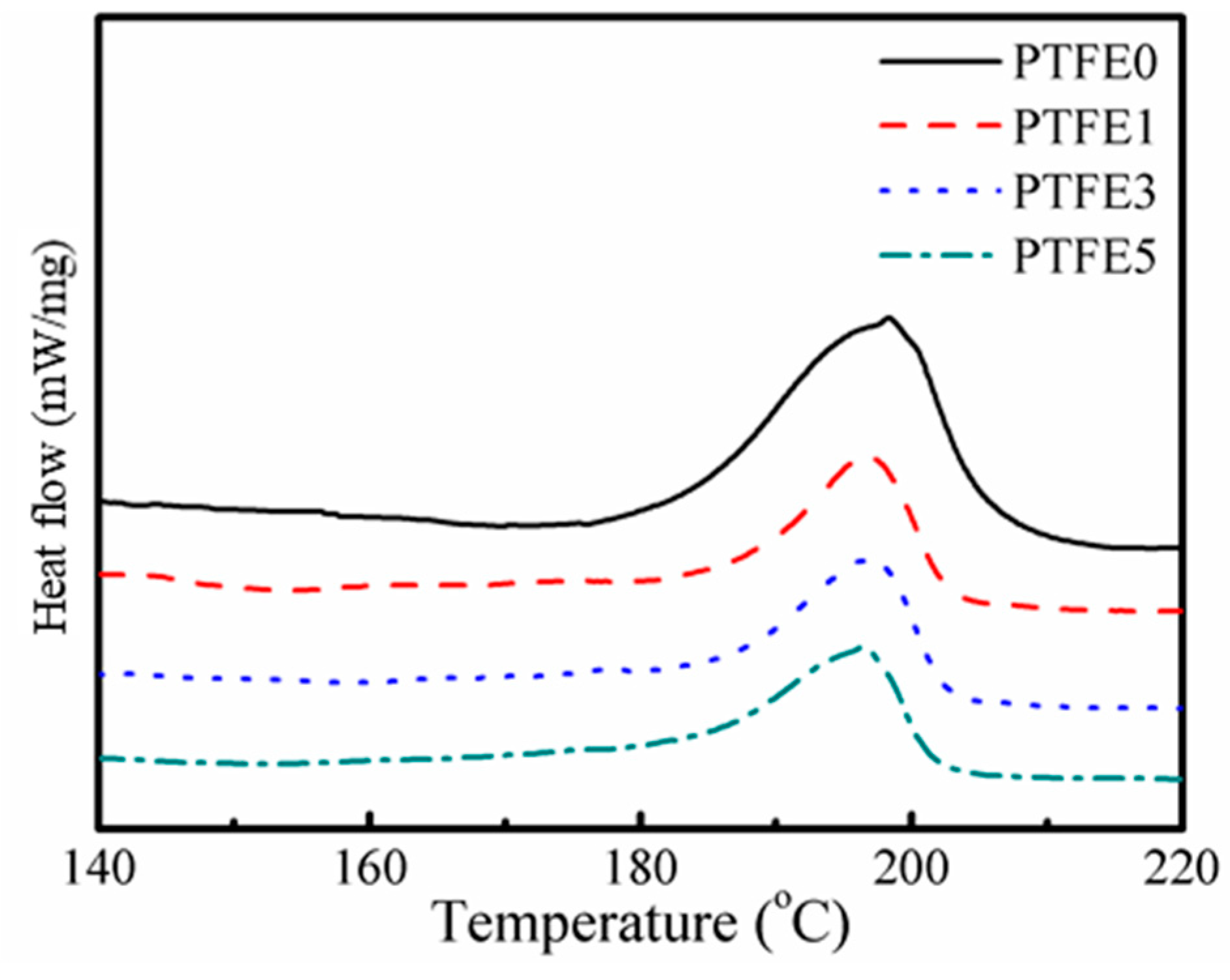

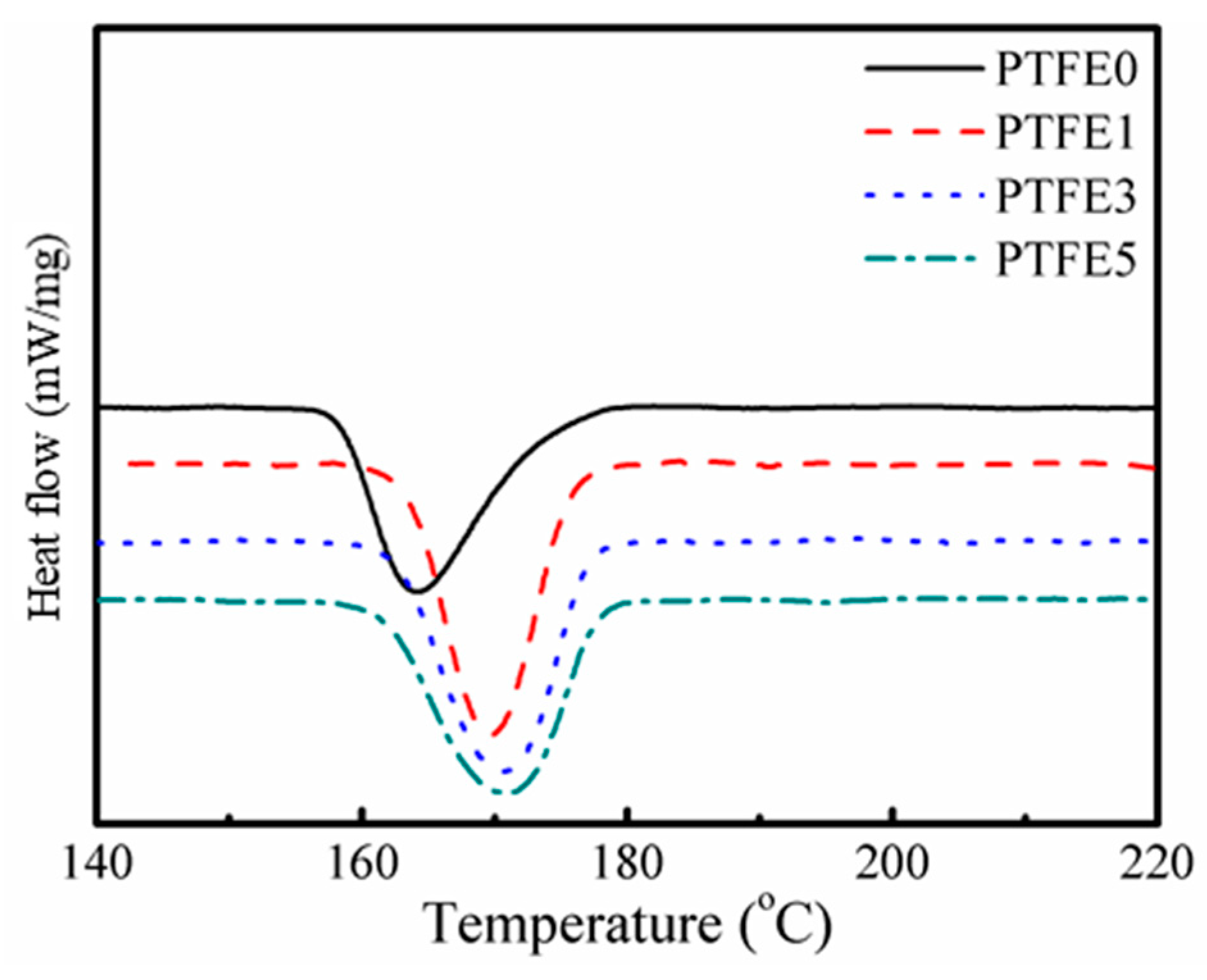

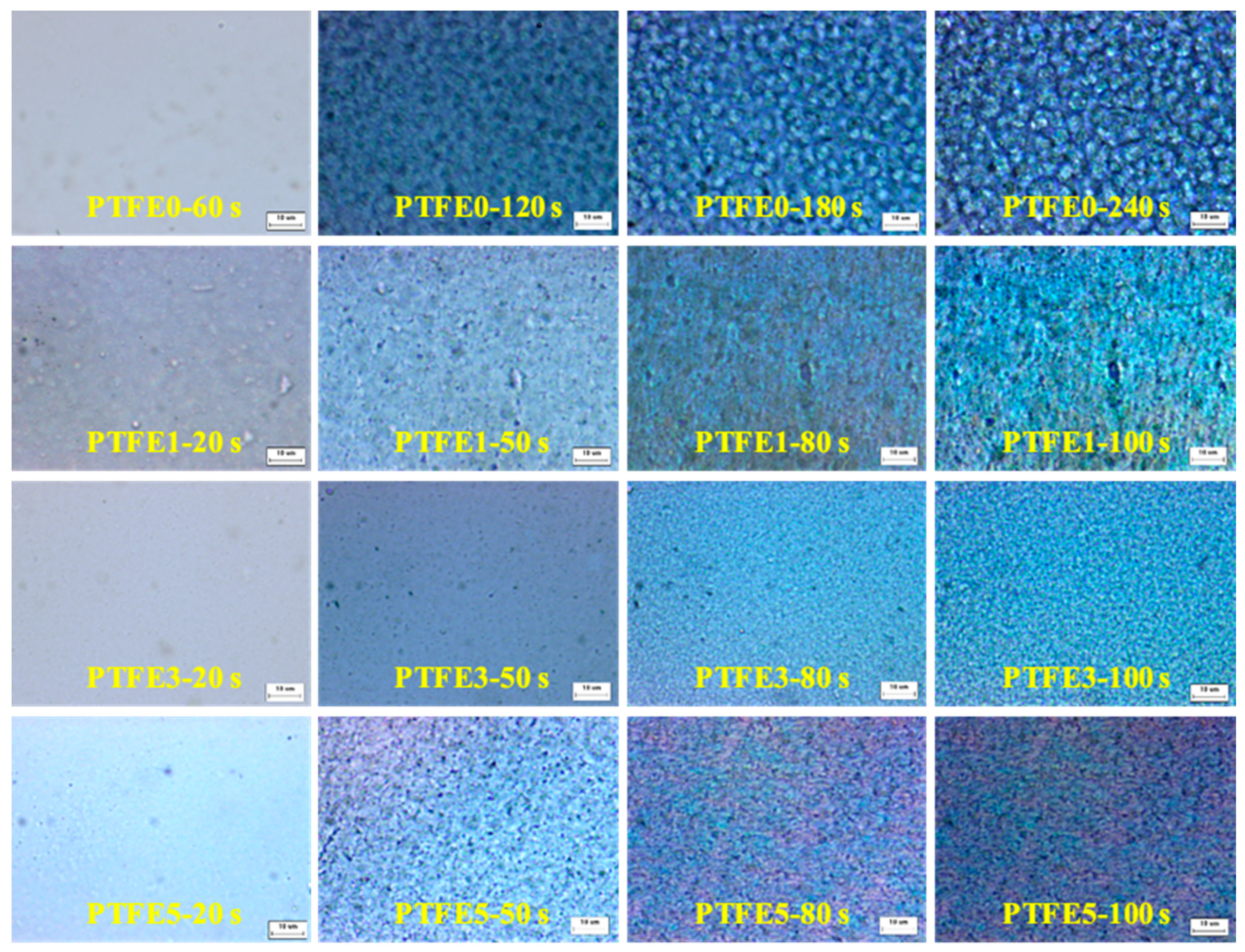

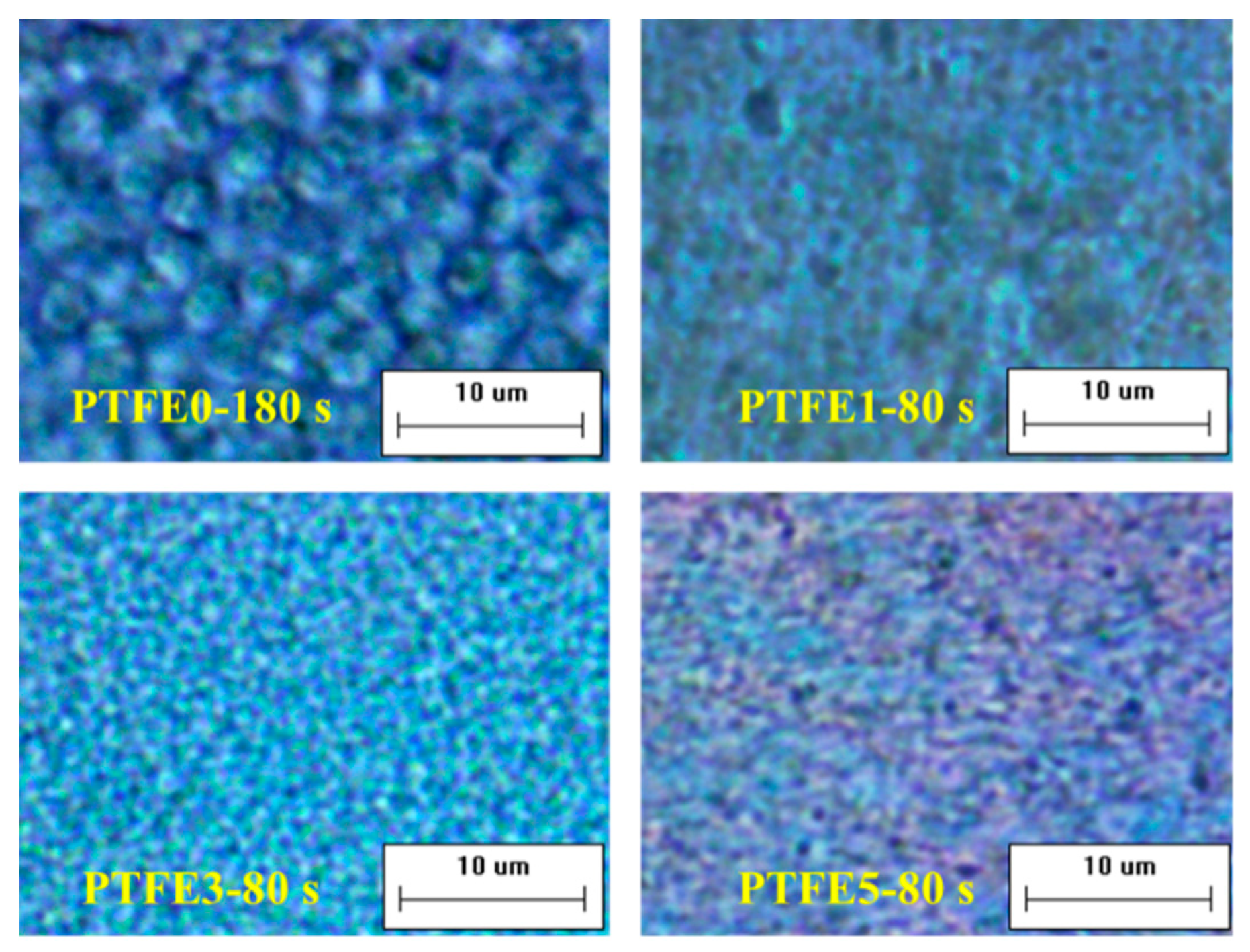

3.3. Thermal Behavior of the TPEE/PTFE Nanocomposites

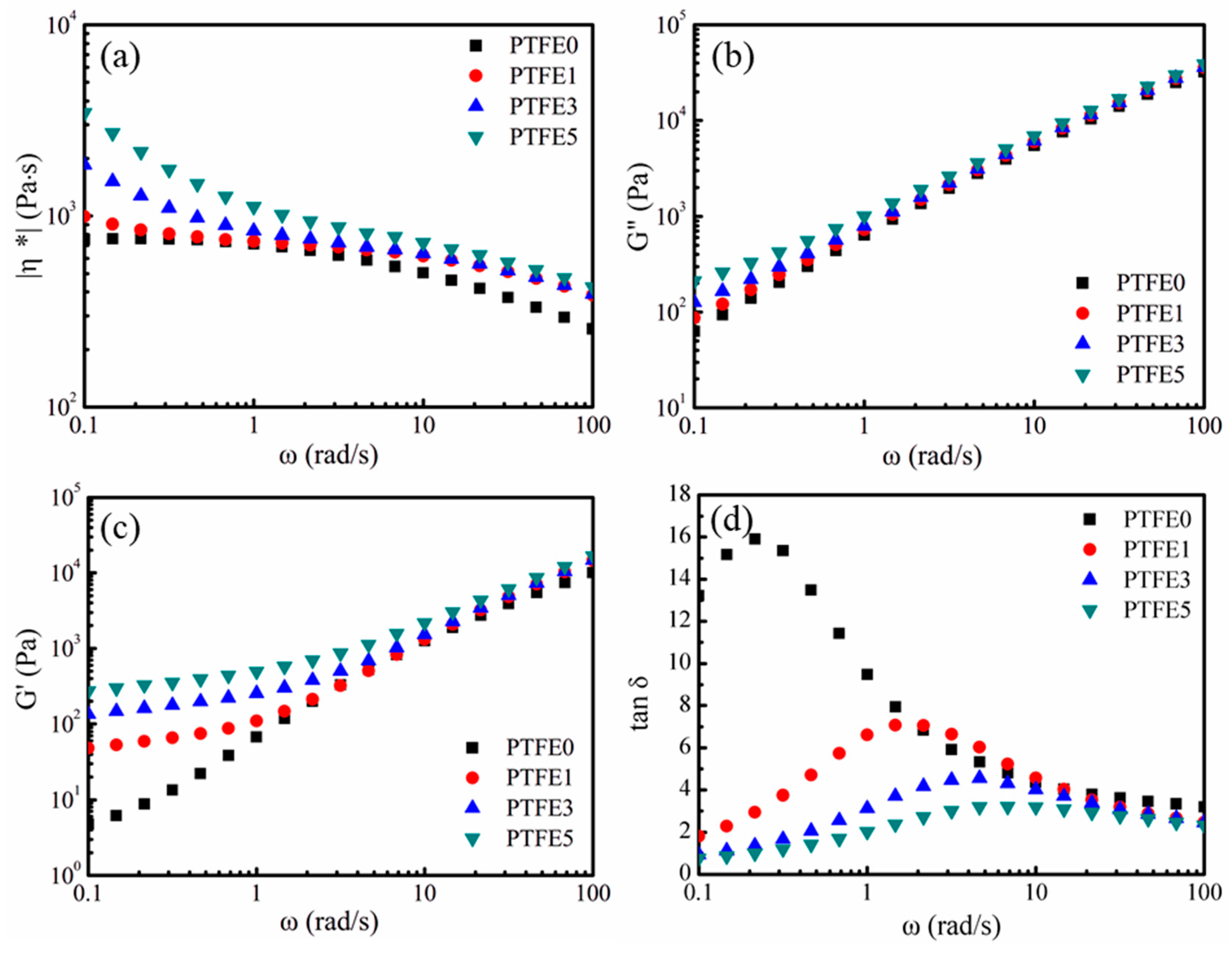

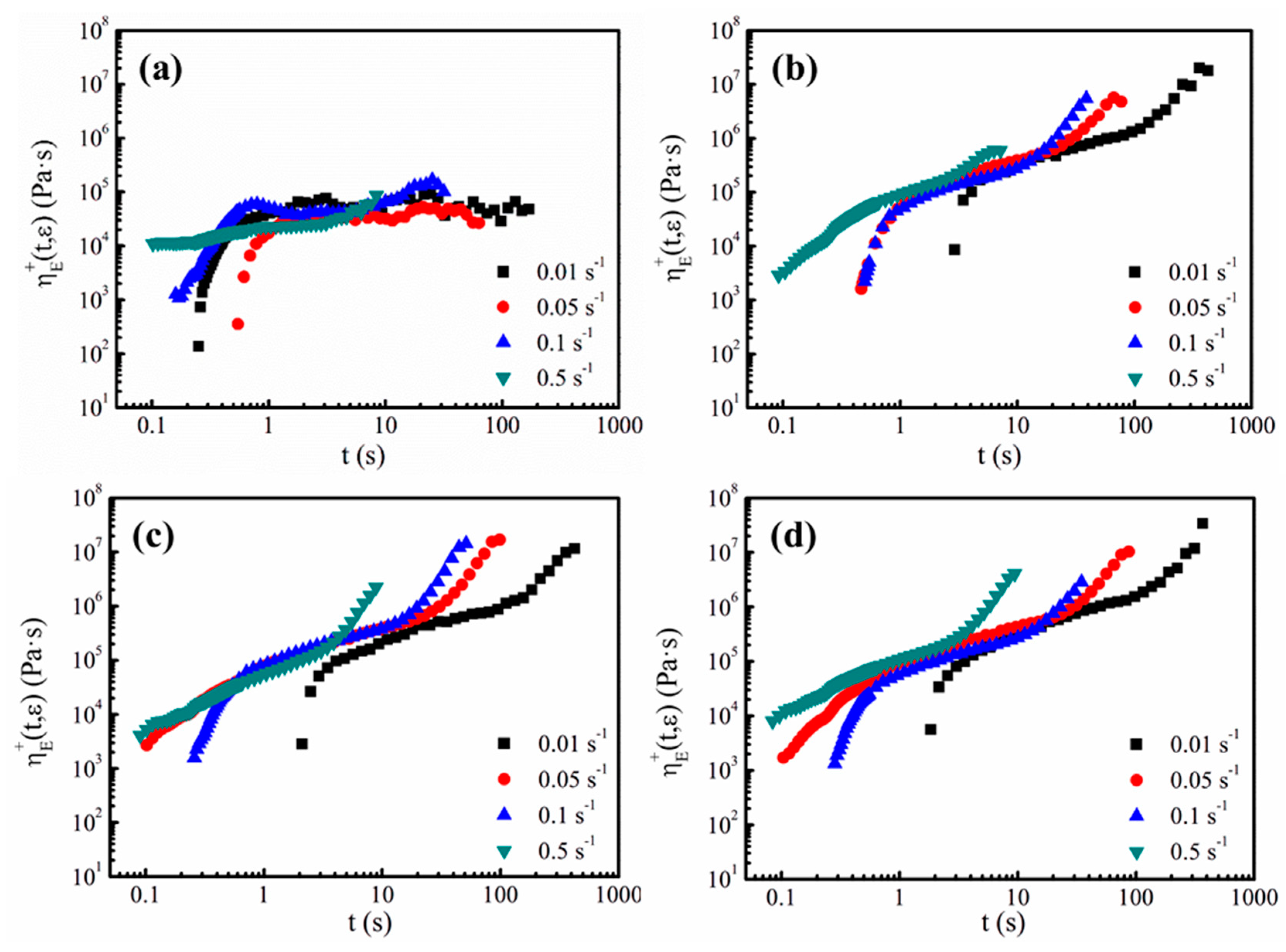

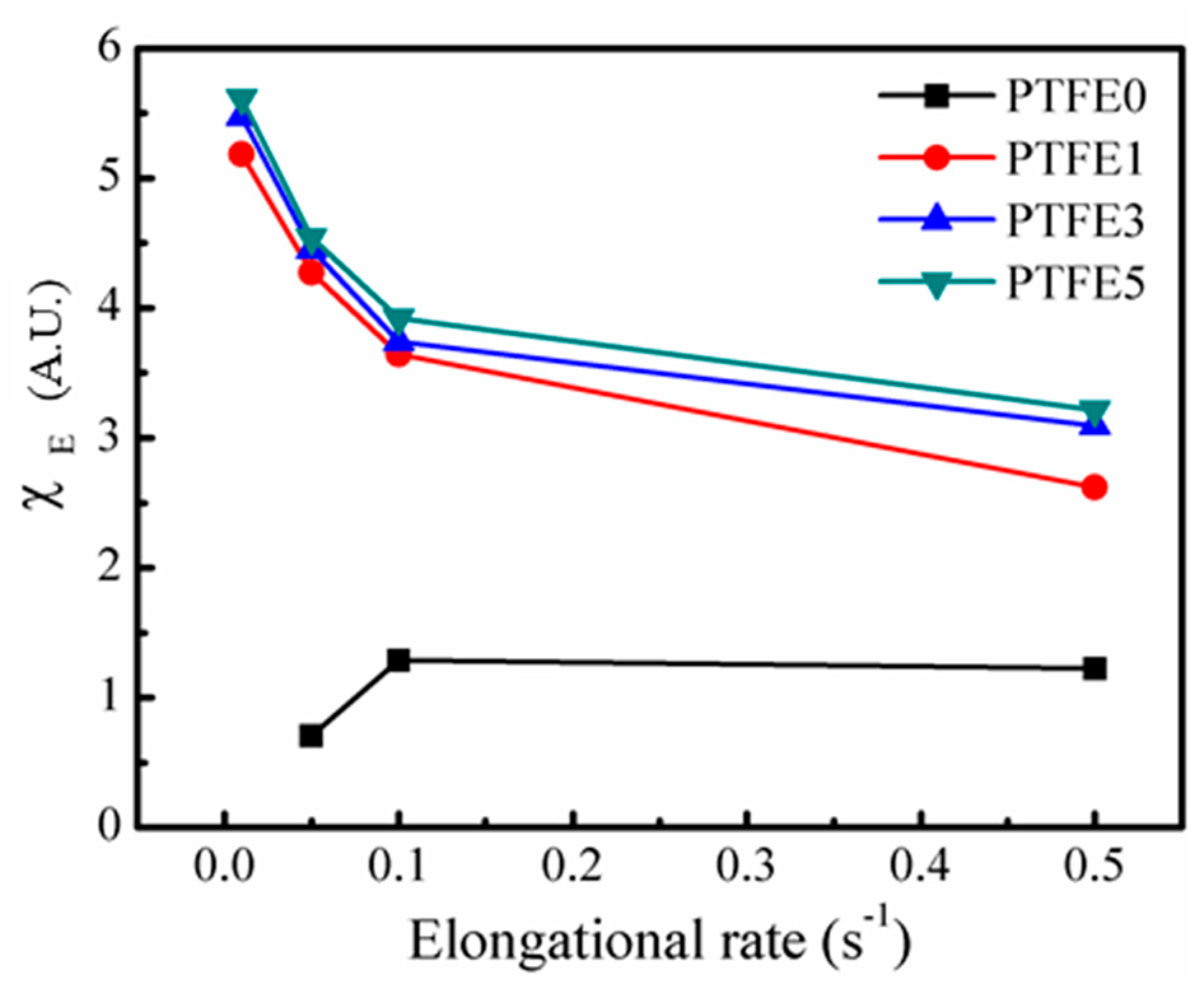

3.4. Rheological Analysis

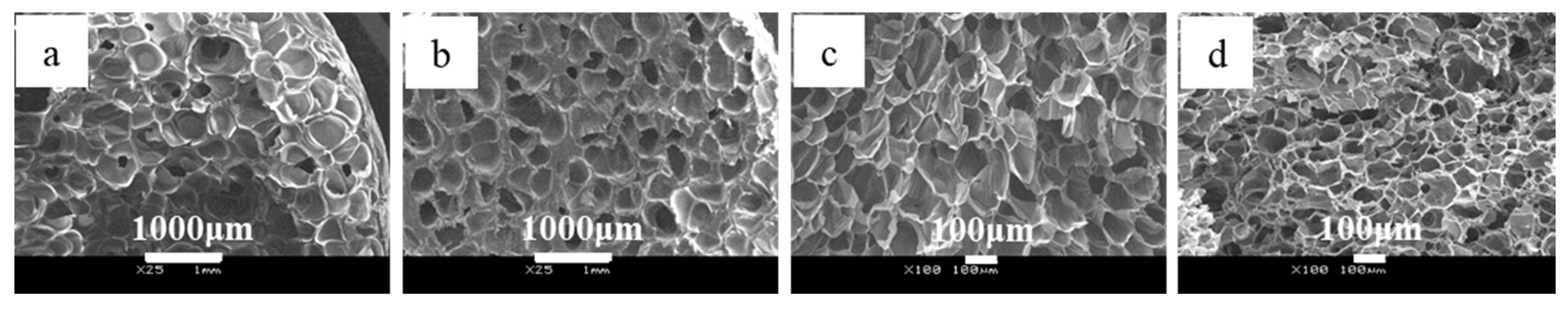

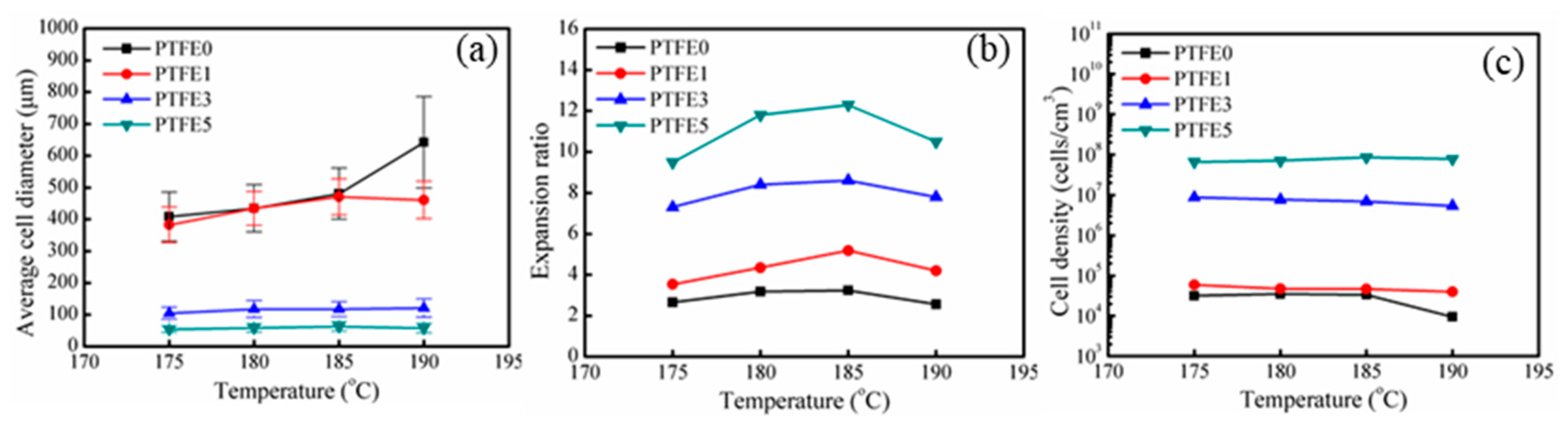

3.5. Extrusion Foaming of TPEE/PTFE Nanocomposites

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Cho, H.; Mayer, S.; Pöselt, E.; Susoff, M.; In’t Veld, P.J.; Rutledge, G.C.; Boyce, M.C. Deformation mechanisms of thermoplastic elastomers: Stress-strain behavior and constitutive modeling. Polymer 2017, 128, 87–99. [Google Scholar] [CrossRef]

- Zhou, W.; Zhang, Y.; Xu, Y.; Wang, P.; Gao, L.; Zhang, W.; Ji, J. Synthesis and characterization of bio-based poly(butylene furandicarboxylate)-b-poly(tetramethylene glycol) copolymers. Polym. Degrad. Stab. 2014, 109, 21–26. [Google Scholar] [CrossRef]

- Wang, L.; Wang, Y.; Zhang, F.; Bai, Y.; Ding, L. Syntheses and properties of the PET-co -PEA copolyester. J. Appl. Polym. Sci. 2017, 134, 44967. [Google Scholar] [CrossRef]

- Zhong, Y.; Li, M.; Zhang, L.; Zhang, X.; Zhu, S.; Wu, W. Adding the combination of CNTs and MoS2 into halogen-free flame retarding TPEE with enhanced the anti-dripping behavior and char forming properties. Thermochim. Acta 2015, 613, 87–93. [Google Scholar] [CrossRef]

- Fu, X.; Dong, X.; Liu, Y.; Zhao, X.; Zhang, N.; Qi, S.; Wang, D.; Yang, G. Combined graphene and poly (butylene terephthalate)-block-poly (tetramethylene glycol) enhance the mechanical performance of polyamide-6. Eur. Polym. J. 2019, 110, 97–106. [Google Scholar] [CrossRef]

- Szymczyk, A.; Senderek, E.; Nastalczyk, J.; Roslaniec, Z. New multiblock poly(ether-ester)s based on poly(trimethylene terephthalate) as rigid segments. Eur. Polym. J. 2008, 44, 436–443. [Google Scholar] [CrossRef]

- Zhang, Y.; Feng, Z.; Cui, F. Preparation and properties of poly(butylene terephthalate-co-cyclohexanedimethylene terephthalate)-b-poly(ethylene glycol) segmented random copolymers. Polym. Degrad. Stab. 2004, 85, 559–570. [Google Scholar] [CrossRef]

- Huang, J.; Wang, J.; Qiu, Y.; Wu, D. Mechanical properties of thermoplastic polyester elastomer controlled by blending with poly(butylene terephthalate). Polym. Test. 2016, 55, 152–159. [Google Scholar] [CrossRef]

- Aso, O.; Eguiazábal, J.I.; Nazábal, J. The influence of surface modification on the structure and properties of a nanosilica filled thermoplastic elastomer. Compos. Sci. Technol. 2007, 67, 2854–2863. [Google Scholar] [CrossRef]

- Paszkiewicz, S.; Szymczyk, A.; Špitalský, Z.; Mosnacek, J.; Kwiatkowski, K.; Rosłaniec, Z. Structure and properties of nanocomposites based on PTT-block-PTMO copolymer and graphene oxide prepared by in situ polymerization. Eur. Polym. J. 2014, 50, 69–77. [Google Scholar] [CrossRef]

- Kim, Y.; Kim, M.; Seong, H.G.; Jung, J.Y.; Baeck, S.H.; Shim, S.E. Roles of silica-coated layer on graphite for thermal conductivity, heat dissipation, thermal stability, and electrical resistivity of polymer composites. Polymer 2018, 148, 295–302. [Google Scholar] [CrossRef]

- Paszkiewicz, S.; Szymczyk, A.; Sui, X.M.; Wagner, H.D.; Linares, A.; Ezquerra, T.A.; Rosłaniec, Z. Synergetic effect of single-walled carbon nanotubes (SWCNT) and graphene nanoplatelets (GNP) in electrically conductive PTT-block-PTMO hybrid nanocomposites prepared by in situ polymerization. Compos. Sci. Technol. 2015, 118, 72–77. [Google Scholar] [CrossRef]

- Qiu, Y.; Wu, D.; Xie, W.; Wang, Z.; Peng, S. Thermoplastic polyester elastomer composites containing two types of filler particles with different dimensions: Structure design and mechanical property control. Compos. Struct. 2018, 197, 21–27. [Google Scholar] [CrossRef]

- Wang, G.; Zhao, J.; Mark, L.H.; Wang, G.; Yu, K.; Wang, C.; Park, C.B.; Zhao, G. Ultra-tough and super thermal-insulation nanocellular PMMA/TPU. Chem. Eng. J. 2017, 325, 632–646. [Google Scholar] [CrossRef]

- Bao, J.B.; Junior, A.N.; Weng, G.S.; Wang, J.; Fang, Y.W.; Hu, G.H. Tensile and impact properties of microcellular isotactic polypropylene (PP) foams obtained by supercritical carbon dioxide. J. Supercrit. Fluids 2016, 111, 63–73. [Google Scholar] [CrossRef]

- Wang, G.; Zhao, G.; Dong, G.; Mu, Y.; Park, C.B.; Wang, G. Lightweight, super-elastic, and thermal-sound insulation bio-based PEBA foams fabricated by high-pressure foam injection molding with mold-opening. Eur. Polym. J. 2018, 103, 68–79. [Google Scholar] [CrossRef]

- Mi, H.Y.; Jing, X.; Liu, Y.J.; Li, L.; Li, H.; Peng, X.F.; Zhou, H. Highly Durable Superhydrophobic Polymer Foams Fabricated by Extrusion and Supercritical CO2 Foaming for Selective Oil Absorption. ACS Appl. Mater. Interfaces 2019, 11, 7479–7487. [Google Scholar] [CrossRef]

- Ge, C.; Ren, Q.; Wang, S.; Zheng, W.; Zhai, W.; Park, C.B. Steam-chest molding of expanded thermoplastic polyurethane bead foams and their mechanical properties. Chem. Eng. Sci. 2017, 174, 337–346. [Google Scholar] [CrossRef]

- Jia, Y.; Bai, S.; Park, C.B.; Wang, Q. Effect of boric acid on the foaming properties and cell structure of poly(vinyl alcohol) foam prepared by supercritical-CO2 thermoplastic extrusion foaming. Ind. Eng. Chem. Res. 2017, 56, 6655–6663. [Google Scholar] [CrossRef]

- Wang, L.; Hikima, Y.; Ohshima, M.; Yusa, A.; Yamamoto, S.; Goto, H. Unusual fabrication of lightweight injection-molded polypropylene foams by using air as the novel foaming agent. Ind. Eng. Chem. Res. 2018, 57, 3800–3804. [Google Scholar] [CrossRef]

- Liu, H.; Chuai, C.; Iqbal, M.; Wang, H.; Kalsoom, B.B.; Khattak, M.; Khattak, M.Q. Improving foam ability of polypropylene by crosslinking. J. Appl. Polym. Sci. 2011, 122, 973–980. [Google Scholar] [CrossRef]

- Keshtkar, M.; Nofar, M.; Park, C.; Carreau, P. Extruded PLA/clay nanocomposite foams blown with supercritical CO2. Polymer 2014, 55, 4077–4090. [Google Scholar] [CrossRef]

- Mihai, M.; Huneault, M.A.; Favis, B.D. Rheology and extrusion foaming of chain-branched poly(lactic acid). Polym. Eng. Sci. 2010, 50, 629–642. [Google Scholar]

- Banerjee, S.S.; Janke, A.; Gohs, U.; Fery, A.; Heinrich, G. Some nanomechanical properties and degree of branching of electron beam modified polyamide-6. Eur. Polym. J. 2017, 88, 221–230. [Google Scholar] [CrossRef]

- Romani, F.; Corrieri, R.; Braga, V.; Ciardelli, F. Monitoring the chemical crosslinking of propylene polymers through rheology. Polymer 2002, 43, 1115–1131. [Google Scholar] [CrossRef]

- Zhang, C.; Zhu, B.; Lee, L.J. Extrusion foaming of polystyrene/carbon particles using carbon dioxide and water as co-blowing agents. Polymer 2011, 52, 1847–1855. [Google Scholar] [CrossRef]

- Rizvi, A.; Andalib, Z.K.; Park, C.B. Fiber-spun polypropylene/polyethylene terephthalate microfibrillar composites with enhanced tensile and rheological properties and foaming ability. Polymer 2017, 110, 139–148. [Google Scholar] [CrossRef]

- Rizvi, A.; Park, C.B. Dispersed polypropylene fibrils improve the foaming ability of a polyethylene matrix. Polymer 2014, 55, 4199–4205. [Google Scholar] [CrossRef]

- Huang, A.; Peng, X.; Turng, L.S. In-situ fibrillated polytetrafluoroethylene (PTFE) in thermoplastic polyurethane (TPU) via melt blending: Effect on rheological behavior, mechanical properties, and microcellular foamability. Polymer 2018, 134, 263–274. [Google Scholar] [CrossRef]

- Zhao, J.; Zhao, Q.; Wang, L.; Wang, C.; Guo, B.; Park, C.B.; Wang, G. Development of high thermal insulation and compressive strength BPP foams using mold-opening foam injection molding with in-situ fibrillated PTFE fibers. Eur. Polym. J. 2018, 98, 1–10. [Google Scholar] [CrossRef]

- Rizvi, A.; Tabatabaei, A.; Barzegari, M.R.; Mahmood, S.H.; Park, C.B. In situ fibrillation of CO2-philic polymers: Sustainable route to polymer foams in a continuous process. Polymer 2013, 54, 4645–4652. [Google Scholar] [CrossRef]

- Jurczuk, K.; Galeski, A. Thermoplastic elastomers reinforced with poly(tetrafluoroethylene) nanofibers. Eur. Polym. J. 2016, 80, 58–69. [Google Scholar] [CrossRef]

- Jurczuk, K.; Galeski, A.; Morawiec, J. Effect of poly(tetrafluoroethylene) nanofibers on foaming behavior of linear and branched polypropylenes. Eur. Polym. J. 2017, 88, 171–182. [Google Scholar] [CrossRef]

- Jurczuk, K.; Galeski, A.; Piorkowska, E. All-polymer nanocomposites with nanofibrillar inclusions generated in situ during compounding. Polymer 2013, 54, 4617–4628. [Google Scholar] [CrossRef]

- Jiang, R.; Yao, S.; Chen, Y.; Liu, T.; Xu, Z.; Park, C.B.; Zhao, L. Effect of chain topological structure on the crystallization, rheological behavior and foamability of TPEE using supercritical CO2 as a blowing agent. J. Supercrit. Fluids 2019, 147, 48–58. [Google Scholar] [CrossRef]

- Jiang, R.; Chen, Y.; Yao, S.; Liu, T.; Xu, Z.; Park, C.B.; Zhao, L. Preparation and characterization of high melt strength thermoplastic polyester elastomer with different topological structure using a two-step functional group reaction. Polymer 2019, 179, 121628. [Google Scholar] [CrossRef]

- Xu, X.; Park, C.B.; Xu, D.; Pop-Iliev, R. Effects of die geometry on cell nucleation of PS foams blown with CO2. Polym. Eng. Sci. 2003, 43, 1378–1390. [Google Scholar] [CrossRef]

- Zhao, J.; Zhao, Q.; Wang, C.; Guo, B.; Park, C.B.; Wang, G. High thermal insulation and compressive strength polypropylene foams fabricated by high-pressure foam injection molding and mold opening of nano-fibrillar composites. Mater. Des. 2017, 131, 1–11. [Google Scholar] [CrossRef]

- Xia, T.; Xi, Z.; Yi, X.; Liu, T.; Zhao, L. Melt foamability of poly(ethylene terephthalate)/clay nanocomposites prepared by extrusion blending in the presence of pyromellitic dianhydride. Ind. Eng. Chem. Res. 2015, 54, 6922–6931. [Google Scholar] [CrossRef]

- Nofar, M.; Tabatabaei, A.; Ameli, A.; Park, C.B. Comparison of melting and crystallization behaviors of polylactide under high-pressure CO2, N2, and He. Polymer 2013, 54, 6471–6478. [Google Scholar] [CrossRef]

- Nofar, M.; Zhu, W.; Park, C. Effect of dissolved CO2 on the crystallization behavior of linear and branched PLA. Polymer 2012, 53, 3341–3353. [Google Scholar] [CrossRef]

- Gao, T.; Zhao, S.J.; Bao, R.Y.; Zhong, G.J.; Li, Z.M.; Yang, M.B.; Yang, W. Constructing Sandwich-Architectured Poly(l-lactide)/High-Melting-Point Poly(l-lactide) Nonwoven Fabrics: Toward Heat-Resistant Poly(l-lactide) Barrier Biocomposites with Full Biodegradability. ACS Appl. Bio Mater. 2019, 2, 1357–1367. [Google Scholar] [CrossRef]

- Zhou, S.Y.; Huang, H.D.; Xu, L.; Yan, Z.; Zhong, G.J.; Hsiao, B.S.; Li, Z.M. In Situ Nanofibrillar Networks Composed of Densely Oriented Polylactide Crystals as Efficient Reinforcement and Promising Barrier Wall for Fully Biodegradable Poly(butylene succinate) Composite Films. ACS Sustain. Chem. Eng. 2016, 4, 2887–2897. [Google Scholar] [CrossRef]

- Wong, A.; Guo, Y.; Park, C.B. Fundamental mechanisms of cell nucleation in polypropylene foaming with supercritical carbon dioxide-Effects of extensional stresses and crystals. J. Supercrit. Fluids 2013, 79, 142–151. [Google Scholar] [CrossRef]

- Durmus, A.; Kaşgöz, A.; Macosko, C.W. Linear low density polyethylene (LLDPE)/clay nanocomposites. Part I: Structural characterization and quantifying clay dispersion by melt rheology. Polymer 2007, 48, 4492–4502. [Google Scholar] [CrossRef]

- Rahmaoui, F.E.Z.; Mederic, P.; Hocine, N.A.; Saada, A.A.; Poirot, N.; Belaidi, I. Contribution of the organo-montmorillonite/graphene pair to the rheological and mechanical properties of polyethylene matrix based nanocomposites. Appl. Clay Sci. 2017, 150, 244–251. [Google Scholar] [CrossRef]

- Kakroodi, A.R.; Kazemi, Y.; Ding, W.; Ameli, A.; Park, C.B. Poly(lactic acid)-Based in Situ Microfibrillar Composites with Enhanced Crystallization Kinetics, Mechanical Properties, Rheological Behavior, and Foaming Ability. Biomacromolecules 2015, 16, 3925–3935. [Google Scholar] [CrossRef]

- Liu, J.; Lou, L.; Yu, W.; Liao, R.; Li, R.; Zhou, C. Long chain branching polylactide: Structures and properties. Polymer 2010, 51, 5186–5197. [Google Scholar] [CrossRef]

| Sample | PTFE Content (wt %) | 2,2′-BOZ Content (wt %) | η0.01a (Pa·s) |

|---|---|---|---|

| PTFE0 | 0 | 0.5 | 752.4 |

| PTFE1 | 1 | 0.5 | 993.5 |

| PTFE3 | 3 | 0.5 | 1853.5 |

| PTFE5 | 5 | 0.5 | 3467.6 |

| Sample | Crystallization Onset Temperature (Tc, onset (°C)) | Crystallization Temperature (Tc (°C)) | Melting Temperature (Tm (°C)) | Enthalpy of Crystallization (ΔHc (J/g)) | Crystallization Rate Constant (k’) | Avrami Exponent (n) | Half Crystallization Time (t1/2 (min)) | Variance (r2) |

|---|---|---|---|---|---|---|---|---|

| PTFE0 | 180.4 | 164.3 | 197.1 | 28.33 | 0.80 | 1.52 | 4.78 | 0.9908 |

| PTFE1 | 175.5 | 169.6 | 196.7 | 25.68 | 0.67 | 3.04 | 1.71 | 0.9990 |

| PTFE3 | 177.1 | 170.6 | 196.8 | 25.12 | 0.68 | 2.87 | 1.73 | 0.9997 |

| PTFE5 | 177.8 | 170.8 | 197.3 | 24.72 | 0.65 | 2.85 | 1.92 | 0.9996 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, R.; Liu, T.; Xu, Z.; Park, C.B.; Zhao, L. Improving the Continuous Microcellular Extrusion Foaming Ability with Supercritical CO2 of Thermoplastic Polyether Ester Elastomer through In-Situ Fibrillation of Polytetrafluoroethylene. Polymers 2019, 11, 1983. https://doi.org/10.3390/polym11121983

Jiang R, Liu T, Xu Z, Park CB, Zhao L. Improving the Continuous Microcellular Extrusion Foaming Ability with Supercritical CO2 of Thermoplastic Polyether Ester Elastomer through In-Situ Fibrillation of Polytetrafluoroethylene. Polymers. 2019; 11(12):1983. https://doi.org/10.3390/polym11121983

Chicago/Turabian StyleJiang, Rui, Tao Liu, Zhimei Xu, Chul B. Park, and Ling Zhao. 2019. "Improving the Continuous Microcellular Extrusion Foaming Ability with Supercritical CO2 of Thermoplastic Polyether Ester Elastomer through In-Situ Fibrillation of Polytetrafluoroethylene" Polymers 11, no. 12: 1983. https://doi.org/10.3390/polym11121983

APA StyleJiang, R., Liu, T., Xu, Z., Park, C. B., & Zhao, L. (2019). Improving the Continuous Microcellular Extrusion Foaming Ability with Supercritical CO2 of Thermoplastic Polyether Ester Elastomer through In-Situ Fibrillation of Polytetrafluoroethylene. Polymers, 11(12), 1983. https://doi.org/10.3390/polym11121983