Development, Fabrication, and Characterization of Composite Polycaprolactone Membranes Reinforced with TiO2 Nanoparticles

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. TiO2 Synthesis by Sol-gel Method

2.3. PCL Composite Membranes Manufacturing Process

2.4. Differential Scanning Calorimetry (DSC)

2.5. Thermogravimetric Analysis (TGA)

2.6. X-ray Diffraction (XRD)

2.7. Scanning Electron Microscopy (SEM)

2.8. Fourier-Transform Infrared (FTIR) Analysis

2.9. Contact Angle (CA) Test

2.10. Uniaxial and Biaxial Tensile Tests

2.11. Surface Roughness Measurements

3. Results and Discussion

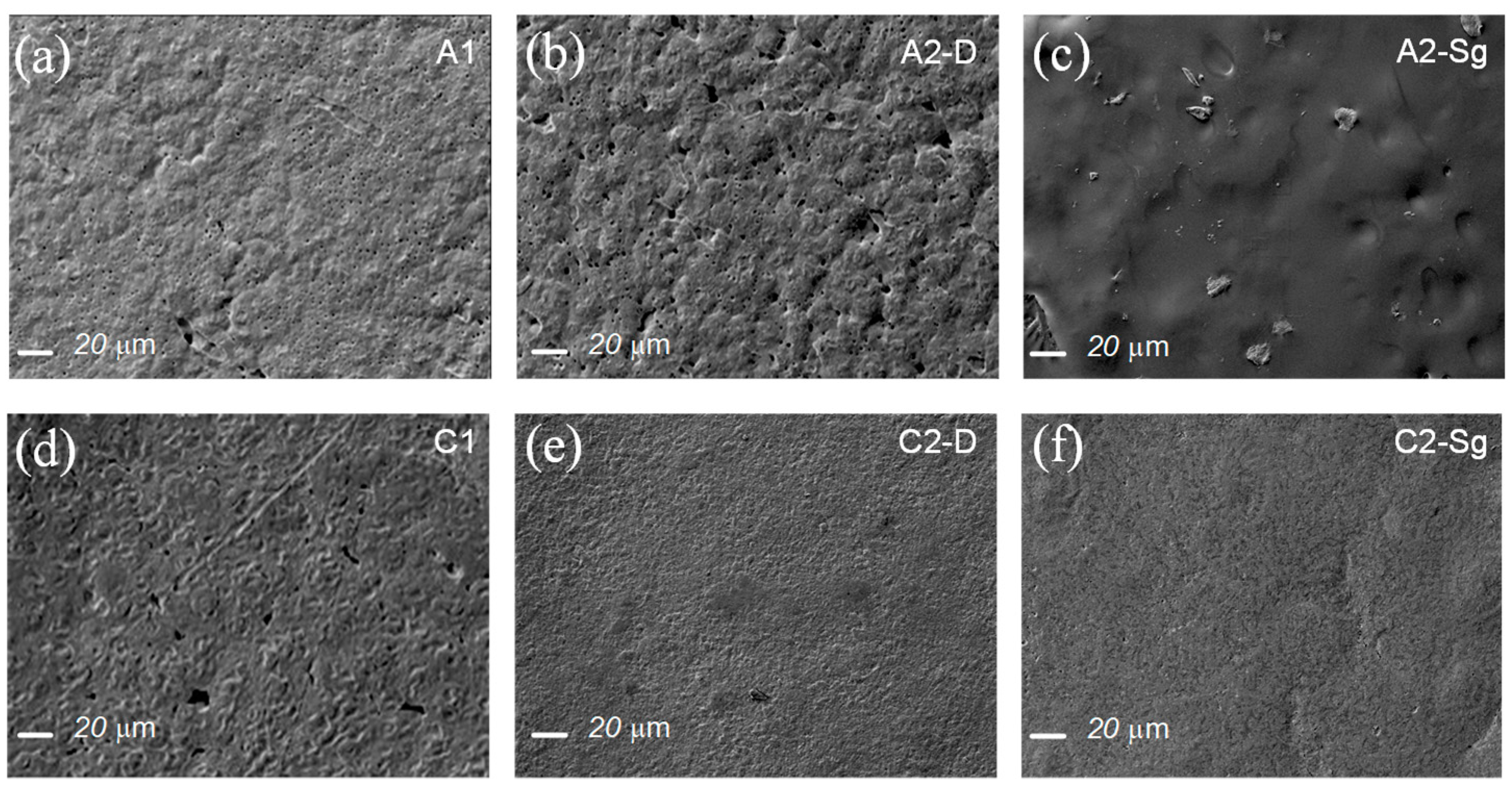

3.1. Morphology of PCL Membrane

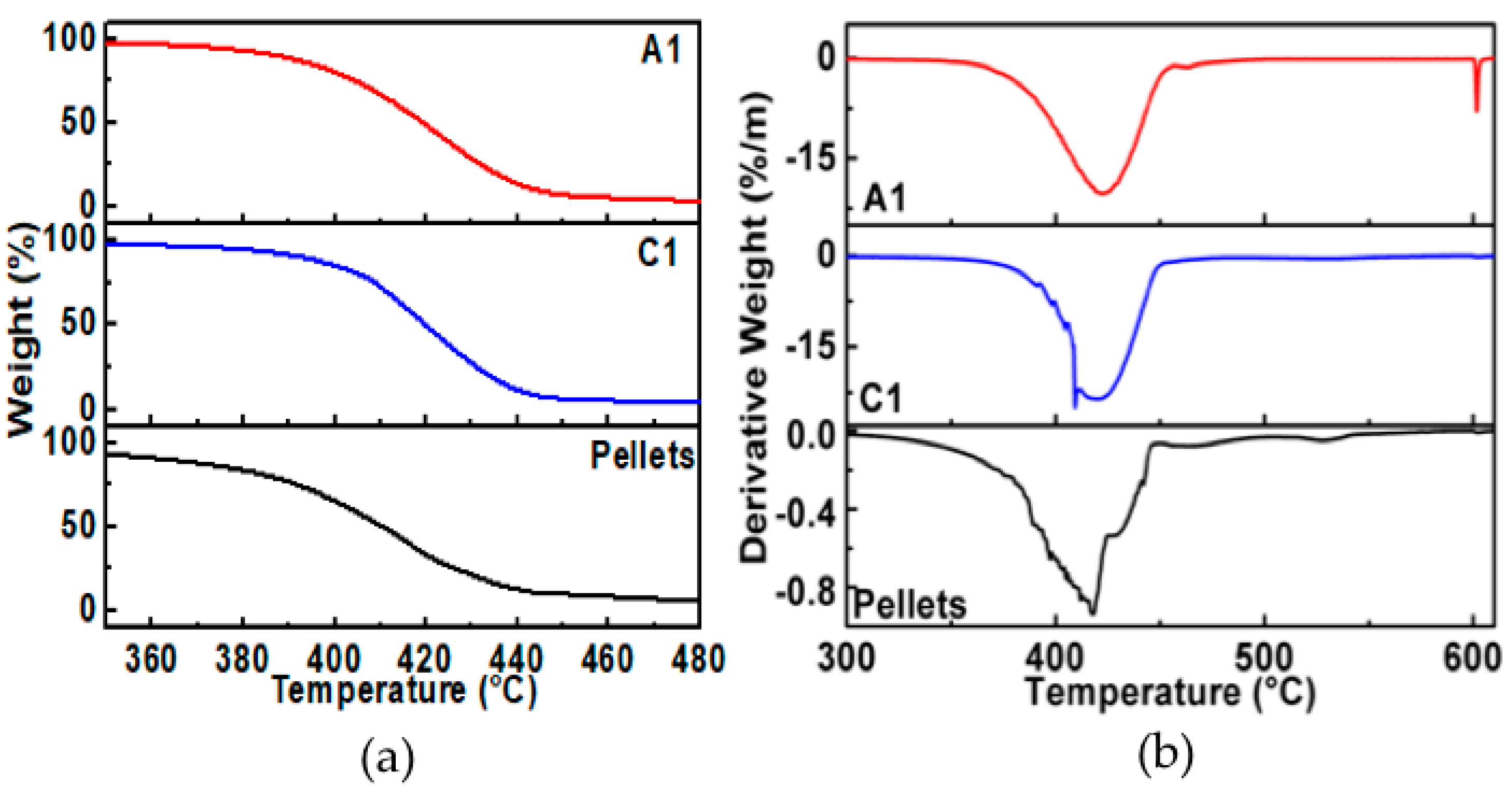

3.2. Thermogravimetry Analysis

3.3. Differential Scanning Calorimetry (DSC)

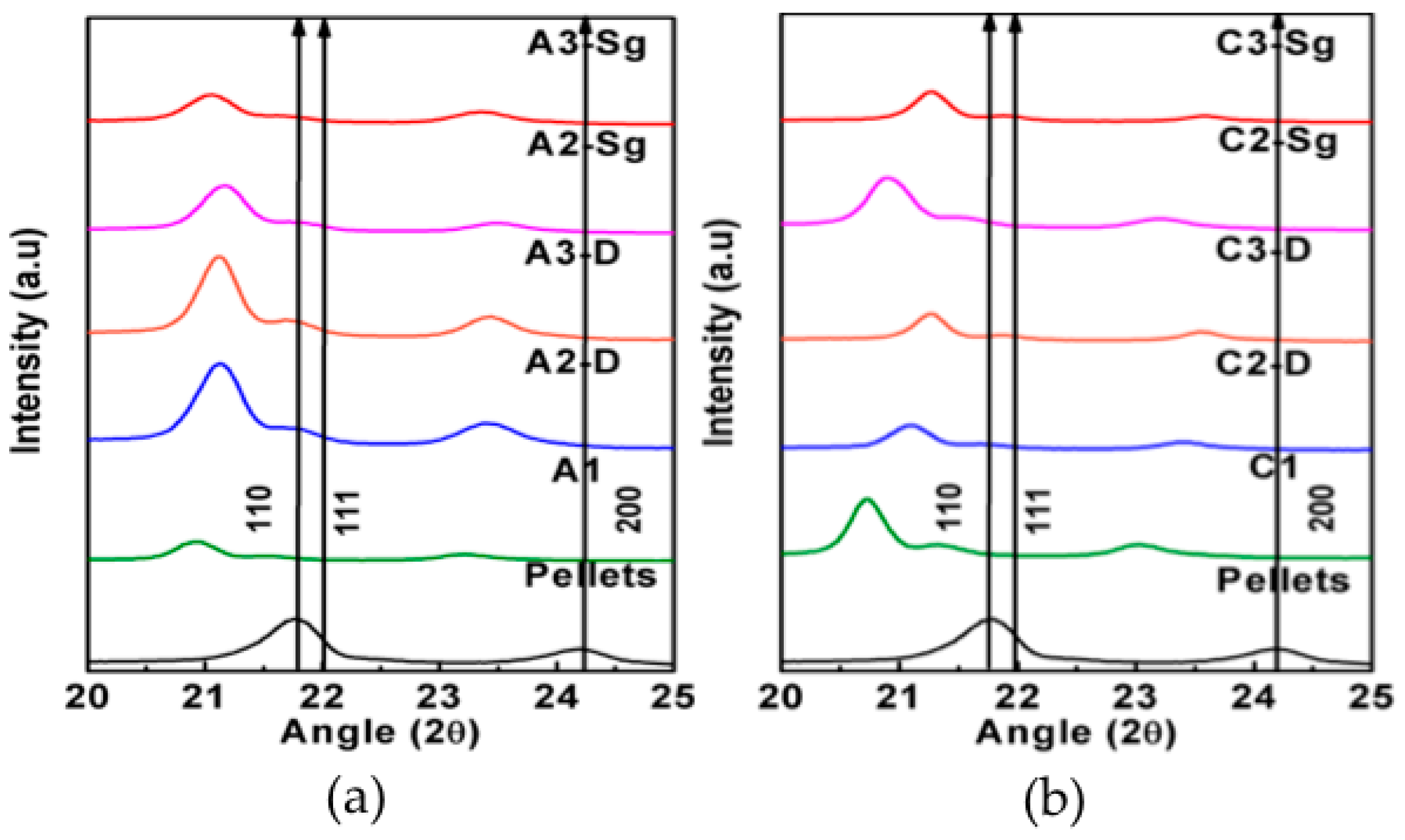

3.4. X-ray Diffraction (XRD)

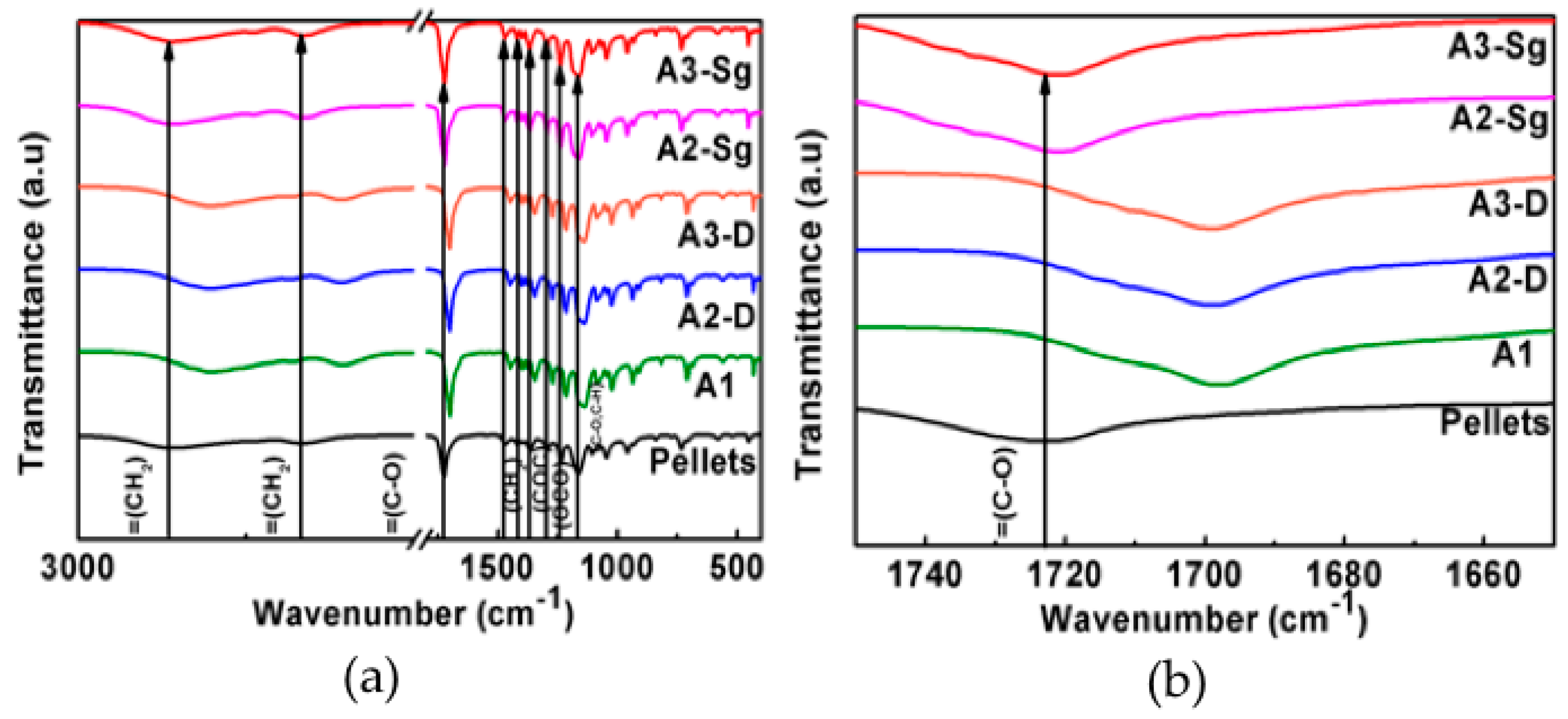

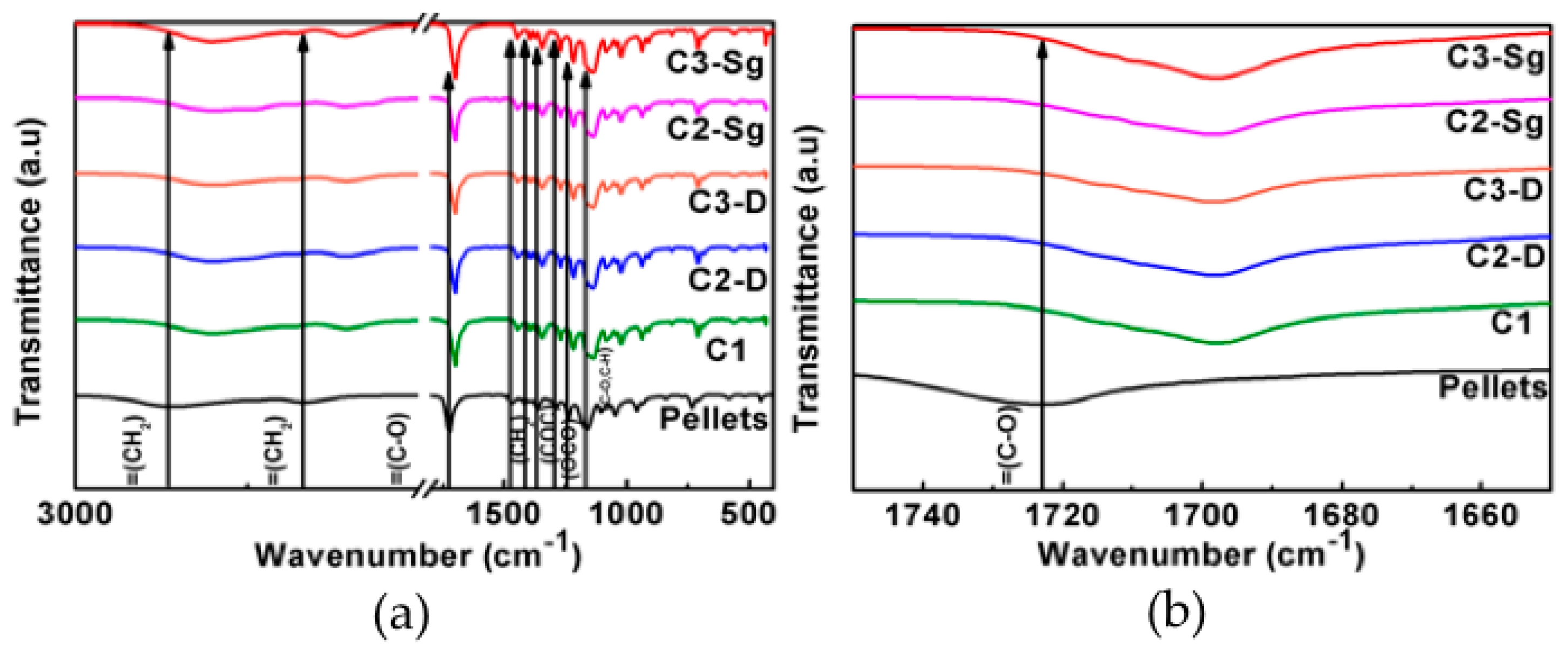

3.5. Fourier-Transform Infra Red (FTIR)

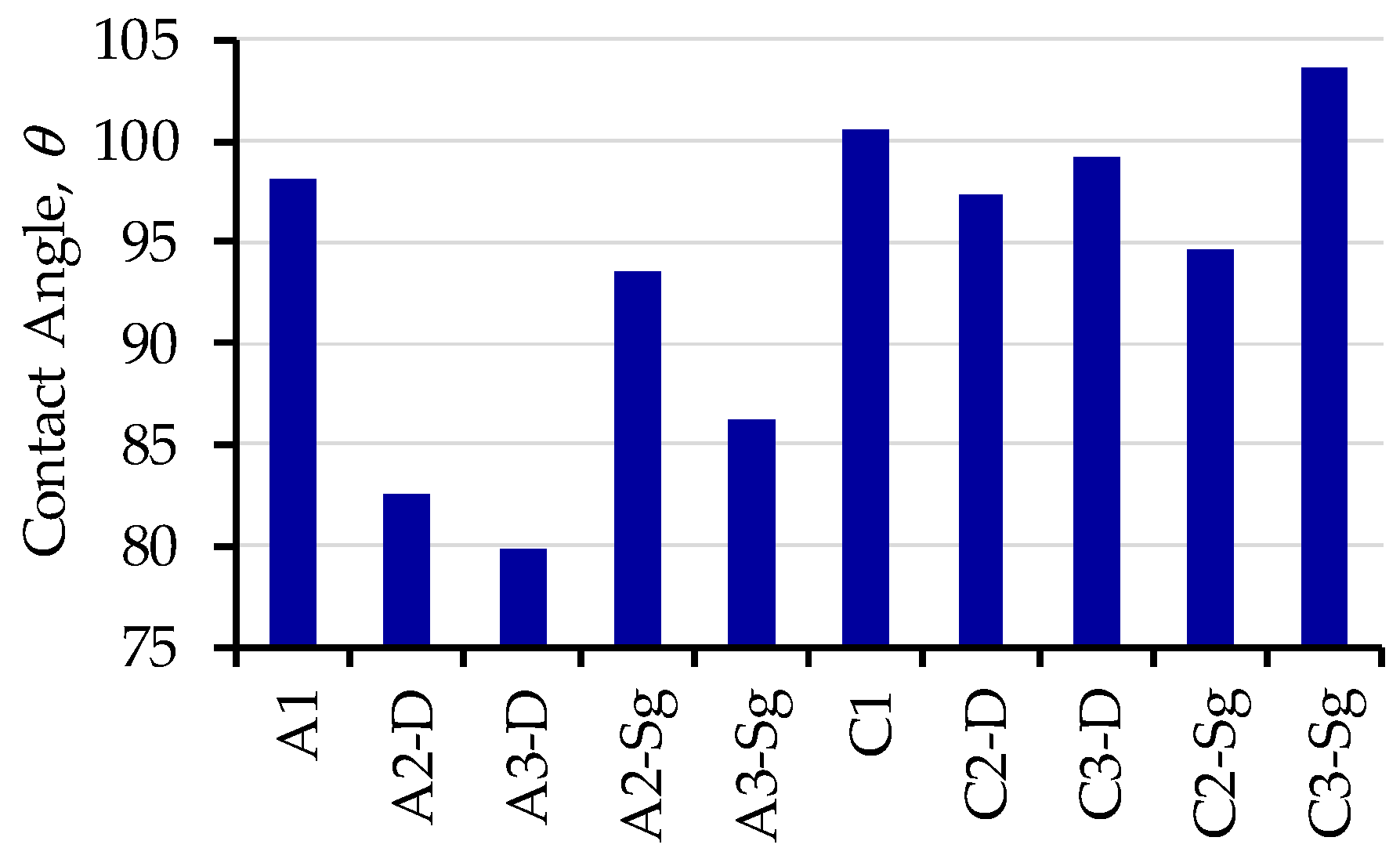

3.6. Contact Angle Tests

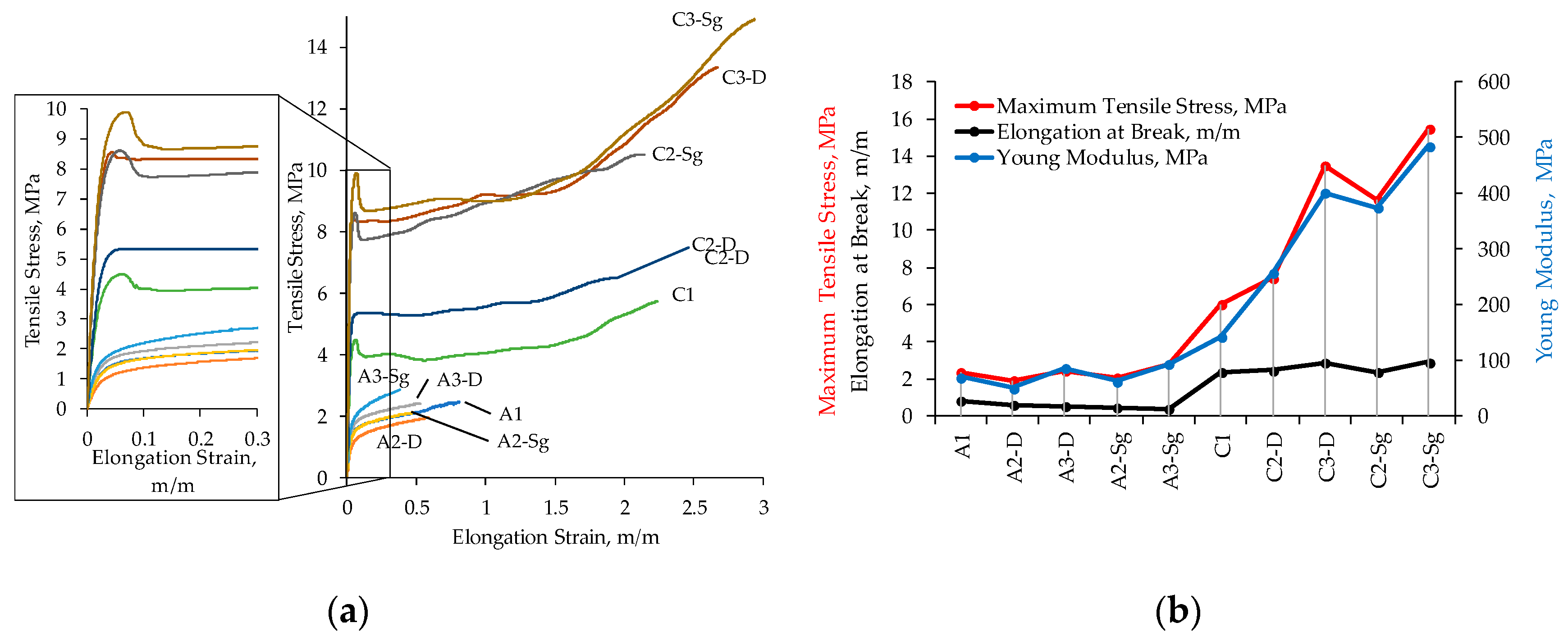

3.7. Uniaxial Extension Tests

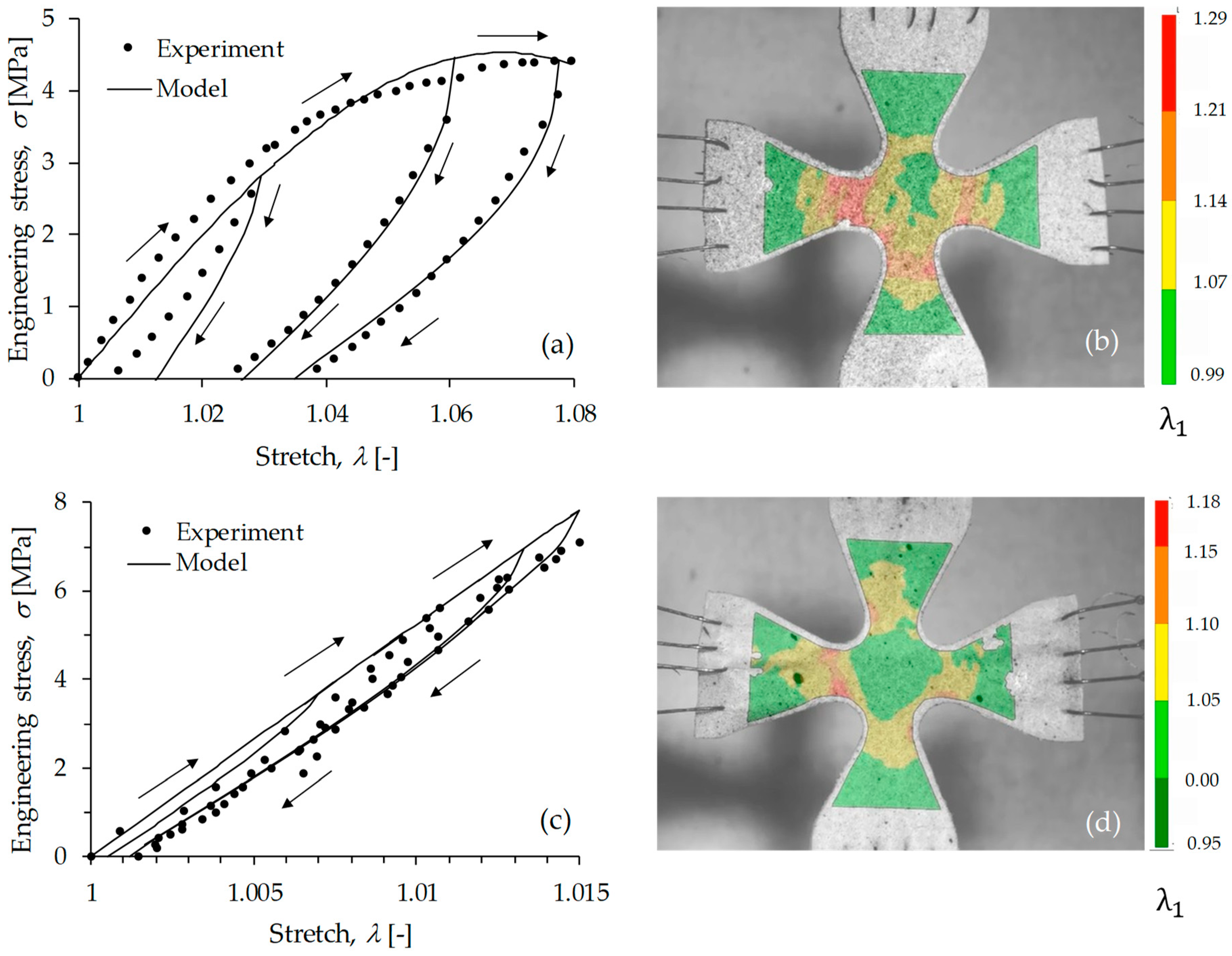

3.8. Cyclic Biaxial Tests

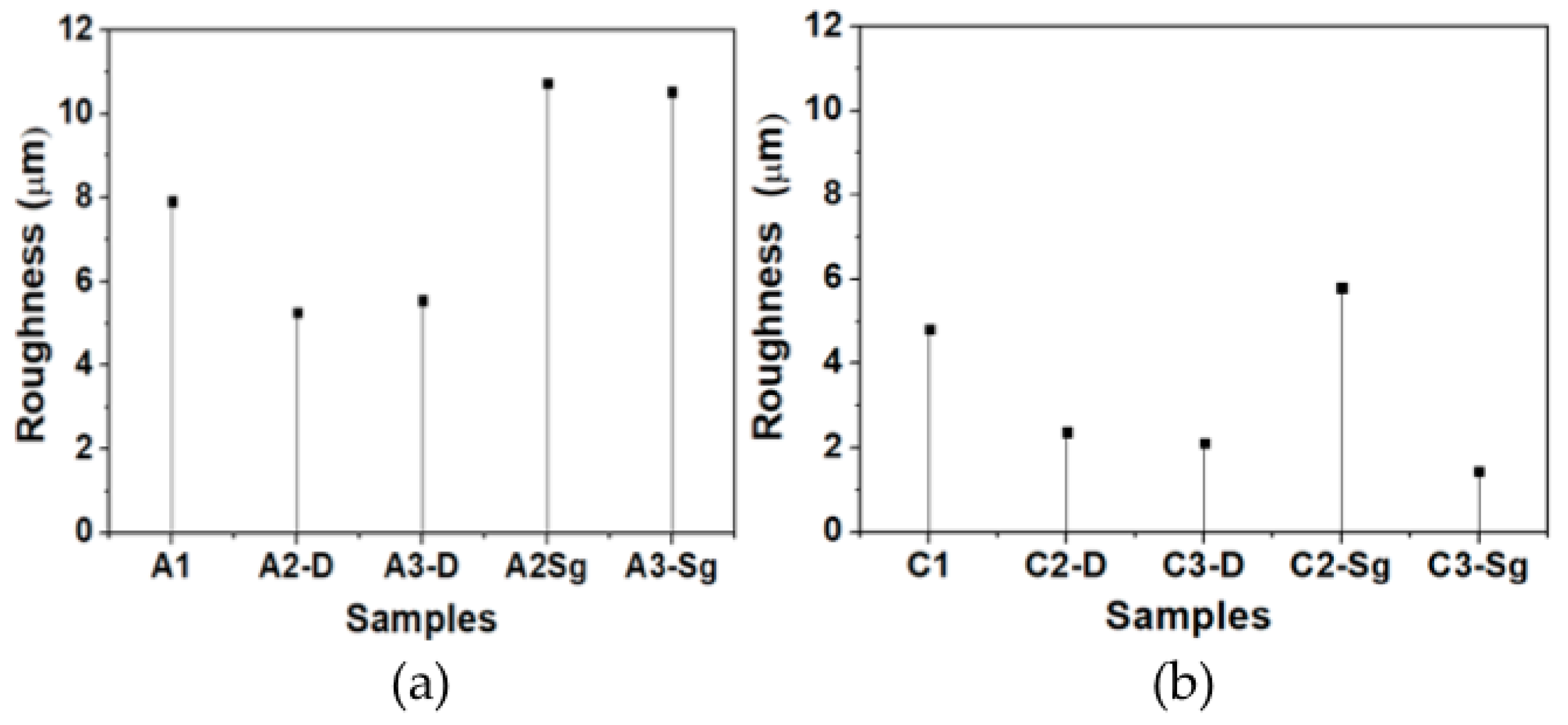

3.9. Roughness Measurements

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Guarino, V.; Gentile, G.; Sorrentino, L.; Ambrosio, L. Polycaprolactone: Synthesis, properties, and applications. In Encyclopedia of Polymer Science and Technology, 4th ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2017; pp. 1–35. [Google Scholar]

- Woodruff, M.A.; Hutmacher, D.W. The return of a forgotten polymer—Polycaprolactone in the 21st century. Prog. Polym. Sci. 2010, 35, 1217–1256. [Google Scholar] [CrossRef]

- Mohamed, R.M.; Yusoh, K. A review on the recent research of polycaprolactone (PCL). Adv. Mater. Res. 2016, 1134, 249–255. [Google Scholar] [CrossRef]

- Rhim, J.W.; Park, H.M.; Ha, C.S. Bio-nanocomposites for food packaging applications. Prog. Polym. Sci. 2013, 38, 1629–1652. [Google Scholar] [CrossRef]

- Jeong, H.T.; Kim, Y.R.; Kim, B.C. Flexible polycaprolactone (PCL) supercapacitor based on reduced graphene oxide (rGO)/single-wall carbon nanotubes (SWNTs) composite electrodes. J. Alloys Compd. 2017, 727, 721–727. [Google Scholar] [CrossRef]

- Zhou, H.; Luo, H.; Zhou, X. Healable, flexible supercapacitors based on shape memory polymers. Appl. Sci. 2018, 8, 1732. [Google Scholar] [CrossRef]

- Narancic, T.; Verstichel, S.; Reddy Chaganti, S.; Morales-Gamez, L.; Kenny, S.T.; De Wilde, B.; Babu Padamati, R.; O’Connor, K.E. Biodegradable plastic blends create new possibilities for end-of-life management of plastics but they are not a panacea for plastic pollution. Environ. Sci. Technol. 2018, 52, 10441–10452. [Google Scholar] [CrossRef]

- Idumah, C. Novel trends in self-healable polymer nanocomposites. J. Thermoplast. Compos. 2019, 1–25. [Google Scholar] [CrossRef]

- Gupta, K.K.; Kundan, A.; Mishra, P.K.; Srivastava, P.; Mohanty, S.; Singh, N.K.; Mishra, A.; Maiti, P. 9847247Polycaprolactone composites with TiO2 for potential nanobiomaterials: Tunable properties using different phases. Phys. Chem. Chem. Phys. 2012, 14, 12844–12853. [Google Scholar] [CrossRef]

- Ghosal, K.; Thomas, S.; Kalarikkal, N.; Gnanamanis, A. Collagen coated electrospun polycaprolactone (PCL) with titanium dioxide (TiO2) from an environmentally benign solvent: Preliminary physico-chemical studies for skin substitute. J. Polym. Res. 2014, 21, 2–6. [Google Scholar] [CrossRef]

- Kim, J.; Lee, O.; Sheikh, F.; Ju, H.; Moon, B.M.; Park, H.J.; Park, C.H. Fabrication and Characterization of PCL/TiO2 Nanoparticle 3D Scaffold. Polym. Korea 2014, 38, 150–155. [Google Scholar] [CrossRef][Green Version]

- Bartnikowski, M.; Dargaville, T.R.; Ivanovski, S.; Hutmacher, D.W. Degradation mechanisms of polycaprolactone in the context of chemistry, geometry and environment. Prog. Polym. Sci. 2019, 96, 1–20. [Google Scholar] [CrossRef]

- Del Ángel-Sánchez, K.; Vázquez-Cuchillo, O.; Salazar-Villanueva, M.; Sánchez-Ramírez, J.F.; Cruz-López, A.; Aguilar-Elguezabal, A. Preparation, characterization and photocatalytic properties of TiO2 nanostructured spheres synthesized by the Sol–Gel method modified with ethylene glycol. J. Sol. Gel. Sci. Technol. 2011, 58, 360–365. [Google Scholar] [CrossRef]

- Palacios-Pineda, L.M.; Perales-Martínez, I.A.; Moreno-Guerra, M.; Elías-Zúñiga, A. An Optimum Specimen Geometry for Equibiaxial Experimental Tests of Reinforced Magnetorheological Elastomers with Iron Micro- and Nanoparticles. Nanomaterials 2017, 7, 254. [Google Scholar] [CrossRef] [PubMed]

- Elías-Zúñiga, A.; Baylón, K.; Ferrer, I.; Serenó, L.; García-Romeu, M.L.; Bagudanch, I.; Grabalosa, J.; Pérez-Recio, T.; Martínez-Romero, O.; Ortega-Lara, W.; et al. On the rule of mixtures for predicting stress-softening and residual strain effects in biological tissues and biocompatible materials. Materials 2014, 7, 441–456. [Google Scholar] [CrossRef]

- Belmares, M.; Blanco, M.; Caldwell, G.; Chou, S.H.; Goddard, W.A.; Olofson, P.M.; Pham, J.; Ross, R.B.; Thomas, C. Hildebrand and Hansen solubility parameters from molecular dynamics with applications to electronic nose polymer sensors. J. Comput. Chem. 2004, 25, 1814–1826. [Google Scholar] [CrossRef]

- Safaei, F.; Khalili, S.; Khorasani, S.N.; Ghasemi-Mobarakeh, L.; Neisiany, R.E. Porogen Effect of Solvents on Pore Size Distribution of Solvent-Casted Polycaprolactone Thin Films. J. Polym. Sci. Eng. 2018, 1, 1–5. [Google Scholar] [CrossRef]

- Kanani, A.G.; Bahrami, S.G. Effect of changing solvents on poly(ε-caprolactone) nanofibrous webs morphology. J. Nanomater. 2011, 2011, 31. [Google Scholar]

- Qin, X.; Wu, D. Effect of different solvents on poly(caprolactone) (PCL) electrospun nonwoven membranes. J. Therm. Anal. Calorim. 2012, 107, 1007–1013. [Google Scholar] [CrossRef]

- Katsogiannis, K.A.G.; Vladisavljevic, G.T.; Georgiadou, S. Porous electrospun polycaprolactone (PCL) fibres by phase separation. Eur. Polym. J. 2015, 69, 284–295. [Google Scholar] [CrossRef]

- Mane, S. Effect of porogens (type and amount) on polymer porosity: A review. Can. Chem. Trans. 2016, 4, 210–225. [Google Scholar]

- Unger, M.; Vogel, C.; Siesler, H.W. Molecular weight dependence of the thermal degradation of poly(ε-caprolactone): A thermogravimetric differential thermal Fourier transform infrared spectroscopy study. Appl. Spectrosc. 2010, 64, 805–809. [Google Scholar] [CrossRef] [PubMed]

- Bittiger, H.; Marchessault, R.H.; Niegisch, W.D. Crystal structure of poly-ε-caprolactone. Acta Crystallogr. Sect. B Struct. Crystallogr. Cryst. Chem. 1970, 26, 1923–1927. [Google Scholar] [CrossRef]

- Chung, F.H.; Scotta, R.W. A New Approach to the Determination of Crystallinity of Polymers by X-ray Diffraction. J. Appl. Cryst. 1973, 6, 225–230. [Google Scholar] [CrossRef]

- Shen, Y.; Lua, A.C. Preparation and characterization of mixed matrix membranes based on PVDF and three inorganic fillers (fumed nonporous silica, zeolite 4A and mesoporous MCM-41) for gas separation. Chem. Eng. J. 2012, 192, 201–210. [Google Scholar] [CrossRef]

- Wei, Z.; Wang, G.; Wang, P.; Liu, L.; Qi, M. Crystallization behaviour of Poly(ε-caprolactone)/TiO2 nanocomposites obtained by in situ polymerization. Polym. Eng. Sci. 2012, 52, 1046–1057. [Google Scholar] [CrossRef]

- Casado-Coterillo, C.; del Mar López-Guerrero, M.; Irabien, A. Synthesis and Characterisation of ETS-10/Acetate-based Ionic Liquid/Chitosan Mixed Matrix Membranes for CO2/N2 Permeation. Membranes 2014, 4, 287–301. [Google Scholar] [CrossRef]

- Beatty, M.F. Constitutive equations for the back stress in amorphous glassy polymers. Math. Mech. Solids 2005, 10, 167–181. [Google Scholar] [CrossRef]

- Mulliken, A.D.; Boyce, M.C. Mechanics of the rate-dependent elastic–plastic deformation of glassy polymers from low to high strain rates. Int. J. Solids Struct. 2006, 43, 1331–1356. [Google Scholar] [CrossRef]

| Sample | Compound | Solvent | PCL (%) | TiO2 (M) | P25 Degussa (M) |

|---|---|---|---|---|---|

| A1 | PCL | Acetic acid | 10 | - | - |

| A2-D | PCL-P25 | Acetic acid | 10 | - | 0.015 |

| A3-D | PCL-P25 | Acetic acid | 10 | - | 0.030 |

| A2-Sg | PCL-TiO2 400 °C | Acetic acid | 10 | 0.015 | - |

| A3-Sg | PCL-TiO2 400 °C | Acetic acid | 10 | 0.030 | - |

| C1 | PCL | Chloroform-DMF | 10 | - | - |

| C2-D | PCL-P25 | Chloroform-DMF | 10 | - | 0.015 |

| C3-D | PCL-P25 | Chloroform-DMF | 10 | - | 0.030 |

| C2-Sg | PCL-TiO2 400 °C | Chloroform-DMF | 10 | 0.015 | - |

| C3-Sg | PCL-TiO2 400 °C | Chloroform-DMF | 10 | 0.030 | - |

| Solvent | Boiling Point (°C) | Relative Polarity | Solubility Parameter (cal1/2 cm−3/2) | PCL Solubility | Porogenic Type |

|---|---|---|---|---|---|

| Chloroform | 61.2 | 0.259 | 9.3 | Good | Non-Solvating |

| Acetic Acid | 118.1 | 0.648 | 13.01 | - | Solvating |

| DMF | 62.6 | 0.386 | 11.79 | Good | - |

| Samples | |||

|---|---|---|---|

| PCL Reference | 58.8 | 54.7 | 39.2 |

| A1 | 56.6 | 74.7 | 53.6 |

| C1 | 55.9 | 42.3 | 30.3 |

| Sample | Maximum Tensile Stress, MPa | Elongation at Break, m/m | Young Modulus, MPa |

|---|---|---|---|

| A1 | 2.36 | 0.82 | 69.91 |

| A2-D | 1.91 | 0.60 | 51.3 |

| A3-D | 2.45 | 0.55 | 85.81 |

| A2-Sg | 2.08 | 0.47 | 62.75 |

| A3-Sg | 2.79 | 0.39 | 93.54 |

| C1 | 6.04 | 2.35 | 141.97 |

| C2-D | 7.47 | 2.46 | 258.77 |

| C3-D | 13.49 | 2.87 | 400.47 |

| C2-Sg | 11.67 | 2.37 | 374.77 |

| C3-Sg | 15.47 | 2.93 | 485.29 |

| Sample | μ (MPa) | N (-) | A1 (MPa) | A2 (MPa) | b (-) | c (MPa) | f (-) | Permanent Set |

|---|---|---|---|---|---|---|---|---|

| A1 | 130 | 4 | 0 | −2700 | 7 | 2.5 | 0.7 | 0.035 |

| C1 | 450 | 40 | 0 | 0 | 10 | 15 | 0.6 | 0.001 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

del Ángel-Sánchez, K.; Borbolla-Torres, C.I.; Palacios-Pineda, L.M.; Ulloa-Castillo, N.A.; Elías-Zúñiga, A. Development, Fabrication, and Characterization of Composite Polycaprolactone Membranes Reinforced with TiO2 Nanoparticles. Polymers 2019, 11, 1955. https://doi.org/10.3390/polym11121955

del Ángel-Sánchez K, Borbolla-Torres CI, Palacios-Pineda LM, Ulloa-Castillo NA, Elías-Zúñiga A. Development, Fabrication, and Characterization of Composite Polycaprolactone Membranes Reinforced with TiO2 Nanoparticles. Polymers. 2019; 11(12):1955. https://doi.org/10.3390/polym11121955

Chicago/Turabian Styledel Ángel-Sánchez, Karina, César I. Borbolla-Torres, Luis M. Palacios-Pineda, Nicolás A. Ulloa-Castillo, and Alex Elías-Zúñiga. 2019. "Development, Fabrication, and Characterization of Composite Polycaprolactone Membranes Reinforced with TiO2 Nanoparticles" Polymers 11, no. 12: 1955. https://doi.org/10.3390/polym11121955

APA Styledel Ángel-Sánchez, K., Borbolla-Torres, C. I., Palacios-Pineda, L. M., Ulloa-Castillo, N. A., & Elías-Zúñiga, A. (2019). Development, Fabrication, and Characterization of Composite Polycaprolactone Membranes Reinforced with TiO2 Nanoparticles. Polymers, 11(12), 1955. https://doi.org/10.3390/polym11121955