Crystalline Modification of Isotactic Polypropylene with a Rare Earth Nucleating Agent Based on Ultrasonic Vibration

Abstract

:1. Introduction

2. Experimental Section

2.1. Materials

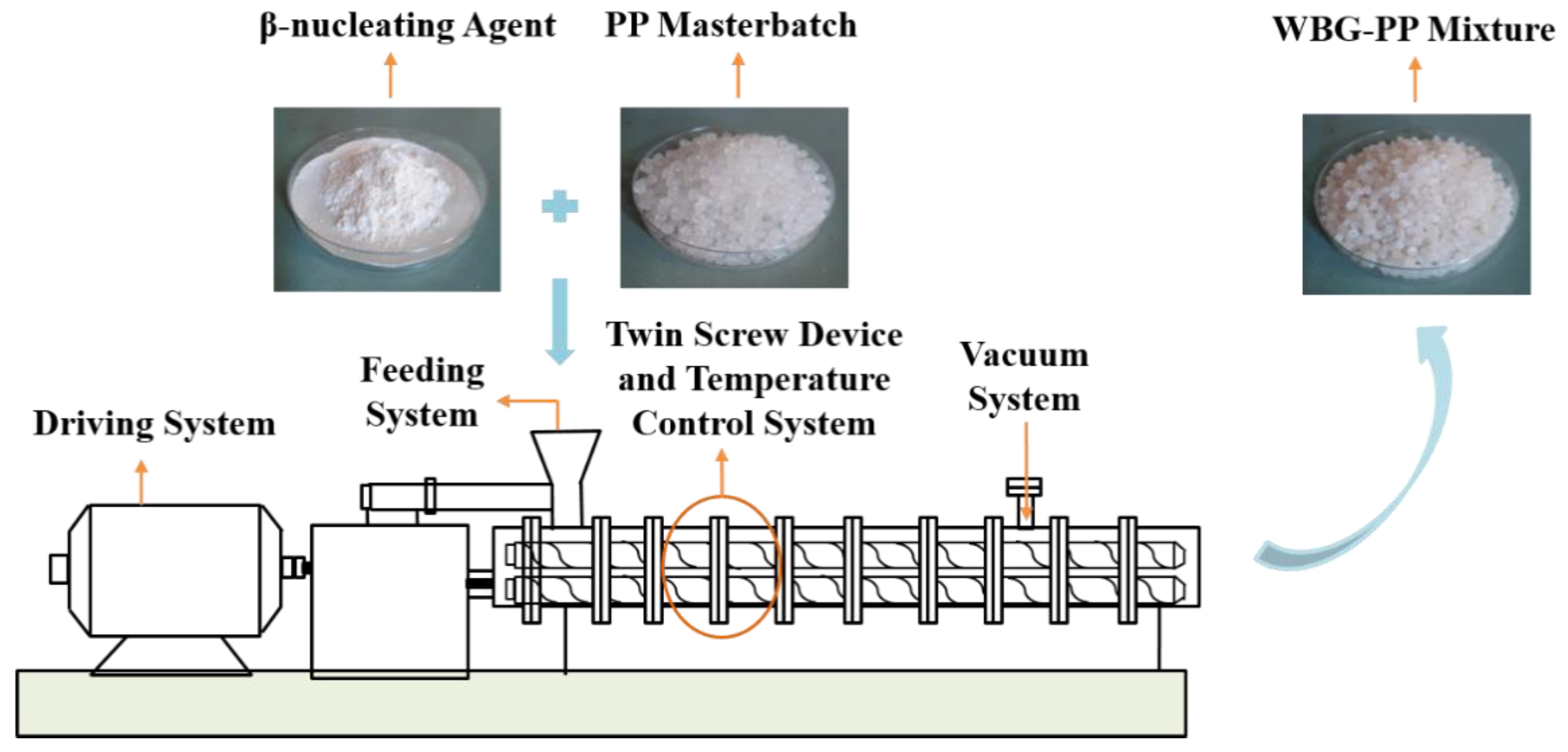

2.2. Composites Preparation

2.3. Sample Prepared under Different Conditions

2.4. Characterization

3. Results and Discussion

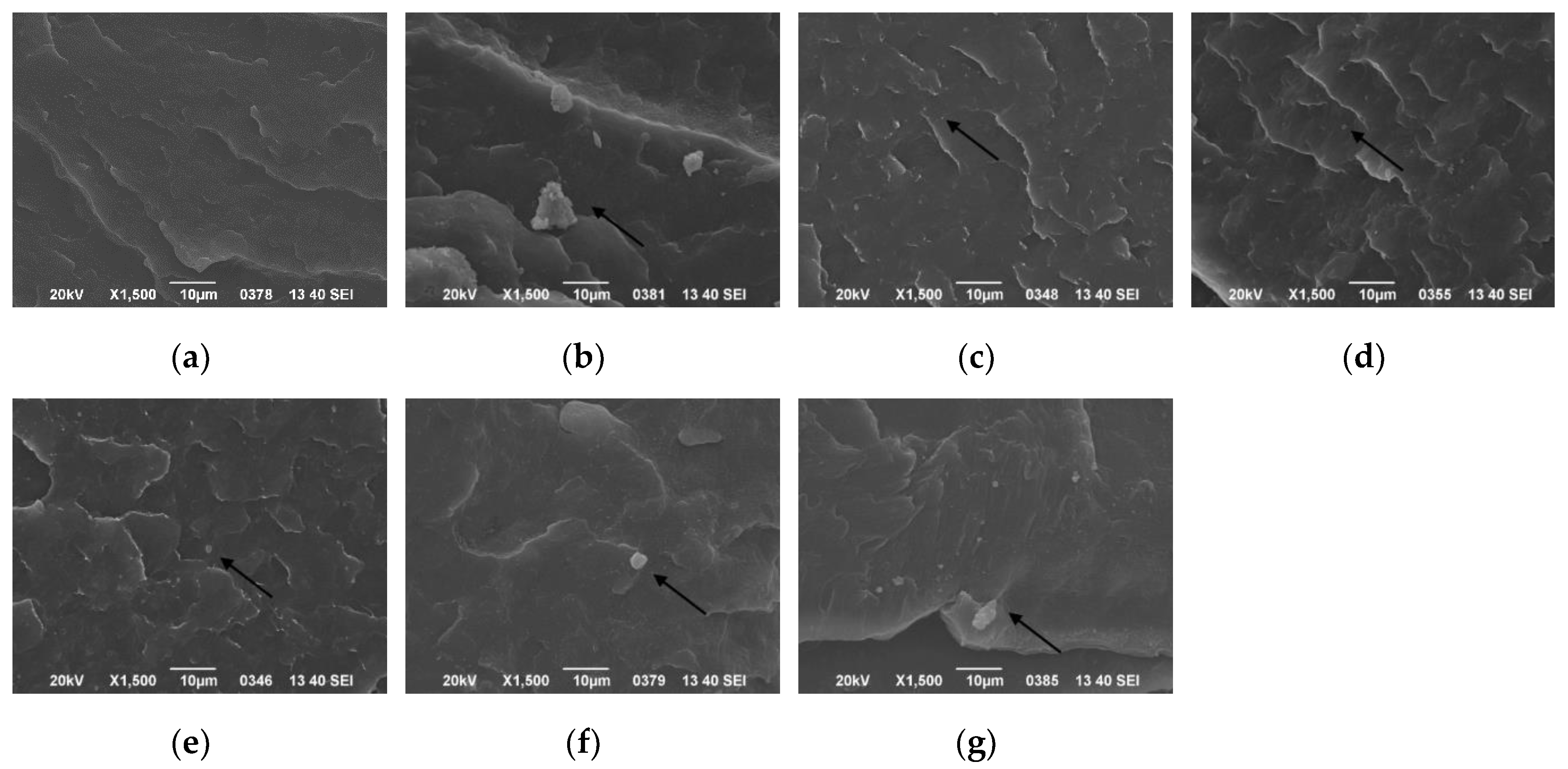

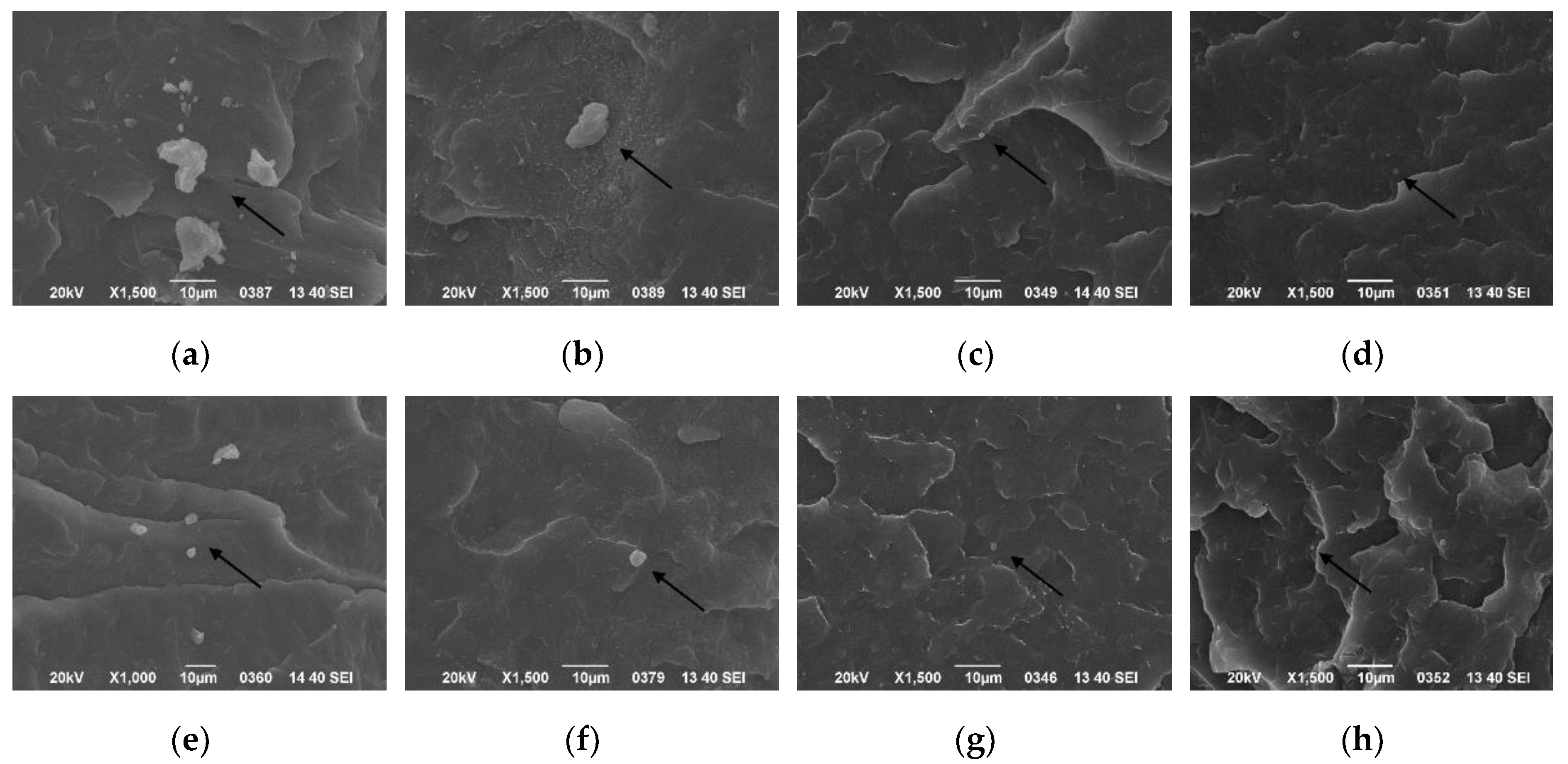

3.1. The Effect of Different Ultrasound Condition on the Dispersion of β-Nucleating Agent in PP

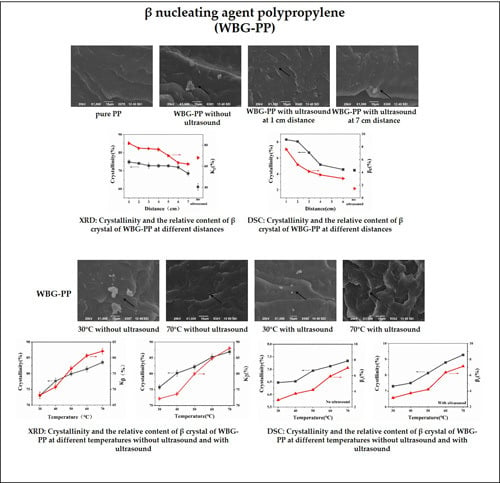

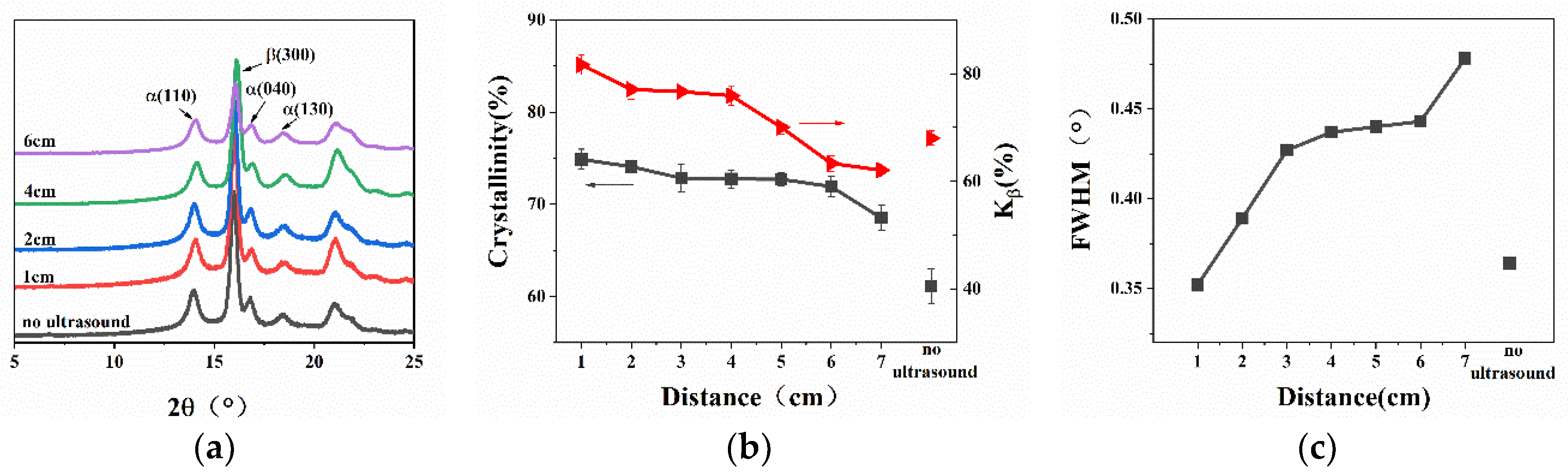

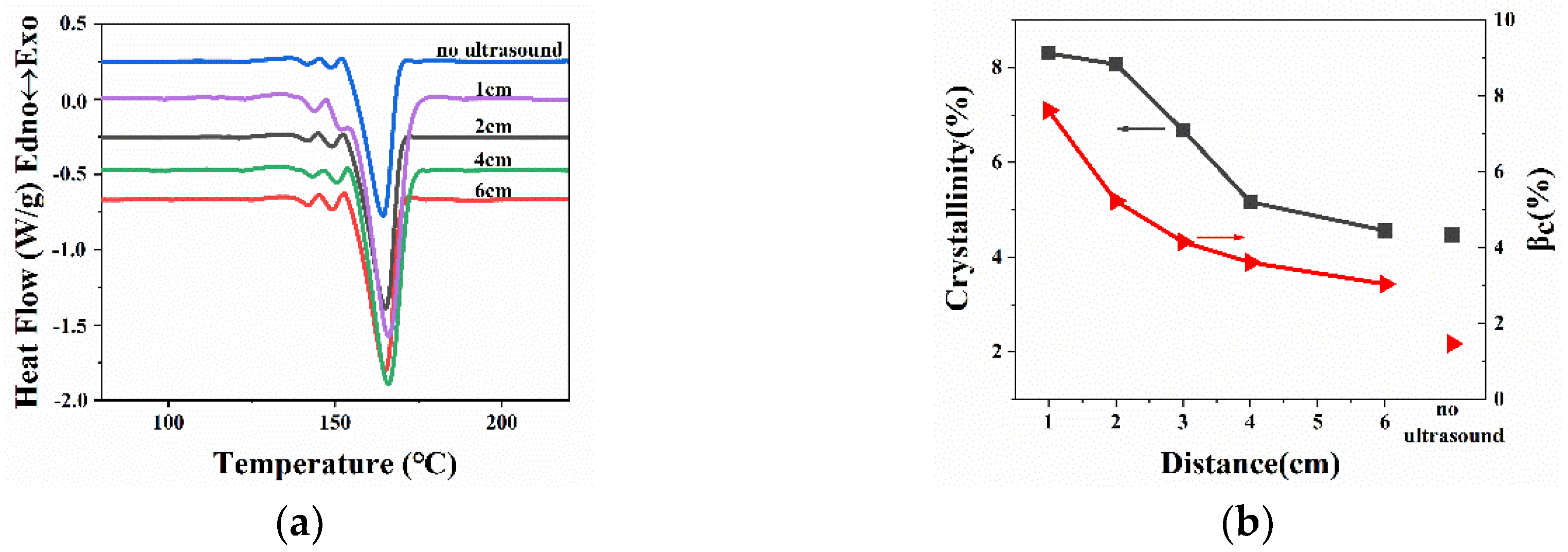

3.2. The Effect of Ultrasound Distance on the Crystallinity of WBG-PP

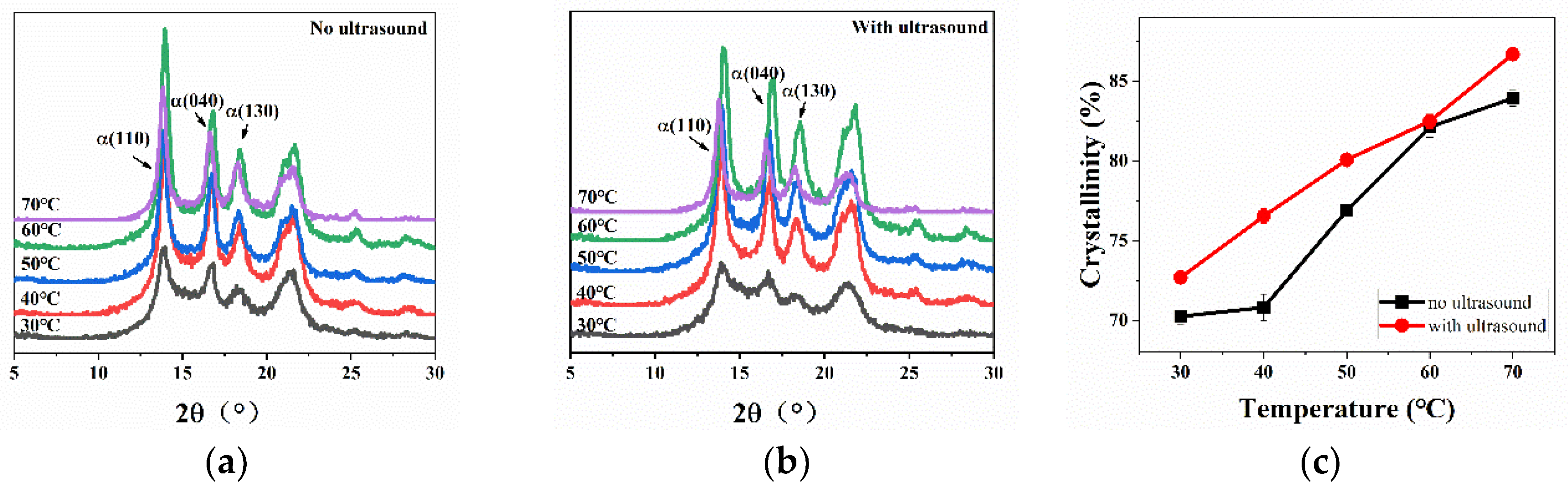

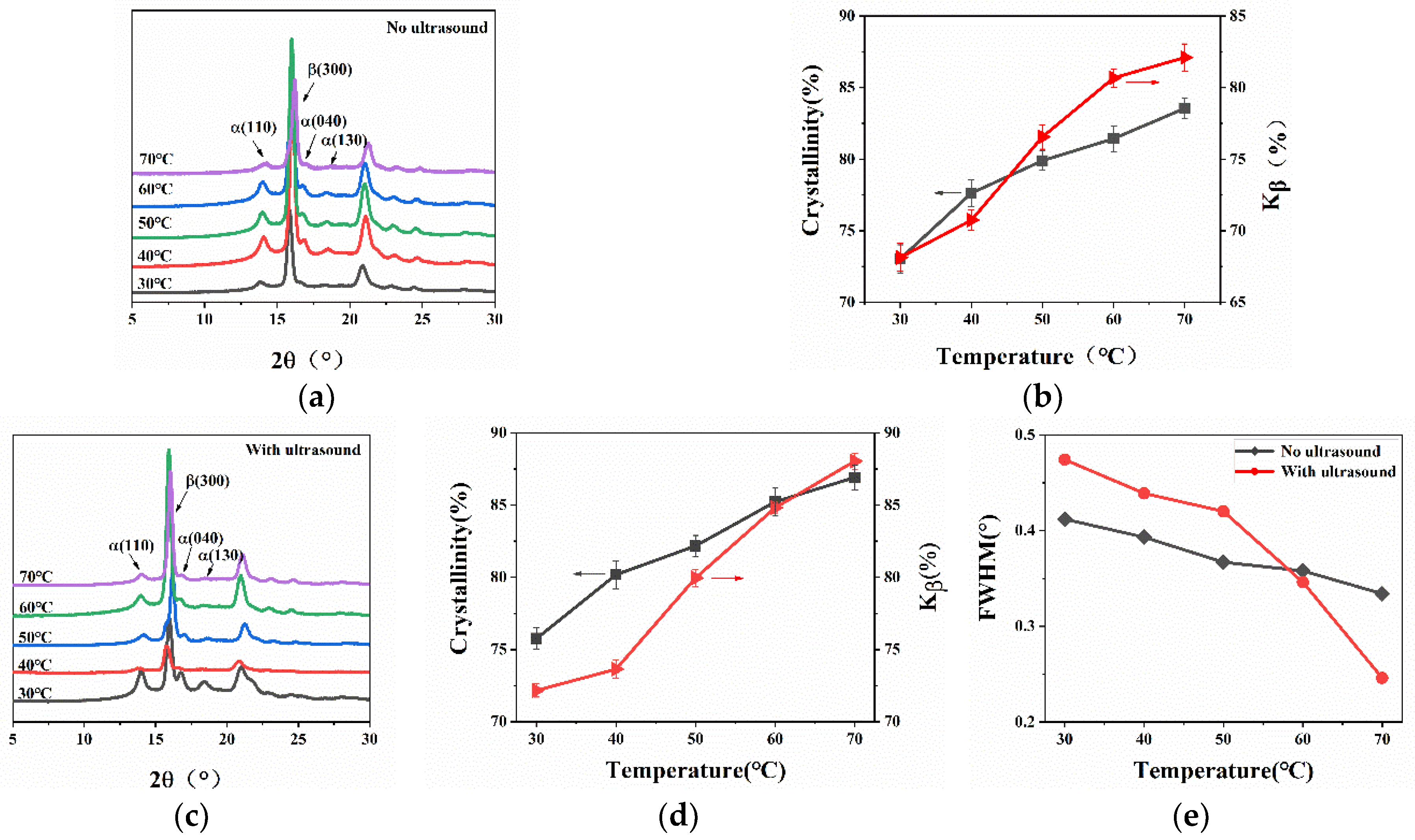

3.3. The Effect of Ultrasound Temperature on the Crystallinity of WBG-PP

3.4. The Effect of Ultrasound Conditions on Mechanical Properties of WBG-PP

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Galli, P.; Danesi, S.; Simonazzi, T. Polypropylene based polymer blends: Fields of application and new trends. Polym. Eng. Sci. 1984, 24, 544–554. [Google Scholar] [CrossRef]

- Shengjun, J.; Zongjian, L. Status and development of polypropylene speciality for automobile in China. Chin. Synth. Resin Plast. 1999, 3. Available online: http://en.cnki.com.cn/Article_en/CJFDTotal-HCSZ199903003.htm (accessed on 17 September 2019).

- Muñoz-Pascual, S.; Lopez-Gonzalez, E.; Saiz-Arroyo, C.; Rodriguez-Perez, M.A. Effect of mold temperature on the impact behavior and morphology of injection molded foams based on polypropylene polyethylene-octene copolymer blends. Polymers 2019, 11, 894. [Google Scholar] [CrossRef] [PubMed]

- Gao, M.; Yang, J.; Zhao, H.; He, H.; Xie, S. Preparation methods of polypropylene/nano-silica/styrene-ethylene-butylene-styrene composite and its effect on electrical properties. Polymers 2019, 11, 797. [Google Scholar] [CrossRef]

- Yuanming, Z.; Tingting, S.; Wei, J.; Han, G. Crystalline modification of a rare earth nucleating agent for isotactic polypropylene based on its self-assembly. R. Soc. Open Sci. 2018, 5, 180247. [Google Scholar] [Green Version]

- Housmans, J.W.; Gahleitner, M.; Peters, G.W.M.; Meijer, H.E.H. Structure-property relations in molded, nucleated isotactic polypropylene. Polymer 2009, 50, 2304–2319. [Google Scholar] [CrossRef]

- Lotz, B.; Wittmann, J.C.; Lovinger, A.J. Structure and morphology of poly(propylenes): A molecular analysis. Polymer 1996, 37, 4979–4992. [Google Scholar] [CrossRef]

- Yamamoto, Y.; Inoue, Y.; Onai, T.; Doshu, C.; Takahshi, H.; Uehara, H. Deconvolution analyses of differential scanning calorimetry profiles of β-crystallized polypropylenes with synchronized X-ray measurements. Macromolecules 2007, 40, 2745–2750. [Google Scholar] [CrossRef]

- Wang, K.; Zhou, C. The effects of melt vibration blending on the subsequent crystallization and melting behavior of polypropylene/ultra high molecular weight polyethylene. Polym. Eng. Sci. 2010, 41, 2249–2258. [Google Scholar] [CrossRef]

- Lin, Z.; Guan, Z.; Xu, B.; Chen, C.; Guo, G.; Zhou, J.; Xian, J.; Gao, L.; Wang, Y.; Li, M.; et al. Crystallization and melting behavior of polypropylene in β-PP/polyamide 6 blends containing PP-g-MA. J. Ind. Eng. Chem. 2013, 19, 692–697. [Google Scholar] [CrossRef]

- Yang, Z.; Chen, C.; Liang, D.; Zhang, Z.; Mai, K. Melting characteristic and β-crystal content of β-nucleated polypropylene/polyamide 6 alloys prepared using different compounding methods. Polym. Int. 2009, 58, 1366–1372. [Google Scholar] [CrossRef]

- Wang, J.; Dong, W.; Zhu, B.; Dong, Q.; Zhang, G. Advances in post-functionalzation of polypropylene by grafting modification. Chem. Ind. Eng. Prog. 2011, 30, 2235–2239. [Google Scholar]

- Han, R.; Nie, M.; Wang, Q. Control over β-form hybrid shish-kebab crystals in polypropylene pipe via coupled effect of self-assembly β nucleating agent and rotation extrusion. J. Taiwan Inst. Chem. Eng. 2015, 52, 158–164. [Google Scholar] [CrossRef]

- Wang, D.; Xie, X.M.; Jow, J.; Chen, H.Y.; Lai, S.Y. Styrene-assisted melt free-radical grafting of pentaerythritol triacrylate onto polypropylene and its crystallization behavior. J. Appl. Polym. Sci. 2008, 108, 1737–1743. [Google Scholar] [CrossRef]

- Ji, H.; Zhou, X.; Chen, X.; Zhao, H.; Wang, Y.; Zhu, H.; Shan, X.; Sha, J.; Ma, Y.; Xie, L. Effects of solid-state stretching on microstructure evolution and physical properties of isotactic polypropylene sheets. Polymers 2019, 11, 618. [Google Scholar] [CrossRef] [PubMed]

- Feng, J.; Chen, M.; Huang, Z.; Guo, Y.; Hu, H. Effects of mineral additives on the β-crystalline form of isotactic polypropylene. J. Appl. Polym. Sci. 2002, 85, 1742–1748. [Google Scholar] [CrossRef]

- Varga, J.; Stoll, K.; Menyhárd, A.; Horváth, Z. Crystallization of isotactic polypropylene in the presence of a β-nucleating agent based on a trisamide of trimesic acid. J. Appl. Polym. Sci. 2011, 121, 1469–1480. [Google Scholar] [CrossRef]

- Chen, J.; Chen, Y.; Li, H.; Lai, S.; Jow, J. Physical and chemical effects of ultrasound vibration on polymer melt in extrusion. Ultrason. Sonochem. 2010, 17, 66–71. [Google Scholar] [CrossRef]

- Elgegren, M.; Kim, S.; Cordova, D.; Silva, C.; Noro, J.; Cavaco-Paulo, A.; Nakamatsu, J. Ultrasound-assisted encapsulation of sacha inchi (plukenetia volubilis linneo.) oil in alginate-chitosan nanoparticles. Polymers 2019, 11, 1245. [Google Scholar] [CrossRef]

- Eskin, G.I.; Pimenov, Y.P.; Makarov, G.S. Effect of cavitation melt treatment on the structure refinement and property improvement in cast and deformed hypereutectic Al-Si alloys. Mater. Sci. Forum 1997, 242, 65–70. [Google Scholar] [CrossRef]

- Li, Y.L.; Ding, H.; Cao, F.R. Effects of high density ultrasonic field coupling on the microstructures and properties of Al-Si alloy. Adv. Mater. Res. 2011, 291, 1981–1988. [Google Scholar] [CrossRef]

- Kang, J.; Chen, J.; Cao, Y.; Li, H. Effects of ultrasound on the conformation and crystallization behavior of isotactic polypropylene and β-isotactic polypropylene. Polymer 2010, 51, 249–256. [Google Scholar] [CrossRef]

- Turnerjones, A.; Cobbold, A.J. The β crystalline form of isotactic polypropylene. J. Polym. Sci. Part B Polym. Lett. 1968, 6, 539–546. [Google Scholar] [CrossRef]

- Jones, A.T.; Aizlewood, J.M.; Beckett, D.R. Crystalline forms of isotactic polypropylene. Macromol. Chem. Phys. 1964, 75, 134–158. [Google Scholar] [CrossRef]

- Hill, R.J.; Howard, C.J. Quantitative phase analysis from neutron powder diffraction data using the Rietveld method. J. Appl. Crystallogr. 1987, 20, 467–474. [Google Scholar] [CrossRef]

- Guien, Z. X-ray Diffraction of Polymer; University of Sci. and Tech. of China Press: Beijing, China, 1989; pp. 183–184. [Google Scholar]

- Li, J.; Cheung, W. On the deformation mechanisms of β-polypropylene: 1. Effect of necking on β-phase PP crystals. Polymer 1998, 39, 6935–6940. [Google Scholar] [CrossRef]

- Shangguan, Y.; Song, Y.; Peng, M.; Li, B.; Zheng, Q. Formation of β-crystal from nonisothermal crystallization of compression-molded isotactic polypropylene melt. Eur. Polym. J. 2005, 41, 1766–1771. [Google Scholar] [CrossRef]

- Kargar-Kocsis, J. Polypropylene: An AZ Reference; Springer Science & Business Media: Berlin, Germany, 2012. [Google Scholar]

- Li, J.X.; Cheung, W.L.; Jia, D. A study on the heat of fusion of β-polypropylene. Polymer 1999, 40, 1219–1222. [Google Scholar] [CrossRef]

- Lai, W.J.; Cheng, K.C. Crystallization and luminescence properties of polypropylene fiber containing rare earth aluminates and a sorbital derivative nucleating agent. Fibers Polym. 2018, 19, 22–30. [Google Scholar] [CrossRef]

- Abdou, J.P.; Braggin, G.A.; Luo, Y.; Stevenson, A.R.; Chun, D.; Zhang, S. Graphene-induced oriented interfacial microstructures in single fiber polymer composites. ACS Appl. Mater. Interfaces 2015, 7, 13620–13626. [Google Scholar] [CrossRef]

- Patel, K.K.; Kumar, V.; Purohit, R.; Gupta, G.K.; Modi, O.P. Effect of ultrasonic stirring on changes in microstructure and mechanical properties of cast in-situ Al 5083 alloy composites containing 5wt.% and 10wt.% TiC particles. Mater. Today Proc. 2017, 4, 3494–3500. [Google Scholar] [CrossRef]

- Dietemann, M.; Baillon, F.; Espitalier, F.; Calvet, R.; Accart, P.; Confetto, S.D.; Green-Hooper, M. Evaluation of the physico-chemical properties of an amorphous magnesium silicate synthesized by an ultrasound-assisted precipitation. Chem. Eng. J. 2013, 215, 658–670. [Google Scholar] [CrossRef]

- Heubner, W.; Eckardt, J.; Muller, S. Ultrasonic sensor technology in hydraulic cylinders. ATZ Worldwide 2016, 118, 42–45. [Google Scholar] [CrossRef]

- Gao, J.G.; Yu, M.S.; Li, Z.T. Nonisothermal crystallization kinetics and melting behavior of bimodal medium density polyethylene/low density polyethylene blends. Eur. Polym. J. 2004, 40, 1533–1539. [Google Scholar] [CrossRef]

- Varga, J. β-Modification of polypropylene and its two-component systems. J. Therm. Anal. 1989, 35, 1891–1912. [Google Scholar] [CrossRef]

- Lotz, B.; Fillon, B.; Thierry, A.; Wittmann, J.C. Low Tc growth transitions in isotactic polypropylene: β to α and α to smectic phases. Polym. Bull. 1991, 25, 101–105. [Google Scholar]

- Lotz, B.; Wittmann, J.C. Isotactic polypropylene: Growth transitions and crystal polymorphism. In Solidification Processes in Polymers; Steinkopff: Berlin, Germany, 1992; pp. 2–7. [Google Scholar]

- Jian, X.; Xu, H.; Meek, T.T.; Han, Q. Effect of power ultrasound on solidification of aluminum A356 alloy. Mater. Lett. 2005, 59, 190–193. [Google Scholar] [CrossRef]

| Temperature Zone | 1 | 2 | 3 | 4 |

|---|---|---|---|---|

| Temperature Setting | 160 | 190 | 220 | 240 |

| Other Parameters | The content of the β-nucleating agent | Twin-screw speed | Cooling temperature | Cooling time |

| 0.4% | 60 r/min | 20 °C | 120 s |

| Sample | Xα (%) | Xβ (%) | βc (%) | θ (%) |

|---|---|---|---|---|

| 0 | 5.2050 | 0.0768 | 1.47 | 4.47 |

| 1 | 9.0887 | 0.7493 | 7.62 | 8.30 |

| 2 | 9.0600 | 0.5000 | 5.23 | 8.07 |

| 4 | 5.8800 | 0.2200 | 3.61 | 5.16 |

| 6 | 5.2250 | 0.1640 | 3.04 | 4.56 |

| Sample | Without Ultrasound | With Ultrasound | ||||||

|---|---|---|---|---|---|---|---|---|

| Xα (%) | Xβ (%) | βc (%) | θ (%) | Xα (%) | Xβ (%) | βc (%) | θ (%) | |

| 30 °C | 7.3762 | 0.2217 | 2.92 | 6.43 | 8.3626 | 0.2714 | 3.14 | 7.30 |

| 40 °C | 7.4441 | 0.2848 | 3.68 | 6.57 | 8.5855 | 0.3326 | 3.73 | 7.50 |

| 50 °C | 7.8146 | 0.3411 | 4.18 | 6.95 | 9.2790 | 0.4063 | 4.19 | 8.13 |

| 60 °C | 7.8276 | 0.4891 | 5.88 | 7.17 | 9.9229 | 0.6716 | 6.34 | 8.80 |

| 70 °C | 7.9046 | 0.5934 | 6.98 | 7.34 | 10.3914 | 0.7960 | 7.11 | 9.28 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, D.; Xin, Y.; Song, Y.; Dong, T.; Ben, H.; Yu, R.; Han, G.; Zhang, Y. Crystalline Modification of Isotactic Polypropylene with a Rare Earth Nucleating Agent Based on Ultrasonic Vibration. Polymers 2019, 11, 1777. https://doi.org/10.3390/polym11111777

Li D, Xin Y, Song Y, Dong T, Ben H, Yu R, Han G, Zhang Y. Crystalline Modification of Isotactic Polypropylene with a Rare Earth Nucleating Agent Based on Ultrasonic Vibration. Polymers. 2019; 11(11):1777. https://doi.org/10.3390/polym11111777

Chicago/Turabian StyleLi, Dan, Yujun Xin, Yan Song, Ting Dong, Haoxi Ben, Renxia Yu, Guangting Han, and Yuanming Zhang. 2019. "Crystalline Modification of Isotactic Polypropylene with a Rare Earth Nucleating Agent Based on Ultrasonic Vibration" Polymers 11, no. 11: 1777. https://doi.org/10.3390/polym11111777

APA StyleLi, D., Xin, Y., Song, Y., Dong, T., Ben, H., Yu, R., Han, G., & Zhang, Y. (2019). Crystalline Modification of Isotactic Polypropylene with a Rare Earth Nucleating Agent Based on Ultrasonic Vibration. Polymers, 11(11), 1777. https://doi.org/10.3390/polym11111777