Cytocompatible and Antibacterial Properties of Chitosan-Siloxane Hybrid Spheres

Abstract

1. Introduction

2. Materials and Methods

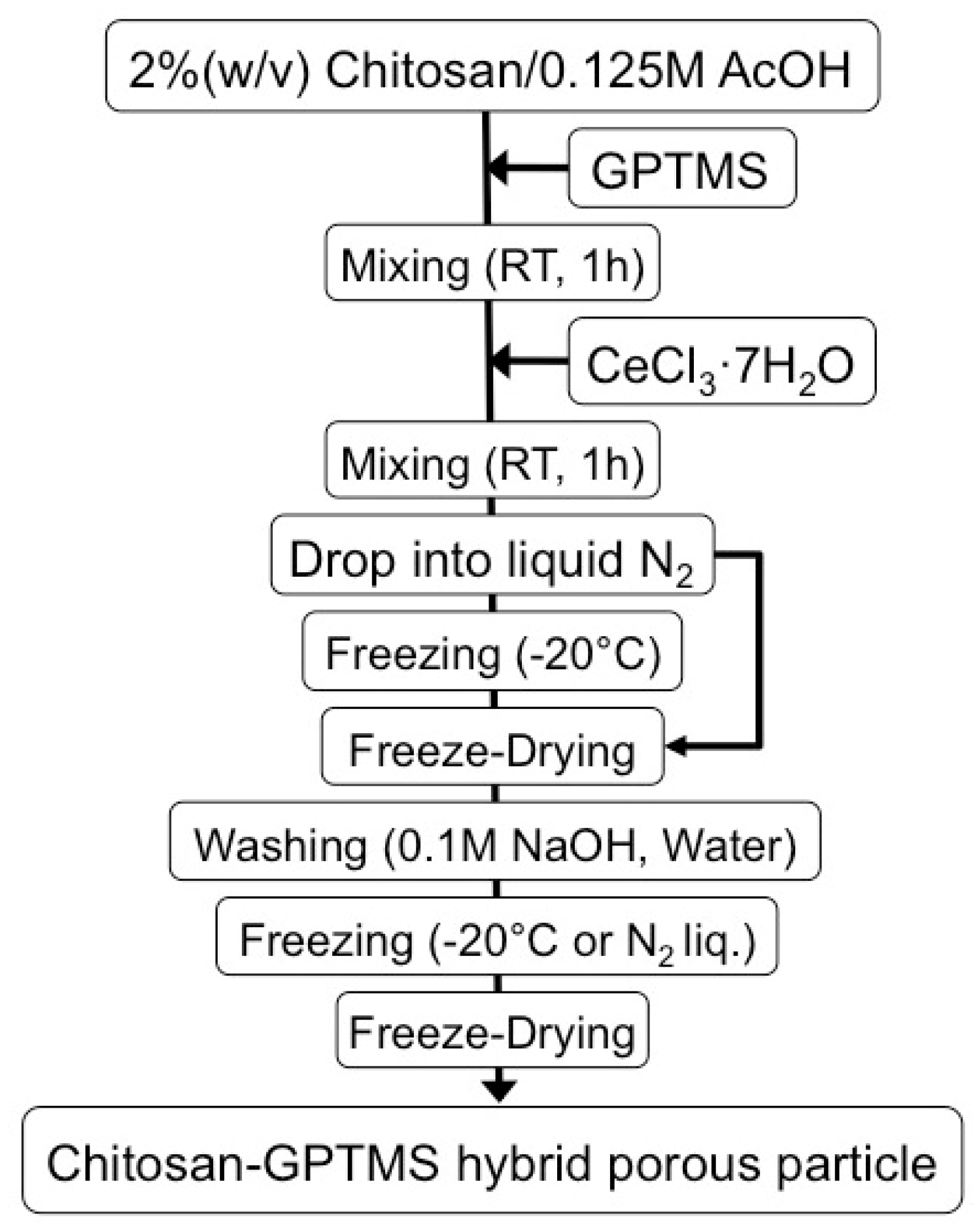

2.1. Preparation of Chitosan-Siloxane Hybrid Spheres without/with Cerium Ions

2.2. Characterization of Chitosan-Siloxane Hybrid Spheres

2.3. In Vitro Cytocompatibility Tests

2.4. In Vitro Antibacterial Property Tests

3. Results and Discussion

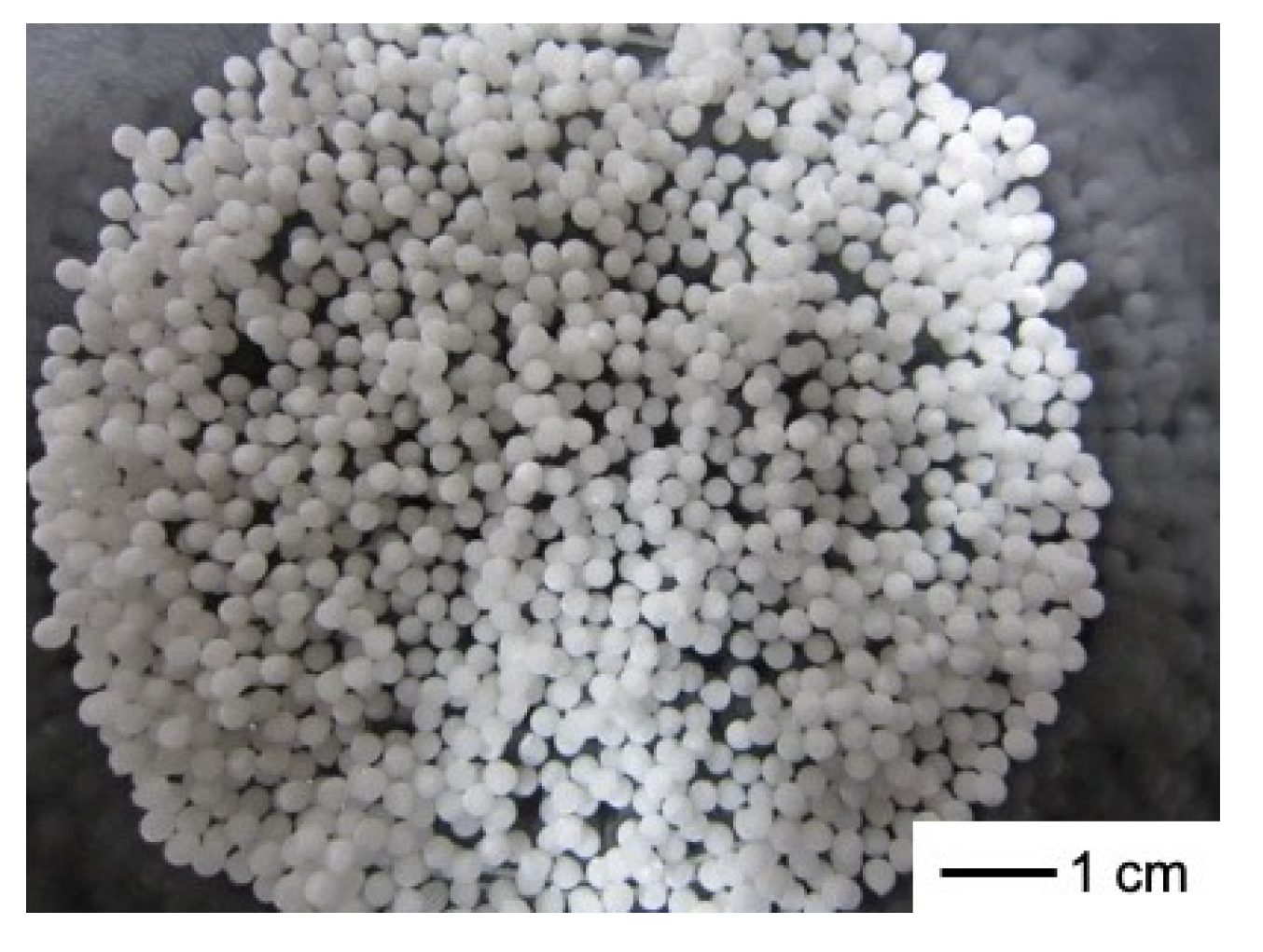

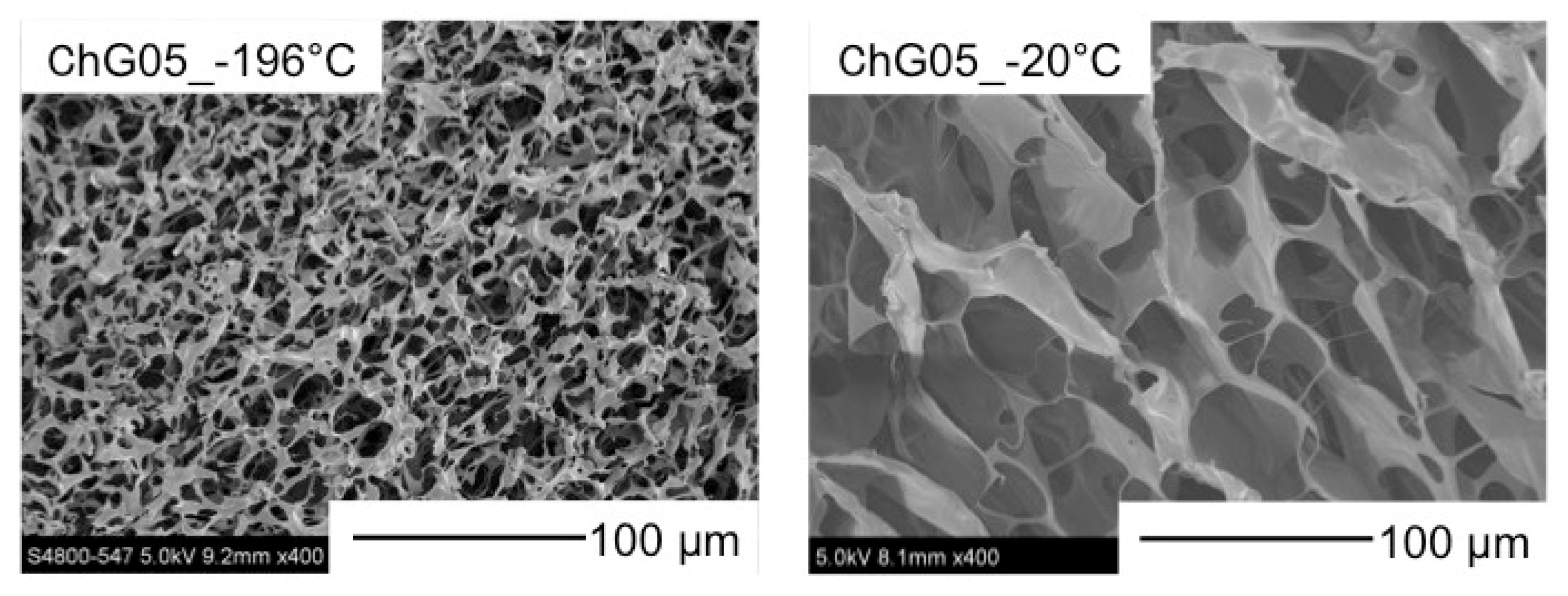

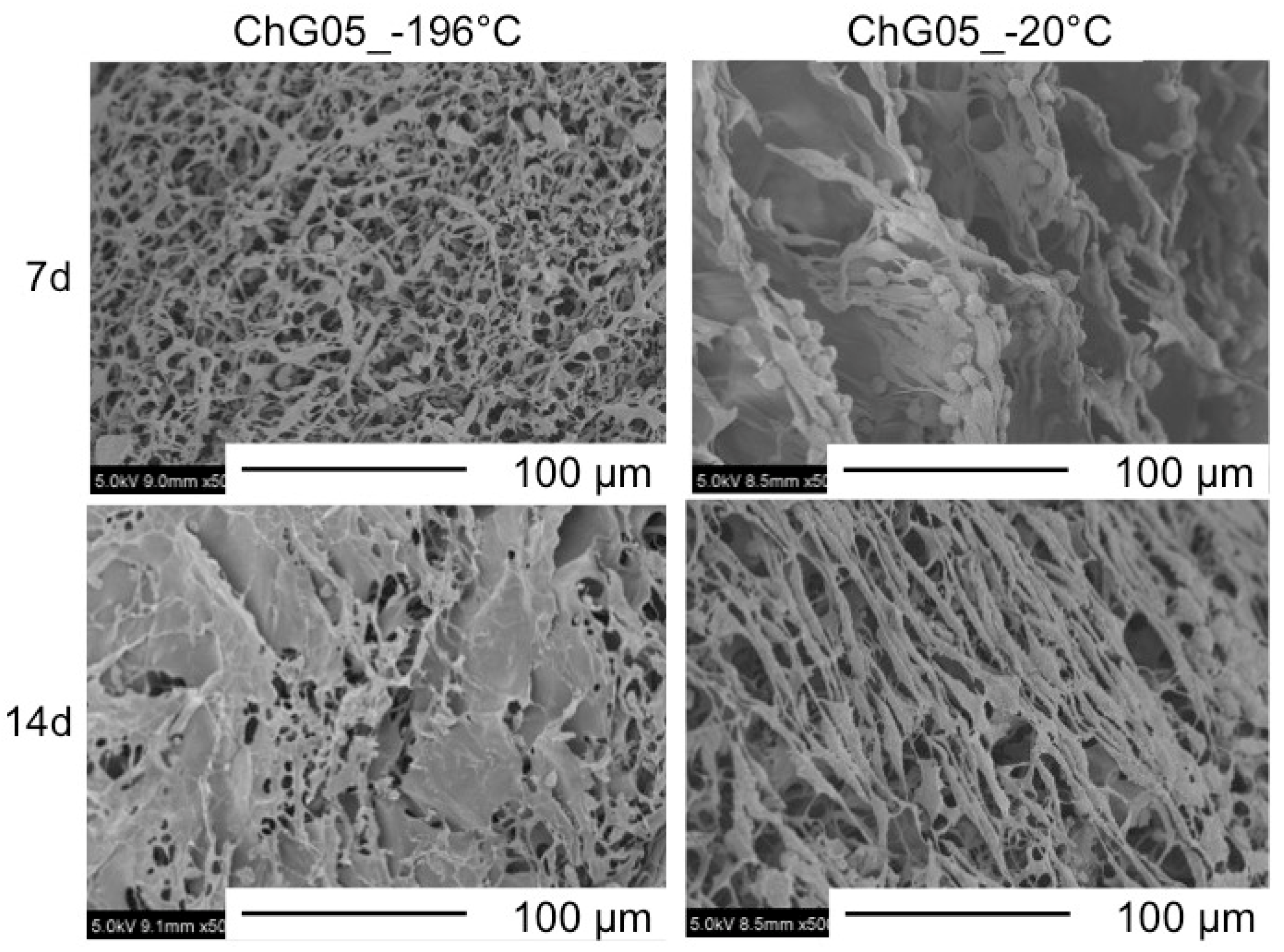

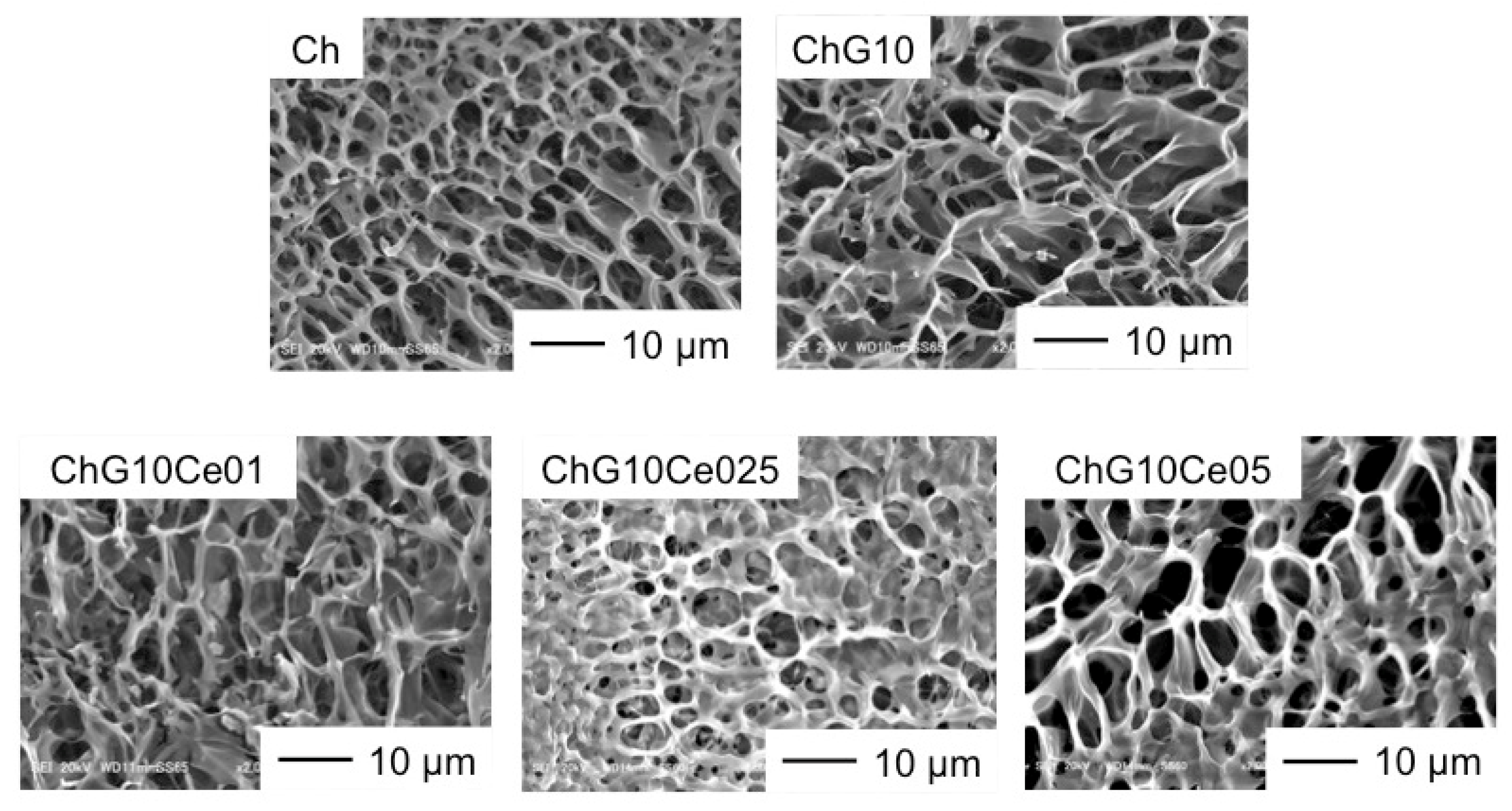

3.1. Sphere Micromorphologies

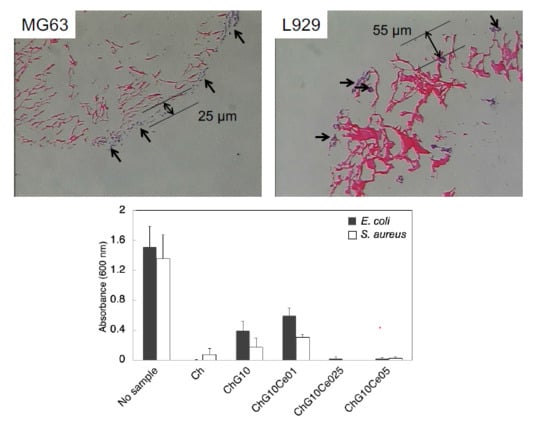

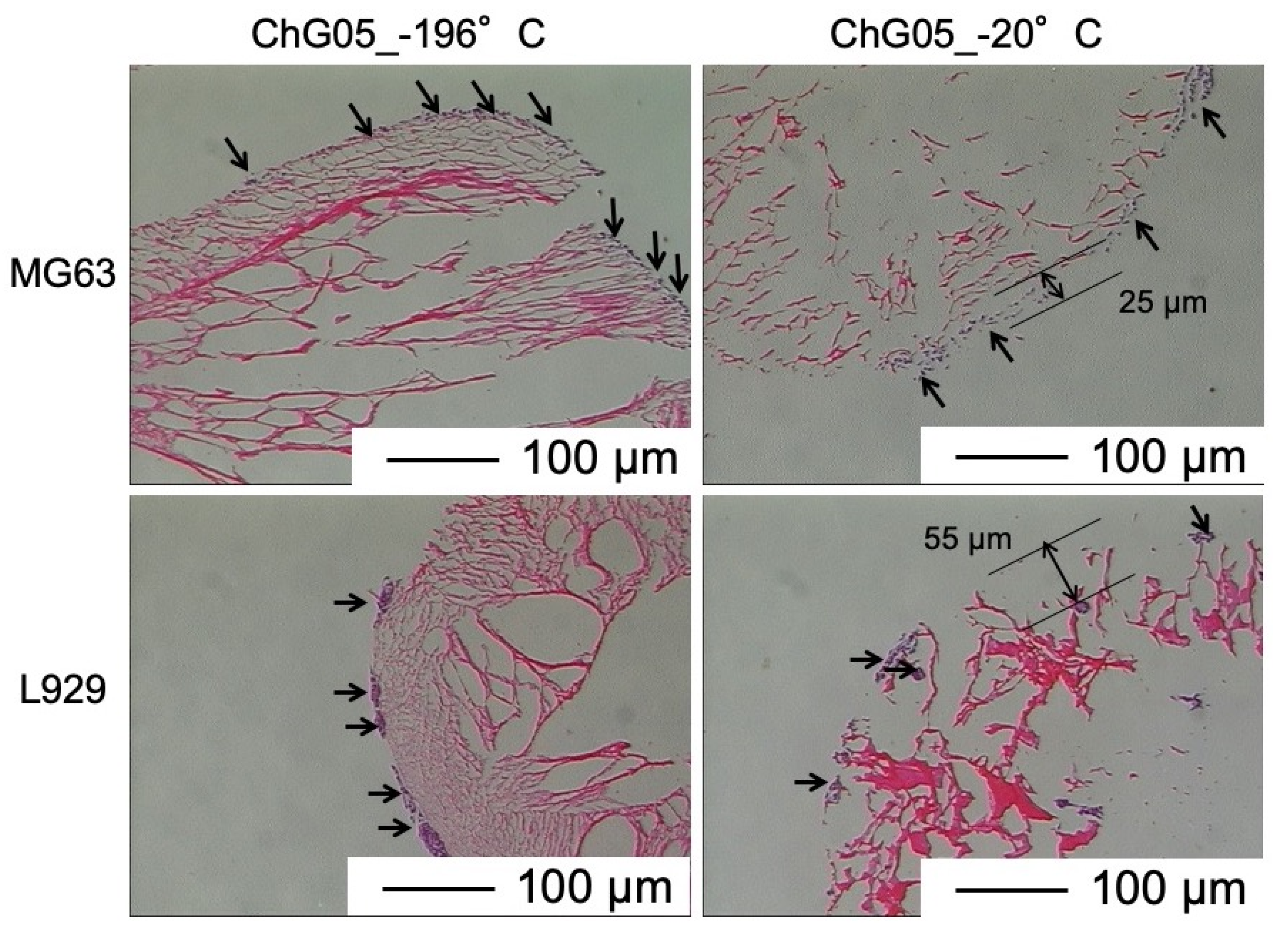

3.2. Cell Proliferation and Migration

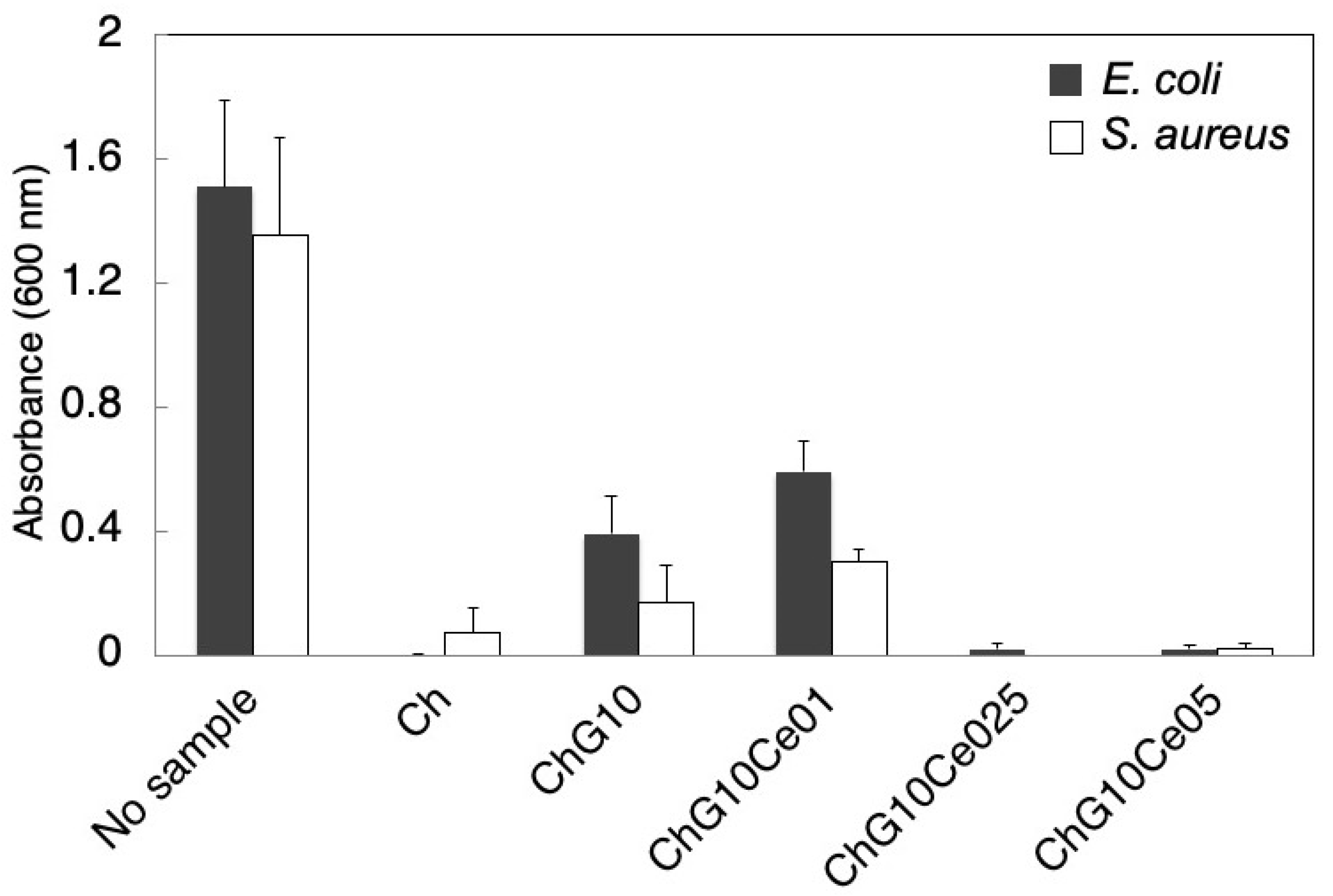

3.3. Antibacterial Properties of Spheres with Cerium Chloride

4. Conclusions

Supplementary Materials

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Keshaw, H.; Georgiou, G.; Blaker, J.J.; Forbes, A.; Knowles, J.C.; Day, R.M. Assessment of polymer/bioactive glass-composite microporous spheres for tissue regeneration applications. Tissue Eng. 2009, 15, 1451–1461. [Google Scholar] [CrossRef] [PubMed]

- Keshaw, H.; Thapar, N.; Burns, A.J.; Mordan, N.; Knowles, J.C.; Forbes, A.; Day, R.M. Microporous collagen spheres produced via thermally induced phase separation for tissue regeneration. Acta Biomater. 2010, 6, 1158–1166. [Google Scholar] [CrossRef] [PubMed]

- Shirosaki, Y.; Tsuru, K.; Hayakawa, S.; Osaka, A.; Lopes, M.A.; Santos, J.D.; Fernandes, M.H. In vitro cytocompatibility of MG63 cells on chitosan-organosiloxane hybrid membranes. Biomaterials 2005, 26. [Google Scholar] [CrossRef] [PubMed]

- Shirosaki, Y.; Tsuru, K.; Hayakawa, S.; Osaka, A.; Lopes, M.A.; Santos, J.D.; Fernandes, M.H. Physical, chemical and in vitro biological profile of chitosan hybrid membrane as a function of organosiloxane concentration. Acta Biomater. 2009, 5. [Google Scholar] [CrossRef] [PubMed]

- Shirosaki, Y. Preparation of organic-inorganic hybrids with silicate network for the medical applications. J. Ceram. Soc. Jpn. 2012, 120. [Google Scholar] [CrossRef]

- Shirosaki, Y.; Okayama, T.; Tsuru, K.; Hayakawa, S.; Osaka, A. Synthesis and cytocompatibility of porous chitosan-silicate hybrids for tissue engineering scaffold application. Chem. Eng. J. 2008, 137. [Google Scholar] [CrossRef]

- Whang, K.; Healy, K.E.; Elenz, D.R.; Nam, E.K.; Tsai, D.C.; Thomas, C.H.; Sprague, S.M. Engineering bone regeneration with bioabsorbable scaffolds with novel microarchitecture. Tissue Eng. 1999, 5, 35–51. [Google Scholar] [CrossRef]

- Kong, M.; Chen, X.G.; Xing, K.; Park, H.J. Antimicrobial properties of chitosan and mode of action: A state of the art review. Int. J. Food Microbiol. 2010, 144, 51–63. [Google Scholar] [CrossRef]

- Dutta, P.K.; Tripathi, S.; Mehrotra, G.K.; Dutta, J. Perspectives for chitosan based antimicrobial films in food applications. Food Chem. 2009, 114, 1173–1182. [Google Scholar] [CrossRef]

- Connell, L.S.; Romer, F.; Suárez, M.; Valliant, E.M.; Zhang, Z.; Lee, P.D.; Smith, M.E.; Hanna, J.V.; Jones, J.R. Chemical characterisation and fabrication of chitosan-silica hybrid scaffolds with 3-glycidoxypropyl trimethoxysilane. J. Mater. Chem. B 2014, 2, 668–680. [Google Scholar] [CrossRef]

- Jakupec, M.A.; Unfried, P.; Keppler, B.K. Pharmacological properties of cerium compunds. In Reviews of Physiology, Biochemistry and Pharmacology; Springer: Berlin/Heidelberg, Germany, 2005; Volume 153. [Google Scholar] [CrossRef]

- Azevedo, M.M.; Cobrado, L.; Silva Dias, A.; Ramalho, P.; Pina-Vaz, C.; Rodrigues, A.G. Antibiofilm effect of cerium nitrate against bacteria and yeast. SOJ Microbiol. Infect. Dis. 2013, 1, 2011–2014. [Google Scholar] [CrossRef][Green Version]

- Morais, D.S.; Rodrigues, M.A.; Lopes, M.A.; Coelho, M.J.; Maurício, A.C.; Gomes, R.; Botelho, C.M. Biological evaluation of alginate-based hydrogels, with antimicrobial features by Ce(III) incorporation, as vehicles for a bone substitute. J. Mater. Sci. Mater. Med. 2013, 24, 2145–2155. [Google Scholar] [CrossRef] [PubMed]

- Shah, V.; Shah, S.; Shah, H.; Rispoli, F.J.; McDonnell, K.T.; Workeneh, S.; Seal, S. Antibacterial activity of polymer coated cerium oxide nanoparticles. PLoS ONE 2012, 7, e47827. [Google Scholar] [CrossRef] [PubMed]

- Gopinath, K.; Karthika, V.; Sundaravadivelan, C.; Gowri, S.; Arumugam, A. Mycogenesis of cerium oxide nanoparticles using Aspergillus niger culture filtrate and their applications for antibacterial and larvicidal activities. J. Nanostruct. Chem. 2015, 5, 295–303. [Google Scholar] [CrossRef]

- Cobrado, L.; Azevedo, M.M.; Silva-Dias, A.; Ramos, J.P.; Pina-Vaz, C.; Rodrigues, A.G. Cerium, chitosan and hamamelitannin as novel biofilm inhibitors? J. Antimicrob. Chemother. 2012, 67, 1159–1162. [Google Scholar] [CrossRef]

- Garner, J.P.; Heppell, P.S.J. Cerium nitrate in the management of burns. Burns 2005, 31, 539–547. [Google Scholar] [CrossRef]

- Prochazkova, S.; Vårum, K.M.; Ostgaard, K. Quantitative determination of chitosans by ninhydrin. Carbohydr. Polym. 1999, 38, 115–122. [Google Scholar] [CrossRef]

- Hansen, A.; Ababa, A. Use of 3-(4,5-dimethylthiazol-2-yl)-2,5-diphenyl tetrazolium bromide for rapid detection of rifampin-resistant mycobacterium tuberculosis. J. Clin. Microbiol. 1998, 36, 1214–1219. [Google Scholar]

- Kang, H.W.; Tabata, Y.; Ikada, Y. Fabrication of porous gelatin scaffolds for tissue engineering. Biomaterials 1999, 20, 1339–1344. [Google Scholar] [CrossRef]

- Shirosaki, Y.; Okamoto, K.; Hayakawa, S.; Osaka, A.; Asano, T. Preparation of porous chitosan-siloxane hybrids coated with hydroxyapatite particles. BioMed Res. Int. 2015. [Google Scholar] [CrossRef]

- Salem, A.K.; Stevens, R.; Pearson, R.G.; Davies, M.C.; Tendler, S.J.B.; Roberts, C.J.; Shakesheff, K.M. Interactions of 3T3 fibroblasts and endothelial cells with defined pore features. J. Biomed. Mater. Res. 2002, 61, 212–217. [Google Scholar] [CrossRef] [PubMed]

- Teixeira, L.N.; Crippa, G.E.; Lefebvre, L.P.; De Oliveira, P.T.; Rosa, A.L.; Beloti, M.M. The influence of pore size on osteoblast phenotype expression in cultures grown on porous titanium. Int. J. Oral Maxillofac. Surg. 2012, 41, 1097–1101. [Google Scholar] [CrossRef] [PubMed]

- Yamaguchi, I.; Tokuchi, K.; Fukuzaki, H.; Koyama, Y.; Takakuda, K.; Monma, H.; Tanaka, J. Preparation and microstructure analysis of chitosan/hydroxyapatite nanocomposites. J. Biomed. Mater. Res. 2001, 55, 20–27. [Google Scholar] [CrossRef]

- Shahidi, F.; Arachchi, J.K.V.; Jeon, Y.J. Food applications of chitin and chitosans. Trends Food Sci. Technol. 1999, 10, 37–51. [Google Scholar] [CrossRef]

- Coma, V.; Deschamps, A.; Martial-Gros, A. Bioactive packaging materials from edible chitosan polymer—Antimicrobial activity assessment on dairy-related contaminants. J. Food Sci. 2003, 68, 2788–2792. [Google Scholar] [CrossRef]

- Palla-Rubio, B.; Araújo-Gomes, N.; Fernández-Gutiérrez, M.; Rojo, L.; Suay, J.; Gurruchaga, M.; Goñi, I. Synthesis and characterization of silica-chitosan hybrid materials as antibacterial coatings for titanium implants. Carbohydr. Polym. 2019, 203, 331–341. [Google Scholar] [CrossRef]

- No, H.K.; Young Park, N.; Ho Lee, S.; Meyers, S.P. Antibacterial activity of chitosans and chitosan oligomers with different molecular weights. Int. J. Food Microbiol. 2002, 74, 65–72. [Google Scholar] [CrossRef]

- Salton, M.R.J.; Kim, K.S. Structure. In Medical Microbiology, 4th ed.; Baron, S., Ed.; University of Texas Medical Branch at Galveston: Galveston, TX, USA, 1996; Chapter 2. [Google Scholar]

- Schneck, E.; Schubert, T.; Konovalov, O.V.; Quinn, B.E.; Gutsmann, T.; Brandenburg, K.; Tanaka, M. Quantitative determination of ion distributions in bacterial lipopolysaccharide membranes by grazing-incidence X-ray fluorescence. Proc. Natl. Acad. Sci. USA 2010, 107, 9147–9151. [Google Scholar] [CrossRef]

| Sample | Chitosan | GPTMS | CeCl3 |

|---|---|---|---|

| Ch | 1.0 | 0 | 0 |

| ChG05 | 1.0 | 0 | 0 |

| ChG10 | 1.0 | 1.0 | 0 |

| ChG10Ce01 | 1.0 | 1.0 | 0.1 |

| ChG10Ce025 | 1.0 | 1.0 | 0.25 |

| ChG10Ce05 | 1.0 | 1.0 | 0.5 |

| Sample | Freezing Temperature (°C) | Pore Size (μm) |

|---|---|---|

| Ch | −196 | 5.6 ± 13.6 |

| ChG05 | −20 | 48.6 ± 16.5 |

| ChG05 | −196 | 10.3 ± 3.7 |

| ChG10 | −196 | 5.9 ± 5.2 |

| ChG10Ce01 | −196 | 6.2 ± 5.1 |

| ChG10Ce025 | −196 | 5.6 ± 2.2 |

| ChG10Ce05 | −196 | 6.6 ± 3.7 |

| Sample | Ce/C | pH |

|---|---|---|

| Ch | 0 | 6.8 |

| ChG10 | 0 | 6.6 |

| ChG10Ce01 | 0.007 | 6.1 |

| ChG10Ce025 | 0.019 | 5.8 |

| ChG10Ce05 | 0.032 | 5.9 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shirosaki, Y.; Nakatsukasa, M.; Yasutomi, S.; Cruz-Neves, S.; Hayakawa, S.; Osaka, A.; Maeda, T.; Miyazaki, T. Cytocompatible and Antibacterial Properties of Chitosan-Siloxane Hybrid Spheres. Polymers 2019, 11, 1676. https://doi.org/10.3390/polym11101676

Shirosaki Y, Nakatsukasa M, Yasutomi S, Cruz-Neves S, Hayakawa S, Osaka A, Maeda T, Miyazaki T. Cytocompatible and Antibacterial Properties of Chitosan-Siloxane Hybrid Spheres. Polymers. 2019; 11(10):1676. https://doi.org/10.3390/polym11101676

Chicago/Turabian StyleShirosaki, Yuki, Manato Nakatsukasa, Saki Yasutomi, Susana Cruz-Neves, Satoshi Hayakawa, Akiyoshi Osaka, Toshinari Maeda, and Toshiki Miyazaki. 2019. "Cytocompatible and Antibacterial Properties of Chitosan-Siloxane Hybrid Spheres" Polymers 11, no. 10: 1676. https://doi.org/10.3390/polym11101676

APA StyleShirosaki, Y., Nakatsukasa, M., Yasutomi, S., Cruz-Neves, S., Hayakawa, S., Osaka, A., Maeda, T., & Miyazaki, T. (2019). Cytocompatible and Antibacterial Properties of Chitosan-Siloxane Hybrid Spheres. Polymers, 11(10), 1676. https://doi.org/10.3390/polym11101676