Piezoelastic PVDF/TPU Nanofibrous Composite Membrane: Fabrication and Characterization

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Membrane Fabrication

2.3. Morphological Characterization

2.4. Physical Characterization

2.5. Mechanical Characterization

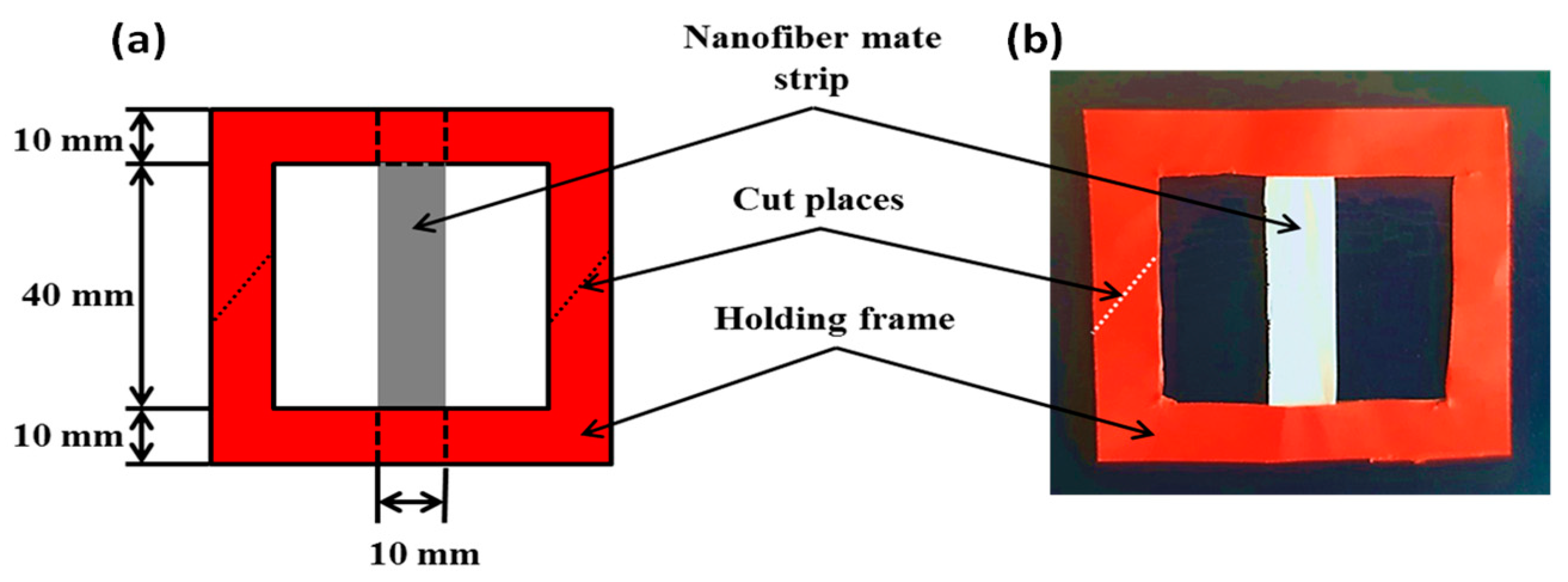

2.6. Piezoelectric Measurements

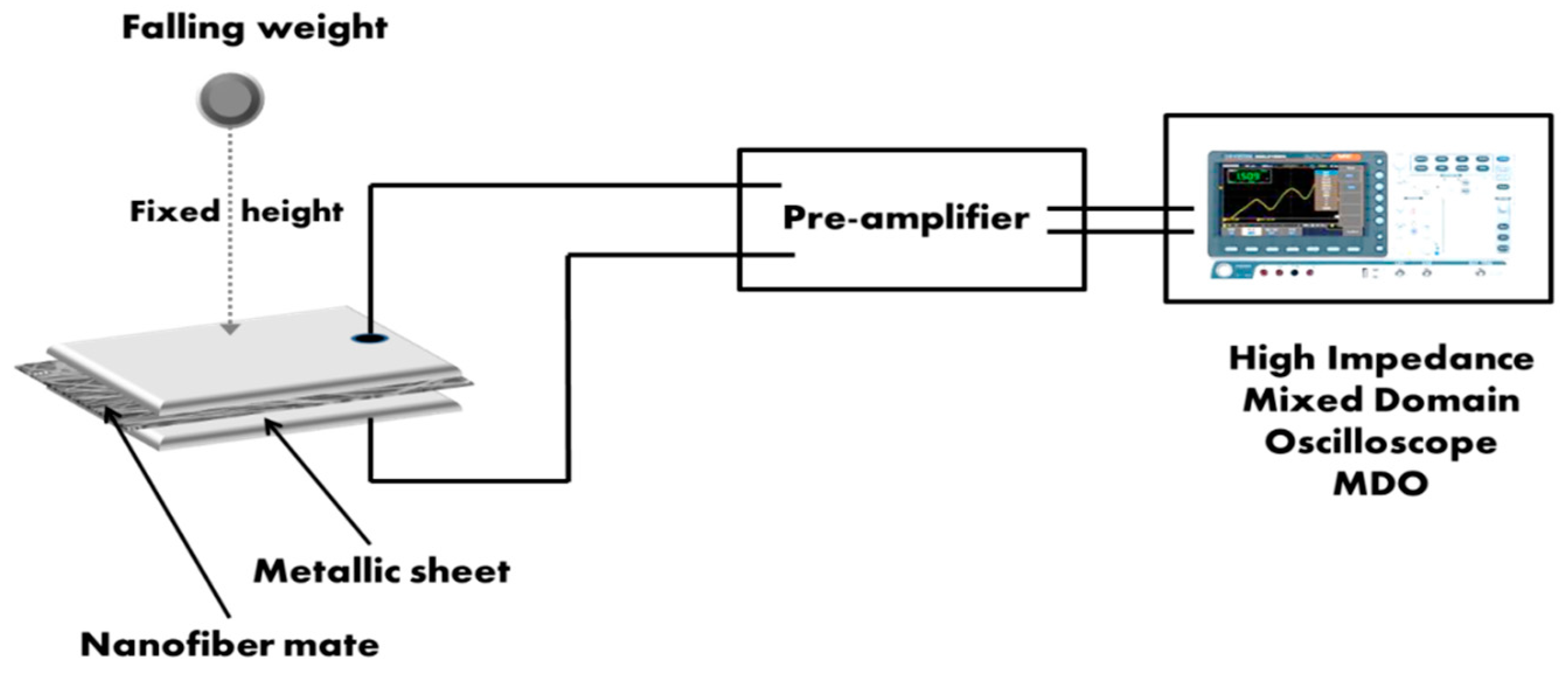

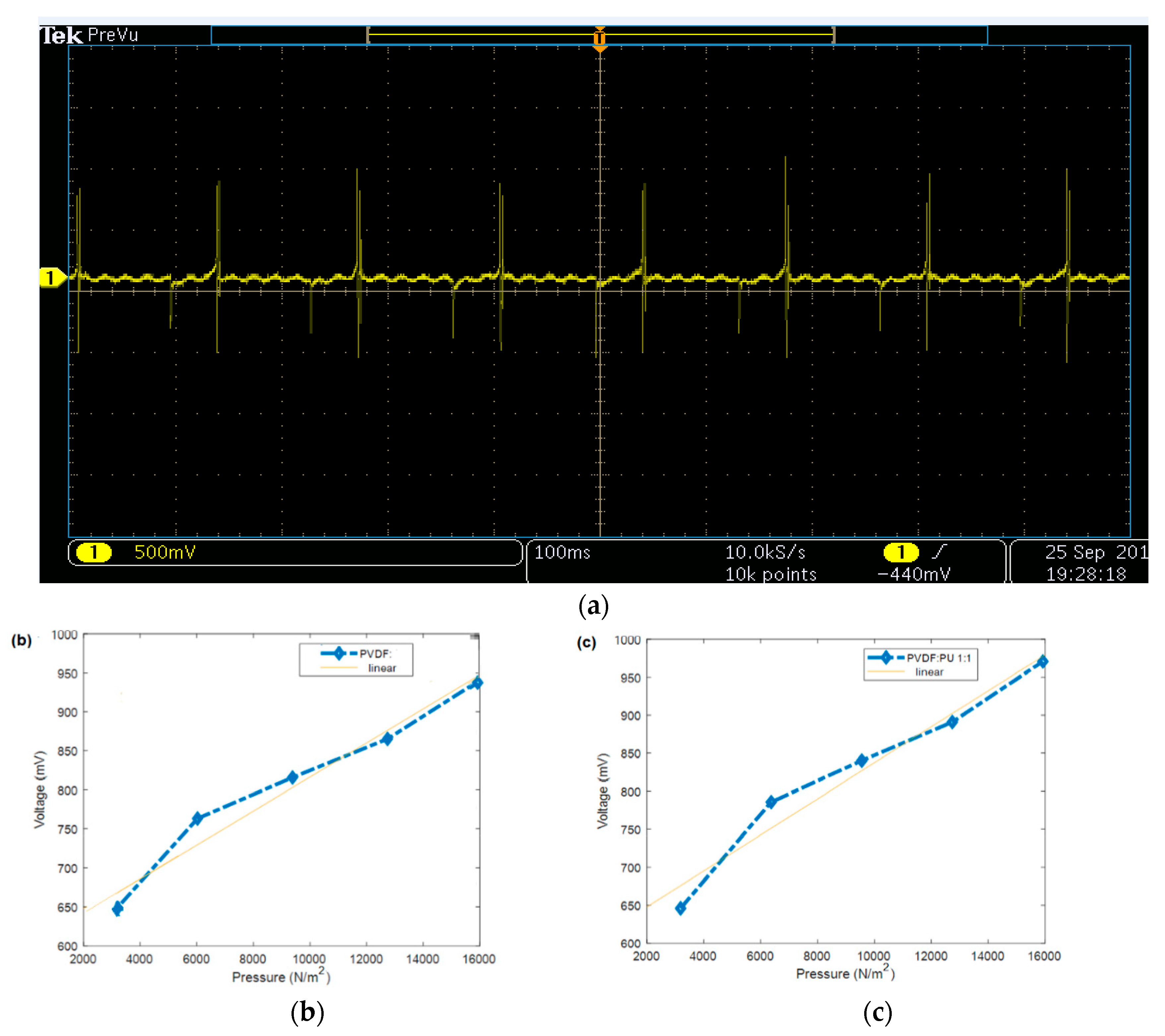

2.6.1. Impulse Load Test

2.6.2. Pressure Test

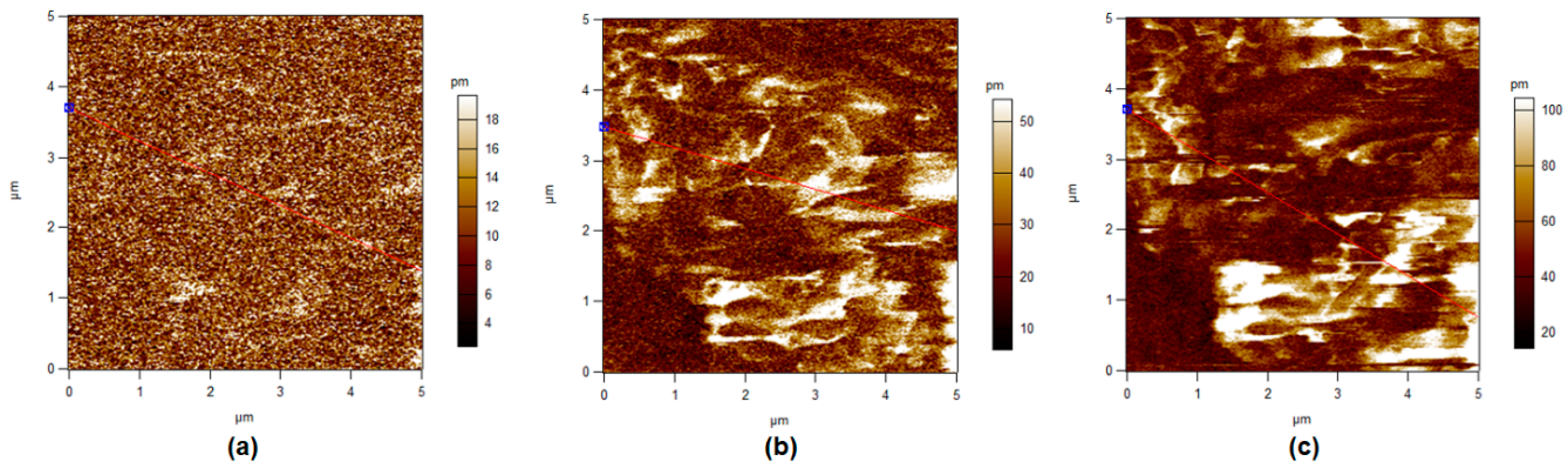

2.6.3. Piezoresponse Force Microscope (PFM)

3. Results

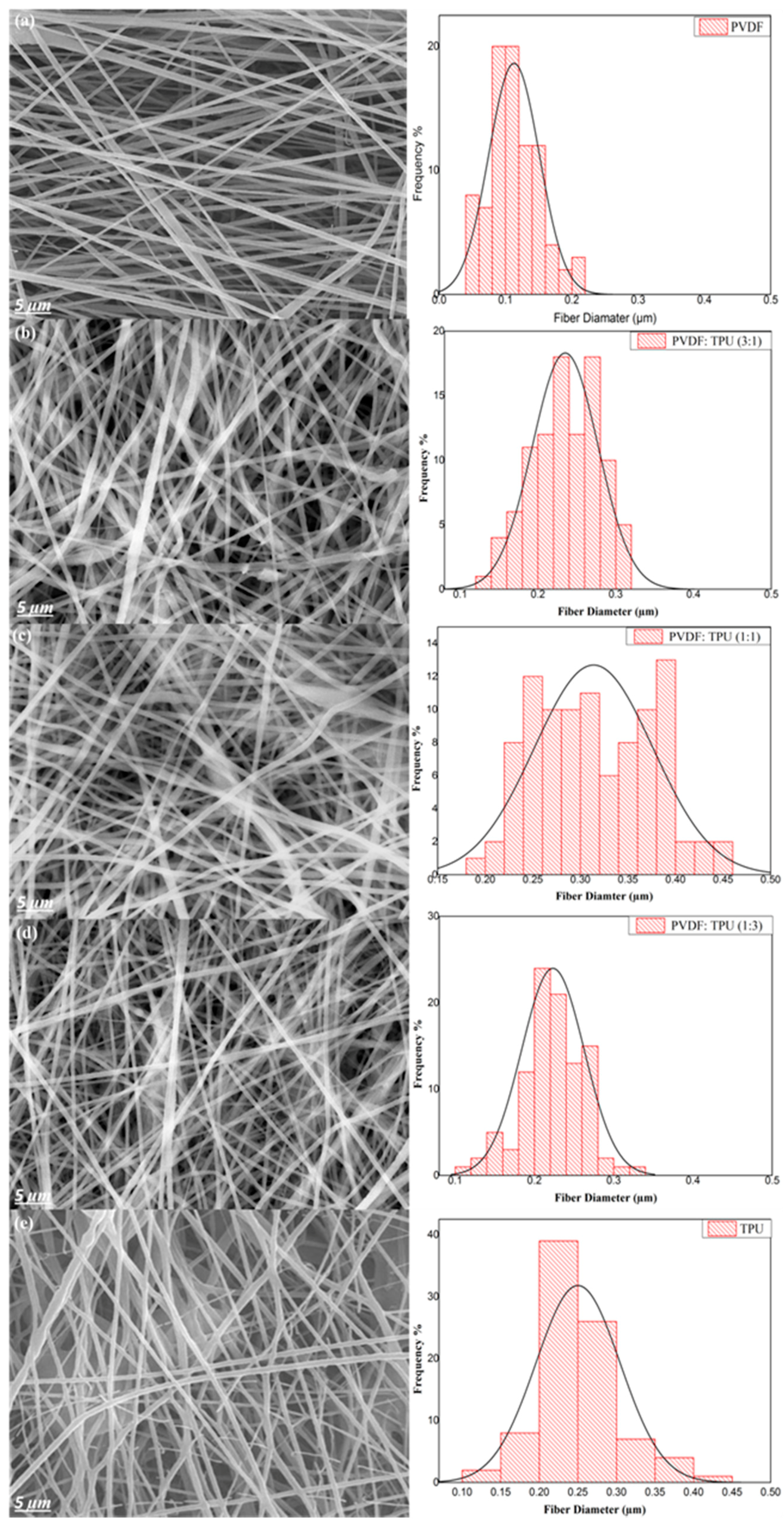

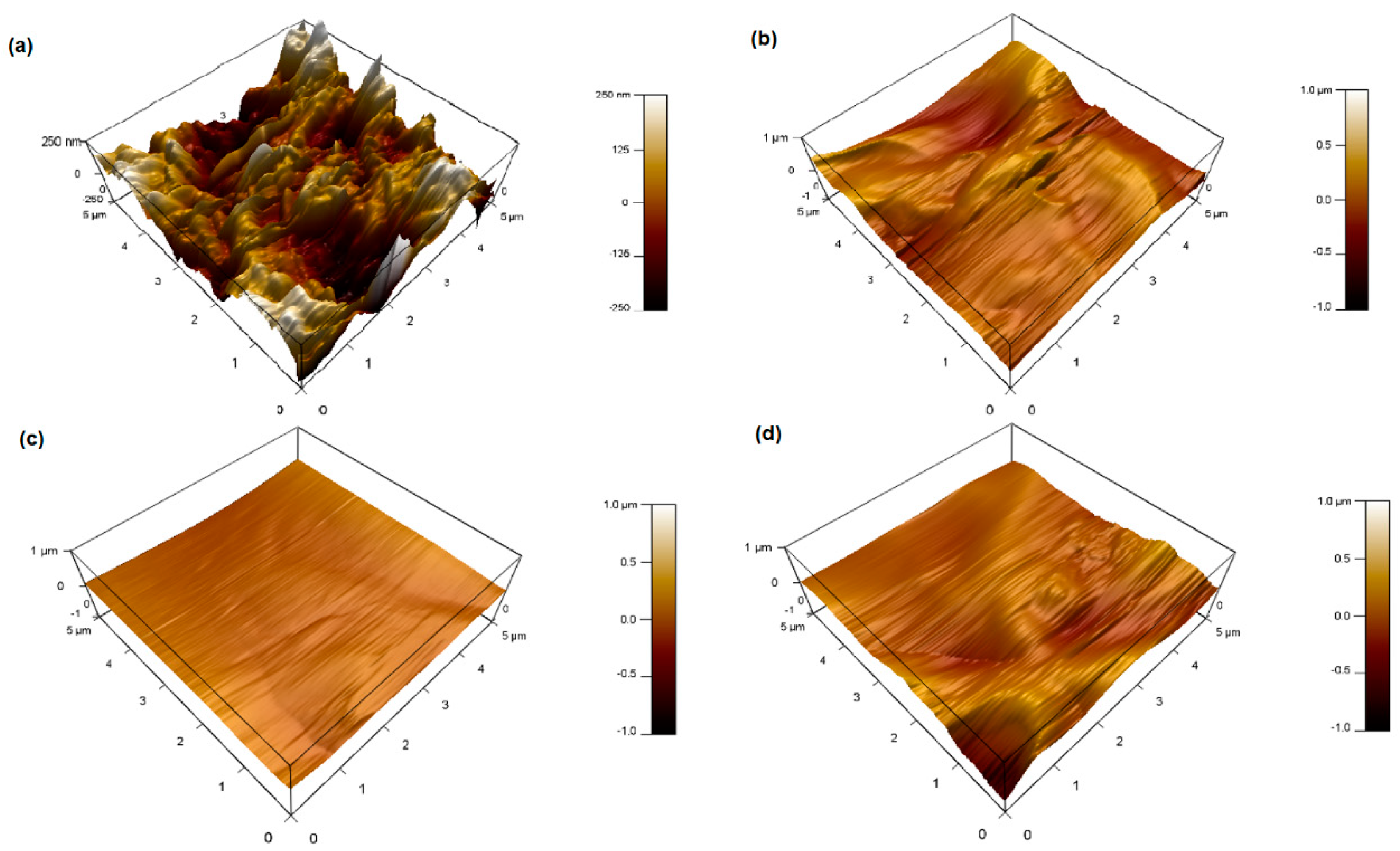

3.1. Morphological Characterization

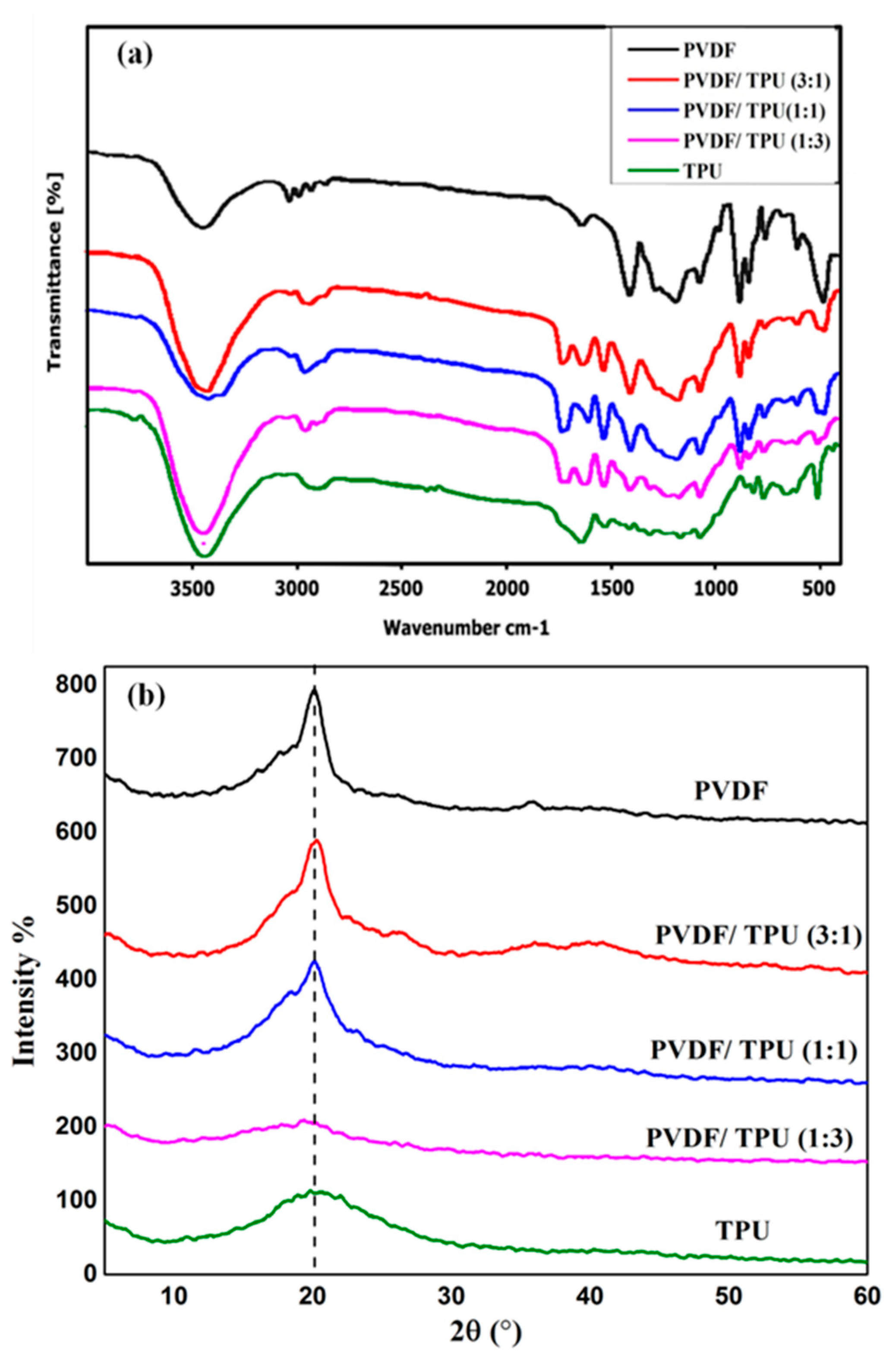

3.2. Crystalline Phase Characterization

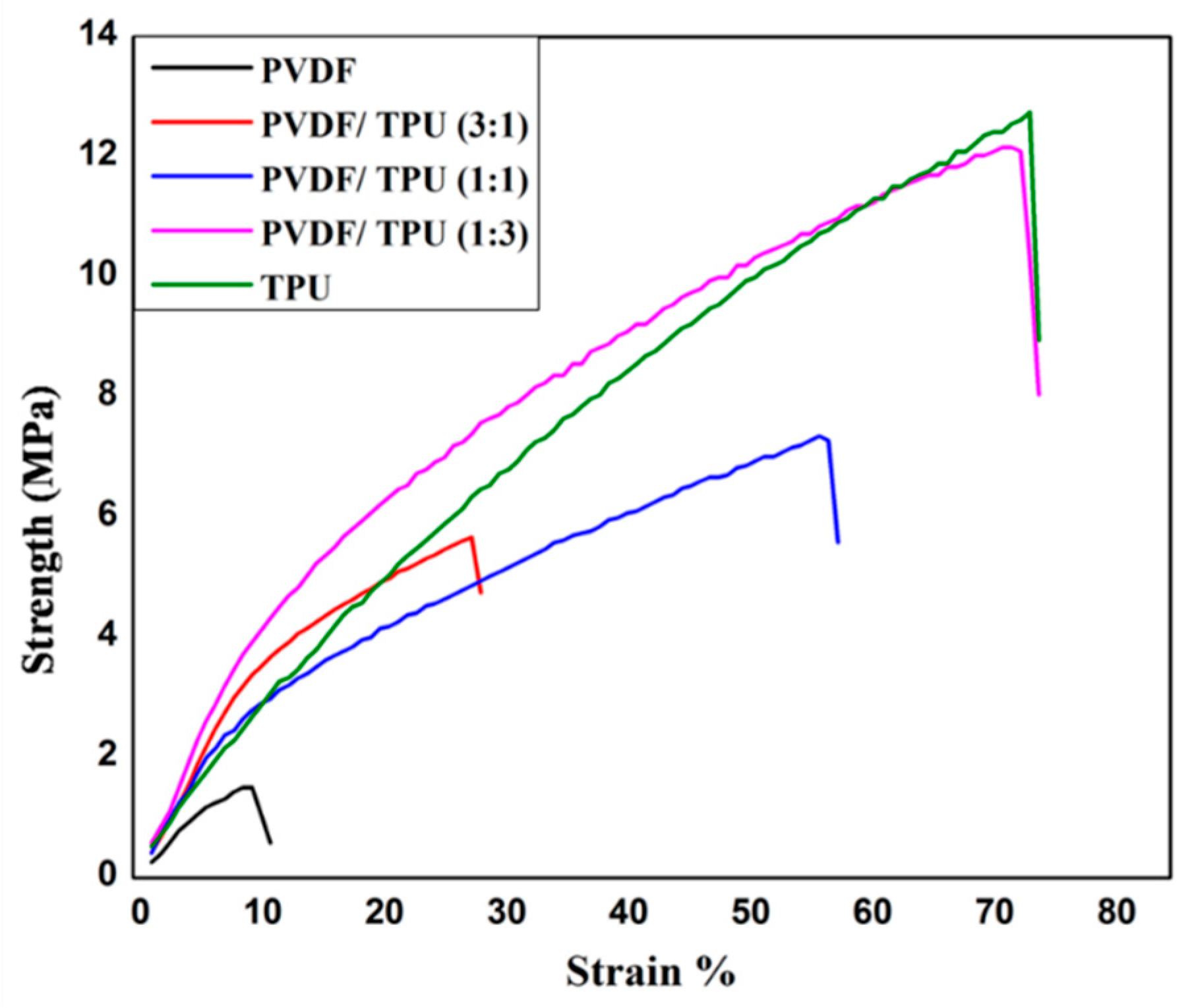

3.3. Mechanical Analysis

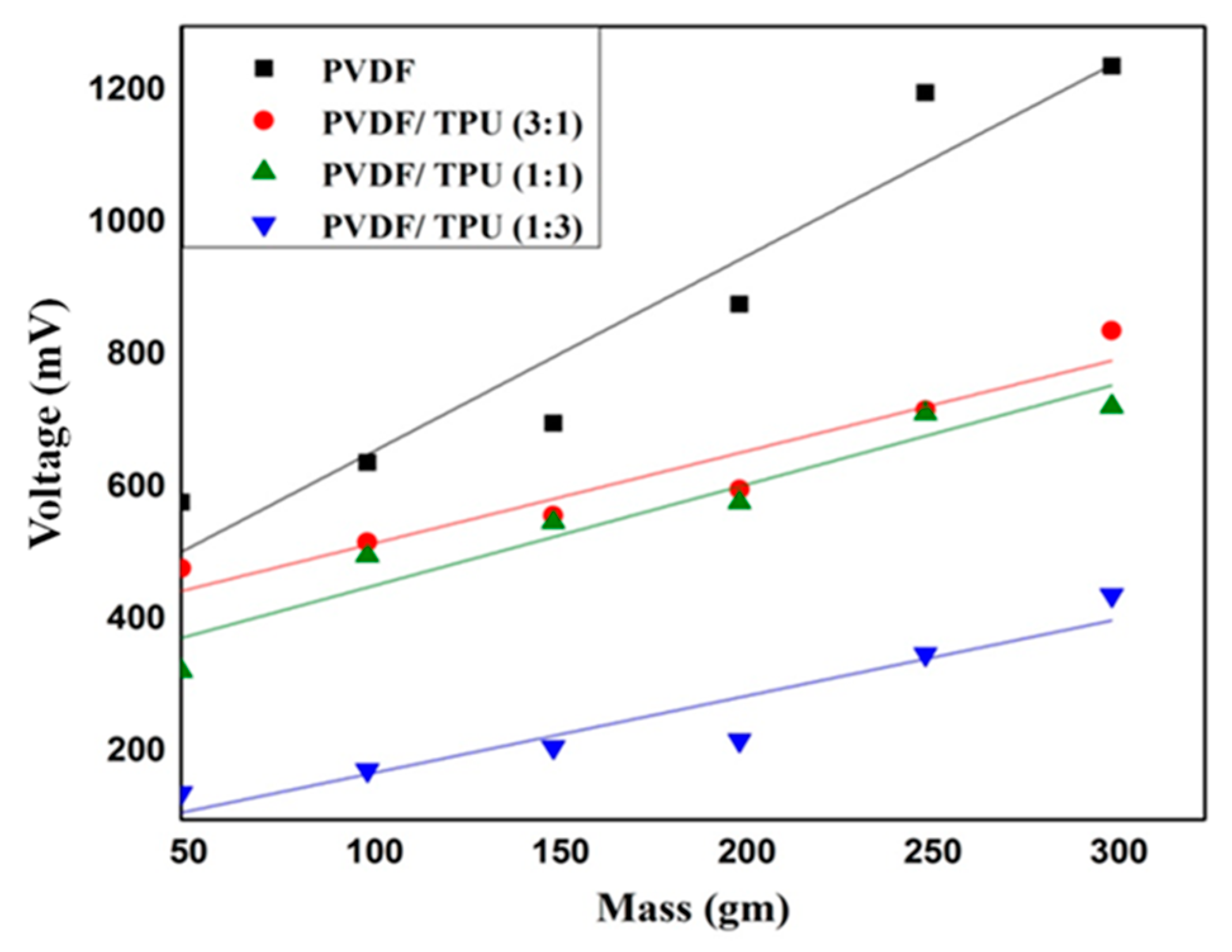

3.4. Piezoelectric Analysis

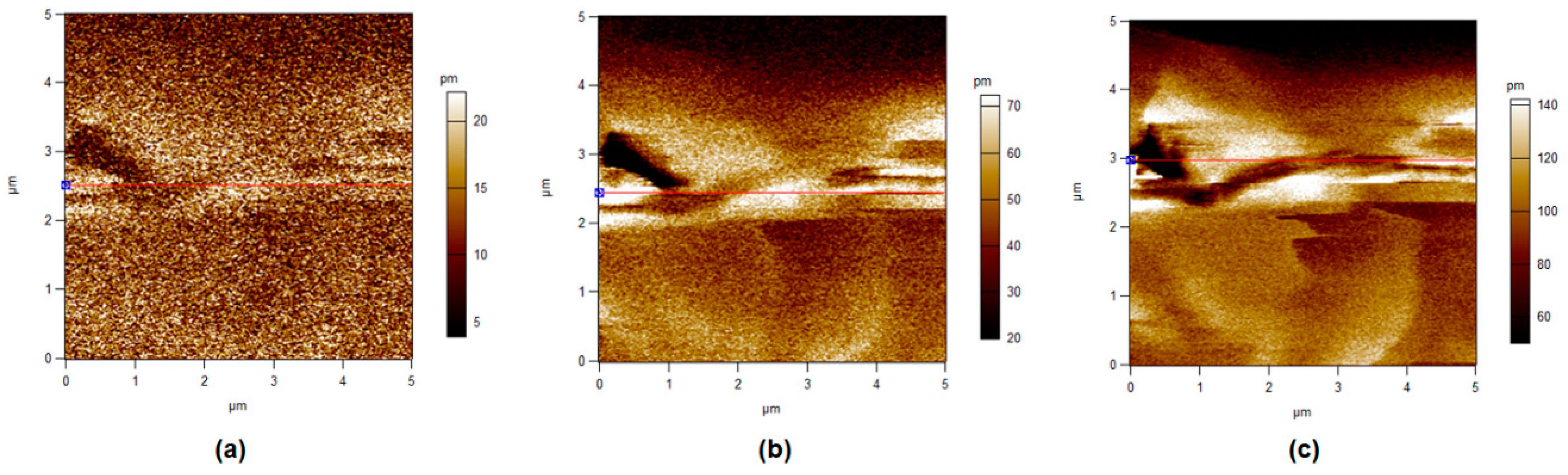

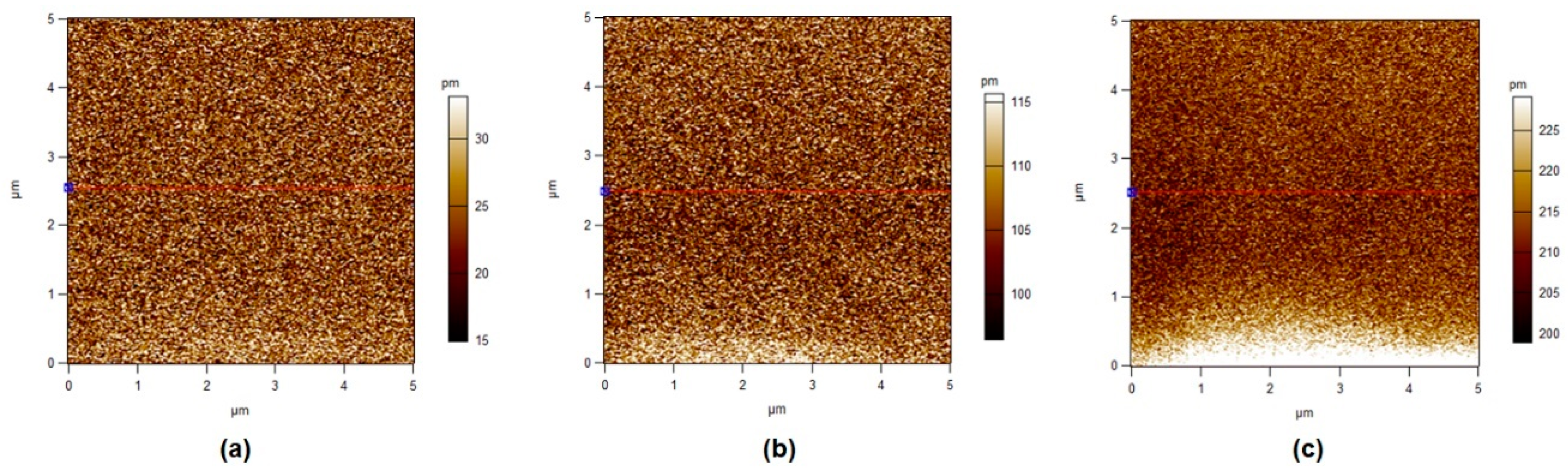

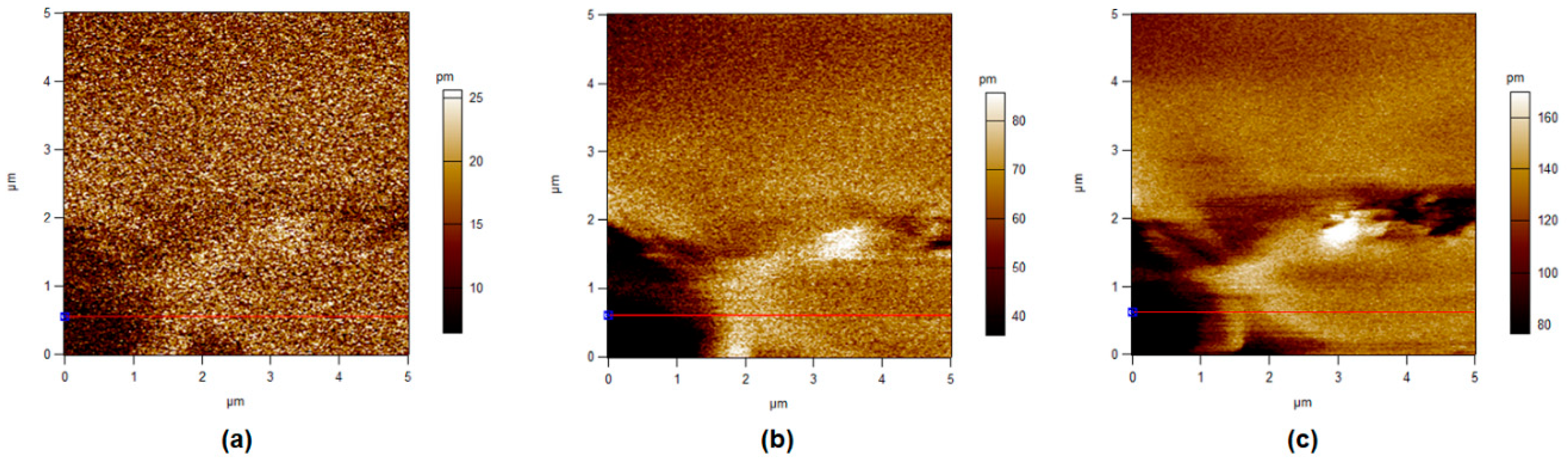

3.5. Piezoelectric Force Microscopy

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Dresselhaus, M.; Thomas, I. Alternative energy technologies. Nature 2001, 414, 332. [Google Scholar] [CrossRef] [PubMed]

- Kay, E.R.; Leigh, D.A.; Zerbetto, F. Synthetic molecular motors and mechanical machines. Angew. Chem. Int. Ed. 2007, 46, 72–191. [Google Scholar] [CrossRef] [PubMed]

- Heil, T.; Butler, S.; Dalgarno, A. Charge transfer of multiply charged ions at thermal energies. Phys. Rev. A 1981, 23, 1100. [Google Scholar] [CrossRef]

- Quitoras, M.R.D.; Abundo, M.L.S.; Danao, L.A.M. A techno-economic assessment of wave energy resources in the Philippines. Renew. Sustain. Energy Rev. 2018, 88, 68–81. [Google Scholar] [CrossRef]

- Fogaing, M.B.T.; Gordon, H.; Lange, C.F.; Wood, D.H.; Fleck, B.A. A Review of Wind Energy Resource Assessment in the Urban Environment. In Advances in Sustainable Energy; Springer: Berlin/Heidelberg, Germany, 2019; pp. 7–36. [Google Scholar]

- Fontes, C.H.d.O.; Freires, F.G.M. Sustainable and renewable energy supply chain: A system dynamics overview. Renew. Sustain. Energy Rev. 2018, 82, 247–259. [Google Scholar]

- Ali, S.; Xu, H.; Al-amin, A.Q.; Ahmad, N. Energy sources choice and environmental sustainability disputes: An evolutional graph model approach. Qual. Quant. 2019, 53, 561–581. [Google Scholar]

- Walubita, L.; Sohoulande Djebou, D.; Faruk, A.; Lee, S.; Dessouky, S.; Hu, X. Prospective of societal and environmental benefits of piezoelectric technology in road energy harvesting. Sustainability 2018, 10, 383. [Google Scholar] [CrossRef]

- Turkmen, A.C.; Celik, C. Energy harvesting with the piezoelectric material integrated shoe. Energy 2018, 150, 556–564. [Google Scholar] [CrossRef]

- Taware, S.; Deshmukh, S. A review of energy harvesting from piezoelectric materials. IOSR J. Mech. Civ. Eng. (IOSR-JMCE) 2013, 43–50. [Google Scholar]

- Han, M.; Wang, H.; Yang, Y.; Liang, C.; Bai, W.; Yan, Z.; Li, H.; Xue, Y.; Wang, X.; Akar, B. Three-dimensional piezoelectric polymer microsystems for vibrational energy harvesting, robotic interfaces and biomedical implants. Nat. Electron. 2019, 2, 26. [Google Scholar] [CrossRef]

- Brenes, A.; Lefeuvre, E.; Seok, S.; Yoo, C.-S. Tunable unipolar synchronized electric charge extraction strategy for piezoelectric energy harvesting. J. Intell. Mater. Syst. Struct. 2019, 1045389X19844329. [Google Scholar] [CrossRef]

- Kumar, A.; Kumar, R.; Jain, S.C.; Vaish, R. Vibration induced refrigeration and energy harvesting using piezoelectric materials: A finite element study. RSC Adv. 2019, 9, 3918–3926. [Google Scholar] [CrossRef]

- Hossain, S.M.; Uddin, M.N. Energy harvesting from human foot movement. Int. J. Ambient Energy 2018, 1–6. [Google Scholar] [CrossRef]

- Tandon, B.; Kamble, P.; Olsson, R.T.; Blaker, J.J.; Cartmell, S.H. Fabrication and Characterisation of Stimuli Responsive Piezoelectric PVDF and Hydroxyapatite-Filled PVDF Fibrous Membranes. Molecules 2019, 24, 1903. [Google Scholar] [CrossRef] [PubMed]

- Jin, L.; Ma, S.; Deng, W.; Yan, C.; Yang, T.; Chu, X.; Tian, G.; Xiong, D.; Lu, J.; Yang, W. Polarization-free high-crystallization β-PVDF piezoelectric nanogenerator toward self-powered 3D acceleration sensor. Nano Energy 2018, 50, 632–638. [Google Scholar] [CrossRef]

- Biswas, A.; Garain, S.; Maity, K.; Henkel, K.; Schmeißer, D.; Mandal, D. Influence of in situ synthesized bismuth oxide nanostructures in self-poled PVDF-based nanogenerator for mechanical energy harvesting application. Polym. Compos. 2019, 40, E265–E274. [Google Scholar] [CrossRef]

- Lang, C.; Fang, J.; Shao, H.; Ding, X.; Lin, T. High-sensitivity acoustic sensors from nanofibre webs. Nat. Commun. 2016, 7, 11108. [Google Scholar] [CrossRef]

- Burnham-Fay, E.D.; Le, T.; Tarbutton, J.A.; Ellis, J.D. Strain characteristics of additive manufactured polyvinylidene fluoride (PVDF) actuators. Sens. Actuators A Phys. 2017, 266, 85–92. [Google Scholar] [CrossRef]

- Xue, J.; Wu, T.; Dai, Y.; Xia, Y. Electrospinning and electrospun nanofibers: Methods, materials, and applications. Chem. Rev. 2019, 119, 5298–5415. [Google Scholar] [CrossRef]

- Hou, J.; Wang, Y.; Xue, H.; Dou, Y. Biomimetic Growth of Hydroxyapatite on Electrospun CA/PVP Core–Shell Nanofiber Membranes. Polymers 2018, 10, 1032. [Google Scholar] [CrossRef]

- Niiyama, E.; Uto, K.; Lee, C.; Sakura, K.; Ebara, M. Alternating magnetic field-triggered switchable nanofiber mesh for cancer thermo-chemotherapy. Polymers 2018, 10, 1018. [Google Scholar] [CrossRef] [PubMed]

- Lee, H.; Inoue, Y.; Kim, M.; Ren, X.; Kim, I. Effective Formation of Well-Defined Polymeric Microfibers and Nanofibers with Exceptional Uniformity by Simple Mechanical Needle Spinning. Polymers 2018, 10, 980. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Sun, F.; Yin, G.; Wang, Y.; Liu, B.; Dong, M. Tactile-sensing based on flexible PVDF nanofibers via electrospinning: A review. Sensors 2018, 18, 330. [Google Scholar] [CrossRef] [PubMed]

- Chang, J.; Dommer, M.; Chang, C.; Lin, L. Piezoelectric nanofibers for energy scavenging applications. Nano Energy 2012, 1, 356–371. [Google Scholar] [CrossRef]

- Wang, Y.; Zheng, J.; Ren, G.; Zhang, P.; Xu, C. A flexible piezoelectric force sensor based on PVDF fabrics. Smart Mater. Struct. 2011, 20, 045009. [Google Scholar] [CrossRef]

- Bhardwaj, N.; Kundu, S.C. Electrospinning: A fascinating fiber fabrication technique. Biotechnol. Adv. 2010, 28, 325–347. [Google Scholar] [CrossRef]

- Frenot, A.; Chronakis, I.S. Polymer nanofibers assembled by electrospinning. Curr. Opin. Colloid Interface Sci. 2003, 8, 64–75. [Google Scholar]

- Bafqi, M.S.S.; Bagherzadeh, R.; Latifi, M. Fabrication of composite PVDF-ZnO nanofiber mats by electrospinning for energy scavenging application with enhanced efficiency. J. Polym. Res. 2015, 22, 130. [Google Scholar] [CrossRef]

- Mansouri, S.; Sheikholeslami, T.F.; Behzadmehr, A. Investigation on the electrospun PVDF/NP-ZnO nanofibers for application in environmental energy harvesting. J. Mater. Res. Technol. 2019, 8, 1608–1615. [Google Scholar] [CrossRef]

- Shehata, N.; Elnabawy, E.; Abdelkader, M.; Hassanin, A.; Salah, M.; Nair, R.; Ahmad Bhat, S. Static-Aligned Piezoelectric Poly (Vinylidene Fluoride) Electrospun Nanofibers/MWCNT Composite Membrane: Facile Method. Polymers 2018, 10, 965. [Google Scholar] [CrossRef]

- Zhou, J.; Cai, Q.; Liu, X.; Ding, Y.; Xu, F. Temperature Effect on the Mechanical Properties of Electrospun PU Nanofibers. Nanoscale Res. Lett. 2018, 13, 384. [Google Scholar] [CrossRef] [PubMed]

- Hacker, C.; Karahaliloglu, Z.; Seide, G.; Denkbas, E.B.; Gries, T. Functionally modified, melt-electrospun thermoplastic polyurethane mats for wound-dressing applications. J. Appl. Polym. Sci. 2014, 131. [Google Scholar] [CrossRef]

- Polat, Y.; Pampal, E.S.; Stojanovska, E.; Simsek, R.; Hassanin, A.; Kilic, A.; Demir, A.; Yilmaz, S. Solution blowing of thermoplastic polyurethane nanofibers: A facile method to produce flexible porous materials. J. Appl. Polym. Sci. 2016, 133. [Google Scholar] [CrossRef]

- Liu, H.; Li, Y.; Dai, K.; Zheng, G.; Liu, C.; Shen, C.; Yan, X.; Guo, J.; Guo, Z. Electrically conductive thermoplastic elastomer nanocomposites at ultralow graphene loading levels for strain sensor applications. J. Mater. Chem. C 2016, 4, 157–166. [Google Scholar] [CrossRef]

- Mothé, C.; De Araujo, C. Properties of polyurethane elastomers and composites by thermal analysis. Thermochim. Acta 2000, 357, 321–325. [Google Scholar] [CrossRef]

- Chen, R.; Huang, C.; Ke, Q.; He, C.; Wang, H.; Mo, X. Preparation and characterization of coaxial electrospun thermoplastic polyurethane/collagen compound nanofibers for tissue engineering applications. Colloids Surf. B Biointerfaces 2010, 79, 315–325. [Google Scholar] [CrossRef] [PubMed]

- Shaker, A.; Hassanin, A.H.; Shaalan, N.; Hassan, M.; El-Moneim, A.A. Micropatterned flexible strain gauge sensor based on wet electrospun polyurethane/PEDOT: PSS nanofibers. Smart Mater. Struct. 2019, 28, 075029. [Google Scholar] [CrossRef]

- YUAN, Z.; Xi, D.-L. Effect of PVP additive on PVDF/TPU blend hollow fibre membranes by phase inversion. Iran. Polym. J. 2007, 16, 241–250. [Google Scholar]

- Guo, H.-F.; Li, Z.-S.; Dong, S.-W.; Chen, W.-J.; Deng, L.; Wang, Y.-F.; Ying, D.-J. Piezoelectric PU/PVDF electrospun scaffolds for wound healing applications. Colloids Surf. B Biointerfaces 2012, 96, 29–36. [Google Scholar] [CrossRef]

- Cai, M.; Zhu, J.; Yang, C.; Gao, R.; Shi, C.; Zhao, J. A parallel bicomponent TPU/PI membrane with mechanical strength enhanced isotropic interfaces used as polymer electrolyte for lithium-ion battery. Polymers 2019, 11, 185. [Google Scholar] [CrossRef]

- Martins, P.; Lopes, A.; Lanceros-Mendez, S. Electroactive phases of poly (vinylidene fluoride): Determination, processing and applications. Prog. Polym. Sci. 2014, 39, 683–706. [Google Scholar] [CrossRef]

- Andrew, J.; Clarke, D. Effect of electrospinning on the ferroelectric phase content of polyvinylidene difluoride fibers. Langmuir 2008, 24, 670–672. [Google Scholar] [CrossRef] [PubMed]

- Gregorio, R., Jr.; Cestari, M. Effect of crystallization temperature on the crystalline phase content and morphology of poly (vinylidene fluoride). J. Polym. Sci. Part B Polym. Phys. 1994, 32, 859–870. [Google Scholar] [CrossRef]

- Wu, T.; Zhou, B.; Zhu, T.; Shi, J.; Xu, Z.; Hu, C.; Wang, J. Facile and low-cost approach towards a PVDF ultrafiltration membrane with enhanced hydrophilicity and antifouling performance via graphene oxide/water-bath coagulation. RSC Adv. 2015, 5, 7880–7889. [Google Scholar] [CrossRef]

- You, M.-H.; Wang, X.-X.; Yan, X.; Zhang, J.; Song, W.-Z.; Yu, M.; Fan, Z.-Y.; Ramakrishna, S.; Long, Y.-Z. A self-powered flexible hybrid piezoelectric–pyroelectric nanogenerator based on non-woven nanofiber membranes. J. Mater. Chem. A 2018, 6, 3500–3509. [Google Scholar] [CrossRef]

- Wu, C.-M.; Chou, M.-H.; Zeng, W.-Y. Piezoelectric Response of Aligned Electrospun Polyvinylidene Fluoride/Carbon Nanotube Nanofibrous Membranes. Nanomaterials 2018, 8, 420. [Google Scholar] [CrossRef] [PubMed]

| Sample | Poly (Vinylidene Fluoride) (PVDF) | PVDF/Thermoplastic Polyurethane (TPU) (3:1) | PVDF/TPU (1:1) | PVDF/TPU (1:3) | TPU |

|---|---|---|---|---|---|

| Average fiber diameter (nm) | 110 ± 13 | 230 ± 25 | 311 ± 40 | 212 ± 18 | 275 ± 80 |

| Sample | Max. Strength, (MPa) | Elongation at Break, (%) | Toughness, (J·m−3) |

|---|---|---|---|

| PVDF | 1.63 ± 0.2 | 12.25 ± 3.6 | 14.2 ± 8.9 |

| PVDF/TPU (3:1) | 7.49 ± 1.8 | 45.5 ± 18.7 | 252.3 ± 152 |

| PVDF/TPU (1:1) | 8.34 ± 1.3 | 68 ± 12 | 389.3 ± 171 |

| PVDF/TPU (1:3) | 13.20 ± 3.6 | 85 ± 21.8 | 792 ± 434 |

| TPU | 14.98 ± 3.1 | 97.25 ± 21.3 | 921 ± 384 |

| Sample | Minimum Voltage at Impulse Load of 50 gm, (mV) | Maximum Voltage at Impulse Load of 300 gm, (mV) | Piezoresponse Sensitivity (mV/gm) | Toughness, (J·m−3) |

|---|---|---|---|---|

| PVDF | 590 | 1240 | 2.9 | 14.2 |

| PVDF/TPU (3:1) | 480 | 830 | 1.6 | 252.3 |

| PVDF/TPU (1:1) | 350 | 680 | 1.5 | 389.3 |

| PVDF/TPU (1:3) | 170 | 400 | 1.1 | 792 |

| TPU | 0 | 0 | 0 | 921 |

| Sample | 1 V | 3 V | 5 V | 7 V | 10 V |

|---|---|---|---|---|---|

| PVDF | 10.6 ± 4.0 | 16.6 ± 5.7 | 24.1 ± 6.6 | 32.5 ± 7.6 | 46.0 ± 9.7 |

| PVDF/TPU (3:1) | 13.5 ± 4.5 | 29.0 ± 8.5 | 61.0 ± 22.0 | 85.1 + 23.0 | 110.0 ± 31.5 |

| PVDF/TPU (1:1) | 24.5 ± 11.0 | 62.5 ± 12.4 | 104.4 ± 9.9 | 142.5 ± 9.5 | 209.9 ± 10.0 |

| PVDF/TPU (1:3) | 16.0 ± 4.9 | 38.0 ± 8.1 | 61.0 ± 12.4 | 83.0 ± 17.0 | 140.9 ± 17.8 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Elnabawy, E.; Hassanain, A.H.; Shehata, N.; Popelka, A.; Nair, R.; Yousef, S.; Kandas, I. Piezoelastic PVDF/TPU Nanofibrous Composite Membrane: Fabrication and Characterization. Polymers 2019, 11, 1634. https://doi.org/10.3390/polym11101634

Elnabawy E, Hassanain AH, Shehata N, Popelka A, Nair R, Yousef S, Kandas I. Piezoelastic PVDF/TPU Nanofibrous Composite Membrane: Fabrication and Characterization. Polymers. 2019; 11(10):1634. https://doi.org/10.3390/polym11101634

Chicago/Turabian StyleElnabawy, Eman, Ahmed H. Hassanain, Nader Shehata, Anton Popelka, Remya Nair, Saifallah Yousef, and Ishac Kandas. 2019. "Piezoelastic PVDF/TPU Nanofibrous Composite Membrane: Fabrication and Characterization" Polymers 11, no. 10: 1634. https://doi.org/10.3390/polym11101634

APA StyleElnabawy, E., Hassanain, A. H., Shehata, N., Popelka, A., Nair, R., Yousef, S., & Kandas, I. (2019). Piezoelastic PVDF/TPU Nanofibrous Composite Membrane: Fabrication and Characterization. Polymers, 11(10), 1634. https://doi.org/10.3390/polym11101634