Dynamically Cross-Linked Tannin as a Reinforcement of Polypropylene and UV Protection Properties

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of PP/TH Composites

2.3. Characterization

3. Results and Discussion

3.1. The Effects of Dynamically Cross-Linked Tannin and Its Reinforcing Function on PP

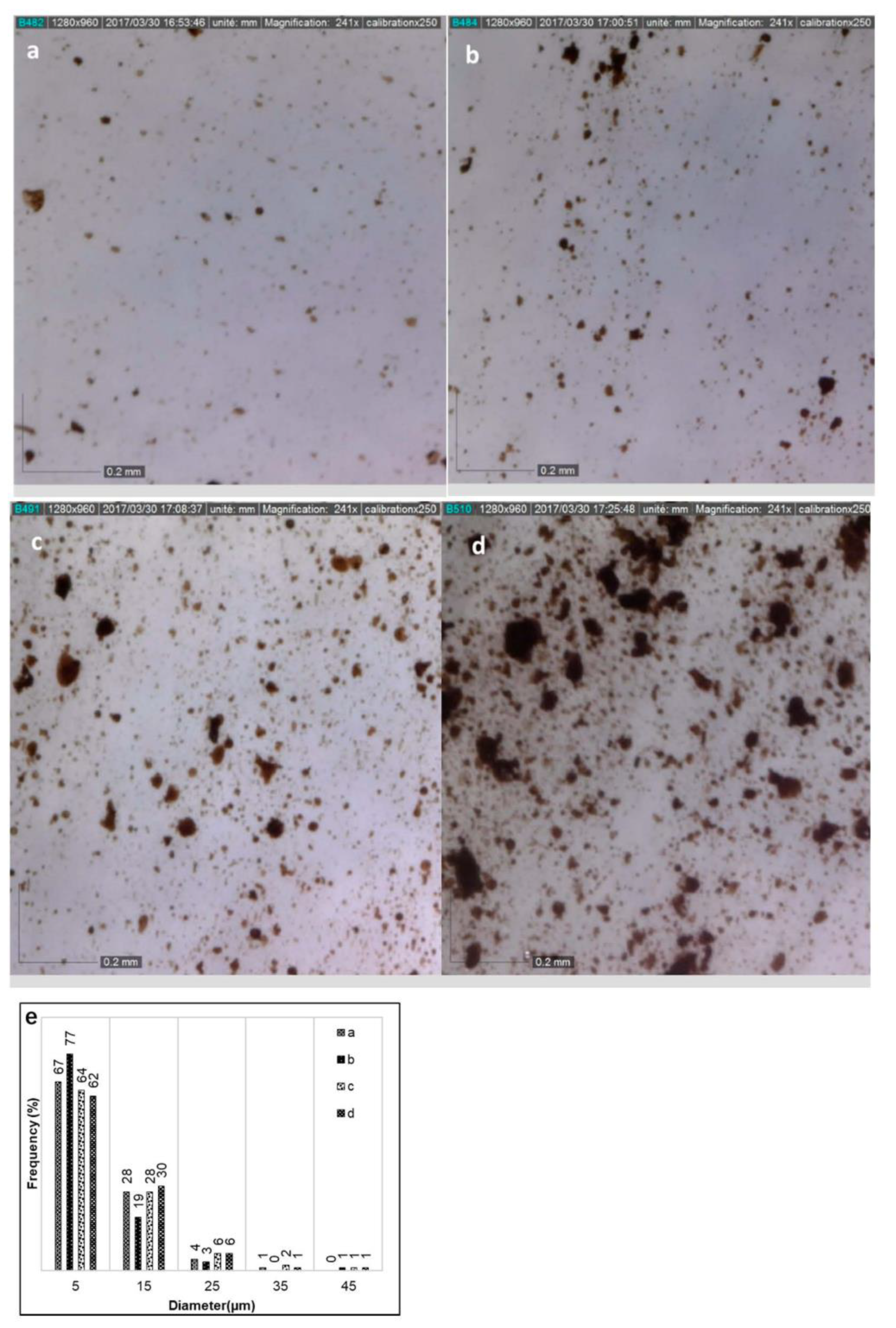

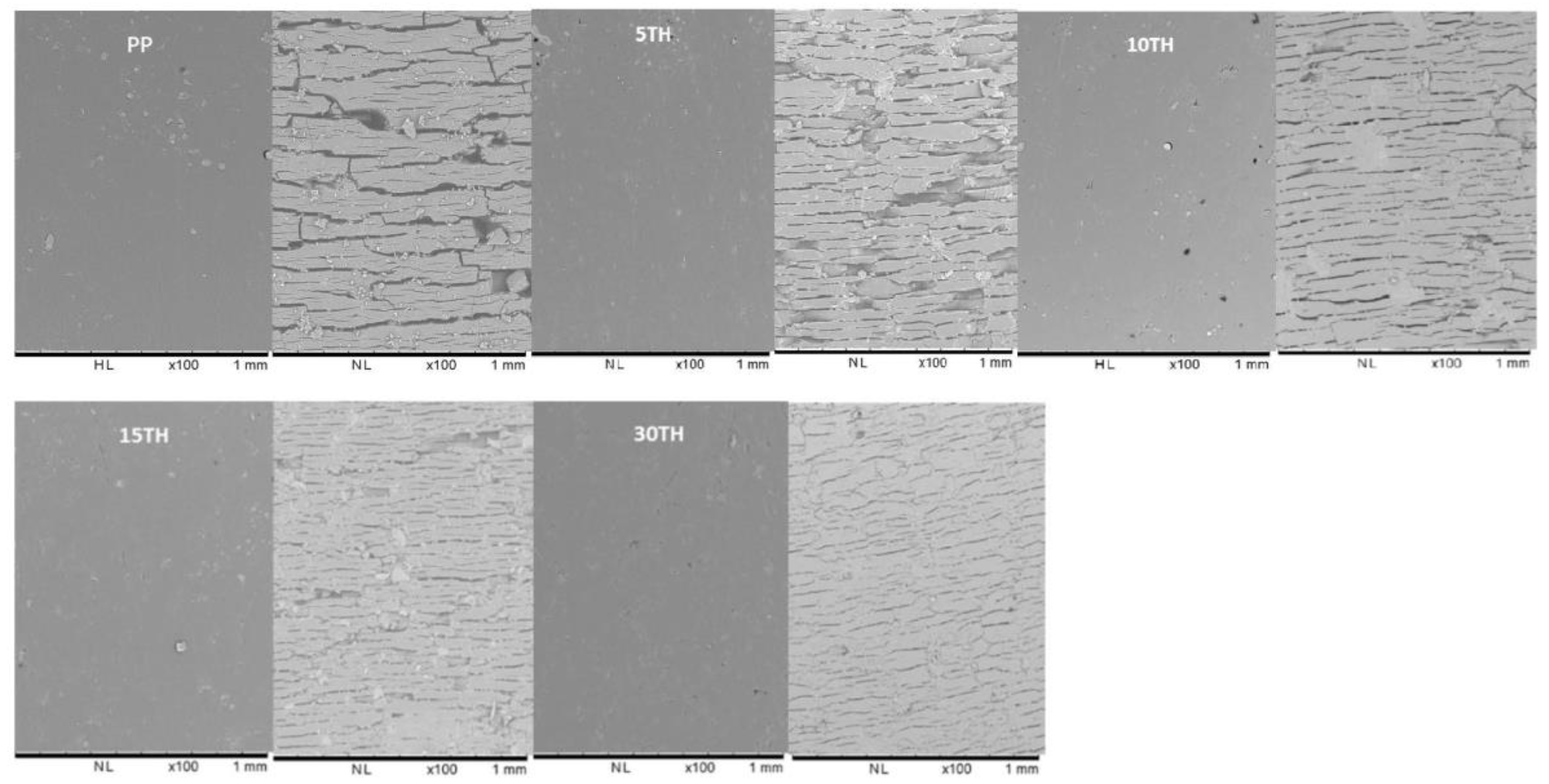

3.1.1. Morphology

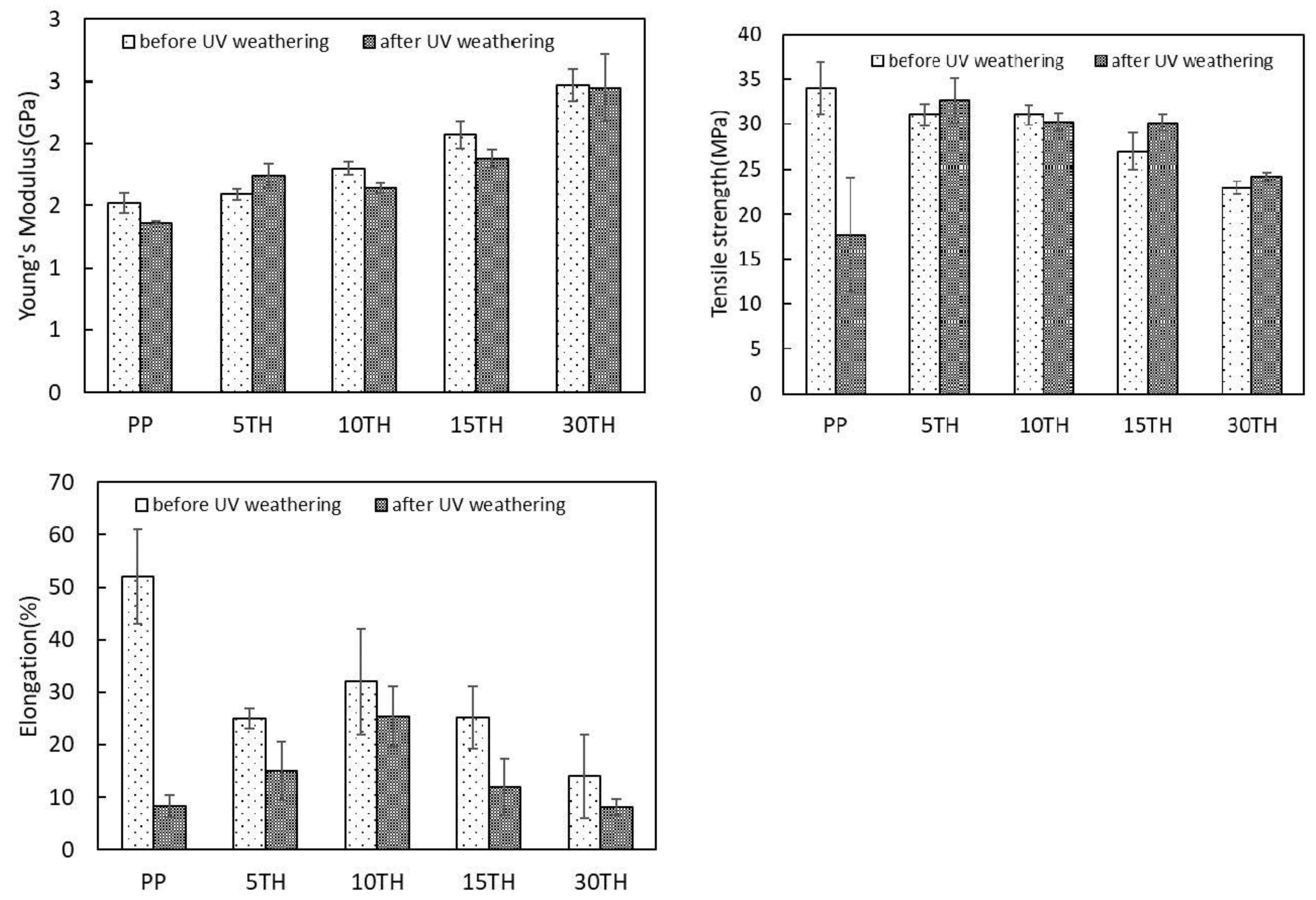

3.1.2. Tensile Properties

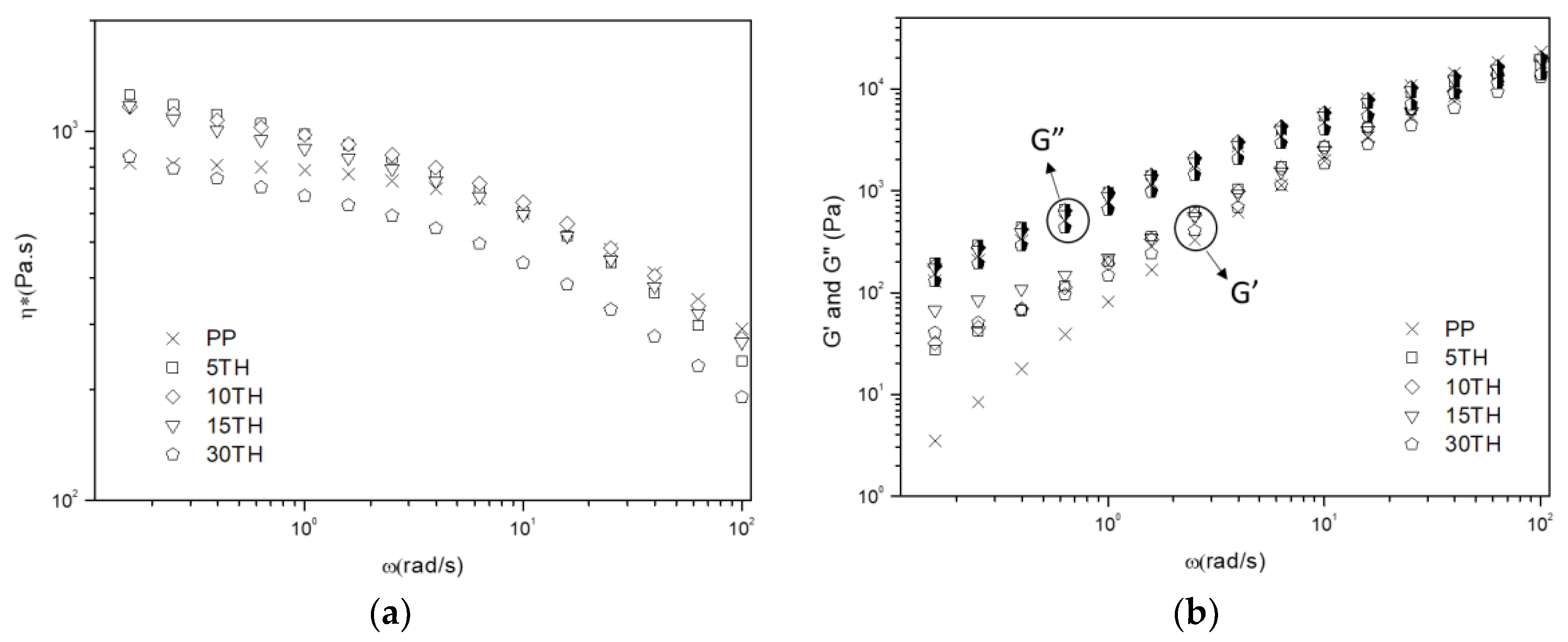

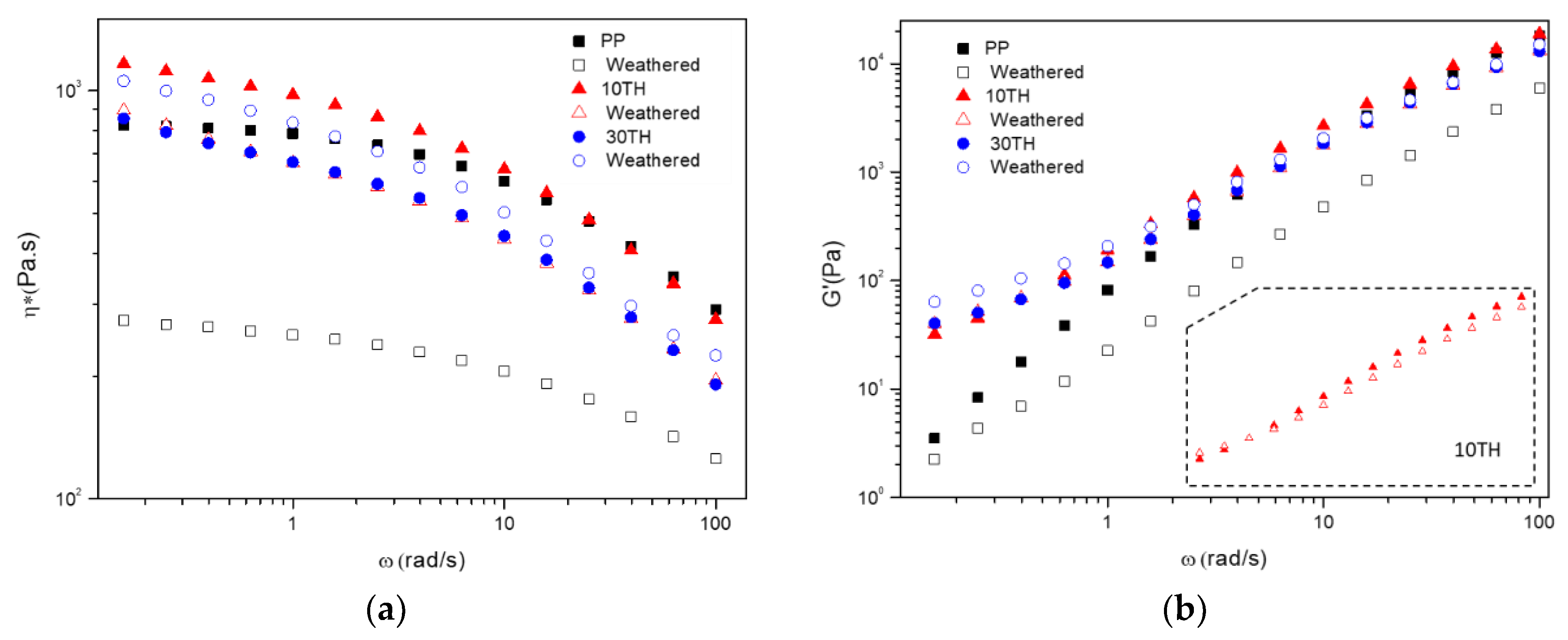

3.1.3. Rheological Behavior

3.1.4. Crystallinity

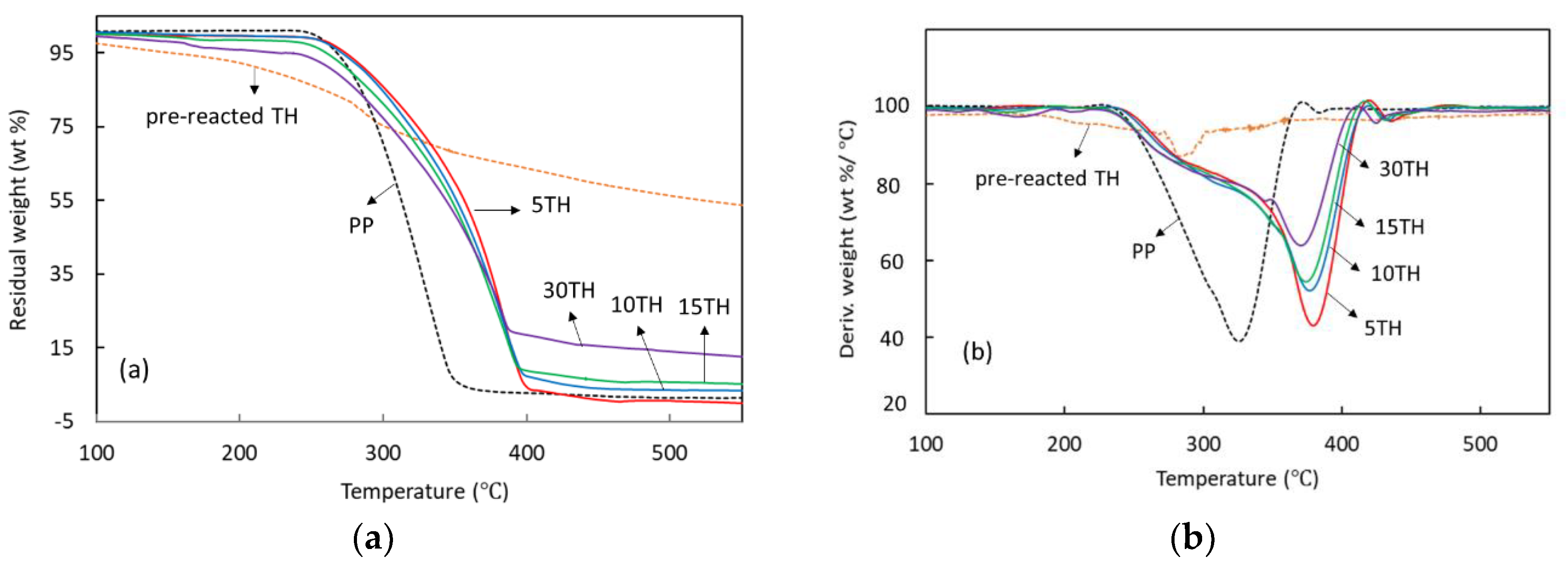

3.1.5. Thermogravimetric Analyses

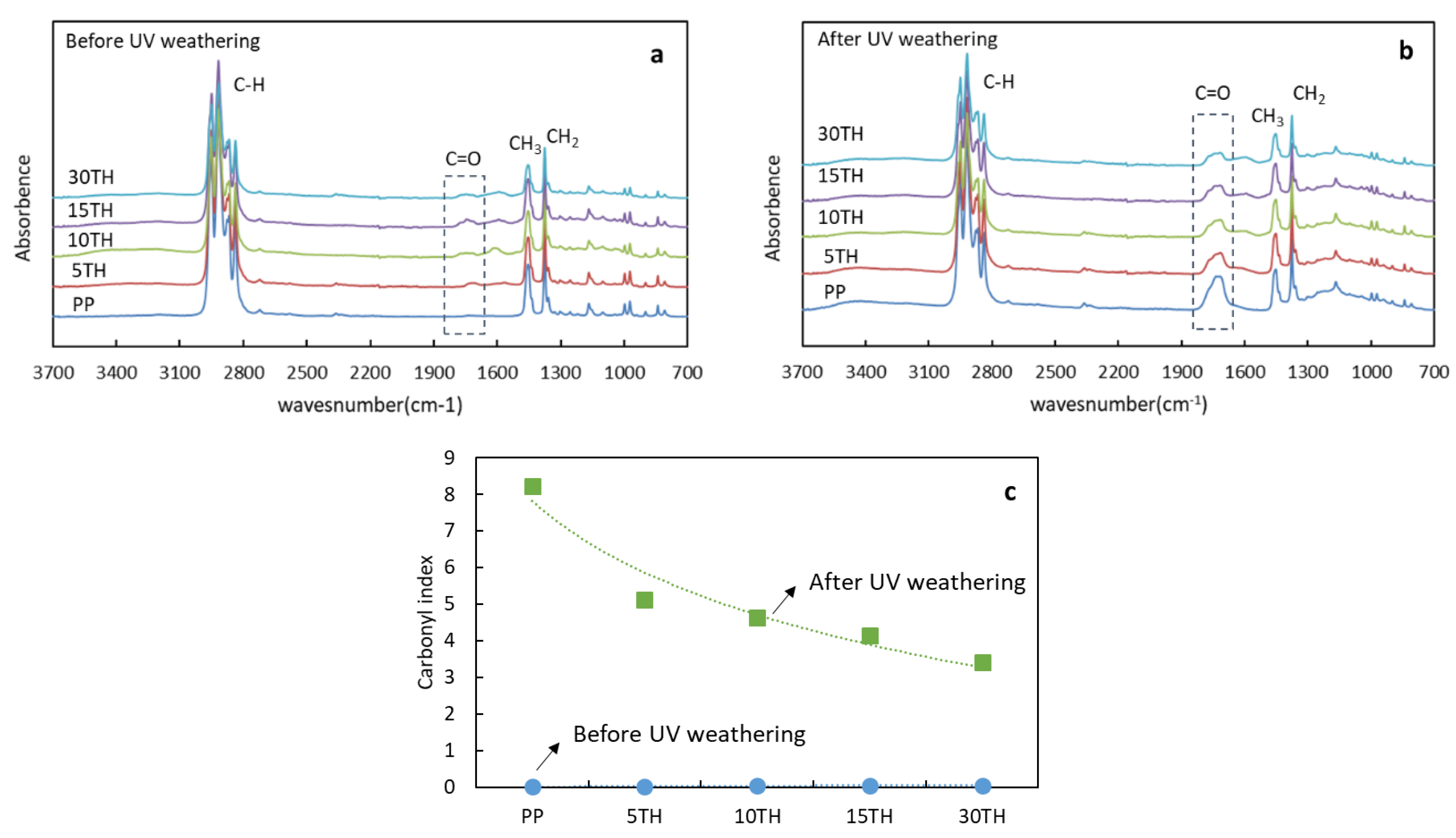

3.2. Anti-UV Performance of Cross-Linked TH

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Visakh, P.; Poletto, M. Polypropylene-Based Biocomposites and Bionanocomposites; John Wiley & Sons: Hoboken, NJ, USA, 2017. [Google Scholar]

- Hisham, M.H. Polypropylene as a promising plastic: A review. Am. J. Polym. Sci. 2016, 1, 1–11. [Google Scholar]

- Yang, J.; Lu, S.; Luo, Q.; Song, L.; Li, Y.; Yu, J. Enhanced mechanical and thermal properties of polypropylene/cellulose fibers composites with modified tannic as a compatibilizer. Polym. Compos. 2018, 39, 2036–2045. [Google Scholar] [CrossRef]

- Jang, S.; Kim, D. Preparation and physical properties of polypropylene/cellulose composites. Polym. Korea 2015, 39, 130–135. [Google Scholar] [CrossRef]

- De la Orden, M.U.; Sánchez, G.C.; Quesada, G.M.; Urreaga, M.J. Novel polypropylene–cellulose composites using polyethylenimine as coupling agent. Compos. Part A 2007, 38, 2005–2012. [Google Scholar] [CrossRef]

- Qiu, W.; Zhang, F.; Endo, T.; Hirotsu, T. Effect of maleated polypropylene on the performance of polypropylene/cellulose composite. Polym. Compos. 2005, 26, 448–453. [Google Scholar] [CrossRef]

- Tolinski, M. Additives for Polyolefins: Getting the Most out of Polypropylene, Polyethylene and TPO; William: New York, NY, USA, 2015. [Google Scholar]

- Beg, H.; Pickering, K.L. Accelerated weathering of unbleached and bleached Kraft wood fibre reinforced polypropylene composites. Polym. Degrad. Stab. 2008, 93, 1939–1946. [Google Scholar] [CrossRef]

- Stark, N.; Matuana, L.M. Surface chemistry and mechanical property changes of wood-flour/high-density-polyethylene composites after accelerated weathering. J. Appl. Polym. Sci. 2004, 94, 2263–2273. [Google Scholar] [CrossRef]

- Stewart, D. Lignin as a base material for materials applications: Chemistry, application and economics. Ind. Crop. Prod. 2008, 27, 202–207. [Google Scholar] [CrossRef]

- Alexy, P.; Košıková, B.; Podstránska, G. The effect of blending lignin with polyethylene and polypropylene on physical properties. Polymer 2000, 41, 4901–4908. [Google Scholar] [CrossRef]

- Gadioli, R.; Waldman, W.; Paoli, M. Lignin as a green primary antioxidant for polypropylene. J. Appl. Polym. Sci. 2016, 133, 43558. [Google Scholar] [CrossRef]

- Pouteau, C.; Dole, P.; Cathala, B.; Averous, L.; Boquillon, N. Antioxidant properties of lignin in polypropylene. Polym. Degrad. Stab. 2003, 81, 9–18. [Google Scholar] [CrossRef]

- Gregorová, A.; Cibulková, Z.; Košíková, B.; Šimon, P. Stabilization effect of lignin in polypropylene and recycled polypropylene. Polym. Degrad. Stab. 2005, 89, 553–558. [Google Scholar] [CrossRef]

- García, D.E.; Glasser, W.G.; Pizzi, A.; Paczkowski, S.P.; Laborie, M.-P. Modification of condensed tannins: From polyphenol chemistry to materials engineering. New J. Chem. 2015, 40, 36–49. [Google Scholar] [CrossRef]

- Arbenz, A.; Avérous, L. Chemical modification of tannins to elaborate aromatic biobased macromolecular architectures. Green Chem. 2015, 17, 2626–2646. [Google Scholar] [CrossRef]

- Pizzi, A. Tannin-based adhesives. In Wood Adhesives: Chemistry and Technology; Marcel Dekker: New York, NY, USA, 1983. [Google Scholar]

- Bele, A.A.; Jadhav, V.M.; Kadam, V. Potential of tannnins: A review. Asian J. Plant Sci. 2010, 9, 209. [Google Scholar]

- Samper, M.D.; Fages, E.; Fenollar, O.; Boronat, T.; Balart, R. The potential of flavonoids as natural antioxidants and UV light stabilizers for polypropylene. J. Appl. Polym. Sci. 2013, 129, 1707–1716. [Google Scholar] [CrossRef]

- Ambrogi, V.; Cerruti, P.; Carfagna, C.; Malinconico, M.; Marturano, V.; Perrotti, M.; Persico, P. Natural antioxidants for polypropylene stabilization. Polym. Degrad. Stab. 2011, 96, 2152–2158. [Google Scholar] [CrossRef]

- Shnawa, H.; Jahani, Y.; Khalaf, M.; Taobi, A. The potential of tannins as thermal co-stabilizer additive for polyvinyl chloride. J. Anal. Calorim. 2016, 123, 1253–1261. [Google Scholar] [CrossRef]

- Bridson, J.H.; Kaur, J.; Zhang, Z.; Donaldson, L.; Fernyhough, A. Polymeric flavonoids processed with co-polymers as UV and thermal stabilisers for polyethylene films. Polym. Degrad. Stab. 2015, 122, 18–24. [Google Scholar] [CrossRef]

- Zhai, Y.; Wang, J.; Wang, H.; Song, T.; Hu, W.; Li, S. Preparation and Characterization of Antioxidative and UV-Protective Larch Bark Tannin/PVA Composite Membranes. Molecules 2018, 23, 2073. [Google Scholar] [CrossRef]

- Yeo, J.-S.; Seong, D.-W.; Hwang, S.-H. Chemical surface modification of lignin particle and its application as filler in the polypropylene composites. J. Ind. Eng. Chem. 2015, 31, 80–85. [Google Scholar] [CrossRef]

- Laurichesse, S.; Avérous, L. Chemical modification of lignins: Towards biobased polymers. Prog. Polym. Sci. 2014, 39, 1266–1290. [Google Scholar] [CrossRef]

- Shnawa, H.; Jahani, Y.; Khalaf, M. Rheological properties of PVC stabilized with tannin based epoxy resin as non metallic thermal stabilizer. Polym. Bull. 2017, 74, 1077–1090. [Google Scholar] [CrossRef]

- Gaugler, M.; Grigsby, W.; Harper, D.; Rials, T. Chemical imaging of the spatial distribution and interactions of tannin dispersal in bioplastic systems. Adv. Mater. Res. 2007, 29, 173–176. [Google Scholar] [CrossRef]

- Grigsby, W.J.; Bridson, J.H.; Lomas, C.; Elliot, J.-A. Esterification of Condensed Tannins and Their Impact on the Properties of Poly(Lactic Acid). Polymers 2013, 5, 344–360. [Google Scholar] [CrossRef]

- Grigsby, W.J.; Bridson, J.H.; Lomas, C.; Frey, H. Evaluating Modified Tannin Esters as Functional Additives in Polypropylene and Biodegradable Aliphatic Polyester. Macromol. Mater. Eng. 2014, 299, 1251–1258. [Google Scholar] [CrossRef]

- Kim, S.-J.; Moon, J.-B.; Kim, G.-H.; Ha, C.-S. Mechanical properties of polypropylene/natural fiber composites: Comparison of wood fiber and cotton fiber. Polym. Test. 2008, 27, 801–806. [Google Scholar] [CrossRef]

- Karian, H. Handbook of Polypropylene and Polypropylene Composites, Revised and Expanded; CRC Press: Boca Raton, FL, USA, 2003. [Google Scholar]

- Jiang, X.; Zhang, Y.; Zhang, Y. Crystallization behavior of dynamically cured polypropylene/epoxy blends. J. Polym. Sci. Part B Polym. Phys. 2004, 42, 1181–1191. [Google Scholar] [CrossRef]

- Cui, L.; Wang, S.; Zhang, Y.; Zhang, Y. Dynamically cured polypropylene/Novolac blends compatibilized with maleic anhydride-g-polypropylene. J. Appl. Polym. Sci. 2007, 104, 3337–3346. [Google Scholar] [CrossRef]

- Chen, F.; Dai, H.; Dong, X.; Yang, J.; Zhong, M. Physical properties of lignin-based polypropylene blends. Polym. Compos. 2011, 32, 1019–1025. [Google Scholar] [CrossRef]

- Chiang, W.; Wu, W.; Pukánszky, B. Modification of polypropylene, blending with resole type phenol-formaldehyde resins. Eur. Polym. J. 1994, 30, 573–580. [Google Scholar] [CrossRef]

- Jilkén, L.; Mälhammar, G.; Seldén, R. The effect of mineral fillers on impact and tensile properties of polypropylene. Polym. Test. 1991, 10, 329–344. [Google Scholar] [CrossRef]

- Wu, C.; Zhang, M.; Rong, M.; Friedrich, K. Tensile performance improvement of low nanoparticles filled-polypropylene composites. Compos. Sci. Technol. 2002, 62, 1327–1340. [Google Scholar] [CrossRef]

- Wacker, G.; Bledzki, A.K.; Chate, A. Effect of interphase on the transverse Young’s modulus of glass/epoxy composites. Compos. Part A 1998, 29, 619–626. [Google Scholar] [CrossRef]

- Bozsódi, B.; Romhányi, V.; Pataki, P.; Kun, D.; Renner, K.; Pukánszky, B. Modification of interactions in polypropylene/lignosulfonate blends. Mater. Des. 2016, 103, 32–39. [Google Scholar] [CrossRef]

- Nayak, S.K.; Mohanty, S.; Samal, S.K. Influence of short bamboo/glass fiber on the thermal, dynamic mechanical and rheological properties of polypropylene hybrid composites. Mater. Sci. Eng. A 2009, 523, 32–38. [Google Scholar] [CrossRef]

- Tajvidi, M.; Falk, R.H.; Hermanson, J.C. Effect of natural fibers on thermal and mechanical properties of natural fiber polypropylene composites studied by dynamic mechanical analysis. J. Appl. Polym. Sci. 2006, 101, 4341–4349. [Google Scholar] [CrossRef]

- Lin, X.; Zhang, K.; Li, K.; Ren, D. Dependence of rheological behaviors of polymeric composites on the morphological structure of carbonaceous nanoparticles. J. Appl. Polym. Sci. 2018, 135, 46416. [Google Scholar] [CrossRef]

- Azizi, H.; Ghasemi, I. Investigation on the dynamic melt rheological properties of polypropylene/wood flour composites. Polym. Compos. 2009, 30, 429–435. [Google Scholar] [CrossRef]

- Zoukrami, F.; Haddaoui, N.; Sclavons, M.; Devaux, J.; Vanzeveren, C. Rheological properties and thermal stability of compatibilized polypropylene/untreated silica composites prepared by water injection extrusion process. Polym. Bull. 2018, 75, 1–16. [Google Scholar] [CrossRef]

- Peng, Y.; Liu, R.; Cao, J. Characterization of surface chemistry and crystallization behavior of polypropylene composites reinforced with wood flour, cellulose, and lignin during accelerated weathering. Appl. Surf. Sci. 2015, 332, 253–259. [Google Scholar] [CrossRef]

- Liang, J.-Z.; Du, Q.; Tsui, G.; Tang, C.-Y. Tensile properties of graphene nano-platelets reinforced polypropylene composites. Compos. Part B 2016, 95, 166–171. [Google Scholar] [CrossRef]

- Badji, C.; Soccalingame, L.; Garay, H.; Bergeret, A.; Bénézet, J.-C. Influence of weathering on visual and surface aspect of wood plastic composites: Correlation approach with mechanical properties and microstructure. Polym. Degrad. Stab. 2017, 137, 162–172. [Google Scholar] [CrossRef]

- Fabiyi, J.S.; Nald, A.G.; Wolcott, M.P.; Griffiths, P.R. Wood plastic composites weathering: Visual appearance and chemical changes. Polym. Degrad. Stab. 2008, 93, 1405–1414. [Google Scholar] [CrossRef]

- Matuana, L.M.; Jin, S.; Stark, N. Ultraviolet weathering of HDPE/wood-flour composites coextruded with a clear HDPE cap layer. Polym. Degrad. Stab. 2011, 96, 97–106. [Google Scholar] [CrossRef]

- Pizzi, A.; Tekely, P. Mechanism of polyphenolic tannin resin hardening by hexamethylenetetramine: CP–MAS 13C-NMR. J. Appl. Polym. Sci. 1995, 56, 1645–1650. [Google Scholar] [CrossRef]

- Pichelin, F.; Kamoun, C.; Pizzi, A. Hexamine hardener behaviour: Effects on wood glueing, tannin and other wood adhesives. Holz als Roh-und Werkstoff 1999, 57, 305–317. [Google Scholar] [CrossRef]

- Noferi, M.; Masson, E.; Merlin, A.; Pizzi, A.; Deglise, X. Antioxidant characteristics of hydrolysable and polyflavonoid tannins: An ESR kinetics study. J. Appl. Polym. Sci. 1997, 63, 475–482. [Google Scholar] [CrossRef]

- Theis, M.; Grohe, B. Biodegradable lightweight construction boards based on tannin/hexamine bonded hemp shaves. Holz als Roh-und Werkstoff 2002, 60, 291–296. [Google Scholar] [CrossRef]

- Hussein, I.A. Rheological investigation of the influence of molecular structure on natural and accelerated UV degradation of linear low density polyethylene. Polym. Degrad. Stab. 2007, 92, 2026–2032. [Google Scholar] [CrossRef]

| Sample | Before | After | ||||

|---|---|---|---|---|---|---|

| Hm | Xc | Tm | Hm | Xc | Tm | |

| (J/g) | % | °C | (J/g) | % | °C | |

| PP | −71.6 | 34.6 | 165.0 | −53.3 | 25.7 | 163.3 |

| 5TH | −74.9 | 38.1 | 166.5 | −72.0 | 36.6 | 166.8 |

| 10TH | −75.6 | 40.6 | 164.1 | −62.0 | 33.3 | 167.6 |

| 15TH | −71.3 | 40.5 | 164.0 | −57.7 | 32.8 | 164.7 |

| 30TH | −59.1 | 40.8 | 164.2 | −49.6 | 34.2 | 165.1 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liao, J.; Brosse, N.; Pizzi, A.; Hoppe, S. Dynamically Cross-Linked Tannin as a Reinforcement of Polypropylene and UV Protection Properties. Polymers 2019, 11, 102. https://doi.org/10.3390/polym11010102

Liao J, Brosse N, Pizzi A, Hoppe S. Dynamically Cross-Linked Tannin as a Reinforcement of Polypropylene and UV Protection Properties. Polymers. 2019; 11(1):102. https://doi.org/10.3390/polym11010102

Chicago/Turabian StyleLiao, Jingjing, Nicolas Brosse, Antonio Pizzi, and Sandrine Hoppe. 2019. "Dynamically Cross-Linked Tannin as a Reinforcement of Polypropylene and UV Protection Properties" Polymers 11, no. 1: 102. https://doi.org/10.3390/polym11010102

APA StyleLiao, J., Brosse, N., Pizzi, A., & Hoppe, S. (2019). Dynamically Cross-Linked Tannin as a Reinforcement of Polypropylene and UV Protection Properties. Polymers, 11(1), 102. https://doi.org/10.3390/polym11010102