Enhanced Flexibility of Biodegradable Polylactic Acid/Starch Blends Using Epoxidized Palm Oil as Plasticizer

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Blend Preparation

2.3. Materials Characterizations

3. Results and Discussion

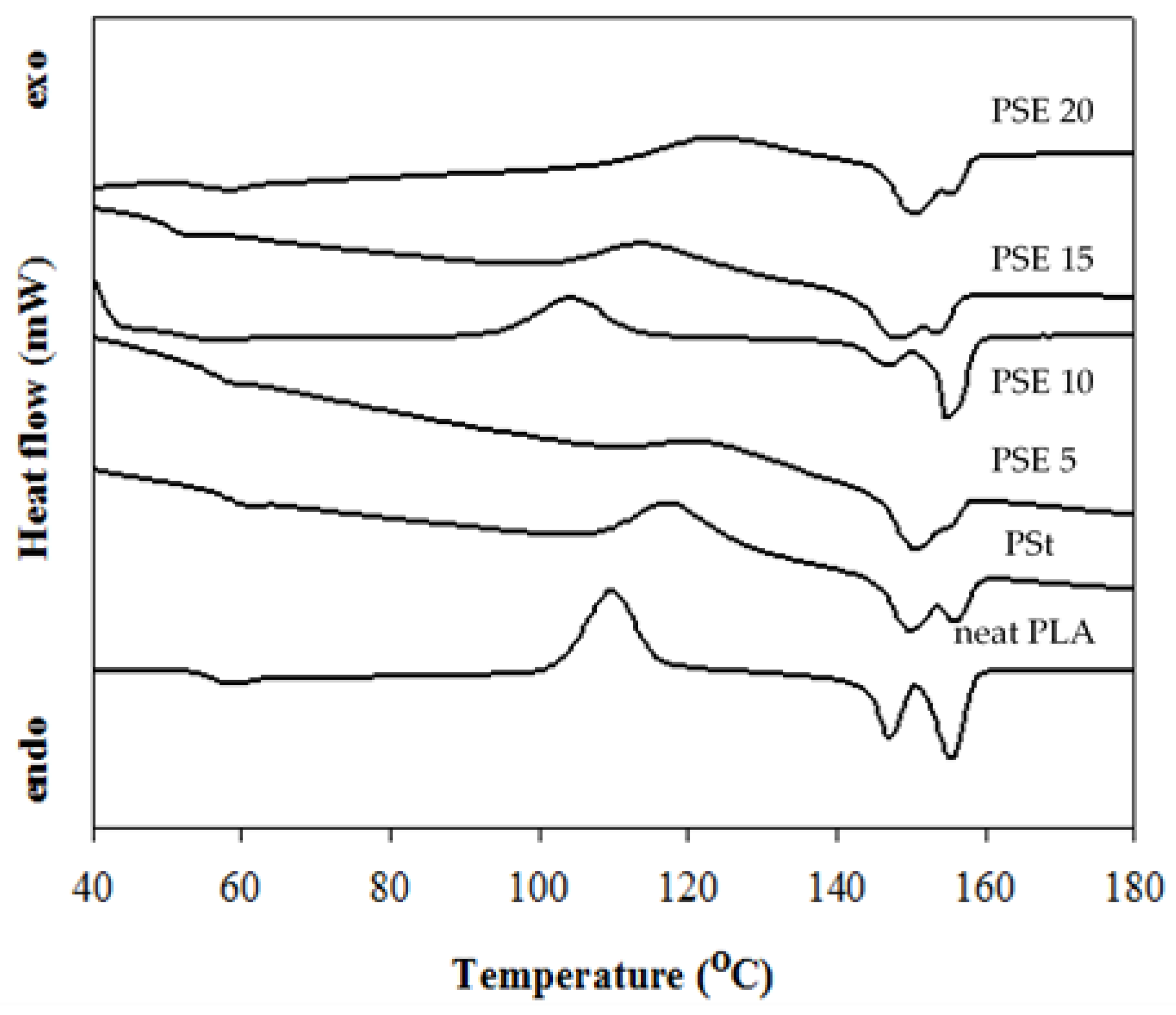

3.1. Thermal Properties

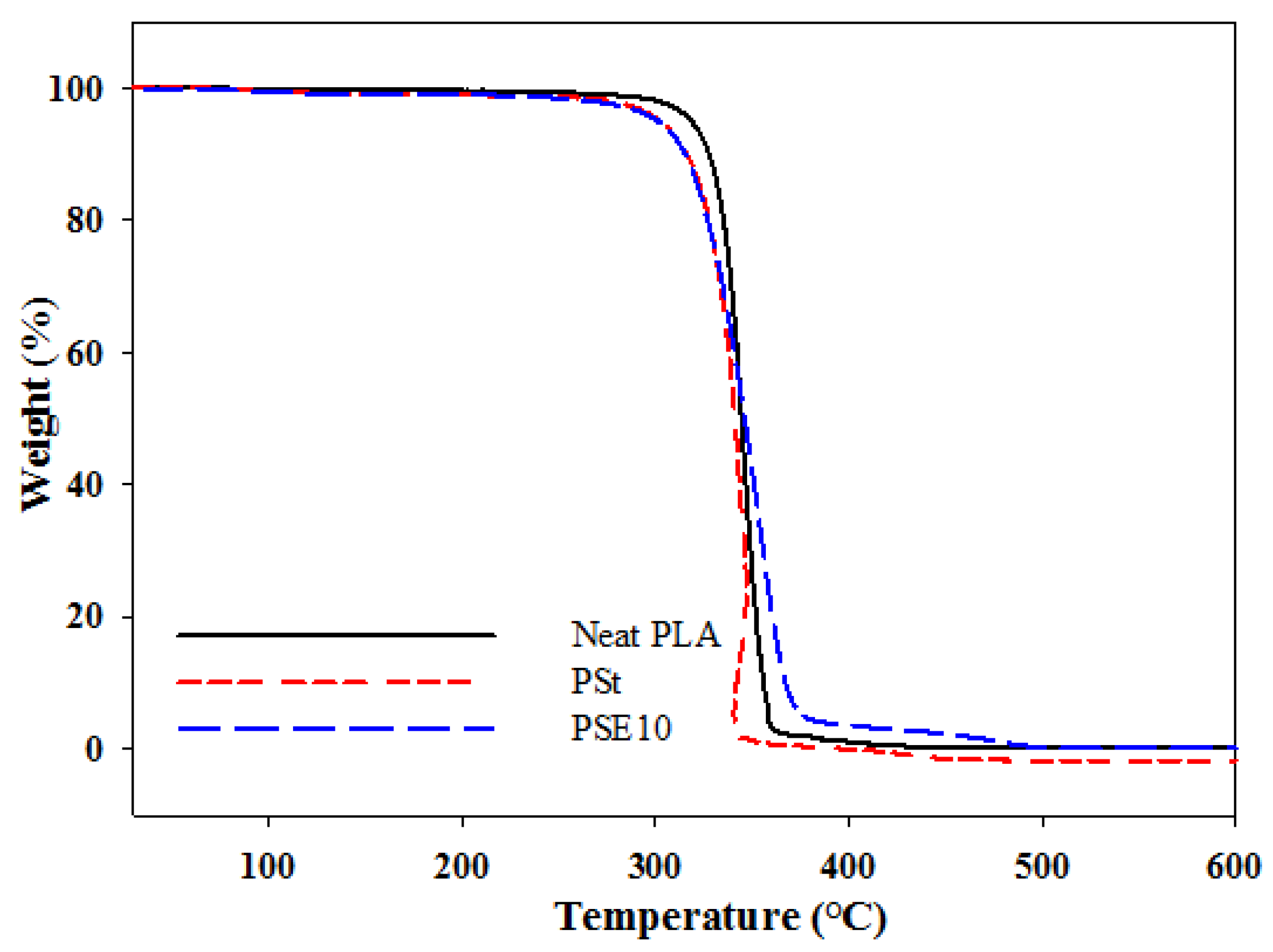

3.2. Thermogravimetric Analysis

3.3. Mechanical Properties

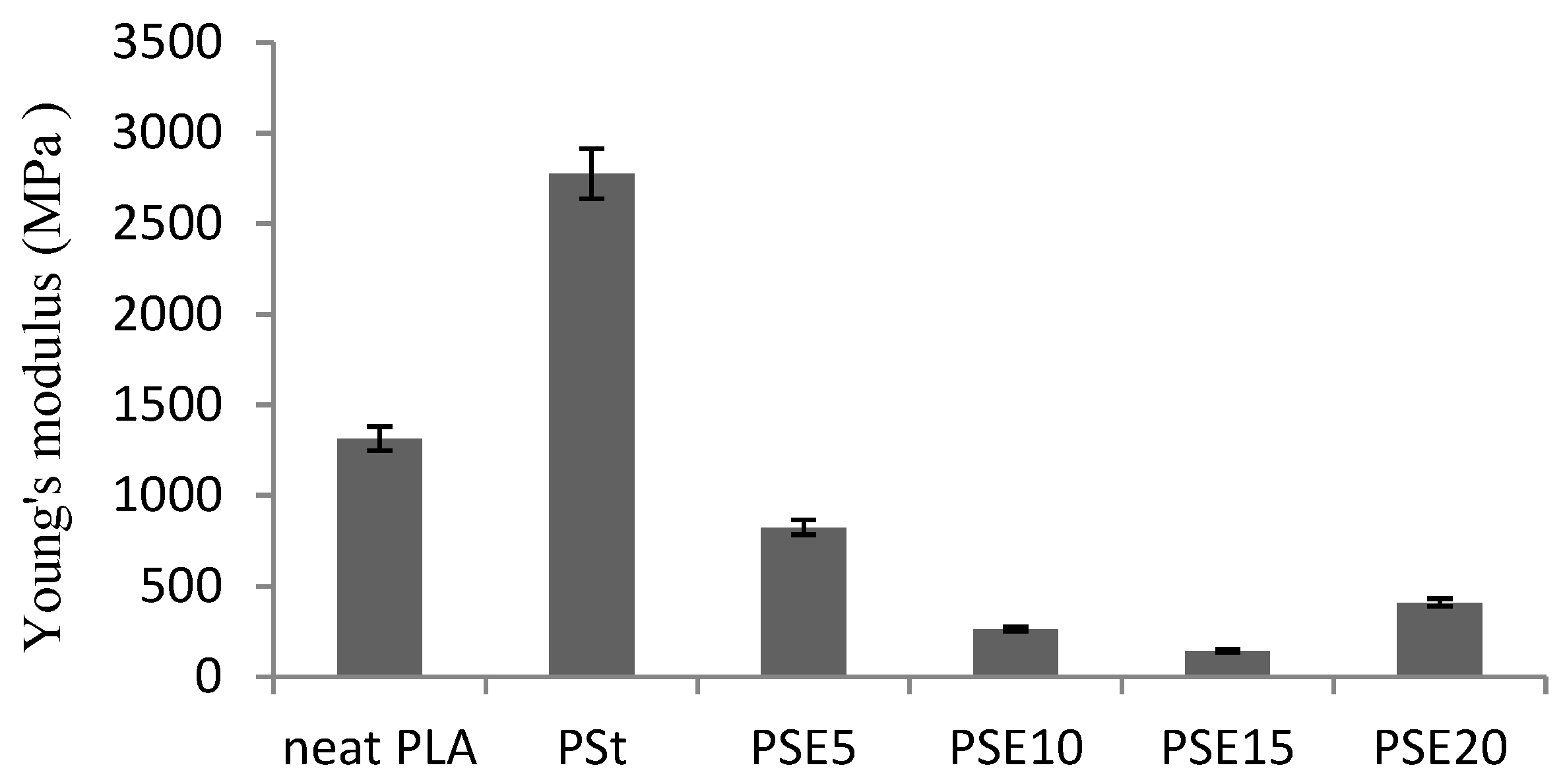

3.3.1. Young’s Modulus

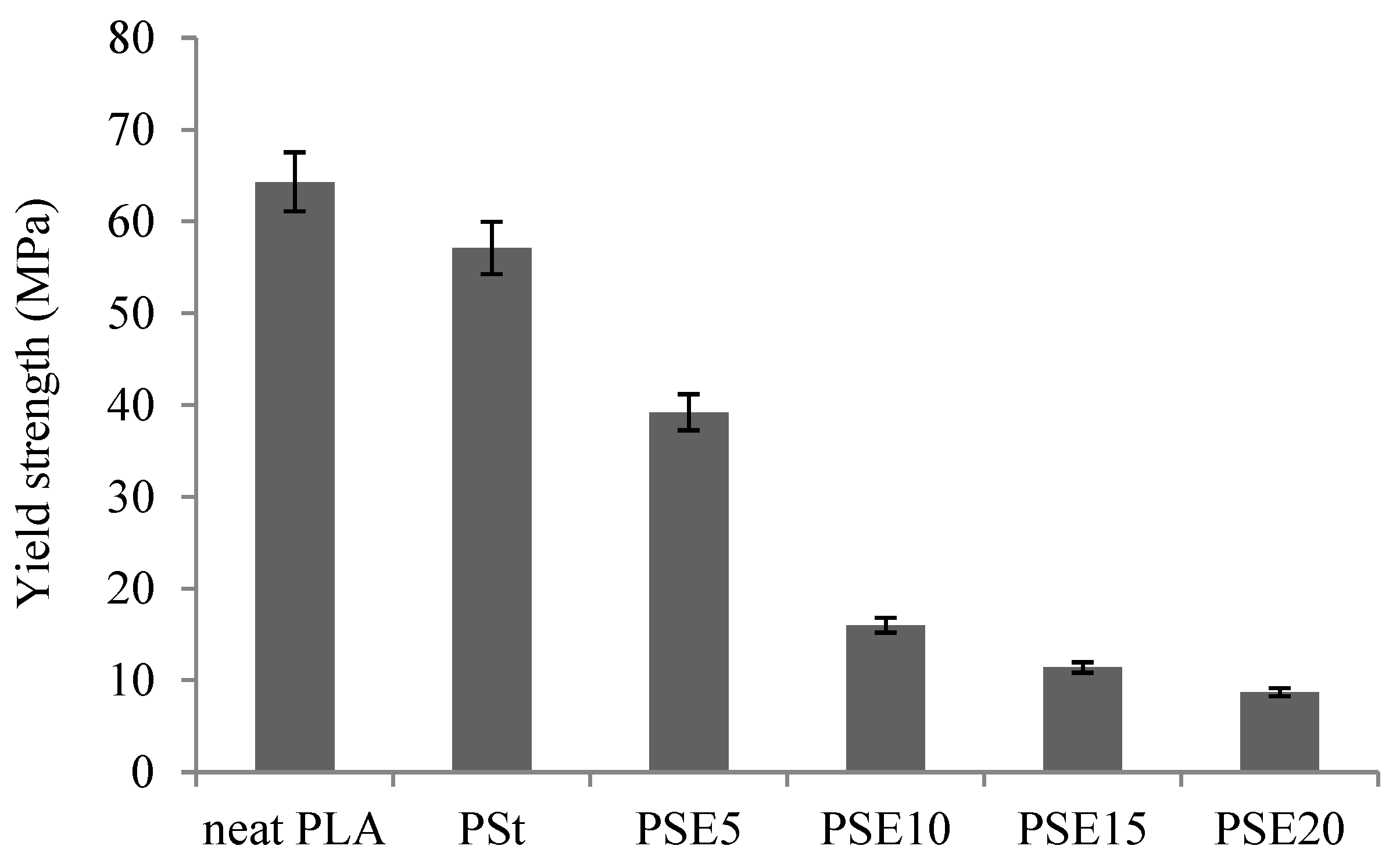

3.3.2. Yield Strength

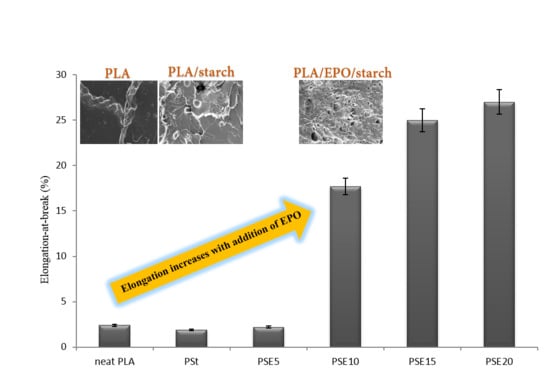

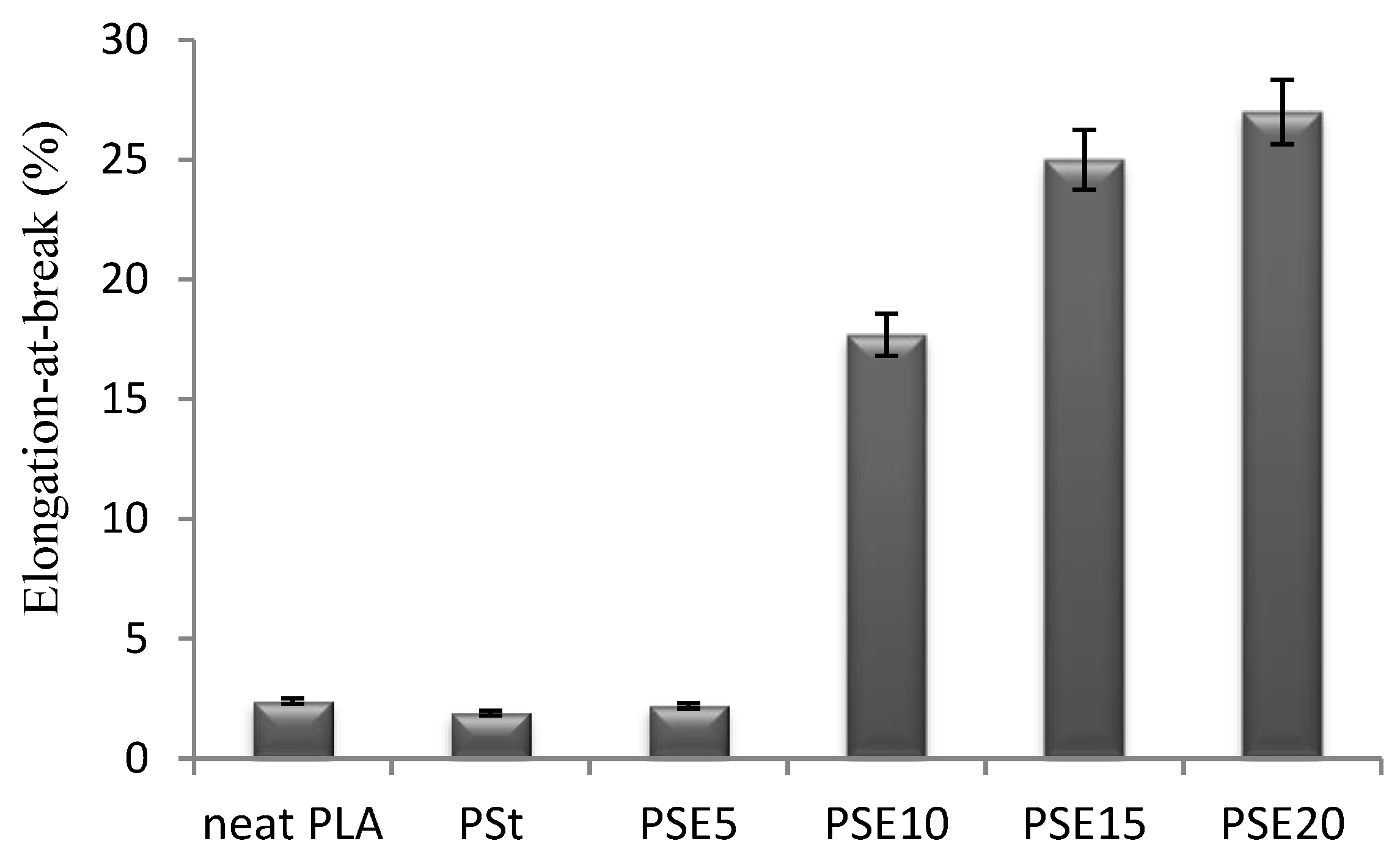

3.3.3. Elongation-at-Break

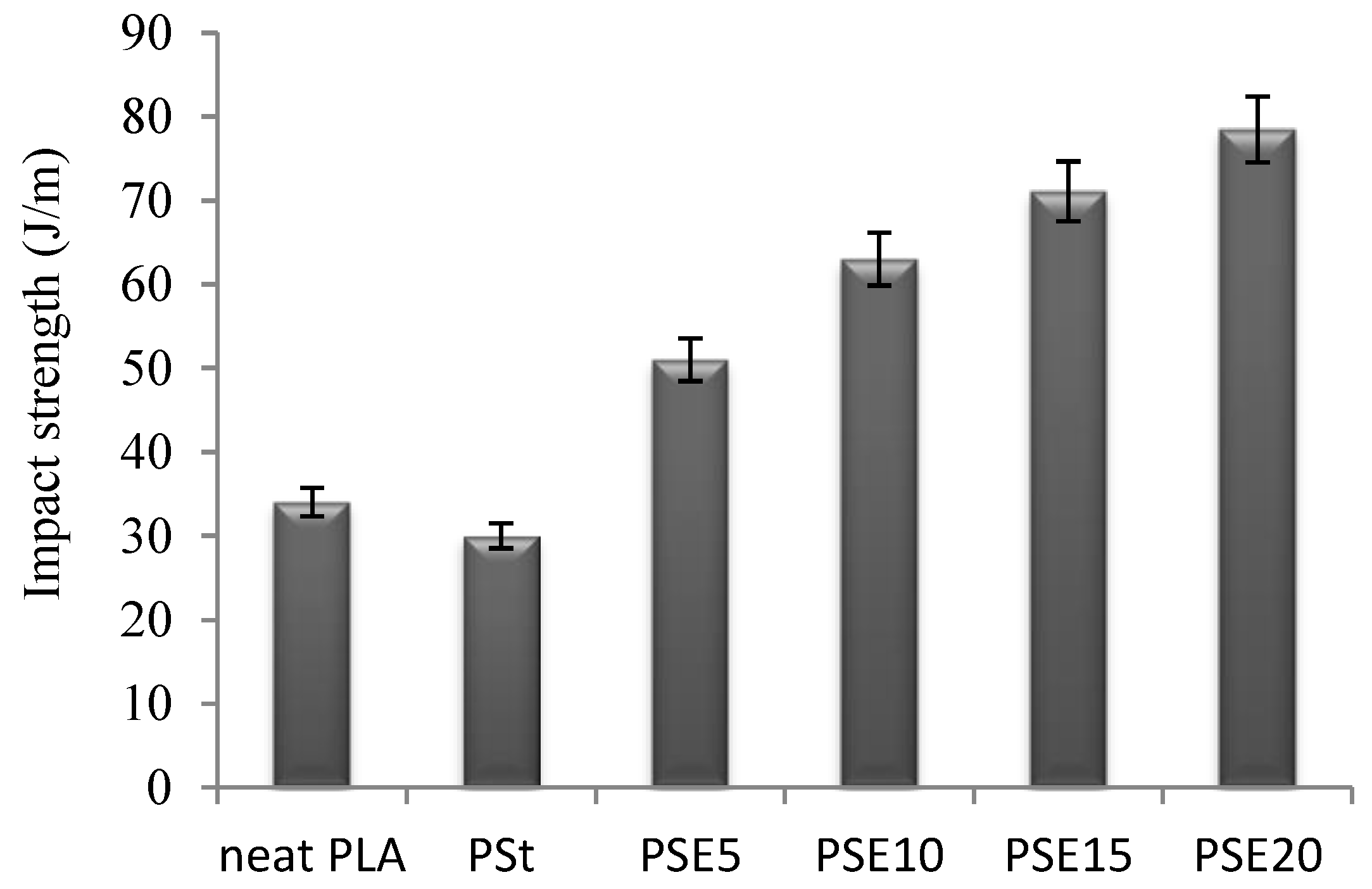

3.3.4. Impact Test

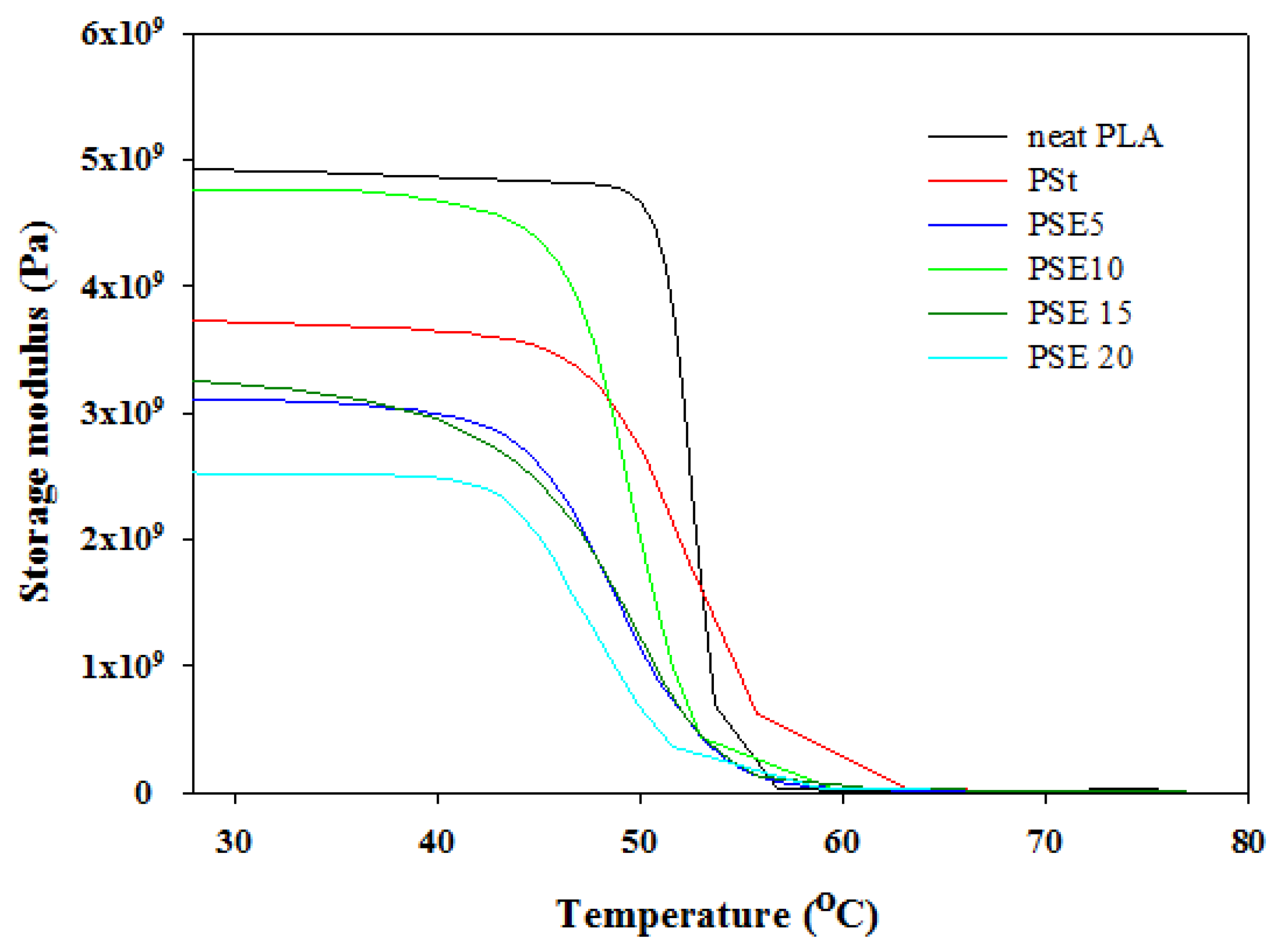

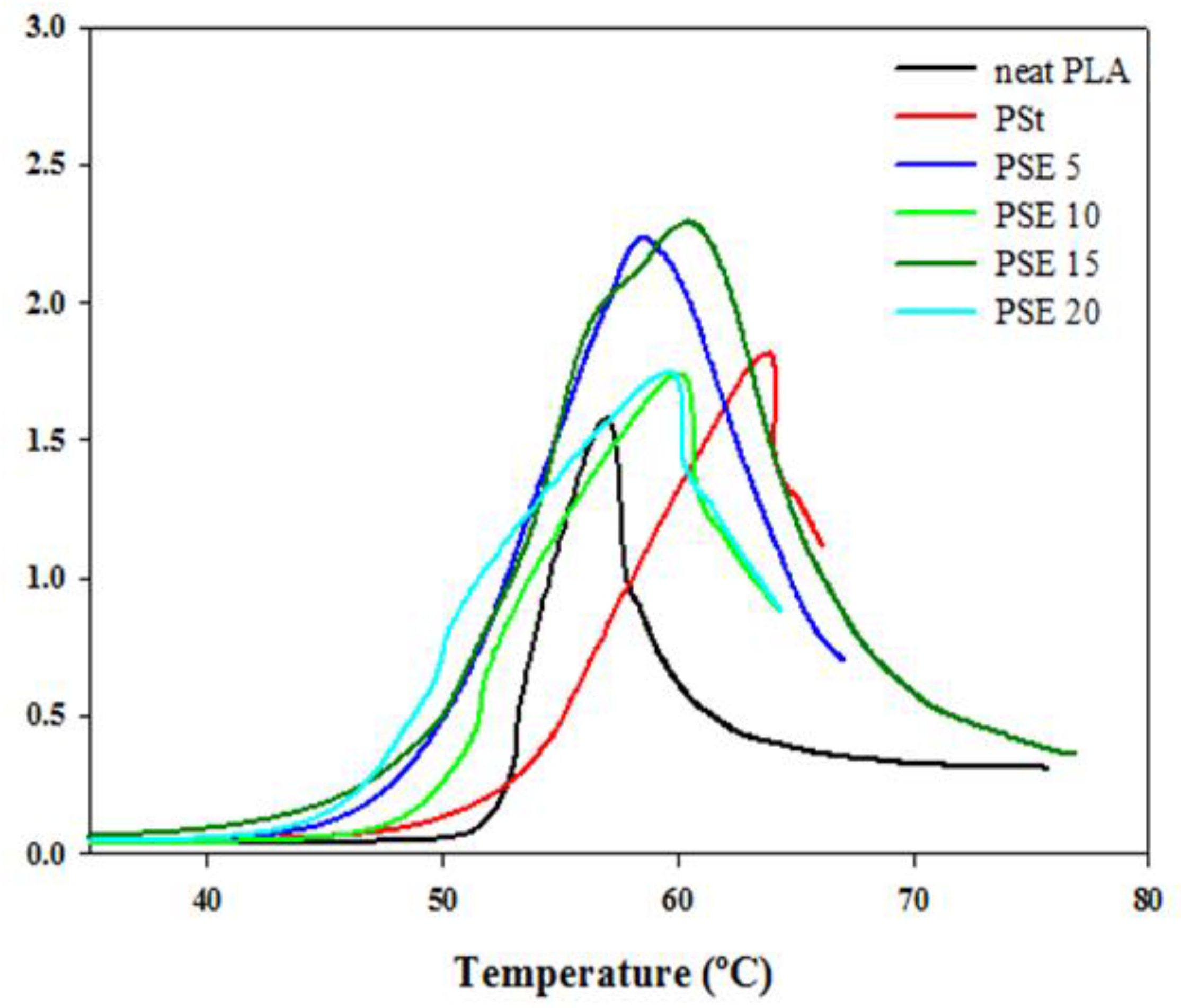

3.3.5. Dynamic Mechanical Analyzer (DMA)

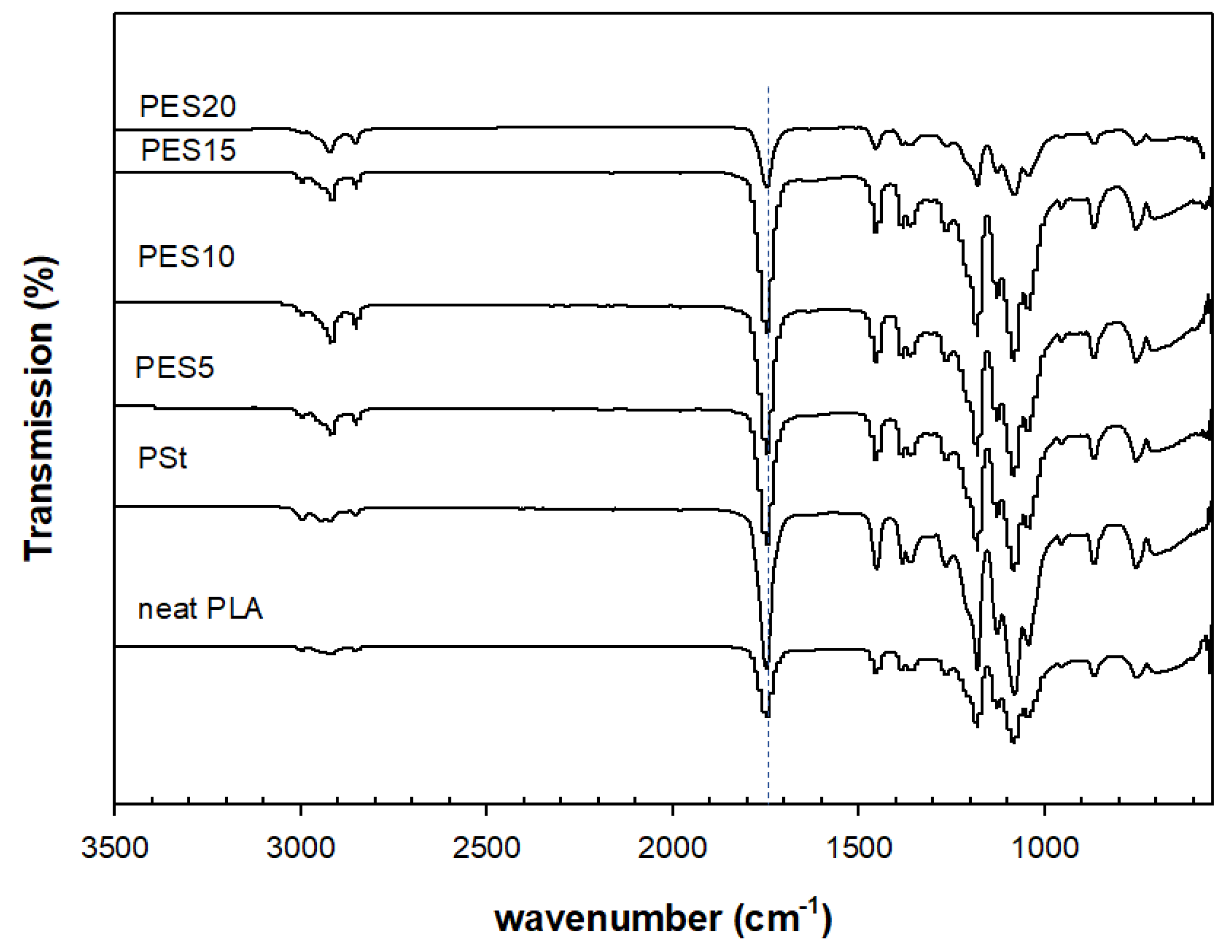

3.4. Fourier Transform Infrared Spectroscopy (FTIR)

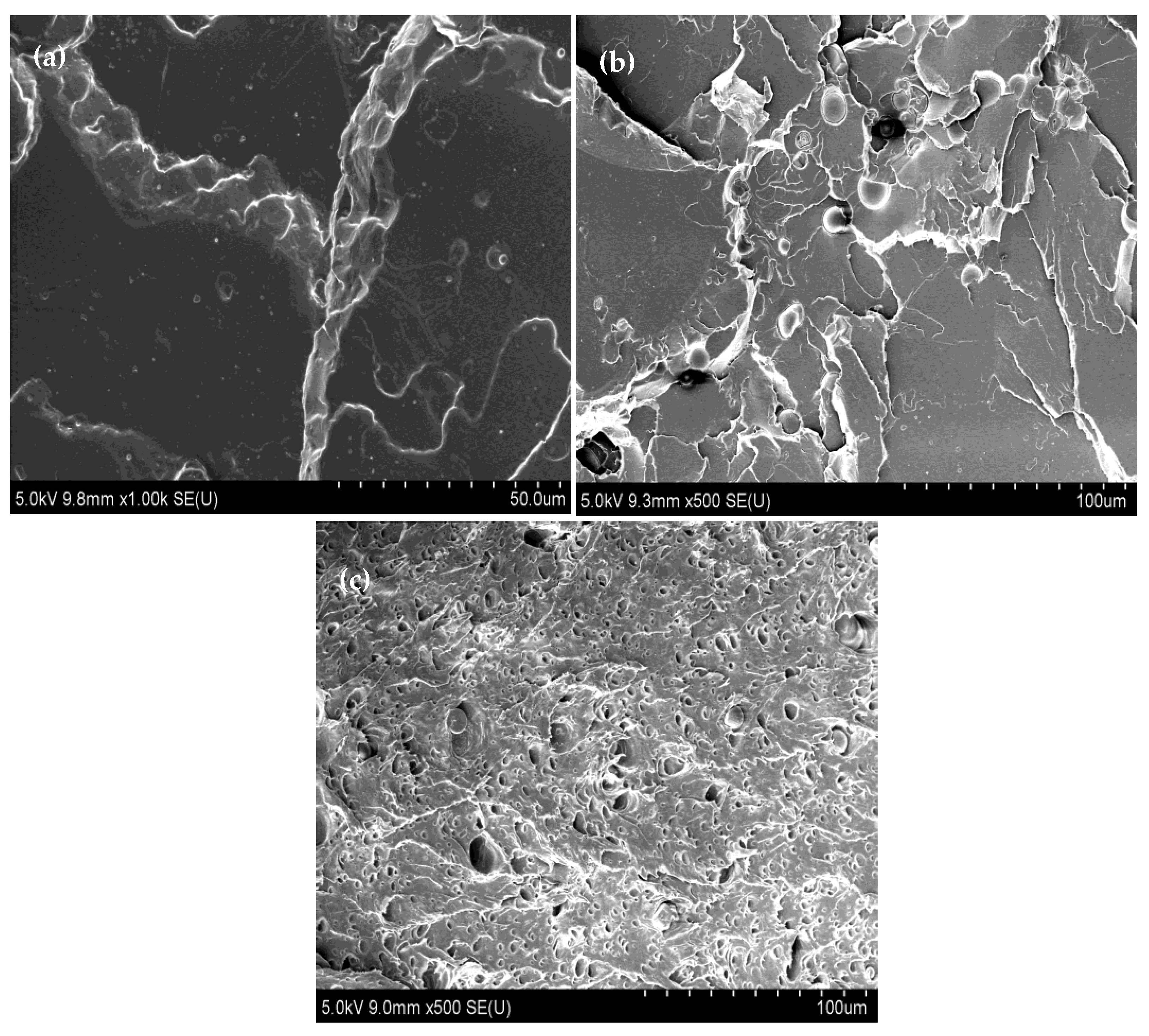

3.5. Surface Morphology

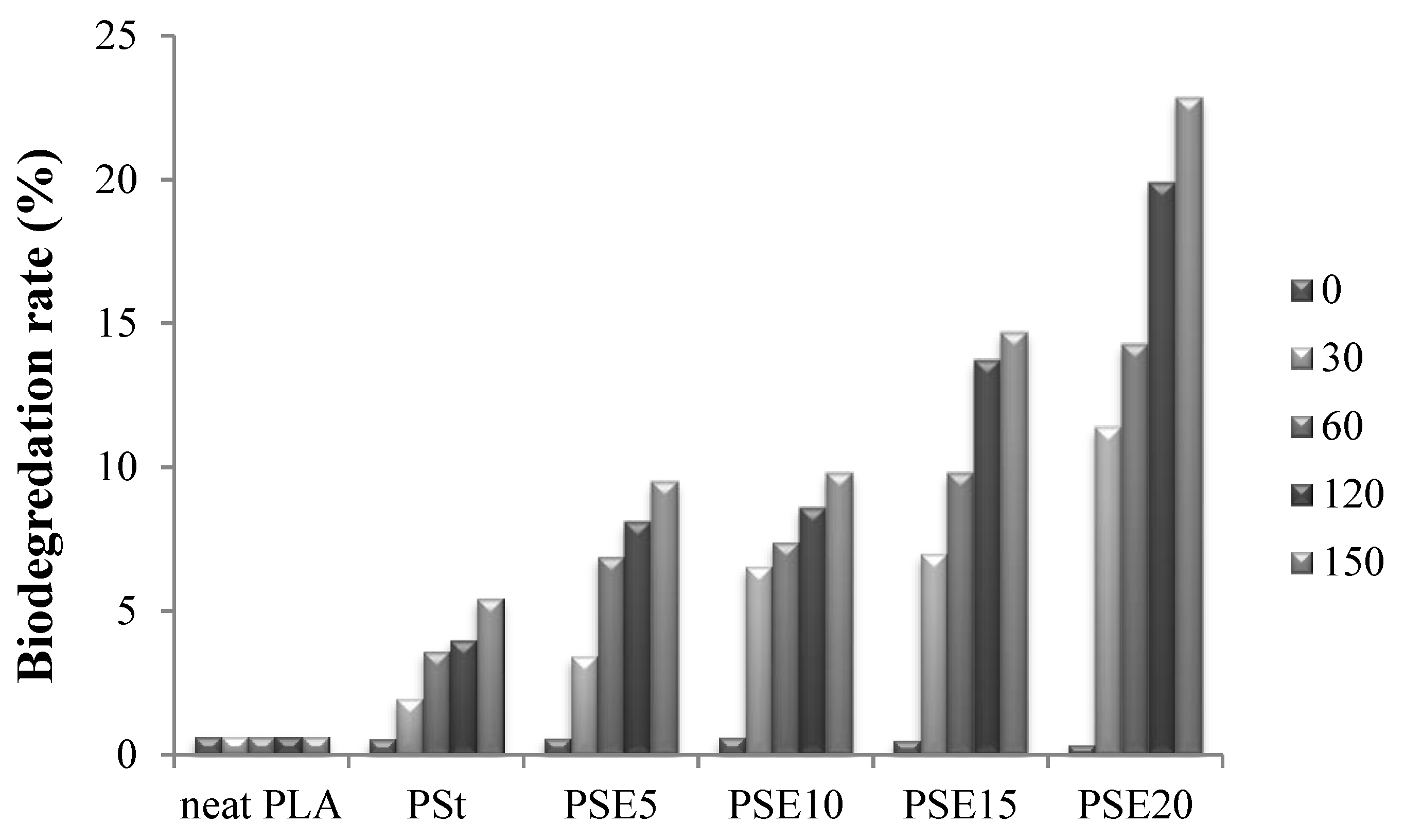

3.6. Soil Burial Test

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Jamshidian, M.; Tehrany, E.A.; Imran, M.; Jacquot, M.; Desobry, S. Poly-Lactic acid: Production, applications, nanocomposites, and release studies. Compr. Rev. Food Sci. Food Saf. 2010, 9, 552–571. [Google Scholar] [CrossRef]

- Avérous, L.; Pollet, E. Biodegradable Polymers. In Environmental Silicate Nano-Biocomposites; Springer: London, UK, 2012; pp. 13–39. ISBN 978-1-4471-4108-2. [Google Scholar]

- Xiao, L.; Wang, B.; Yang, G.; Gauthier, M. Poly(Lactic Acid)-Based biomaterials: Synthesis, modification and applications. In Biomedical Science, Engineering and Technology; InTech: Rijeka, Croatia, 2012. [Google Scholar]

- Anderson, J.M.; Shive, M.S. Biodegradation and biocompatibility of PLA and PLGA microspheres. Adv. Drug Deliv. Rev. 1997, 28, 5–24. [Google Scholar] [CrossRef]

- Lasprilla, A.J.R.; Martinez, G.A.R.; Lunelli, B.H.; Jardini, A.L.; Filho, R.M. Poly-lactic acid synthesis for application in biomedical devices—A review. Biotechnol. Adv. 2012, 30, 321–328. [Google Scholar] [CrossRef] [PubMed]

- Shukor, F.; Hassan, A.; Islam, M.S.; Mokhtar, M.; Hasan, M. Effect of ammonium polyphosphate on flame retardancy, thermal stability and mechanical properties of alkali treated kenaf fiber filled PLA biocomposites. Mater. Des. 2014, 54, 425–429. [Google Scholar] [CrossRef]

- Petinakis, E.; Liu, X.; Yu, L.; Way, C.; Sangwan, P.; Dean, K.; Bateman, S.; Edward, G. Biodegradation and thermal decomposition of poly(lactic acid)-based materials reinforced by hydrophilic fillers. Polym. Degrad. Stab. 2010, 95, 1704–1707. [Google Scholar] [CrossRef]

- Fowlks, A.C.; Narayan, R. The effect of maleated polylactic acid (PLA) as an interfacial modifier in PLA-talc composites. J. Appl. Polym. Sci. 2010, 118, 2810–2820. [Google Scholar] [CrossRef]

- Muller, J.; González-Martínez, C.; Chiralt, A. Combination of poly(lactic) acid and starch for biodegradable food packaging. Materials 2017, 10, 952. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Jiang, H.; Chen, L. Grafting of glycidyl methacrylate onto poly(lactide) and properties of PLA/starch blends compatibilized by the grafted copolymer. J. Polym. Environ. 2012, 20, 810–816. [Google Scholar] [CrossRef]

- Ali, F.; Chang, Y.W.; Kang, S.C.; Yoon, J.Y. Thermal, mechanical and rheological properties of poly (lactic acid)/epoxidized soybean oil blends. Polym. Bull. 2009, 62, 91–98. [Google Scholar] [CrossRef]

- Czub, P.; Franek, I. Epoxy resins modified with palm oil derivatives—Preoaration and properties. Polymery 2013, 58, 135–139. [Google Scholar] [CrossRef]

- Al-Mulla, E.A.J.; Yunus, W.M.Z.W.; Ibrahim, N.A.B.; Rahman, M.Z.A. Properties of epoxidized palm oil plasticized polytlactic acid. J. Mater. Sci. 2010, 45, 1942–1946. [Google Scholar] [CrossRef]

- Chabrat, E.; Abdillahi, H.; Rouilly, A.; Rigal, L. Influence of citric acid and water on thermoplastic wheat flour/poly(lactic acid) blends. I: Thermal, mechanical and morphological properties. Ind. Crop. Prod. 2012, 37, 238–246. [Google Scholar] [CrossRef]

- Grigale-Soročina, Z.; Kalniņš, M.; Dzene, A.; Tupureina, V. Biodegradable Plasticized Poly (lactic acid) Films. Mater. Sci. Appl. Chem. 2010, 21, 97–103. [Google Scholar]

- Shi, X.; Zhang, G.; Phuong, T.V.; Lazzeri, A. Synergistic effects of nucleating agents and plasticizers on the crystallization behavior of poly(lactic acid). Molecules 2015, 20, 1579–1593. [Google Scholar] [CrossRef] [PubMed]

- Abdelwahab, M.A.; Flynn, A.; Chiou, B.S.; Imam, S.; Orts, W.; Chiellini, E. Thermal, mechanical and morphological characterization of plasticized PLA-PHB blends. Polym. Degrad. Stab. 2012, 97, 1822–1828. [Google Scholar] [CrossRef]

- Guan, X. Fabrication of Poly-Lactic Acid (PLA) Composite Films and Their Degradation Properties. Master’s Thesis, University of Toledo, Toledo, OH, USA, 2012. [Google Scholar]

- Tee, Y.B.; Talib, R.A.; Abdan, K.; Chin, N.L.; Basha, R.K.; Yunos, K.F.M. Comparative study of chemical, mechanical, thermal, and barrier properties of poly(lactic acid) plasticized with epoxidized soybean oil and epoxidized palm oil. BioResources 2016, 11, 1518–1540. [Google Scholar] [CrossRef]

- Silverajah, V.S.G.; Ibrahim, N.A.; Yunus, W.M.Z.W.; Hassan, H.A.; Woei, C.B. A comparative study on the mechanical, thermal and morphological characterization of poly(lactic acid)/epoxidized palm oil blend. Int. J. Mol. Sci. 2012, 13, 5878–5898. [Google Scholar] [CrossRef] [PubMed]

- Chieng, B.W.; Ibrahim, N.A.; Yunus, W.M.Z.W.; Hussein, M.Z.; Silverajah, V.S.G. Graphene nanoplatelets as novel reinforcement filler in poly(lactic acid)/epoxidized palm oil green nanocomposites: Mechanical properties. Int. J. Mol. Sci. 2012, 13, 10920–10934. [Google Scholar] [CrossRef] [PubMed]

- Tsou, C.H.; Suen, M.C.; Yao, W.H.; Yeh, J.T.; Wu, C.S.; Tsou, C.Y.; Chiu, S.H.; Chen, J.C.; Wang, R.Y.; Lin, S.M.; et al. Preparation and characterization of bioplastic-based green renewable composites from tapioca with acetyl tributyl citrate as a plasticizer. Materials 2014, 7, 5617–5632. [Google Scholar] [CrossRef] [PubMed]

- Shirai, M.A.; Grossmann, M.V.E.; Mali, S.; Yamashita, F.; Garcia, P.S.; Müller, C.M.O. Development of biodegradable flexible films of starch and poly(lactic acid) plasticized with adipate or citrate esters. Carbohydr. Polym. 2013, 92, 19–22. [Google Scholar] [CrossRef] [PubMed]

- Leu, Y.Y.; Chow, W.S. Kinetics of water absorption and thermal properties of poly(lactic acid)/organomontmorillonite/poly(ethylene glycol) nanocomposites. J. Vinyl Addit. Technol. 2011, 17, 40–47. [Google Scholar] [CrossRef]

| Blend ID | Composition Ratio (wt %) | ||

|---|---|---|---|

| PLA | Starch | EPO | |

| Neat PLA | 100 | 0 | 0 |

| PLA/starch (PSt) | 95 | 5 | |

| PSE5 | 90 | 5 | 5 |

| PSE10 | 85 | 5 | 10 |

| PSE15 | 80 | 5 | 15 |

| PSE20 | 75 | 5 | 20 |

| Blend ID | Tg (°C) | Tcc (°C) | ∆Hcc (J/g) | Tm1 (°C) | Tm2 (°C) | ∆Hm (J/g) |

|---|---|---|---|---|---|---|

| neat PLA | 59.1 | 109.1 | 37 | 148.0 | 156 | 22 |

| PSt | 58.5 | 118.3 | 38 | 151.5 | 157 | 10 |

| PSE5 | 57.5 | 124.1 | 12 | 151.0 | 156 | 10 |

| PSE10 | 52.5 | 110.0 | 12 | 147.1 | 155 | 5.5 |

| PSE15 | 55.4 | 109.0 | 25 | 150.1 | 155 | 11 |

| PSE20 | 56.1 | 115.1 | 30 | 151.2 | 155 | 12 |

| Samples | Tg (°C) | Tmax (°C) | T50 (°C) | T95 (°C) |

|---|---|---|---|---|

| Neat PLA | 395 | 360 | 344 | 358 |

| PSt | 268 | 346 | 341 | 340 |

| PSE10 | 268 | 384 | 346 | 376 |

| Samples | Tg (°C) | Tan δ |

|---|---|---|

| Neat PLA | 64.2 | 1.043 |

| PSt | 62.4 | 1.76 |

| PSE 5 | 60.2 | 2.37 |

| PSE 10 | 60.1 | 1.16 |

| PSE 15 | 62.1 | 2.12 |

| PSE 20 | 63.1 | 2.37 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Awale, R.J.; Ali, F.B.; Azmi, A.S.; Puad, N.I.M.; Anuar, H.; Hassan, A. Enhanced Flexibility of Biodegradable Polylactic Acid/Starch Blends Using Epoxidized Palm Oil as Plasticizer. Polymers 2018, 10, 977. https://doi.org/10.3390/polym10090977

Awale RJ, Ali FB, Azmi AS, Puad NIM, Anuar H, Hassan A. Enhanced Flexibility of Biodegradable Polylactic Acid/Starch Blends Using Epoxidized Palm Oil as Plasticizer. Polymers. 2018; 10(9):977. https://doi.org/10.3390/polym10090977

Chicago/Turabian StyleAwale, Raina Jama, Fathilah Binti Ali, Azlin Suhaida Azmi, Noor Illi Mohamad Puad, Hazleen Anuar, and Azman Hassan. 2018. "Enhanced Flexibility of Biodegradable Polylactic Acid/Starch Blends Using Epoxidized Palm Oil as Plasticizer" Polymers 10, no. 9: 977. https://doi.org/10.3390/polym10090977

APA StyleAwale, R. J., Ali, F. B., Azmi, A. S., Puad, N. I. M., Anuar, H., & Hassan, A. (2018). Enhanced Flexibility of Biodegradable Polylactic Acid/Starch Blends Using Epoxidized Palm Oil as Plasticizer. Polymers, 10(9), 977. https://doi.org/10.3390/polym10090977