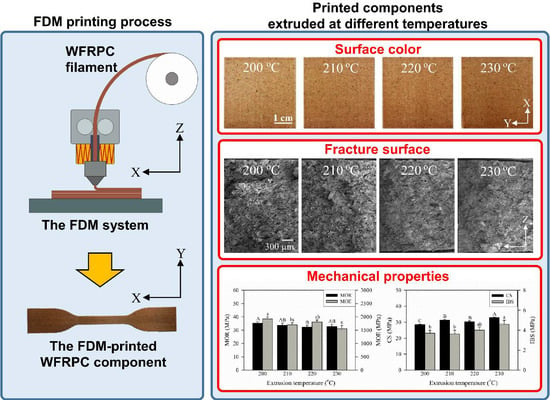

Effect of Extrusion Temperature on the Physico-Mechanical Properties of Unidirectional Wood Fiber-Reinforced Polylactic Acid Composite (WFRPC) Components Using Fused Deposition Modeling

Abstract

:1. Introduction

2. Experimental

2.1. Materials

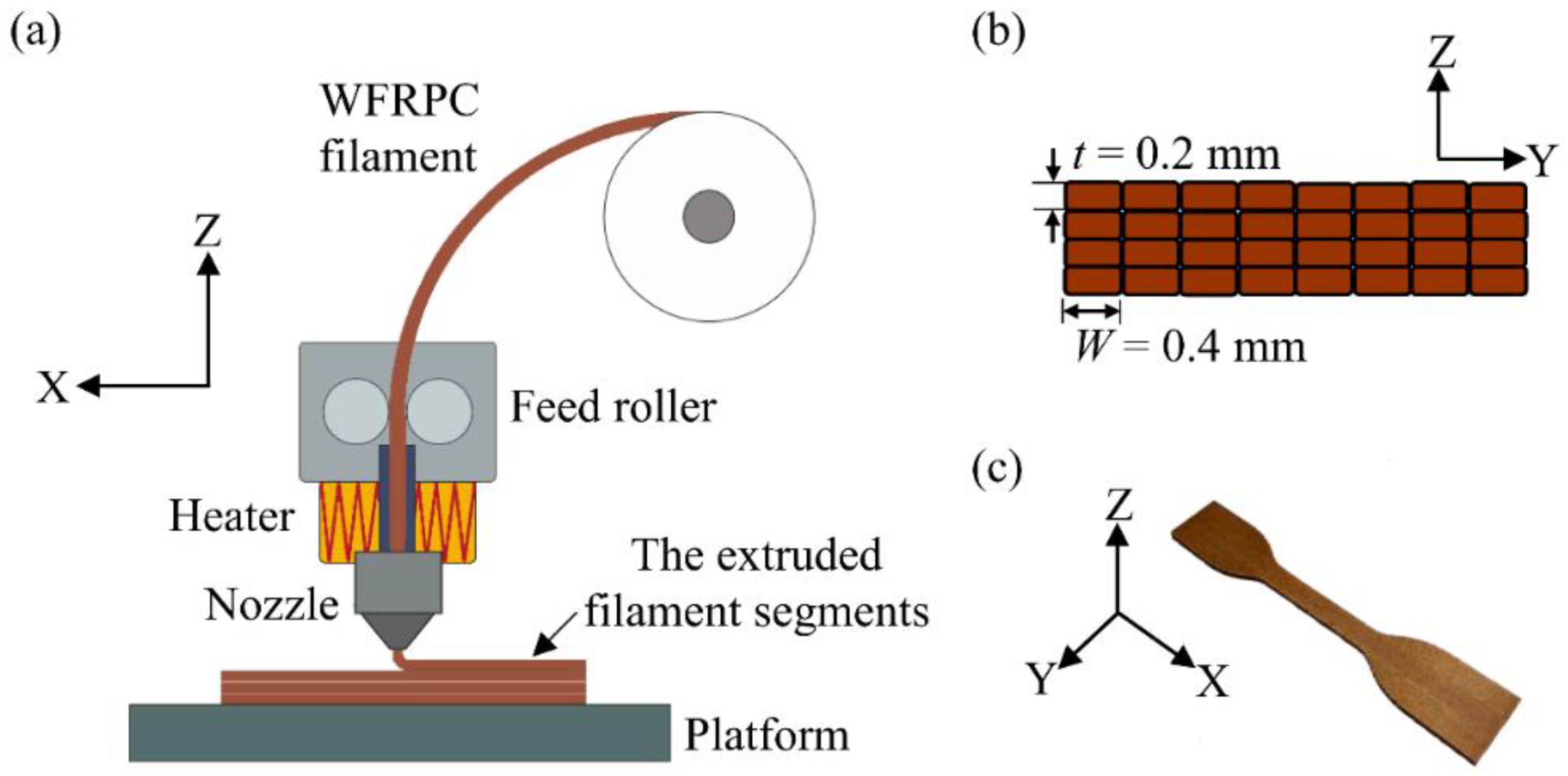

2.2. 3D Printing of Unidirectional WFRPC Components

2.3. Determining the Printed Component Properties

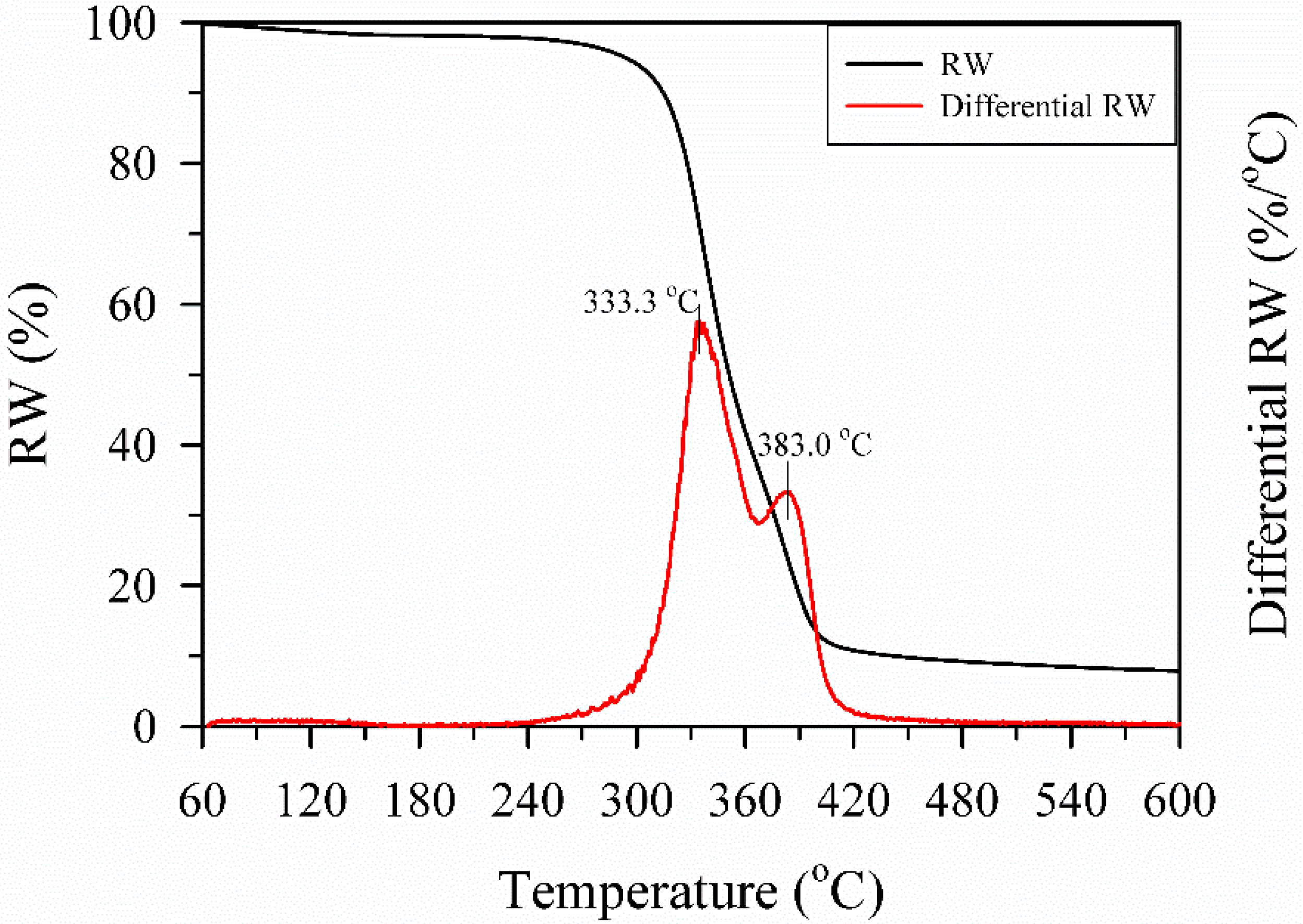

2.4. Thermogravimetric Analysis (TGA)

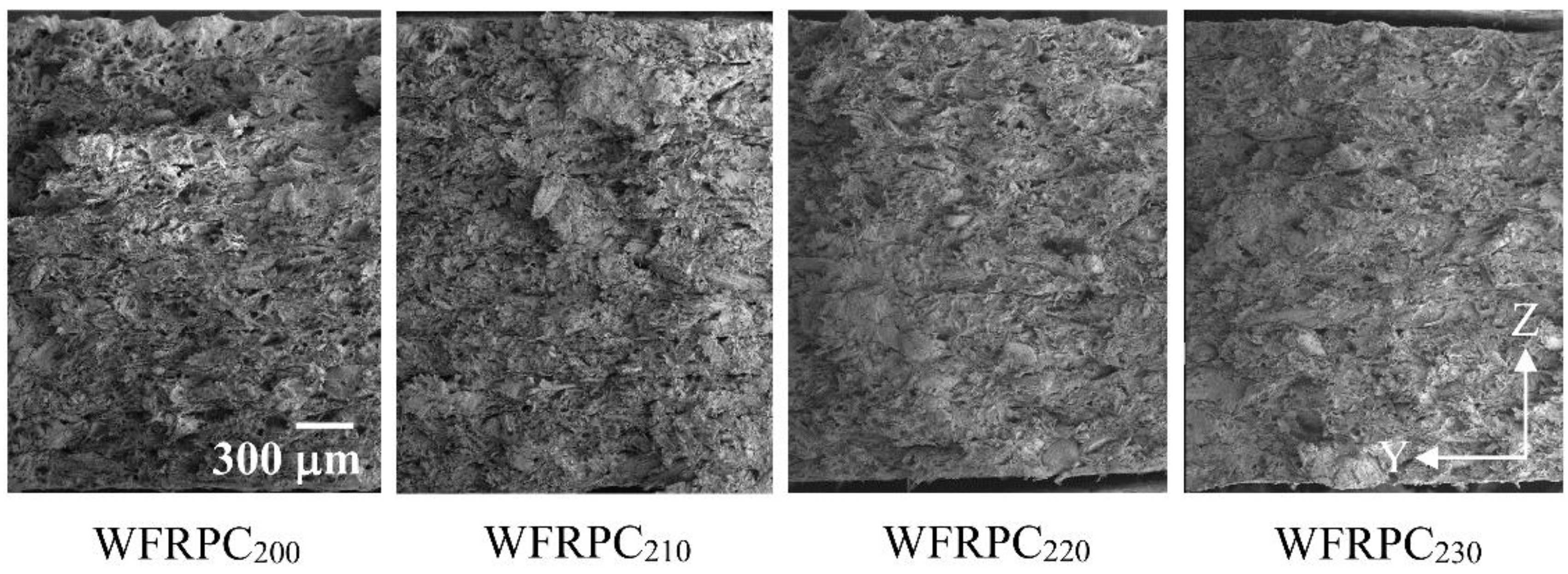

2.5. Scanning Electron Microscopy (SEM)

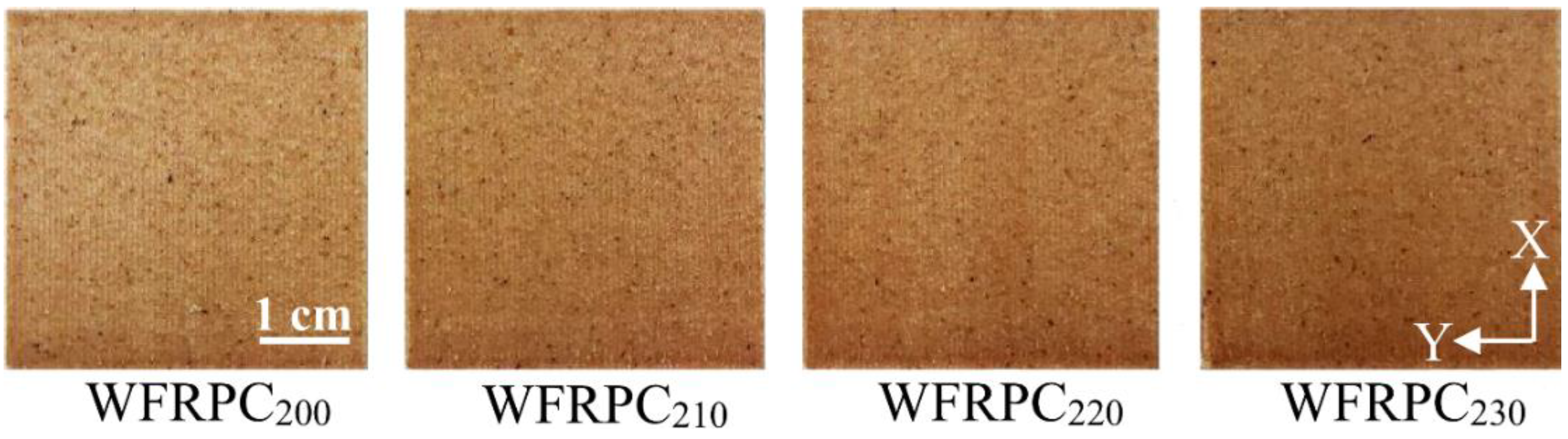

2.6. Surface Color of the Printed Components

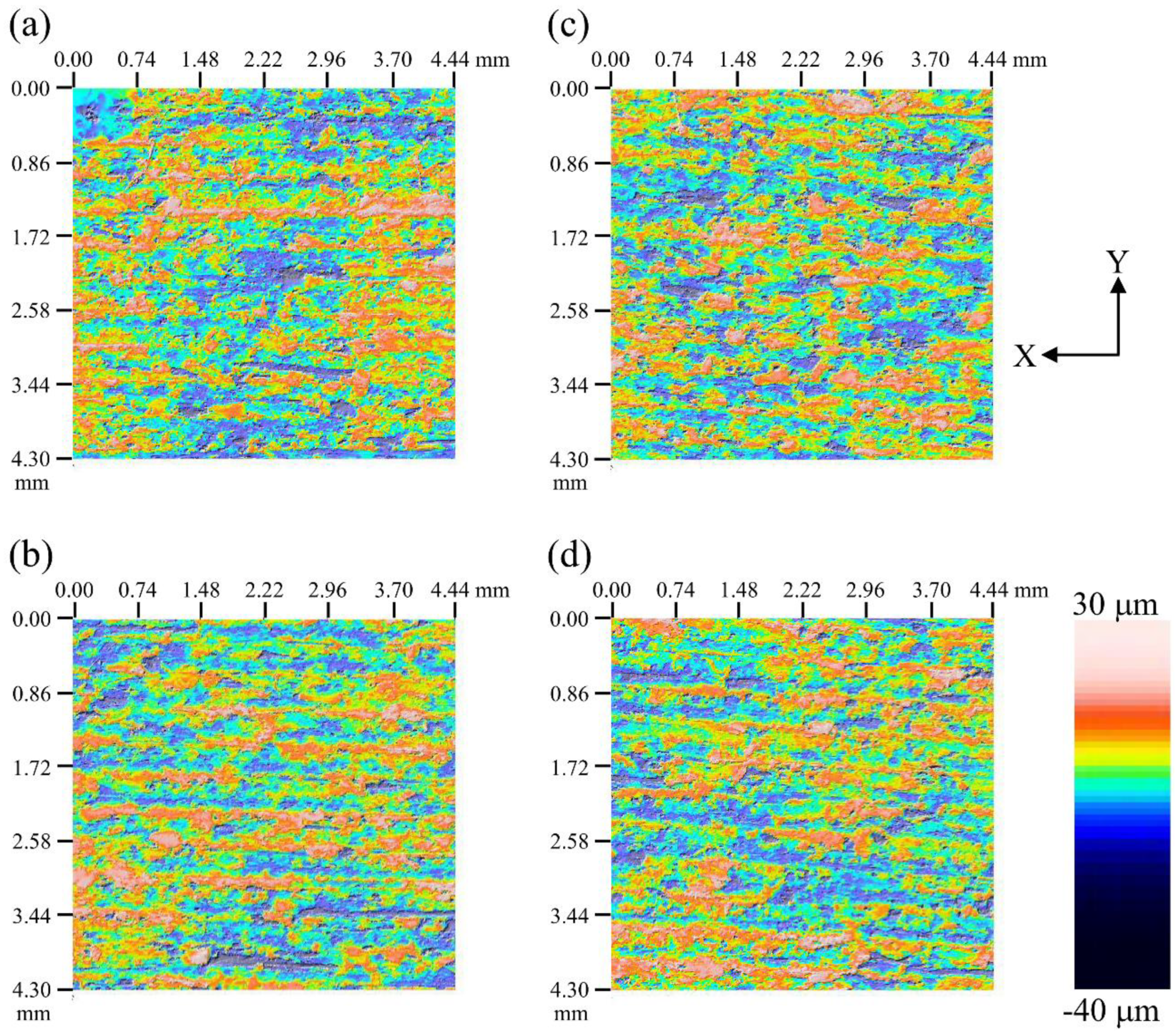

2.7. Surface Roughness of the Printed Components

2.8. Statistical Analysis

3. Results and Discussion

3.1. Thermal Properties of a WFRPC Filament

3.2. Physical Properties of the Printed Components

3.3. Mechanical Properties of the Printed Components

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Gibson, I.; Rosen, D.; Stucker, B. Additive Manufacturing Technologies: 3D Printing, Rapid Prototyping, and Direct Digital Manufacturing, 2nd ed.; Springer: New York, NY, USA, 2015. [Google Scholar]

- Carneiro, O.S.; Silva, A.F.; Gomes, R. Fused deposition modeling with polypropylene. Mater. Des. 2015, 83, 768–776. [Google Scholar] [CrossRef]

- Kuznetsov, V.E.; Solonin, A.N.; Urzhumtsev, O.D.; Schilling, R.; Tavitov, A.G. Strength of PLA components fabricated with fused deposition technology using a desktop 3D printer as a function of geometrical parameters of the process. Polymers 2018, 10, 313. [Google Scholar] [CrossRef]

- Chacón, J.M.; Caminero, M.A.; García-Plaza, E.; Núñez, P.J. Additive manufacturing of PLA structures using fused deposition modelling: Effect of process parameters on mechanical properties and their optimal selection. Mater. Des. 2017, 124, 143–157. [Google Scholar] [CrossRef]

- Tymrak, B.M.; Kreiger, M.; Pearce, J.M. Mechanical properties of components fabricated with open-source 3-D printers under realistic environmental conditions. Mater. Des. 2014, 58, 242–246. [Google Scholar] [CrossRef]

- Ullu, E.; Korkmaz, E.; Yay, K.; Ozdoganlar, O.B.; Kara, L.B. Enhancing the structural performance of additively manufactured objects through build orientation optimization. J. Mech. Des. 2015, 137, 111410–111419. [Google Scholar] [CrossRef]

- Song, Y.; Li, Y.; Song, W.; Yee, K.; Lee, K.-Y.; Tagarielli, V.L. Measurement of the mechanical response of unidirectional 3D-printed PLA. Mater. Des. 2017, 123, 154–164. [Google Scholar] [CrossRef]

- Letcher, T.; Waytashek, M. Material property testing of 3D-printed specimen in PLA on an entry-level 3D printer. In Proceedings of the ASME 2014 International Mechanical Engineering Congress and Exposition, Montreal, QC, Canada, 14–20 November 2014. [Google Scholar]

- Tsouknidas, A.; Pantazopoulos, M.; Katsoulis, I.; Fasnakis, D.; Maropoulos, S.; Michailidis, N. Impact absorption capacity of 3D-printed components fabricated by fused deposition modelling. Mater. Des. 2016, 102, 41–44. [Google Scholar] [CrossRef]

- Ning, F.; Cong, W.; Hu, Y.; Wang, H. Additive manufacturing of carbon fiber-reinforced plastic composites using fused deposition modeling: Effects of process parameters on tensile properties. J. Compos. Mater. 2017, 51, 451–462. [Google Scholar] [CrossRef]

- Oksman, K.; Skrifvars, M.; Selin, J.-F. Natural fibers as reinforcement in polylactic acid (PLA) composites. Compos. Sci. Technol. 2003, 63, 1317–1324. [Google Scholar] [CrossRef]

- Mukherjee, T.; Nao, N. PLA based biopolymer reinforced with natural fibre: A review. J. Polym. Environ. 2011, 19, 714–725. [Google Scholar] [CrossRef]

- Huda, M.S.; Drzal, L.T.; Mohanty, A.K.; Misra, M. Chopped glass and recycled newspaper as reinforcement fibers in injection molded poly(lactic acid) (PLA) composites: a comparative study. Compos. Sci. Technol. 2006, 66, 1813–1824. [Google Scholar] [CrossRef]

- Faruk, O.; Bledzki, A.K.; Fink, H.-P.; Sain, M. Biocomposites reinforced with natural fibers: 2000–2010. Prog. Polym. Sci. 2012, 37, 1552–1596. [Google Scholar] [CrossRef]

- Le Duigou, A.; Castro, M.; Bevan, R.; Martin, N. 3D printing of wood fibre biocomposites: From mechanical to actuation functionality. Mater. Des. 2016, 96, 106–144. [Google Scholar] [CrossRef]

- Yu, W.W.; Zhang, J.; Wu, J.R.; Deng, Y.H. Incorporation of graphitic nano-filler and poly(lactic acid) in fused deposition modeling. J. Appl. Polym. Sci. 2017, 134, 44703. [Google Scholar] [CrossRef]

- Drummer, D.; Cifuentes-Cuéllar, S.; Rietzel, D. Suitability of PLA TCP for fused deposition modeling. Rapid Prototyp. J. 2012, 18, 500–507. [Google Scholar] [CrossRef]

- Liu, X.; Li, S.; Liu, Z.; Zheng, X.; Chen, X.; Wang, Z. An investigation on distortion of PLA thin-plate part in the FDM process. Int. J. Adv. Manuf. Technol. 2015, 79, 1117–1126. [Google Scholar]

- Pelaez-Samaniego, M.R.; Yadama, V.; Lowell, E.; Espinoza-Herrera, R. A review of wood thermal pretreatments to improve composites properties. Wood Sci. Technol. 2013, 47, 1285–1319. [Google Scholar] [CrossRef]

- Kaboorani, A. Thermal properties of composites made of heat-treated wood and polypropylene. J. Compos. Mater. 2009, 43, 2599–2607. [Google Scholar] [CrossRef]

- Kocaefe, D.; Poncsak, S.; Boluk, Y. Effect of heat treatment on the chemical composition and mechanical properties of birch and aspen. BioResources 2008, 3, 517–537. [Google Scholar]

- Korkut, S.; Kök, M.S.; Korkut, D.S.; Gürleyen, T. The effects of heat treatment on technological properties in Red-bud maple (Acer trautvetteri Medw.) wood. Bioresour. Technol. 2008, 99, 1538–1543. [Google Scholar] [CrossRef] [PubMed]

- Órfão, J.J.M.; Antunes, F.J.A.; Figueiredo, J.L. Pyrolysis kinetics of lignocellulosic materials-three independent reactions model. Fuel 1999, 78, 349–358. [Google Scholar] [CrossRef]

- Awal, A.; Rana, M.; Sain, M. Thermorheological and mechanical properties of cellulose reinforced PLA bio-composites. Mech. Mater. 2015, 80, 87–95. [Google Scholar] [CrossRef]

- Bekhta, P.; Niemz, P. Effect of high temperature on the change in color, dimensional stability and mechanical properties of spruce wood. Holzforschung 2003, 57, 539–546. [Google Scholar] [CrossRef]

- Chen, Y.; Fan, Y.; Gao, J.; Stark, N.M. The effect of heat treatment on the chemical and color change of black locust (Robinia pseudoacacia) wood flour. BioResources 2012, 7, 1157–1170. [Google Scholar] [CrossRef]

- Kačíková, D.; Kačík, F.; Čabalová, I.; Ďurkovč, J. Effects of thermal treatment on colour traits in Norway spruce wood. Bioresour. Technol. 2013, 144, 669–674. [Google Scholar] [CrossRef] [PubMed]

- Bourgois, P.J.; Janin, G.; Guyonnet, R. The color measurement: A fast method to study and to optimize the chemical transformations undergone in the thermically treated wood. Holzforschung 1991, 45, 377–382. [Google Scholar] [CrossRef]

- Hwang, S.; Reyes, E.I.; Moom, K.S.; Rumpf, R.C.; Kim, N.S. Thermal-mechanical characterization of metal/polymer composite filaments and printing parameter study for fused deposition modeling in the 3D printing process. J. Electron. Mater. 2015, 4, 771–777. [Google Scholar] [CrossRef]

- Ashori, A.; Sheshmani, S. Hybrid composites made from recycled materials: Moisture absorption and thickness swelling behavior. Bioresour. Technol. 2010, 101, 4717–4720. [Google Scholar] [CrossRef] [PubMed]

- Yang, T.-C.; Chien, Y.-C.; Wu, T.-L.; Hung, K.-C.; Wu, J.-H. Effects of heat-treated wood particles on the physico-mechanical properties and extended creep behavior of wood/recycled-HDPE composites using the time-temperature superposition principle. Materials 2017, 10, 365. [Google Scholar] [CrossRef] [PubMed]

- Ayrilmis, N.; Jarusombuti, S.; Fueangvivat, V.; Bauchongkol, P. Effect of thermal-treatment of wood fibers on properties of flat-pressed wood plastic composites. Polym. Degrad. Stab. 2011, 96, 818–822. [Google Scholar] [CrossRef]

- Garrote, G.; Dominiguez, H.; Parajó, J.C. Study on the deactylation of hemicelluloses during the hydrothermal processing of Eucalyptus wood. Holz. Roh. Werkst. 2001, 59, 53–59. [Google Scholar] [CrossRef]

- Çolak, S.; Çolakoğlu, G.; Aydin, I.; Kalaycioğlu, H. Effects of steaming process on some properties of eucalyptus particleboard bonded with UF and MUF adhesives. Build. Environ. 2007, 42, 304–309. [Google Scholar] [CrossRef]

- Kubojima, Y.; Okano, T.; Ohta, M. Bending strength and toughness of heat-treated wood. J. Wood Sci. 2000, 46, 8–15. [Google Scholar] [CrossRef]

- Yildiz, S.; Gezer, E.D.; Yildiz, U.C. Mechanical and chemical behavior of spruce wood modified by heat. Build. Environ. 2006, 41, 1762–1766. [Google Scholar] [CrossRef]

- Ayrilmis, N.; Jarusombuti, S.; Fuengvivat, V.; Bauchongkol, P. Effects of thermal treatment of rubber wood fibres on physical and mechanical properties of medium density fibreboard. J. Trop. Forest Sci. 2011, 23, 10–16. [Google Scholar]

- Aydemir, D.; Kiziltas, A.; Erbas Kiziltas, E.; Gardner, D.J.; Gunduz, G. Heat treated wood-nylon 6 composites. Compos. Part B Eng. 2015, 68, 414–423. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Jaszkiewicz, A.; Scherzer, D. Mechanical properties of PLA composites with man-made cellulose and abaca fibres. Compos. Part A Appl. Sci. Manuf. 2009, 40, 404–412. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Jaszkiewicz, A. Mechanical performance of biocomposites based on PLA and PHBV reinforced with natural fibres-A comparative study to PP. Compos. Sci. Technol. 2010, 70, 1687–1696. [Google Scholar] [CrossRef]

- Robin, J.J.; Breton, Y. Reinforcement of recycled polyethylene with wood fibers heat treated. J. Reinf. Plast. Compos. 2001, 20, 1253–1262. [Google Scholar] [CrossRef]

- Maldas, D.; Kokta, B.V.; Daneault, C. Influence of coupling agents and treatments on the mechanical properties of cellulose fiber-polystyrene composites. J. Appl. Polym. Sci. 1989, 37, 751–775. [Google Scholar] [CrossRef]

- Harper, D.; Wolcott, M. Interaction between coupling agent and lubricants in wood-polypropylene composites. Compos. Part A Appl. Sci. Manuf. 2004, 35, 385–394. [Google Scholar] [CrossRef]

| Code | L* | a* | b* | ΔE* |

|---|---|---|---|---|

| WFRPC200 | 57.3 ± 0.6 a | 13.7 ± 0.1 c | 22.5 ± 0.1 a | - |

| WFRPC210 | 56.1 ± 1.0 a,b | 14.0 ± 0.2 b,c | 22.7 ± 0.2 a | 1.1 ± 0.4 b |

| WFRPC220 | 54.0 ± 0.8 b,c | 14.2 ± 0.2 a,b | 22.4 ± 0.3 a | 2.7 ± 0.9 a |

| WFRPC230 | 52.9 ± 0.2 c | 14.4 ± 0.1 a | 22.4 ± 0.1 a | 3.9 ± 0.1 a |

| Code | w (g) | V (cm3) | Density (kg/m3) | MC (%) | Ra (μm) | 24 h of Soaking | |

|---|---|---|---|---|---|---|---|

| WAR (%) | TSR (%) | ||||||

| WFRPC200 | 2.79 ± 0.08 b | 2.71 ± 0.04 a | 1032 ± 17 b | 2.1 ± 0.3 a | 6.0 ± 0.6 a | 3.1 ± 0.5 a | 0.8 ± 0.1 a |

| WFRPC210 | 2.83 ± 0.04 a,b | 2.70 ± 0.01 a | 1048 ± 12 a,b | 1.9 ± 0.2 a | 6.2 ± 0.6 a | 2.9 ± 0.2 a | 1.1 ± 0.1 a |

| WFRPC220 | 2.81 ± 0.07 b | 2.70 ± 0.02 a | 1041 ± 17 b | 1.8 ± 0.2 a | 6.0 ± 0.7 a | 3.1 ± 0.2 a | 0.9 ± 0.1 a |

| WFRPC230 | 2.91 ± 0.01 a | 2.73 ± 0.01 a | 1065 ± 6 a | 1.9 ± 0.2 a | 6.3 ± 0.5 a | 2.6 ± 0.2 a | 1.0 ± 0.3 a |

| Code | Tensile properties | Flexural properties | CS (MPa) | IBS (MPa) | ||

|---|---|---|---|---|---|---|

| TS (MPa) | TM (MPa) | MOR (MPa) | MOE (MPa) | |||

| WFRPC200 | 20.0 ± 0.5 a | 1802 ± 32 a | 35.2 ± 1.0 a | 1928 ± 66 a | 28.5 ± 0.4 c | 3.7 ± 0.3 b |

| WFRPC210 | 19.5 ± 1.0 a | 1717 ± 63 b | 33.7 ± 1.6 a,b | 1699 ± 84 b,c | 31.2 ± 0.6 b | 3.6 ± 0.4 b |

| WFRPC220 | 18.1 ± 0.4 b | 1711 ± 39 b | 32.2 ± 1.4 b | 1806 ± 75 a,b | 30.4 ± 0.5 b | 4.0 ± 0.3 a,b |

| WFRPC230 | 18.0 ± 0.1 b | 1713 ± 15 b | 32.8 ± 1.4 a,b | 1557 ± 128 c | 32.8 ± 0.5 a | 4.6 ± 0.4 a |

© 2018 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, T.-C. Effect of Extrusion Temperature on the Physico-Mechanical Properties of Unidirectional Wood Fiber-Reinforced Polylactic Acid Composite (WFRPC) Components Using Fused Deposition Modeling. Polymers 2018, 10, 976. https://doi.org/10.3390/polym10090976

Yang T-C. Effect of Extrusion Temperature on the Physico-Mechanical Properties of Unidirectional Wood Fiber-Reinforced Polylactic Acid Composite (WFRPC) Components Using Fused Deposition Modeling. Polymers. 2018; 10(9):976. https://doi.org/10.3390/polym10090976

Chicago/Turabian StyleYang, Teng-Chun. 2018. "Effect of Extrusion Temperature on the Physico-Mechanical Properties of Unidirectional Wood Fiber-Reinforced Polylactic Acid Composite (WFRPC) Components Using Fused Deposition Modeling" Polymers 10, no. 9: 976. https://doi.org/10.3390/polym10090976

APA StyleYang, T.-C. (2018). Effect of Extrusion Temperature on the Physico-Mechanical Properties of Unidirectional Wood Fiber-Reinforced Polylactic Acid Composite (WFRPC) Components Using Fused Deposition Modeling. Polymers, 10(9), 976. https://doi.org/10.3390/polym10090976