Ultraviolet Weathering Performance of High-Density Polyethylene/Wood-Flour Composites with a Basalt-Fiber-Included Shell

Abstract

1. Introduction

2. Experimental Section

2.1. Materials

2.2. Sample Preparation

2.2.1. Surface Treatment of BFs

2.2.2. Preparation of Composite Samples

2.2.3. Accelerated Weathering Treatment

2.3. Characterization

2.3.1. Colorimetric Analysis

2.3.2. Scanning Electron Microscopy (SEM)

2.3.3. Fourier Transform Infrared (FTIR) Spectroscopy

2.3.4. X-ray Photoelectron Spectroscopy (XPS) Analysis

3. Results and Discussion

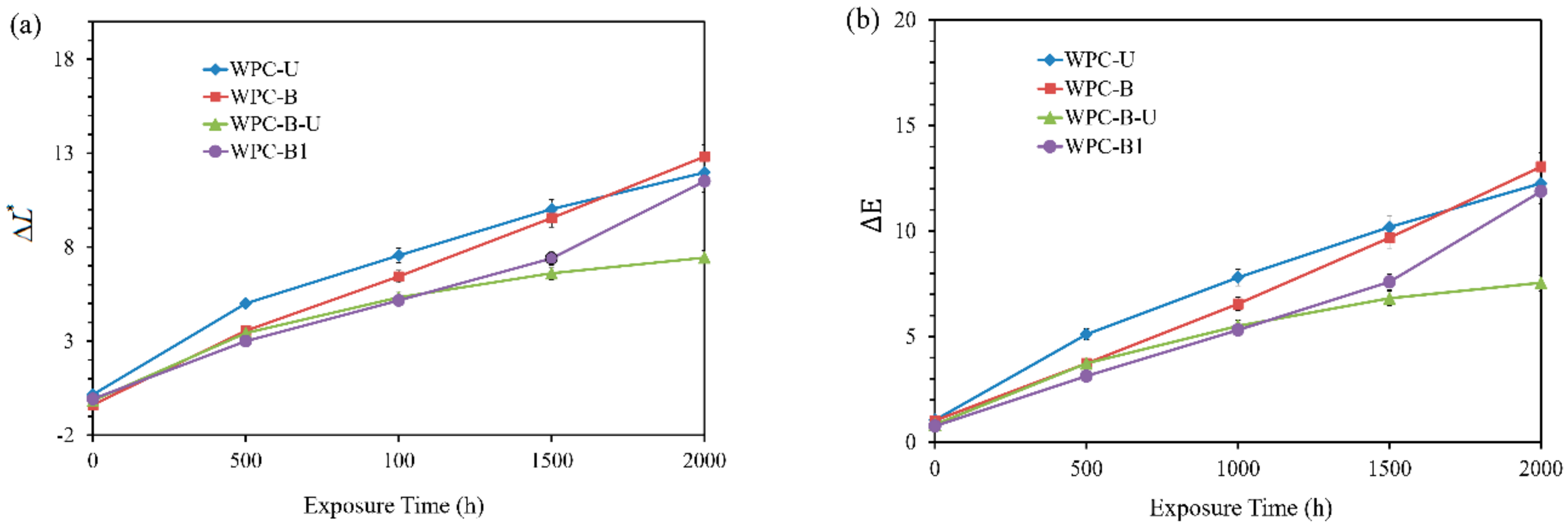

3.1. Colorimetric Analysis

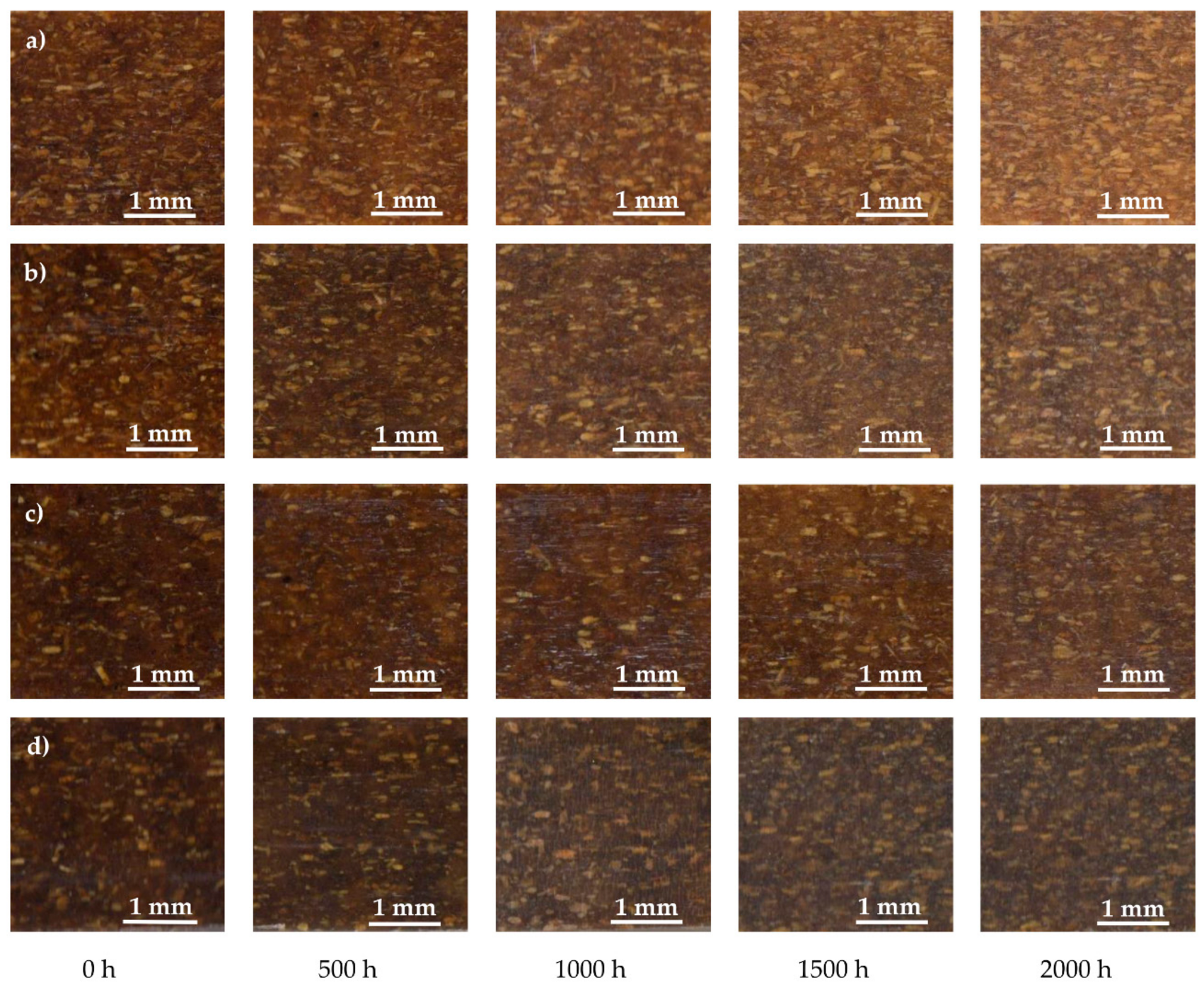

3.2. Surface Morphology of Composites

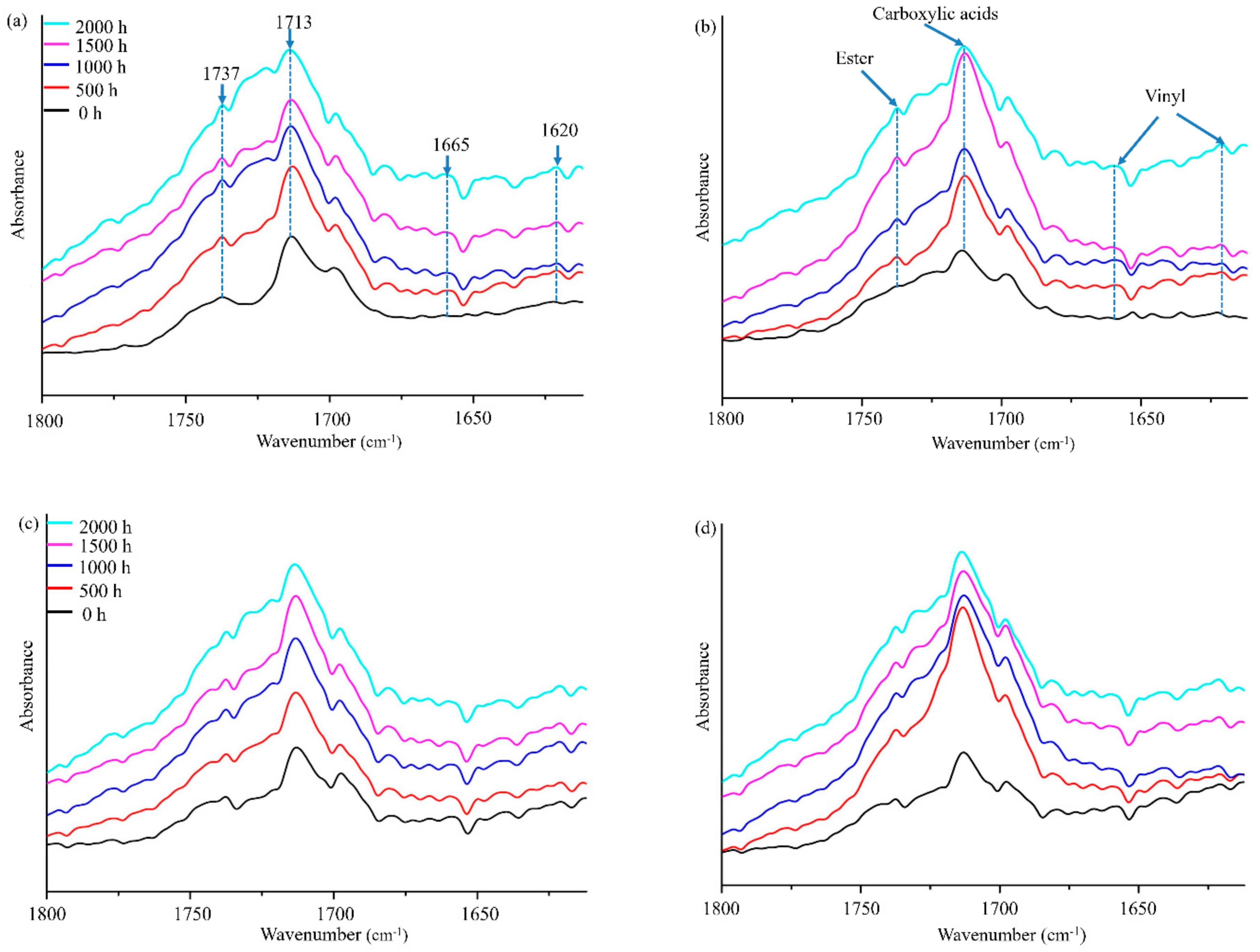

3.3. Surface Chemistry Analysis by FTIR

3.4. XPS Analysis

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Morton, J.; Quarmley, J.; Rossi, L. Current and emerging applications for natural and woodfiber composites. In Proceedings of the 7th International Conference on Wood Fiber-Plastic Composites, Forest Products Society, Madison, WI, USA, 19–20 May 2003. [Google Scholar]

- Kim, J.K.; Pal, K. Recent Advances in the Processing of Wood-Plastic Composites; Springer: Berlin/Heidelberg, Germany, 2010; Volume 32. [Google Scholar]

- Falk, R.H.; Lundin, T.; Felton, C. The effects of weathering on wood-thermoplastic composites intended for outdoor applications. In Proceedings of the 2nd Annual Conference Durability and Disaster Mitigation in Wood-Frame Housing, Madison, WI, USA, 6–8 November 2000; pp. 175–179. [Google Scholar]

- Lundin, T. Effect of Accelerated Weathering on the Physical and Mechanical Properties of Natural-Fiber Thermoplastic Composites; University of Wisconsin-Madison: Madison, WI, USA, 2002. [Google Scholar]

- Peng, Y.; Liu, R.; Cao, J.Z.; Chen, Y. Effects of UV weathering on surface properties of polypropylene composites reinforced with wood flour, lignin, and cellulose. Appl. Surf. Sci. 2014, 317, 385–392. [Google Scholar] [CrossRef]

- Matuana, L.M.; Kamdem, D.P. Accelerated ultraviolet weathering of PVC/wood-flour composites. Polym. Eng. Sci. 2002, 42, 1657–1666. [Google Scholar] [CrossRef]

- Stark, N.M.; Matuana, L.M. Surface chemistry and mechanical property changes of wood-flour/high-density-polyethylene composites after accelerated weathering. J. Appl. Polym. Sci. 2004, 94, 2263–2273. [Google Scholar] [CrossRef]

- Jiang, L.; Wolcott, M.P.; Zhang, J.; Englund, K. Flexural properties of surface reinforced wood/plastic deck board. Polym. Eng. Sci. 2007, 47, 281–288. [Google Scholar] [CrossRef]

- Yang, T.H.; Yang, T.H.; Chao, W.C.; Leu, S.Y. Characterization of the property changes of extruded wood–plastic composites during year round subtropical weathering. Constr. Build. Mater. 2015, 88, 159–168. [Google Scholar] [CrossRef]

- Chen, Y.; Stark, N.M.; Tshabalala, M.A.; Gao, J.; Fan, Y. Weathering characteristics of wood plastic composites reinforced with extracted or delignified wood flour. Materials 2016, 9, 610. [Google Scholar] [CrossRef] [PubMed]

- Soccalingame, L.; Perrin, D.; Bénézet, J.C.; Bergeret, A. Reprocessing of UV-Weathered wood flour reinforced polypropylene composites: Study of a natural outdoor exposure. Polym. Degrad. Stab. 2016, 133, 389–398. [Google Scholar] [CrossRef]

- Matuana, L.M.; Kamdem, D.P.; Zhang, J. Photoaging and stabilization of rigid PVC/wood-fiber composites. J. Appl. Polym. Sci. 2001, 80, 1943–1950. [Google Scholar] [CrossRef]

- Muasher, M.; Sain, M. The efficacy of photostabilizers on the color change of wood filled plastic composites. Polym. Degrad. Stab. 2006, 91, 1156–1165. [Google Scholar] [CrossRef]

- Stark, N.M.; Mueller, S.A. Improving the color stability of wood-plastic composites through fiber pre-treatment. Wood Fiber Sci. J. 2008, 40, 271–278. [Google Scholar]

- Fabiyi, J.S.; Mcdonald, A.G.; Mcilroy, D. Wood Modification Effects on Weathering of HDPE-Based Wood Plastic Composites. J. Polym. Environ. 2009, 17, 34–48. [Google Scholar] [CrossRef]

- Fabiyi, J.S.; Mcdonald, A.G. Physical Morphology and Quantitative Characterization of Chemical Changes of Weathered PVC/Pine Composites. J. Polym. Environ. 2010, 18, 57–64. [Google Scholar] [CrossRef]

- Stark, N.M.; Matuana, L.M. Ultraviolet weathering of photostabilized wood-flour-filled high-density polyethylene composites. J. Appl. Polym. Sci. 2010, 90, 2609–2617. [Google Scholar] [CrossRef]

- Liu, C.; Mei, C.; Xu, B.; Chen, W.; Yong, C.; Wang, K.; Wu, Q. Light stabilizers added to the shell of co-extruded wood/high-density polyethylene composites to improve mechanical and anti-UV ageing properties. R. Soc. Open Sci. 2018, 5, 180074. [Google Scholar] [CrossRef] [PubMed]

- Krehula, L.K.; Katančić, Z.; Siročić, A.P.; Hrnjak-Murgić, Z. Weathering of High-Density Polyethylene-Wood Plastic Composites. J. Wood. Chem. Technol. 2014, 34, 39–54. [Google Scholar] [CrossRef]

- Liu, M.; Horrocks, A.R. Effect of Carbon Black on UV stability of LLDPE films under artificial weathering conditions. Polym. Degrad. Stab. 2002, 75, 485–499. [Google Scholar] [CrossRef]

- Du, H.; Wang, W.; Wang, Q.; Zhang, Z.; Sui, S.; Zhang, Y. Effects of pigments on the UV degradation of wood-flour/HDPE composites. J. Appl. Polym. Sci. 2010, 118, 1068–1076. [Google Scholar] [CrossRef]

- Deka, B.K.; Maji, T.K. Effect of SiO2 and nanoclay on the properties of wood polymer nanocomposite. Polym. Bull. 2013, 70, 403–417. [Google Scholar] [CrossRef]

- Butylina, S.; Martikka, O.; Kärki, T. Weathering properties of coextruded polypropylene-based composites containing inorganic pigments. Polym. Degrad. Stab. 2015, 120, 10–16. [Google Scholar] [CrossRef]

- Wang, X.; Song, K.; Ou, R. Effects of carbon black and titanium dioxide on ultraviolet weathering of wood flour-HDPE/using multi-phase co-extrusion technology. Bioresources 2017, 12, 6173–6186. [Google Scholar] [CrossRef]

- Stark, N.M.; Matuana, L.M. Coating WPCs using co-extrusion to improve durability. Conf. Coat. Wood Wood Compos. Des. Durab. 2007, 1, 12. [Google Scholar]

- Jin, S.; Matuana, L.M. Coextruded PVC/wood-flour composites with WPC cap layers. J. Vinyl. Addit. Technol. 2008, 14, 197–203. [Google Scholar] [CrossRef]

- Stark, N.M.; Matuana, L.M. Coextrusion of WPCs with a clear cap layer to improve color stability. In Proceedings of the 4th Wood Fibre Polymer Composites International Symposium, Bordeaux, France, 30–31 March 2009. [Google Scholar]

- Jin, S.; Matuana, L.M. Wood/plastic composites co-extruded with multi-walled carbon nanotube-filled rigid poly(vinyl chloride) cap layer. Polym. Int. 2010, 59, 648–657. [Google Scholar] [CrossRef]

- Wang, X.; Huang, L.; Hao, X.; Wang, H.; Wang, Q.; Yi, X.; Wang, W.; Song, K. Composition and Preparation of Composites Made of Wood Core and Woodplastic-Composite Shell. International Patent, Application No. PCT/CN2015/072178, 25 September 2015. [Google Scholar]

- Matuana, L.M.; Jin, S.; Stark, N.M. Ultraviolet weathering of HDPE/wood-flour composites coextruded with a clear HDPE cap layer. Polym. Degrad. Stab. 2011, 96, 97–106. [Google Scholar] [CrossRef]

- Kim, B.J.; Yao, F.; Han, G.; Wang, Q.; Wu, Q. Mechanical and physical properties of core–shell structured wood plastic composites: Effect of shells with hybrid mineral and wood fillers. Compos. Part. B Eng. 2013, 45, 1040–1048. [Google Scholar] [CrossRef]

- Czigány, T.; Vad, J.; Pölöskei, K. Basalt fiber as a reinforcement of polymer composites. Period. Polytech. Eng. Mech. Eng. 2005, 49, 3. [Google Scholar]

- Sim, J.; Park, C. Characteristics of basalt fiber as a strengthening material for concrete structures. Compos. Part. B 2005, 36, 504–512. [Google Scholar] [CrossRef]

- Wang, M.; Zhang, Z.; Li, Y.; Li, M.; Sun, Z. Chemical durability and mechanical properties of alkali-proof basalt fiber and its reinforced epoxy composites. J. Reinf. Plast. Comp. 2008, 27, 393–407. [Google Scholar] [CrossRef]

- Botev, M.; Betchev, H.; Bikiaris, D.; Panayiotou, C. Mechanical properties and viscoelastic behavior of basalt fiber-reinforced polypropylene. J. Appl. Polym. Sci. 1999, 74, 523–531. [Google Scholar] [CrossRef]

- Liu, Q.; Shaw, M.T.; Parnas, R.S.; McDonnell, A.M. Investigation of basalt fiber composite mechanical properties for applications in transportation. Polym. Compos. 2006, 27, 41–48. [Google Scholar] [CrossRef]

- Dalinkevich, A.; Gumargalieva, K.; Marakhovsky, S.; Soukhanov, A. Modern basalt fibrous materials and basalt fiber-based polymeric composites. J. Nat. Fibers 2009, 6, 248–271. [Google Scholar] [CrossRef]

- Chen, J.; Wang, Y.; Gu, C.; Liu, J.; Liu, Y.; Li, M.; Lu, Y. Enhancement of the mechanical properties of basalt fiber-wood-plastic composites via maleic anhydride grafted high-density polyethylene (MAPE) addition. Materials 2013, 6, 2483–2496. [Google Scholar] [CrossRef] [PubMed]

- Lu, G.; Wang, W.; Shen, S. Mechanical properties of wood flour reinforced high density polyethylene composites with basalt fibers. Mater. Sci. 2014, 20, 464–467. [Google Scholar] [CrossRef]

- Wu, Q.; Chi, K.; Wu, Y.; Lee, S. Mechanical, thermal expansion, and flammability properties of co-extruded wood polymer composites with basalt fiber reinforced shells. Mater. Des. 2014, 60, 334–342. [Google Scholar] [CrossRef]

- Huang, R.; Mei, C.; Xu, X.; Kärki, T.; Lee, S.; Wu, Q. Effect of Hybrid Talc-Basalt Fillers in the Shell Layer on Thermal and Mechanical Performance of Co-Extruded Wood Plastic Composites. Materials 2015, 8, 8510–8523. [Google Scholar] [CrossRef] [PubMed]

- American Society for Testing and Materials (ASTM) International. Practice for Operating Fluorescent Ultraviolet (UV) Lamp Apparatus for Exposure of Nonmetallic Materials; ASTM G154-12a; ASTM International, West Conshohocken: Conshohocken, PA, USA, 2012. [Google Scholar]

- American Society for Testing and Materials (ASTM) International. Practice for Calculation of Color Tolerances and Color Differences from Instrumentally Measured Color Coordinates; ASTM D 2244-02; ASTM International, West Conshohocken: Conshohocken, PA, USA, 2003. [Google Scholar]

- Stark, N.M.; Matuana, L.M. Characterization of weathered wood–plastic composite surfaces using FTIR spectroscopy, contact angle, and XPS. Polym. Degrad. Stab. 2007, 92, 1883–1890. [Google Scholar] [CrossRef]

- Klyosov, A.A. Wood-Plastic Composites; John Wiley & Sons: Hoboken, NJ, USA, 2007. [Google Scholar]

- Stark, N.M.; Matuana, L.M. Surface chemistry changes of weathered HDPE/wood-flour composites studied by XPS and FTIR spectroscopy. Polym. Degrad. Stab. 2004, 86, 1–9. [Google Scholar] [CrossRef]

- Fabiyi, J.S.; Mcdonald, A.G.; Wolcott, M.P.; Griffiths, P.R. Wood plastic composites weathering: Visual appearance and chemical changes. Polym. Degrad. Stab. 2008, 93, 1405–1414. [Google Scholar] [CrossRef]

- Jabarin, S.A.; Lofgren, E.A. Photooxidative effects on properties and structure of high-density polyethylene. J. Appl. Polym. Sci. 2010, 53, 411–414. [Google Scholar] [CrossRef]

- Wypych, G. Handbook of Material Weathering, 3rd ed.; Society of Plastics Engineers Inc.: Hamilton, OH, USA, 2003; Volume 59, p. 5. [Google Scholar]

- Park, J.M.; Shin, W.G.; Yoon, D.J. A study of interfacial aspects of epoxy-based composites reinforced with dual basalt and SiC fibres by means of the fragmentation and acoustic emission techniques. Compos. Sci. Technol. 1999, 59, 355–370. [Google Scholar] [CrossRef]

- Hu, L.; Shang, D.; Li, S.; Chen, W.; Song, B. Study on the interfacial functionary mechanism of plant fiber/basalt fiber composite material. Polym. Mater. Sci. Eng. 2004, 20, 29–32. [Google Scholar]

- Nachtigall, S.M.B.; Cerveira, G.S.; Rosa, S.M.L. New polymeric-coupling agent for polypropylene/wood-flour composites. Polym. Test. 2007, 26, 619–628. [Google Scholar] [CrossRef]

| Layer | WF | HDPE | MAPE | Lub | UV326 | Basalt fiber | Sample code |

|---|---|---|---|---|---|---|---|

| Core | 60 | 37 | 3 | 2 a | |||

| Shell | 20 | 77 | 3 | 2 a | 2 a | WPC-U | |

| 12 | 77 | 3 | 2 a | 8 | WPC-B | ||

| 12 | 77 | 3 | 2 a | 2 a | 8 | WPC-B-U | |

| 8 | 77 | 3 | 2 a | 12 | WPC-B1 |

| Carbon Group | Binding Energy (eV) | Bond |

|---|---|---|

| C1 | 285.0 | C–C or C–H |

| C2 | 286.5 | C–O |

| C3 | 288.0 | O–C–O or C=O |

| C4 | 289.5 | O–C=O |

| Wavenumber (cm−1) | Assignments [46,47] |

|---|---|

| 1737 | C=O stretching (ester carbonyl) |

| 1713 | C=O stretching (acid carbonyl) |

| 1670–1610 | C=C stretching (vinyl groups) |

| Sample | Analysis of C1s Peaks (%) | ||||

|---|---|---|---|---|---|

| C1 | C2 | C3 | C4 | Cox/unox | |

| Sample with UV326 | |||||

| Unweathered | 76.05 | 13.77 | 8.37 | 1.81 | 0.31 |

| Weathered for 2000 h | 73.37 | 18.07 | 5.78 | 2.77 | 0.36 |

| Sample with BFs | |||||

| Unweathered | 78.30 | 12.30 | 7.73 | 1.67 | 0.28 |

| Weathered for 2000 h | 81.01 | 9.67 | 5.14 | 4.18 | 0.23 |

| Sample with UV326 and BF | |||||

| Unweathered | 80.04 | 9.89 | 8.11 | 1.96 | 0.25 |

| Weathered for 2000 h | 81.16 | 10.71 | 4.54 | 3.58 | 0.23 |

| Sample with BF1 | |||||

| Unweathered | 77.97 | 12.58 | 7.77 | 1.68 | 0.28 |

| Weathered for 2000 h | 82.11 | 10.28 | 4.56 | 3.04 | 0.22 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nguyen, V.D.; Hao, J.; Wang, W. Ultraviolet Weathering Performance of High-Density Polyethylene/Wood-Flour Composites with a Basalt-Fiber-Included Shell. Polymers 2018, 10, 831. https://doi.org/10.3390/polym10080831

Nguyen VD, Hao J, Wang W. Ultraviolet Weathering Performance of High-Density Polyethylene/Wood-Flour Composites with a Basalt-Fiber-Included Shell. Polymers. 2018; 10(8):831. https://doi.org/10.3390/polym10080831

Chicago/Turabian StyleNguyen, Van Dinh, Jianxiu Hao, and Weihong Wang. 2018. "Ultraviolet Weathering Performance of High-Density Polyethylene/Wood-Flour Composites with a Basalt-Fiber-Included Shell" Polymers 10, no. 8: 831. https://doi.org/10.3390/polym10080831

APA StyleNguyen, V. D., Hao, J., & Wang, W. (2018). Ultraviolet Weathering Performance of High-Density Polyethylene/Wood-Flour Composites with a Basalt-Fiber-Included Shell. Polymers, 10(8), 831. https://doi.org/10.3390/polym10080831