Shear-Thickening Fluid Using Oxygen-Plasma-Modified Multi-Walled Carbon Nanotubes to Improve the Quasi-Static Stab Resistance of Kevlar Fabrics

Abstract

1. Introduction

2. Experimental

2.1. Materials

2.2. Preparation

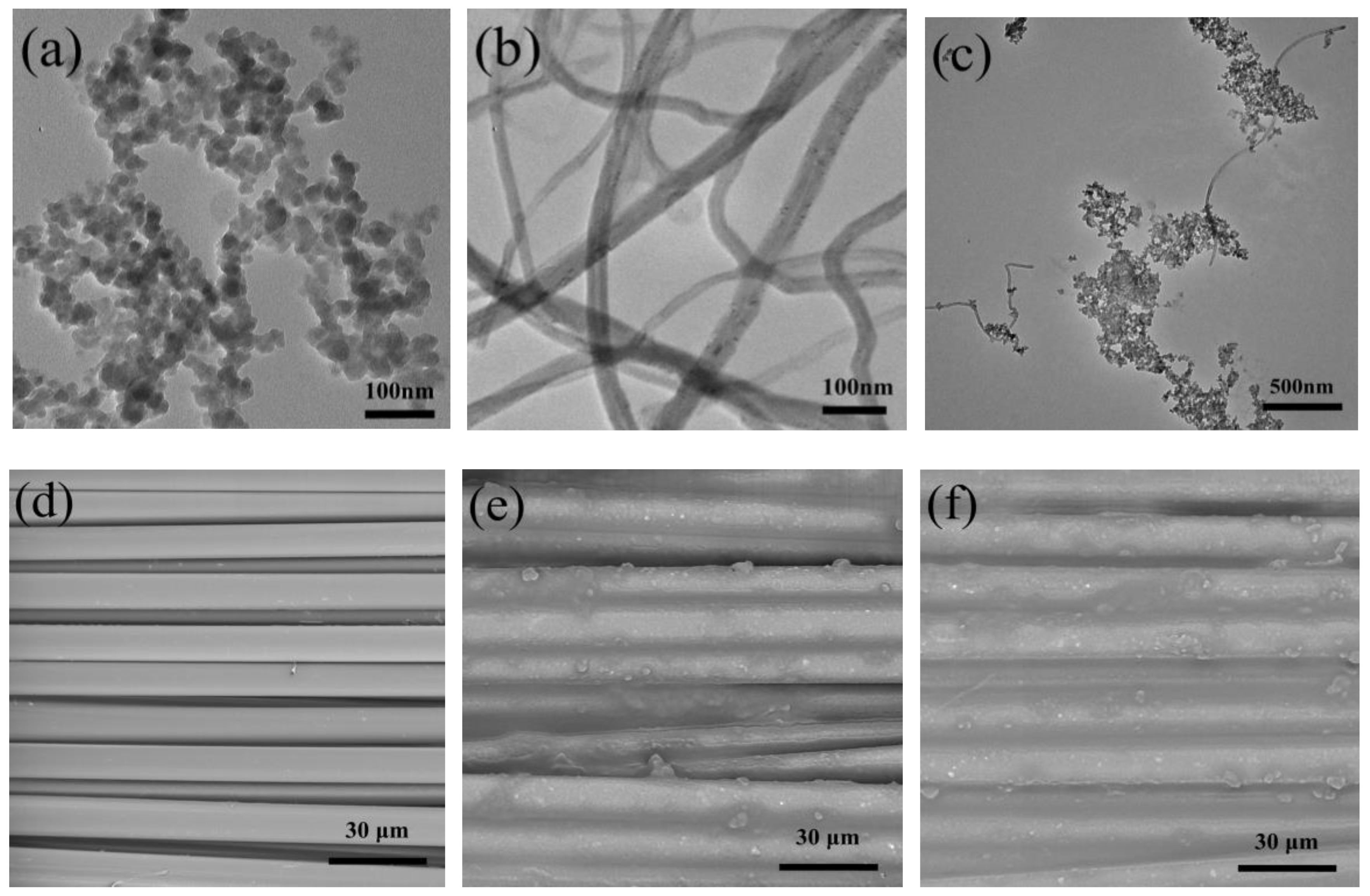

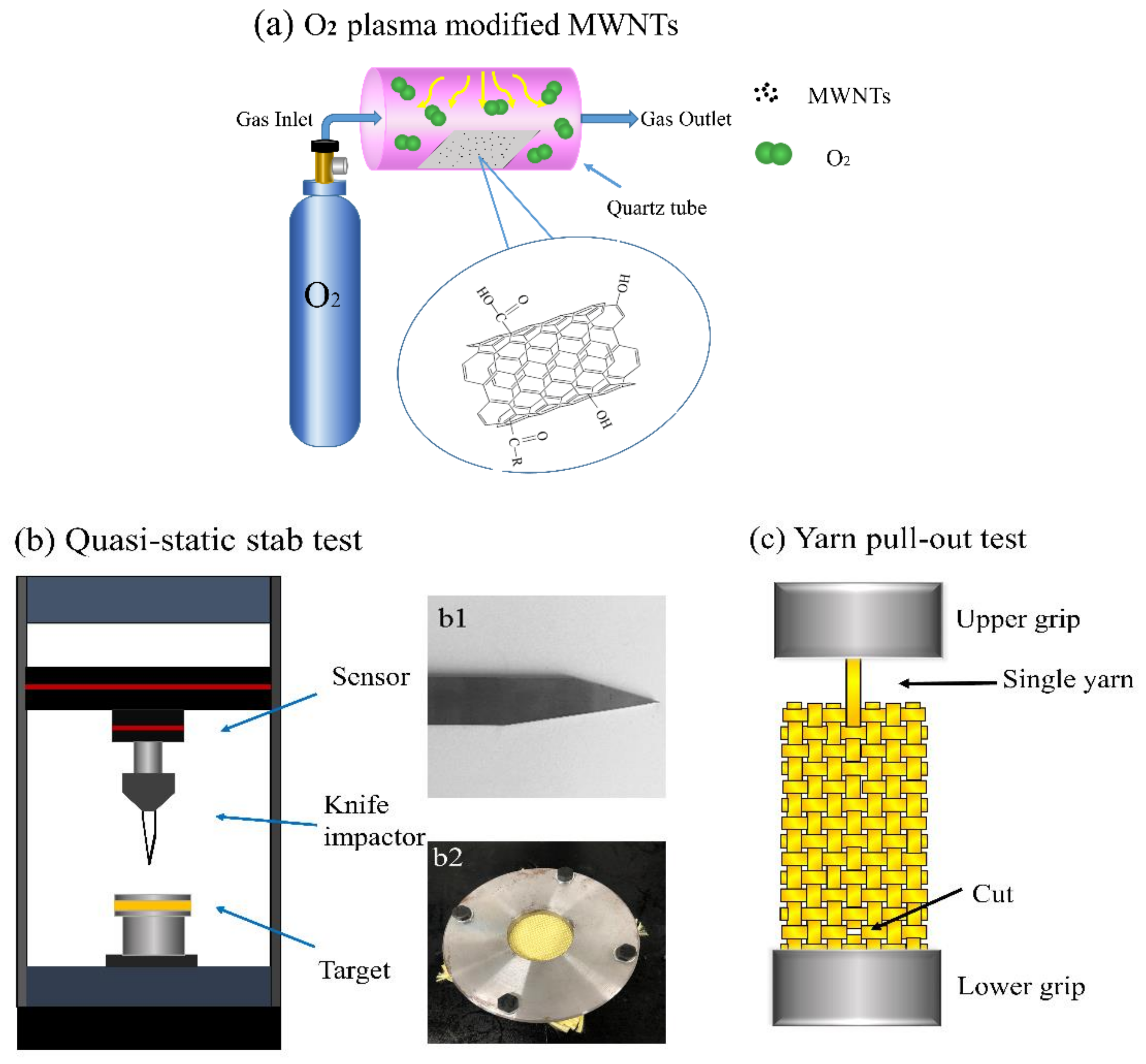

2.2.1. Preparation of the O2-Plasma-Modified MWNTs

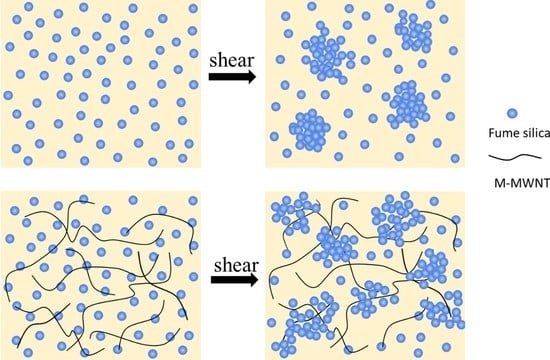

2.2.2. Preparation of STF

2.2.3. Preparation of STF-Treated Fabric

2.3. Characterizations

3. Result and Discussion

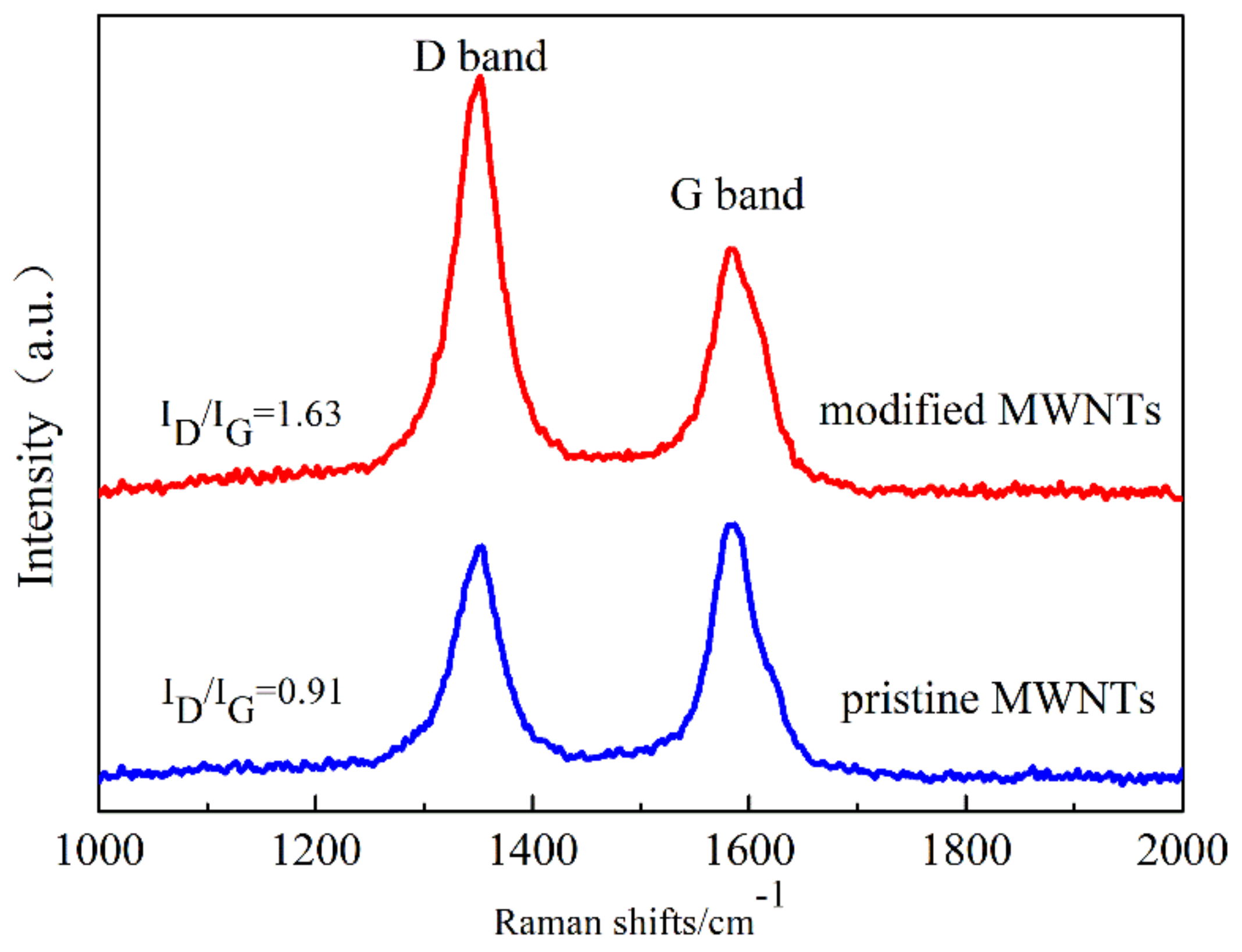

3.1. Raman Spectroscopy

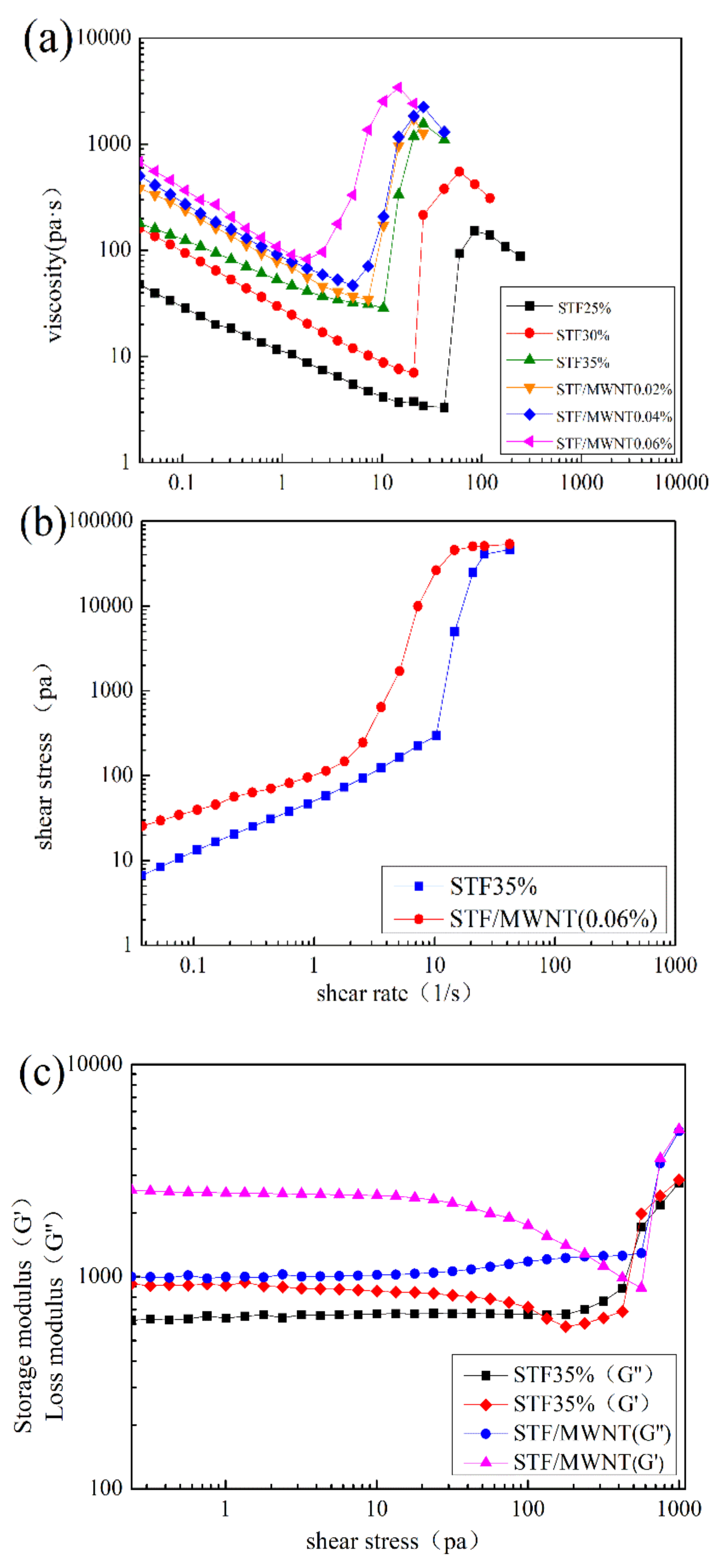

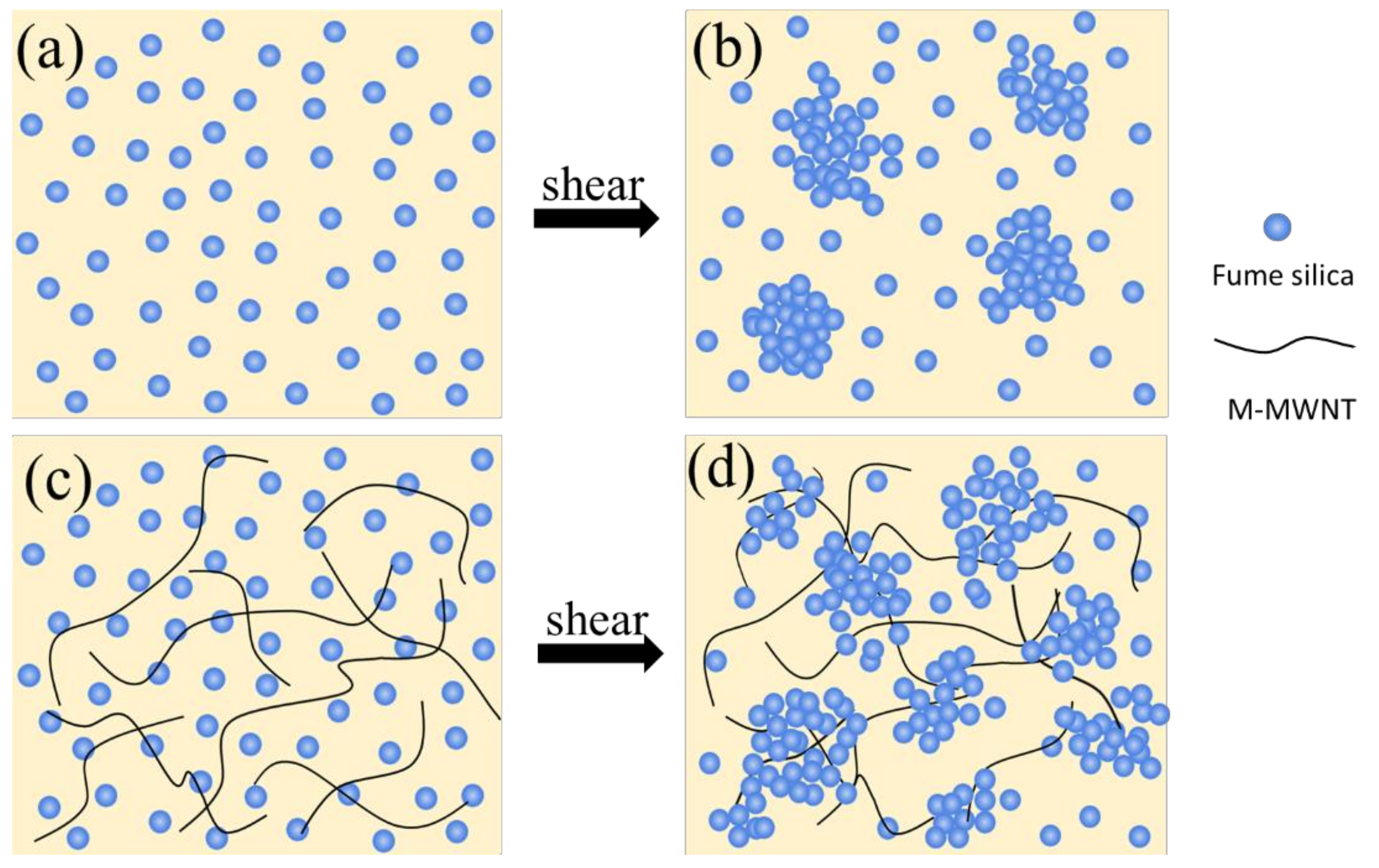

3.2. Rheological Behavior of STFs

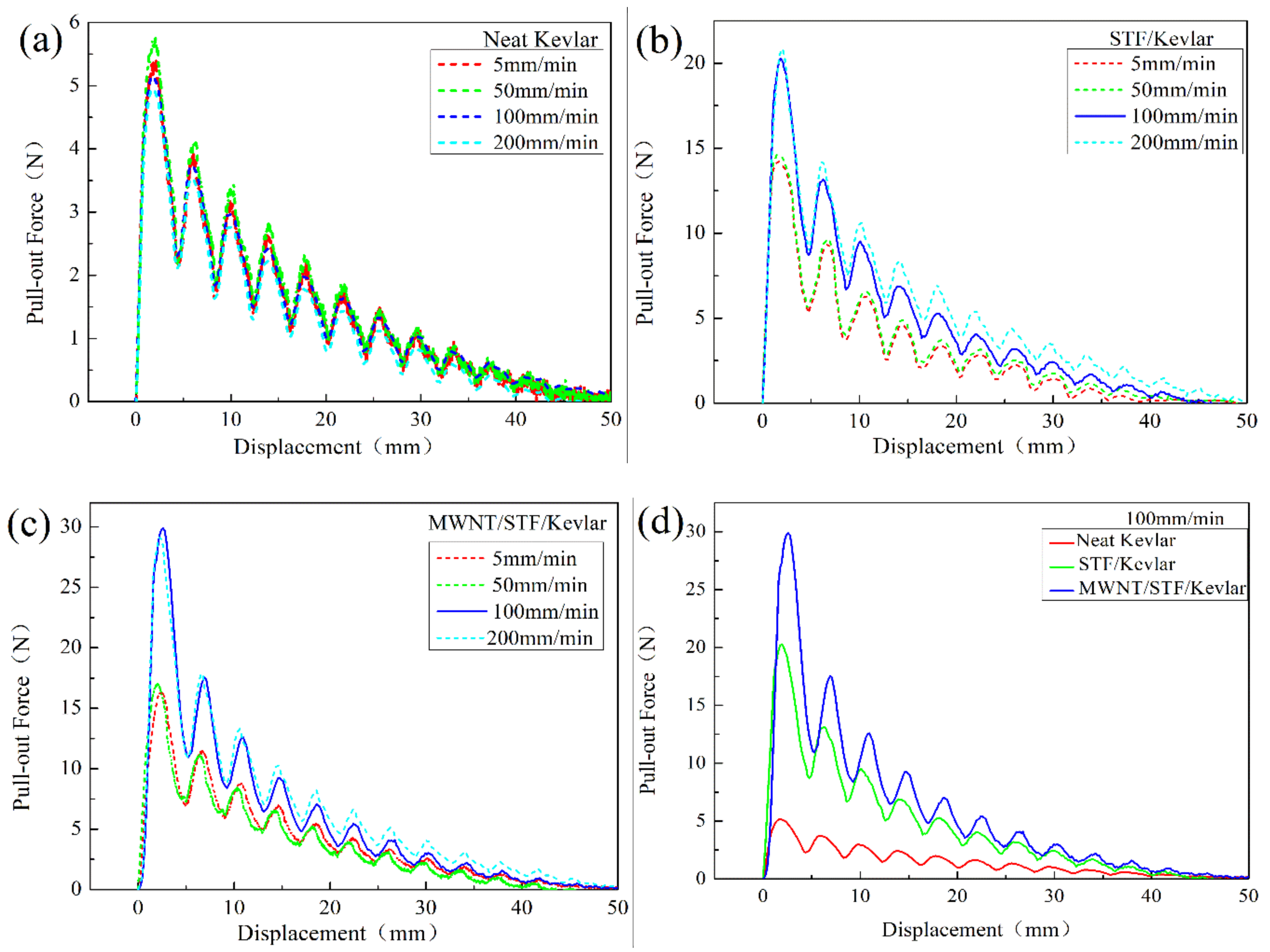

3.3. Yarn Pull-Out Test Results

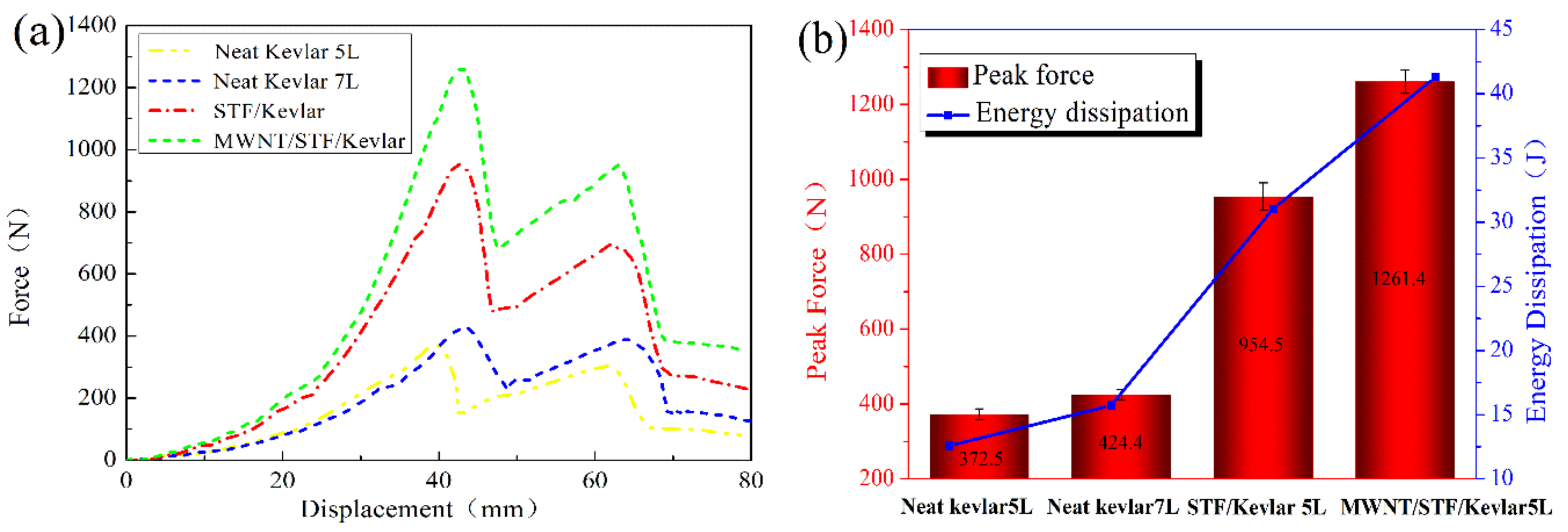

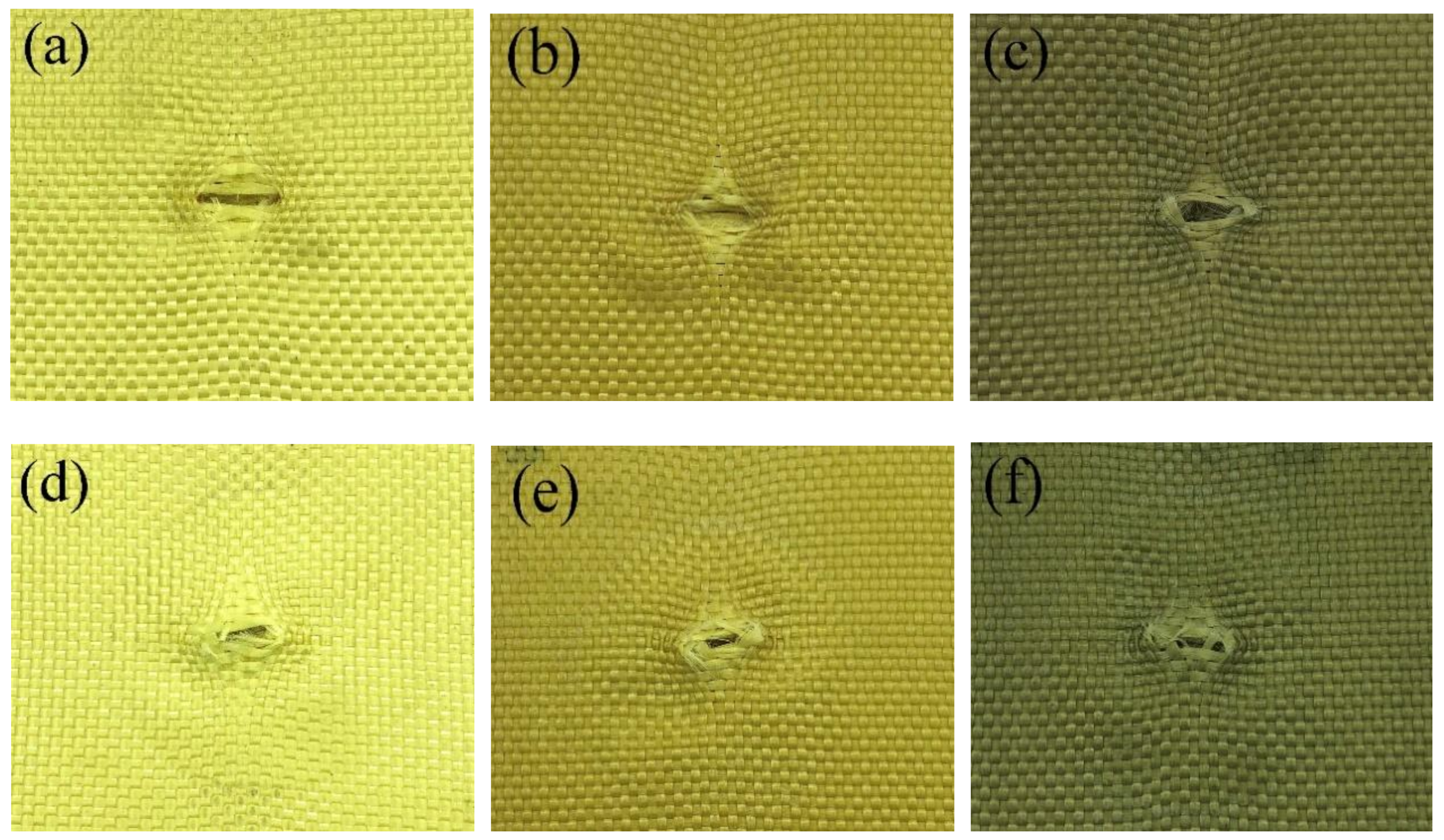

3.4. Quasi-Static Stab Test

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Wang, S.; Xuan, S.; Wang, Y.; Xu, C.; Mao, Y.; Liu, M.; Bai, L.; Jiang, W.; Gong, X. Stretchable Polyurethane Sponge Scaffold Strengthened Shear Stiffening Polymer and Its Enhanced Safeguarding Performance. ACS Appl. Mater. Interfaces 2016, 8, 4946–4954. [Google Scholar] [CrossRef] [PubMed]

- Xu, Y.; Chen, X.; Wang, Y.; Yuan, Z. Stabbing resistance of body armour panels impregnated with shear thickening fluid. Compos. Struct. 2017, 163, 465–473. [Google Scholar] [CrossRef]

- Firouzi, D.; Russel, M.K.; Rizvi, S.N.; Ching, C.Y.; Selvaganapathy, P.R. Development of flexible particle-laden elastomeric textiles with improved penetration resistance to hypodermic needles. Mater. Des. 2018, 156, 419–428. [Google Scholar] [CrossRef]

- Rodríguez-Millán, M.; Díaz-Álvarez, A.; Aranda-Ruiz, J.; Díaz-Álvarez, J.; Loya, J.A. Experimental analysis for stabbing resistance of different aramid composite architectures. Compos. Struct. 2019, 208, 525–534. [Google Scholar] [CrossRef]

- Hasanzadeh, M.; Mottaghitalab, V.; Babaei, H.; Rezaei, M. The influence of carbon nanotubes on quasi-static puncture resistance and yarn pull-out behavior of shear-thickening fluids (STFs) impregnated woven fabrics. Compos. Part A 2016, 88, 263–271. [Google Scholar] [CrossRef]

- Majumdar, A.; Butola, B.S.; Srivastava, A. Development of soft composite materials with improved impact resistance using Kevlar fabric and nano-silica based shear thickening fluid. Mater. Des. 2014, 54, 295–300. [Google Scholar] [CrossRef]

- Gürgen, S.; Kuşhan, M.C. The stab resistance of fabrics impregnated with shear thickening fluids including various particle size of additives. Compos. Part A 2017, 94, 50–60. [Google Scholar] [CrossRef]

- Li, W.; Xiong, D.; Zhao, X.; Sun, L.; Liu, J. Dynamic stab resistance of ultra-high molecular weight polyethylene fabric impregnated with shear thickening fluid. Maters. Des. 2016, 102, 162–167. [Google Scholar] [CrossRef]

- Warren, J.; Offenberger, S.; Toghiani, H.; Pittman, C.U., Jr.; Lacy, T.E.; Kundu, S. Effect of Temperature on the Shear-Thickening Behavior of Fumed Silica Suspensions. ACS Appl. Mater. Interfaces 2015, 7, 18650–18661. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, X.; Chen, Q.; Li, X.; Wang, P.; Yang, E.-H.; Duan, F.; Gong, X.; Zhang, Z.; Yang, J. Encapsulation of shear thickening fluid as an easy-to-apply impact-resistant material. J. Mater. Chem. A 2017, 5, 22472–22479. [Google Scholar] [CrossRef]

- He, Q.; Cao, S.; Wang, Y.; Xuan, S.; Wang, P.; Gong, X. Impact resistance of shear thickening fluid/Kevlar composite treated with shear-stiffening gel. Compos. Part A 2018, 106, 82–90. [Google Scholar] [CrossRef]

- Lee, Y.S.; Wetzel, E.D.; Wagner, N.J. The ballistic impact characteristics of Kevlar® woven fabrics impregnated with a colloidal shear thickening fluid. J. Mater. Sci. 2003, 38, 2825–2833. [Google Scholar] [CrossRef]

- Hasanzadeh, M.; Mottaghitalab, V.; Rezaei, M. Rheological and viscoelastic behavior of concentrated colloidal suspensions of silica nanoparticles: A response surface methodology approach. Adv. Powder Technol. 2015, 26, 1570–1577. [Google Scholar] [CrossRef]

- Feng, X.; Li, S.; Wang, Y.; Wang, Y.; Liu, J. Effects of different silica particles on quasi-static stab resistant properties of fabrics impregnated with shear thickening fluids. Mater. Des. 2014, 64, 456–461. [Google Scholar] [CrossRef]

- Kalman, D.P.; Merrill, R.L.; Wagner, N.J.; Wetzel, E.D. Effect of particle hardness on the penetration behavior of fabrics intercalated with dry particles and concentrated particle-fluid suspensions. ACS Appl. Mater. Interfaces 2009, 1, 2602–2612. [Google Scholar] [CrossRef] [PubMed]

- Antosik, A.; Gluszek, M.; Zurowski, R.; Szafran, M. Influence of carrier fluid on the electrokinetic and rheological properties of shear thickening fluids. Ceram. Int. 2017, 43, 12293–12301. [Google Scholar] [CrossRef]

- Laha, A.; Majumdar, A. Interactive effects of p-aramid fabric structure and shear thickening fluid on impact resistance performance of soft armor materials. Mater. Des. 2016, 89, 286–293. [Google Scholar] [CrossRef]

- Wang, F.F.; Zhang, Y.; Zhang, H.; Xu, L.; Wang, P.; Guo, C. The influence of graphene nanoplatelets (GNPs) on the semi-blunt puncture behavior of woven fabrics impregnated with shear thickening fluid (STF). RSC Adv. 2018, 8, 5268–5279. [Google Scholar] [CrossRef]

- Ghosh, A.; Chauhan, I.; Majumdar, A.; Butola, B.S. Influence of cellulose nanofibers on the rheological behavior of silica-based shear-thickening fluid. Cellulose 2017, 24, 4163–4171. [Google Scholar] [CrossRef]

- Laha, A.; Majumdar, A. Shear thickening fluids using silica-halloysite nanotubes to improve the impact resistance of p-aramid fabrics. Appl. Clay Sci. 2016, 132–133, 468–474. [Google Scholar] [CrossRef]

- Calle, D.; Negri, V.; Munuera, C.; Mateos, L.; Touriño, I.L.; Viñegla, P.R.; Mariola, O.; García-Hernández, M.; Cerdán, S.; Ballesteros, P. Magnetic anisotropy of functionalized multi-walled carbon nanotube suspensions. Carbon 2018, 131, 229–237. [Google Scholar] [CrossRef]

- Kong, L.; Li, F.; Wang, F.; Miao, Y.; Huang, X.; Zhu, H.; Lu, Y. High-performing multi-walled carbon nanotubes/silica nanocomposites for elastomer application. Compos. Sci. Technol. 2018, 162, 23–32. [Google Scholar] [CrossRef]

- Sun, Y.; Wang, R.; Liu, X.; Li, M.; Yang, H.; Li, B. Improvements in the thermal conductivity and mechanical properties of phase-change microcapsules with oxygen-plasma-modified multiwalled carbon nanotubes. J. Appl. Polym. Sci. 2017, 134, 45269. [Google Scholar] [CrossRef]

- Usman, F.M.; Luan, H.Y.; Wang, Y.; Huang, H.; An, A.K.; Jalil, K.R. Increased adsorption of aqueous zinc species by Ar/O2 plasma-treated carbon nanotubes immobilized in hollow-fiber ultrafiltration membrane. Chem. Eng. J. 2017, 325, 239–248. [Google Scholar] [CrossRef]

- Xu, T.; Yang, J.; Liu, J.; Fu, Q. Surface modification of multi-walled carbon nanotubes by O2 plasma. Appl. Surf. Sci. 2007, 253, 8945–8951. [Google Scholar] [CrossRef]

- Chen, Q.; Liu, M.; Xuan, S.; Jiang, W.; Cao, S.; Gong, X. Shear dependent electrical property of conductive shear thickening fluid. Mater. Des. 2017, 121, 92–100. [Google Scholar] [CrossRef]

- Sha, X.; Yu, K.; Cao, H.; Qian, K. Shear thickening behavior of nanoparticle suspensions with carbon nanofillers. J. Nanopart. Res. 2013, 15, 1816. [Google Scholar] [CrossRef]

- Liu, Q.; Zhao, H.Q.; Li, L.; He, P.P.; Wang, Y.X.; Yang, H.Y.; Hu, Z.; Mu, Y. Effect of surface modification on carbon nanotubes (CNTs) catalyzed nitrobenzene reduction by sulfide. J. Hazard. Mater. 2018, 357, 235–243. [Google Scholar] [CrossRef]

- Brady, J.F.; Bossis, G. Stokesian dynamics. Annu. Rev. Fluid Mech. 1988, 20, 111–157. [Google Scholar] [CrossRef]

- Brady, J.F.; Bossis, G. The rheology of concentrated suspensions of spheres in simple shear flow by numerical simulation. J. Fluid Mech. 2006, 155, 105–129. [Google Scholar] [CrossRef]

- Cheng, X.; McCoy, J.H.; Israelachvili, J.N.; Cohen, I. Imaging the microscopic structure of shear thinning and thickening colloidal suspensions. Science 2011, 333, 1276–1279. [Google Scholar] [CrossRef] [PubMed]

- Qin, J.; Zhang, G.; Zhou, L.; Li, J.; Shi, X. Dynamic/quasi-static stab-resistance and mechanical properties of soft body armour composites constructed from Kevlar fabrics and shear thickening fluids. RSC Adv. 2017, 7, 39803–39813. [Google Scholar] [CrossRef]

- Majumdar, A.; Butola, B.S.; Srivastava, A. An analysis of deformation and energy absorption modes of shear thickening fluid treated Kevlar fabrics as soft body armour materials. Mater. Des. 2013, 51, 148–153. [Google Scholar] [CrossRef]

| Filler Type | Additive Amount (wt%) | SiO2 Dia | SiO2 (wt. %) | Dispersing Medium | γc (s−1) | ηmax (pa·s) | Ref. |

|---|---|---|---|---|---|---|---|

| MWNTs | 0.8 | 12 nm | 44 | PEG-200 | 196 | 77.7 | [5] |

| MWNTs | 0.4 | 2 μm | 64 | EG | 3.5 | 13.4 | [26] |

| CNTs + GNs | 2 + 1 | 650 nm | 75 | PEG-200 | ~0.24 | ~2302 | [27] |

| GNs | 0.8 | 12 nm | 20 | PEG-200 | ~4.2 | ~105 | [18] |

| CNFs | 0.2 | 500 nm | 65 | PEG-200 | 16.6 | 139 | [19] |

| HNTs | 0.05 | 100 nm | 65 | PEG-200 | 40 | 550 | [20] |

| M-MWNTs | 0.06 | 12 nm | 35 | PEG-200 | 2.53 | 3417 | This work |

| Fabric Structure Parameters | Value |

|---|---|

| Weave | Plain |

| Areal density (g/m2) | 420 |

| Fabric thickness (mm) | 0.56 |

| Warp density (ends/cm) | 6 |

| Weft density (ends/cm) | 6 |

| Sample | SiO2 wt. % | M-MWNT wt. % | γc 1 s−1 | ηmax 2 pa·s | Fitting Function | R2 |

|---|---|---|---|---|---|---|

| STF | 25 | 0 | 59.89 | 152.3 | 0.9989 | |

| 30 | 0 | 29.64 | 215.2 | 0.9962 | ||

| 35 | 0 | 14.68 | 1563 | 0.9789 | ||

| M-MWNT/STF | 35 | 0.02 | 10.33 | 1728 | 0.9805 | |

| 35 | 0.04 | 7.27 | 2243 | 0.9723 | ||

| 35 | 0.06 | 2.54 | 3417 | 0.9795 |

| Sample | V (mm/min) | Fitting Function | R2 |

|---|---|---|---|

| Neat fabric | 50 | 0.9895 | |

| 100 | 0.992 | ||

| STF/Kevlar | 50 | 0.9962 | |

| 100 | 0.9915 | ||

| M-MWNT/STF/Kevlar | 50 | 0.9897 | |

| 100 | 0.989 |

| Samples | Number of Layers | Thickness (mm) | Areal Density (g/m2) |

|---|---|---|---|

| Neat fabric | 5 | 2.79 | 2100 |

| Neat fabric | 7 | 3.92 | 2940 |

| STF/Kevlar | 5 | 3.12 | 2821.5 |

| M-MWNT/STF/Kevlar | 5 | 3.19 | 2788.7 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, D.; Wang, R.; Liu, X.; Fang, S.; Sun, Y. Shear-Thickening Fluid Using Oxygen-Plasma-Modified Multi-Walled Carbon Nanotubes to Improve the Quasi-Static Stab Resistance of Kevlar Fabrics. Polymers 2018, 10, 1356. https://doi.org/10.3390/polym10121356

Li D, Wang R, Liu X, Fang S, Sun Y. Shear-Thickening Fluid Using Oxygen-Plasma-Modified Multi-Walled Carbon Nanotubes to Improve the Quasi-Static Stab Resistance of Kevlar Fabrics. Polymers. 2018; 10(12):1356. https://doi.org/10.3390/polym10121356

Chicago/Turabian StyleLi, Danyang, Rui Wang, Xing Liu, Shu Fang, and Yanli Sun. 2018. "Shear-Thickening Fluid Using Oxygen-Plasma-Modified Multi-Walled Carbon Nanotubes to Improve the Quasi-Static Stab Resistance of Kevlar Fabrics" Polymers 10, no. 12: 1356. https://doi.org/10.3390/polym10121356

APA StyleLi, D., Wang, R., Liu, X., Fang, S., & Sun, Y. (2018). Shear-Thickening Fluid Using Oxygen-Plasma-Modified Multi-Walled Carbon Nanotubes to Improve the Quasi-Static Stab Resistance of Kevlar Fabrics. Polymers, 10(12), 1356. https://doi.org/10.3390/polym10121356