Mechanical Properties of Polypropylene Warp-Knitted Hernia Repair Mesh with Different Pull Densities

Abstract

1. Introduction

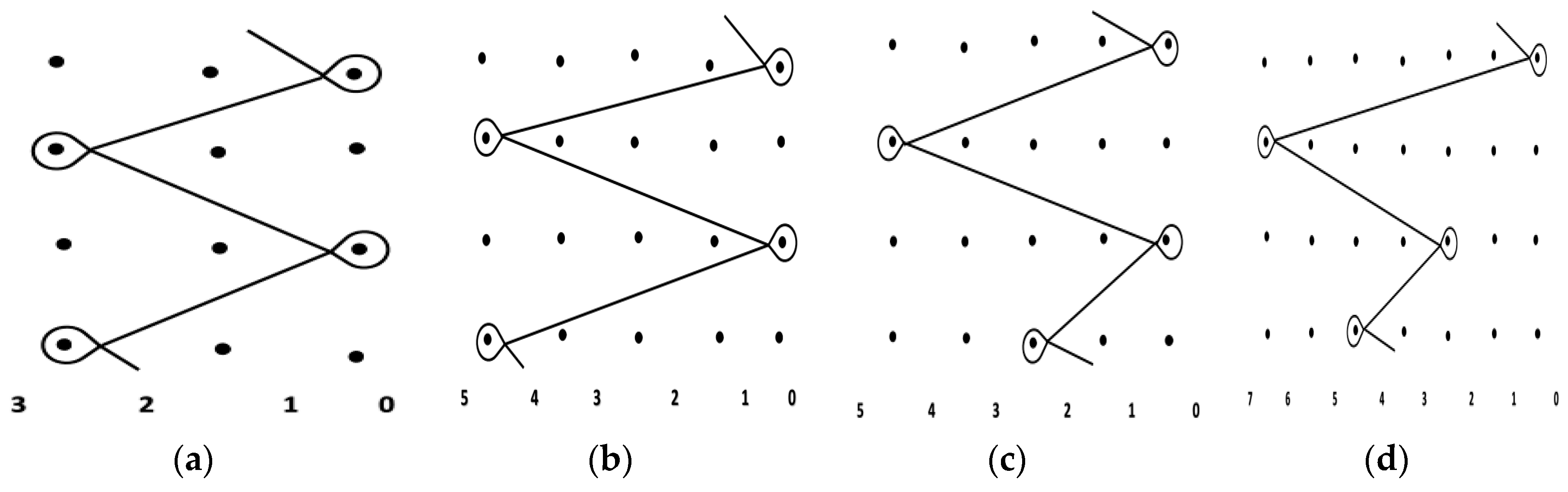

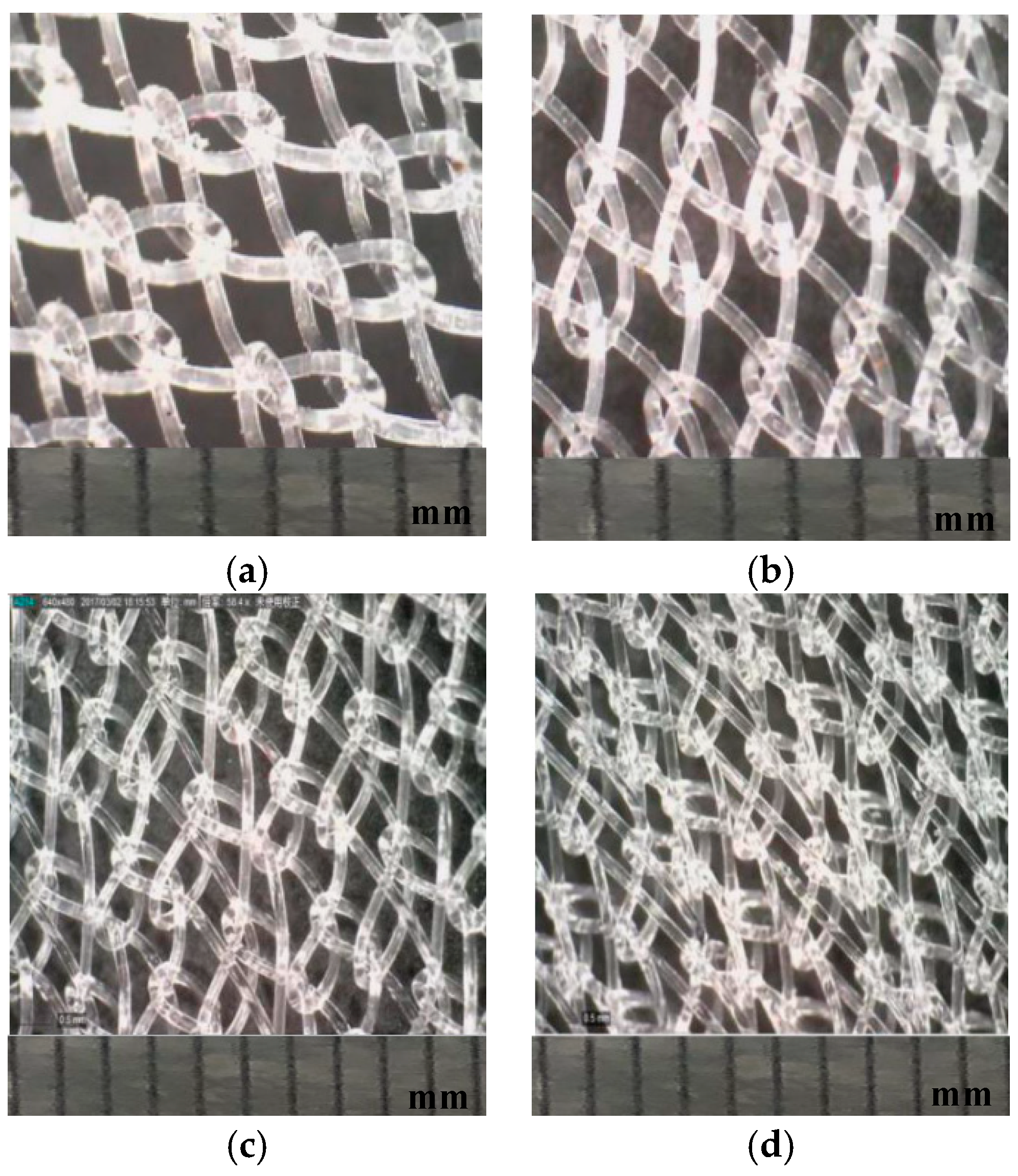

2. Experimental Section

2.1. Materials

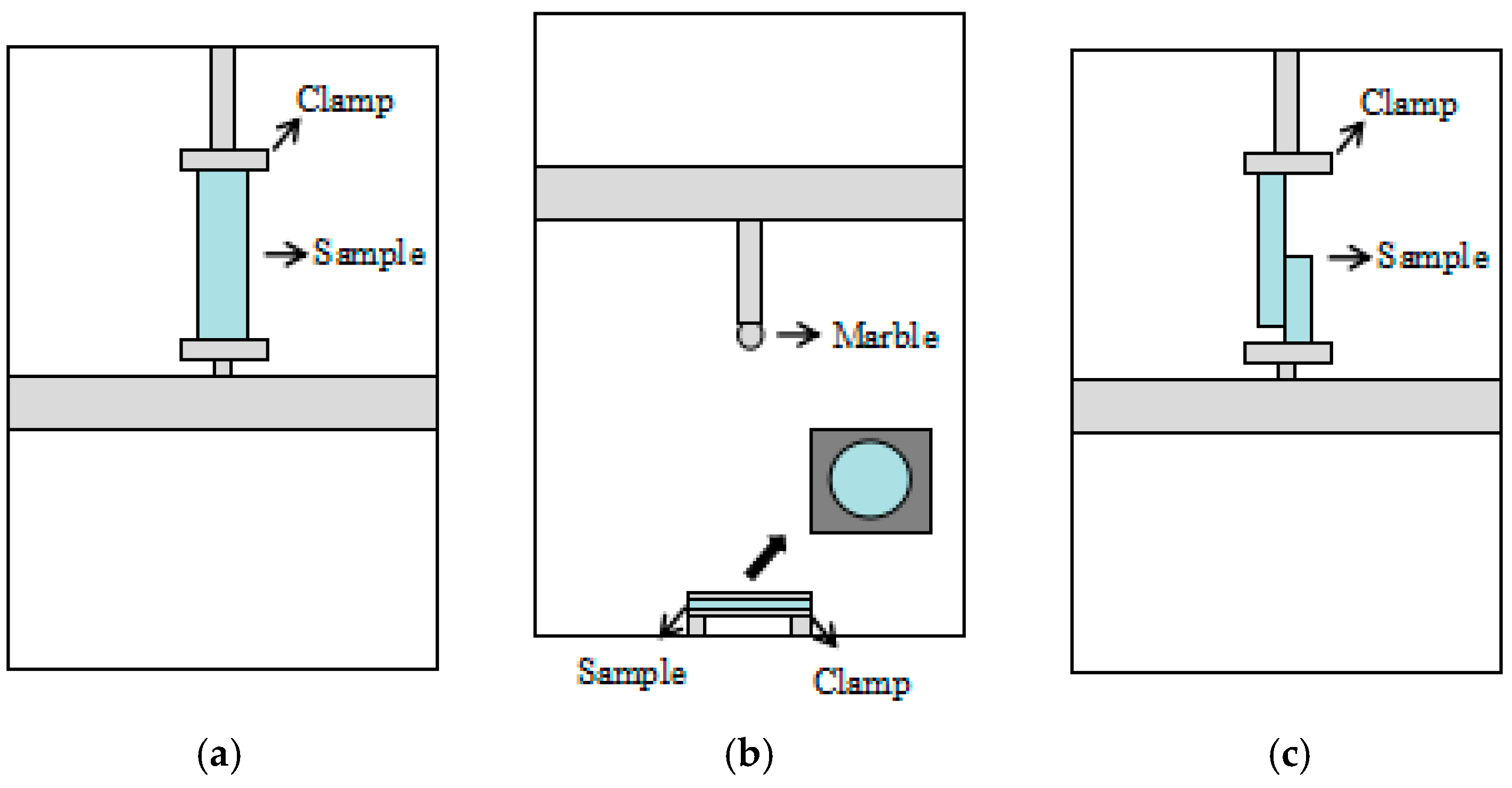

2.2. Mechanical Performance Test

2.2.1. Tensile Property

2.2.2. Bursting Properties

2.2.3. Tearing Properties

3. Results and Discussion

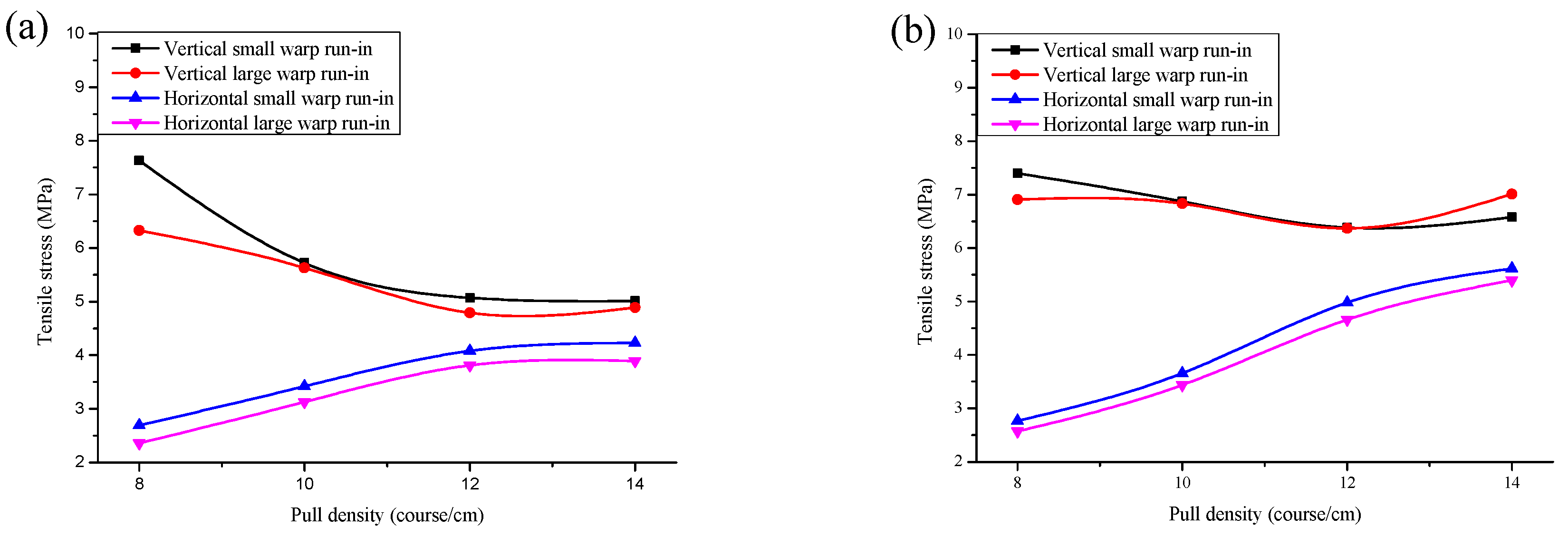

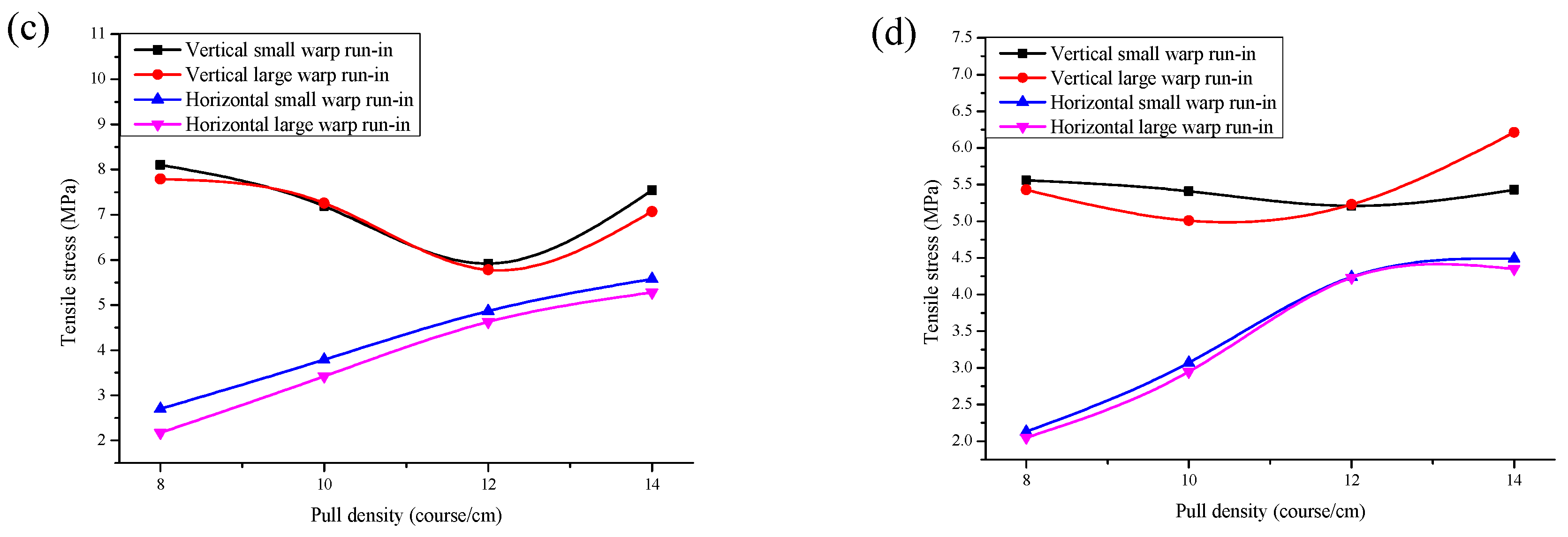

3.1. Effect of Pull Density on Tensile Properties

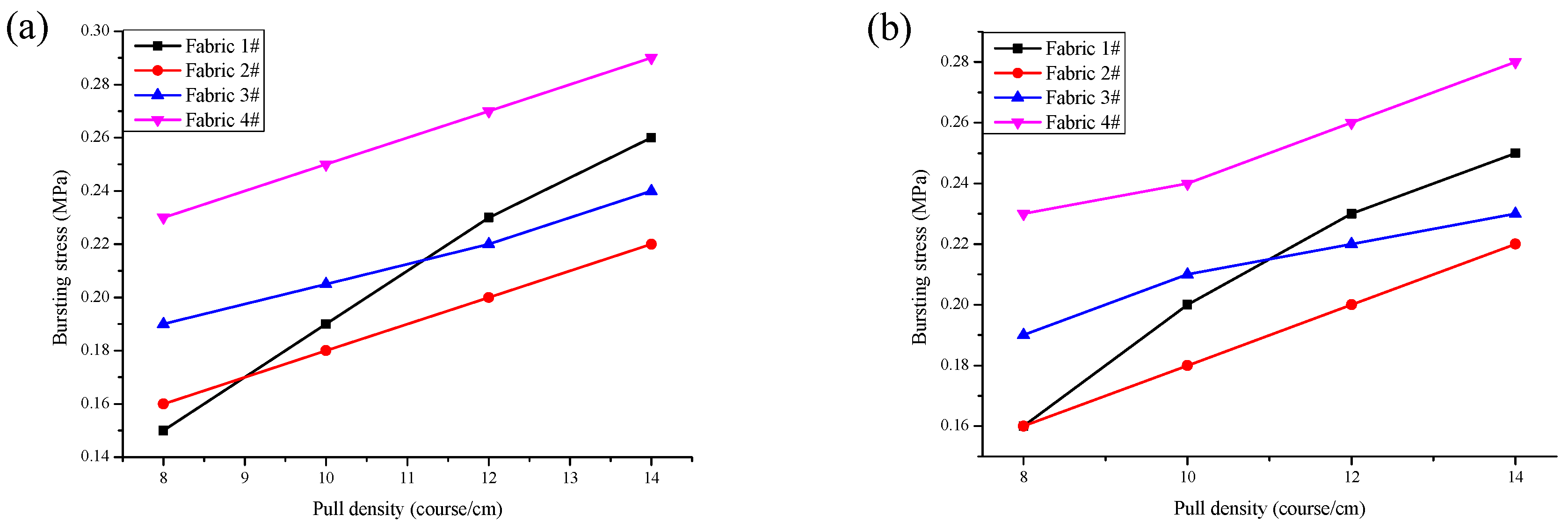

3.2. Effect of Pull Density on Bursting Properties

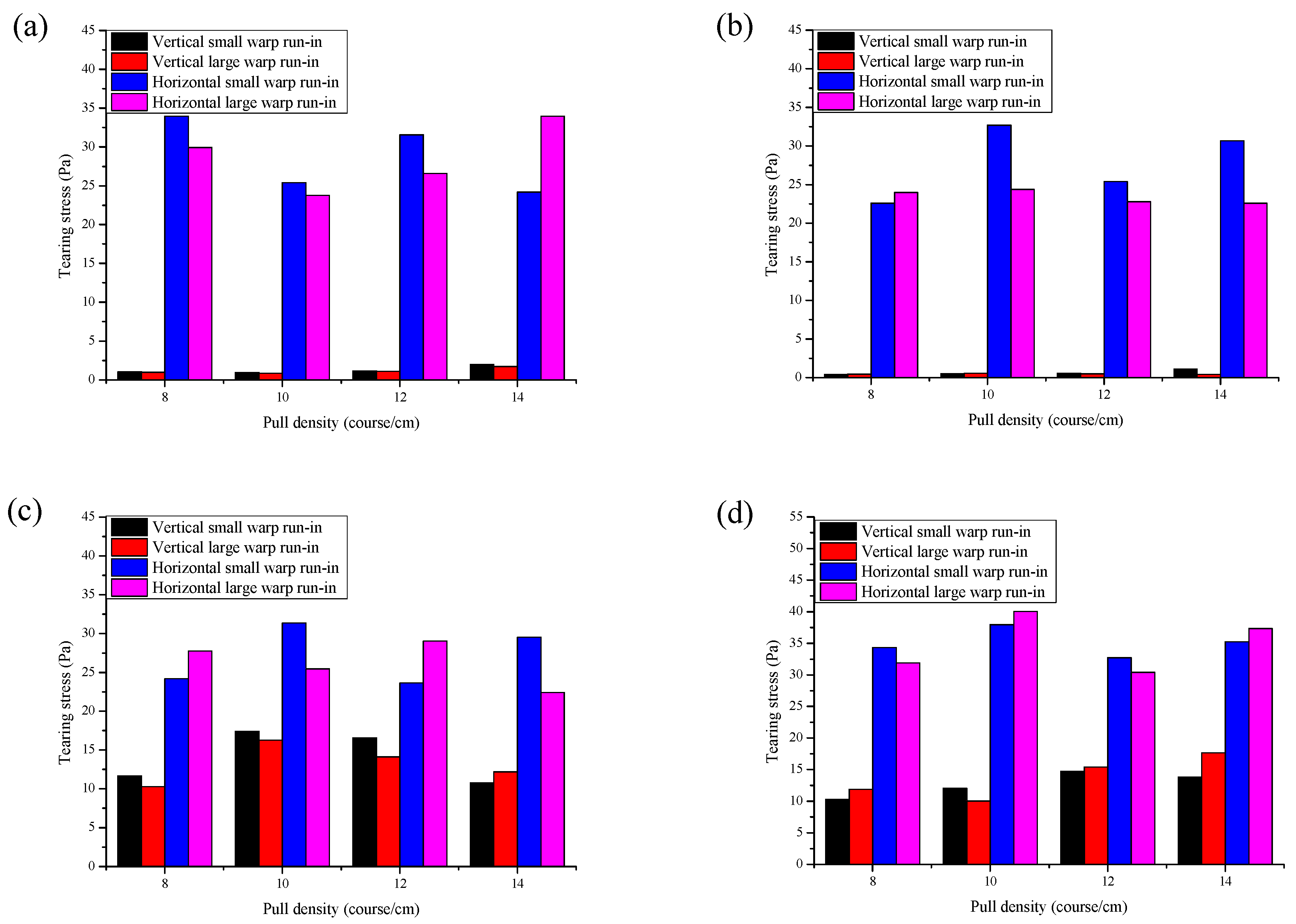

3.3. Effect of Pull Density on Tearing Properties

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Goepel, R. Uber die verschliessung von bruchpforten durch einheilung geflocuhtener fertiger silberdrahtnetze. Verh. Deutsch Ges. Chir. 1900, 9, 174–179. [Google Scholar]

- Aquaviva, D.; Bounet, P. Cure d’une volumineuse eventration par plaque de Crinofil. Extraits Bull Soc Chir De Marseille 1944, 17, 5–9. [Google Scholar]

- Koontz, A.R.; Kimberly, R.C. Further experimental work on prostheses for hernia repair. Surg. Gynecol. Obstet. 1959, 109, 321–327. [Google Scholar] [PubMed]

- Procter, L.; Falco, E.E.; Fisher, J.P.; Roth, J.S. Abdominal Wall Hernias and Biomaterialsin: Bioengineering Research of Chronic Wounds, 1st ed.; Gefen, A., Ed.; Springer: Berlin/Heidelberg, Germany, 2009; pp. 425–447. [Google Scholar]

- Cozad, M.J.; Grant, D.A.; Bachman, S.L.; Grant, D.N.; Ramshaw, B.J.; Grant, S.A. Materials characterization of explanted polypropylene, polyethylene terephthalate, and expanded polytetrafluoroethylene composite: Spectral and thermal analysis. J. Biomed. Mater. Res. B Appl. Biomater. 2010, 94, 455–462. [Google Scholar] [CrossRef] [PubMed]

- Dalenback, J.; Andersson, C.; Ribokas, D.; Rimback, G. Long-term follow-up after elective adult umbilical hernia repair: Low recurrence rates also after non-mesh repairs. Hernia 2013, 17, 493–497. [Google Scholar] [CrossRef] [PubMed]

- Abo-Ryia, M.H.; El-Khadrawy, O.H.; Moussa, G.I.; Saleh, A.M. Prospective randomized evaluation of open preperitoneal versus preaponeurotic primary elective mesh repair for paraumbilical hernias. Sug. Today 2015, 45, 429–433. [Google Scholar] [CrossRef] [PubMed]

- Bessa, S.S.; El-Gendi, A.M.; Ghazal, A.H.; Al-Fayourni, T.A. Comparison between the short-term results of onlay and sublay mesh placement in the management of uncomplicated para-umbilical hernia: A prospective randomized study. Hernia 2015, 19, 141–146. [Google Scholar] [CrossRef] [PubMed]

- Nardi, J.M.; Millo, P.; Bracher, C.R. Laparoscopic ventral hernia repair with composite mesh: Analysis of risk factors for recurrence in 185 patients with 5 years follow-up. Int. J. Surg. 2017, 40, 38–44. [Google Scholar] [CrossRef] [PubMed]

- Amid, P.K. Classification of biomaterials and their related complications in abdominal wall hernia surgery. Hernia 1997, 1, 15–21. [Google Scholar] [CrossRef]

- Brown, C.N.; Finch, J.G. Which mesh for hernia repair? Ann. R. Coll. Surg. Eng. 2010, 92, 272–278. [Google Scholar] [CrossRef] [PubMed]

- Bellon, J.M.; Rodriguez, M.; Garcia-Honduvilla, N.; Gomez-Gil, V.; Pascual, G.; Bujan, J. Comparing the behavior of different polypropylene meshes (heavy and light weight) in an experimental model of ventral hernia repair. J. Biomed. Mater. Res. B Appl. Biomater. 2009, 89, 448–455. [Google Scholar]

- Klinge, U.; Klosterhalfen, B.; Birkenhauer, V.; Junge, K.; Conze, J.; Schumpelick, V. Impact of polymer pore size on the interface scar formation in rat model. J. Surg. Res. 2002, 103, 208–214. [Google Scholar] [CrossRef] [PubMed]

- Costello, C.R.; Bachman, S.L.; Ramshaw, B.J.; Grant, S.A. Materials characterization of explanted polypropylene hernia meshes. J. Biomed. Mater. Res. B Appl. Biomater. 2007, 83, 44–49. [Google Scholar] [CrossRef] [PubMed]

- Pawtowska, S.; Kowalewski, T.A.; Pierini, F. Fibrous polymer nanomaterials for biomedical applications and their transport by fluids: An overview. Soft Matter 2018, 14, 8421–8444. [Google Scholar] [CrossRef] [PubMed]

- Ling, S.J.; Jin, K.; Qin, Z.; Li, C.; Zheng, K.; Zhao, Y.; Wang, Q.; Kaplan, D.L. Combining in silico design and biomimetic assembly: A new approach for developing high-performance dynamic responsive bio-nanomaterials. Adv. Mater. 2018, 30. [Google Scholar] [CrossRef] [PubMed]

- Barretta, R.; Luciano, R.; Marotti de Sciarra, F.; Ruta, G. Stress-driven nonlocal integral model for Timoshenko elastic nano-beams. Eur. J. Mech./A Solids 2018. [Google Scholar] [CrossRef]

- Barretta, R.; Fazelzadeh, S.A.; Feo, L.; Ghavanloo, E.; Luciano, R. Nonlocal inflected nano-beams: A stress-driven approach of bi-Helmholtz type. Compos. Struct. 2018, 200, 239–245. [Google Scholar] [CrossRef]

| No. | Setting | Drawing | Pull Density (course/cm) | Warp Run-in (mm/rack) | Porosity (%) | Gram Weight (g/cm2) | Thickness (mm) |

|---|---|---|---|---|---|---|---|

| 1-11 | 2-3/1-0// | 1 miss-1 in | 8 | 2500 | 37.0 | 95.1 | 0.56 |

| 1-12 | 8 | 2600 | 36.6 | 92.3 | 0.62 | ||

| 1-21 | 10 | 2200 | 36. 5 | 98.1 | 0.56 | ||

| 1-22 | 10 | 2300 | 36.1 | 94.3 | 0.58 | ||

| 1-31 | 12 | 2100 | 35.5 | 10.3 | 0.55 | ||

| 1-32 | 12 | 2200 | 34.8 | 10.2 | 0.57 | ||

| 1-41 | 14 | 2000 | 33.4 | 92.1 | 0.58 | ||

| 1-42 | 14 | 2100 | 33.0 | 90.2 | 0.59 | ||

| 2-11 | 4-5/1-0// | 1 miss-1 in | 8 | 3200 | 51.4 | 48.1 | 0.54 |

| 2-12 | 8 | 3300 | 50.3 | 48.0 | 0.55 | ||

| 2-21 | 10 | 3000 | 48.1 | 78.1 | 0.54 | ||

| 2-22 | 10 | 3100 | 47.4 | 77.8 | 0.54 | ||

| 2-31 | 12 | 2900 | 46.4 | 79.9 | 0.55 | ||

| 2-32 | 12 | 3000 | 45.3 | 79.1 | 0.56 | ||

| 2-41 | 14 | 2800 | 43.2 | 81.2 | 0.56 | ||

| 2-42 | 14 | 2900 | 42.9 | 80.6 | 0.57 | ||

| 3-11 | 2-3/1-0/ | 1 miss-1 in | 8 | 2900 | 48.0 | 86.8 | 0.57 |

| 3-12 | 8 | 3000 | 46.1 | 86.1 | 0.56 | ||

| 3-21 | 10 | 2700 | 45.1 | 89.0 | 0.54 | ||

| 3-22 | 10 | 2800 | 44. | 88.2 | 0.53 | ||

| 3-31 | 4-5/1-0// | 12 | 2500 | 39.0 | 89.7 | 0.52 | |

| 4-32 | 12 | 2600 | 36.6 | 89.1 | 0.52 | ||

| 3-41 | 14 | 2400 | 35.9 | 91.2 | 0.50 | ||

| 3-42 | 14 | 2500 | 34.8 | 90.8 | 0.51 | ||

| 4-11 | 4-5/3-2/ | 1 miss-1 in | 8 | 3200 | 51.2 | 10.0 | 0.67 |

| 4-12 | 8 | 3300 | 50.2 | 10.0 | 0.66 | ||

| 4-21 | 10 | 2900 | 47.3 | 10.1 | 0.63 | ||

| 4-22 | 10 | 3000 | 45.0 | 10.1 | 0.64 | ||

| 4-31 | 6-7/1-0// | 12 | 2800 | 40.7 | 10.8 | 0.60 | |

| 4-32 | 12 | 2900 | 39.5 | 10.2 | 0.60 | ||

| 4-41 | 14 | 2700 | 38.1 | 11.0 | 0.59 | ||

| 4-42 | 14 | 2800 | 37.3 | 10.8 | 0.60 |

| No. | Pull Density (course/cm) | Warp Run-in (mm/rack) | Vertical Tensile Stress (MPa) | Horizontal Tensile Stress (MPa) | Vertical Tearing Stress (Pa) | Horizontal Tearing Stress (Pa) | Bursting Stress (MPa) |

|---|---|---|---|---|---|---|---|

| 1-11 | 8 | 2500 | 7.63 | 2.69 | 1.03 | 33.97 | 0.15 |

| 1-12 | 8 | 2600 | 6.33 | 2.36 | 0.99 | 29.92 | 0.16 |

| 1-21 | 10 | 2200 | 5.72 | 3.42 | 0.93 | 25.40 | 0.19 |

| 1-22 | 10 | 2300 | 5.63 | 3.13 | 0.85 | 23.78 | 0.20 |

| 1-31 | 12 | 2100 | 5.07 | 4.08 | 1.15 | 31.57 | 0.23 |

| 1-32 | 12 | 2200 | 4.79 | 3.81 | 1.11 | 26.57 | 0.23 |

| 1-41 | 14 | 2000 | 5.01 | 4.23 | 1.99 | 24.18 | 0.26 |

| 1-42 | 14 | 2100 | 4.89 | 3.89 | 1.72 | 33.97 | 0.25 |

| 2-11 | 8 | 3200 | 7.40 | 2.77 | 0.43 | 22.60 | 0.16 |

| 2-12 | 8 | 3300 | 6.91 | 2.57 | 0.46 | 23.97 | 0.16 |

| 2-21 | 10 | 3000 | 6.87 | 3.66 | 0.51 | 32.69 | 0.18 |

| 2-22 | 10 | 3100 | 6.83 | 3.44 | 0.57 | 24.39 | 0.18 |

| 2-31 | 12 | 2900 | 6.38 | 4.98 | 0.55 | 25.40 | 0.20 |

| 2-32 | 12 | 3000 | 6.37 | 4.66 | 0.50 | 22.79 | 0.20 |

| 2-41 | 14 | 2800 | 6.58 | 5.62 | 1.12 | 30.68 | 0.22 |

| 2-42 | 14 | 2900 | 7.01 | 5.40 | 0.43 | 22.60 | 0.22 |

| 3-11 | 8 | 2900 | 8.10 | 2.70 | 11.68 | 24.18 | 0.19 |

| 3-12 | 8 | 3000 | 7.79 | 2.17 | 10.29 | 27.75 | 0.19 |

| 3-21 | 10 | 2700 | 7.19 | 3.79 | 17.41 | 31.36 | 0.205 |

| 3-22 | 10 | 2800 | 7.26 | 3.42 | 16.28 | 25.45 | 0.21 |

| 3-31 | 12 | 2500 | 5.92 | 4.87 | 16.55 | 23.64 | 0.22 |

| 3-32 | 12 | 2600 | 5.78 | 4.63 | 14.13 | 29.02 | 0.22 |

| 3-41 | 14 | 2400 | 7.54 | 5.58 | 10.76 | 29.54 | 0.24 |

| 3-42 | 14 | 2500 | 7.07 | 5.28 | 12.18 | 22.41 | 0.23 |

| 4-11 | 8 | 3200 | 5.56 | 2.13 | 10.28 | 34.34 | 0.23 |

| 4-12 | 8 | 3300 | 5.43 | 2.05 | 11.90 | 31.91 | 0.23 |

| 4-21 | 10 | 2900 | 5.41 | 3.07 | 12.04 | 37.96 | 0.25 |

| 4-22 | 10 | 3000 | 5.01 | 2.95 | 10.04 | 40.06 | 0.24 |

| 4-31 | 12 | 2800 | 5.21 | 4.24 | 14.73 | 32.70 | 0.27 |

| 4-32 | 12 | 2900 | 5.23 | 4.23 | 15.40 | 30.42 | 0.26 |

| 4-41 | 14 | 2700 | 5.43 | 4.49 | 13.85 | 35.25 | 0.29 |

| 4-42 | 14 | 2800 | 6.21 | 4.35 | 17.67 | 37.34 | 0.28 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, W.; Ma, P.; Jiang, G.; Wan, A. Mechanical Properties of Polypropylene Warp-Knitted Hernia Repair Mesh with Different Pull Densities. Polymers 2018, 10, 1322. https://doi.org/10.3390/polym10121322

Xu W, Ma P, Jiang G, Wan A. Mechanical Properties of Polypropylene Warp-Knitted Hernia Repair Mesh with Different Pull Densities. Polymers. 2018; 10(12):1322. https://doi.org/10.3390/polym10121322

Chicago/Turabian StyleXu, Wanli, Pibo Ma, Gaoming Jiang, and Ailan Wan. 2018. "Mechanical Properties of Polypropylene Warp-Knitted Hernia Repair Mesh with Different Pull Densities" Polymers 10, no. 12: 1322. https://doi.org/10.3390/polym10121322

APA StyleXu, W., Ma, P., Jiang, G., & Wan, A. (2018). Mechanical Properties of Polypropylene Warp-Knitted Hernia Repair Mesh with Different Pull Densities. Polymers, 10(12), 1322. https://doi.org/10.3390/polym10121322