Polymer Lasing in a Periodic-Random Compound Cavity

Abstract

1. Introduction

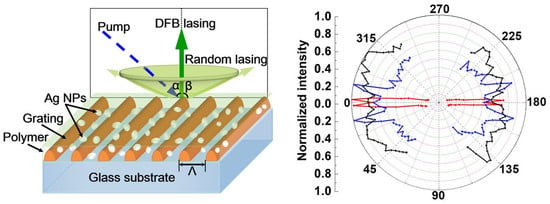

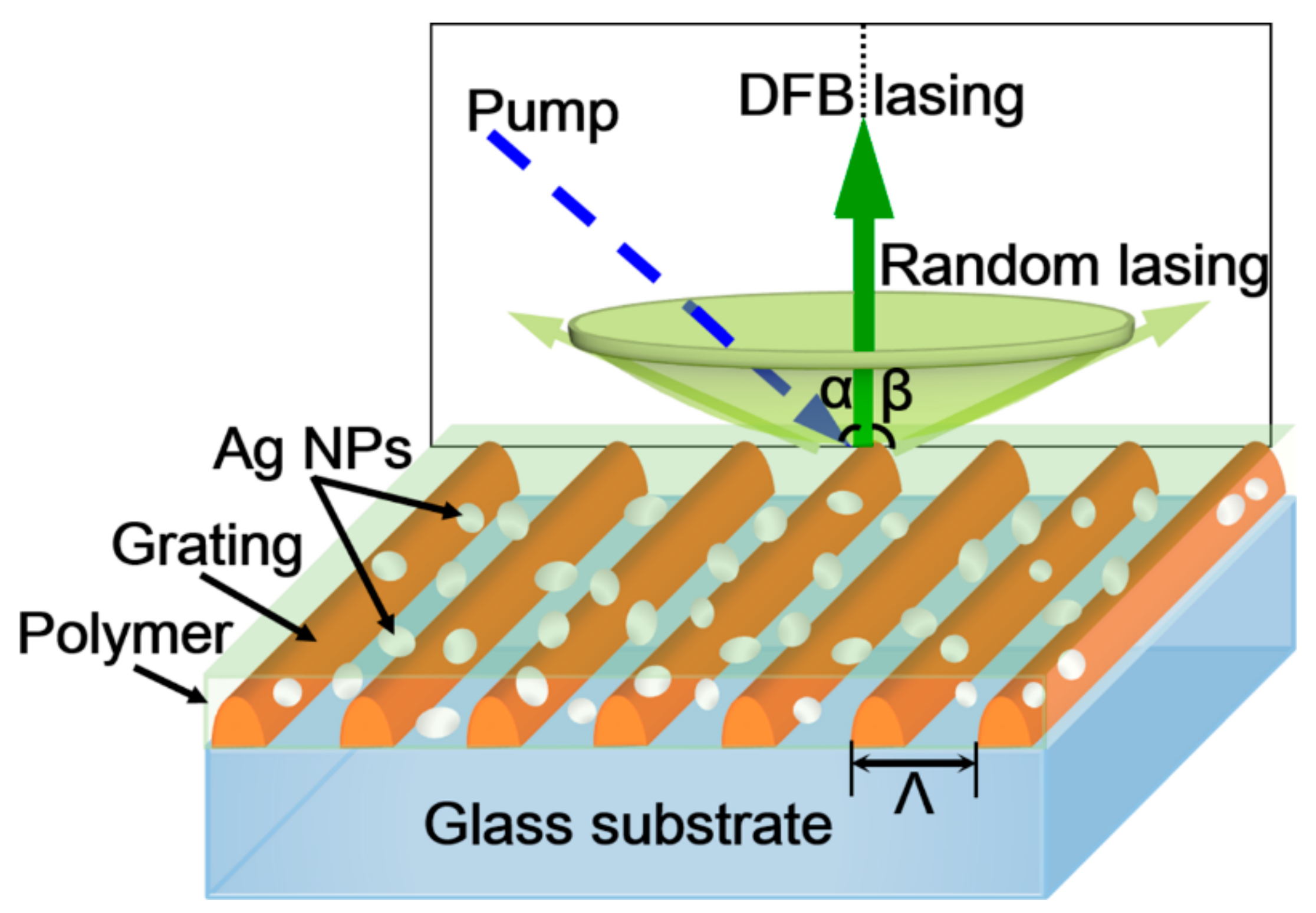

2. Fabrication of the Periodic-Random Compound Cavity

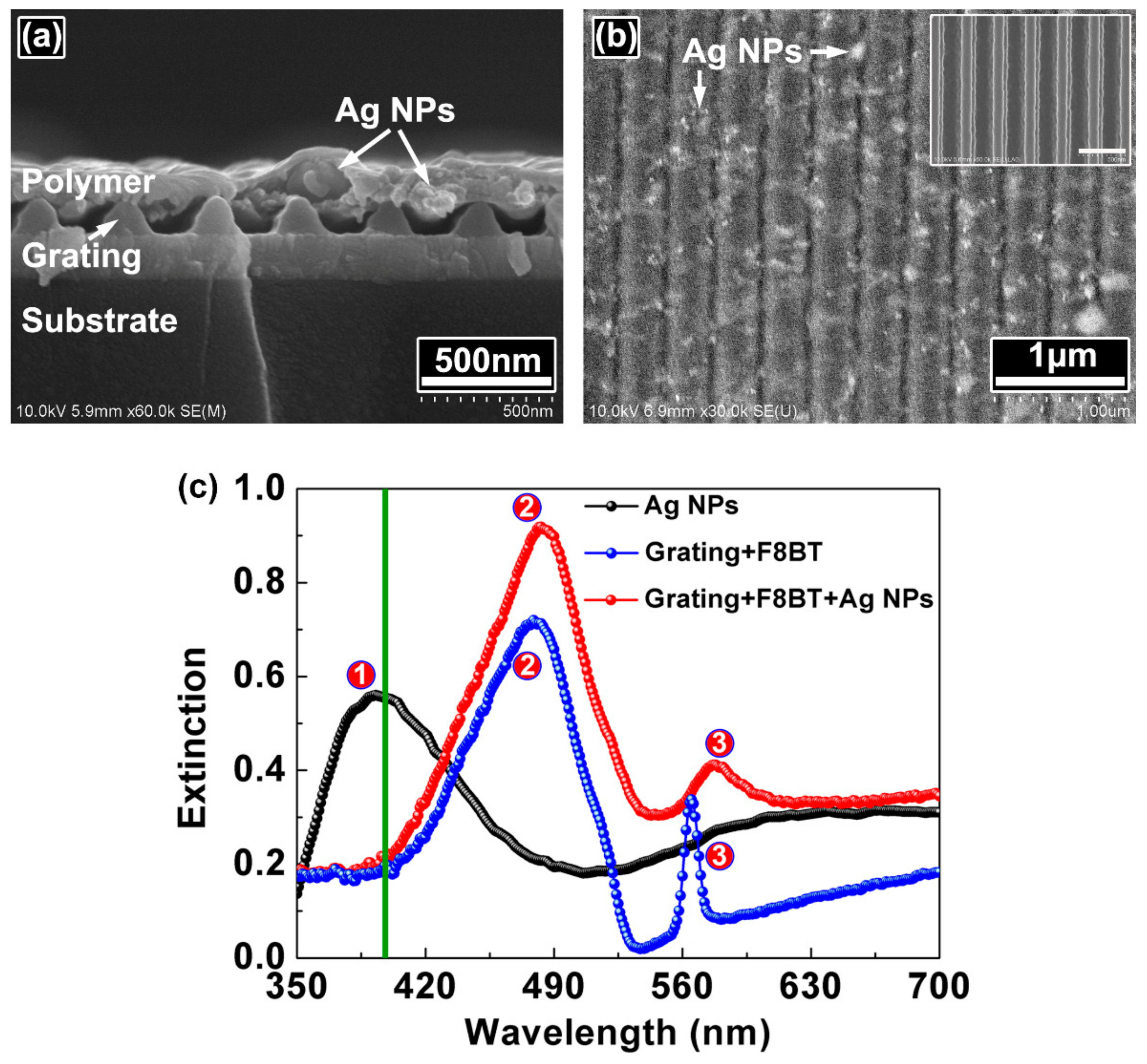

3. Spectra Characterization of the Periodic-Random Compound Cavity

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Stöferle, T.; Moll, N.; Wahlbrink, T.; Bolten, J.; Mollenhauer, T.; Scherf, U.; Mahrt, R.F. Ultracompact silicon/polymer laser with an absorption-insensitive nanophotonic resonator. Nano Lett. 2010, 10, 3675–3678. [Google Scholar] [CrossRef] [PubMed]

- Vannahme, C.; Klinkhammer, S.; Lemmer, U.; Mappes, T. Plastic lab-on-a-chip for fluorescence excitation with integrated organic semiconductor lasers. Opt. Express 2011, 19, 8179–8186. [Google Scholar] [CrossRef] [PubMed]

- Kuehne, A.J.C.; Gather, M.C. Organic lasers: Recent developments on materials, device geometries, and fabrication techniques. Chem. Rev. 2016, 116, 12823–12864. [Google Scholar] [CrossRef] [PubMed]

- Grivas, C. Optically pumped planar waveguide lasers: Part II: Gain media, laser systems, and applications. Prog. Quantum Electron. 2016, 45, 3–160. [Google Scholar] [CrossRef]

- Herrnsdorf, J.; Wang, Y.; McKendry, J.J.; Gong, Z.; Massoubre, D.; Guilhabert, B.; Tsiminis, G.; Turnbull, G.A.; Samuel, I.D.; Laurand, N. Micro-LED pumped polymer laser: A discussion of future pump sources for organic lasers. Laser Photonics Rev. 2013, 7, 1065–1078. [Google Scholar] [CrossRef]

- Deotare, P.B.; Mahony, T.S.; Bulović, V. Ultracompact low-threshold organic laser. ACS Nano 2014, 8, 11080–11085. [Google Scholar] [CrossRef] [PubMed]

- Yamashita, K.; Arimatsu, A.; Takeuchi, N.; Takayama, M.; Oe, K.; Yanagi, H. Multilayered solid-state organic laser for simultaneous multiwavelength oscillations. Appl. Phys. Lett. 2008, 93, 233303. [Google Scholar] [CrossRef]

- Foucher, C.; Guilhabert, B.; Kanibolotsky, A.L.; Skabara, P.J.; Laurand, N.; Dawson, M.D. RGB and white-emitting organic lasers on flexible glass. Opt. Express 2016, 24, 2273–2280. [Google Scholar] [CrossRef] [PubMed]

- Yamashita, K.; Takeuchi, N.; Oe, K.; Yanagi, H. Simultaneous RGB lasing from a single-chip polymer device. Opt. Lett. 2010, 35, 2451–2453. [Google Scholar] [CrossRef] [PubMed]

- Andrews, J.H.; Crescimanno, M.; Singer, K.D.; Baer, E. Melt-processed polymer multilayer distributed feedback lasers: Progress and prospects. J. Polym. Sci. Phys. 2014, 52, 251–271. [Google Scholar] [CrossRef]

- Yamashita, K.; Yanagi, H.; Oe, K. Array of a dye-doped polymer-based microlaser with multiwavelength emission. Opt. Lett. 2011, 36, 1875–1877. [Google Scholar] [CrossRef] [PubMed]

- Fan, F.; Turkdogan, S.; Liu, Z.; Shelhammer, D.; Ning, C.Z. A monolithic white laser. Nat. Nanotechnol. 2015, 10, 796–803. [Google Scholar] [CrossRef] [PubMed]

- Huang, W.; Pu, D.; Qiao, W.; Wan, W.; Liu, Y.; Ye, Y.; Wu, S.; Chen, L. Tunable multi-wavelength polymer laser based on a triangular-lattice photonic crystal structure. J. Phys. D 2016, 49, 335103. [Google Scholar] [CrossRef]

- Zhai, T.; Wang, Y.; Chen, L.; Zhang, X. Direct writing of tunable multi-wavelength polymer lasers on a flexible substrate. Nanoscale 2015, 7, 12312–12317. [Google Scholar] [CrossRef] [PubMed]

- Zhai, T.; Wu, X.; Tong, F.; Li, S.; Wang, M.; Zhang, X. Multi-wavelength lasing in a beat structure. Appl. Phys. Lett. 2016, 109, 261906. [Google Scholar] [CrossRef]

- Zhai, T.; Zhang, X.; Pang, Z.; Dou, F. Direct writing of polymer lasers using interference ablation. Adv. Mater. 2011, 23, 1860–1864. [Google Scholar] [CrossRef] [PubMed]

- Cao, H.; Zhao, Y.; Ho, S.; Seelig, E.; Wang, Q.; Chang, R. Random laser action in semiconductor powder. Phys. Rev. Lett. 1999, 82, 2278–2281. [Google Scholar] [CrossRef]

- Wiersma, D. The physics and applications of random lasers. Nat. Phys. 2008, 4, 359–367. [Google Scholar] [CrossRef]

- Zhai, T.; Zhang, X.; Pang, Z.; Su, X.; Liu, H.; Feng, S.; Wang, L. Random laser based on waveguided plasmonic gain channels. Nano Lett. 2011, 11, 4295–4298. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Zhang, J.; Pang, Z. Numerical and experimental investigation into the subsequent thermal cycling during selective laser melting of multi-layer 316L stainless. Opt. Laser Technol. 2018, 98, 23–32. [Google Scholar] [CrossRef]

- Tomazio, N.B.; Sciuti, L.F.; Almeida, G.F.B.; Boni, L.; Mendonca, C.R. Solid-state random microlasers fabricated via femtosecond laser writing. Sci. Rep. 2018, 8, 13561. [Google Scholar] [CrossRef] [PubMed]

- Consoli, A.; Lopez, C. Emission regimes of random lasers with spatial localized feedback. Opt. Express 2016, 24, 10912–10920. [Google Scholar] [CrossRef] [PubMed]

- Chang, S.-H.; Cao, H.; Ho, S.T. Cavity formation and light propagation in partially ordered and completely random one-dimensional systems. IEEE J. Quantum Electron. 2003, 39, 364–374. [Google Scholar] [CrossRef]

- Zhai, T.; Zhang, X.; Pang, Z. Polymer laser based on active waveguide grating structures. Opt. Express 2011, 19, 6487–6492. [Google Scholar] [CrossRef] [PubMed]

- Dong, T.; Chen, W.; Wang, C.; Chen, C.; Chen, C.; Lin, M.; Song, J.; Chen, I.; Kao, T. One-step synthesis of uniform silver nanoparticles capped by saturated decanoate: Direct spray printing ink to form metallic silver films. Phys. Chem. Chem. Phys. 2009, 11, 6269–6275. [Google Scholar] [CrossRef] [PubMed]

- Li, S.; Wang, L.; Zhai, T.; Chen, L.; Wang, M.; Wang, Y.; Tong, F.; Wang, Y.; Zhang, X. Plasmonic random lasing in polymer fiber. Opt. Express 2016, 24, 12748–12754. [Google Scholar] [CrossRef] [PubMed]

- Zhai, T.; Xu, Z.; Li, S.; Zhang, X. Red-green-blue plasmonic random laser. Opt. Express 2017, 25, 2100–2106. [Google Scholar] [CrossRef] [PubMed]

- Zhai, T.; Zhang, X. Gain-and feedback-channel matching in lasers based on radiative-waveguide gratings. Appl. Phys. Lett. 2012, 101, 143507. [Google Scholar] [CrossRef]

- Turnbull, G.; Andrew, P.; Jory, M.; Barnes, W.L.; Samuel, I. Relationship between photonic band structure and emission characteristics of a polymer distributed feedback laser. Phys. Rev. B 2001, 64, 125122. [Google Scholar] [CrossRef]

- Whitworth, G.L.; Zhang, S.; Stevenson, J.R.Y.; Ebenhoch, B.; Samuel, I.D.W.; Turnbull, G.A. Solvent immersion nanoimprint lithography of fluorescent conjugated polymers. Appl. Phys. Lett. 2015, 107, 163301. [Google Scholar] [CrossRef]

- Gianordoli, S.; Hainberger, R.; Köck, A.; Finger, N.; Gornik, E.; Hanke, C.; Korte, L. Optimization of the emission characteristics of light emitting diodes by surface plasmons and surface waveguide modes. Appl. Phys. Lett. 2000, 77, 2295–2297. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhai, T.; Wu, X.; Li, S.; Liang, S.; Niu, L.; Wang, M.; Feng, S.; Liu, H.; Zhang, X. Polymer Lasing in a Periodic-Random Compound Cavity. Polymers 2018, 10, 1194. https://doi.org/10.3390/polym10111194

Zhai T, Wu X, Li S, Liang S, Niu L, Wang M, Feng S, Liu H, Zhang X. Polymer Lasing in a Periodic-Random Compound Cavity. Polymers. 2018; 10(11):1194. https://doi.org/10.3390/polym10111194

Chicago/Turabian StyleZhai, Tianrui, Xiaofeng Wu, Songtao Li, Shuyan Liang, Lianze Niu, Meng Wang, Shengfei Feng, Hongmei Liu, and Xinping Zhang. 2018. "Polymer Lasing in a Periodic-Random Compound Cavity" Polymers 10, no. 11: 1194. https://doi.org/10.3390/polym10111194

APA StyleZhai, T., Wu, X., Li, S., Liang, S., Niu, L., Wang, M., Feng, S., Liu, H., & Zhang, X. (2018). Polymer Lasing in a Periodic-Random Compound Cavity. Polymers, 10(11), 1194. https://doi.org/10.3390/polym10111194