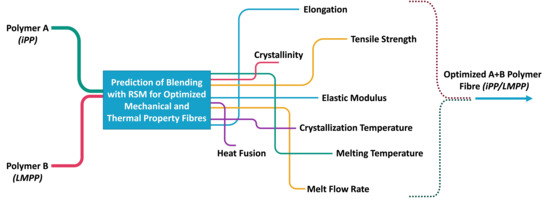

Optimization of Mechanical and Thermal Properties of iPP and LMPP Blend Fibres by Surface Response Methodology

Abstract

:1. Introduction

Response Surface Methodology

2. Materials and Methods

2.1. Materials and Sample Preparations

2.2. Characterization of Mechanical and Thermal Properties

2.3. Methods

Model Development for Surface Response Methodology (RSM)

3. Results and Discussion

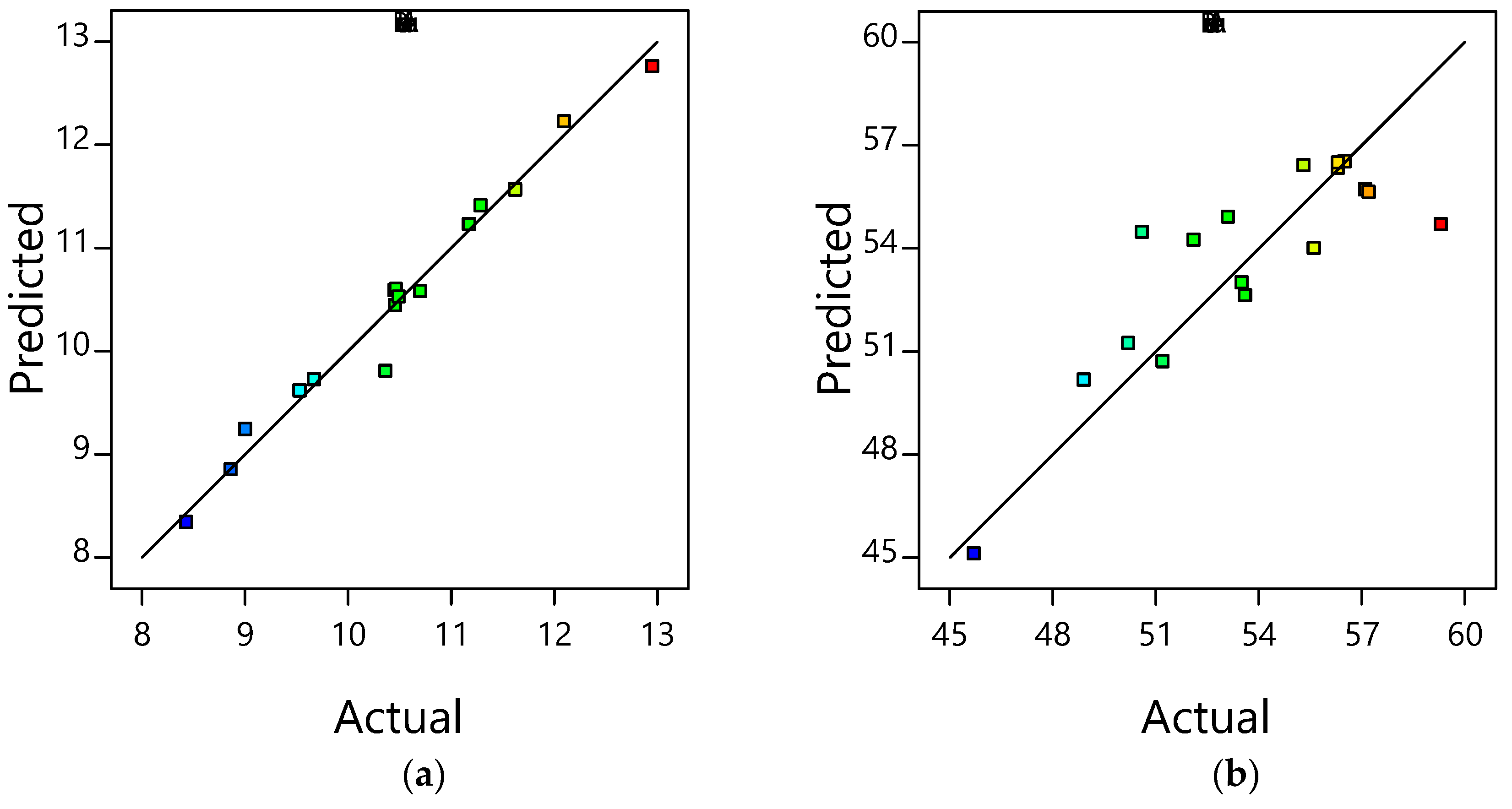

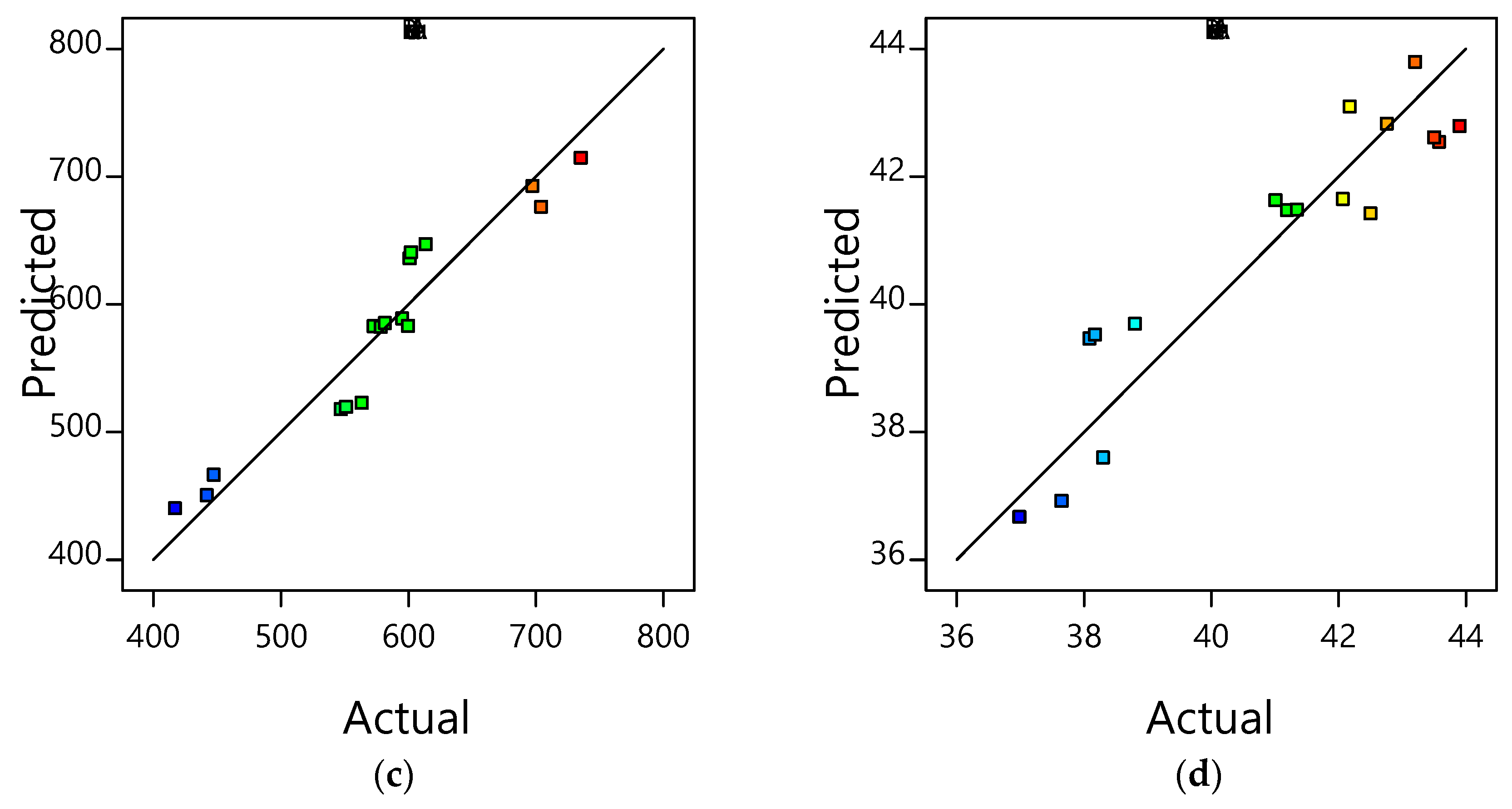

3.1. Regression Models Development

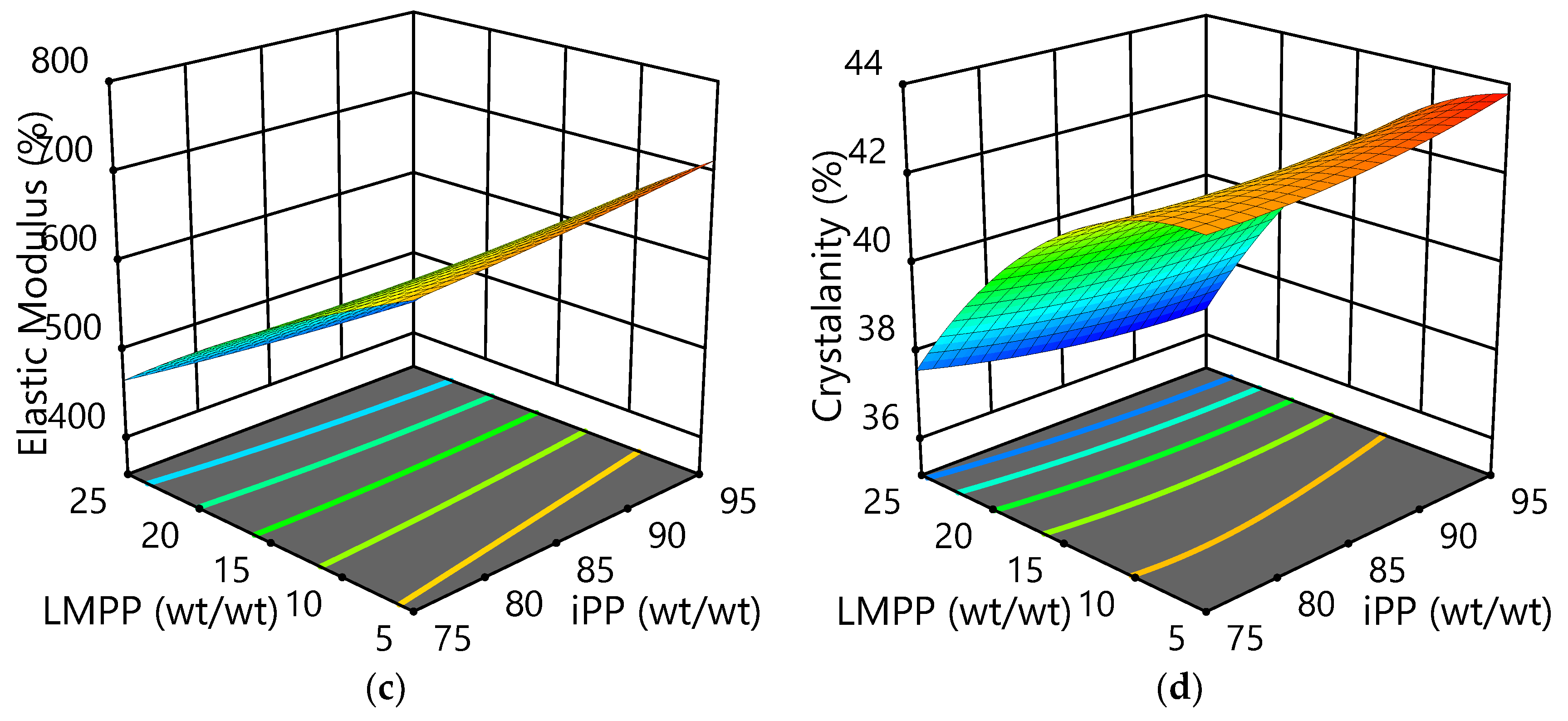

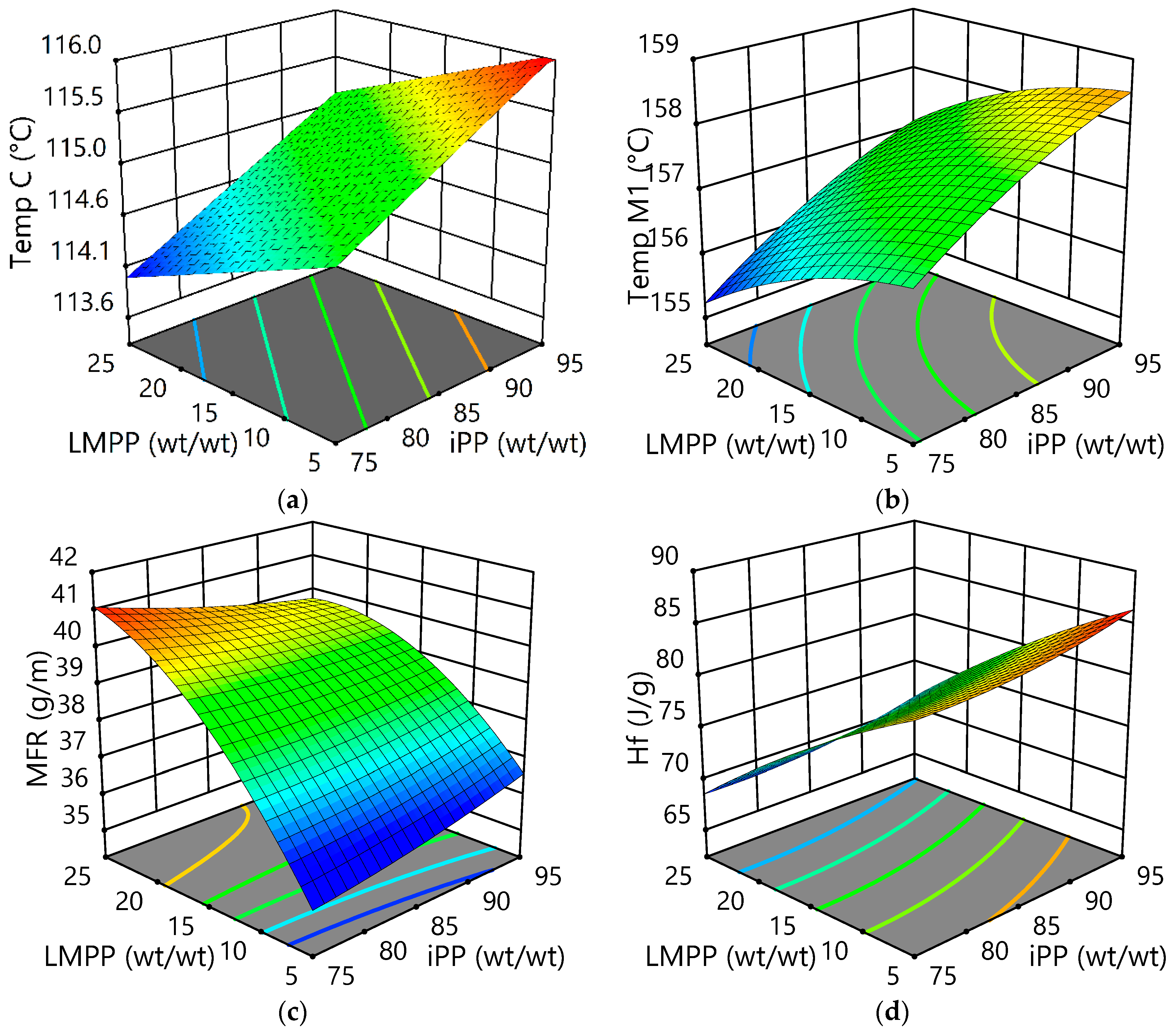

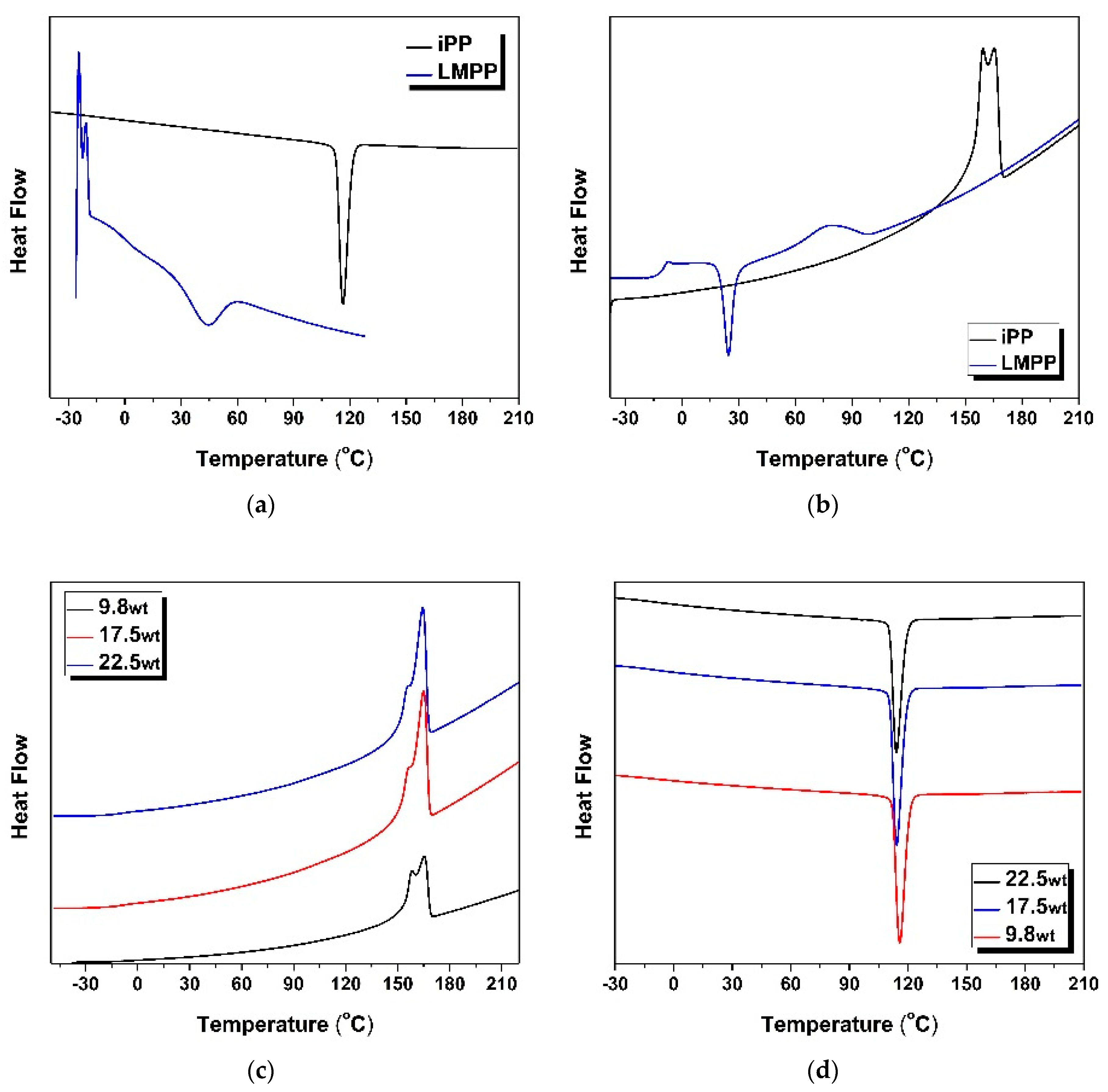

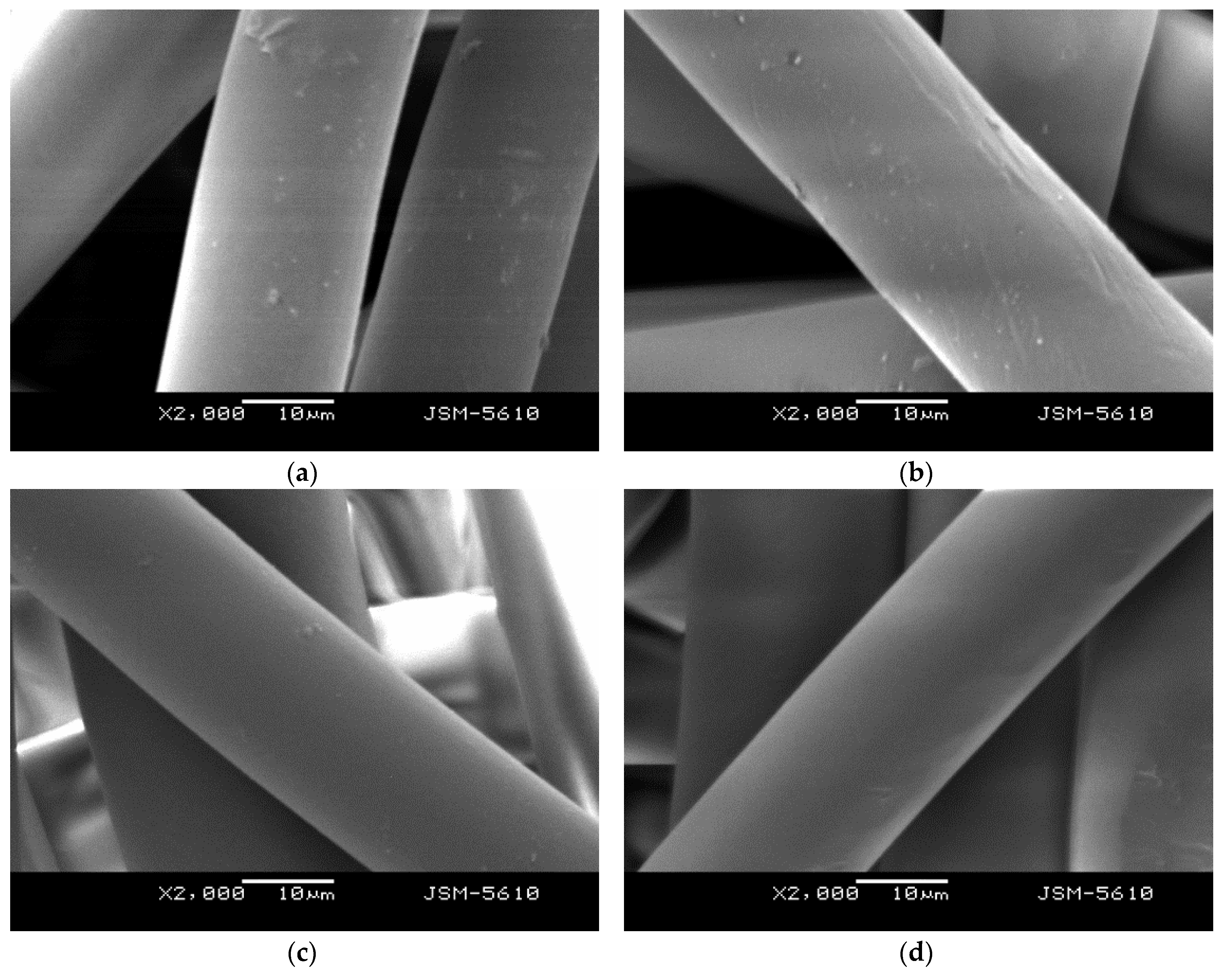

3.2. Effects of LMPP on Thermal and Mechanical Properties

3.3. Optimization of Thermal and Mechanical Responses

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Hussain, M.; Zhu, F.; Zhu, F.; Yu, B.; Han, J.; Memon, H.; Yasin, S. LMPP Effects on Morphology, Crystallization, Thermal and Mechanical Properties of iPP/LMPP Blend Fibres. Fibres Text. East. Eur. 2018, 26, 26–31. [Google Scholar] [CrossRef]

- Leong, Y.W.; Ishak, Z.A.; Ariffin, A. Mechanical and thermal properties of talc and calcium carbonate filled polypropylene hybrid composites. J. Appl. Polym. Sci. 2004, 91, 3327–3336. [Google Scholar] [CrossRef]

- Jašo, V.; Milić, J.; Divjaković, V.; Petrović, Z.S. Novel elastomeric polyurethane fibers modified with polypropylene microfibers. Eur. Polym. J. 2013, 49, 3947–3955. [Google Scholar] [CrossRef]

- Kanai, T.; Egoshi, K.; Ohno, S.; Takebe, T. The evaluation of stretchability and its applications for biaxially oriented polypropylene film. Adv. Polym. Technol. 2017. [Google Scholar] [CrossRef]

- Minami, Y.; Takebe, T.; Kanamaru, M.; Okamoto, T. Development of low isotactic polyolefin. Polym. J. 2015, 47, 227. [Google Scholar] [CrossRef]

- Coelho, A.M.; de Carvalho, G. Methodology for optimization of polymer blends composition. In Principal Component Analysis-Engineering Applications; InTech: London, UK, 2012. [Google Scholar]

- Tang, T.; Lei, Z.; Zhang, X.; Chen, H.; Huang, B. Studies on simultaneous crystallization of polypropylene/nylon 12 blends. Polymer 1995, 36, 5061–5063. [Google Scholar] [CrossRef]

- Li, H.; Wang, J.; He, L.; Nan, F.; Wang, F.; Yang, W.; Zhang, M.; Sun, T.; Huang, Q.; Yi, J. Study on hydrogen sensitivity of Ziegler–Natta catalysts with novel cycloalkoxy silane compounds as external electron donor. Polymers 2016, 8, 433. [Google Scholar] [CrossRef]

- Coleman, M.M.; Graf, J.F.; Painter, P.C. Specific Interactions and the Miscibility of Polymer Blends; Technomic: Lancaster, PA, USA, 1991. [Google Scholar]

- Cho, K.; Li, F.; Choi, J. Crystallization and melting behavior of polypropylene and maleated polypropylene blends. Polymer 1999, 40, 1719–1729. [Google Scholar] [CrossRef]

- Malinov, S.; Sha, W. Software products for modelling and simulation in materials science. Comput. Mater. Sci. 2003, 28, 179–198. [Google Scholar] [CrossRef]

- Yasin, S.; Parag, B.; Nemeshwaree, B.; Giorgio, R. Optimizing Organophosphorus Fire Resistant Finish for Cotton Fabric Using Box-Behnken Design. Int. J. Environ. Res. 2016, 10, 313–320. [Google Scholar]

- Yasin, S.; Curti, M.; Behary, N.; Perwuelz, A.; Giraud, S.; Rovero, G.; Guan, J.; Chen, G. Process Optimization of Eco-Friendly Flame Retardant Finish For Cotton Fabric: A Response Surface Methodology Approach. Surf. Rev. Lett. 2017, 24, 1750114. [Google Scholar] [CrossRef]

- Chitichotpanya, P.; Pisitsak, P.; Chitichotpanya, C. Sericin–copper-functionalized silk fabrics for enhanced ultraviolet protection and antibacterial properties using response surface methodology. Text. Res. J. 2018. [Google Scholar] [CrossRef]

- Wu, C.-Y.; Lui, W.-B.; Peng, J. Optimization of Extrusion Variables and Maleic Anhydride Content on Biopolymer Blends Based on Poly(hydroxybutyrate-co-hydroxyvalerate)/Poly(vinyl acetate) with Tapioca Starch. Polymers 2018, 10, 827. [Google Scholar] [CrossRef]

- Khan, M.J.H.; Hussain, M.A.; Mujtaba, I.M. Developed hybrid model for propylene polymerisation at optimum reaction conditions. Polymers 2016, 8, 47. [Google Scholar] [CrossRef]

- Ghasemi, F.A.; Ghasemi, I.; Menbari, S.; Ayaz, M.; Ashori, A. Optimization of mechanical properties of polypropylene/talc/graphene composites using response surface methodology. Polym. Test. 2016, 53, 283–292. [Google Scholar] [CrossRef]

- Spoerk, M.; Gonzalez-Gutierrez, J.; Lichal, C.; Cajner, H.; Berger, G.R.; Schuschnigg, S.; Cardon, L.; Holzer, C. Optimisation of the Adhesion of Polypropylene-Based Materials during Extrusion-Based Additive Manufacturing. Polymers 2018, 10, 490. [Google Scholar] [CrossRef]

- Noordin, M.Y.; Venkatesh, V.C.; Sharif, S.; Elting, S.; Abdullah, A. Application of response surface methodology in describing the performance of coated carbide tools when turning AISI 1045 steel. J. Mater. Process. Technol. 2004, 145, 46–58. [Google Scholar] [CrossRef] [Green Version]

- Box, G.E.; Wilson, K.B. On the experimental attainment of optimum conditions. In Breakthroughs in Statistics; Springer: New York, NY, USA, 1992; pp. 270–310. [Google Scholar]

- Box, G.E. Robustness in the strategy of scientific model building. In Robustness in Statistics; Elsevier: New York, NY, USA, 1979; pp. 201–236. [Google Scholar]

- Gunst, R.F. Response Surface Methodology: Process and Product Optimization Using Designed Experiments; Taylor & Francis Group: Park Drive, UK, 1996. [Google Scholar]

- Güllü, H.; Fedakar, H.İ. Response surface methodology for optimization of stabilizer dosage rates of marginal sand stabilized with Sludge Ash and fiber based on UCS performances. KSCE J. Civ. Eng. 2017, 21, 1717–1727. [Google Scholar] [CrossRef]

- Olgun, M. The effects and optimization of additives for expansive clays under freeze–thaw conditions. Cold Reg. Sci. Technol. 2013, 93, 36–46. [Google Scholar] [CrossRef]

- Bezerra, M.A.; Santelli, R.E.; Oliveira, E.P.; Villar, L.S.; Escaleira, L.A. Response surface methodology (RSM) as a tool for optimization in analytical chemistry. Talanta 2008, 76, 965–977. [Google Scholar] [CrossRef] [PubMed]

- Design-Expert® Software (Version 11); Stat-Ease, Inc.: Minneapolis, MN, USA, 2018.

- Nazarenko, S.; Meneghetti, P.; Julmon, P.; Olson, B.G.; Qutubuddin, S. Gas barrier of polystyrene montmorillonite clay nanocomposites: Effect of mineral layer aggregation. J. Polym. Sci. Part B Polym. Phys. 2007, 45, 1733–1753. [Google Scholar] [CrossRef]

- Cui, F.J.; Li, Y.; Xu, Z.H.; Xu, H.Y.; Sun, K.; Tao, W.Y. Optimization of the medium composition for production of mycelial biomass and exo-polymer by Grifola frondosa GF9801 using response surface methodology. Bioresour. Technol. 2006, 97, 1209–1216. [Google Scholar] [CrossRef] [PubMed]

- Kanai, T.; Kohri, Y.; Takebe, T. Theoretical analysis of the spunbond process and its applications for polypropylenes. AIP Conf. Proc. 2016, 1779, 120001. [Google Scholar] [Green Version]

- Chadwick, J.C.; van der Burgt, F.P.; Rastogi, S.; Busico, V.; Cipullo, R.; Talarico, G.; Heere, J.J. Influence of Ziegler- Natta Catalyst Regioselectivity on Polypropylene Molecular Weight Distribution and Rheological and Crystallization Behavior. Macromolecules 2004, 37, 9722–9727. [Google Scholar] [CrossRef]

- Kohri, Y.; Takebe, T.; Minami, Y.; Kanai, T.; Takarada, W.; Kikutani, T. Structure and Properties of Low-Isotacticity Polypropylene Elastomeric Fibers Prepared by Sheath-Core Bicomponent Spinning. Sen’i Gakkaishi 2014, 70, 203–212. [Google Scholar] [CrossRef] [Green Version]

- Kohri, Y.; Takebe, T.; Minami, Y.; Kanai, T.; Takarada, W.; Kikutani, T. Structure and properties of low-isotacticity polypropylene elastomeric fibers prepared by sheath-core bicomponent spinning: Effect of localization of high-isotacticity component near the fiber surface. J. Polym. Eng. 2014, 35, 277–285. [Google Scholar] [CrossRef]

- Yin, S.; Wang, S.; Rials, T.G.; Kit, K.M.; Hansen, M.G. Polypropylene composites filled with steam-exploded wood fibers from beetle-killed loblolly pine by compression-molding. Wood Fiber Sci. 2007, 39, 95–108. [Google Scholar]

- Gui, Q.; Xin, Z.; Zhu, W.; Dai, G. Effects of an organic phosphorus nucleating agent on crystallization behaviors and mechanical properties of poly(propylene). J. Appl. Polym. Sci. 2003, 88, 297–301. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, R.; Huang, Y.; Lei, J.; Chen, Y.-H.; Tang, J.; Li, Z.-M. Efficient utilization of atactic polypropylene in its isotactic polypropylene blends via “structuring” processing. Ind. Eng. Chem. Res. 2014, 53, 10144–10154. [Google Scholar] [CrossRef]

- Choi, P.; Mattice, W.L. Molecular origin of demixing, prior to crystallization, of atactic polypropylene/isotactic polypropylene blends upon cooling from the melt. J. Chem. Phys. 2004, 121, 8647–8651. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Lei, J.; Chen, Y.; Chen, J.; Ji, X.; Tang, J.; Li, Z.-M. Tailored structure and properties of injection-molded atactic polypropylene/isotactic polypropylene blend. ACS Sustain. Chem. Eng. 2013, 1, 937–949. [Google Scholar] [CrossRef]

- Zhang, Z.-C.; Deng, L.; Lei, J.; Li, Z.-M. Isotactic polypropylene reinforced atactic polypropylene by formation of shish-kebab superstructure. Polymer 2015, 78, 120–133. [Google Scholar] [CrossRef]

- Chen, J.-H.; Tsai, F.-C.; Nien, Y.-H.; Yeh, P.-H. Isothermal crystallization of isotactic polypropylene blended with low molecular weight atactic polypropylene. Part I. Thermal properties and morphology development. Polymer 2005, 46, 5680–5688. [Google Scholar] [CrossRef]

- Nassiri, H.; Arabi, H.; Hakim, S.; Bolandi, S. Polymerization of propylene with Ziegler–Natta catalyst: Optimization of operating conditions by response surface methodology (RSM). Polym. Bull. 2011, 67, 1393–1411. [Google Scholar] [CrossRef]

- Singh, R.; Kumar, R.; Feo, L.; Fraternali, F. Friction welding of dissimilar plastic/polymer materials with metal powder reinforcement for engineering applications. Compos. Part B Eng. 2016, 101, 77–86. [Google Scholar] [CrossRef]

| Materials | Type | Catalyst | Mw1 | Mw/Mn2 | Density (kg/m3) | MFR 3 (g/10 min) | TM4 (°C) |

|---|---|---|---|---|---|---|---|

| iPP | Isotactic | Ziegler Natta | 200,000 | 3.5 | 900 | 36 | 165.5 |

| LMPP | Atactic | Metallocene | 130,000 | 2 | 870 | 50 | 79.1 |

| Run | iPP (wt/wt) | LMPP (wt/wt) | Elongation (%) | Tensile Strength (MPa) | Elastic Modulus (MPa) | Crystallinity (%) | Crystallization Temperature-TC (°C) | First Melting Temperature-TM1 (°C) | Melt Flow Rate-MFR (g/10 min) | Heat Fusion-Hf (J/g) |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 75 | 5 | 8.4 | 45.7 | 704.1 | 42.7 | 114.7 | 156.8 | 36.1 | 82.4 |

| 2 | 90 | 10 | 10.3 | 59.3 | 613.5 | 43.9 | 115.8 | 159.1 | 37.2 | 81.9 |

| 3 | 90 | 15 | 10.4 | 57.1 | 581.5 | 41.3 | 115.2 | 157.5 | 40.2 | 77.8 |

| 4 | 85 | 25 | 12.0 | 56.3 | 441.8 | 37.6 | 114.6 | 156.4 | 41.2 | 69.3 |

| 5 | 80 | 15 | 10.4 | 53.6 | 578.2 | 41.1 | 114.7 | 156.7 | 39.3 | 77.6 |

| 6 | 75 | 15 | 10.4 | 48.9 | 572.7 | 41.0 | 114.5 | 156.3 | 39.1 | 77.3 |

| 7 | 80 | 10 | 9.5 | 51.2 | 600.9 | 43.5 | 114.9 | 157.0 | 36.8 | 80.0 |

| 8 | 95 | 25 | 11.6 | 56.5 | 416.9 | 36.9 | 115.1 | 157.2 | 38.8 | 71.7 |

| 9 | 85 | 5 | 8.8 | 50.2 | 697.4 | 42.1 | 115.3 | 157.8 | 36.1 | 84.6 |

| 10 | 85 | 10 | 9.6 | 53.5 | 601.9 | 43.5 | 115.1 | 157.4 | 36.9 | 80.5 |

| 11 | 90 | 20 | 11.1 | 55.3 | 547.0 | 38.0 | 115.0 | 157.1 | 40.1 | 74.3 |

| 12 | 85 | 20 | 11.2 | 57.2 | 551.0 | 38.1 | 114.8 | 156.7 | 39.7 | 73.2 |

| 13 | 85 | 15 | 10.7 | 50.6 | 599.7 | 42.5 | 115.3 | 157.4 | 39.4 | 77.4 |

| 14 | 95 | 5 | 9.0 | 53.1 | 735.2 | 43.2 | 116.0 | 158.2 | 36.5 | 86.5 |

| 15 | 95 | 15 | 10.4 | 56.3 | 595.1 | 42.0 | 115.5 | 158.0 | 39.8 | 79.6 |

| 16 | 75 | 25 | 12.9 | 55.6 | 447.3 | 38.3 | 114.0 | 155.3 | 41.1 | 68.3 |

| 17 | 80 | 20 | 11.6 | 52.1 | 563.4 | 38.8 | 114.2 | 156.5 | 39.5 | 72.8 |

| * C | 100 | 0 | 2.2 | 52.8 | 753.7 | 40.2 | 116.3 | 159.1 | 34.8 | 91.4 |

| * C | 0 | 100 | 9.5 | 25.3 | 89.4 | 16.5 | 40.1 | 79.1 | 49.9 | 20.6 |

| Experiment | iPP (wt/wt) | LMPP (wt/wt) | Elongation (%) | Tensile Strength (MPa) | Elastic Modulus (MPa) | Crystallinity (%) | Crystallization Temperature-TC (°C) | First melting Temperature-TM1 (°C) | Melt Flow Rate-MFR (g/10 min) | Heat Fusion-Hf (J/g) |

|---|---|---|---|---|---|---|---|---|---|---|

| 1-Predicted | 77.5 | 22.5 | 12.15 | 53.33 | 519.70 | 37.97 | 114.24 | 155.93 | 40.37 | 70.77 |

| 1-Actual | 77.5 | 22.5 | 12.90 | 54.85 | 510.10 | 38.23 | 114.10 | 155.23 | 41.56 | 68.90 |

| 2-Predicted | 91.2 | 9.80 | 09.78 | 53.15 | 616.31 | 43.99 | 115.61 | 158.11 | 37.52 | 82.30 |

| 2-Actual | 91.2 | 9.80 | 10.59 | 55.43 | 614.24 | 43.23 | 115.31 | 157.91 | 37.12 | 81.99 |

| 3-Predicted | 82.5 | 17.5 | 11.00 | 51.98 | 576.36 | 39.90 | 114.70 | 165.05 | 39.25 | 75.15 |

| 3-Actual | 82.5 | 17.5 | 10.79 | 50.51 | 597.94 | 42.12 | 115.24 | 159.96 | 39.51 | 77.01 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yasin, S.; Sun, D.; Memon, H.; Zhu, F.; Jian, H.; Bin, Y.; Mingbo, M.; Hussain, M. Optimization of Mechanical and Thermal Properties of iPP and LMPP Blend Fibres by Surface Response Methodology. Polymers 2018, 10, 1135. https://doi.org/10.3390/polym10101135

Yasin S, Sun D, Memon H, Zhu F, Jian H, Bin Y, Mingbo M, Hussain M. Optimization of Mechanical and Thermal Properties of iPP and LMPP Blend Fibres by Surface Response Methodology. Polymers. 2018; 10(10):1135. https://doi.org/10.3390/polym10101135

Chicago/Turabian StyleYasin, Sohail, Danmei Sun, Hafeezullah Memon, Feichao Zhu, Han Jian, Yu Bin, Ma Mingbo, and Munir Hussain. 2018. "Optimization of Mechanical and Thermal Properties of iPP and LMPP Blend Fibres by Surface Response Methodology" Polymers 10, no. 10: 1135. https://doi.org/10.3390/polym10101135

APA StyleYasin, S., Sun, D., Memon, H., Zhu, F., Jian, H., Bin, Y., Mingbo, M., & Hussain, M. (2018). Optimization of Mechanical and Thermal Properties of iPP and LMPP Blend Fibres by Surface Response Methodology. Polymers, 10(10), 1135. https://doi.org/10.3390/polym10101135