A 3D Printable Thermal Energy Storage Crystalline Gel Using Mask-Projection Stereolithography

Abstract

1. Introduction

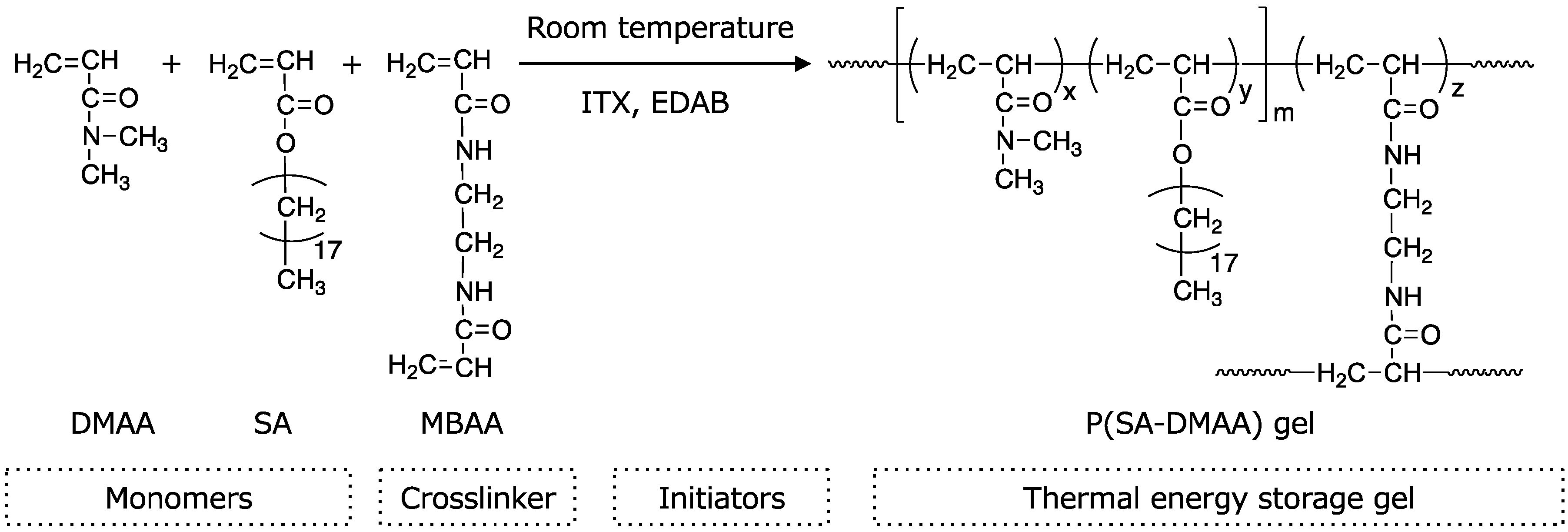

2. Materials and Methods

2.1. Materials

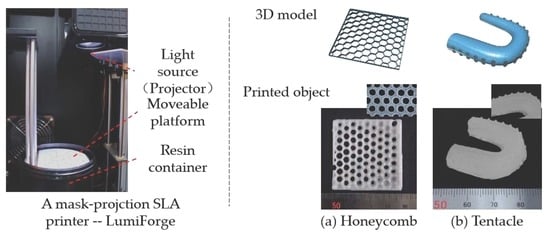

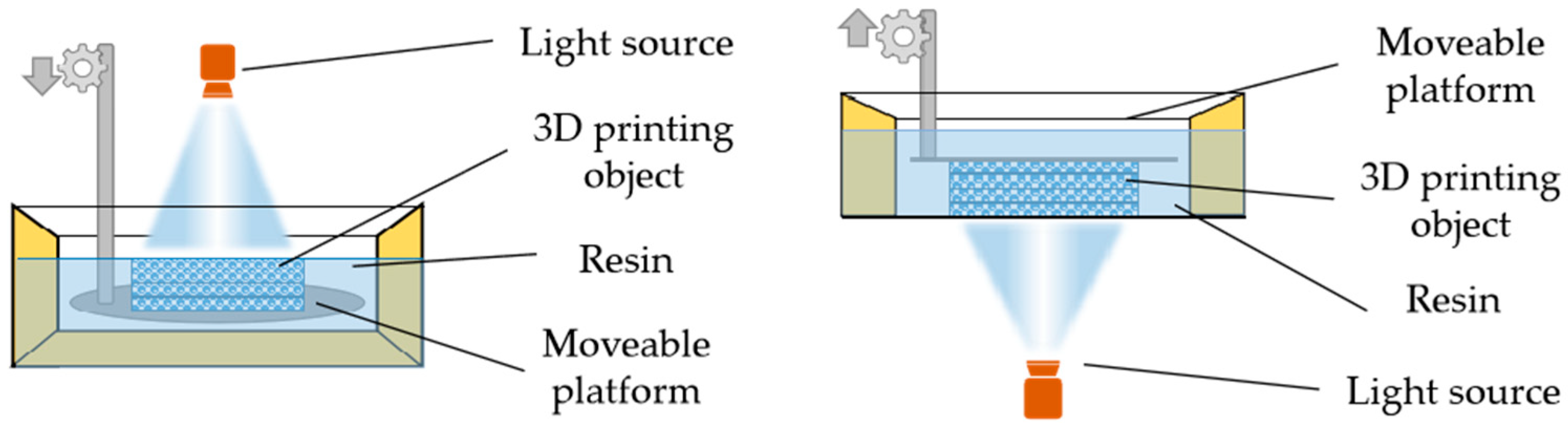

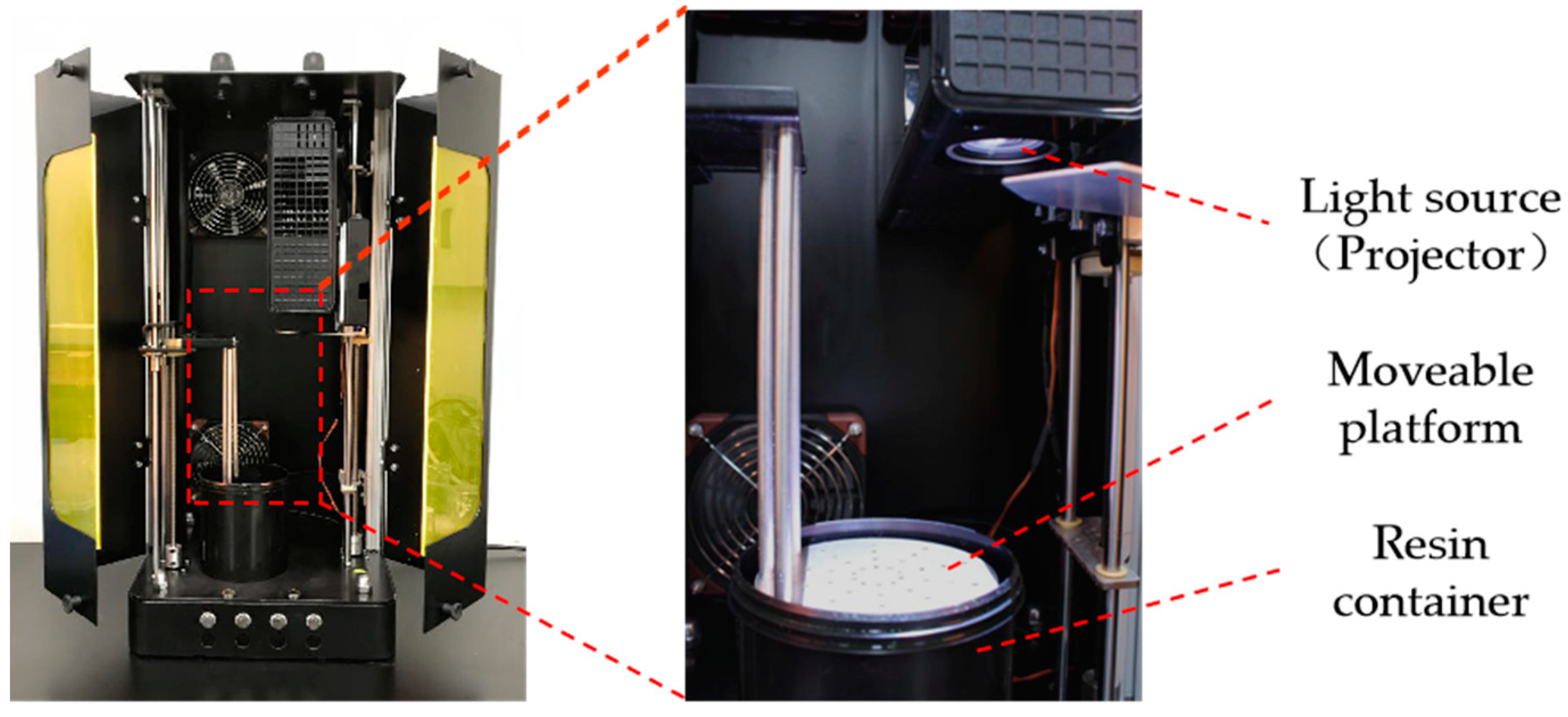

2.2. 3D Printing

2.3. Preparation of Gel Sheets by Conventional Mold

2.4. Characterization of 3D Printed P(SA-DMAA) Gels

2.4.1. Fourier Transform Infrared Spectrometer (FTIR)

2.4.2. Wide-Angle X-ray Scattering (WAXS)

2.4.3. Differential Scanning Calorimetry (DSC)

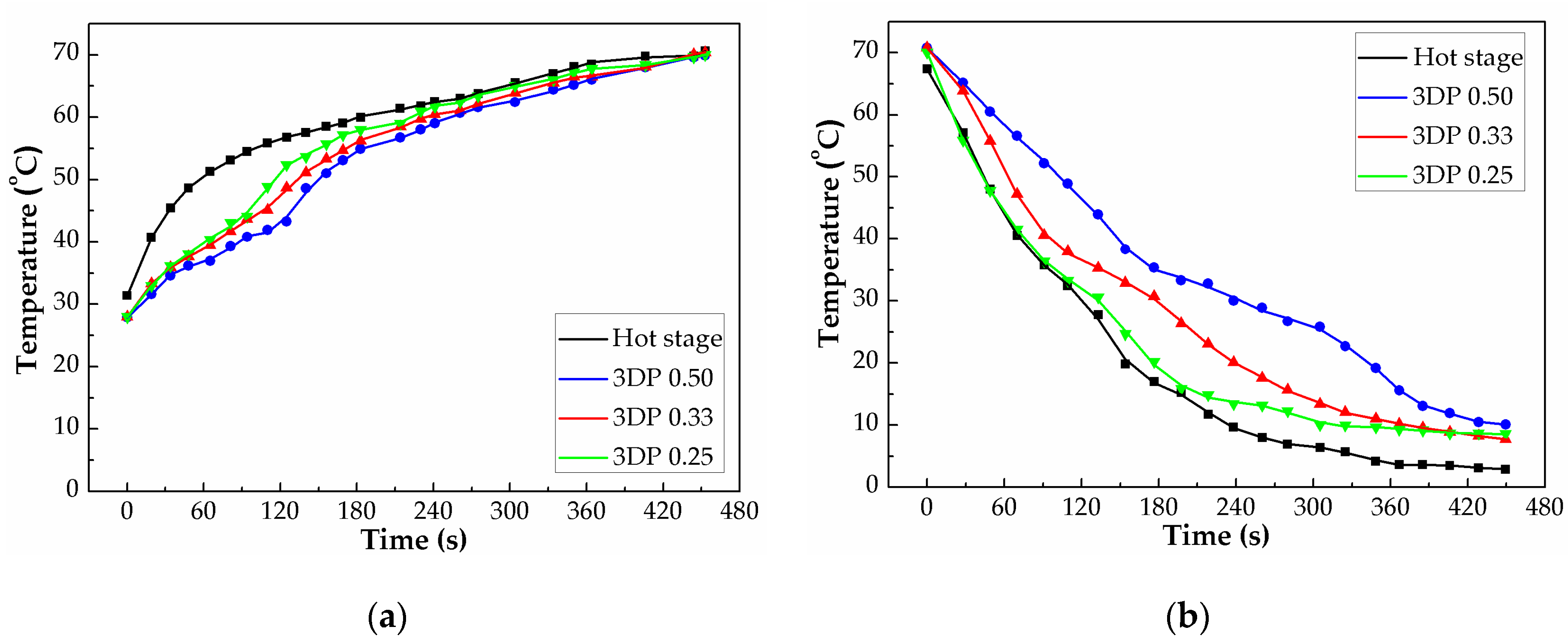

2.4.4. Infrared Thermography

3. Results and Discussion

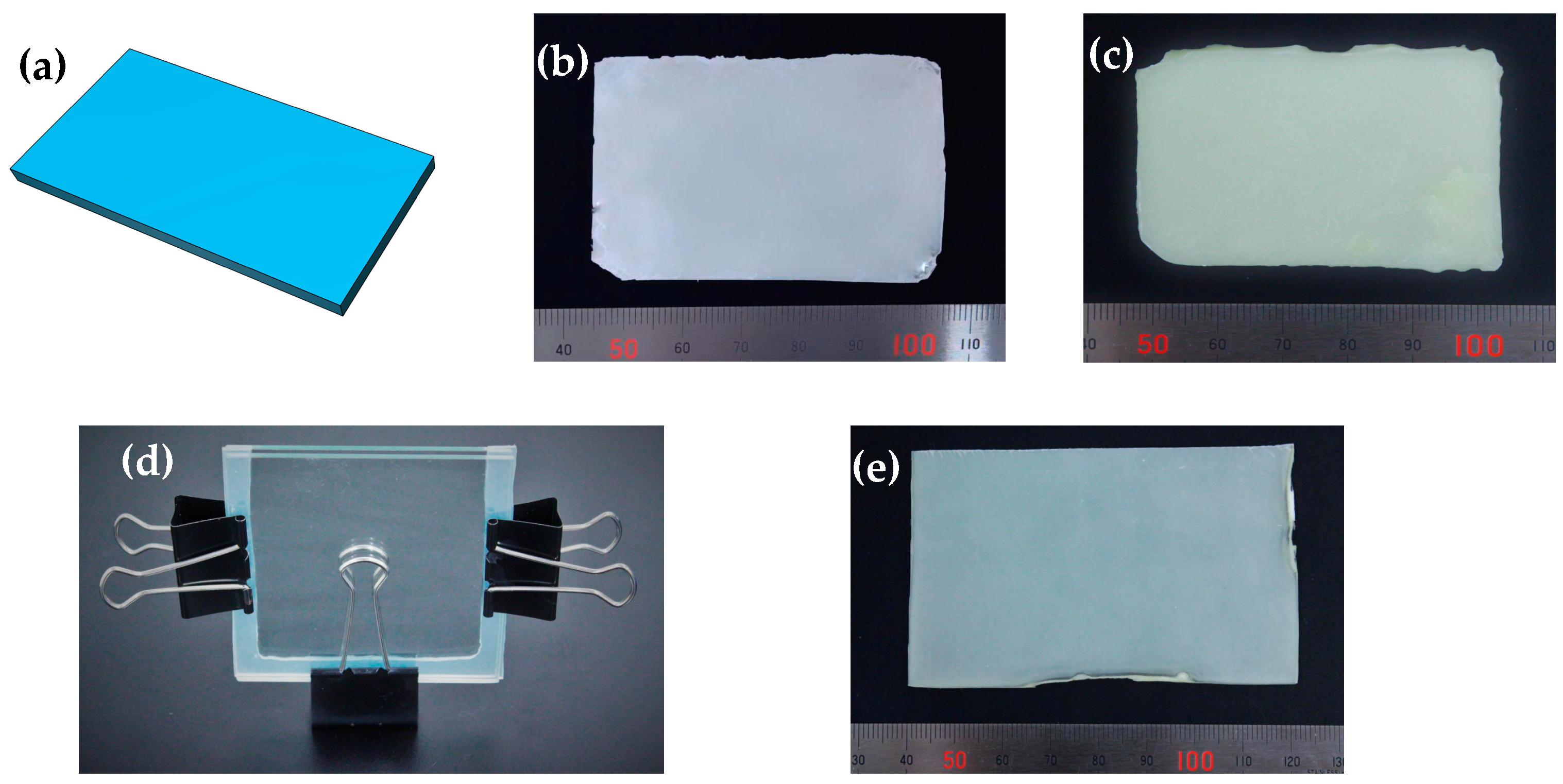

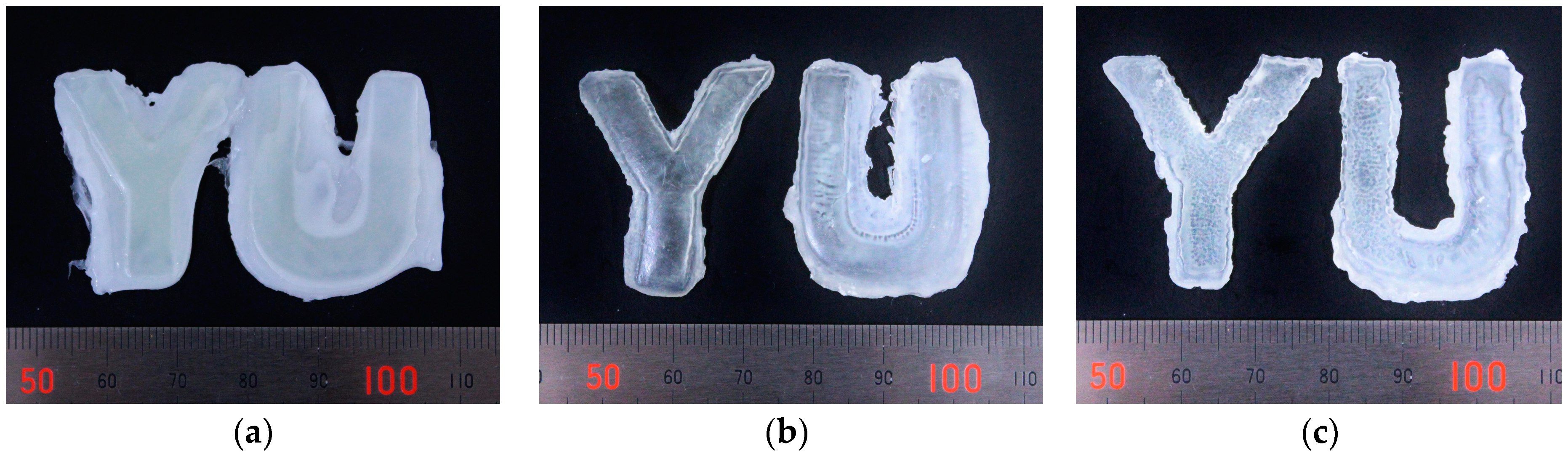

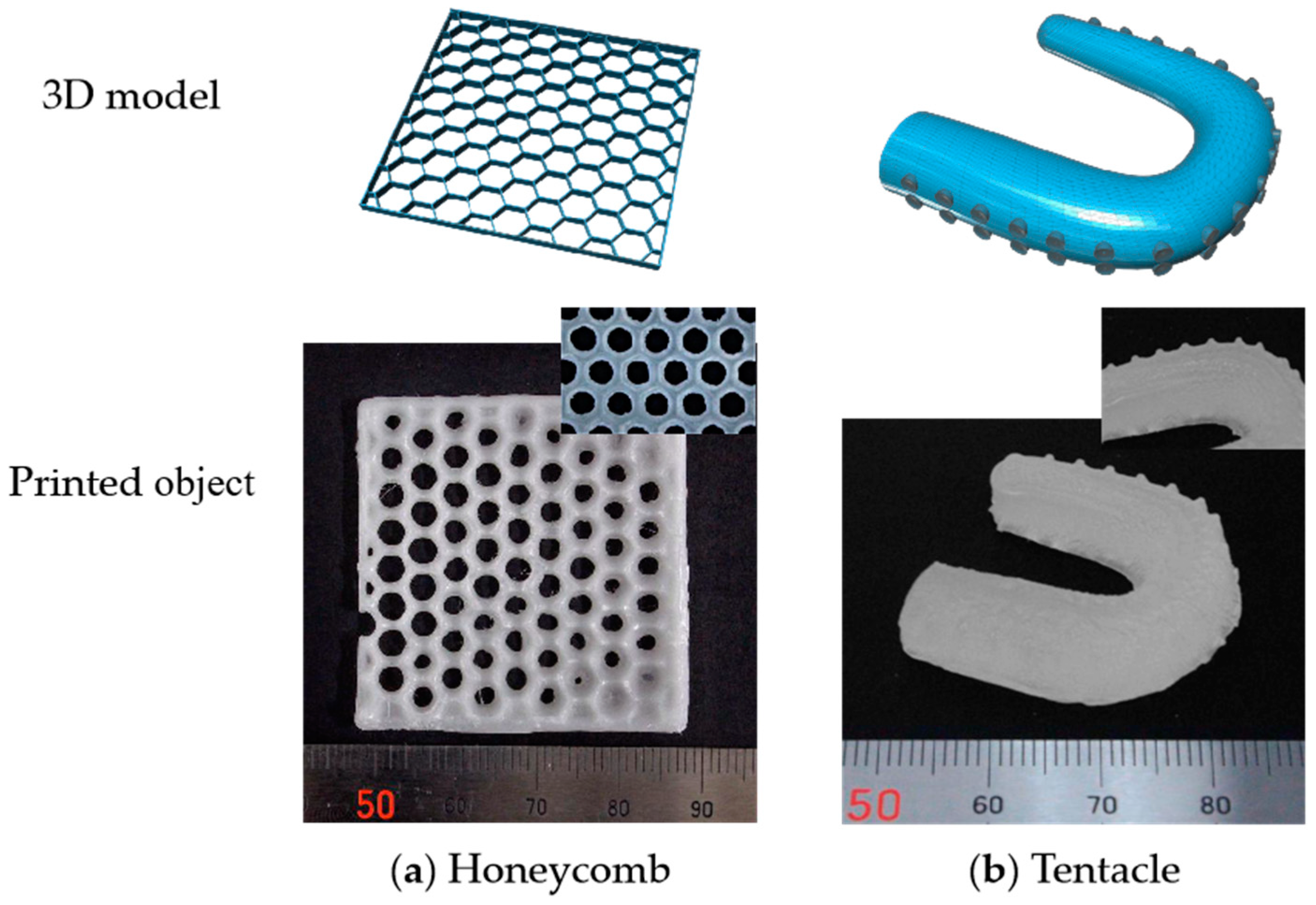

3.1. Printing Performance of Thermal Energy Storage Crystalline Gels

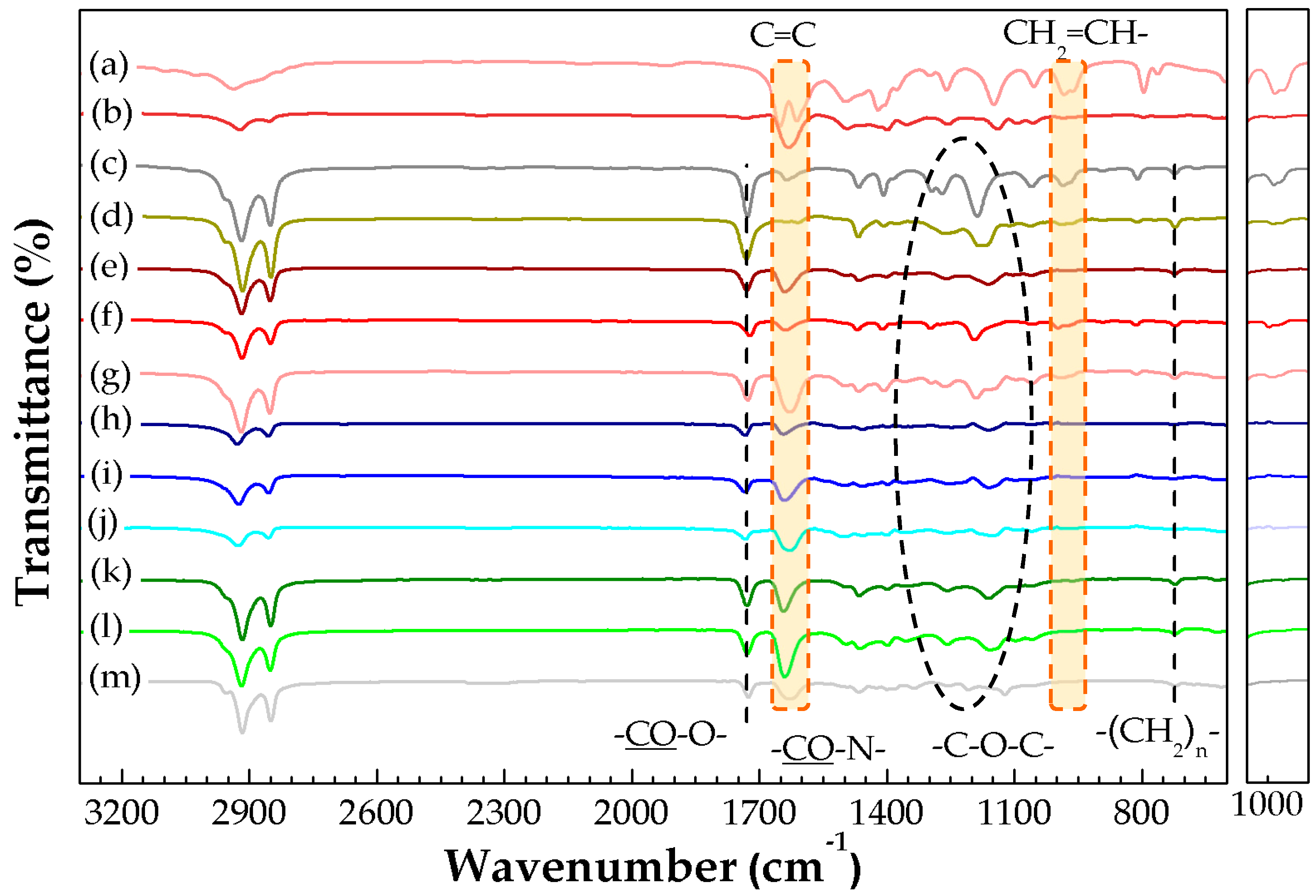

3.2. Chemical Composition and Structure

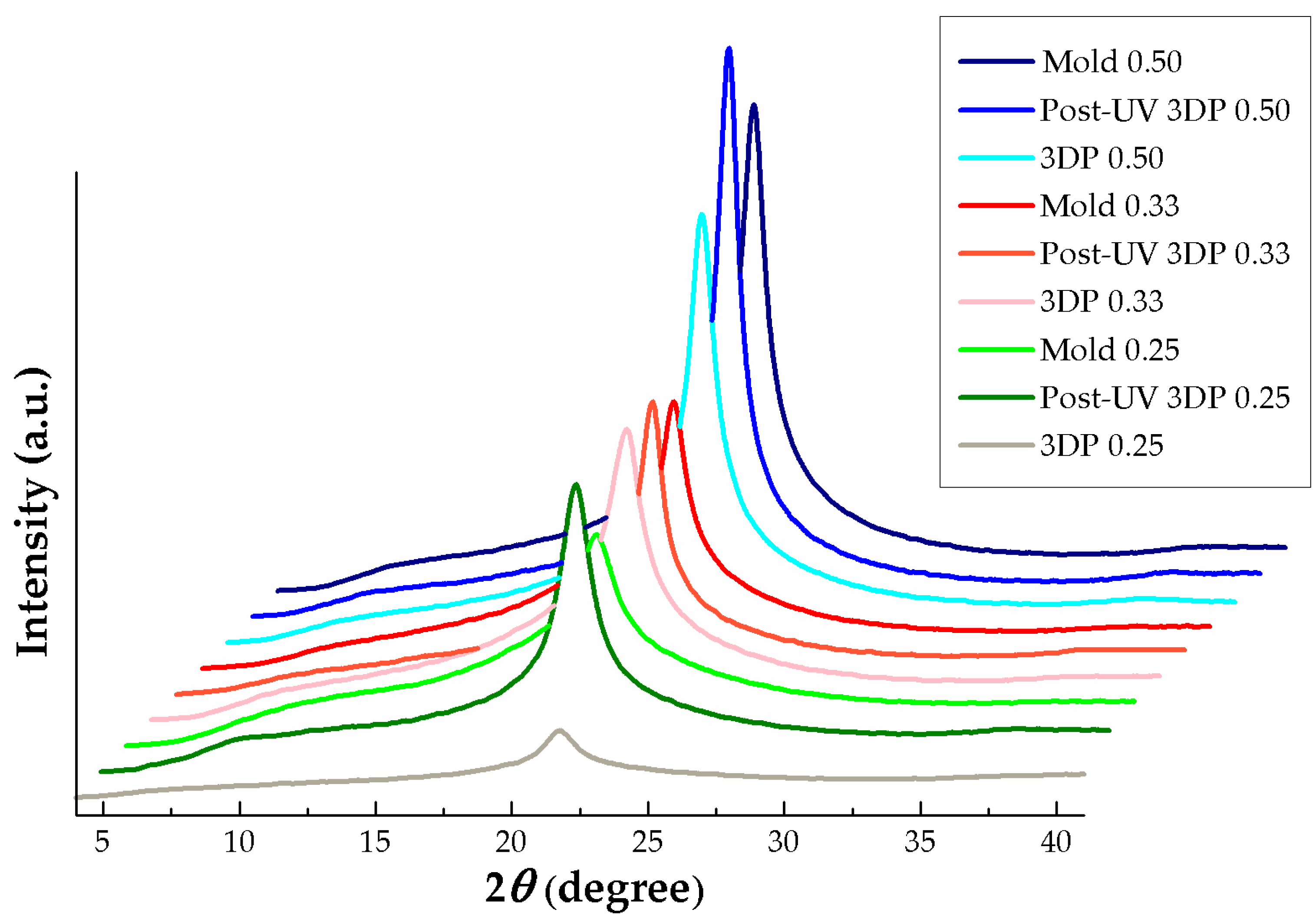

3.3. Crystalline Structure and Behavior

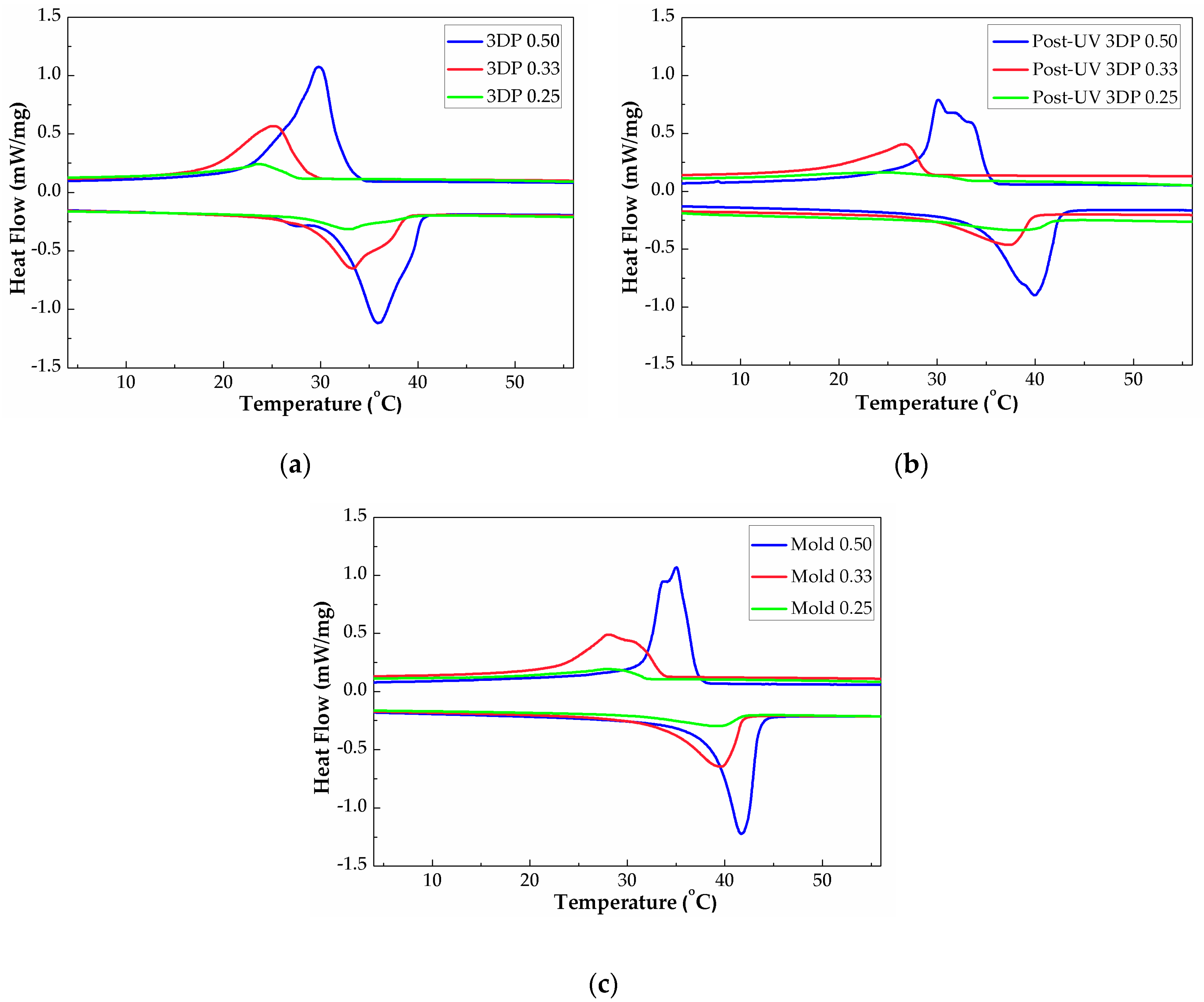

3.4. Energy Storage Capacity

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Yataganbaba, A.; Ozkahraman, B.; Kurtbas, I. Worldwide trends on encapsulation of phase change materials: A bibliometric analysis (1990–2015). Appl. Energy 2017, 185, 720–731. [Google Scholar] [CrossRef]

- Castellón, C.; Martorell, I.; Cabeza, L.F.; Fernández, A.I.; Manich, A.M. Compatibility of plastic with phase change materials (PCM). Int. J. Energy Res. 2011, 35, 765–771. [Google Scholar] [CrossRef]

- Mondal, S. Phase change materials for smart textiles—An overview. Appl. Therm. Eng. 2008, 28, 1536–1550. [Google Scholar] [CrossRef]

- Mahlia, T.M.I.; Saktisahdan, T.J.; Jannifar, A.; Hasan, M.H.; Matseelar, H.S.C. A review of available methods and development on energy storage; technology update. Renew. Sustain. Energy Rev. 2014, 33, 532–545. [Google Scholar] [CrossRef]

- Pereira da Cunha, J.; Eames, P. Thermal energy storage for low and medium temperature applications using phase change materials—A review. Appl. Energy 2016, 177, 227–238. [Google Scholar] [CrossRef]

- Tyagi, V.V.; Kaushik, S.C.; Tyagi, S.K.; Akiyama, T. Development of phase change materials based microencapsulated technology for buildings: A review. Renew. Sustain. Energy Rev. 2011, 15, 1373–1391. [Google Scholar] [CrossRef]

- Kalaiselvam, S.; Parameshwaran, R.; Harikrishnan, S. Analytical and experimental investigations of nanoparticles embedded phase change materials for cooling application in modern buildings. Renew. Energy 2012, 39, 375–387. [Google Scholar] [CrossRef]

- Huang, M.; Eames, P.; Hewitt, N. The application of a validated numerical model to predict the energy conservation potential of using phase change materials in the fabric of a building. Sol. Energy Mater. Sol. Cells 2006, 90, 1951–1960. [Google Scholar] [CrossRef]

- Hegde, M.; Meenakshisundaram, V.; Chartrain, N.; Sekhar, S.; Tafti, D.; Williams, C.B.; Long, T.E. 3D printing all-aromatic polyimides using mask-projection stereolithography: Processing the nonprocessable. Adv. Mater. 2017, 29. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.S.; Davoudi, F.; Walch, P.; Manbachi, A.; Luo, X.; Dell’Erba, V.; Miri, A.K.; Albadawi, H.; Arneri, A.; Li, X.; et al. Bioprinted thrombosis-on-a-chip. Lab Chip 2016, 16, 4097–4105. [Google Scholar] [CrossRef] [PubMed]

- Chia, H.N.; Wu, B.M. Recent advances in 3D printing of biomaterials. J. Biol. Eng. 2015, 9, 4. [Google Scholar] [CrossRef] [PubMed]

- Patra, S.; Young, V. A review of 3D printing techniques and the future in biofabrication of bioprinted tissue. Cell Biochem. Biophys. 2016, 74, 93–98. [Google Scholar] [CrossRef] [PubMed]

- Senatov, F.S.; Zadorozhnyy, M.Y.; Niaza, K.V.; Medvedev, V.V.; Kaloshkin, S.D.; Anisimova, N.Y.; Kiselevskiy, M.V.; Yang, K.-C. Shape memory effect in 3D-printed scaffolds for self-fitting implants. Eur. Polym. J. 2017, 93, 222–231. [Google Scholar] [CrossRef]

- Kuznetsov, V.; Solonin, A.; Urzhumtsev, O.; Schilling, R.; Tavitov, A. Strength of pla components fabricated with fused deposition technology using a desktop 3D printer as a function of geometrical parameters of the process. Polymers 2018, 10, 313. [Google Scholar] [CrossRef]

- Zhang, M.; Vora, A.; Han, W.; Wojtecki, R.J.; Maune, H.; Le, A.B.A.; Thompson, L.E.; McClelland, G.M.; Ribet, F.; Engler, A.C.; et al. Dual-responsive hydrogels for direct-write 3D printing. Macromolecules 2015, 48, 6482–6488. [Google Scholar] [CrossRef]

- Ge, Q.; Sakhaei, A.H.; Lee, H.; Dunn, C.K.; Fang, N.X.; Dunn, M.L. Multimaterial 4D printing with tailorable shape memory polymers. Sci. Rep. 2016, 6, 31110. [Google Scholar] [CrossRef] [PubMed]

- Pirlo, R.K.; Wu, P.; Liu, J.; Ringeisen, B. Plga/hydrogel biopapers as a stackable substrate for printing huvec networks via biolp. Biotechnol. Bioeng. 2012, 109, 262–273. [Google Scholar] [CrossRef] [PubMed]

- Oesterreicher, A.; Wiener, J.; Roth, M.; Moser, A.; Gmeiner, R.; Edler, M.; Pinter, G.; Griesser, T. Tough and degradable photopolymers derived from alkyne monomers for 3D printing of biomedical materials. Polym. Chem. 2016, 7, 5169–5180. [Google Scholar] [CrossRef]

- Rodriguez, J.N.; Zhu, C.; Duoss, E.B.; Wilson, T.S.; Spadaccini, C.M.; Lewicki, J.P. Shape-morphing composites with designed micro-architectures. Sci. Rep. 2016, 6, 27933. [Google Scholar] [CrossRef] [PubMed]

- Scalfani, V.F.; Turner, C.H.; Rupar, P.A.; Jenkins, A.H.; Bara, J.E. 3D printed block copolymer nanostructures. J. Chem. Educ. 2015, 92, 1866–1870. [Google Scholar] [CrossRef]

- Gong, J.; Azusa, S.; Makino, M.; Kawakami, M.; Furukawa, H. 3D printing of medical and edible gels. J. Jpn. Soc. Abras. Technol. 2016, 60, 134–137. [Google Scholar]

- Gong, J.; Igarashi, S.; Sawamura, K.; Makino, M.; Hasnat Kabir, M.; Furukawa, H. Gel engineering materials meso-decorated with polymorphic crystals. Adv. Mater. Res. 2013, 746, 325–329. [Google Scholar] [CrossRef]

- Gong, J.; Furukawa, H. Smart optical device of varifocal lens developed with high transparent shape memory gels. Expected Mater. Future 2013, 13, 5–8. [Google Scholar]

- Mao, Y.; Gong, J.; Zhu, M.; Ito, H. Excellent thermal stability P(BeA-co-MMA) microcapsules with high thermal energy storage capacity. Polymer 2018, 150, 267–274. [Google Scholar] [CrossRef]

- Gong, J.; Hosaka, E.; Sakai, K.; Ito, H.; Shibata, Y.; Sato, K.; Nakanishi, D.; Ishihara, S.; Hamada, K. Processing and thermal response of temperature-sensitive-gel(TSG)/polymer composites. Polymers 2018, 10, 486. [Google Scholar] [CrossRef]

- Schmidt, L.E.; Leterrier, Y.; Vesin, J.-M.; Wilhelm, M.; Månson, J.-A.E. Photorheology of fast UV-curing multifunctional acrylates. Macromol. Mater. Eng. 2005, 290, 1115–1124. [Google Scholar] [CrossRef]

- De Beer, N. Advances in three dimensional printing—state of the art and future perspectives. J. New Gener. Sci. 2006, 4, 21–49. [Google Scholar] [CrossRef]

- Mao, Y.; Yu, K.; Isakov, M.S.; Wu, J.; Dunn, M.L.; Jerry Qi, H. Sequential self-folding structures by 3D printed digital shape memory polymers. Sci. Rep. 2015, 5, 13616. [Google Scholar] [CrossRef] [PubMed]

- Kong, Z.; Wang, C.; Ren, Y.; Gu, M.; Hu, Y.; Yue, B.; He, H. Synthesis, structure, and properties of two supramolecular compounds based on silicotungstic acid and transition metal(ii) coordinated isonicotinic acid. Chin. J. Chem. 2012, 30, 759–764. [Google Scholar] [CrossRef]

- Heller, C.; Schwentenwein, M.; Russmueller, G.; Varga, F.; Stampfl, J.; Liska, R. Vinyl esters: Low cytotoxicity monomers for the fabrication of biocompatible 3D scaffolds by lithography based additive manufacturing. J. Polym. Sci. Part A 2009, 47, 6941–6954. [Google Scholar] [CrossRef]

- Han, D.; Lu, Z.; Chester, S.A.; Lee, H. Micro 3D printing of a temperature-responsive hydrogel using projection micro-stereolithography. Sci. Rep. 2018, 8, 1963. [Google Scholar] [CrossRef] [PubMed]

- Ruland, W. X-ray determination of crystallinity and diffuse disorder scattering. Acta Crystallogr. 1961, 14, 1180–1185. [Google Scholar] [CrossRef]

- Ryan, A.J.; Bras, W.; Mant, G.R.; Derbyshire, G.E. A direct method to determine the degree of crystallinity and lamellar thickness of polymers: Application to polyethylene. Polymer 1994, 35, 4537–4544. [Google Scholar] [CrossRef]

- Mo, Z.; Zhang, H. The degree of crystallinity in polymers by wide-angle X-ray diffraction (waxd). J. Macromol. Sci. Part C 1995, 35, 555–580. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, X.; Wu, D. Design and fabrication of dual-functional microcapsules containing phase change material core and zirconium oxide shell with fluorescent characteristics. Sol. Energy Mater. Sol. Cells 2015, 133, 56–68. [Google Scholar] [CrossRef]

- Mukherjee, P.K. Phase transitions among the rotator phases of the normal alkanes: A review. Phys. Rep. 2015, 588, 1–54. [Google Scholar] [CrossRef]

- Tracy, J.; D’hooge, D.R.; Bosco, N.; Delgado, C.; Dauskardt, R. Evaluating and predicting molecular mechanisms of adhesive degradation during field and accelerated aging of photovoltaic modules. Process. Photovolt. Res. Appl. 2018. [Google Scholar] [CrossRef]

| Sample | Wc (%) | Sample | Wc (%) | Sample | Wc (%) |

|---|---|---|---|---|---|

| Mold 0.50 | 39.16 | 3DP 0.50 | 41.24 | Post-UV 3DP 0.50 | 41.52 |

| Mold 0.33 | 27.61 | 3DP 0.33 | 28.79 | Post-UV 3DP 0.33 | 26.30 |

| Mold 0.25 | 19.05 | 3DP 0.25 | 23.57 | Post-UV 3DP 0.25 | 22.52 |

| Sample | Tc (°C) | ΔHc (J·g−1) | Tm (°C) | ΔHm (J·g−1) |

|---|---|---|---|---|

| 3DP 0.50 | 29.78 | 69.22 | 35.88 | 69.58 |

| 3DP 0.33 | 25.27 | 37.65 | 33.16 | 41.24 |

| 3DP 0.25 | 23.55 | 12.04 | 32.67 | 13.49 |

| Post-UV 3DP 0.50 | 30.10 | 53.01 | 39.88 | 56.68 |

| Post-UV 3DP 0.33 | 26.89 | 23.53 | 37.32 | 23.95 |

| Post-UV 3DP 0.25 | 24.48 | 11.54 | 37.76 | 11.71 |

| Mold 0.50 | 35.03 | 53.73 | 41.66 | 53.42 |

| Mold 0.33 | 28.01 | 36.12 | 39.56 | 34.48 |

| Mold 0.25 | 28.01 | 9.54 | 39.00 | 10.58 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mao, Y.; Miyazaki, T.; Sakai, K.; Gong, J.; Zhu, M.; Ito, H. A 3D Printable Thermal Energy Storage Crystalline Gel Using Mask-Projection Stereolithography. Polymers 2018, 10, 1117. https://doi.org/10.3390/polym10101117

Mao Y, Miyazaki T, Sakai K, Gong J, Zhu M, Ito H. A 3D Printable Thermal Energy Storage Crystalline Gel Using Mask-Projection Stereolithography. Polymers. 2018; 10(10):1117. https://doi.org/10.3390/polym10101117

Chicago/Turabian StyleMao, Yuchen, Takuya Miyazaki, Kohei Sakai, Jin Gong, Meifang Zhu, and Hiroshi Ito. 2018. "A 3D Printable Thermal Energy Storage Crystalline Gel Using Mask-Projection Stereolithography" Polymers 10, no. 10: 1117. https://doi.org/10.3390/polym10101117

APA StyleMao, Y., Miyazaki, T., Sakai, K., Gong, J., Zhu, M., & Ito, H. (2018). A 3D Printable Thermal Energy Storage Crystalline Gel Using Mask-Projection Stereolithography. Polymers, 10(10), 1117. https://doi.org/10.3390/polym10101117