Nanocellulose Stabilized Pickering Emulsion Templating for Thermosetting AESO Nanocomposite Foams

Abstract

:1. Introduction

2. Materials and Methods

2.1. Chemicals and Materials

2.2. Preparation and Characterization of CNCs

2.3. Synthesis and Characterization of AESO

2.4. Emulsion Preparation and Characterization

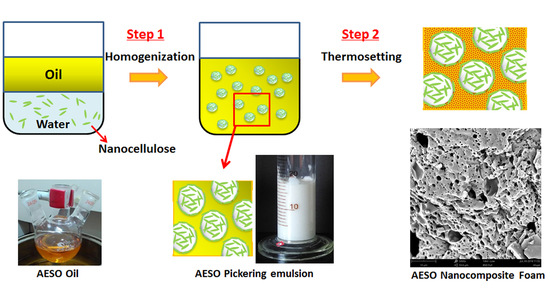

2.5. Synthesis and Characterization of AESO-Based Nanocomposite Foam

2.6. Statistical Analysis

3. Results and Discussion

3.1. The CNCs Material

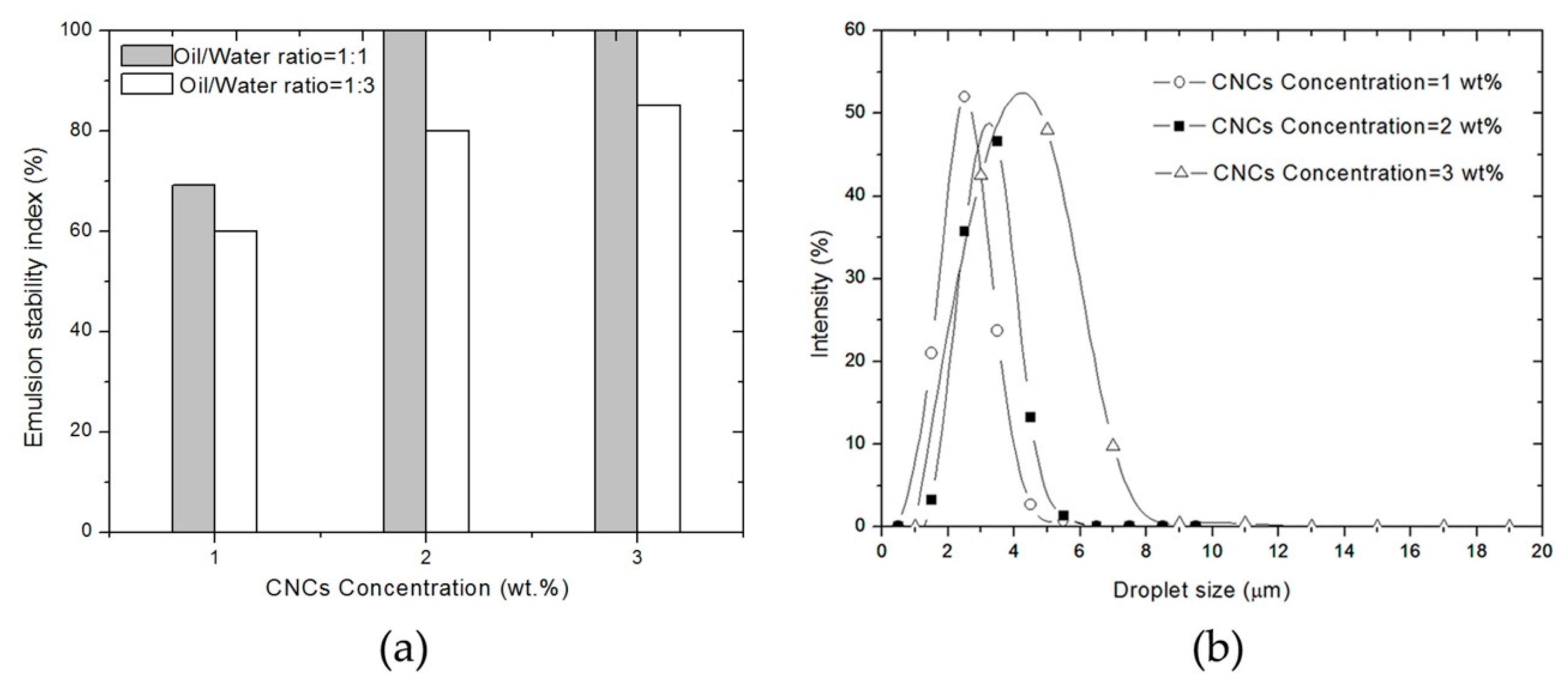

3.2. The Pickering Emulsion

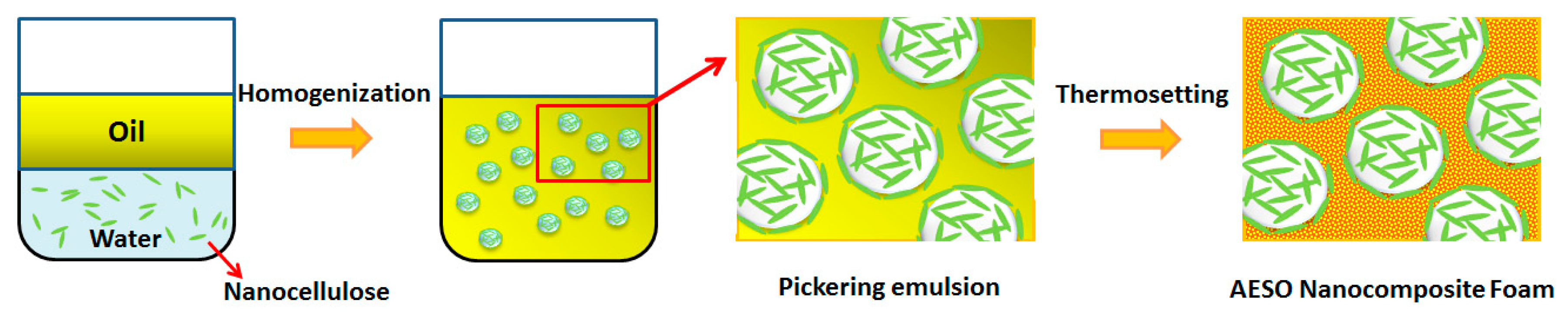

3.3. Effect of Oil to Water Ratio on the Emulsion Stability

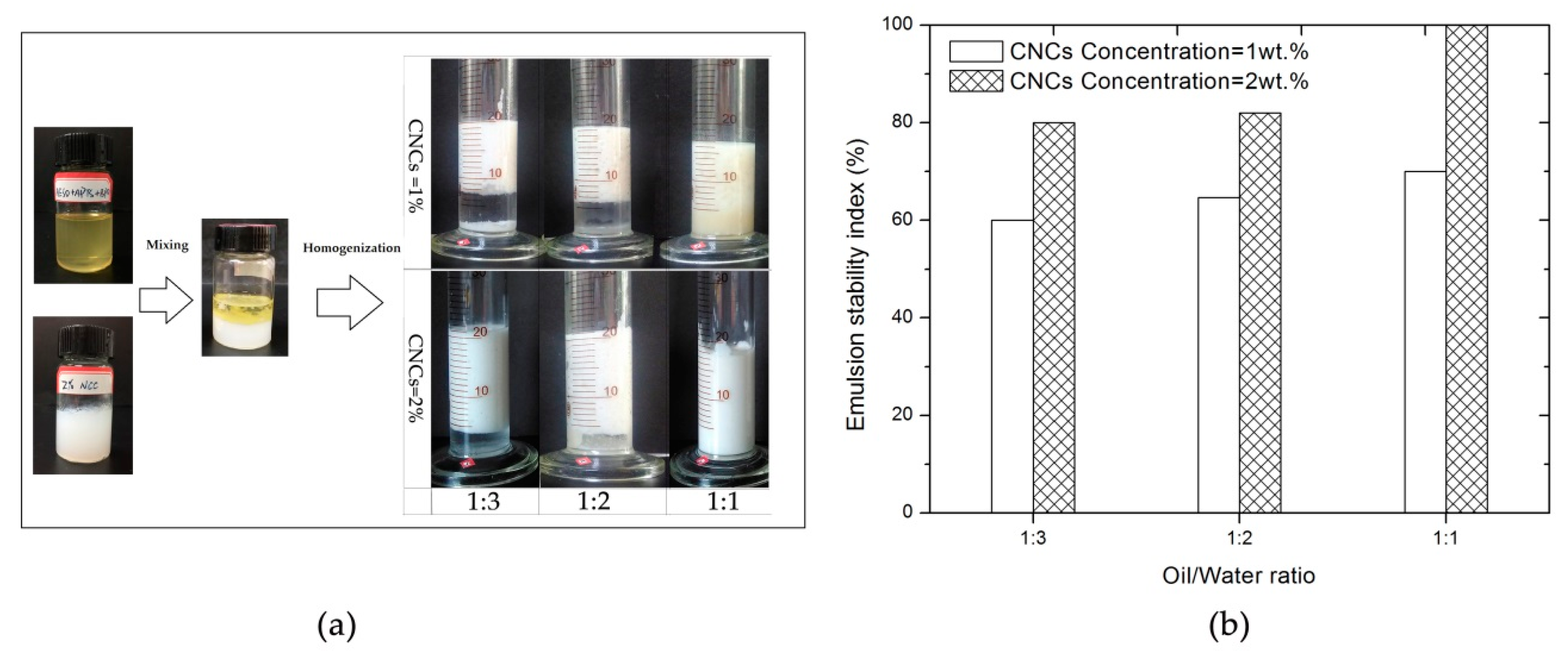

3.4. Effect of Concentration of CNCs on the Emulsion Stability

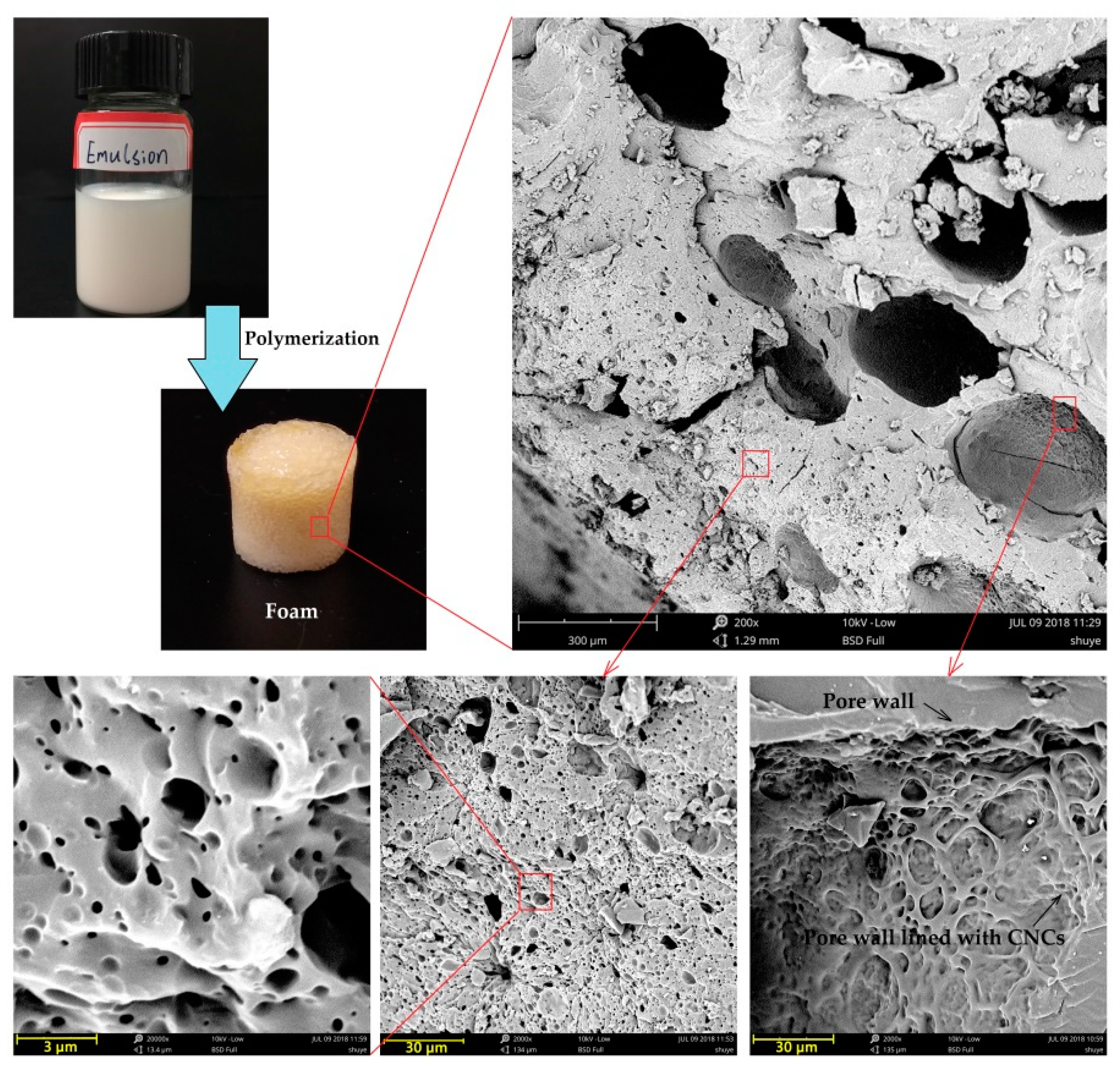

3.5. The AESO-based Nanocomposite Foam

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Hussain, F.; Hojjati, M.; Okamoto, M.; Gorga, R.E. Review article: Polymer-matrix Nanocomposites, Processing, Manufacturing, and Application: An Overview. J. Compos. Mater. 2006, 40, 1511–1576. [Google Scholar] [CrossRef]

- Lee, L.J.; Zeng, C.; Cao, X.; Han, X.; Shen, J.; Xu, G. Polymer nanocomposite foams. Compos. Sci. Technol. 2005, 65, 2344–2363. [Google Scholar] [CrossRef]

- Kumari, S.; Chauhan, G.S.; Ahn, J.H. Novel cellulose nanowhiskers-based polyurethane foam for rapid and persistent removal of methylene blue from its aqueous solutions. Chem. Eng. J. 2016, 304, 728–736. [Google Scholar] [CrossRef]

- Li, Y.; Ren, H.; Ragauskas, A.J. Rigid polyurethane foam reinforced with cellulosewhiskers: Synthesis and characterization. Nano-Micro Lett. 2010, 2, 89–94. [Google Scholar] [CrossRef]

- Cao, X.; Lee, L.J.; Widya, T.; Macosko, C. Polyurethane/clay nanocomposites foams: Processing, structure and properties. Polymer 2005, 46, 775–783. [Google Scholar] [CrossRef]

- Chen, L.; Goren, B.K.; Ozisik, R.; Schadler, L.S. Controlling bubble density in MWNT/polymer nanocomposite foams by MWNT surface modification. Compos. Sci. Technol. 2012, 72, 190–196. [Google Scholar] [CrossRef]

- Leng, W.; Li, J.; Cai, Z. Synthesis and Characterization of Cellulose Nanofibril-Reinforced Polyurethane Foam. Polymers 2017, 9, 597. [Google Scholar] [CrossRef]

- Zhang, H.; Cooper, A.I. Synthesis and applications of emulsion-templated porous materials. Soft Matter 2005, 1, 107–113. [Google Scholar] [CrossRef]

- Cunha, A.G.; Mougel, J.-B.; Cathala, B.; Berglund, L.A.; Capron, I. Preparation of Double Pickering Emulsions Stabilized by Chemically Tailored Nanocelluloses. Langmuir 2014, 30, 9327–9335. [Google Scholar] [CrossRef] [PubMed]

- Haaj, S.B.; Thielemans, W.; Magnin, A.; Boufi, S. Starch Nanocrystal Stabilized Pickering Emulsion Polymerization for Nanocomposites with Improved Performance. ACS Appl. Mater. Interfaces 2014, 6, 8263–8273. [Google Scholar] [CrossRef] [PubMed]

- Sousa, A.F.; Ferreira, S.; Lopez, A.; Borges, I.; Pinto, R.J.B.; Silvestre, A.J.D.; Freire, C.S.R. Thermosetting AESO-bacterial cellulose nanocomposite foams with tailored mechanical properties obtained by Pickering emulsion templating. Polymer 2017, 118, 127–134. [Google Scholar] [CrossRef]

- Lumelsky, Y.; Silverstein, M.S. Biodegradable Porous Polymers through Emulsion Templating. Macromolecules 2012, 42, 1627–1633. [Google Scholar] [CrossRef]

- Busby, W.; Cameron, N.R.; Jahoda, C.A.B. Tissue engineering matrixes by emulsion templating. Polym. Int. 2002, 51, 871–881. [Google Scholar] [CrossRef]

- Capron, I.; Rojas, O.J.; Bordes, R. Behavior of nanocelluloses at interfaces. Curr. Opin. Colloid Interface Sci. 2017, 29, 83–95. [Google Scholar] [CrossRef]

- Kalashnikova, I.; Bizot, H.; Bertoncini, P.; Cathala, B.; Capron, I. Cellulosic nanorods of various aspect ratios for oil in water Pickering emulsions. Soft Matter 2013, 9, 952–959. [Google Scholar] [CrossRef]

- Blaker, J.J.; Lee, K.Y.; Li, X.; Menner, A.; Bismarck, A. Renewable nanocomposite polymer foams synthesized from Pickering emulsion templates. Green Chem. 2009, 11, 1321–1326. [Google Scholar] [CrossRef]

- Lee, K.Y.; Blaker, J.J.; Murakami, R.; Heng, J.Y.Y.; Bismarck, A. Phase Behavior of Medium and High Internal Phase Water-in-Oil Emulsions Stabilized Solely by Hydrophobized Bacterial Cellulose Nanofibrils. Langmuir 2014, 30, 452–460. [Google Scholar] [CrossRef] [PubMed]

- Martin, A.; Per, S. Water-in-oil Emulsions Stabilized by Hydrophobized Microfibrillated Cellulose. J. Dispers. Sci. Technol. 2007, 28, 837–844. [Google Scholar] [CrossRef]

- Bai, L.; Huan, S.; Xiang, W.; Rojas, O.J. Pickering emulsions by combining cellulose nanofibrils and nanocrystals: Phase behavior and depletion stabilization. Green Chem. 2018, 20, 1571–1582. [Google Scholar] [CrossRef]

- Capron, I.; Cathala, B. Surfactant-Free High Internal Phase Emulsions Stabilized by Cellulose Nanocrystals. Biomacromolecules 2013, 14, 291–296. [Google Scholar] [CrossRef] [PubMed]

- Cherhal, F.; Cousin, F.; Capron, I. Structural Description of the Interface of Pickering Emulsions Stabilized by Cellulose Nanocrystals. Biomacromolecules 2016, 17, 496–502. [Google Scholar] [CrossRef] [PubMed]

- Bai, L.; Xiang, W.; Huan, S.; Rojas, O.J. Formulation and Stabilization of Concentrated Edible Oil-in-Water Emulsions Based on Electrostatic Complexes of a Food-Grade Cationic Surfactant (Ethyl Lauroyl Arginate) and Cellulose Nanocrystals. Biomacromolecules 2018, 19, 1674–1685. [Google Scholar] [CrossRef] [PubMed]

- Du, W.; Guo, J.; Li, H.; Gao, Y. Heterogeneously Modified Cellulose Nanocrystals-Stabilized Pickering Emulsion: Preparation and Their Template Application for the Creation of PS Microspheres with Amino-Rich Surfaces. ACS Sustain. Chem. Eng. 2017, 5, 7514–7523. [Google Scholar] [CrossRef]

- Liu, B.; Yang, D.; Man, H.; Liu, Y.; Chen, H.; Xu, H.; Wang, W.; Bai, L. A green Pickering emulsion stabilized by cellulose nanocrystals via RAFT polymerization. Cellulose 2017, 25, 77–85. [Google Scholar] [CrossRef]

- Werner, A.; Schmitt, V.; Sèbe, G.; Héroguez, V. Synthesis of surfactant-free micro- and nanolatexes from Pickering emulsions stabilized by acetylated cellulose nanocrystals. Polym. Chem. 2017, 8, 6064–6072. [Google Scholar] [CrossRef]

- Saidane, D.; Perrin, E.; Cherhal, F.; Guellec, F.; Capron, I. Some modification of cellulose nanocrystals for functional Pickering emulsions. Philos. Trans. A Math. Phys. Eng. Sci. 2016, 374, 20150139. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hu, Z.; Ballinger, S.; Pelton, R.; Cranston, E.D. Surfactant-enhanced cellulose nanocrystal Pickering emulsions. J. Colloid Interface Sci. 2015, 439, 139–148. [Google Scholar] [CrossRef] [PubMed]

- Fujisawa, S.; Togawa, E.; Kuroda, K. Nanocellulose-stabilized Pickering emulsions and their applications. Sci. Technol. Adv. Mater. 2017, 18, 959–971. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lu, P.; Tian, X.; Liu, Y.; Wang, Z. Effects of Cellulosic Base Sheet Pore Structure and Soybean Oil-Based Polymer Layer on Cellulosic Packaging Performance as a Barrier for Water and Water Vapor. Bioresources 2016, 11, 8483–8495. [Google Scholar] [CrossRef]

- Rong, M.Z.; Zhang, M.Q.; Wu, S.P.; Wang, H.J.; Czigány, T. Ecomaterials-Foam Plastics Synthesized from Plant Oil-Based Resins. Mater. Sci. Forum 2007, 539–543, 2311–2316. [Google Scholar] [CrossRef]

- Bonnaillie, L.M.; Wool, R.P. Thermosetting foam with a high bio-based content from acrylated epoxidized soybean oil and carbon dioxide. J. Appl. Polym. Sci. 2010, 105, 1042–1052. [Google Scholar] [CrossRef]

- Liu, W.; Fei, M.; Ban, Y.; Jia, A.; Qiu, R. Preparation and Evaluation of Green Composites from Microcrystalline Cellulose and a Soybean-Oil Derivative. Polymers 2017, 9, 541. [Google Scholar] [CrossRef]

- Li, X.; Li, J.; Gong, J.; Kuang, Y.; Mo, L.; Song, T. Cellulose nanocrystals (CNCs) with different crystalline allomorph for oil in water Pickering emulsions. Carbohydr. Polym. 2018, 183, 303–310. [Google Scholar] [CrossRef] [PubMed]

- Jiang, F.; Hsieh, Y.-L. Holocellulose Nanocrystals: Amphiphilicity, Oil/Water Emulsion, and Self-Assembly. Biomacromolecules 2015, 16, 1433–1441. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yu, D.; Lin, Z.; Li, Y. Octadecenylsuccinic anhydride pickering emulsion stabilized by γ-methacryloxy propyl trimethoxysilane grafted montmorillonite. Colloids Surface A 2013, 422, 100–109. [Google Scholar] [CrossRef]

- Rondóngonzález, M.; Madariaga, L.F.; Sadtler, V.; Choplin, L.; Salager, J.L. Emulsion Catastrophic Inversion from Abnormal to Normal Morphology. 8. Effect of Formulation on the Inversion Produced by Continuous Stirring. Ind. Eng. Chem. Res. 2009, 46, 161–174. [Google Scholar] [CrossRef]

- Aveyard, R.; Binks, B.P.; Clint, J.H. Emulsions stabilised solely by colloidal particles. Adv. Colloid Interface Sci. 2003, 100, 503–546. [Google Scholar] [CrossRef]

- Kalashnikova, I.; Bizot, H.; Cathala, B.; Capron, I. New Pickering Emulsions Stabilized by Bacterial Cellulose Nanocrystals. Langmuir 2011, 27, 7471–7479. [Google Scholar] [CrossRef] [PubMed]

- Ling, L.C.W.; Barg, S.; Menner, A.; Pereira, P.D.V.; Eda, G.; Chowalla, M.; Saiz, E.; Bismarck, A. Macroporous polymer nanocomposites synthesised from high internal phase emulsion templates stabilised by reduced graphene oxide. Polymer 2014, 55, 395–402. [Google Scholar] [CrossRef]

- Binks, B.P.; Rodrigues, J.A. Types of Phase Inversion of Silica Particle Stabilized Emulsions Containing Triglyceride Oil. Langmuir 2003, 19, 4905–4912. [Google Scholar] [CrossRef]

- Ҫolak, S.; Küsefoğlu, S.H. Synthesis and interfacial properties of aminosilane derivative of acrylated epoxidized soybean oil. J. Appl. Polym. Sci. 2007, 104, 2244–2253. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, P.; Guo, M.; Yang, Y.; Wu, M. Nanocellulose Stabilized Pickering Emulsion Templating for Thermosetting AESO Nanocomposite Foams. Polymers 2018, 10, 1111. https://doi.org/10.3390/polym10101111

Lu P, Guo M, Yang Y, Wu M. Nanocellulose Stabilized Pickering Emulsion Templating for Thermosetting AESO Nanocomposite Foams. Polymers. 2018; 10(10):1111. https://doi.org/10.3390/polym10101111

Chicago/Turabian StyleLu, Peng, Mengya Guo, Yang Yang, and Min Wu. 2018. "Nanocellulose Stabilized Pickering Emulsion Templating for Thermosetting AESO Nanocomposite Foams" Polymers 10, no. 10: 1111. https://doi.org/10.3390/polym10101111

APA StyleLu, P., Guo, M., Yang, Y., & Wu, M. (2018). Nanocellulose Stabilized Pickering Emulsion Templating for Thermosetting AESO Nanocomposite Foams. Polymers, 10(10), 1111. https://doi.org/10.3390/polym10101111