Dielectric and Piezoelectric Properties of Textured Lead-Free Na0.5Bi0.5TiO3-Based Ceramics

Abstract

:1. Introduction

2. Materials and Methods

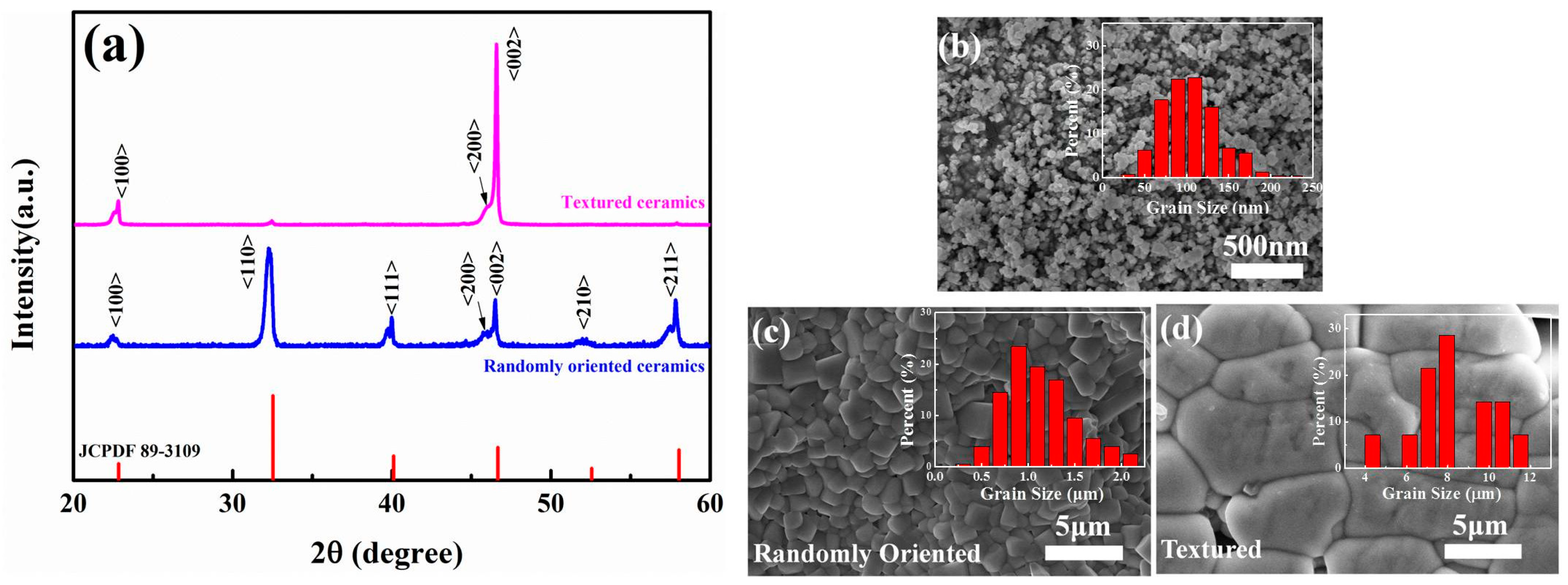

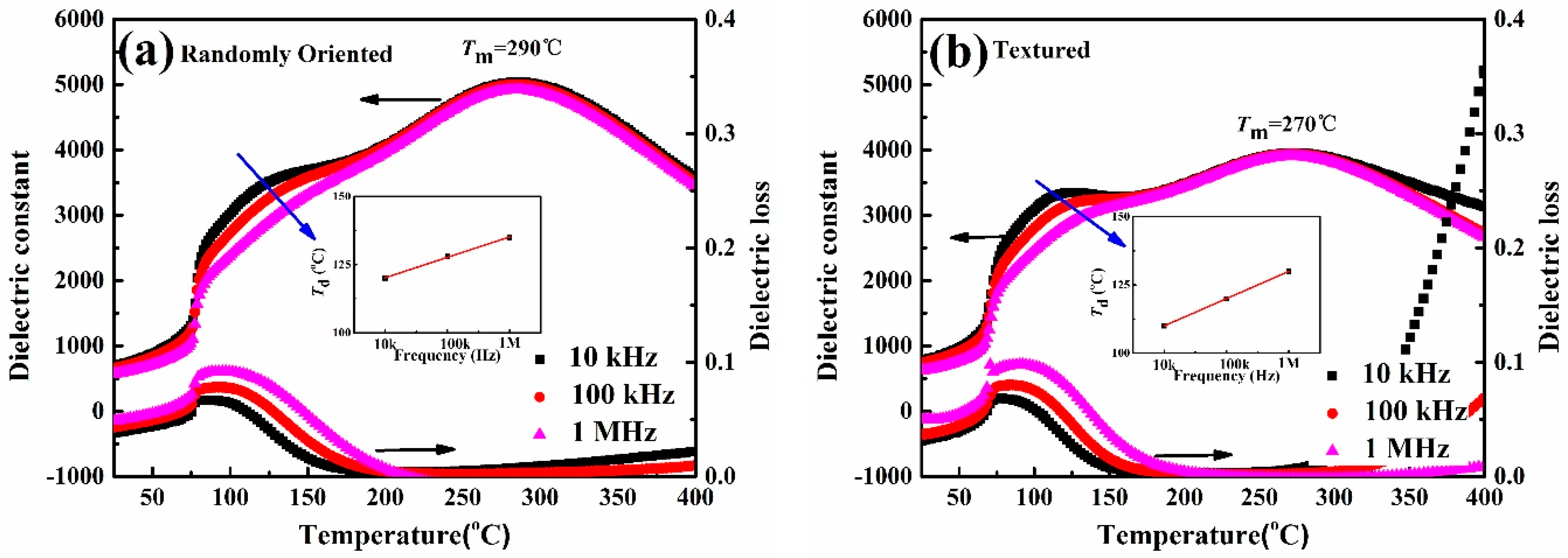

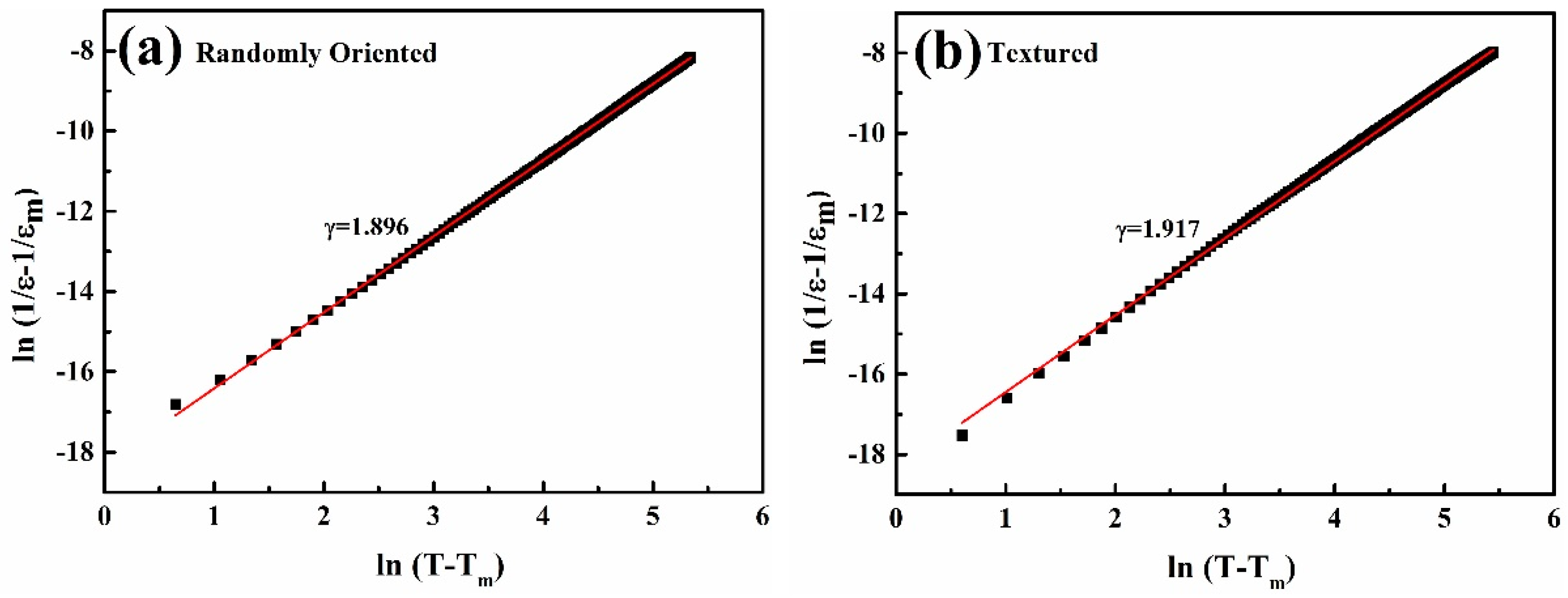

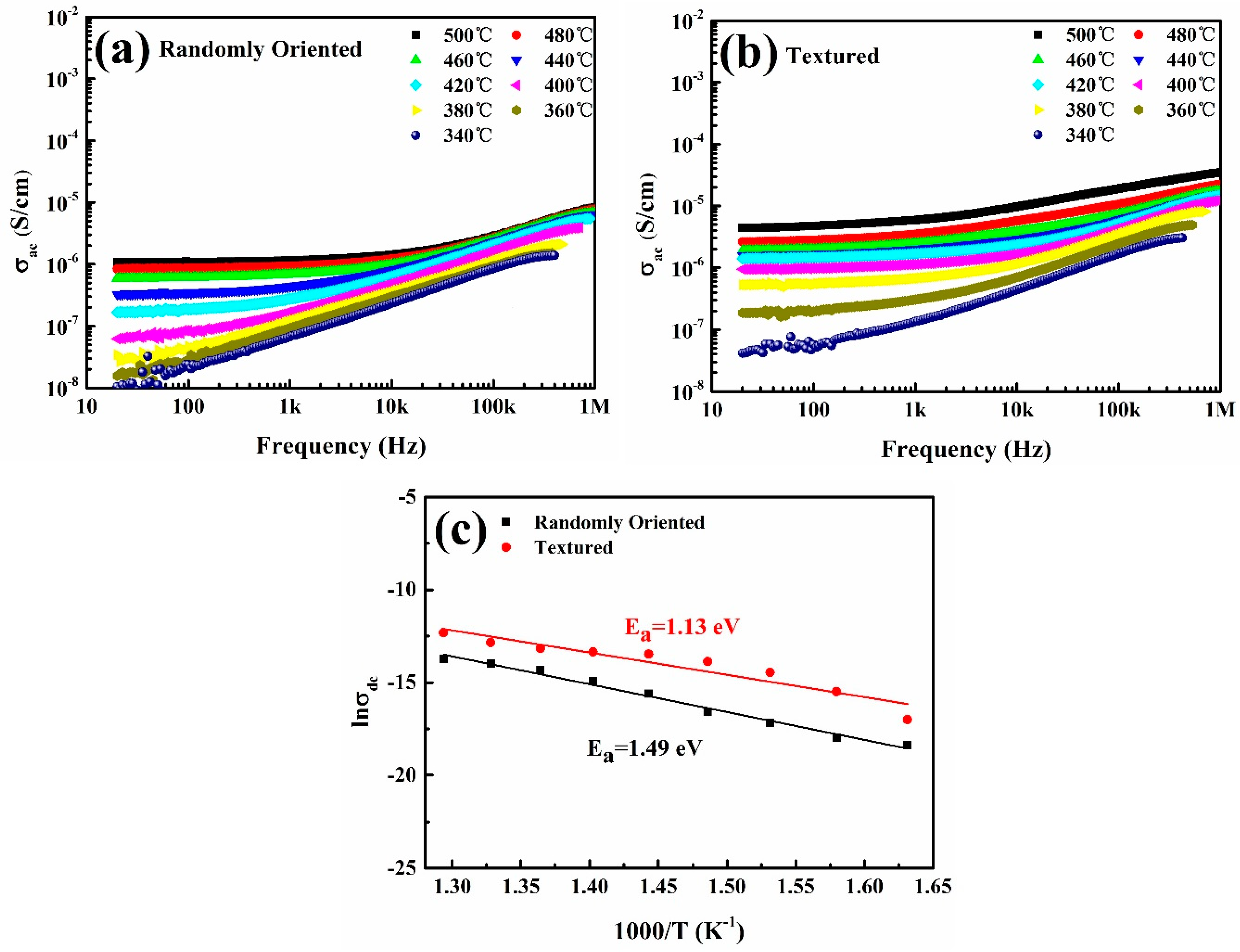

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Smolenskii, G.A.; Isupov, V.A.; Agranovskaya, A.I.; Krainik, N.N. New Ferroelectrics of Complex Composition. Sov. Phys. Solid State 1961, 2, 2651–2654. [Google Scholar]

- Xu, Q.; Chen, X.-L.; Chen, W.; Chen, M.; Xu, S.-L.; Kim, B.-H.; Lee, J.-H. Effect of MnO addition on structure and electrical properties of (Na0.5Bi0.5)0.94Ba0.06TiO3 ceramics prepared by citrate method. Mater. Sci. Eng. B 2006, 130, 94–100. [Google Scholar] [CrossRef]

- Chen, M.; Xu, Q.; Kim, B.H.; Ahn, B.K.; Ko, J.H.; Kang, W.J.; Nam, O.J. Structure and electrical properties of (Na0.5Bi0.5)1−xBaxTiO3 piezoelectric ceramics. J. Eur. Ceram. Soc. 2008, 28, 843–849. [Google Scholar] [CrossRef]

- Hajra, S.; Sahoo, S.; Das, R.; Choudhary, R.N.P. Structural, dielectric and impedance characteristics of (Bi0.5Na0.5)TiO3-BaTiO3 electronic system. J. Alloys Compd. 2018, 750, 507–514. [Google Scholar] [CrossRef]

- Otonicar, M.; Park, J.; Logar, M.; Esteves, G.; Jones, J.L.; Jancar, B. External-field-induced crystal structure and domain texture in (1−x)Na0.5Bi0.5TiO3−xK0.5Bi0.5TiO3 piezoceramics. Acta Mater. 2017, 127, 319–331. [Google Scholar] [CrossRef]

- Muneeswaran, M.; Choi, B.C.; Chang, S.H.; Jung, J.H. Effect of dysprosium doping on structural and vibrational properties of lead-free (Na0.7K0.3)0.5Bi0.5TiO3 ferroelectric ceramics. Ceram. Int. 2017, 43, 13696–13701. [Google Scholar] [CrossRef]

- Hussain, A.; Rahman, J.U.; Maqbool, A.; Kim, M.S.; Song, T.K.; Kim, W.J.; Kim, M.H. Structural and electromechanical properties of lead-free Na0.5Bi0.5TiO3-BaZrO3 ceramics. Phys. Status Solidi A 2014, 211, 1704–1708. [Google Scholar] [CrossRef]

- Xu, Q.; Lanagan, M.T.; Luo, W.; Zhang, L.; Xie, J.; Hao, H.; Cao, M.H.; Yao, Z.H.; Liu, H.X. Electrical properties and relaxation behavior of Bi0.5Na0.5TiO3-BaTiO3 ceramics modified with NaNbO3. J. Eur. Ceram. Soc. 2016, 36, 2469–2477. [Google Scholar] [CrossRef]

- Zhang, S.; Shrout, T.R.; Nagata, H.; Hiruma, Y.; Takenaka, T. Piezoelectric properties in (K0.5Bi0.5)TiO3-(Na0.5Bi0.5)TiO3-BaTiO3 lead-free ceramics. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2007, 54, 910–917. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Chen, W.; Xu, Q.; Zhou, J.; Gu, X. Piezoelectric and ferroelectric properties of Na0.5Bi0.5TiO3-K0.5Bi0.5TiO3-BaTiO3 piezoelectric ceramics. Mater. Lett. 2005, 59, 1361–1364. [Google Scholar] [CrossRef]

- Liu, G.; Jiang, W.; Zhang, L.; Cai, J.; Wang, Z.; Liu, K.; Liu, X.; Chen, Y.; Liu, H.; Yan, Y. Effects of sintering temperature and KBT content on microstructure and electrical properties of (Bi0.5Na0.5)TiO3-BaTiO3-(Bi0.5K0.5)TiO3 Pb-free ceramics. Ceram. Int. 2018, 44, 9303–9311. [Google Scholar] [CrossRef]

- Zhang, S.-T.; Yang, B.; Cao, W. The temperature-dependent electrical properties of Bi0.5Na0.5TiO3-BaTiO3-Bi0.5K0.5TiO3 near the morphotropic phase boundary. Acta Mater. 2012, 60, 469–475. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, Y.; Sun, H.; Liu, X.; Sui, H.; Zhou, D.; Guo, Q. Phase structure and electrical properties of lead-free (1−2x)NBT-xKBT-xBT ceramics. J. Mater. Sci. Mater. Electron. 2018, 29, 7851–7856. [Google Scholar] [CrossRef]

- Praharaj, S.; Subramanian, V.; Kang, S.J.L.; Rout, D. Origin of relaxor behavior in 0.78(Na0.5Bi0.5)TiO3-0.2SrTiO3-0.02BaTiO3 ceramic: An electrical modulus study. Mater. Res. Bull. 2018, 106, 459–464. [Google Scholar] [CrossRef]

- Moriana, A.D.; Zhang, S. Lead-free textured piezoceramics using tape casting: A review. J. Mater. 2018, 4, 277–303. [Google Scholar] [CrossRef]

- Maurya, D.; Zhou, Y.; Yan, Y.; Priya, S. Synthesis mechanism of grain-oriented lead-free piezoelectric Na0.5Bi0.5TiO3-BaTiO3 ceramics with giant piezoelectric response. J. Mater. Chem. C 2013, 1, 2102–2111. [Google Scholar] [CrossRef]

- Bai, W.; Chen, D.; Zheng, P.; Xi, J.; Zhou, Y.; Shen, B.; Zhai, J.; Ji, Z. NaNbO3 templates-induced phase evolution and enhancement of electromechanical properties in <001> grain oriented lead-free BNT-based piezoelectric materials. J. Eur. Ceram. Soc. 2017, 37, 2591–2604. [Google Scholar] [CrossRef]

- Maurya, D.; Zhou, Y.; Wang, Y.; Yan, Y.; Li, J.; Viehland, D.; Priya, S. Giant strain with ultra-low hysteresis and high temperature stability in grain oriented lead-free K0.5Bi0.5TiO3-BaTiO3-Na0.5Bi0.5TiO3 piezoelectric materials. Sci. Rep. 2015, 5, 8595. [Google Scholar] [CrossRef]

- Ma, S.; Zhang, Y.; Liu, Z.; Dai, X.; Huang, J.; Fan, P.; Xie, B.; Jiang, S.; Zhang, H. Preparation and enhanced electric-field-induced strain of textured 91BNT-6BT-3KNN lead-free piezoceramics by TGG method. J. Mater. Sci. Mater. Electron. 2015, 27, 3076–3081. [Google Scholar] [CrossRef]

- Zhang, H.; Xu, P.; Patterson, E.; Zang, J.; Jiang, S.; Rödel, J. Preparation and enhanced electrical properties of grain-oriented (Bi1/2Na1/2)TiO3-based lead-free incipient piezoceramics. J. Eur. Ceram. Soc. 2015, 35, 2501–2512. [Google Scholar] [CrossRef]

- Bai, W.; Chen, D.; Zheng, P.; Zhang, J.; Shen, B.; Zhai, J.; Ji, Z. Low electric field-driven giant strain response in <001> textured BNT-based lead-free piezoelectric materials. J. Mater. Sci. 2016, 52, 3169–3178. [Google Scholar] [CrossRef]

- Chandrasekhar, M.; Khatua, D.K.; Pattanayak, R.; Kumar, P. Dielectric relaxation and conduction mechanism studies of BNT-BT-BKT ceramics. J. Phys. Chem. Solids 2017, 111, 160–166. [Google Scholar] [CrossRef]

- Bongkarn, T.; Cann, D.P.; Prasertpalichat, S.; Kumar, N.; Sumang, R. Impedance spectroscopy of lead-free (1−x−y)Bi0.5Na0.5TiO3–xBi0.5K0.5TiO3–yBi0.5Li0.5TiO3 piezoelectric ceramics. Integr. Ferroelectr. 2017, 177, 79–89. [Google Scholar] [CrossRef]

- Xu, Q.; Lanagan, M.T.; Huang, X.C.; Xie, J.; Zhang, L.; Hao, H.; Liu, H.X. Dielectric behavior and impedance spectroscopy in lead-free BNT-BT-NBN perovskite ceramics for energy storage. Ceram. Int. 2016, 42, 9728–9736. [Google Scholar] [CrossRef]

- Zidi, N.; Chaouchi, A.; d’Astorg, S.; Rguiti, M.; Courtois, C. Dielectric and impedance spectroscopy characterizations of CuO added (Na0.5Bi0.5)0.94Ba0.06TiO3 lead-free piezoelectric ceramics. J. Alloys Compd. 2014, 590, 557–564. [Google Scholar] [CrossRef]

- Yan, Y.; Liu, D.; Zhao, W.; Zhou, H.; Fang, H. Topochemical synthesis of a high-aspect-ratio platelet NaNbO3 template. J. Am. Ceram. Soc. 2007, 90, 2399–2403. [Google Scholar] [CrossRef]

- Zhang, M.; Fan, H.; Chen, L.; Yang, C. Synthesis and formation mechanisms of high aspect ratio platelike NaNbO3 particles by topochemical microcrystal conversion. J. Alloys Compd. 2009, 476, 847–853. [Google Scholar] [CrossRef]

- Li, L.; Zhang, Y.; Bai, W.; Shen, B.; Zhai, J.; Chen, H. Synthesis of high aspect ratio (K,Na)NbO3 plate-like particles and study on the synthesis mechanism. Dalton Trans. 2015, 44, 11621–11625. [Google Scholar] [CrossRef]

- Zhao, W.; Ya, J.; Xin, Y.; Lie, E.; Zhao, D.; Zhou, H. Fabrication of Na0.5Bi0.5TiO3-BaTiO3-Textured Ceramics Templated by Plate-Like Na0.5Bi0.5TiO3 Particles. J. Am. Ceram. Soc. 2009, 92, 1607–1609. [Google Scholar] [CrossRef]

- Lotgering, F.K. Topotactical reactions with ferrimagnetic oxides having hexagonal crystal structures-I. J. Inorg. Nucl. Chem. 1959, 9, 113–123. [Google Scholar] [CrossRef]

- Messing, G.L.; Trolier-McKinstry, S.; Sabolsky, E.M.; Duran, C.; Kwon, S.; Brahmaroutu, B.; Park, P.; Yilmaz, H.; Rehrig, P.W.; Eitel, K.B.; et al. Templated Grain Growth of Textured Piezoelectric Ceramics. Crit. Rev. Solid State Mater. Sci. 2004, 29, 45–96. [Google Scholar] [CrossRef]

- Deng, M.; Li, X.; Zhao, Z.; Li, T.; Dai, Y.; Ji, H. Crystallographic textured evolution in 0.85Na0.5Bi0.5TiO3-0.04BaTiO3-0.11K0.5Bi0.5TiO3 ceramics prepared by reactive-templated grain growth method. J. Mater. Sci. Mater. Electron. 2014, 25, 1873–1879. [Google Scholar] [CrossRef]

- Bai, W.; Wang, L.; Zheng, P.; Wen, F.; Zhai, J.; Ji, Z. Pairing high piezoelectric properties and enhanced thermal stability in grain-oriented BNT-based lead-free piezoceramics. Ceram. Int. 2018, 44, 11402–11409. [Google Scholar] [CrossRef]

- Bai, W.; Li, H.; Xi, J.; Zhang, J.; Shen, B.; Zhai, J. Effect of different templates and texture on structure evolution and strain behavior of <001>-textured lead-free piezoelectric BNT-based ceramics. J. Alloys Compd. 2016, 656, 13–23. [Google Scholar] [CrossRef]

- Chen, X.; Ma, H.; Pan, W.; Pang, M.; Liu, P.; Zhou, J. Microstructure, dielectric and ferroelectric properties of (NaxBi0.5)0.94Ba0.06TiO3 lead-free ferroelectric ceramics: Effect of Na nonstoichiometry. Mater. Chem. Phys. 2012, 132, 368–374. [Google Scholar] [CrossRef]

- Wei, M.; Zhang, J.; Zhang, M.; Yao, Z.; Chen, H.; Yang, C. Relaxor behavior of BaTiO3-BiYO3 perovskite materials for high energy density capacitors. Ceram. Int. 2017, 43, 4768–4774. [Google Scholar] [CrossRef]

- Rani, R.; Sharma, S.; Rai, R.; Kholkin, A.L. Dielectric behavior and impedance analysis of lead-free CuO doped (Na0.50K0.50)0.95(Li0.05Sb0.05Nb0.95)O3 ceramics. Solid State Sci. 2013, 17, 46–53. [Google Scholar] [CrossRef]

- Kim, J.S.; Hussain, A.; Kim, M.-H.; Song, T.K.; Chung, S.T.; Chung, C.H.; Lee, H.S. Dielectric and conduction behaviors of lead-free LiNbO3-modified Bi0.5Na0.5TiO3 ceramics. J. Korean Phys. Soc. 2012, 61, 951–955. [Google Scholar] [CrossRef]

- Roy, A.K.; Singh, A.; Kumari, K.; Amar Nath, K.; Prasad, A.; Prasad, K. Electrical Properties and AC Conductivity of (Bi0.5Na0.5)0.94Ba0.06TiO3 Ceramic. ISRN Ceram. 2012, 2012, 1–10. [Google Scholar] [CrossRef]

- Moure, A.; Pardo, L. Microstructure and texture dependence of the dielectric anomalies and dc conductivity of Bi3TiNbO9 ferroelectric ceramics. J. Appl. Phys. 2005, 97, 084103. [Google Scholar] [CrossRef]

- Zang, J.; Li, M.; Sinclair, D.C.; Jo, W.; Rödel, J.; Zhang, S. Impedance Spectroscopy of (Bi1/2Na1/2)TiO3-BaTiO3 Ceramics Modified with (K0.5Na0.5)NbO3. J. Am. Ceram. Soc. 2014, 97, 1523–1529. [Google Scholar] [CrossRef]

- East, J.; Sinclair, D.C. Characterization of (Bi1/2Na1/2)TiO3 using electric modulus spectroscopy. J. Mater. Sci. Lett. 1997, 16, 422–425. [Google Scholar] [CrossRef]

- Cernea, M.; Galca, A.C.; Cioangher, M.C.; Dragoi, C.; Ioncea, G. Piezoelectric BNT-BT0.11 thin films processed by sol-gel technique. J. Mater. Sci. 2011, 46, 5621–5627. [Google Scholar] [CrossRef]

- Kungl, H.; Fett, T.; Wagner, S.; Hoffmann, M.J. Nonlinearity of strain and strain hysteresis in morphotropic LaSr-doped lead zirconate titanate under unipolar cycling with high electric fields. J. Appl. Phys. 2007, 101, 044101. [Google Scholar] [CrossRef]

- Zhang, S.; Li, F. High performance ferroelectric relaxor-PbTiO3 single crystals: Status and perspective. J. Appl. Phys. 2012, 111, 031301. [Google Scholar] [CrossRef]

- Haugen, A.B.; Morozov, M.I.; Jones, J.L.; Einarsrud, M.-A. Rayleigh analysis of dielectric properties in textured K0.5Na0.5NbO3 ceramics. J. Appl. Phys. 2014, 116, 214101. [Google Scholar] [CrossRef]

- Huan, Y.; Wang, X.; Li, L.; Koruza, J. Strong domain configuration dependence of the nonlinear dielectric response in (K,Na)NbO3-based ceramics. Appl. Phys. Lett. 2015, 107, 202903. [Google Scholar] [CrossRef]

- Li, P.; Zhai, J.; Shen, B.; Zhang, S.; Li, X.; Zhu, F.; Zhang, X. Ultrahigh piezoelectric properties in textured (K,Na)NbO3 -based lead-free ceramics. Adv. Mater. 2018, 30, 1705171. [Google Scholar] [CrossRef] [PubMed]

- Liu, B.; Li, P.; Shen, B.; Zhai, J.; Zhang, Y.; Li, F.; Liu, X. Enhanced piezoelectric properties and temperature-insensitive strain behavior of <001>-textured KNN-based ceramics. Ceram. Int. 2017, 43, 8004–8009. [Google Scholar] [CrossRef]

| Temperature (°C) | Randomly-Oriented | Textured | ||

|---|---|---|---|---|

| R1 (kΩ) | R2 (MΩ) | R1 (kΩ) | R2 (MΩ) | |

| 500 | 12.8 | 0.2 | 24.9 | 0.07 |

| 480 | 18.1 | 0.25 | 45.0 | 0.13 |

| 460 | 25.3 | 0.35 | 69.4 | 0.18 |

| 440 | 33.6 | 0.66 | 93.23 | 0.22 |

| 420 | 57.1 | 1.33 | 108.9 | 0.24 |

| 400 | 65.8 | 3.66 | 113.9 | 0.40 |

| 380 | 66.2 | 8.41 | 127.0 | 0.79 |

| 360 | 68.5 | 14.3 | 149.4 | 2.7 |

| 340 | 73.5 | 24.3 | 168.2 | 9.2 |

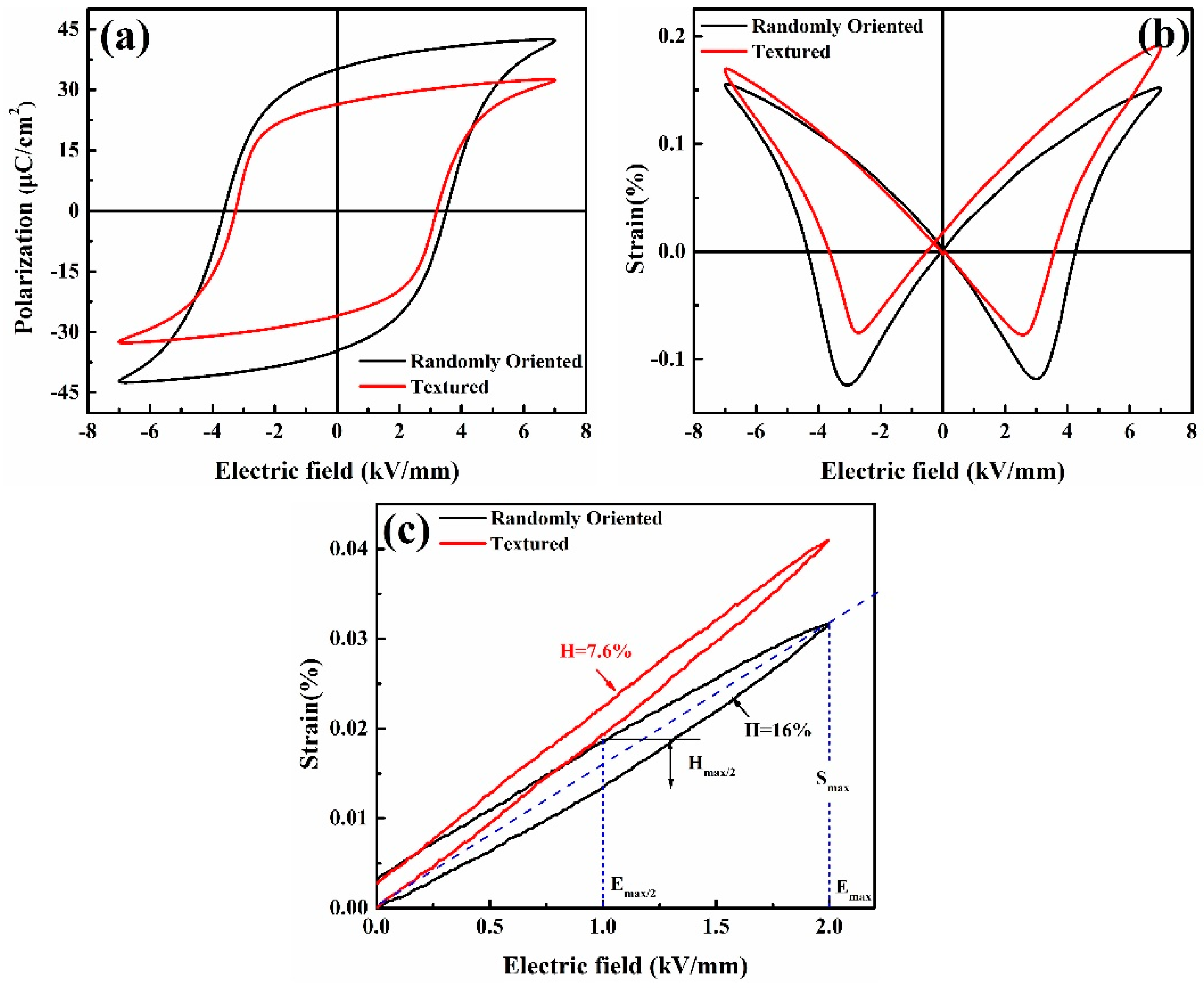

| Sample | Pr (μC/cm2) | Ec (kV/mm) | Smax | H | d33 * (pm/V) | d33 (pC/N) | Td (°C) | Tm (°C) | ε25 °C (at 10 kHz) | εmax (at 10 kHz) | tanδ (25 °C) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Random | 35.2 | 3.5 | 0.032% | 16% | 160 | 150 | 120 | 290 | 800 | 5350 | 0.038 |

| Textured | 26.4 | 3.1 | 0.041% | 7.6% | 200 | 185 | 110 | 270 | 810 | 3950 | 0.032 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dong, N.; Gao, X.; Xia, F.; Liu, H.; Hao, H.; Zhang, S. Dielectric and Piezoelectric Properties of Textured Lead-Free Na0.5Bi0.5TiO3-Based Ceramics. Crystals 2019, 9, 206. https://doi.org/10.3390/cryst9040206

Dong N, Gao X, Xia F, Liu H, Hao H, Zhang S. Dielectric and Piezoelectric Properties of Textured Lead-Free Na0.5Bi0.5TiO3-Based Ceramics. Crystals. 2019; 9(4):206. https://doi.org/10.3390/cryst9040206

Chicago/Turabian StyleDong, Nannan, Xiaoyi Gao, Fangquan Xia, Hanxing Liu, Hua Hao, and Shujun Zhang. 2019. "Dielectric and Piezoelectric Properties of Textured Lead-Free Na0.5Bi0.5TiO3-Based Ceramics" Crystals 9, no. 4: 206. https://doi.org/10.3390/cryst9040206

APA StyleDong, N., Gao, X., Xia, F., Liu, H., Hao, H., & Zhang, S. (2019). Dielectric and Piezoelectric Properties of Textured Lead-Free Na0.5Bi0.5TiO3-Based Ceramics. Crystals, 9(4), 206. https://doi.org/10.3390/cryst9040206