Hysteresis Reduction for Organic Thin Film Transistors with Multiple Stacked Functional Zirconia Polymeric Films

Abstract

:1. Introduction

2. Materials and Methods

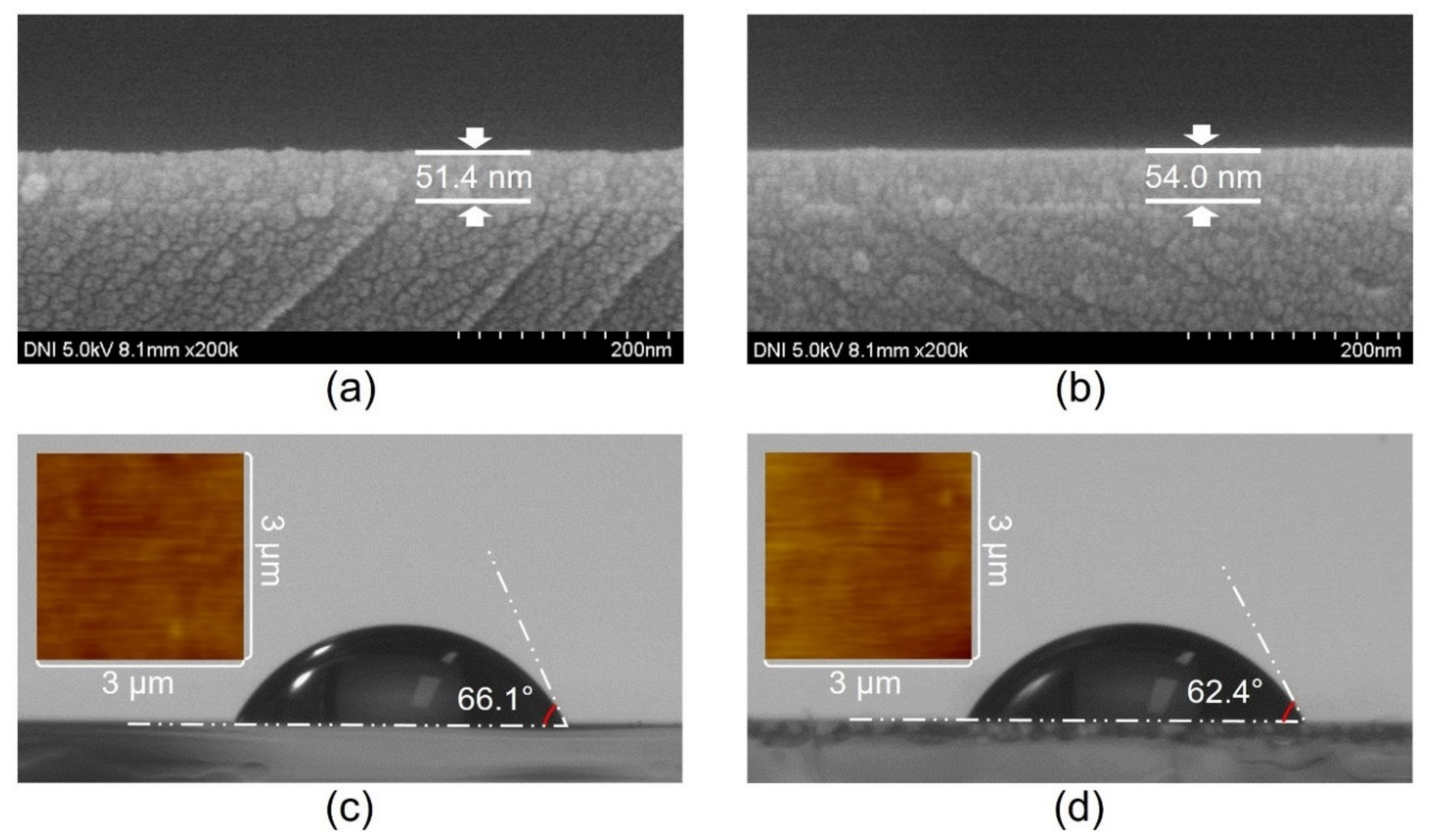

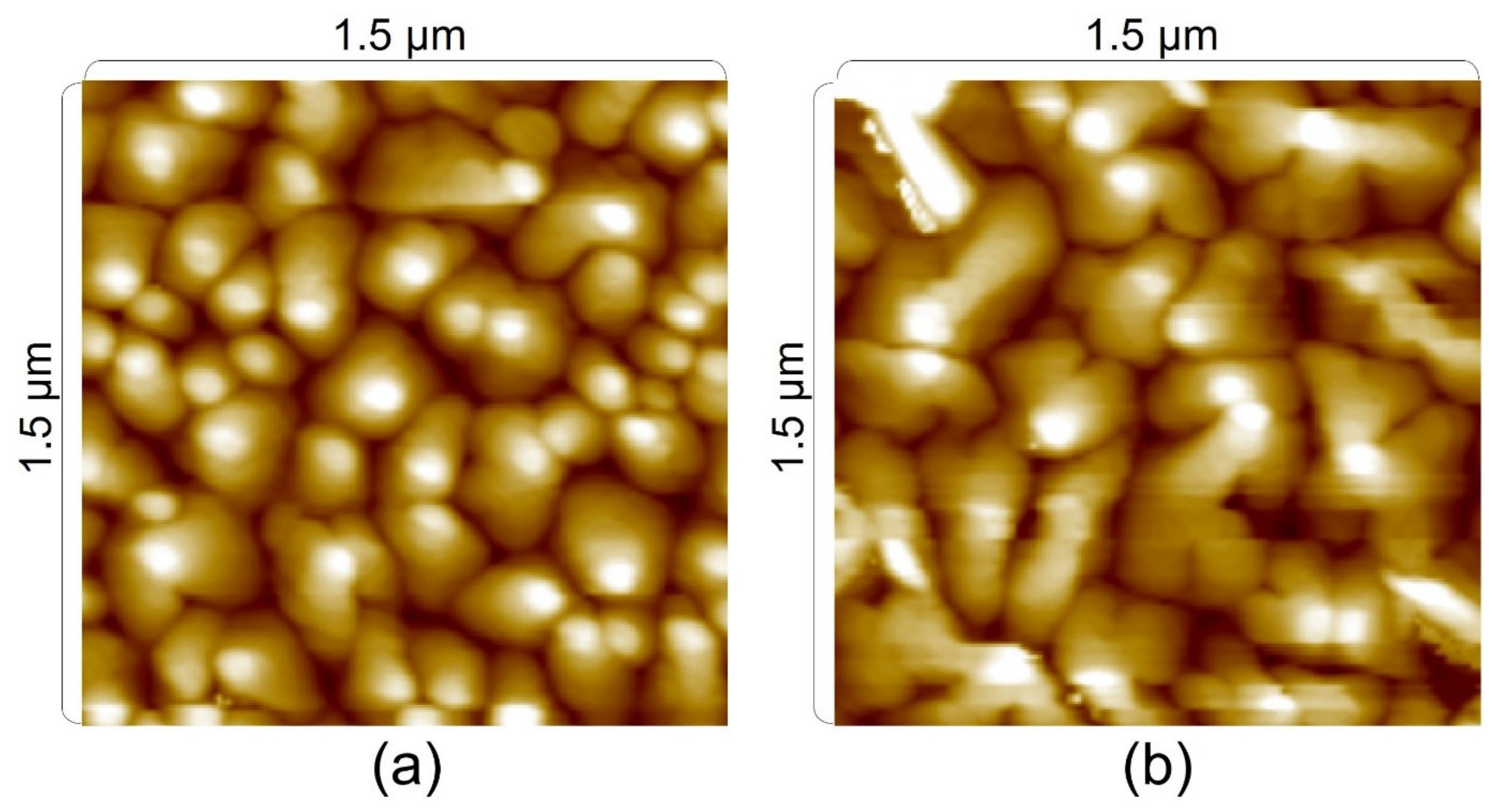

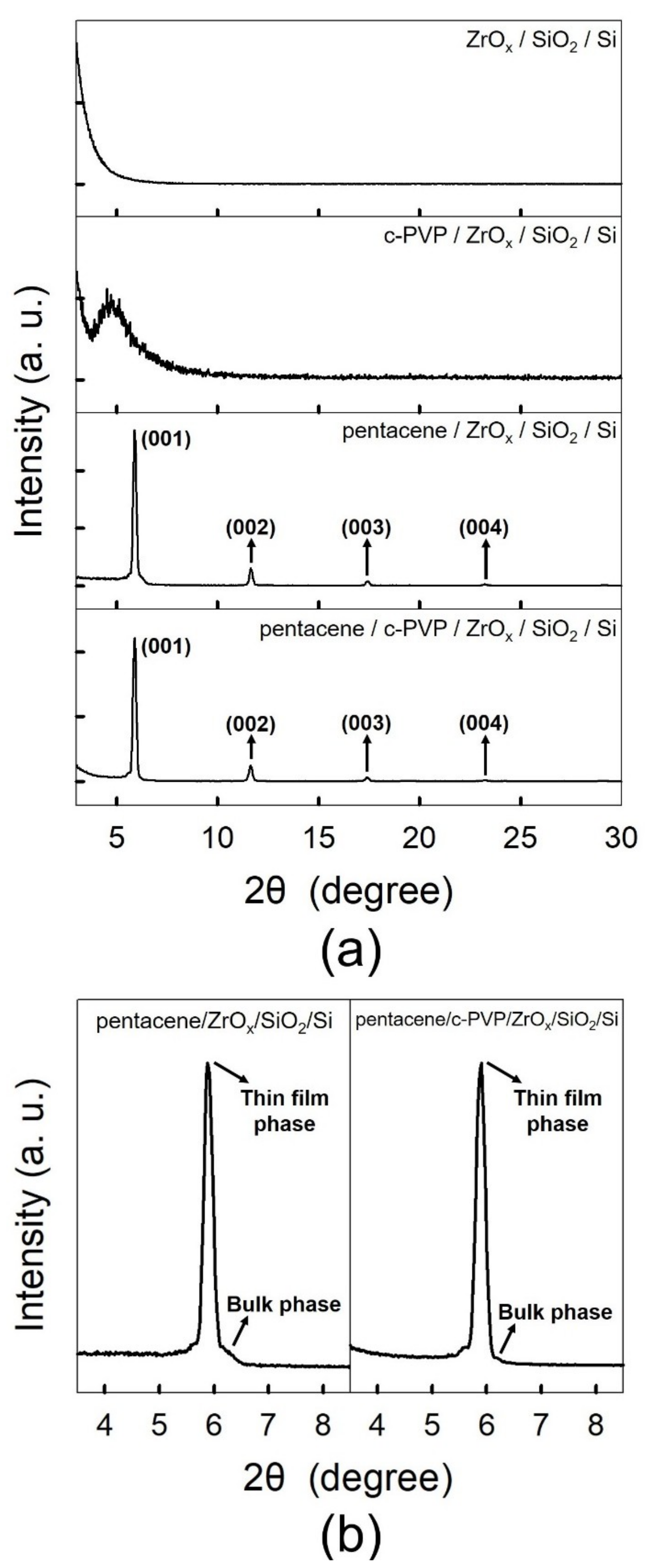

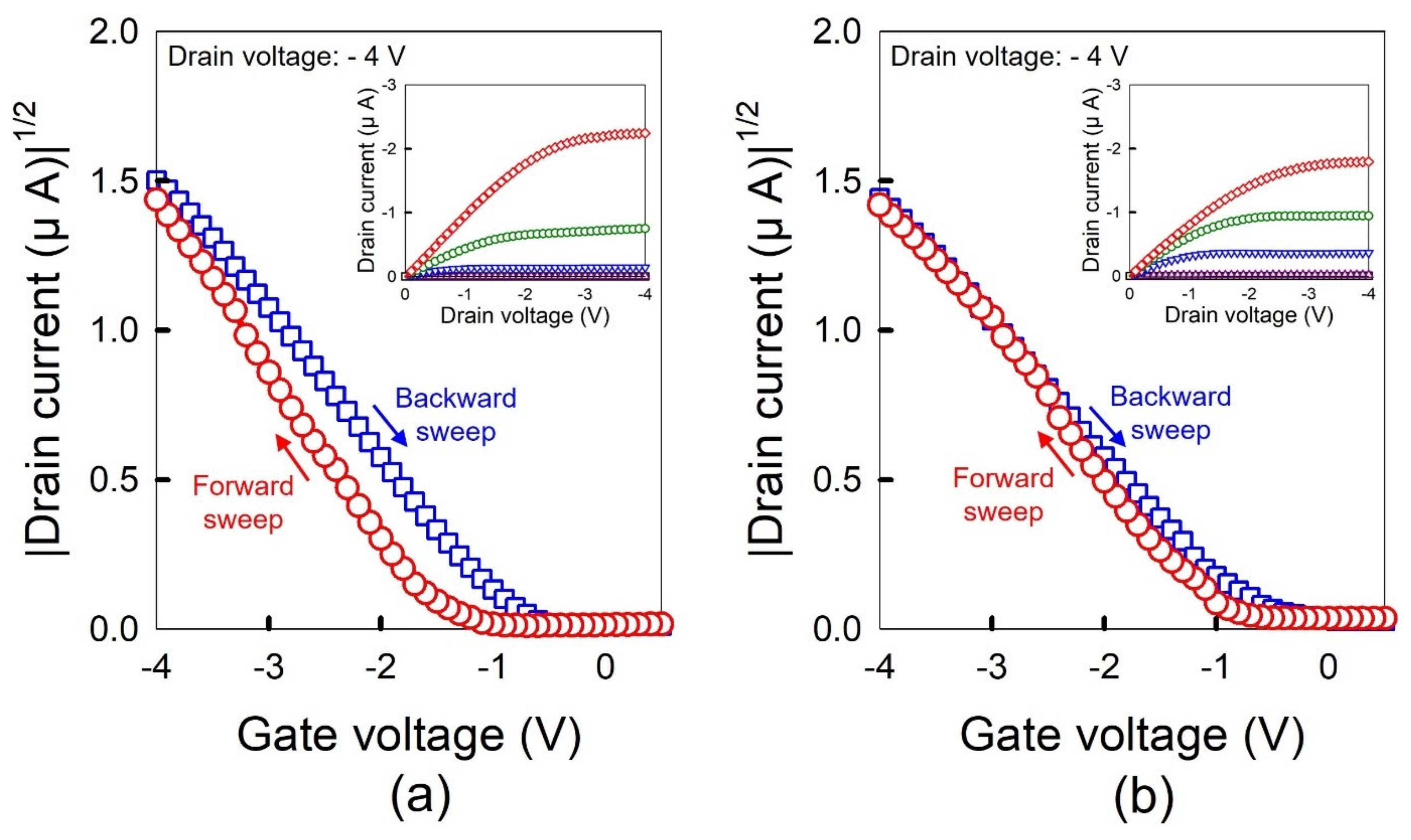

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Han, C.Y.; Tang, W.M.; Leung, C.H.; Che, C.-M.; Lai, P.T. A study on La incorporation in transition-metal (Y, Zr, and Nb) oxides as gate dielectric of pentacene organic thin-film transistor. IEEE Trans. Electron Devices 2015, 62, 2313–2319. [Google Scholar] [CrossRef]

- Li, X.; Xie, F.; Zhang, S.; Hou, J.; Choy, W.C.H. MoOx and V2Ox as hole and electron transport layers through functionalized intercalation in normal and inverted organic optoelectronic devices. Light Sci. Appl. 2015, 4, 1–7. [Google Scholar] [CrossRef]

- Pecunia, V.; Banger, K.; Sirringhaus, H. High-performance solution-processed amorphous-oxide-semiconductor TFTs with organic polymeric gate dielectrics. Adv. Electron. Mater. 2015, 1, 1400024. [Google Scholar] [CrossRef]

- Chang, J.-F.; Shie, H.-S.; Yang, Y.-W.; Wang, C.-H. Study on correlation between structural and electronic properties of fluorinated oligothiophenes transistors by controlling film thickness. Crystals 2019, 9, 1–14. [Google Scholar] [CrossRef]

- Yu, X.; Marks, T.J.; Facchetti, A. Metal oxides for optoelectronic applications. Nat. Mater. 2016, 15, 383–396. [Google Scholar] [CrossRef] [PubMed]

- Rim, Y.S.; Bae, S.-H.; Chen, H.; Yang, J.L.; Kim, J.; Andrews, A.M.; Weiss, P.S.; Yang, Y.; Tseng, H.-R. Printable ultrathin metal oxide semiconductor-based conformal biosensors. ACS Nano 2015, 9, 12174–12181. [Google Scholar] [CrossRef]

- Esposito, S. “Traditional” sol-gel chemistry as a powerful tool for the preparation of supported metal and metal oxide catalysts. Materials 2019, 12, 668. [Google Scholar] [CrossRef]

- Rullyani, C.; Sung, C.-F.; Lin, H.-C.; Chu, C.-W. Flexible organic thin film transistors incorporating a biodegradable CO2-based polymer as the substrate and dielectric material. Sci. Rep. 2018, 8, 1–10. [Google Scholar] [CrossRef]

- Sharma, V.; Vyas, R.; Bazylewski, P.; Chang, G.S.; Asokane, K.; Sachdev, K. Probing the highly transparent and conducting SnOx/Au/SnOx structure for futuristic TCO applications. RSC Adv. 2016, 6, 29135–29141. [Google Scholar] [CrossRef]

- Kwon, J.-H.; Lee, H.; Bae, J.-H.; Park, J. Surface modification of solution-processed ZrO2 films through double coating for pentacene thin-film transistors. J. Korean Phys. Soc. 2019, 72, 570–576. [Google Scholar] [CrossRef]

- Pavlidis, S.; Bayraktaroglu, B.; Leedy, K.; Henderson, W.; Vogel, E.; Brand, O. ALD TiOx as a top-gate dielectric and passivation layer for InGaZnO115 ISFETs. Semicond. Sci. Technol. 2017, 32, 114004. [Google Scholar] [CrossRef]

- Ruan, D.-B.; Liu, P.-T.; Chiu, Y.-C.; Kan, K.-Z.; Yu, M.-C.; Chien, T.-C.; Chen, Y.-H.; Kuo, P.-Y.; Sze, S.M. Investigation of low operation voltage InZnSnO thin-film transistors with different high-k gate dielectric by physical vapor deposition. Thin Solid Film. 2018, 660, 885–890. [Google Scholar] [CrossRef]

- Choi, W.-H.; Sheng, J.; Jeong, H.-J.; Park, J.-S.; Kim, M.J.; Jeon, W. Improved performance and stability of In-Sn-Zn-O thin film transistor by introducing a meso-crystalline ZrO2 high-k gate insulator. J. Vac. Sci. Technol. A 2019, 37, 020924. [Google Scholar] [CrossRef]

- Fang, R.-C.; Sun, Q.-Q.; Zhou, P.; Yang, W.; Wang, P.-F.; Zhang, D.W. High-performance bilayer flexible resistive random access memory based on low-temperature thermal atomic layer deposition. Nanoscale Res. Lett. 2013, 8, 1–7. [Google Scholar] [CrossRef]

- Zhu, C.; Liu, A.; Liu, G.; Jiang, G.; Meng, Y.; Fortunato, E.; Martins, R.; Shan, F. Low-temperature, nontoxic water-induced high-k zirconium oxide dielectrics for low-voltage, high-performance oxide thin-film transistors. J. Mater. Chem. C 2016, 4, 10715–10721. [Google Scholar] [CrossRef]

- Ha, T.-J.; Dodabalapur, A. Photo stability of solution-processed low-voltage high mobility zinc-tin-oxide/ZrO2 thin-film transistors for transparent display applications. Appl. Phys. Lett. 2013, 102, 123506. [Google Scholar] [CrossRef]

- Cai, W.; Zhu, Z.; Wei, J.; Fang, Z.; Ning, H.; Zheng, Z.; Zhou, S.; Yao, R.; Peng, J.; Lu, X. A simple method for high-performance, solution-processed, amorphous ZrO2 gate insulator TFT with a high concentration precursor. Materials 2017, 10, 972. [Google Scholar] [CrossRef]

- Adamopoulos, G.; Thomas, S.; Wöbkenberg, P.H.; Bradley, D.D.C.; McLachlan, M.A.; Anthopoulos, T.D. High-mobility low-voltage ZnO and Li-doped ZnO transistors based on ZrO2 high-k dielectric grown by spray pyrolysis in ambient air. Adv. Mater. 2011, 23, 1894–1898. [Google Scholar] [CrossRef]

- Vicca, P.; Steudel, S.; Smout, S.; Raats, A.; Genoe, J.; Heremans, P. A low-temperature-cross-linked poly (4-vinylphenol) gate-dielectric for organic thin film transistors. Thin Solid Film. 2010, 519, 391–393. [Google Scholar] [CrossRef]

- Duca, M.D.; Plosceanu, C.L.; Pop, T. Surface modifications of polyvinylidene fluoride (PVDF) under rf Ar plasma. Polym. Degrad. Stab. 1998, 61, 65–72. [Google Scholar] [CrossRef]

- Kwak, S.-Y.; Choi, C.G.; Bae, B.-S. Effect of surface energy on pentacene growth and characteristics of organic thin-film transistors. Electrochem. Solid State Lett. 2009, 12, G37–G39. [Google Scholar] [CrossRef]

- Shioya, N.; Murdey, R.; Nakao, K.; Yoshida, H.; Koganezawa, T.; Eda, K.; Shimoaka, T.; Hasegawa, T. Alternative face-on thin film structure of pentacene. Sci. Rep. 2019, 9, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Srnanek, R.; Jakabovic, J.; Dobrocka, E.; Irmer, G.; Heinemeyer, U.; Broch, K.; Schreiber, F.; Vincze, A.; Machovic, V.; Kovac, J.; et al. Evidence of pentacene bulk and thin film phase transformation into an orthorhombic phase by iodine diffusion. Chem. Phys. Lett. 2010, 484, 299–303. [Google Scholar] [CrossRef]

- Kwon, J.-H.; Lee, H.; Bae, J.-H.; Park, J. Dimethyl ketone treatment of cross-linked poly(4-vinylphenol) insulators for pentacene thin-film transistors. J. Korean Phys. Soc. 2019, 74, 280–285. [Google Scholar] [CrossRef]

- Werzer, O.; Stadlober, B.; Haase, A.; Oehzelt, M.; Resel, R. Full X-ray pattern analysis of vacuum deposited pentacene thin films. Eur. Phys. J. B 2008, 66, 455–459. [Google Scholar] [CrossRef]

- Sirringhaus, H. 25th anniversary article: Organic field-effect transistors: The path beyond amorphous silicon. Adv. Mater. 2014, 26, 1319–1335. [Google Scholar] [CrossRef]

- Kwon, J.-H.; Zhang, X.; Piao, S.H.; Choi, H.J.; Bae, J.-H.; Park, J. Stability study of flexible 6,13-bis(triisopropylsilylethynyl)pentacene thin-film transistors with a cross-linked poly(4-vinylphenol)/yttrium oxide nanocomposite gate insulator. Polymers 2016, 8, 88. [Google Scholar] [CrossRef]

- Banger, K.K.; Yamashita, Y.; Mori, K.; Peterson, R.L.; Leedham, T.; Rickard, J.; Sirringhaus, H. Low-temperature, high-performance solution-processed metal oxide thin-film transistors formed by a ‘sol–gel on chip’ process. Nat. Mater. 2011, 10, 45–50. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kwon, J.-H.; Choi, J.-H.; Bae, J.-H.; Park, a.J. Hysteresis Reduction for Organic Thin Film Transistors with Multiple Stacked Functional Zirconia Polymeric Films. Crystals 2019, 9, 634. https://doi.org/10.3390/cryst9120634

Kwon J-H, Choi J-H, Bae J-H, Park aJ. Hysteresis Reduction for Organic Thin Film Transistors with Multiple Stacked Functional Zirconia Polymeric Films. Crystals. 2019; 9(12):634. https://doi.org/10.3390/cryst9120634

Chicago/Turabian StyleKwon, Jin-Hyuk, Ji-Hoon Choi, Jin-Hyuk Bae, and and Jaehoon Park. 2019. "Hysteresis Reduction for Organic Thin Film Transistors with Multiple Stacked Functional Zirconia Polymeric Films" Crystals 9, no. 12: 634. https://doi.org/10.3390/cryst9120634

APA StyleKwon, J.-H., Choi, J.-H., Bae, J.-H., & Park, a. J. (2019). Hysteresis Reduction for Organic Thin Film Transistors with Multiple Stacked Functional Zirconia Polymeric Films. Crystals, 9(12), 634. https://doi.org/10.3390/cryst9120634