Energy Storage Performance of Sandwich Structured Pb(Zr0.4Ti0.6)O3/BaZr0.2Ti0.8O3/Pb(Zr0.4Ti0.6)O3 Films

Abstract

1. Introduction

2. Experiment

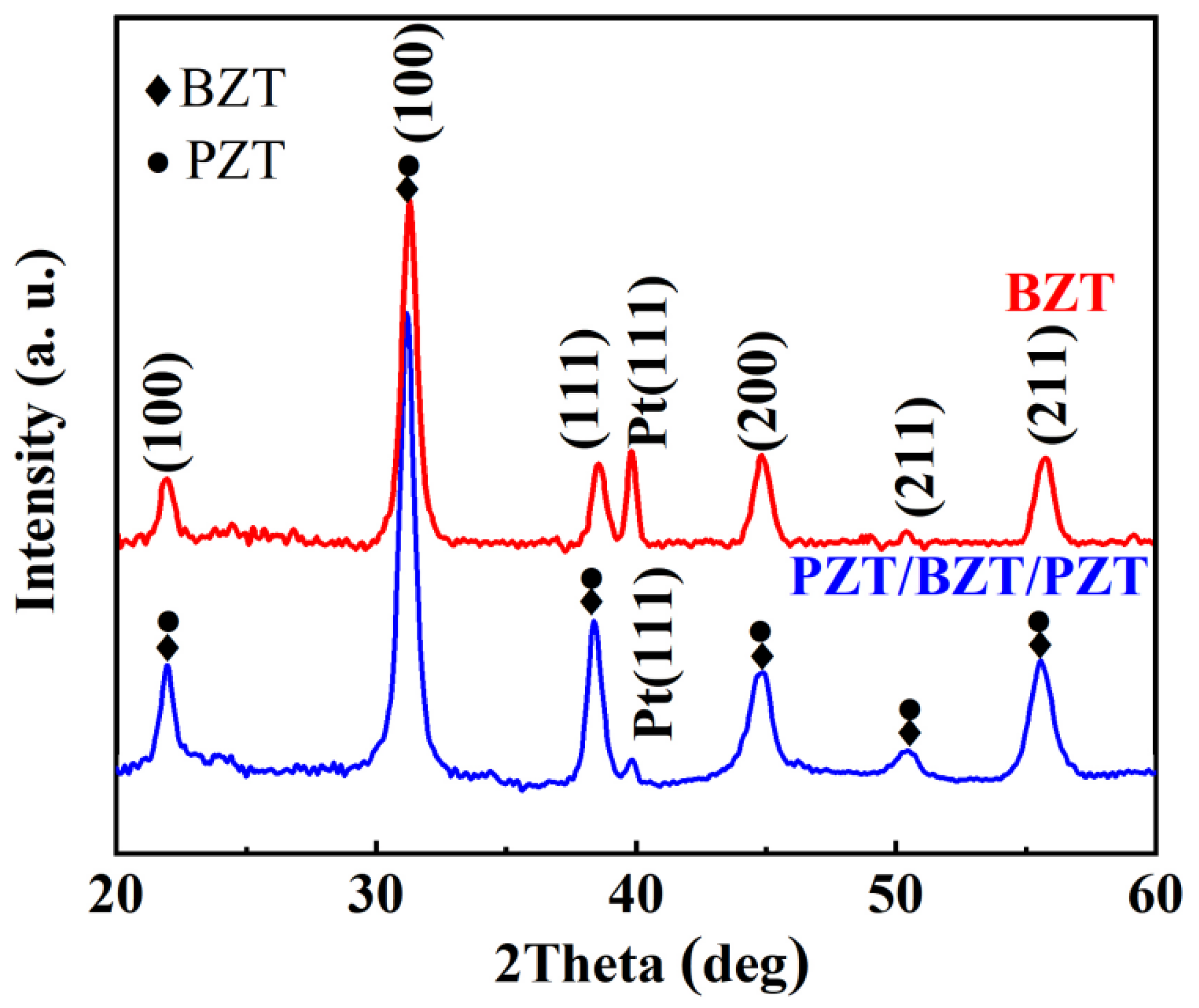

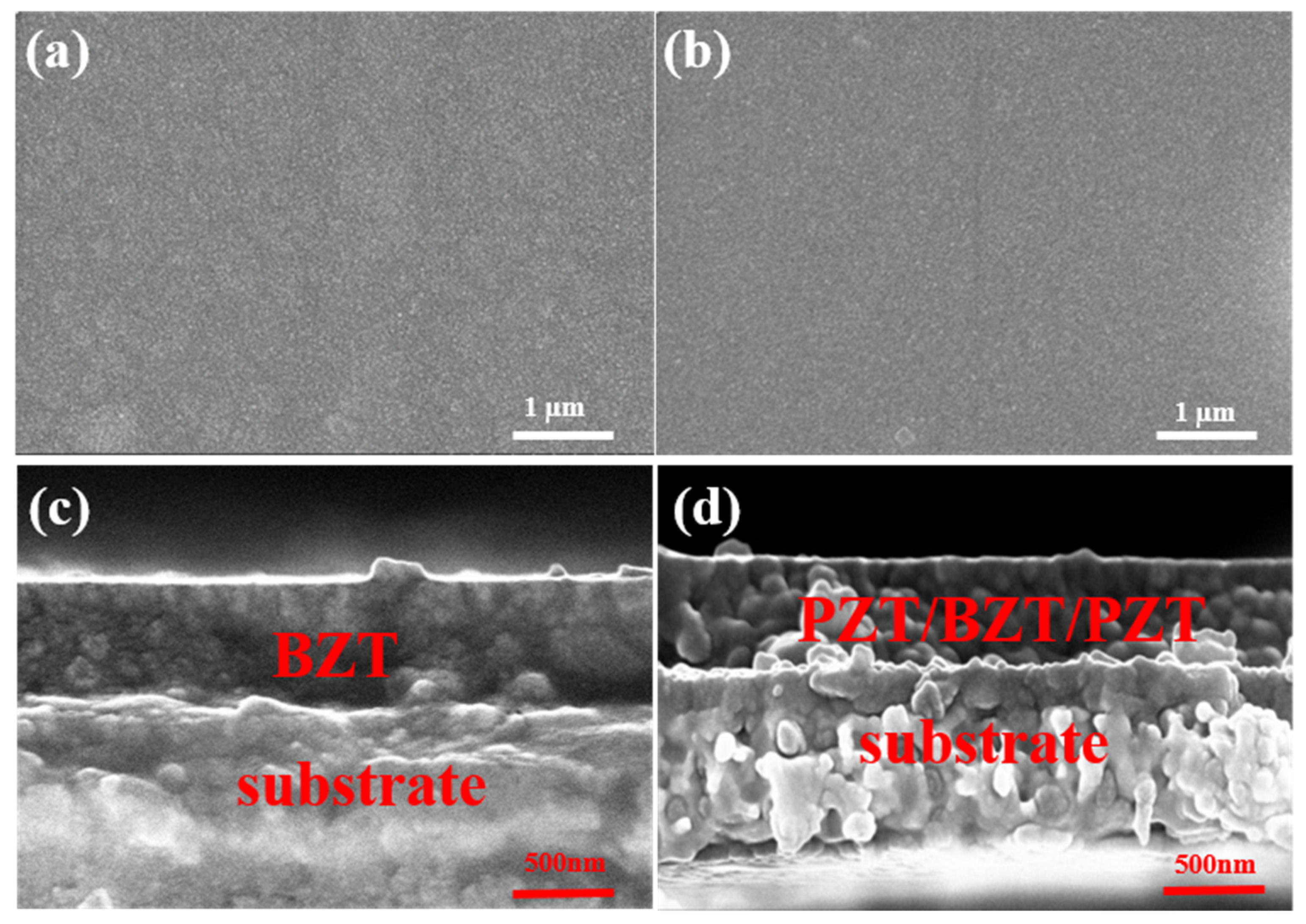

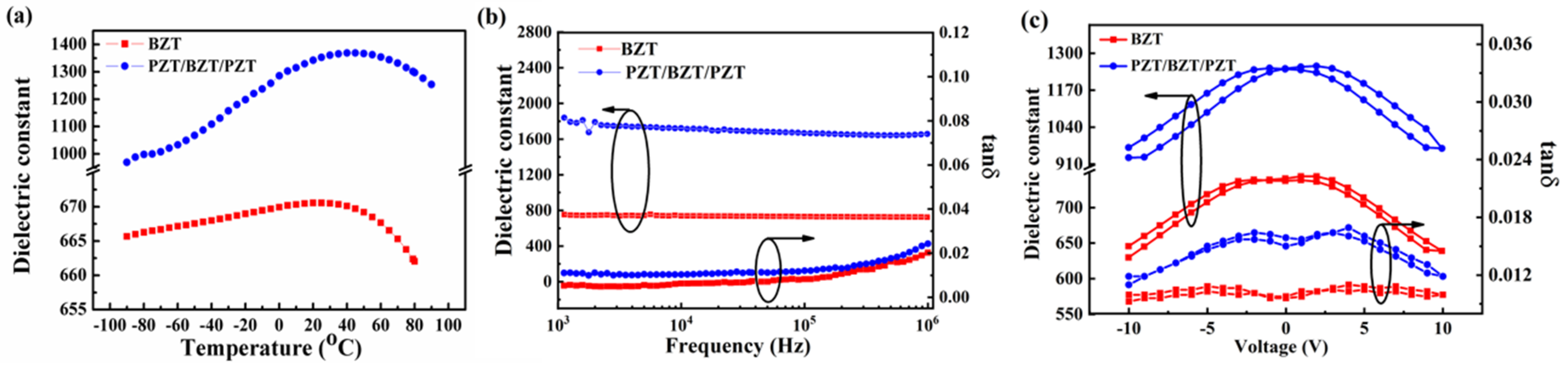

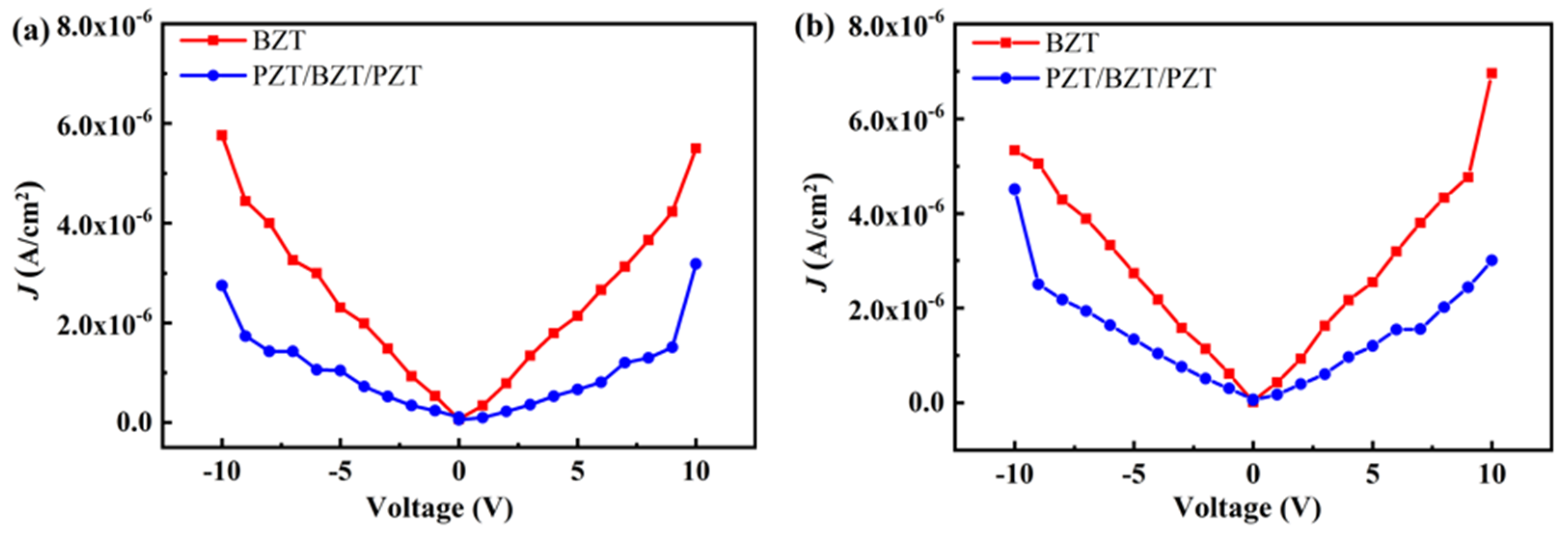

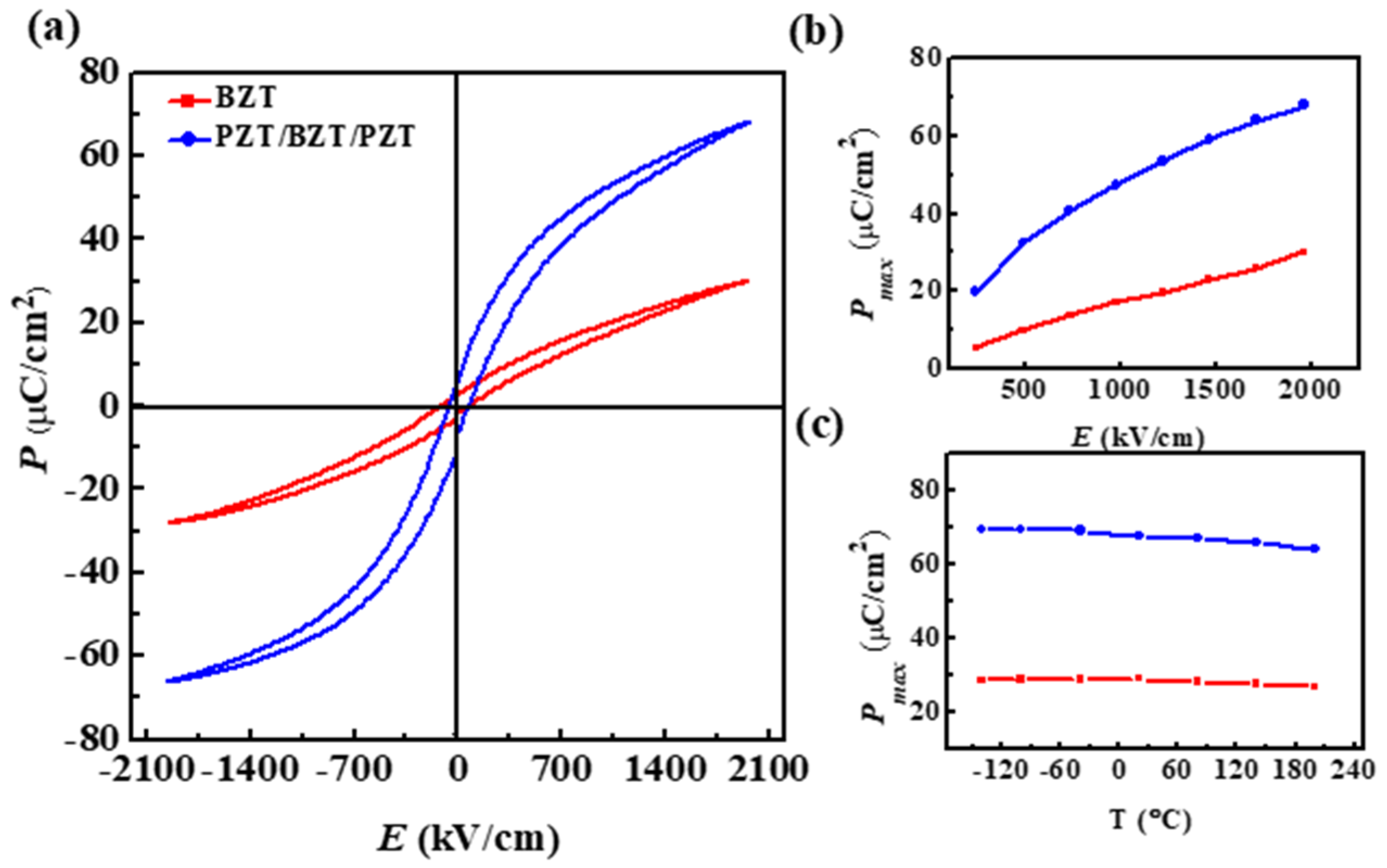

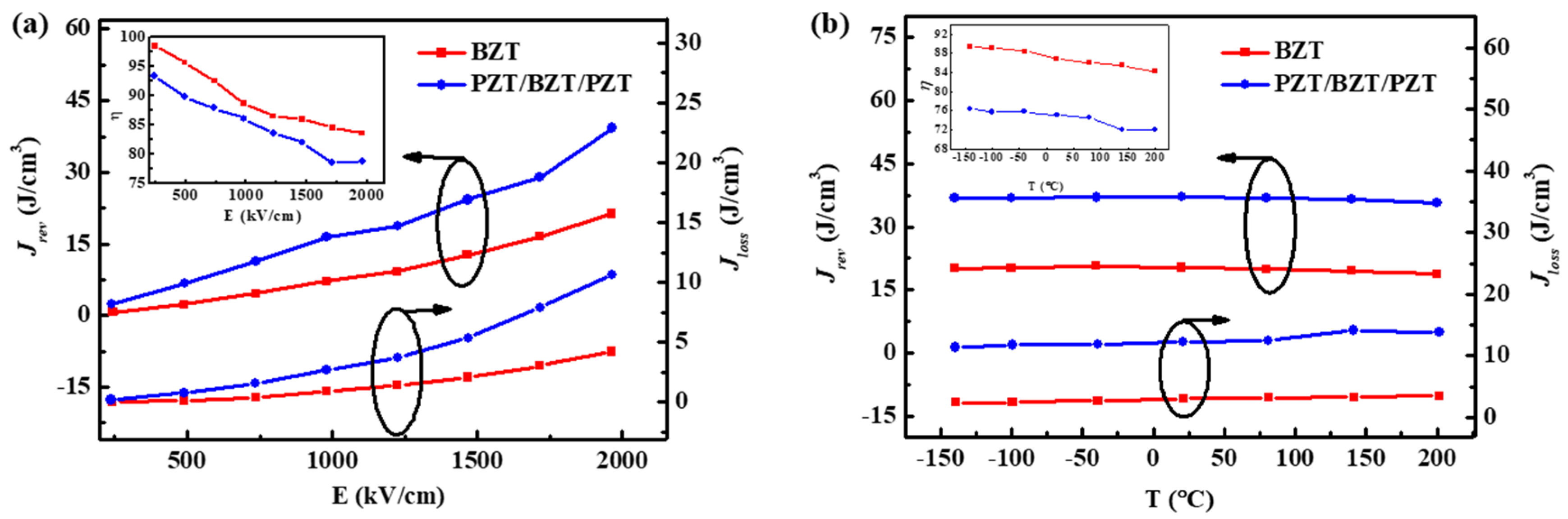

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Puli, V.S.; Pradhan, D.K.; Chrisey, D.B.; Tomozawa, M.; Sharma, G.L.; ScottRam, J.F.; Katiyar, S. Structure, dielectric, ferroelectric, and energy density properties of (1−x) BZT–x BCT ceramic capacitors for energy storage applications. J. Mater. Sci. 2013, 48, 2151–2157. [Google Scholar] [CrossRef]

- Tong, S.; Ma, B.; Narayanan, M.; Liu, S.; Koritala, R.; Balachandran, U.; Shi, D. Lead Lanthanum Zirconate Titanate Ceramic Thin Films for Energy Storage. ACS Appl. Mater. Interfaces 2013, 5, 1474–1480. [Google Scholar] [CrossRef] [PubMed]

- Liu, G.; Zhang, S.; Jiang, W.; Cao, W. Losses in ferroelectric materials. Mater. Sci. Eng. R Rep. 2015, 89, 1–48. [Google Scholar] [CrossRef] [PubMed]

- Ye, M.; Sun, Q.; Chen, X.; Jiang, Z.; Wang, F. Electrical and energy storage performance of Eu-doped PbZrO3 thin films with different gradient sequences. J. Am. Ceram. Soc. 2012, 95, 1486–1488. [Google Scholar] [CrossRef]

- Instan, A.A.; Pavunny, S.P.; Bhattarai, M.K.; Katiyar, R.S. Ultrahigh capacitive energy storage in highly oriented BaZrxTi1-xO3 thin films prepared by pulsed laser deposition. Appl. Phys. Lett. 2017, 111, 142903. [Google Scholar] [CrossRef]

- Guo, Y.; Akai, D.; Sawada, K.; Ishida, M.; Gu, M. Structure and electrical properties of trilayered BaTiO3/(Na0.5Bi0.5)TiO3–BaTiO3/BaTiO3 thin films deposited on Si substrate. Solid State Commun. 2009, 149, 14–17. [Google Scholar] [CrossRef]

- Huang, Z.H.; Lai, Y.M.; Guan, W.M.; Zeng, Y.; Wei, Y.; Wu, S.; Han, J.; Mao, Y.; Xiang, Y. Structure, dielectric and ferroelectric properties of lead-free (1−x)(Ba0.85Ca0.15)(Ti0.9Zr0.1)O3-xBa(Mg1/3Nb2/3)O3 ceramics. Mater. Lett. 2016, 178, 163–165. [Google Scholar] [CrossRef]

- Cai, W.; Fu, C.; Gao, J.; Lin, Z.; Deng, X. Effect of hafnium on the microstructure, dielectric and ferroelectric properties of BaZr0.2Ti0.8O3 ceramics. Ceram. Int. 2012, 38, 3367–3375. [Google Scholar] [CrossRef]

- Qin, W.F.; Xiong, J.; Zhu, J.; Tang, J.L.; Jie, W.J.; Zhang, Y.; Li, Y.R. Enhanced electrical properties of multilayer Ba(Zr0.2Ti0.8)O3/Ba0.6Sr0.4TiO3/Ba(Zr0.2Ti0.8)O3 thin films for tunable microwave applications. J. Mater. Sci. 2008, 43, 409–412. [Google Scholar] [CrossRef]

- Liang, Z.; Liu, M.; Ma, C.; Shen, L.; Lu, L.; Jia, C.-L. High-performance BaZr0.35Ti0.65O3 thin film capacitors with ultrahigh energy storage density and excellent thermal stability. J. Mater. Chem. A 2018, 6, 12165–12796. [Google Scholar] [CrossRef]

- Sun, Z.; Ma, C.; Xi, W.; Liu, M.; Lu, L.; We, M.; Lou, X.; Wang, H.; Jia, C.-J. Large energy density, excellent thermal stability, and high cycling endurance of lead-free BaZr0.2Ti0.8O3 film capacitors. ACS Appl. Mater. Interfaces 2017, 9, 17096. [Google Scholar] [CrossRef] [PubMed]

- Mangalam, R.V.; Karthik, J.; Damodaran, A.R.; Agar, J.C.; Martin, L.W. Unexpected crystal and domain structures and properties in compositionally graded PbZr1-xTixO3 thin films. Adv. Mater. 2013, 25, 1761–1767. [Google Scholar] [CrossRef] [PubMed]

- O"Neill, D.; Bowman, R.M.; Gregg, J.M. Investigation into the dielectric behavior of ferroelectric superlattices formed by pulsed laser deposition. J. Mater. Sci. Mater. Electron. 2000, 11, 537–541. [Google Scholar] [CrossRef]

- Koebernik, G.; Haessler, W.; Pantou, R.; Weiss, F. Thickness dependence on the dielectric properties of BaTiO3/SrTiO3-multilayers. Thin Solid Film. 2004, 449, 80–85. [Google Scholar] [CrossRef]

- Bao, D.; Wakiya, N.; Shinozaki, K.; Mizutani, N. Ferroelectric properties of sandwich structured (Bi, La)4T3O12/Pb(Zr, Ti)O3/ (Bi, La)4Ti3O12 thin films on Pt/Ti/SiO2/Si substrates. J. Phys. D Appl. Phys. 2002, 35, L1. [Google Scholar] [CrossRef]

- Diao, C.; Liu, H.; Zheng, H.; Yao, Z.; Iqbal, J.; Cao, M.; Hao, H. Enhanced energy storage properties of BaTiO3 thin films by Ba0.4Sr0.6TiO3 layers modulation. J. Alloy. Compd. 2018, 765, 362–368. [Google Scholar] [CrossRef]

- Spierings, G.A.C.M.; Ulenaers, M.J.E.; Kampschoer, G.L.M.; van Hal, H.A.M.; Larsen, P.K. Preparation and ferroelectric properties of PbZr0.53Ti0.47O3 thin films by spin coating and metalorganic decomposition. J. Appl. Phys. 1991, 70, 2290. [Google Scholar] [CrossRef]

- Klee, M.; Eusemann, R.; Waser, R.; Brand, W. Processing and electrical properties of PbZrxTi1−xO3 (x = 0.2–0.75) films: Comparison of metallo-organic decomposition and sol-gel processes. J. Appl. Phys. 1992, 72, 1566–1576. [Google Scholar] [CrossRef]

- Lin, Z.; Chen, Y.; Liu, Z.; Wang, G.; Rémiens, D.; Dong, X. Large Energy Storage Density, Low Energy Loss and highly stable (Pb0.97La0.02)(Zr0.66Sn0.23Ti0.11)O3 Antiferroelectric Thin-Film Capacitors. J. Eur. Ceram. Soc. 2018, 38, 3177–3181. [Google Scholar] [CrossRef]

- Tayebi, N.; Kim, S.; Chen, R.J.; Tran, Q.; Franklin, N.; Nishi, Y.; Ma, Q. Tuning the built-in electric field in ferroelectric PbZr0.2Ti0.8O3 films for long-term stability of single-digit nanometer inverted domains. Nano Lett. 2012, 12, 5455. [Google Scholar] [CrossRef]

- Ye, C.; Mcintyre, P.C. Lead zirconate titanate ferroelectric thin film capacitors: Effects of surface treatments on ferroelectric properties. Appl. Phys. Lett. 2007, 91, 064013. [Google Scholar] [CrossRef]

- Liu, B.; Wang, X.; Zhang, Y.; Lv, X.; Yang, Y. Synthesis and characteristics of KTa0.5Nb0.5O3thin films. Ionics 2014, 20, 1795–1799. [Google Scholar] [CrossRef]

- Liu, Z.; Bai, Y.; Chen, X.F.; Dong, X.; Nie, H.; Cao, F.; Wang, G. Linear composition-dependent phase transition behavior and energy storage performance of tetragonal PLZST antiferroelectric ceramics. J. Alloy. Compd. 2017, 691, 721–725. [Google Scholar] [CrossRef]

- Lim, K.W.; Peddigari, M.; Annapureddy, V.; Hwang, G.; Choi, J.; Kim, G.; Yi, S.N.; Ryu, J. Energy storage characteristics of {001 oriented Pb(Zr0.52Ti0.48)O3 thin film grown by chemical solution deposition. Thin Solid Film. 2018, 660, 434–438. [Google Scholar] [CrossRef]

- Chen, L.; Sun, N.; Li, Y.; Zhang, Q.; Zhang, L.; Hao, X. Multifunctional antiferroelectric MLCC with high-energy-storage properties and large field-induced strain. J. Am. Ceram. Soc. 2017, 101, 2313–2320. [Google Scholar] [CrossRef]

- Puli, V.S.; Pradhan, D.K.; Riggs, B.C.; Chrisey, D.B.; Katiyar, R.S. Structure, ferroelectric, dielectric and energy storage studies of BaCaTiO3, BaZrTiO3 ceramic capacitors. Integr. Ferroelectr. 2014, 157, 139–146. [Google Scholar] [CrossRef]

- Kwon, D.K.; Lee, M.H. Temperature-stable high-energy-density capacitors using complex perovskite thin films. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2012, 59, 1894–1899. [Google Scholar] [CrossRef]

- Puli, V.S.; Pradhan, D.K.; Adireddy, S.; Martínez, R.; Silwal, P.; Scott, J.F.; Ramana, C.V.; Chrisey, D.B.; Katiyar, R.S. Nanoscale polarisation switching and leakage currents in (Ba0.955Ca0.045) (Zr0.17Ti0.83)O3 epitaxial thin films. J. Phys. D Appl. Phys. 2015, 48, 355502. [Google Scholar] [CrossRef]

- Hou, Y.; Han, R.; Li, W.; Luo, L.; Fei, W. Significantly enhanced energy storage performance in BiFeO3/BaTiO3/BiFeO3 sandwich-structured films through crystallinity regulation. Phys. Chem. Chem. Phys. 2018, 20, 21917–21924. [Google Scholar] [CrossRef]

- Chi, Q.; Ma, T.; Zhang, Y.; Chen, Q.; Zhang, C.; Cui, Y.; Zhang, T.; Lin, J.; Wang, X.; Lei, Q. Excellent energy storage of sandwich-structured PVDF-based composite at low electric field by introduced the hybrid CoFe2O4@BZT-BCT nanofibers. ACS Sustain. Chem. Eng. 2018, 6, 403–412. [Google Scholar] [CrossRef]

| Material | Jrec (J·cm−3) | η (%) | Electric Strength (MV·cm−1) | Reference |

|---|---|---|---|---|

| (Ba(Zr0.2Ti0.8)O3)0.85((Ba0.7Ca0.3)TiO3)0.15 ceramic | 0.94 | 72 | 0.17 | [1] |

| Ba(Zr0.2Ti0.8)O3 ceramic | 0.71 | - | 0.15 | [26] |

| BaZr0.35Ti0.65O3 film | 78.7 | 80.5 | 4.0 | [10] |

| BaZr0.2Ti0.8O3 film | 30.4 | 81.7 | 3.00 | [11] |

| 0.88 BaTiO3–0.12 Bi(Mg,Ti)O3 film | 37 | - | 1.90 | [27] |

| (Ba0.955Ca0.045)(Zr0.17Ti0.83)O3 film | 39.1 | 50 | 2.08 | [28] |

| Ba0.4Sr0.6TiO3/BaTiO3/Ba0.4Sr0.6TiO3 film | 14.69 | 33.9 | 1.44 | [16] |

| BiFeO3/BaTiO3/BiFeO3 film | 18.5 | 82.3 | 2.32 | [29] |

| PVDF/CFO@BZT–BCT NFs–PVDF/PVDF film | 11.3 | 55.5 | 0.35 | [30] |

| BaZr0.2Ti0.8O3 film | 21.28 | 83.51 | 2.00 | This work |

| Pb(Zr0.4Ti0.6)O3/BaZr0.2Ti0.8O3/Pb(Zr0.4Ti0.6)O3 film | 39.27 | 78.71 | 2.00 | This work |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gu, J.; Sun, Q.; Chen, X.; Song, Y.; Tang, Y.; Wang, D.; Qu, P. Energy Storage Performance of Sandwich Structured Pb(Zr0.4Ti0.6)O3/BaZr0.2Ti0.8O3/Pb(Zr0.4Ti0.6)O3 Films. Crystals 2019, 9, 575. https://doi.org/10.3390/cryst9110575

Gu J, Sun Q, Chen X, Song Y, Tang Y, Wang D, Qu P. Energy Storage Performance of Sandwich Structured Pb(Zr0.4Ti0.6)O3/BaZr0.2Ti0.8O3/Pb(Zr0.4Ti0.6)O3 Films. Crystals. 2019; 9(11):575. https://doi.org/10.3390/cryst9110575

Chicago/Turabian StyleGu, Jinxin, Qiu Sun, Xiangqun Chen, Ying Song, YiLun Tang, Dongbo Wang, and Ping Qu. 2019. "Energy Storage Performance of Sandwich Structured Pb(Zr0.4Ti0.6)O3/BaZr0.2Ti0.8O3/Pb(Zr0.4Ti0.6)O3 Films" Crystals 9, no. 11: 575. https://doi.org/10.3390/cryst9110575

APA StyleGu, J., Sun, Q., Chen, X., Song, Y., Tang, Y., Wang, D., & Qu, P. (2019). Energy Storage Performance of Sandwich Structured Pb(Zr0.4Ti0.6)O3/BaZr0.2Ti0.8O3/Pb(Zr0.4Ti0.6)O3 Films. Crystals, 9(11), 575. https://doi.org/10.3390/cryst9110575