DEMAND, a Dimensional Extreme Magnetic Neutron Diffractometer at the High Flux Isotope Reactor

Abstract

1. Introduction

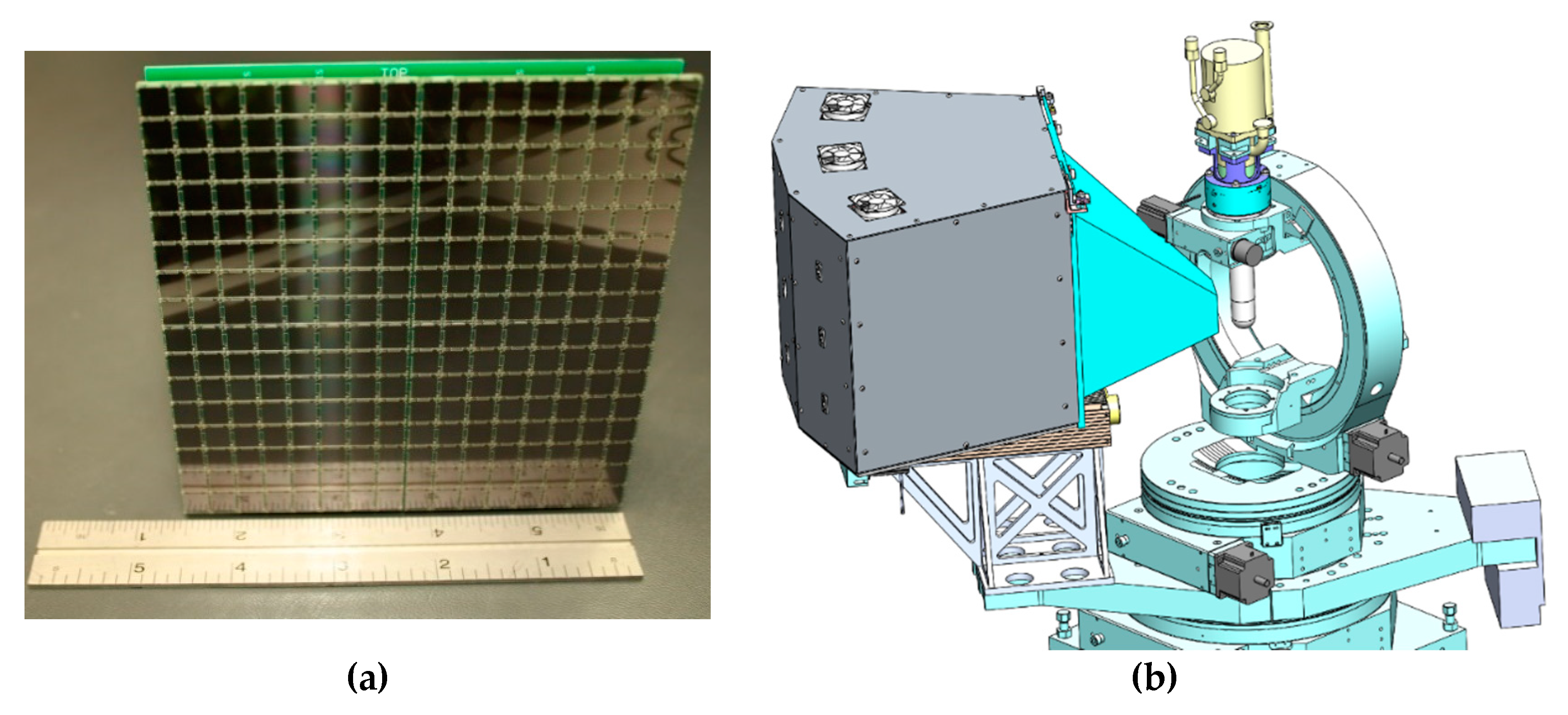

2. Anger Camera Detector

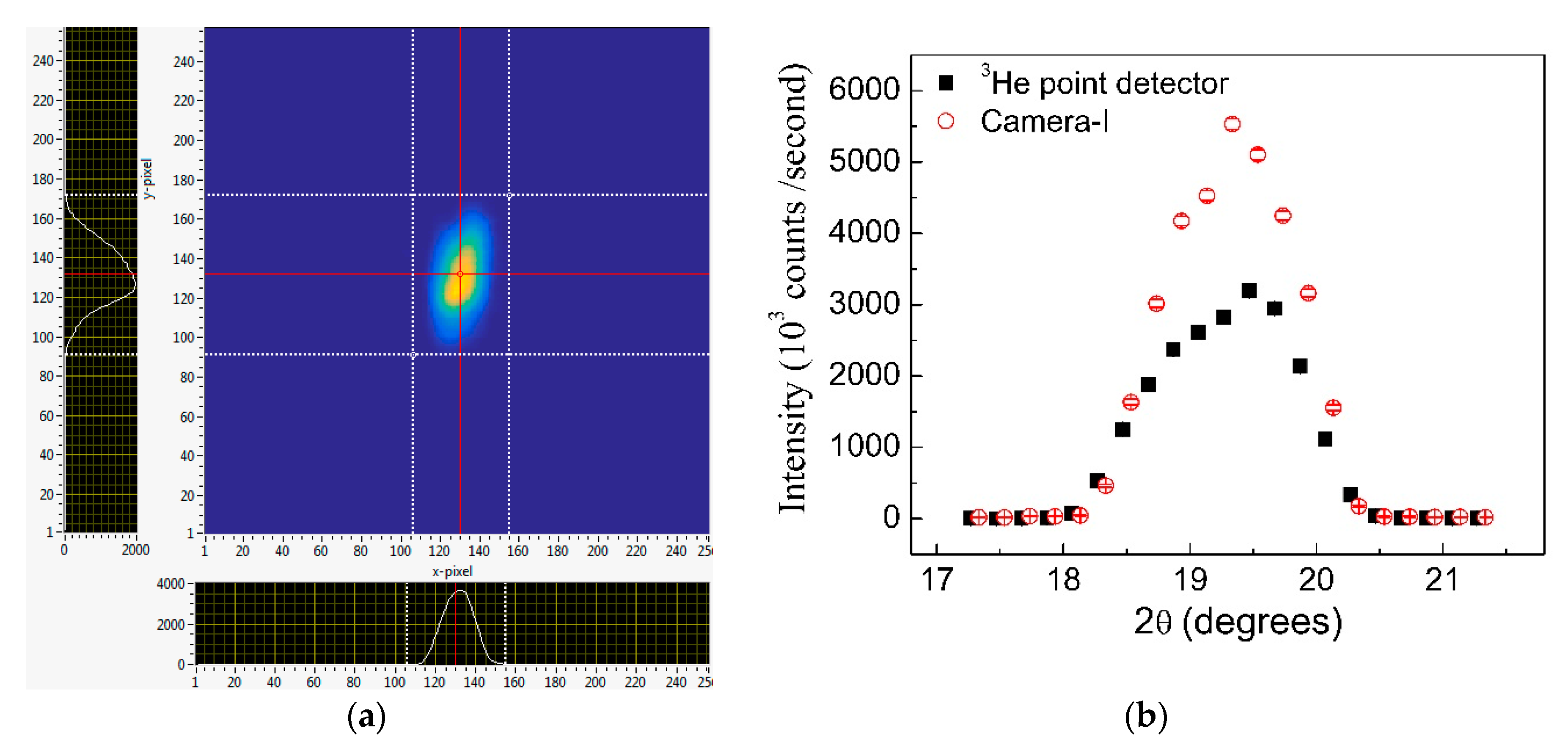

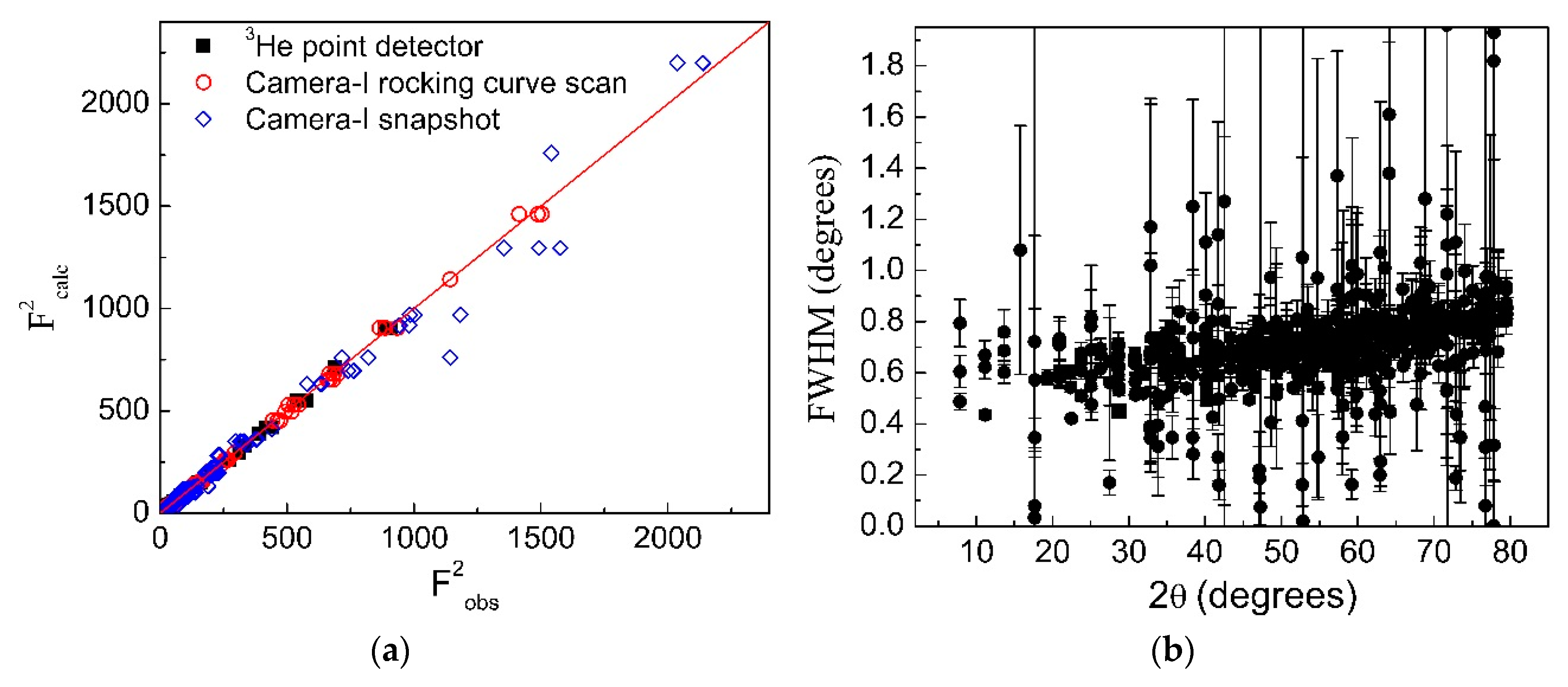

2.1. 3He Detector and 2D Anger Camera Detector

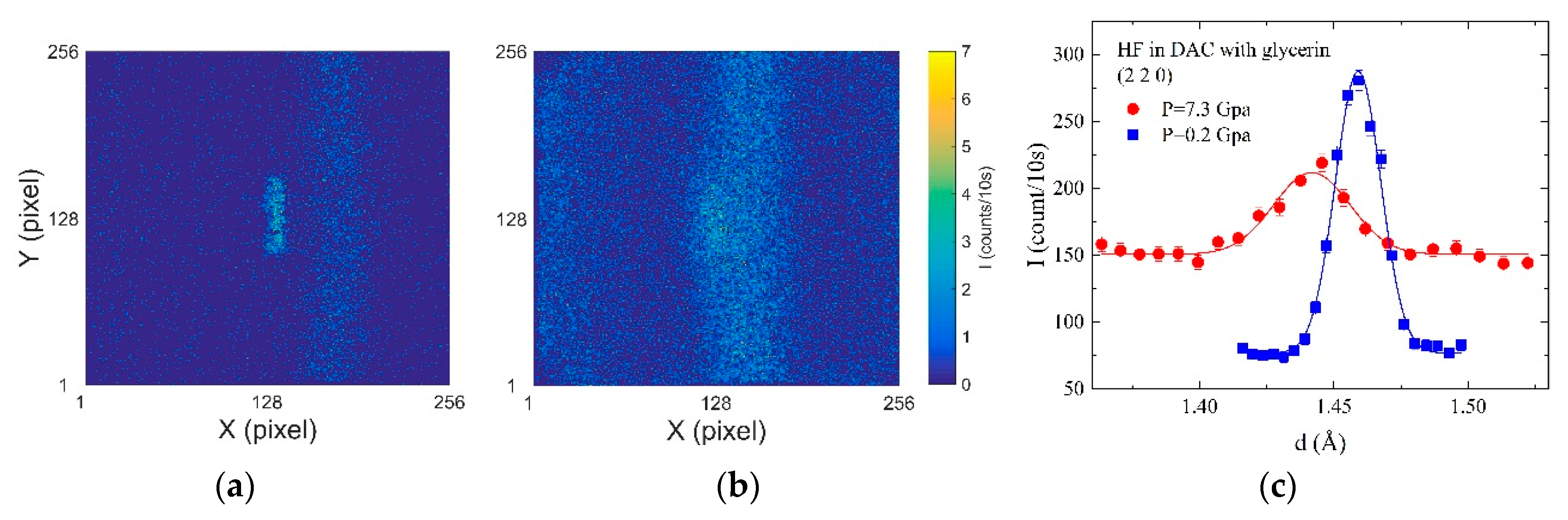

2.2. Capability for Tiny Crystals

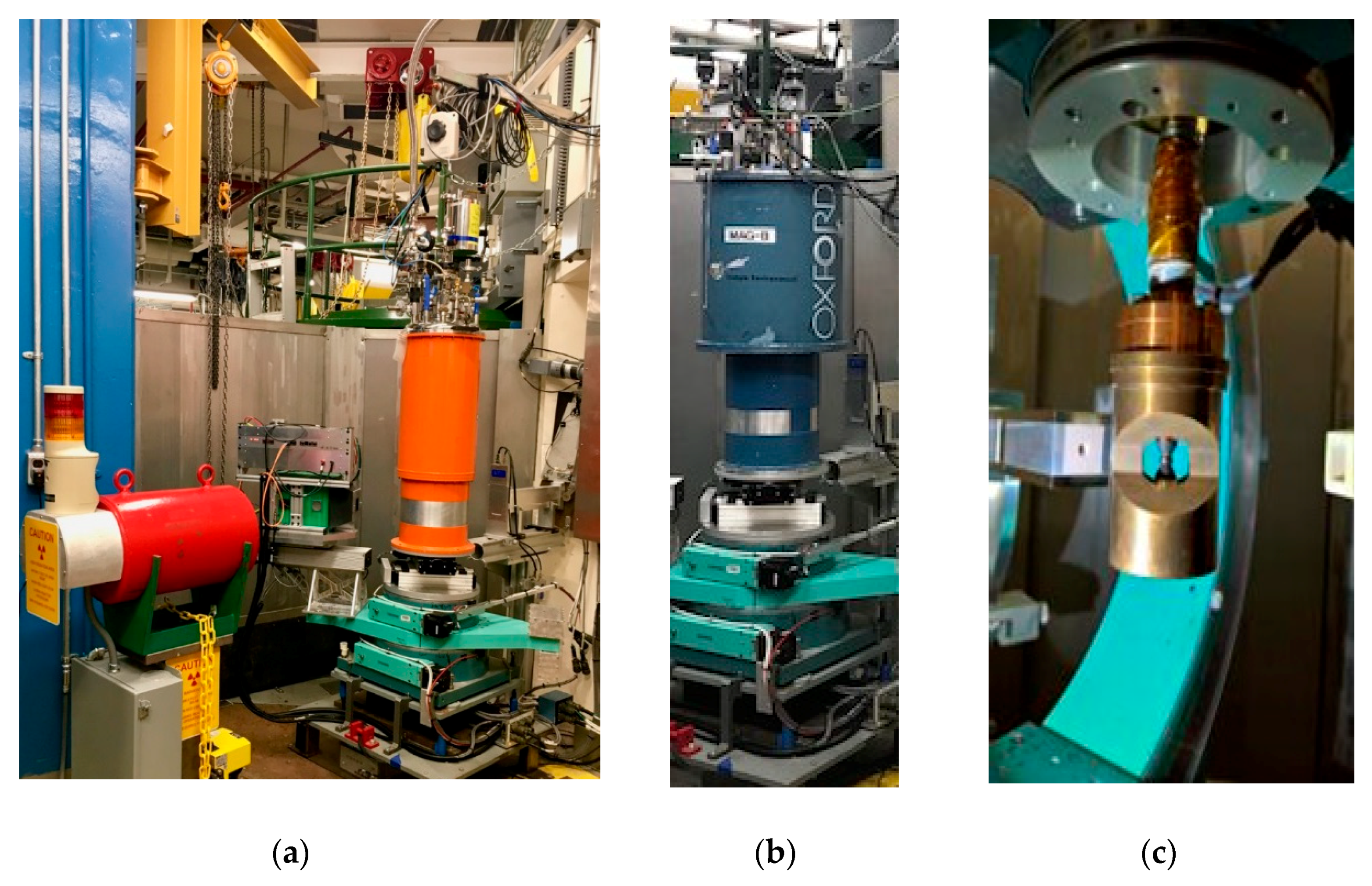

3. Sample Environment

4. Polarized Neutron Diffraction

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Riedel, R.; Donahue, C.; Visscher, T.; Montcalm, C.; Cao, H.B. A High-Resolution Neutron Anger Camera Using Silicon Photo Multipliers (#2498). IEEE NSS&MIC 2017 N-24-5 Atlanta, USA. Available online: https://www.eventclass.org/contxt_ieee2017/online-program/session?s=N-24 (accessed on 20 December 2018).

- Chakoumakos, B.C.; Cao, H.B.; Ye, F.; Stoica, A.D.; Popovici, M.; Sundaram, M.; Zhou, W.; Hicks, J.S.; Lynn, G.W.; Riedel, R.A. Four-circle single-crystal neutron diffractometer at the High Flux Isotope Reactor. J. Appl. Crystallogr. 2011, 44, 655–658. [Google Scholar] [CrossRef]

- 6T2, LLB. Available online: http://www-llb.cea.fr/spectros/spectro/6t2.html (accessed on 20 December 2018).

- D9, ILL. Available online: https://www.ill.eu/users/instruments/instruments-list/d9/description/instrument-layout/ (accessed on 20 December 2018).

- D10, ILL. Available online: https://www.ill.eu/users/instruments/instruments-list/d10/description/instrument-layout/ (accessed on 20 December 2018).

- HEiDi, FRM-II. Available online: https://www.mlz-garching.de/heidi (accessed on 20 December 2018).

- POLI, FRM-II. Available online: https://www.mlz-garching.de/poli (accessed on 20 December 2018).

- ZEBRA, PSI. Available online: https://www.psi.ch/sinq/zebra/ (accessed on 20 December 2018).

- BL18, J-PARC. Available online: http://mlfuser.cross-tokai.jp/en/bl18.html (accessed on 20 December 2018).

- Riedel, R.; Donahue, C.; Visscher, T.; Montcalm, C. Design and performance of a large area neutron sensitive anger camera. Nucl. Instrum. Methods Phys. Res. A 2015, 794, 224–233. [Google Scholar] [CrossRef]

- SPICE–Spectrometer and Instrument Control Environment. Available online: https://neutron.ornl.gov/spice/ (accessed on 20 December 2018).

- Arnold, O.; Bilheux, J.C.; Borreguero, J.M.; Buts, A.; Campbell, S.I.; Chapon, L.; Doucet, M.; Draper, N.; Leal, R.F.; Gigg, M.A.; et al. Mantid—Data analysis and visualization package for neutron scattering and μSR experiments. Nucl. Instrum. Methods Phys. Res. A 2014, 764, 156–166. [Google Scholar] [CrossRef]

- Sinha, K.; Wang, H.; Wang, X.; Zhou, L.; Yin, Y.; Wang, W.; Cheng, X.; Keavney, D.J.; Cao, H.B.; Liu, Y.; et al. Tuning the Néel temperature of hexagonal ferrites by structural distortion. Phys. Rev. Lett. 2018, 121, 237203. [Google Scholar] [CrossRef]

- Song, Y.; Yamani, Z.; Cao, C.; Li, Y.; Zhang, C.; Chen, J.S.; Huang, Q.Z.; Wu, H.; Tao, J.; Zhu, Y.; et al. A Mott insulator continuously connected to iron pnictide superconductors. Nat. Commun. 2016, 7, 13879. [Google Scholar] [CrossRef] [PubMed]

- Zhai, K.; Wu, Y.; Shen, S.; Tian, W.; Cao, H.B.; Chai, Y.S.; Chakoumakos, B.C.; Shang, D.; Yan, L.; Wang, F.; et al. Giant magnetoelectric effects achieved by tuning spin cone symmetry in Y-type hexaferrites. Nat. Commun. 2017, 8, 519. [Google Scholar] [CrossRef] [PubMed]

- Haberl, B.; Dissanayake, S.; Wu, Y.; Myles, D.A.; Santos, A.M.D.; Loguillo, M.J.; Rucker, G.; Armitage, D.; Cochran, M.J.; Andrews, K.M.; et al. Next-generation diamond cell and applications to single-crystal neutron diffraction. Rev. Sci. Instrum. 2018, 89, 092902. [Google Scholar] [CrossRef] [PubMed]

- Boehler, R.; Molaison, J.J.; Haberl, B. Novel diamond cells for neutron diffraction using multi-carat CVD anvils. Rev. Sci. Instrum. 2017, 88, 092902. [Google Scholar] [CrossRef] [PubMed]

| Parameter | 2D Anger Camera (Camera-I) | 3He Point Detector |

|---|---|---|

| Scale | 2.88(5) | 1.81(4) |

| Extinction | 0.19(4) | 0.21(8) |

| RF2 | 4.02 | 4.59 |

| RF2w | 4.89 | 10.8 |

| RF | 3.49 | 5.02 |

| χ2 | 0.309 | 1.99 |

| No. of reflections | 463 | 323 |

| Cu2: z | 0.2169(3) | 0.2163(3) |

| Sb1: x | 0.2652(2) | 0.26511(1) |

| S1: x | 0.8824(4) | 0.8828(2) |

| S1: z | 0.3598(4) | 0.3593(2) |

| Cu1: U11 = U22 | 0.0189(8) | 0.0201(7) |

| Cu1: U33 | 0.023(1) | 0.026(1) |

| Cu2: U11 = U22 | 0.072(1) | 0.073(1) |

| Cu2: U33 | 0.014(1) | 0.013(1) |

| Cu2: U12 | −0.054(2) | −0.051(2) |

| Sb1: U11 = U22 = U33 | 0.009(1) | 0.0090(8) |

| Sb1: U12 | 0.001(1) | 0.0001(9) |

| S1: U11 = U22 | 0.011(1) | 0.013(1) |

| S1: U33 | 0.011(3) | 0.010(2) |

| S1: U12 | −0.0008(19) | −0.002(1) |

| S1: U13 = U23 | 0.001(1) | 0.001(1) |

| S2: U11 = U22 = U33 | 0.020(3) | 0.021(3) |

| Monochromator | Double-Focusing Silicon |

|---|---|

| Incident wavelengths | 1.008 Å Si-331; 1.550 Å Si-220; 2.548 Å Si-111; |

| Detector | 2D Anger camera (SiPM) Magnetic-field insensitive (tested at 300 Gauss) Size: 348 × 348 mm2 (50° × 50°) at SDD = 300 mm; Pixel resolution: 0.65 mm |

| Diffractometer angles | Four-circle mode with a CCR: −27° < 2θ (scattering angle) < 155°; −40° < ω (sample table) < 45° −110° < χ (tilt) < 110°; −181° < ϕ (sample rotation motor) < 181° Two-axis mode with cryostat or cryomagnet: −27° < 2θ < 155°; −177° < ω < 163° −5° < ν (tilt) < 5°; −181° < ϕ (sample stick motor) < 181° |

| Sample-Detector distance (SDD) | 200–400 mm |

| Maximum flux at sample | 2.2 × 107 n/cm2/s |

| Highest resolution | δd/d > 0.3% |

| Polarizers | S-bender supermirror: polarization ratio >95% for λ = 2.548 Å 3He polarizer 90% for λ = 1.550 Å |

| Sample environment | Four-circle mode with a CCR: 4 K < T < 800 K; 0 < H < 1 T; 0 < P < 40 GPa; 0 < E < 104 V/mm; Two-axis mode with cryostat or Furnace or cryomagnet: 0.05 K < T < 1800 K; 0 < H < 8 T; 0 < P < 45 GPa; 0 < E < 11 kV/mm; |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, H.; Chakoumakos, B.C.; Andrews, K.M.; Wu, Y.; Riedel, R.A.; Hodges, J.; Zhou, W.; Gregory, R.; Haberl, B.; Molaison, J.; et al. DEMAND, a Dimensional Extreme Magnetic Neutron Diffractometer at the High Flux Isotope Reactor. Crystals 2019, 9, 5. https://doi.org/10.3390/cryst9010005

Cao H, Chakoumakos BC, Andrews KM, Wu Y, Riedel RA, Hodges J, Zhou W, Gregory R, Haberl B, Molaison J, et al. DEMAND, a Dimensional Extreme Magnetic Neutron Diffractometer at the High Flux Isotope Reactor. Crystals. 2019; 9(1):5. https://doi.org/10.3390/cryst9010005

Chicago/Turabian StyleCao, Huibo, Bryan C. Chakoumakos, Katie M. Andrews, Yan Wu, Richard A. Riedel, Jason Hodges, Wenduo Zhou, Ray Gregory, Bianca Haberl, Jamie Molaison, and et al. 2019. "DEMAND, a Dimensional Extreme Magnetic Neutron Diffractometer at the High Flux Isotope Reactor" Crystals 9, no. 1: 5. https://doi.org/10.3390/cryst9010005

APA StyleCao, H., Chakoumakos, B. C., Andrews, K. M., Wu, Y., Riedel, R. A., Hodges, J., Zhou, W., Gregory, R., Haberl, B., Molaison, J., & Lynn, G. W. (2019). DEMAND, a Dimensional Extreme Magnetic Neutron Diffractometer at the High Flux Isotope Reactor. Crystals, 9(1), 5. https://doi.org/10.3390/cryst9010005