Photonic Crystals with an Eye Pattern Similar to Peacock Tail Feathers

Abstract

:1. Introduction

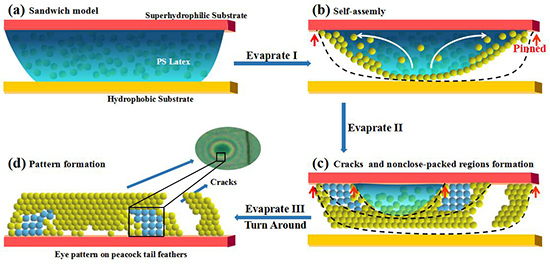

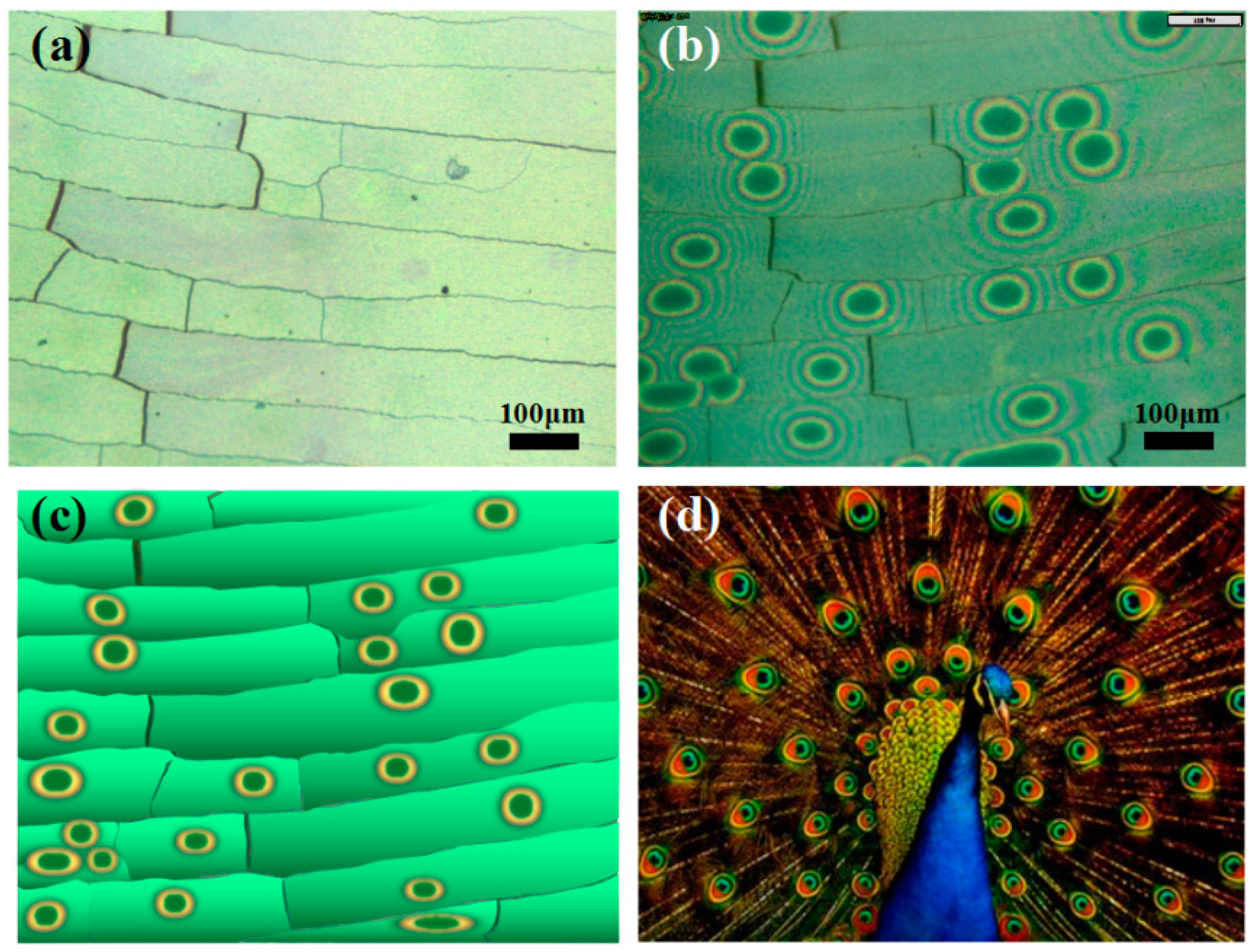

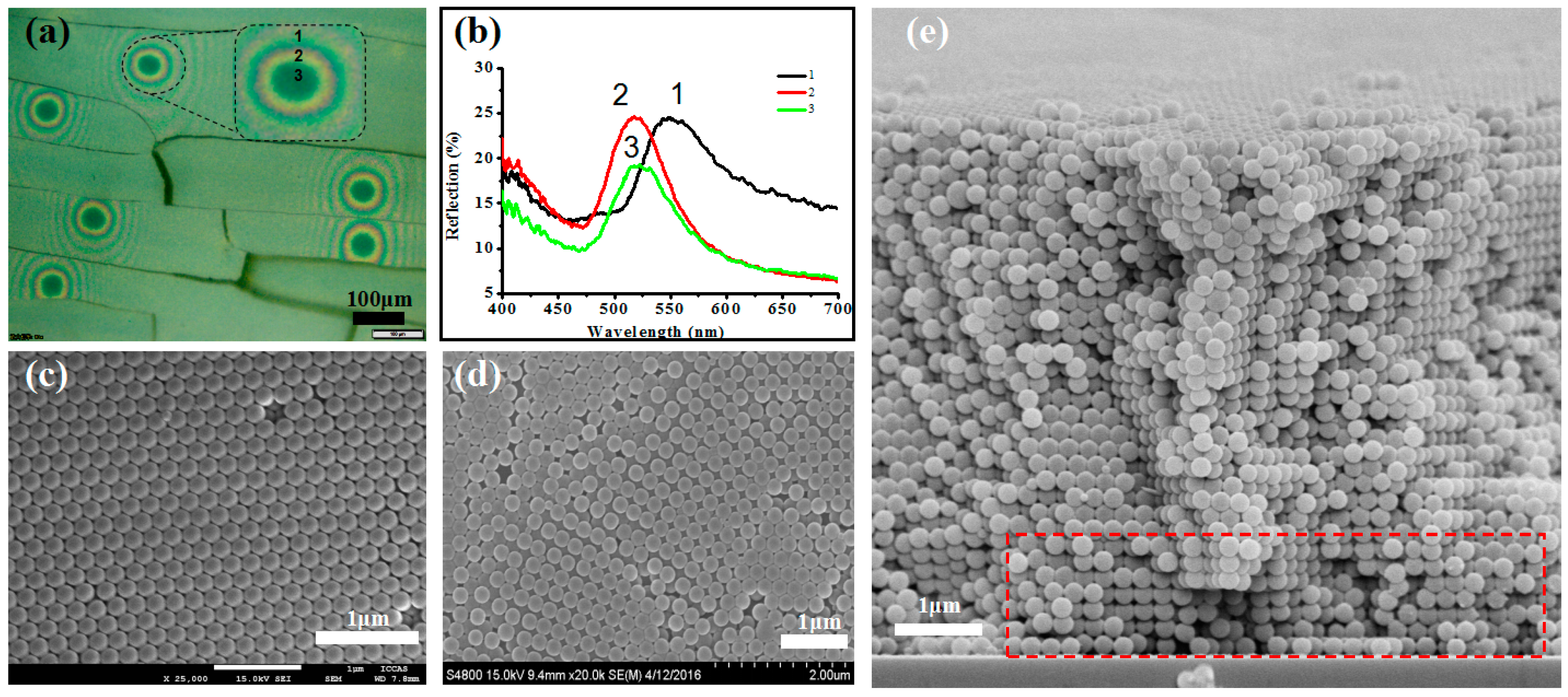

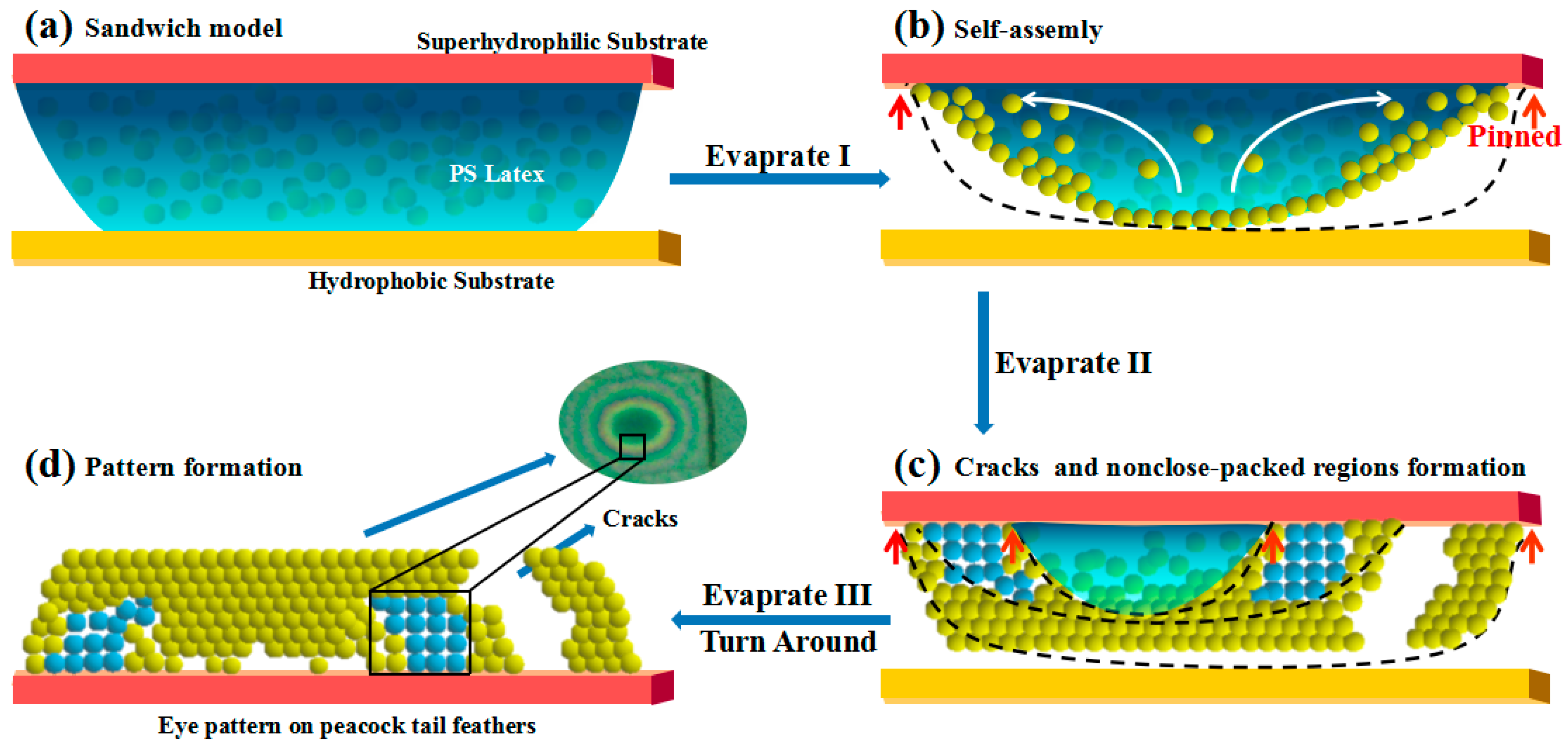

2. Results and Discussion

3. Materials and Methods

4. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Ge, J.P.; Yin, Y.D. Responsive photonic crystals. Angew. Chem. Int. Ed. Engl. 2011, 50, 1492–1522. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.M.; Geng, C.; Hao, Z.B.; Wei, T.B.; Yan, Q.F. Recent advancement on micro-/nano-spherical lens photolithography based on monolayer colloidal crystals. Adv. Colloid Interface Sci. 2016, 228, 105–122. [Google Scholar] [CrossRef] [PubMed]

- Wang, F.Y.; Zhu, Z.G.; Xue, M.; Xue, F.; Wang, Q.H.; Meng, Z.H.; Lu, W.; Chen, W.; Qi, F.L.; Yan, Z.Q. Cellulose photonic crystal film sensor for alcohols. Sens. Actuators B Chem. 2015, 220, 222–226. [Google Scholar] [CrossRef]

- Chen, T.; Deng, Z.Y.; Yin, S.N.; Chen, S.; Xu, C. The fabrication of 2D and 3D photonic crystal arrays towards high performance recognition of metal ions and biomolecules. J. Mater. Chem. C 2016, 4, 1398–1404. [Google Scholar] [CrossRef]

- Li, Y.; Calvo, M.E.; Míguez, H. Integration of Photonic Crystals into Flexible Dye Solar Cells: A Route toward Bendable and Adaptable Optoelectronic Devices Displaying Structural Color and Enhanced Efficiency. Adv. Opt. Mater. 2016, 4, 464–471. [Google Scholar] [CrossRef]

- Colson, P.; Cloots, R.; Henrist, C. Experimental design applied to spin coating of 2D colloidal crystal masks: A relevant method? Langmuir 2011, 27, 12800–12806. [Google Scholar] [CrossRef] [PubMed]

- Li, P.; Wang, Y.; Chen, S.-L.; Wang, A.-J. Enhancement of gas-solid photocatalytic activity of nanocrystalline TiO2 by SiO2 opal photonic crystal. J. Mater. Sci. 2015, 51, 2079–2089. [Google Scholar] [CrossRef]

- Fudouzi, H.; Xia, Y.N. Photonic papers and inks: Color writing with colorless materials. Adv. Mater. 2003, 15, 892–896. [Google Scholar] [CrossRef]

- Yablonovitch, E. Inhibited Spontaneous Emission in Solid-State Physics and Electronics. Phys. Rev. Lett. 1987, 58, 2059–2062. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.X.; Liang, J.; Wu, H.M.; Yuan, W.F.; Wen, Y.Q.; Song, Y.L.; Jiang, L. A facile method of shielding from UV damage by polymer photonic crystals. Polym. Int. 2008, 57, 509–514. [Google Scholar] [CrossRef]

- Zhang, L.J.; Xiong, Z.; Shan, L.; Zheng, L.; Wei, T.B.; Yan, Q.F. Layer-by-Layer Approach to (2+1)D Photonic Crystal Superlattice with Enhanced Crystalline Integrity. Small 2015, 11, 4910–4921. [Google Scholar] [CrossRef] [PubMed]

- Ding, T.; Chen, L.; Long, Y.; Song, K. Micro-patterning of 3D colloidal photonic crystals via solvent-assisted imprint lithography. RSC Adv. 2015, 5, 8509–8513. [Google Scholar] [CrossRef]

- Cui, J.; Zhu, W.; Gao, N.; Li, J.; Yang, H.; Jiang, Y.; Seidel, P.; Ravoo, B.J.; Li, G. Inverse opal spheres based on polyionic liquids as functional microspheres with tunable optical properties and molecular recognition capabilities. Angew. Chem. Int. Ed. Engl. 2014, 53, 3844–3848. [Google Scholar] [CrossRef] [PubMed]

- Yan, Q.F.; Zhou, Z.C.; Zhao, X.S. Inward-growing self-assembly of colloidal crystal films on horizontal substrates. Langmuir 2005, 21, 3158–3164. [Google Scholar] [CrossRef] [PubMed]

- Griesebock, B.; Egen, M.; Zentel, R. Large Photonic Films by Crystallization on Fluid Substrates. Chem. Mater. 2002, 10, 4023. [Google Scholar] [CrossRef]

- Huang, Y.; Zhou, J.M.; Su, B.; Shi, L.; Wang, J.X.; Chen, S.R.; Wang, L.B.; Zi, J.; Song, Y.L.; Jiang, L. Colloidal photonic crystals with narrow stopbands assembled from low-adhesive superhydrophobic substrates. J. Am. Chem. Soc. 2012, 134, 17053–17058. [Google Scholar] [CrossRef] [PubMed]

- Wu, L.; Dong, Z.C.; Kuang, M.X.; Li, Y.N.; Li, F.Y.; Jiang, L.; Song, Y.L. Printing Patterned Fine 3D Structures by Manipulating the Three Phase Contact Line. Adv. Funct. Mater. 2015, 25, 2237–2242. [Google Scholar] [CrossRef]

- Zhang, J.T.; Wang, L.; Lamont, D.N.; Velankar, S.S.; Asher, S.A. Fabrication of large-area two-dimensional colloidal crystals. Angew. Chem. Int. Ed. Engl. 2012, 51, 6117–6120. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.T.; Chao, X.; Asher, S.A. Asymmetric free-standing 2-D photonic crystal films and their Janus particles. J. Am. Chem. Soc. 2013, 135, 11397–11401. [Google Scholar] [CrossRef] [PubMed]

- Yin, S.N.; Yang, S.; Wang, C.F.; Chen, S. Magnetic-Directed Assembly from Janus Building Blocks to Multiplex Molecular-Analogue Photonic Crystal Structures. J. Am. Chem. Soc. 2016, 138, 566–573. [Google Scholar] [CrossRef] [PubMed]

- Zhou, J.M.; Wang, J.X.; Huang, Y.; Liu, G.M.; Wang, L.B.; Chen, S.R.; Li, X.H.; Wang, D.J.; Song, Y.L.; Jiang, L. Large-area crack-free single-crystal photonic crystals via combined effects of polymerization-assisted assembly and flexible substrate. NPG Asia Mater. 2012, 4, e21. [Google Scholar] [CrossRef]

- Yang, H.G.; Su, M.; Li, K.Y.; Jiang, L.; Song, Y.L.; Doi, M.; Wang, J.J. Preparation of patterned ultrathin polymer films. Langmuir 2014, 30, 9436–9441. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.Z.; Wei, C.; Cong, H.L.; Yang, Q.; Wu, Y.C.; Su, B.; Zhao, Y.S.; Wang, J.X.; Jiang, L. Hybrid Top-Down/Bottom-Up Strategy Using Superwettability for the Fabrication of Patterned Colloidal Assembly. ACS Appl. Mater. Interfaces 2016, 8, 4985–4993. [Google Scholar] [CrossRef] [PubMed]

- Zi, J.; Yu, X.D.; Li, Y.Z.; Hu, X.H.; Xu, C.; Wang, X.J.; Liu, X.H.; Fu, R.T. Coloration strategies in peacock feathers. Proc. Natl. Acad. Sci. USA 2003, 100, 12576–12578. [Google Scholar] [CrossRef] [PubMed]

- Paw, Ogon, Kolory. Available online: http://www.tapeciarnia.pl/131841_paw_ogon_kolory (accessed on 14 July 2012).

- Shi, L.; Harris, J.T.; Fenollosal, R.; Rodriguezl, I.; Lu, X.T.; Korgel, B.A.; Meseguerl, F. Monodisperse silicon nanocavities and photonic crystals with magnetic response in the optical region. Nat. Commun. 2013, 4, 1904. [Google Scholar] [CrossRef] [PubMed]

- Cai, J.H.; Chen, S.R.; Cui, L.Y.; Chen, C.C.; Su, B.; Dong, X.; Chen, P.L.; Wang, J.X.; Wang, D.J.; Song, Y.L.; et al. Tailored Porphyrin Assembly at the Oil-aqueous Interface Based on the Receding of Three-phase Contact Line of Droplet Template. Adv. Mater. Interface 2015, 2, 1400365. [Google Scholar] [CrossRef]

- Han, W.; Lin, Z.Q. Learning from “Coffee Rings”: Ordered Structures Enabled by Controlled Evaporative Self-Assembly. Angew. Chem. Int. Ed. 2013, 51, 1534. [Google Scholar] [CrossRef] [PubMed]

- Abkarian, M.; Nunes, J.; Stone, H.A. Colloidal Crystallization and Banding in a Cylindrical Geometry. J. Am. Chem. Soc. 2004, 126, 5978–5979. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.X.; Wen, Y.Q.; Ge, H.L.; Sun, Z.W.; Zheng, Y.M.; Song, Y.L.; Jiang, L. Simple Fabrication of Full Color Colloidal Crystal Films with Tough Mechanical Strength. Macromol. Chem. Phys. 2006, 207, 596–604. [Google Scholar] [CrossRef]

| PS Concentration | Substrate Wettablity | ||

|---|---|---|---|

| 20% |  | superhydrophilic |  |

| 2% |  | hydrophilic |  |

| 0.2% |  | superhydrophobicity | No sample |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, M.; Meng, F.; Wu, H.; Wang, J. Photonic Crystals with an Eye Pattern Similar to Peacock Tail Feathers. Crystals 2016, 6, 99. https://doi.org/10.3390/cryst6080099

Wang M, Meng F, Wu H, Wang J. Photonic Crystals with an Eye Pattern Similar to Peacock Tail Feathers. Crystals. 2016; 6(8):99. https://doi.org/10.3390/cryst6080099

Chicago/Turabian StyleWang, Minghui, Fanshu Meng, Hua Wu, and Jingxia Wang. 2016. "Photonic Crystals with an Eye Pattern Similar to Peacock Tail Feathers" Crystals 6, no. 8: 99. https://doi.org/10.3390/cryst6080099

APA StyleWang, M., Meng, F., Wu, H., & Wang, J. (2016). Photonic Crystals with an Eye Pattern Similar to Peacock Tail Feathers. Crystals, 6(8), 99. https://doi.org/10.3390/cryst6080099