Abstract

In this study, with the rapid development of the field of rail vehicles, the laser welding process with high energy and small thermal deformation is selected, which reduces the working hours of post-welding grinding, repainting, and other processes, and ensures the industrial design requirements of the beautiful body after welding. The welding process for the non-penetration laser lap welding of SUS301L stainless-steel plates was optimized to address the problem of welding marks on the outer surface of railway vehicle car bodies. The impact of laser power, welding speed, and defocusing amount on weld penetration and tensile shear load was investigated using the response surface methodology. The results showed that the optimal response model for tensile shear load was the linear model, while the optimal response model for weld penetration was the 2FI model. The defocusing amount had the greatest influence on tensile shear load and weld penetration. When the laser power was 1.44 kW, the welding speed was 15 mm/s, and the defocusing amount was −4 mm, the tensile shear load reached its maximum by prediction. The actual tensile shear load of welded joints using these parameters was 4293 N with an error of merely 0.31% relative to the predicted value. The shear strength of laser-welded joints was measured at 429.3 N/mm, meeting the criteria established by the relevant standards. The tensile fracture shows characteristics of brittle fracture. The surface of the welded joints was bright white and well-formed, while the back side of the lower plate exhibited no signs of melting or welding marks. The microstructure of the weld zone (WZ) exhibited irregular columnar austenite and plate-like ferrite, while the heat-affected zone (HAZ) comprised columnar austenite and elongated bars or networks of δ-ferrite. The small-angle grain in welded joints can reduce grain boundary defects and mitigate stress concentration. After welding, angular deformation occurred, resulting in a residual stress distribution that shows tensile stress near the weld and compressive stress at a distance from the weld.

1. Introduction

Austenitic stainless steel, commonly referred to as the 300 series, has exceptional corrosion resistance, superior biocompatibility, excellent formability and weldability, as well as a remarkable strength–toughness ratio over a wide temperature range. This is achieved by the addition of Cr (wt.% ≥ 18%) and Ni (wt.% ≥ 8%). It has found extensive application in consumer goods, medical instruments, construction materials, oil and gas storage and transportation, equipment manufacturing, aerospace, and various other light and heavy industries [1,2,3].

SUS301L stainless steel is an ordinary chromium–nickel stainless steel. It contains nickel elements to ensure the structural stability of austenite. Therefore, SUS301L austenitic stainless steel exhibits excellent corrosion resistance in environments such as steam, water, atmosphere, and oxidizing acids. It also possesses good heat resistance and high tensile strength. Its ability to achieve high strength through cold working makes it an ideal choice for manufacturing rail car bodies, which require both durability and light weight. The material’s excellent formability allows it to be shaped into complex structures, such as the intricate profiles of train carriages. Moreover, its corrosion resistance, comparable to that of 304 stainless steel, ensures that the rail vehicles can withstand the rigors of outdoor environments without extensive maintenance. This property is particularly important for rail transit systems that operate in diverse climatic conditions [4].

SUS301L stainless-steel sheets, ranging from 0.8 to 2 mm in thickness, are extensively utilized in urban rail vehicles and high-speed trains. Resistance spot welding is a prevalent method for assembling cold-rolled 301 stainless-steel components, favored for its rapidity and the minimal HAZ it produces, which aids in preserving the material’s high strength. Additionally, laser welding has gained popularity due to its capacity to create narrow, deep welds with minimal heat input, thereby lowering the risk of intergranular corrosion and distortion [5,6]. Traditional resistance spot welding results in electrode indentation and spatter on the outer plate. However, despite the ability of laser butt welding to eliminate these indentations, the back side HAZ still shows blue-purple oxidation discoloration. This affects not only the appearance but also diminishes the corrosion resistance. When these oxidation traces become visible, it becomes necessary to use chemical cleaning to address them, which can result in environmental issues. The laser welding process, when combined with copper backing plates, effectively isolates oxygen, thereby reducing oxidation discoloration, enhancing welding quality, simplifying post-treatment procedures, and minimizing environmental risks. However, despite their ability to suppress oxidation, copper backing plates have an extremely narrow operational window and are highly sensitive to factors such as laser power, welding speed, and cooling flow rate. Consequently, they are unsuitable for environments with significant on-site fluctuations. Non-penetration laser welding is a process in which the laser generates a molten pool on the upper plate and penetrates to a specific depth at the joint interface without penetrating the lower plate. The primary goal is to ensure joint strength and sealing integrity while preserving the “seamless side” (typically the visible surface) with its original metallic luster, devoid of burn marks, indentations, or discoloration. So, the above problems can be solved by non-penetration laser welding through precise control of laser parameters.

The process parameters of laser welding, such as laser power, laser incident position, laser incident angles and so on, have a significant impact on the performance and microstructure of welded joints [7]. Recent industrial studies have shown that inconsistent parameter selection can lead to defects such as surface pitting, interface pores, and reduced joint strength, especially under dynamic loads, which are common in railway operations. The linear relationship between the interface width and the joint strength further highlights the accuracy required for parameter control. The higher power density enlarges the processing window by improving the wettability and fusion width of the interface. Johannes Günther [8] found that the handheld laser beam welding process can produce joints of moderate quality, with good formability and low porosity, which is confirmed by radiological detection and fracture analysis. At the same time, it is also necessary to use nitrogen as a protective gas and use a dissipated laser beam without transverse oscillation. Gnanasekaran [9] studied the influence of laser power on the tensile properties and microstructure of austenitic stainless steel AISI 301 by means of the control variable method. Five different levels of laser power were used to produce five joints, ranging from 350 W to 550 W. For the five different laser powers used, the 550 W joint had superior tensile strength than other joints. Additionally, different incident angles significantly affect the geometry and direction of the weld size. In the study of S. Palanisamy [10], a higher weld joint strength of 1010 MPa (97% of the base metal UTS) was achieved at an 80° incident angle, owing to the formation of more equiaxed dendritic grains and the absence of the secondary phases. The above was a single-factor test of welding parameters to analyze a parameter change, and only the achievement of the best mechanical properties of the results are applicable. However, due to the laser non-penetration lap welding explored in this paper, it is necessary to achieve good tensile strength of the weld and no weld marks on the back.

Therefore, it is very necessary to adopt appropriate methods to obtain the optimal welding process parameters to obtain excellent welded joints. The response surface method has been applied in many research fields. Zoltán Kovács [11] optimized the solvothermal method by the RSM method and simplified the amount of experimental data. Ilhan Celik [12] optimized the deep drawing process parameters with the RSM, which can effectively improve the shortcomings of the deep drawing process. It is further shown that the RSM can obtain enough information to fit the model with a relatively small number of experiments under different numbers of independent variables. It can not only find the optimal solution of the response function but also analyze the influence of independent variables on the response variables and their interaction and determine the optimal combination of independent variables. It can be used to fit mathematical models and forecast results. Qi [13] used a continuous fiber laser 2 mm thick with 4047 and 6061 different aluminum alloys for docking. The Box–Behnken design response surface test design method was used to optimize the three major process parameters: laser power, welding speed, and defocusing degree. Also, Liu [14] studied the method of laser welding DP780 steel to Al5052 joints to optimize the welding width and lap shear force. Ragavendran, M. [15] used the RSM as a method to optimize the welding parameters, and the weld width, weld cross-sectional area, and penetration depth were used as the output of the response surface.

2. Material and Methods

2.1. Experimental Materials

SUS301L stainless steel is an austenitic stainless steel commonly used in the constructions of railway vehicle bodies. Compared with traditional common steel materials, it has a chromium mass fraction of at least 16%. The presence of chromium facilitates the formation of an inert oxide film on the material surface, thereby protecting it from oxidation and corrosion. The respective thicknesses of the from plate and back plate are 1.5 mm and 2 mm. The chemical composition of SUS301L stainless steel is shown in Table 1. The mechanical properties of the experimental materials at room temperature post-rolling are shown in Table 2.

Table 1.

Chemical composition of SUS301L stainless steel.

Table 2.

Mechanical properties of SUS301L stainless steel.

2.2. Welding Equipment

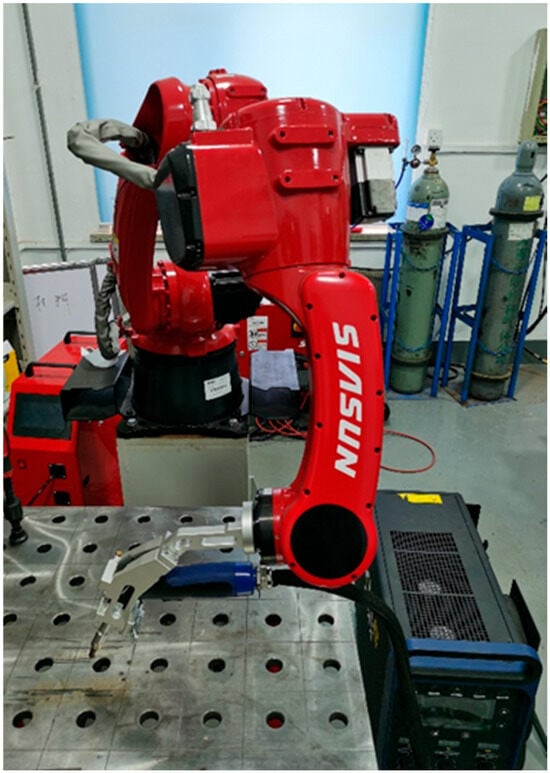

The test equipment is shown in Figure 1. The laser welding equipment (SKY-HW350) used in this work was manufactured by the Wuhan Xiangming Laser Technology Company (Wuhan, China). The device is an integrated welding torch featuring a rated power of 2000 W, a swing frequency of 0 to 200 Hz, and a swing width of 0 to 5 mm. The SR12A-12/1.46 robot arm, produced by Tianjin Siasun Robot (Tianjin, China), regulates the welding speed within a range of 0 to 1000 mm/s. The welding protection gas has a purity of 99.999% argon, a flow rate of 30 L/min, and an input pressure of 0.15 MPa.

Figure 1.

Handheld laser welder with Siasun robotic arm equipment.

2.3. Welding Method

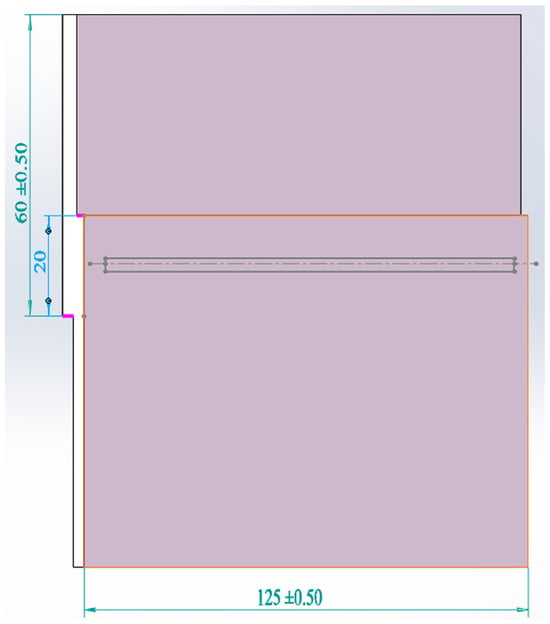

Before welding, the surfaces of the 1.5 mm and 2.0 mm plates were finely polished with #800 sandpaper and subsequently cleaned with anhydrous ethanol to eliminate any impurities, including oil, which could affect welding process. The dimensions of the 1.5 mm and 2.0 mm stainless-steel plates are 125 mm × 60 mm, with a lap joint width of 20 mm, and the welding position is centered, as depicted in Figure 2. The plates were joined using the non-penetrating lap joint method. Laser welding was utilized on the joint of the 1.5 mm stainless-steel plate, ensuring stable adhesion between the upper and lower plates with adequate post-welding strength, while also preventing any welding trails on the underside of the 2.0 mm stainless-steel plate.

Figure 2.

Schematic diagram of lap welding.

2.4. Determination of Welding Parameters

The five adjustable parameters include laser power, welding speed, defocusing amount, swing frequency, and swing width. The range of parameters influencing weld morphology was established through preliminary testing. Given that the tests were conducted in a wire-free welding state, the welds produced at various swing frequencies exhibited synaptic morphology, rendering them unsuitable for non-penetration lap welding. Therefore, the swing frequency should be established at 0 Hz, rendering the swing width inconsequential at this frequency. Thus, the three key parameters subject to modification in this test are laser power, welding speed, and defocusing amount. This experiment utilized the Box–Behnken Response Surface Methodology and Design Expert V10 software to conduct a three-level regression analysis of the welding parameters, aiming to predict the optimal settings.

2.5. Three-Level Regression Analysis Test of Welding Parameters

The welding test design was carried out by using the factorial test design function of DESIGN-EXPERT V10 statistical software, and the test results were analyzed. The welding parameters, including laser power (P), welding speed (v) and defocusing amount (f), were determined as input factors in the welding process. According to the results of previous single-factor experiments, it is necessary to ensure that the heat input per unit of time will not cause welding marks on the back of the bottom plate, and to ensure the tensile shear strength of non-penetration lap welding. In the previous single-factor experiment, the negative defocusing amount had an important influence on improving the weld morphology, and a smaller value had no significant effect on the laser’s deep penetration effect in this experiment. Therefore, the scope of each factor is determined, as detailed in Table 3. The response variables in this experiment are welding penetration (d) and tensile shear load (F). Then the experiment was arranged by the Box-Behnken experimental design, as shown in Table 4.

Table 3.

Test conditions.

Table 4.

Test arrangement and results.

2.6. Mechanical Properties Test

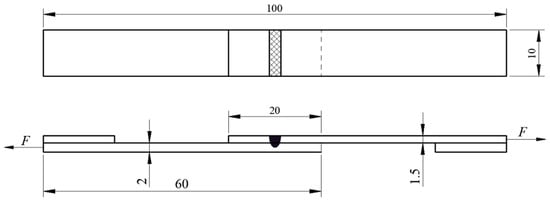

The tensile shear load test of the sample was carried out by using a WDW-300 E electronic universal testing machine (Jinan, China). The sample was cut into a size of 100 mm × 10 mm using a wire-cutting machine, as shown in Figure 3. The specimens at different positions were placed in the fixture to make the shear plane parallel to the tensile force plane, and the loading speed was 0.5 mm/min. The loading was carried out until the sample was separated from the welding point; the test was repeated three times and the relevant data were recorded.

Figure 3.

Schematic diagram of tensile specimen size.

2.7. Microstructure Characterization

The Olympus BX51M optical microscope was utilized in this experiment. Prior to the optical microscope examination, the samples were trimmed to dimensions of 10 mm × 10 mm using a wire cutter, polished with sandpaper ranging from #400 to #2000, and, finally, were treated with a W 1.5 μm polishing agent. The samples were subjected to a stainless-steel welding deep-corrosion liquid (mass ratio: HCl:FeCl3:H2O = 3:5:7) for 20 s, followed by rinsing with alcohol, wiping, and drying.

3. Test Optimization and Result Analysis

3.1. Test Arrangement and Results of Three-Level Regression Analysis

The experiment was conducted according to the test arrangement in Table 4, measuring the maximum tensile shear load for each dataset and assessing the corresponding welding penetration. The Design Expert V10 software was equipped with various mathematical models. During the software’s operation, the appropriate response model for the test was recommended through variance analysis, and the mathematical relationship between the input and the output factor was fitted. The variance (R2) was used for determining the degree of influence of the three parameters on the test results [16,17,18].

3.2. Choice of Response Model

According to the design criteria of the response model in the Design-Expert V10 software, a higher-order model should be preferred. According to the variance analysis and R2 comprehensive analysis of the various models shown in Table 5 and Table 6, the optimal response model of the tensile shear load is the linear model, and the optimal response model of the weld penetration is the 2FI model. The adjusted R2 eliminates the problem of over-fitting due to the large number of independent variables. The adjusted R2 is more objective and reliable for the constructed model. The difference between the adjusted R2 and the predicted R2 is too large, indicating that the model fitting is poor and does not have a reference value.

Table 5.

Comparison of multiple models of tensile shear load.

Table 6.

Comparison of various models of welding penetration.

3.3. Experiment Optimization and Results of Three-Level Regression Analysis

After the fitting process, a p value below 0.05 indicates that the effect of the factor on the model is significant. If the p value exceeds 0.1, the effect of the factor is deemed not significant. Moreover, the lower the p value, the more significant the effect of the factor is. As shown in Table 7 and Table 8, the p values of the models are both less than 0.05, indicating the significance of the two models. The tensile shear load is significantly influenced by the three welding parameters. The welding speed has less influence on weld penetration than the other two process parameters.

Table 7.

Analysis of variance of tensile shear load.

Table 8.

Analysis of weld penetration.

3.4. Verification Test Welding Parameters and Result Analysis

To verify the accuracy of the mathematical model constructed by the response method, welding parameter tests within the range of the mathematical model were designed to optimize these welding parameters as a form of practical verification. Therefore, the following three tests in Table 9 were conducted to assess the discrepancy between the predicted and actual values. The verification test shows that the errors in tensile shear load and weld penetration are both within 6.5%, indicating the reliability of the mathematical model established by this method. Based on this mathematical model, the required tensile shear load and weld penetration can be calculated, which can be used for predicting the optimization of the welding parameters.

Table 9.

Verification test of welding parameters and results analysis.

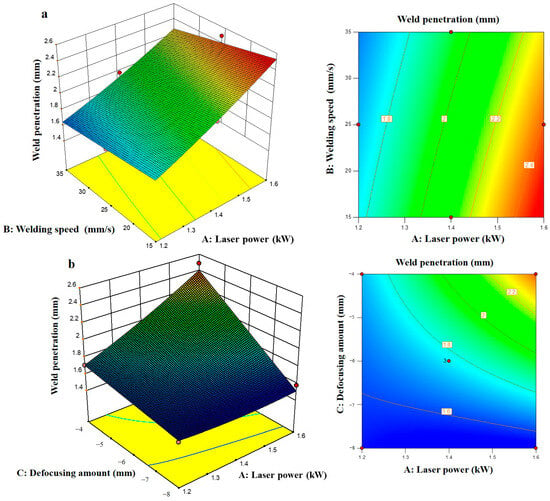

3.5. Interaction of Three Welding Parameters Under the Response Surface Methodology

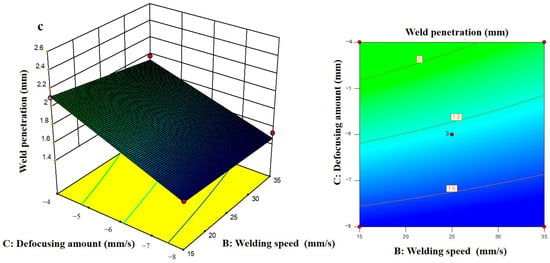

The two mathematical models established using the response surface methodology provide a clear understanding of how tensile shear load and welding penetration are influenced by the interaction of the three welding parameters. As shown in Table 7 and Table 8, the order of significance of the parameters in both mathematical models is C > A > B, confirming that the defocusing amount is the most significant parameter. In the mathematical model of welding penetration, the order of significance of the parameters based on their interaction is as follows: AC > AB > BC. The following part will discuss the influence of the three parameters individually on the welding penetration. Figure 4a presents a response surface graph that illustrates the relationship between laser power and welding speed. The variation in welding penetration with a constant defocusing amount indicates that an increase in laser power significantly influences weld penetration more so than welding speed. Figure 4b presents the response surface graph depicting the relationship between laser power and the defocusing amount. With a fixed welding speed, the response surface exhibits considerable fluctuation, indicating that the defocusing amount exerts a more pronounced effect on penetration than laser power. This is consistent with the principle of adjusting the weld morphology by altering the defocusing amount. Figure 4c shows the response surface graph depicting the relationship between the welding speed and defocusing amount. The welding penetration varies significantly with an increasing defocusing amount when the laser power is held constant, indicating that defocusing has a more pronounced impact on penetration than welding speed.

Figure 4.

The influence of laser power, welding speed, and defocusing amount on weld penetration. (a) Laser power–welding speed surface response graph; (b) laser power–defocusing amount surface response graph. (c) Welding speed–defocusing amount surface response graph.

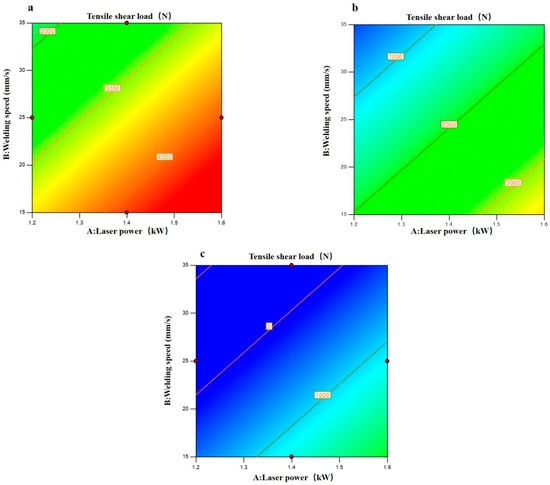

The mathematical model for the tensile shear load on the welded joints is linear. Figure 5 presents the contour map of tensile shear loads at various defocusing amounts. The figure clearly indicates that the maximum tensile shear load is achieved when the laser power ranges from 1.4 kW to 1.6 kW, the welding speed is between 15 mm/s and 25 mm/s, and the defocusing amount is −4 mm. In this region, the tensile shear load can exceed 4000 N. The optimized process parameters should ensure the absence of welding marks on the back side of the lower stainlesssteel plate, while simultaneously maximizing the tensile shear load.

Figure 5.

The influence of laser power and welding speed on tensile shear loads at different defocusing amounts: (a) −4 mm, (b) −6 mm, and (c) −8 mm.

3.6. Optimization and Prediction Results

Numerous single-factor tests and comparative analyses of the macromorphology and microstructure of the welded joints indicated that when the welding penetration for non-penetration lap welding does not exceed 2.2 mm, no visible weld trace appeared on the back side of the lower plate. Consequently, a constructed mathematical model using the RSM has been developed, establishing a maximum welding penetration of 2.2 mm and optimizing the tensile shear load to achieve adequate joining strength. Table 10 shows the detailed parameters for welding optimization. Based on the welding parameter optimization requirements and conditions outlined in Table 10, the resulting welding parameter predictions are shown in Table 11. At a laser power of P = 1.44 kW, a welding speed of v = 15 mm/s, and a defocusing amount of f = −4 mm, the tensile shear load reached its maximum, while the welding penetration was sustained at 2.2 mm.

Table 10.

Welding parameter optimization requirements and conditions.

Table 11.

Welding optimization scheme of non-penetration lap welding of stainless steel.

3.7. Tensile Shear Load, Macrostructure and Microstructure of the Weld Joints with the Optimized Parameters

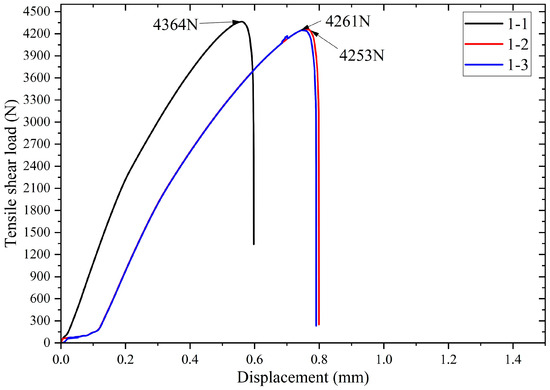

The actual welding test was conducted based on the predicted optimal parameters. The mechanical properties, macrostructure, and microstructure were analyzed. Tensile specimens were extracted from the top, middle, and tail of the weld to accurately assess the overall tensile shear load. The calculation results show that the average tensile shear load is 4293 N, and the shear curves of each part are shown in Figure 6. The error between the actual value and the predicted value is only 0.31 %.

Figure 6.

Schematic diagram of tensile shear load.

The tensile shear load of laser-welded joints in a stainless-steel car was assessed by referencing GB/T37778-2019 [19], due to the absence of a specific standard for evaluation. According to the standard, the laser lap welding between an SUS301L stainless-steel plate with a thickness of 1.5 mm and an SUS301L plate with a thickness of 2.0 mm is carried out. As per GB/T37778, the minimum tensile shear load for the laser lap-welded joint of SUS301 L stainless-steel plates, with thicknesses of 1.5 mm and 2.0 mm, respectively, is specified to be 10.4 kN. For safety considerations, the tensile shear load of all solder joints in the production process of stainless-steel car bodies generally exceeds the strength index outlined by the standard. In addition, GB/T37778 established a definitive standard for the length of the tensile weld in laser lap welding. These standards mandate lap welding for plates with thicknesses ranging from 0.6 mm to 5 mm, and stipulate that the tensile plate width test piece should measure 30 mm. The average shear strength of the laser-welded joints is 429.3 N/mm, with a laser lap weld length of 10 mm. In contrast, the average shear strength of laser lap-welded joints, as calculated by the GB/T37778 standard, is 346.7 N/mm. The laser-welded joint exhibits a shear strength that is considerably greater than the standard value. The tensile shear load exceeds the shear strength, as per the GB/T37778 standard, given the welding parameters of the laser power of 1.44 kW, welding speed of 15 mm/s, and defocusing amount of −4 mm.

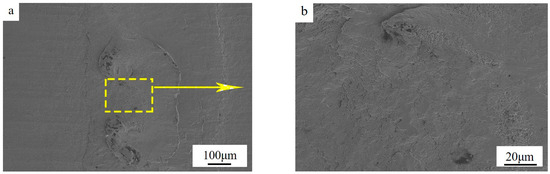

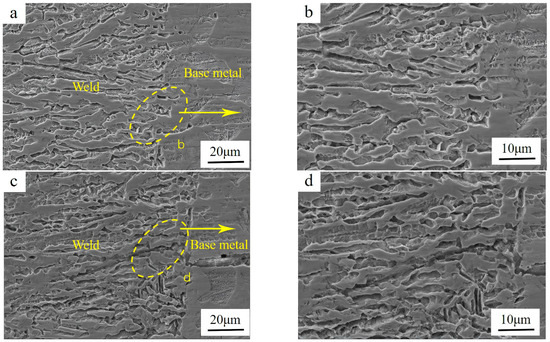

The fracture morphology was analyzed following the tensile test on the weld. Figure 7 illustrates that the overall fracture morphology displayed a predominantly flat shear morphology, mainly characterized by steps and tearing ridges. A limited quantity of dimples was present within the tearing ridges, indicating a predominantly brittle fracture.

Figure 7.

Microstructure of tensile shear fracture. (a) Cross-sectional morphology; (b) enlarged view marked in yellow.

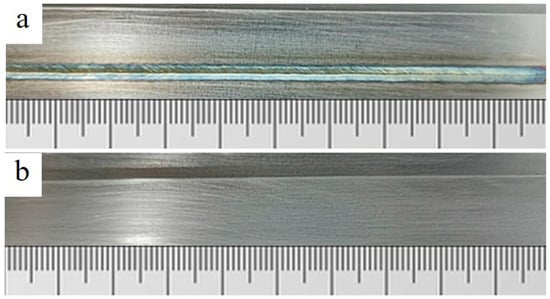

Figure 8 presents the macro morphology and the back side of the welded joints. The weld surface exhibits a bright white appearance and is well-formed. There are no pores or cracks visible on the weld surface, and no defects, such as undercuts or slag inclusions, are present between the edge and the base material. Additionally, the back side of the 2.0 mm plate exhibits no signs of melting or welding marks.

Figure 8.

Macroscopic appearance of weld and weld back. (a) Upper surface; (b) lower surface.

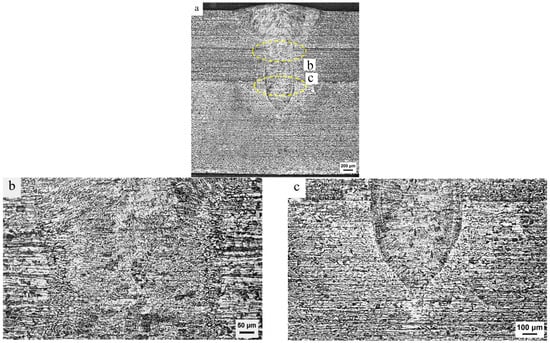

Figure 9 illustrates the overall microstructure of the non-penetration lap weld. The weld exhibits a nail-like shape and presents a relatively smooth and uniform appearance. The fusion between the weld and the substrate is excellent, with the upper and lower plates tightly bonded and devoid of defects throughout the weld. Laser welding, characterized by its high-energy density, exhibits distinct fusion lines and benefits from a minimized HAZ. The tensile shear strength is primarily influenced by the quality of the lap joint weld, which is contingent upon the weld’s width and the presence of defects. Under these parameters, the weld’s width and morphology are favorable, ensuring that laser non-penetration lap welding achieves optimal tensile shear strength.

Figure 9.

Microstructure of welded joints. (a) Cross-sectional morphology; (b) enlarged view marked in (a); (c) enlarged view marked in (a).

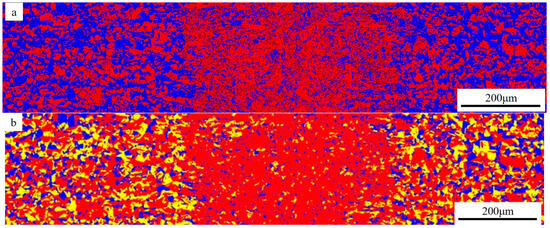

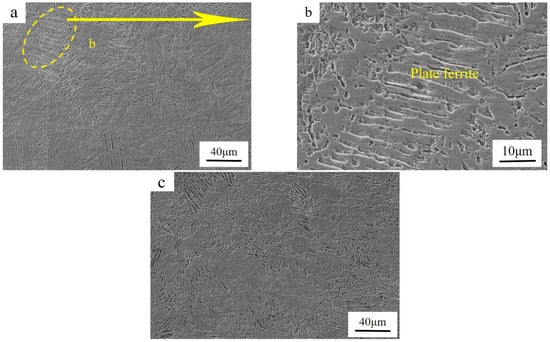

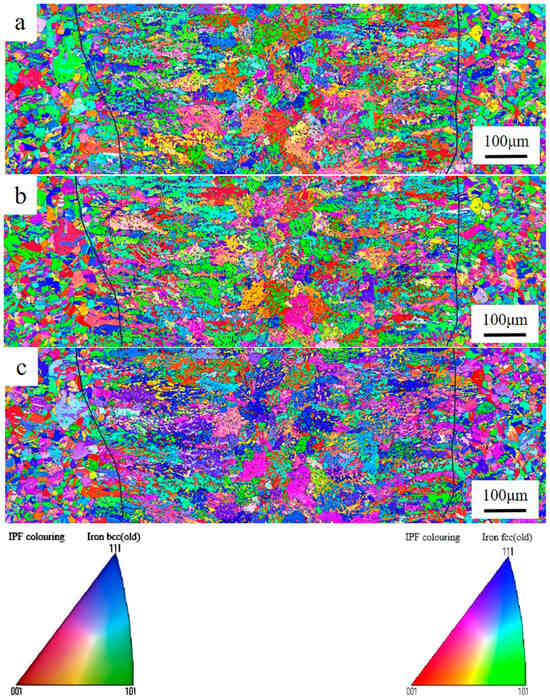

Figure 10 presents the microstructure phase diagrams for the weld seam, HAZ, and base metal, as determined by EBSD analysis. The red regions represent Iron body-centered cubic (BCC), which constitutes 53.9% of the total area, while the blue regions signify Iron face-centered cubic (FCC), constituting 46.1%. The distribution of red regions is predominantly found in the weld beam, because a considerable quantity of austenite undergoes transformation into ferrite during the laser welding process. Figure 11 illustrates that the microstructure of the weld beam features irregular columnar austenite and plate-like ferrite. The irregular columnar crystals grow from the center of the fusion zone along the direction perpendicular to the fusion line, exhibiting a strong directional arrangement and a relatively small grain size. This is attributed to the rapid welding speed, low laser line energy, rapid cooling rate and short residence time of the welded joints within the high-temperature zone. Consequently, the grains lack sufficient time for growth. The solidification mode referred to is identified as the FA mode [20]. A plate-like ferrite morphology is obtained when the rapid cooling rate increases within the FA range. The replacement of skeletal ferrite with plate-like ferrite is due to the fact that diffusion is restricted during the ferrite–austenite phase transformation. A reduction in diffusion distance enhances the efficacy of phase transformation in closely arranged plate-like morphologies. Figure 11b illustrates a significant degree of recrystallization within the weld beam. During the welding process, the ferrite that forms along the grain boundaries tends to be quite stable and will transform into austenite during subsequent cooling. The solidification process initiates with ferrite precipitation, resulting in a clearly discernible solidification substructure.

Figure 10.

EBSD results of welded joints. (a) Phase diagram of welded joint; (b) statistical distribution of recrystallization, substructure, and deformation structure.

Figure 11.

Microstructure of weld beam, the upper plate; (b) enlarged view marked in (a); (c) the lower plate.

Analysis of the fracture revealed that the weld displayed characteristics of brittle fracture, characterized by a concentration of body-centered cubic (BCC) ferrite in the weld zone. The resistance of ferrite to movement at high strain rates resulted in a sudden increase in yield strength, rendering it prone to brittle fracture.

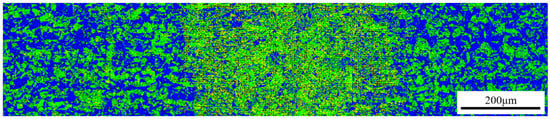

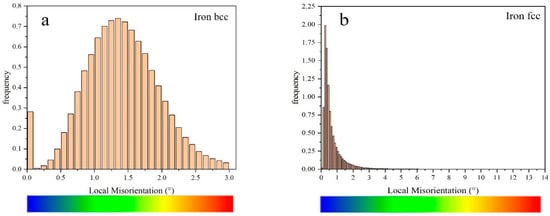

Figure 12 shows the surface orientation distribution of welded joints along the X0, Y0, and Z0 directions. The grain orientation in the X0/Y0 direction exhibits a random distribution, lacking a discernible preferred orientation. However, in the Z0 direction, a specific preferred orientation is observed, primarily aligning with the <111> direction. The grain size in the weld is larger than that in the base metal. Figure 13 and Figure 14 show the Kernel Average Misorientation (KAM) diagram and the corresponding frequency distribution curve of local orientation differences, respectively. The calculated average local orientation difference for Iron BCC is 0.323, whereas for Iron FCC, it is only 0.066. Notably, FCC has a higher dislocation density than BCC. Grain boundaries are interfaces between adjacent grains. Grain boundaries exhibiting an orientation difference of less than 10° are classified as small-angle grain boundaries [21,22]. The grain boundary orientation difference in BCC typically lies between 0.75° and 2.5°, while in FCC, it ranges from 0° to 2.5°. Small-angle grain boundaries reduce grain boundary defects and alleviate stress concentration, thereby enhancing the overall mechanical properties of the material. Additionally, they reduce interface energy, imparting a strengthening effect on the material.

Figure 12.

Surface orientation distribution. (a) X0; (b) Y0; (c) Z0.

Figure 13.

KAM diagram of welded joints.

Figure 14.

Local misorientation difference relative frequency distribution curve. (a) Iron BCC (b) Iron FCC.

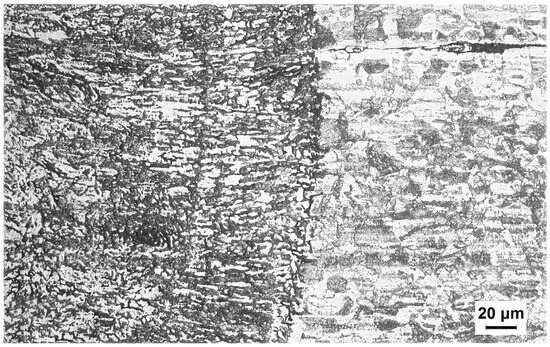

The microstructure in the HAZ consists entirely of austenite and ferrite, characterized by columnar austenite and ferrite distributed in elongated bars or networks at the fusion boundary. As shown in Figure 15 and Figure 16, the long bars of massive ferrite are arranged parallel to one another, exhibiting notable differences from the connected-network ferrite. The network ferrite is mainly located at the fusion boundary, and the welded joints exhibit a distinct fusion boundary [23,24]. The solidification of the principle of cast metal reveals that the crystal structure of liquid metal is mainly influenced by the solute within the liquid metal, the rate of crystallization, and the temperature gradient of the molten pool. Near the fusion boundary, the high thermal conductivity of the solid base metal and the significant temperature gradient result in a rapid crystallization rate of the liquid metal. Consequently, the range of undercooling is extensive, leading to the preferential formation of columnar crystals. Additionally, the precipitation direction of high-temperature ferrite in the heat-affected zone differs from that in the weld zone. δ ferrite is no longer precipitated along the cylindrical austenite grain boundaries, but rather in the vertical direction of the austenite columnar crystals. This phenomenon arises from the rapid heating rate of the heat-affected zone, resulting in prolonged heating and cooling durations, as well as increased segregation of alloying elements at the austenite grain boundaries. Nucleation occurs at the original austenite grain boundaries, resulting in a directional difference in the formation of ferrite.

Figure 15.

Microstructure of heat-affected zone of weld.

Figure 16.

Microstructure of heat affected zone of welded joints, the upper plate; (b) enlarged view marked in (a); (c) the lower plate; (d) enlarged view marked in (c).

3.8. The Distribution of Deformation and Residual Stress After Welding

Under the optimal parameters, the long-plate welding of laser non-penetration lap welding was carried out, resulting in more significant thermal deformation after welding. The selected plate size is shown in Table 12.

Table 12.

The size of the test material and welding parameters.

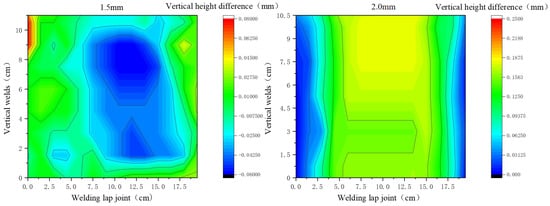

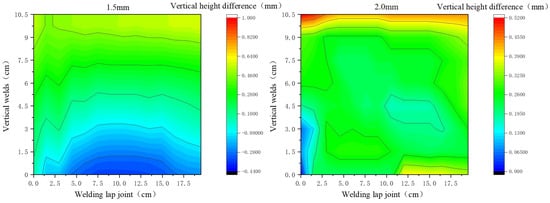

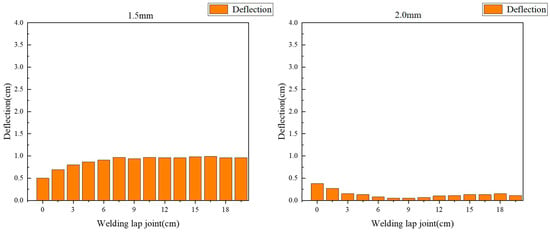

Figure 17 and Figure 18 present the contour maps illustrating the vertical height difference before and following the welding process, respectively. Figure 19 shows the deformation of the steel plate The contour map shows that the overall trend presents an increase in welding deformation at a distance from the weld zone. Consequently, the welding deformation resulting from the lap welding of the non-penetrated long plate is characterized as angular deformation. The vertical height difference from the weld zone is the largest. The deformation range for the 1.5 mm plate is between 0.5 and 0.99 mm, while the deformation range for the 2.0 mm plate is from 0.01 to 0.38 mm.

Figure 17.

Vertical height difference in plate before welding.

Figure 18.

Vertical height difference in plate after welding.

Figure 19.

The amount of deformation of the plate after welding.

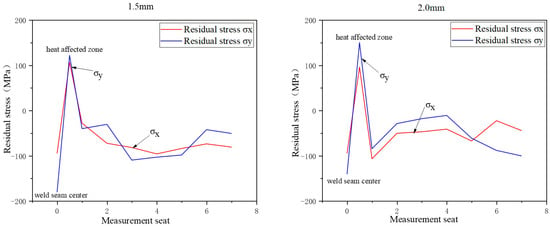

Figure 20 shows the distribution of welding residual stress under the optimal parameters. An X-ray stress instrument was utilized to measure the residual stress in stainless-steel non-penetration lap welded plates following welding, under two distinct conditions. The characteristics of residual stress are as follows: transverse residual stress induces irreversible compressive deformation at the joint. Cooling in air leads to increased tensile stress in the central area of the weld, while compressive stress is observed at a distance from the weld. The longitudinal residual stress field characteristics reveal that tensile stress occurs near the weld axis, whereas the base metal area, located further from the fusion line, exhibits a distinct compressive stress distribution. The residual stress in the 1.5 mm plate is greater than that in the 2.0 mm plate. The fluctuation range is larger because the stiffness of the plate gradually decreases with decreasing thickness. A thinner plate experiences a more significant influence from the heat source, resulting in increased deformation and changes in residual stress upon cooling.

Figure 20.

Welding residual stress distribution under optimal parameters.

Transverse stress affects both the weld bead and the base metal. Therefore, any transverse stress component on the weld or base metal surface must be counteracted by an opposing force within these plate sections. The distribution of transverse residual stress across the cross-section is non-uniform. The resulting inhomogeneity is generated and varied throughout the welding process, resulting in angular deformation of the plate after welding [25].

4. Results

- The RSM not only reduces the number of experiments in the exploration process, but can also carry out mathematical analysis and simulation of the required welding results and accurately obtain the predicted results. The error comparison with the actual welding test further illustrates the reliability of the test results. The shear strength of the laser-welded joint is 429.3 N/mm2, which exceeds the tensile shear strength required by the GB/T37778 standard, and meets the appearance requirements of the lower plate surface without observed weld marks, which improves the welding quality and simplifies the post-welding treatment process.

- Under the calculation of the RSM, the optimal response model of the tensile shear load is a linear model, and the optimal response model of weld penetration is the 2FI model. The error range of the verification test is 6.5%, indicating that the mathematical model has high reliability. The defocusing amount has a crucial influence on the tensile strength and weld penetration of the welded joint. The optimized process parameters are a laser power of 1.44 kW, welding speed of 15 mm/s, and defocusing amount of −4 mm. The penetration depth of the welded joint is 2.2 mm. The tensile fracture shows a brittle fracture mode. The crystal structure of the weld zone is mainly BCC ferrite. The correlation between the BCC crystal structure and brittle fracture further confirms that the weld zone is dominated by ferrite.

- The macroscopic surface of the weld joints exhibited a well-formed structure devoid of defects. Ferrite was formed by the FA mode of solidification. Plate-like ferrite is concentrated in the weld beam. The local orientation differences between the two phases are small-angle grain boundaries. Near the HAZ, plate-like block ferrite and network ferrite are present. Ferrite typically nucleates along the original austenite grain in the HAZ, resulting in an orientation difference due to the presence of ferrite.

- Following welding under optimal parameters, measurements indicate that the overall distance from the weld zone correlates positively with the extent of welding deformation. Thus, the welding deformation caused by non-penetration lap welding is characterized as angular deformation. The distribution of transverse residual stress across the weld cross-section and the base metal is non-uniform, necessitating balance throughout the plate’s interior. In contrast, the distribution of longitudinal residual stress exhibits greater uniformity, resulting in overall angular deformation following the welding process. The residual stress exhibits tensile characteristics near the weld and compressive characteristics further from the weld.

Author Contributions

Conceptualization, Y.L. and Z.C.; Methodology, Y.L.; Software, P.Z. (Peng Zhang) and Z.C.; Validation, H.H., P.Z. (Peng Zhang) and J.L.; Formal analysis, Z.Z.; Investigation, Z.Z. and B.S.; Resources, W.Y., Y.J., B.S. and J.L.; Data curation, P.Z. (Ping Zhu) and Z.X.; Writing—original draft, H.H.; Writing—review & editing, S.H. and P.Z. (Ping Zhu); Supervision, S.H., Z.X. and Y.J.; Project administration, W.Y. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Department of Education of Liaoning Province grant number JYTMS20230023.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

Authors Yuhuan Liu, Weiguo Yan, Zhichao Zhang, and Zhihui Xu were employed by Sonyo Compressor (Dalian) Co., Ltd. Yuncheng Jiang was employed by CRRC Shijiazhuang Rolling Stock Co., Ltd. Bin Shi and Junchang Lin were employed by Xincheng (Liaoning) Power Capacitor Technology Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Kumar, N.; Mukherjee, M.; Bandyopadhyay, A. Comparative study of pulsed Nd: YAG laser welding of AISI 304 and AISI 316 stainless steels. Opt. Laser Technol. 2017, 88, 24–39. [Google Scholar] [CrossRef]

- Romero-Resendiz, L.; El-Tahawy, M.; Zhang, T.; Rossi, M.C.; Marulanda-Cardona, D.M.; Yang, T.; Amigó-Borrás, V.; Huang, Y.; Mirzadeh, H.; Beyerlein, I.J.; et al. Heterostructured stainless steel: Properties, current trends, and future perspectives. Mater. Sci. Eng. R Rep. 2022, 150, 100691. [Google Scholar] [CrossRef]

- Morshed-Behbahani, K.; Zakerin, N. A review on the role of surface nano crystallization in corrosion of stainless steel. J. Mater. Res. Technol. 2022, 19, 1120–1147. [Google Scholar] [CrossRef]

- Liu, Z.; Jin, X.; Zhang, J.; Hao, Z.; Li, J. Microstructure evolution and mechanical properties of SUS301L stainless steel sheet welded joint in ultrasonic vibration assisted laser welding. Opt. Laser Technol. 2022, 153, 108193. [Google Scholar] [CrossRef]

- Cui, C.; Cui, X.; Ren, X.; Liu, T.; Hu, J.; Wang, Y. Microstructure and microhardness of fiber laser butt welded joint of stainless steel plates. Mater. Des. 2013, 49, 761–765. [Google Scholar] [CrossRef]

- Ghorbani, S.; Ghasemi, R.; Ebrahimi-Kahrizsangi, R.; HojjatiNajafabadi, A. Effect of post weld heat treatment (PWHT) on the microstructure, mechanical properties and corrosion resistance of dissimilar stainless steels. Mater. Sci. Eng. A 2017, 688, 470–479. [Google Scholar] [CrossRef]

- Gu, X.; Zhu, K.; Wu, S.; Duan, Z.; Zhu, L. Effect of welding parameters on weld formation quality and tensile-shear property of laser welded SUS301L stainless steel lap filet weld. J. Mater. Res. Technol. 2020, 9, 4840–4854. [Google Scholar] [CrossRef]

- Günther, J.; Prowaznik, R.; Krug, D.; Jahn, S.; Niendorf, T.; Wegener, T. Microstructure and mechanical properties of hand-held laser beam welded S700MC high-strength steel. J. Adv. Join. Process. 2025, 12, 100359. [Google Scholar] [CrossRef]

- Gnanasekaran, S.; Kumar, S.S.; Venugopal, N.; Upadhyaya, M.; Manjunath, T.; Chelladurai, S.J.S.; Padmanaban, G. Effect of laser power on microstructure and tensile properties of pulsed Nd: YAG laser beam welded AISI 301 austenitic stainless steel joints. Mater. Today Proc. 2021, 37, 934–939. [Google Scholar] [CrossRef]

- Palanisamy, S.; Rajendran, R.; Shashi Kumar, S. Effect of incident angle on weld microstructure and mechanical properties of laser beam welded nitronic−50 austenitic stainless steel joints. Micron 2023, 169, 103457. [Google Scholar] [CrossRef]

- Kovács, Z.; Molnár, C.; Štangar, U.L.; Cristea, V.-M.; Pap, Z.; Hernadi, K.; Baia, L. Optimization Method of the Solvothermal Parameters Using Box–Behnken Experimental Design—The Case Study of ZnO Structural and Catalytic Tailoring. Nanomaterials 2021, 11, 1334. [Google Scholar] [CrossRef]

- Celik, I.; Şensoy, A.T.; Seven, G.; Cicek, D. Improving Deep Drawing Quality of DD13 Sheet Metal: Optimization of Process Parameters Using Box–Behnken Design. Materials 2025, 18, 1424. [Google Scholar] [CrossRef] [PubMed]

- Qi, S.; Wang, C.; Liu, Y.; Liu, A.; Bai, Z.; Peng, Z.; Liang, Z.; Narayanaswamy, B.; Wang, L.; Wang, D. Process parameter optimization of laser welding for dissimilar aluminum alloys 4047 and 6061 using response surface methodology: Microstructure and mechanical properties. Opt. Laser Technol. 2025, 190, 113198. [Google Scholar] [CrossRef]

- Liu, G.; Gao, X.; Peng, C.; Huang, Y.; Fang, H.; Zhang, Y.; You, D.; Nanfeng, Z. Optimization of laser welding of DP780 to Al5052 joints for weld width and lap-shear force using response surface methodology. Opt. Laser Technol. 2020, 126, 106072. [Google Scholar] [CrossRef]

- Ragavendran, M.; Chandrasekhar, N.; Ravikumar, R.; Saxena, R.; Vasudevan, M.; Bhaduri, A. Optimization of hybrid laser–TIG welding of 316LN steel using response surface methodology (RSM). Opt. Lasers Eng. 2017, 94, 27–36. [Google Scholar] [CrossRef]

- Altay, M.; Aydin, H. Parameter optimization, microstructural and mechanical properties of fiber laser lap welds of DP1200 steel sheets. Measurement 2024, 235, 114822. [Google Scholar] [CrossRef]

- Mosavi, A.; Soleimani, A.; Karimi, A.; Akbaki, M.; Karimipour, A.; Karimipour, A. Investigating the effect of process parameters on the mechanical properties and temperature distribution in fiber laser welding of AISI304 and AISI 420 sheet using response surface methodology. Infrared Phys. Technol. 2020, 111, 103478. [Google Scholar] [CrossRef]

- Chimklin, K.; Phuangkaew, S.; Deeying, J. Multi-objective optimization of laser spot welding parameters for enhancing mechanical properties of hard disk components using response surface methodology. Results Eng. 2025, 25, 104449. [Google Scholar] [CrossRef]

- GB/T37778-2019; Stainless Steel Laser Welding Recommended Process Specification. Standardization Administration of the People’s Republic of China: Beijing, China, 2019.

- Lippold, J.C.; Kotecki, D.J. Welding Metallurgy and Weldability of Stainless Steels; China Machine Press: Ningbo, China, 2016; pp. 129–158. ISBN 978-1-1182-3070-1. [Google Scholar]

- Bonetti, R.; Neate, N.C.; Morris, A.; Shipway, P.H.; Sun, W. Microstructure evolution and deformation mechanisms of service-exposed P91 steel via interrupted uniaxial creep tests at 660 °C. J. Mater. Res. Technol. 2024, 33, 3529–3549. [Google Scholar] [CrossRef]

- Wang, P.; Siddiqui, M.F.; Poletti, M.C.; Enzinger, N. Phase transformation and recrystallization of cold-rolled AISI 304L austenitic stainless steel during annealing. Mater. Des. 2025, 252, 113738. [Google Scholar] [CrossRef]

- Abe, H.; Watanabe, Y. Role of δ-ferrite in stress corrosion cracking retardation near fusion boundary of 316NG welds. J. Nucl. Mater. 2012, 424, 57–61. [Google Scholar] [CrossRef]

- Zhang, Y.; Guo, J.; Li, Y.; Luo, Z.; Zhang, X. A comparative study between the mechanical and microstructural properties of resistance spot welding joints among ferritic AISI 430 and austenitic AISI 304 stainless steel. J. Mater. Res. Technol. 2020, 9, 574–583. [Google Scholar] [CrossRef]

- Monin, V.I.; Lopes, R.T.; Turibus, S.N.; Filho, J.C.P.; de Assis, J.T. X-Ray Diffraction Technique Applied to Study of Residual Stresses after Welding of Duplex Stainless Steel Plates. Mater. Res. 2014, 17, 64–69. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.