Microstructure and Mechanical Property of Thin-Walled Inconel 718 Parts Fabricated by Ultrasonic-Assisted Laser-Directed Energy Deposition

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

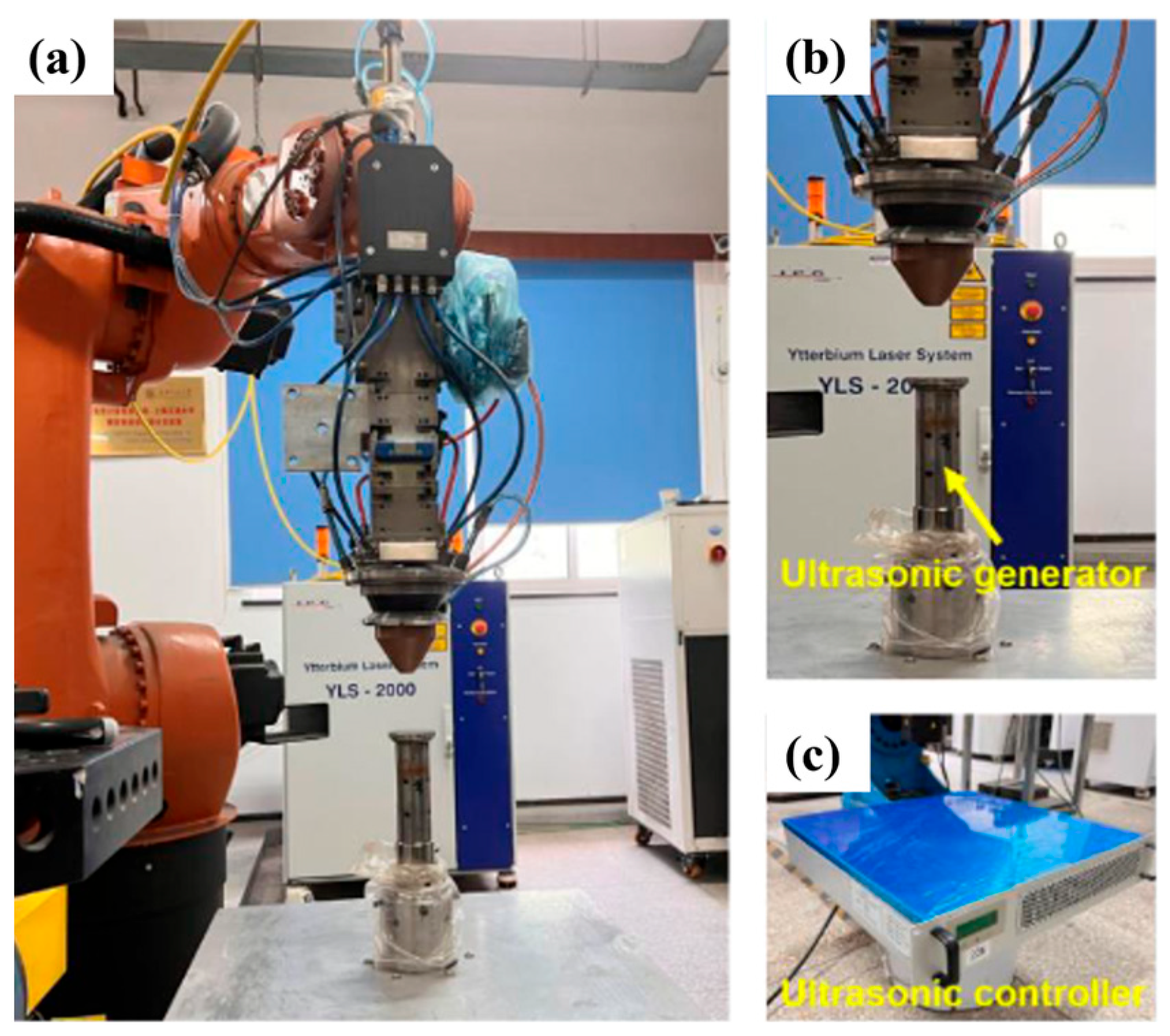

2.2. Setup and DED Procedure

2.3. Microstructure Characterization

2.4. Mechanical Property Test

3. Results

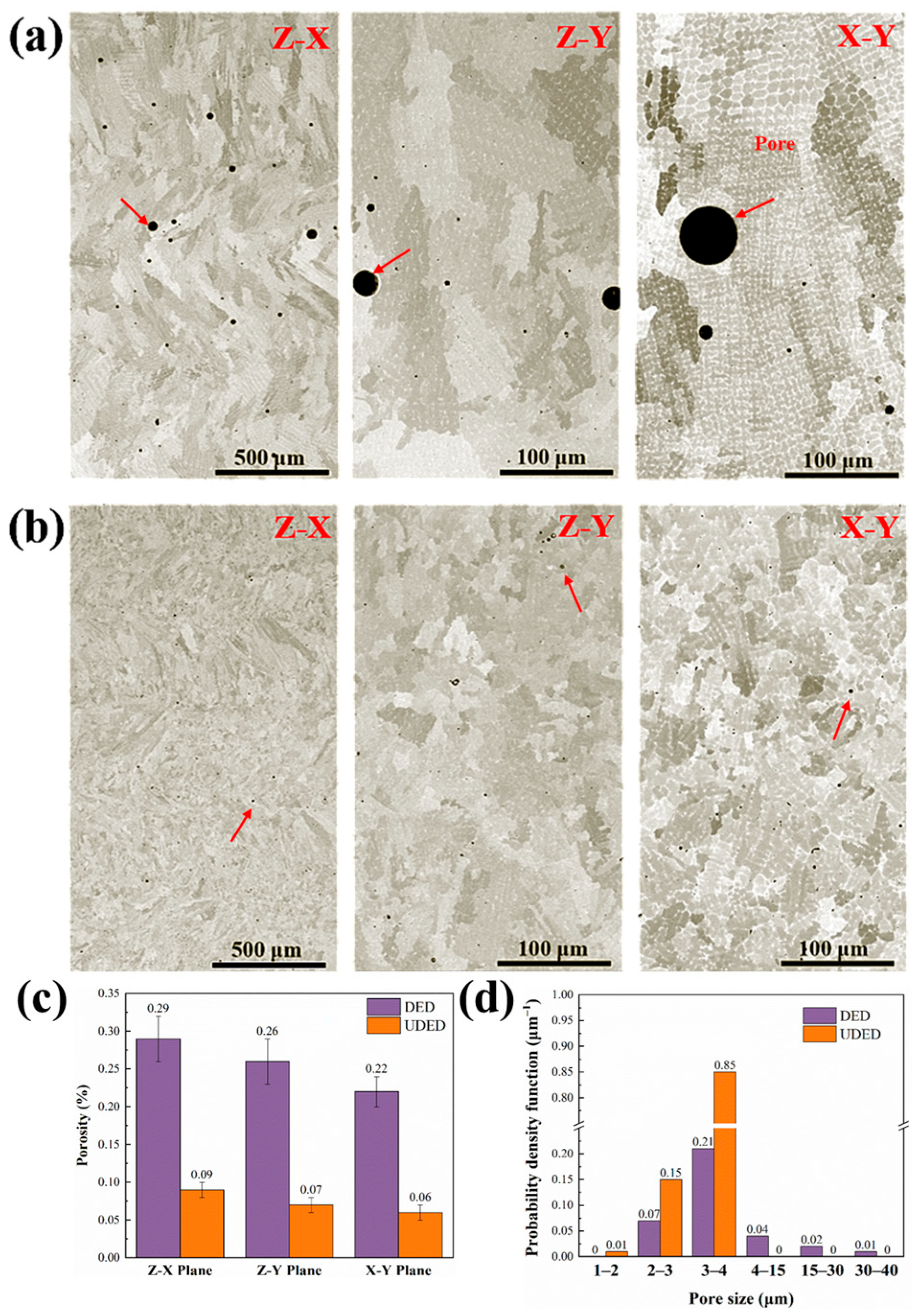

3.1. Pore Analysis

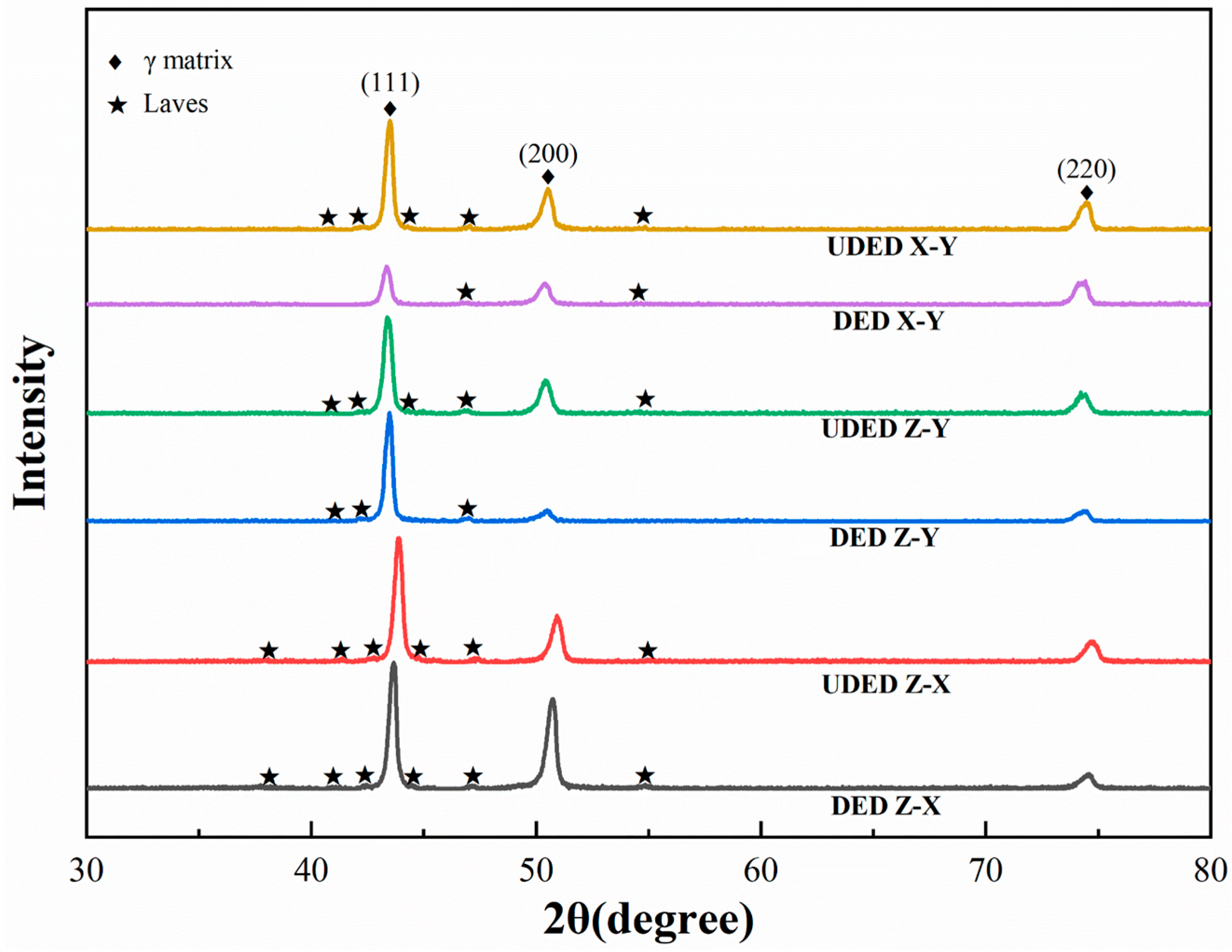

3.2. Phase Analysis by XRD

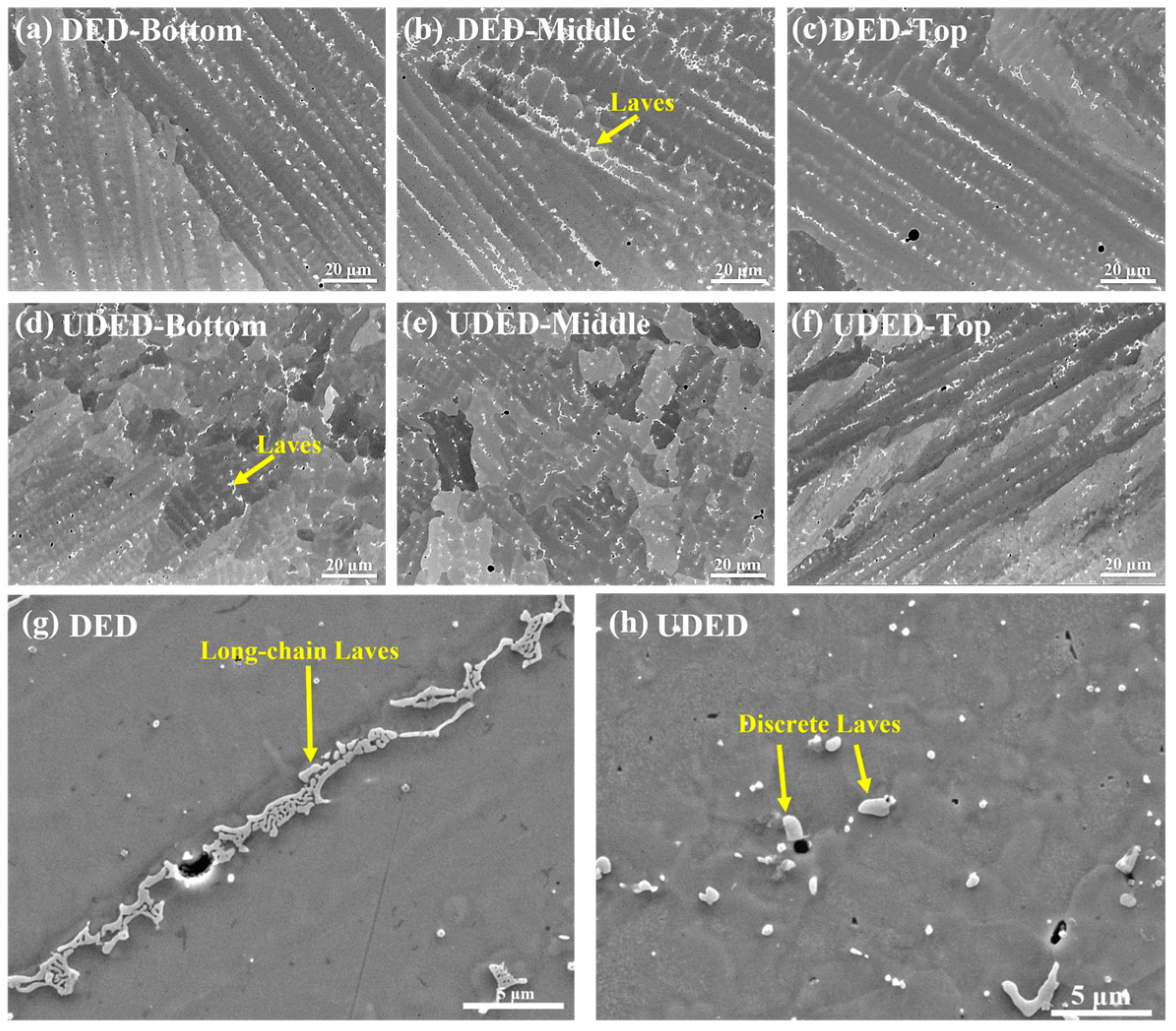

3.3. Laves Phase Morphology and Distribution

3.4. Chemical Composition

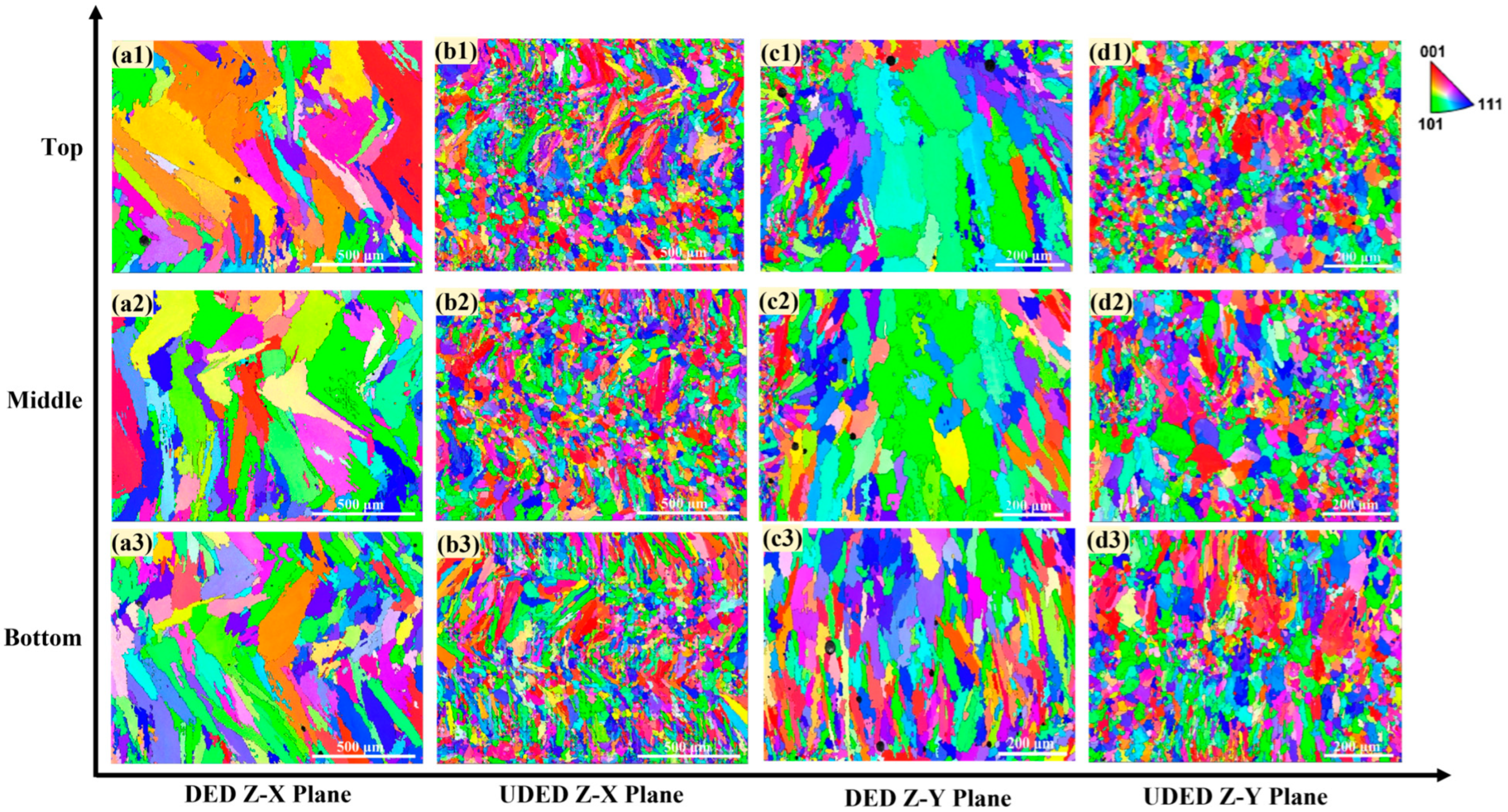

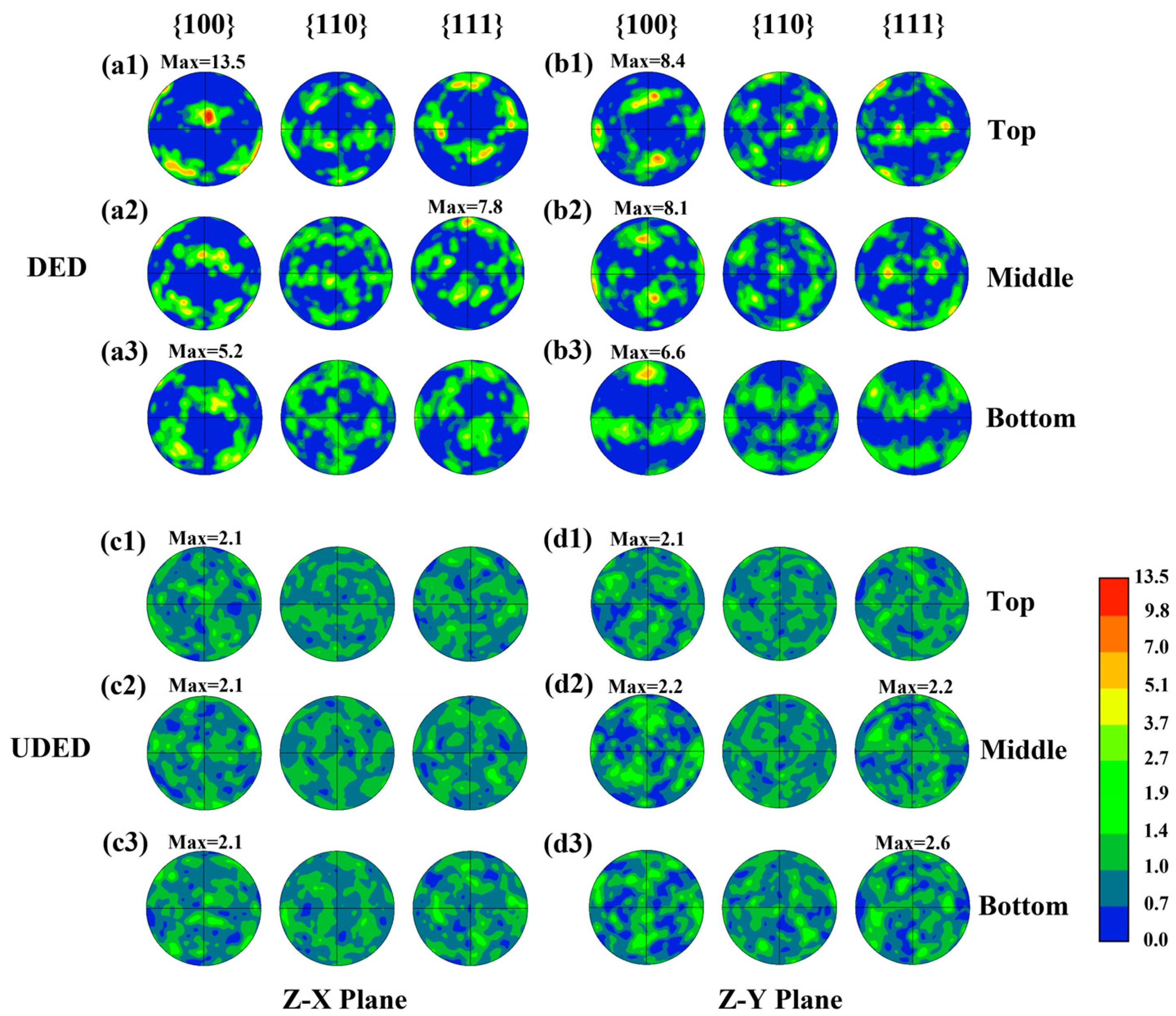

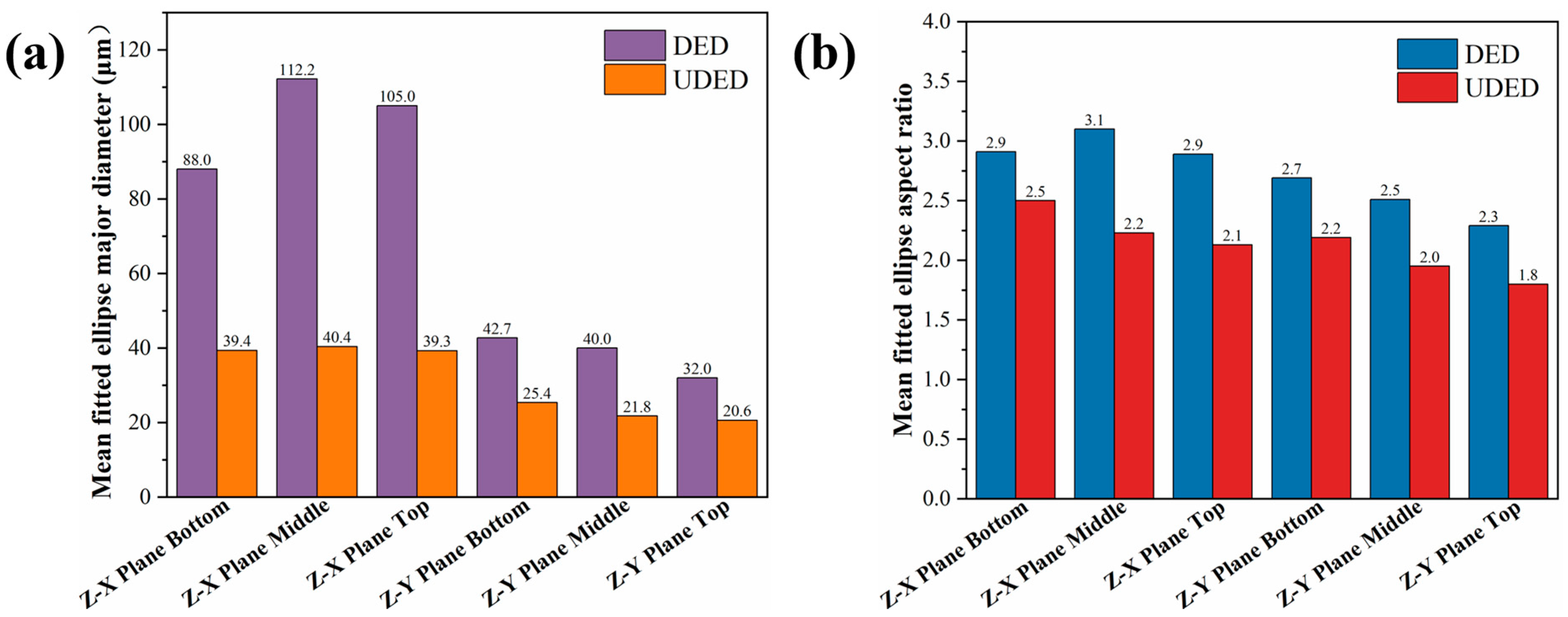

3.5. Matrix Grain Morphology

3.6. Mechanical Properties

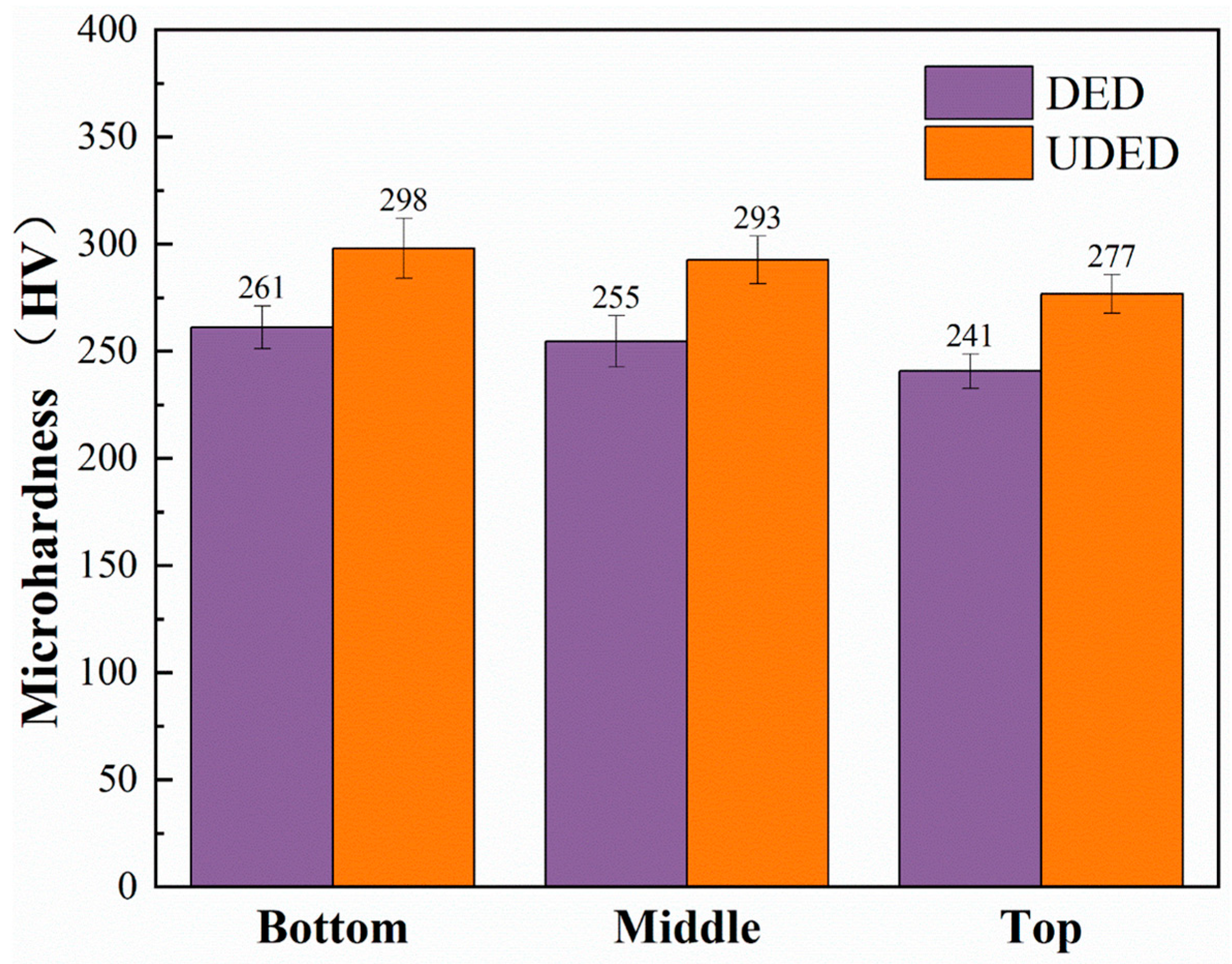

3.6.1. Microhardness

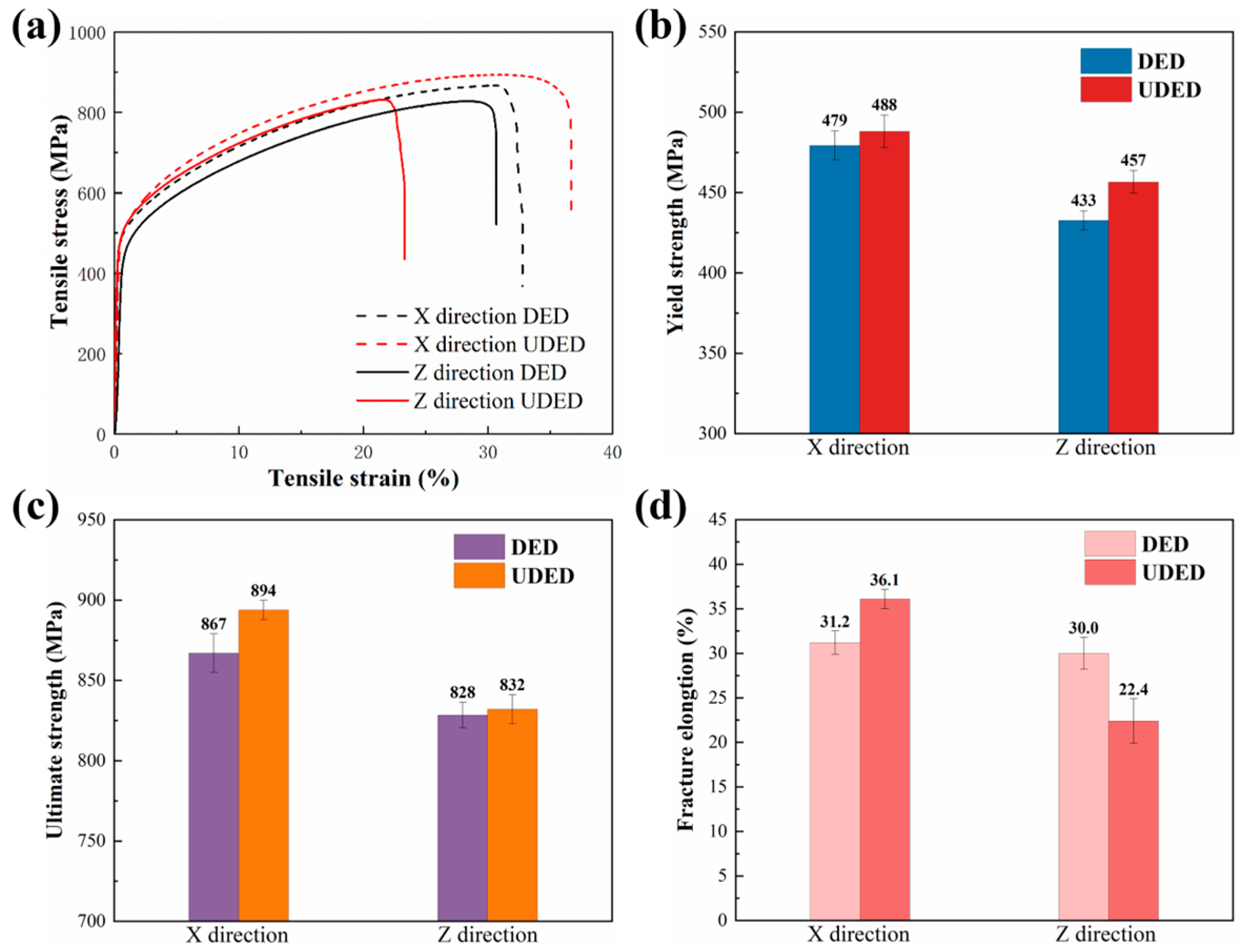

3.6.2. Tensile Property

3.6.3. Fracture Morphology

4. Discussion

4.1. The Effect of Ultrasonic Vibration on the Microstructure of Inconel 718

4.2. The Relationship of Microstructure and Mechanical Properties

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Svetlizky, D.; Das, M.; Zheng, B.; Vyatskikh, A.L.; Bose, S.; Bandyopadhyay, A.; Schoenung, J.M.; Lavernia, E.J.; Eliaz, N. Directed energy deposition (DED) additive manufacturing: Physical characteristics, defects, challenges and applications. Mater. Today 2021, 49, 271–295. [Google Scholar] [CrossRef]

- Wang, Y.; Hu, K.; Li, W.; Wang, L. Prediction of melt pool width and layer height for Laser Directed Energy Deposition enabled by physics-driven temporal convolutional network. J. Manuf. Syst. 2023, 69, 1–17. [Google Scholar] [CrossRef]

- Sommer, N.; Bauer, A.; Kahlmeyer, M.; Wegener, T.; Degener, S.; Liehr, A.; Bolender, A.; Vollmer, M.; Holz, H.; Zeiler, S.; et al. High-throughput alloy development using advanced characterization techniques during directed energy deposition additive manufacturing. Adv. Eng. Mater. 2023, 25, 2300030. [Google Scholar] [CrossRef]

- Kelly, J.P.; Elmer, J.W.; Ryerson, F.J.; Lee, J.R.I.; Haslam, J.J. Directed energy deposition additive manufacturing of functionally graded Al-W composites. Addit. Manuf. 2021, 39, 101845. [Google Scholar] [CrossRef]

- Shinjo, J.; Panwisawas, C. Chemical species mixing during direct energy deposition of bimetallic systems using titanium and dissimilar refractory metals for repair and biomedical applications. Addit. Manuf. 2022, 51, 102654. [Google Scholar] [CrossRef]

- Saboori, A.; Aversa, A.; Marchese, G.; Biamino, S.; Lombardi, M.; Fino, P. Microstructure and Mechanical Properties of AISI 316L Produced by Directed Energy Deposition-Based Additive Manufacturing: A Review. Appl. Sci. 2020, 10, 3310. [Google Scholar] [CrossRef]

- Vashishtha, H.; Kumar, D.; Kim, Y.S.; Lee, S.Y.; Huang, E.W.; Jain, J. Effects of hot isostatic processing and hot rolling on direct energy deposited CoCrNi medium entropy alloy–Microstructural heterogeneity, wear behaviour and corrosion characteristics. Mater. Charact. 2023, 205, 113304. [Google Scholar] [CrossRef]

- Shalnova, S.A.; Kuzminova, Y.O.; Evlashin, S.A.; Klimova-Korsmik, O.G.; Vildanov, A.M.; Shibalova, A.A.; Turichin, G.A. Effect of recycled powder content on the structure and mechanical properties of Ti-6Al-4V alloy produced by direct energy deposition. J. Alloys Compd. 2022, 893, 162264. [Google Scholar] [CrossRef]

- Pasang, T.; Budiman, A.S.; Wang, J.C.; Jiang, C.P.; Boyer, R.; Williams, J.; Misiolek, W.Z. Additive manufacturing of titanium alloys–Enabling re-manufacturing of aerospace and biomedical components. Microelectron. Eng. 2023, 270, 111935. [Google Scholar] [CrossRef]

- Di, T.; Zhao, Y.; Song, C.; Hu, Y.; Ma, G.; Wang, Z.; Niu, F.; Wu, D. Mechanism of grain refinement and mechanical property enhancement of Ti-45Al-8Nb alloy by directed laser deposition. J. Alloys Compd. 2023, 939, 168729. [Google Scholar] [CrossRef]

- Ma, W.; Xie, Y.; Chen, C.; Fukanuma, H.; Wang, J.; Ren, Z.; Huang, R. Microstructural and mechanical properties of high-performance Inconel 718 alloy by cold spraying. J. Alloys Compd. 2019, 792, 456–467. [Google Scholar] [CrossRef]

- Yin, X.; Zhao, S.; Liu, Y.; Zhai, Y.; Li, X.; Geng, D.; Zhang, D. Evaluation of profile accuracy and surface integrity for Inconel 718 blade machined by ultrasonic peening milling. J. Manuf. Process. 2023, 104, 150–163. [Google Scholar] [CrossRef]

- Calandri, M.; Yin, S.; Aldwell, B.; Calignano, F.; Lupoi, R.; Ugues, D. Texture and microstructural features at different length scales in Inconel 718 produced by selective laser melting. Materials 2019, 12, 1293. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.Y.; Xu, B.; Tariq, N.H.; Sun, M.Y.; Li, D.Z.; Li, Y.Y. An innovative approach for grain refinement in Ni-based superalloys: Modification in the classical delta process through γ″ pre-aging treatment. J. Alloys Compd. 2020, 818, 152827. [Google Scholar] [CrossRef]

- Zhou, S.; Liu, Z.; Yang, G.; Li, X.; Wang, J.; Guo, X.; Wang, X. Heterostructure microstructure and laves phase evolution mechanisms during inter-layer hammering hybrid directed energy deposition (DED) process. Mater. Sci. Eng. A 2023, 886, 145668. [Google Scholar] [CrossRef]

- Alfred, S.O.; Amiri, M. High-temperature fatigue of additively manufactured Inconel 718: A short review. J. Eng. Mater. Technol. 2025, 147, 010801. [Google Scholar] [CrossRef]

- Ono, Y.; Yuri, T.; Sumiyoshi, H.; Takeuchi, E.; Matsuoka, S.; Ogata, T. High-cycle fatigue properties at cryogenic temperatures in Inconel 718 nickel-based superalloy. Mater. Trans. 2004, 45, 342–345. [Google Scholar] [CrossRef]

- Li, W.B.; Pang, J.C.; Zhang, H.; Li, S.X.; Zhang, Z.F. The high-cycle fatigue properties of selective laser melted Inconel 718 at room and elevated temperatures. Mater. Sci. Eng. A 2022, 836, 142716. [Google Scholar] [CrossRef]

- Wild, G.; Pollock, L.; Abdelwahab, A.K.; Murray, J. The need for aerospace structural health monitoring: A review of aircraft fatigue accidents. Int. J. Progn. Health Manag. 2021, 12, 1–16. [Google Scholar] [CrossRef]

- Yang, Z.; Zhu, L.; Dun, Y.; Ning, J.; Wang, S.; Xue, P.; Xu, P.; Yu, M.; Yan, B.; Xin, B. In-situ monitoring of the melt pool dynamics in ultrasound-assisted metal 3D printing using machine learning. Virtual Phys. Prototyp. 2023, 18, e2251453. [Google Scholar] [CrossRef]

- Wang, Z.; Jiang, F.; Guo, C.; Xing, X.; Yang, Z.; Li, H.; Liu, C.; Xu, D.; Jiang, G.; Konovalov, S. Effects of ultrasonic vibration on microstructure and mechanical properties of 1Cr12Ni3MoVN alloy fabricated by directed energy deposition. Ultrasonics 2023, 132, 106989. [Google Scholar] [CrossRef]

- Gorunov, A.I. Additive manufacturing of Ti6Al4V parts using ultrasonic assisted direct energy deposition. J. Manuf. Process. 2020, 59, 545–556. [Google Scholar] [CrossRef]

- Todaro, C.J.; Easton, M.A.; Qiu, D.; Brandt, M.; StJohn, D.H.; Qian, M. Grain refinement of stainless steel in ultrasound-assisted additive manufacturing. Addit. Manuf. 2021, 37, 101632. [Google Scholar] [CrossRef]

- Ning, F.; Hu, Y.; Liu, Z.; Wang, X.; Li, Y.; Cong, W. Ultrasonic vibration-assisted laser engineered net shaping of inconel 718 parts: Microstructural and mechanical characterization. J. Manuf. Sci. Eng. 2018, 140, 061012. [Google Scholar] [CrossRef]

- Xu, H.; Jian, X.; Meek, T.T.; Han, Q. Degassing of molten aluminum A356 alloy using ultrasonic vibration. Mater. Lett. 2004, 58, 3669–3673. [Google Scholar] [CrossRef]

- Cong, W.; Ning, F. A fundamental investigation on ultrasonic vibration-assisted laser engineered net shaping of stainless steel. Int. J. Mach. Tools Manuf. 2017, 121, 61–69. [Google Scholar] [CrossRef]

- Yang, Z.; Zhu, L.; Wang, S.; Ning, J.; Dun, Y.; Meng, G.; Xue, P.; Xu, P.; Xin, B. Effects of ultrasound on multilayer forming mechanism of Inconel 718 in directed energy deposition. Addit. Manuf. 2021, 48, 102462. [Google Scholar] [CrossRef]

- Xu, L.; Chai, Z.; Zhang, X.; Peng, B.; Zhou, W.; Chen, X. A new approach to improve strength and ductility of laser powder deposited Inconel 718 thin-wall structure. Mater. Sci. Eng. A 2022, 855, 143871. [Google Scholar] [CrossRef]

- Sohn, H.; Liu, P.; Yoon, H.; Yi, K.; Yang, L.; Kim, S. Real-time porosity reduction during metal directed energy deposition using a pulse laser. J. Mater. Sci. Technol. 2022, 116, 214–223. [Google Scholar] [CrossRef]

- Manikandan, S.G.K.; Sivakumar, D.; Prasad Rao, K.; Kamaraj, M. Effect of weld cooling rate on Laves phase formation in Inconel 718 fusion zone. J. Mater. Process. Technol. 2014, 214, 358–364. [Google Scholar] [CrossRef]

- Ning, F.; Hu, Y.; Cong, W. Microstructure and mechanical property of TiB reinforced Ti matrix composites fabricated by ultrasonic vibration-assisted laser engineered net shaping. Rapid Prototyp. J. 2018, 25, 581–591. [Google Scholar] [CrossRef]

- Xiao, W.; Xu, Y.; Xiao, H.; Li, S.; Song, L. Investigation of the Nb element segregation for laser additive manufacturing of nickel-based superalloys. Int. J. Heat Mass Transf. 2021, 180, 121800. [Google Scholar] [CrossRef]

- Wang, H.; Hu, Y.; Ning, F.; Cong, W. Ultrasonic vibration-assisted laser engineered net shaping of Inconel 718 parts: Effects of ultrasonic frequency on microstructural and mechanical properties. J. Mater. Process. Technol. 2020, 276, 116395. [Google Scholar] [CrossRef]

- Xiao, H.; Xie, P.; Cheng, M.; Song, L. Enhancing mechanical properties of quasi-continuous-wave laser additive manufac-tured Inconel 718 through controlling the niobium-rich precipitates. Addit. Manuf. 2020, 34, 101278. [Google Scholar]

- Chen, Y.; Guo, Y.; Xu, M.; Ma, C.; Zhang, Q.; Wang, L.; Yao, J.; Li, Z. Study on the element segregation and Laves phase formation in the laser metal deposited IN718 superalloy by flat top laser and Gaussian distribution laser. Mater. Sci. Eng. A 2019, 754, 339–347. [Google Scholar] [CrossRef]

- Liu, F.; Cheng, H.; Yu, X.; Yang, G.; Huang, C.; Lin, X.; Chen, J. Control of microstructure and mechanical properties of laser solid formed Inconel 718 superalloy by electromagnetic stirring. Opt. Laser Technol. 2018, 99, 342–350. [Google Scholar] [CrossRef]

- Endo, Y.; Kimura, Y.; Saka, M. Ultrasonic-induced morphological change of micro/nanodeposits and current change in electrochemical migration. MRS Commun. 2019, 9, 1331–1334. [Google Scholar] [CrossRef]

- Farshidianfar, M.H.; Khajepour, A.; Gerlich, A.P. Effect of real-time cooling rate on microstructure in Laser Additive Manufacturing. J. Mater. Process. Technol. 2016, 231, 468–478. [Google Scholar] [CrossRef]

- Schmitt, M.; Stark, H. Marangoni flow at droplet interfaces: Three-dimensional solution and applications. Phys. Fluids 2016, 28, 012106. [Google Scholar] [CrossRef]

- Alexander, A.J.; Camp, P.J. Single pulse, single crystal laser-induced nucleation of potassium chloride. Cryst. Growth Des. 2009, 9, 958–963. [Google Scholar] [CrossRef]

- Lee, J.; Yang, S. Antisolvent sonocrystallisation of sodium chloride and the evaluation of the ultrasound energy using modified classical nucleation theory. Crystals 2018, 8, 320. [Google Scholar] [CrossRef]

- Mullin, J.W. Crystallization, 4th ed.; Butterworth-Heinemann: Oxford, UK, 2011; p. 594. [Google Scholar]

- Wang, F.; Eskin, D.; Mi, J.; Connolley, T.; Lindsay, J.; Mounib, M. A refining mechanism of primary Al3Ti intermetallic particles by ultrasonic treatment in the liquid state. Acta Mater. 2016, 116, 354–363. [Google Scholar] [CrossRef]

- Virone, C.; Kramer, H.J.M.; van Rosmalen, G.M.; Stoop, A.H.; Bakker, T.W. Primary nucleation induced by ultrasonic cavitation. J. Cryst. Growth 2006, 294, 9–15. [Google Scholar] [CrossRef]

- Sui, S.; Chen, J.; Ming, X.; Zhang, S.; Lin, X.; Huang, W. The failure mechanism of 50% laser additive manufactured Inconel 718 and the deformation behavior of Laves phases during a tensile process. Int. J. Adv. Manuf. Technol. 2017, 91, 2733–2740. [Google Scholar] [CrossRef]

- He, M.L.; Cao, H.L.; Liu, Q.; Yi, J.; Ni, Y.; Wang, S. Evolution of dislocation cellular pattern in Inconel 718 alloy fabricated by laser powder-bed fusion. Addit. Manuf. 2022, 55, 102839. [Google Scholar] [CrossRef]

- McAllister, D.; Lv, D.; Feng, L.; Deutchman, H.; Wessman, A.; Wang, Y.; Mills, M.J. Characterization and modeling of deformation mechanisms in Ni-base superalloy 718. In Proceedings of the 9th International Symposium on Superalloy 718 & Derivatives, Pittsburgh, PA, USA, 3–6 June 2018; Springer: Cham, Switzerland, 2018; pp. 319–338. [Google Scholar]

- Bean, G.E.; McLouth, T.D.; Witkin, D.B.; Sitzman, S.D.; Adams, P.M.; Zaldivar, R.J. Build orientation effects on texture and mechanical properties of selective laser melting Inconel 718. J. Mater. Eng. Perform. 2019, 28, 1942–1949. [Google Scholar] [CrossRef]

- Sumi, Y. Stress Concentration Problems. In Mathematical and Computational Analyses of Cracking Formation; Springer: Tokyo, Japan, 2014; pp. 17–30. [Google Scholar]

- Zhou, B.; Meng, D.H.; Wu, D.; Tang, J.F.; Chen, R.S.; Li, P.J.; Han, E.H. Characterization of porosity and its effect on the tensile properties of Mg-6Gd-3Y-0.5Zr alloy. Mater. Charact. 2019, 152, 204–212. [Google Scholar] [CrossRef]

- Lee, C.D.; Shin, K.S. Effect of microporosity on the tensile properties of AZ91 magnesium alloy. Acta Mater. 2007, 55, 4293–4303. [Google Scholar] [CrossRef]

- Lee, C.D. Effects of microporosity on tensile properties of A356 aluminum alloy. Mater. Sci. Eng. A 2007, 464, 249–254. [Google Scholar] [CrossRef]

- Orowan, E. Fracture and strength of solids. Rep. Prog. Phys. 1949, 12, 185. [Google Scholar] [CrossRef]

- Gomez-Ramirez, R.; Pound, G.M. Nucleation of a second solid phase along dislocations. Metall. Trans. 1973, 4, 1563–1570. [Google Scholar] [CrossRef]

- Gunaydin, K.; Gülcan, O. Distortion and dimensional deviation of Inconel 718 auxetic structures produced by DMLM. Addit. Manuf. Technol. 2021, 1, 563. [Google Scholar]

- Hall, E.O. The deformation and ageing of mild steel: III discussion of results. Proc. Phys. Soc. B 1951, 64, 747. [Google Scholar] [CrossRef]

- Hasani, N.; Dharmendra, C.; Sanjari, M.; Fazeli, F.; Amirkhiz, B.S.; Pirgazi, H.; Janaki Ram, G.D.; Mohammadi, M. Laser powder bed fused Inconel 718 in stress-relieved and solution heat-treated conditions. Mater. Charact. 2021, 181, 111499. [Google Scholar] [CrossRef]

- Tekumalla, S.; Seita, M.; Zaefferer, S. Delineating dislocation structures and residual stresses in additively manufactured alloys. Acta Mater. 2024, 262, 119413. [Google Scholar] [CrossRef]

- Di, O.; Zhang, C.; Chen, R.; Li, N.; Chan, K.C.; Liu, L. The microcrack inhibition and mechanical properties of an in-situ synthesized refractory high-entropy alloy fabricated by additive manufacturing. Mater. Sci. Eng. A 2024, 913, 147071. [Google Scholar]

- Gerold, V.; Karnthaler, H.P. On the origin of planar slip in fcc alloys. Acta Metall. 1989, 37, 2177–2183. [Google Scholar] [CrossRef]

- Kad, B.K.; Schoenfeld, S.E.; Asaro, R.J.; McKamey, C.G.; Sikka, V.K. Deformation textures in Fe3Al alloys: An assessment of dominant slip system activity in the 900–1325 K temperature range of hot working. Acta Mater. 1997, 45, 1333–1350. [Google Scholar] [CrossRef]

| Elements | Cr | Nb | Mo | Al | Ti | Mn | Si | C | Fe | Ni |

|---|---|---|---|---|---|---|---|---|---|---|

| Inconel 718 substrate | 17.85 | 5.18 | 3.05 | 0.52 | 0.95 | 0.10 | 0.20 | 0.03 | 19.79 | Bal. |

| Inconel 718 powder | 19.79 | 5.13 | 2.95 | 0.52 | 1.07 | 0.01 | 0.04 | 0.03 | 17.45 | Bal. |

| Position | C | O | Al | Ti | Cr | Fe | Co | Ni | Nb | Mo |

|---|---|---|---|---|---|---|---|---|---|---|

| A (Matrix) | 4.4 | 2.7 | 2.6 | 1.2 | 18.3 | 18.4 | 0.2 | 46.5 | 3.2 | 2.5 |

| B (Laves) | 4.6 | 0.7 | 0.4 | 1.6 | 15.5 | 15 | 0.1 | 45 | 13.5 | 3.6 |

| C (MC) | 5.9 | 1.6 | 1.5 | 5.3 | 16.5 | 15.8 | 0.1 | 39.3 | 11.8 | 2.2 |

| D (Matrix) | 6.6 | 1 | 0.6 | 0.9 | 18.3 | 19 | 0.1 | 46.7 | 4.3 | 2.5 |

| E (Laves) | 5.5 | 0.6 | 0.50 | 1.5 | 16.5 | 16.4 | 0.1 | 46.8 | 9.1 | 3 |

| F (MC) | 8.5 | 1.6 | 0.7 | 3.8 | 14 | 13.5 | 0.1 | 38.3 | 16.9 | 2.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peng, B.; Zhang, X.; Zhang, M.; Chai, Z.; Ba, F.; Chen, X. Microstructure and Mechanical Property of Thin-Walled Inconel 718 Parts Fabricated by Ultrasonic-Assisted Laser-Directed Energy Deposition. Crystals 2025, 15, 815. https://doi.org/10.3390/cryst15090815

Peng B, Zhang X, Zhang M, Chai Z, Ba F, Chen X. Microstructure and Mechanical Property of Thin-Walled Inconel 718 Parts Fabricated by Ultrasonic-Assisted Laser-Directed Energy Deposition. Crystals. 2025; 15(9):815. https://doi.org/10.3390/cryst15090815

Chicago/Turabian StylePeng, Bo, Xiaoqiang Zhang, Mengmeng Zhang, Ze Chai, Fahai Ba, and Xiaoqi Chen. 2025. "Microstructure and Mechanical Property of Thin-Walled Inconel 718 Parts Fabricated by Ultrasonic-Assisted Laser-Directed Energy Deposition" Crystals 15, no. 9: 815. https://doi.org/10.3390/cryst15090815

APA StylePeng, B., Zhang, X., Zhang, M., Chai, Z., Ba, F., & Chen, X. (2025). Microstructure and Mechanical Property of Thin-Walled Inconel 718 Parts Fabricated by Ultrasonic-Assisted Laser-Directed Energy Deposition. Crystals, 15(9), 815. https://doi.org/10.3390/cryst15090815