A Critical Review on Friction Stir Spot Welding of Aluminium Alloys: Tool, Mechanical, and Micro-Structural Characteristics

Abstract

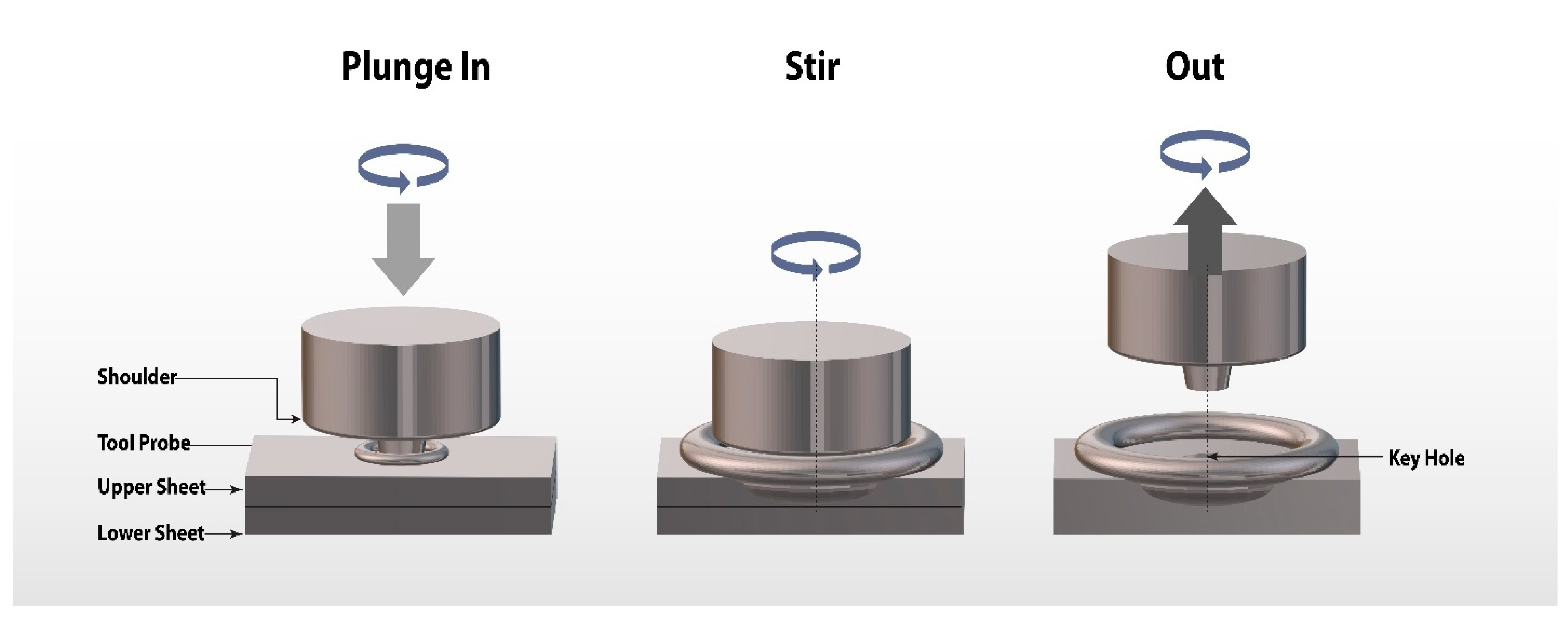

1. Introduction

2. Tools Used in FSSW

2.1. Common Tool Materials

2.2. Tool Steel

2.3. PCBN Tools

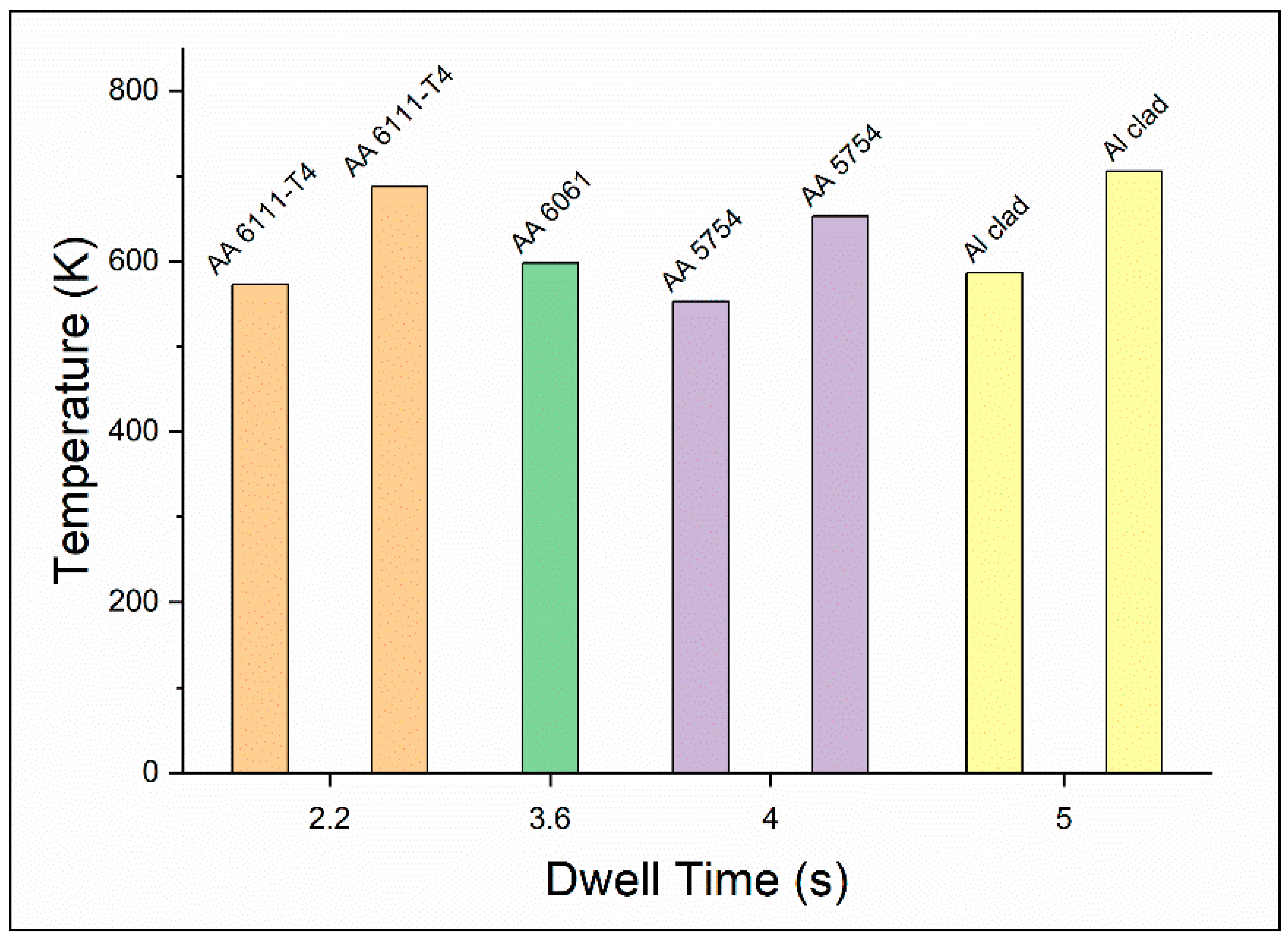

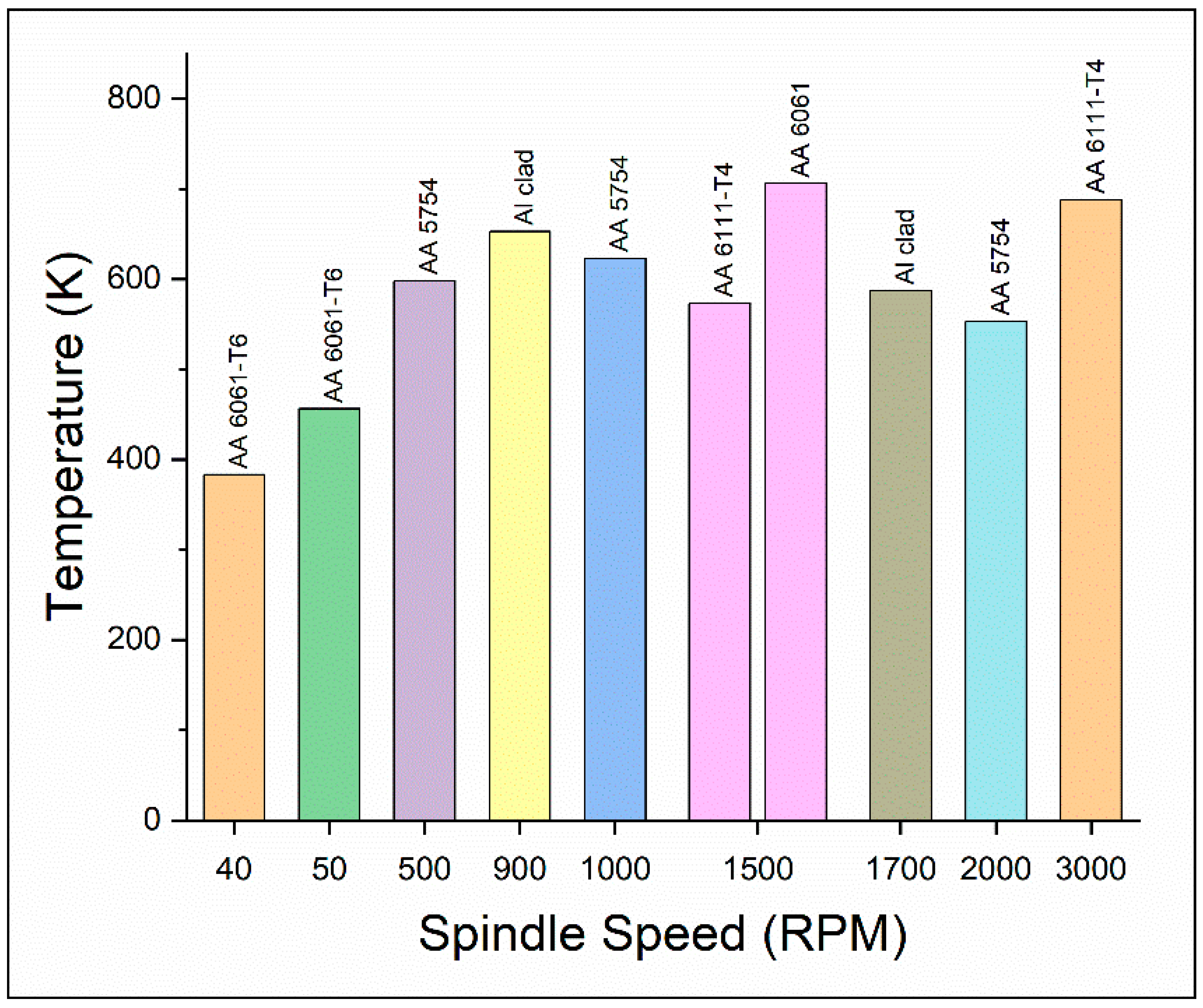

2.4. Temperature Distribution

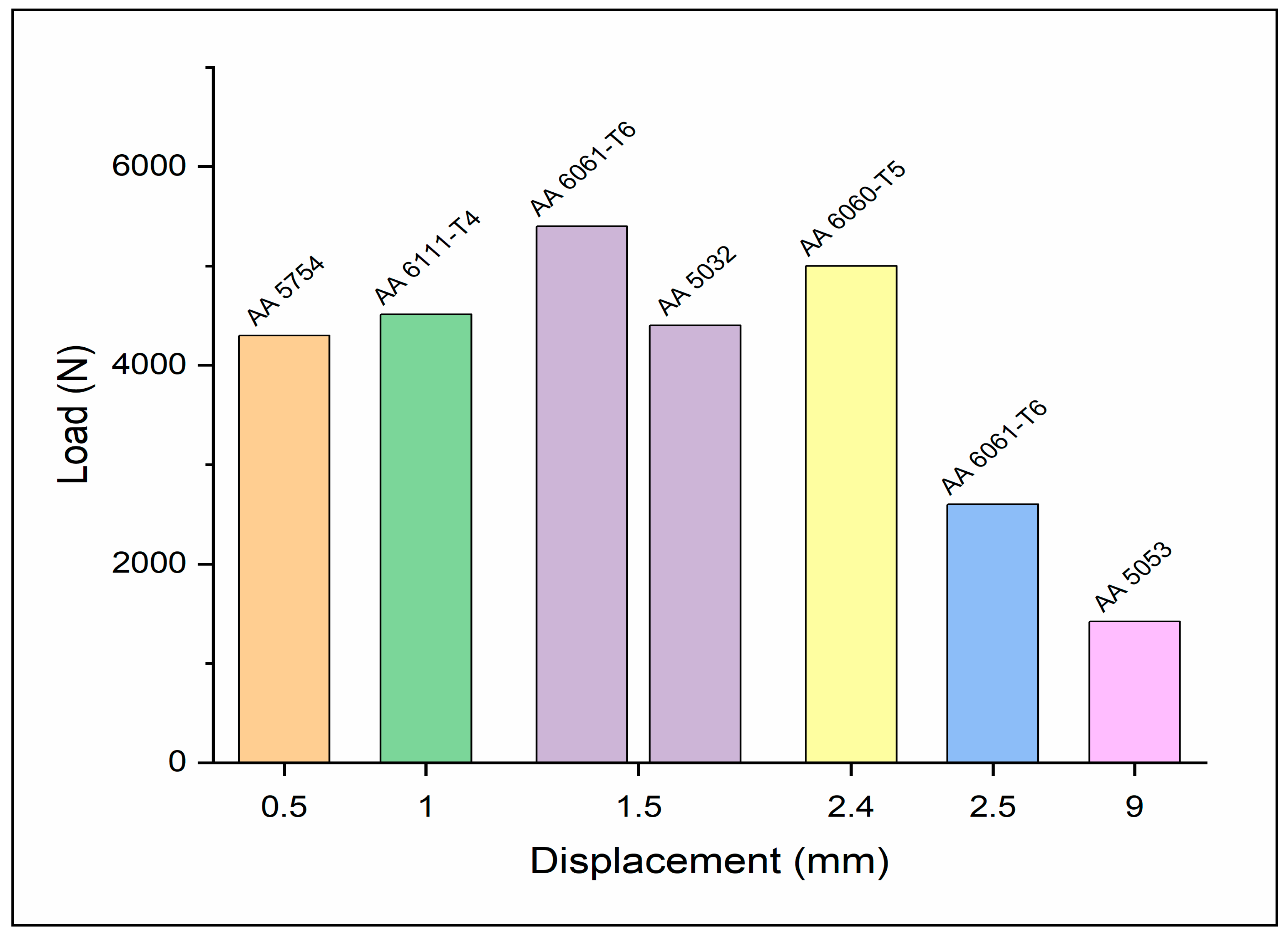

3. Mechanical Behavior

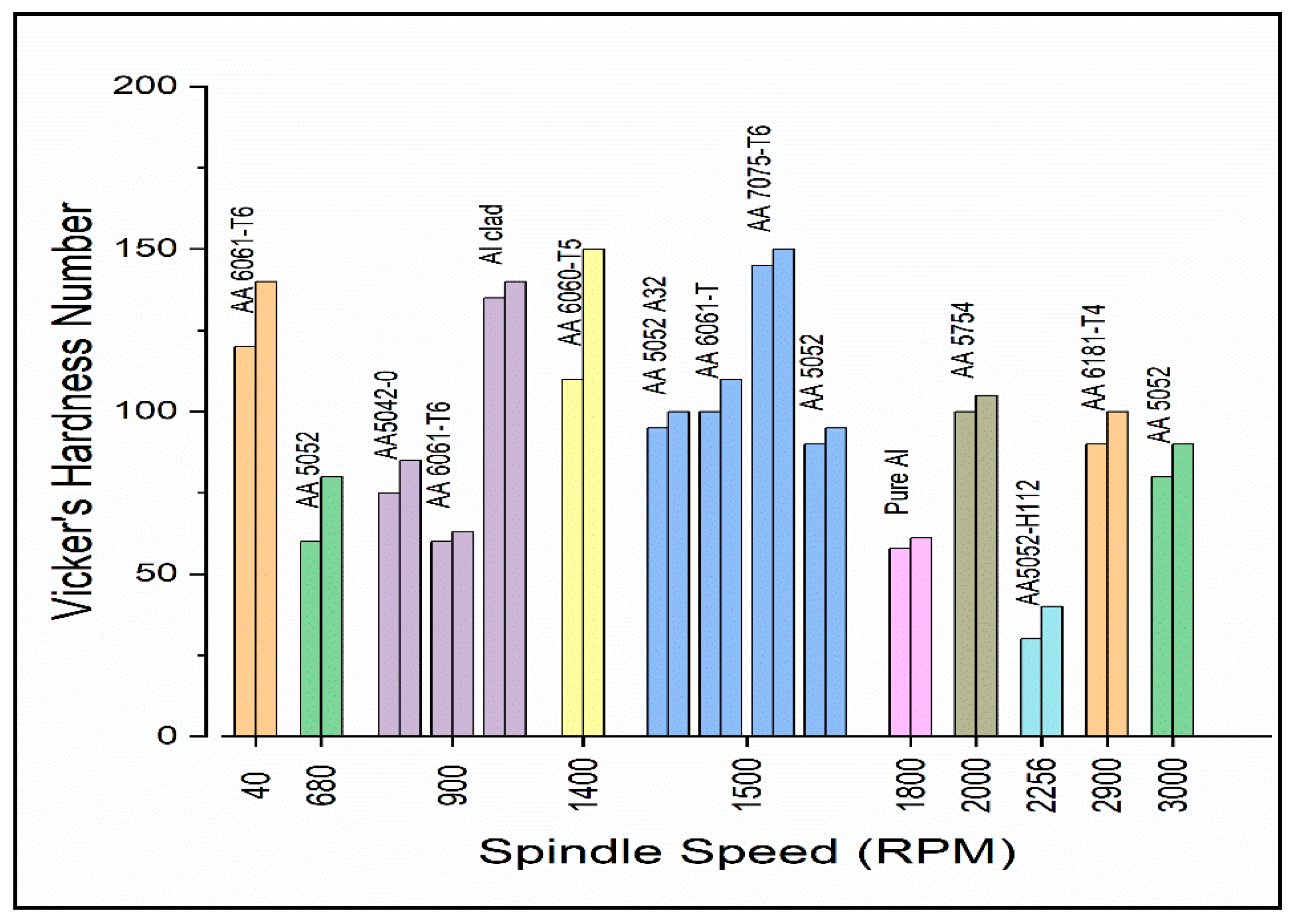

4. Microhardness

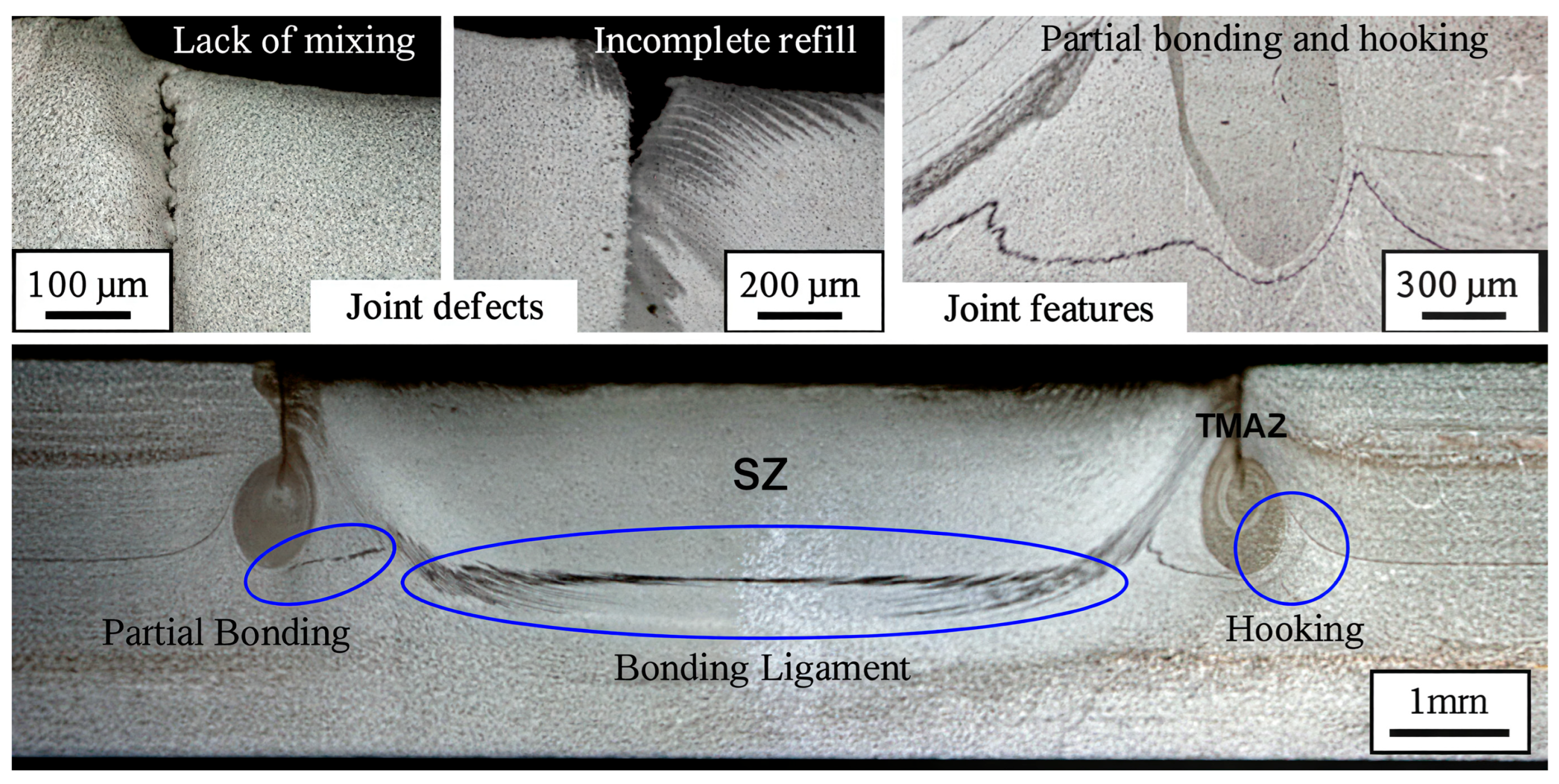

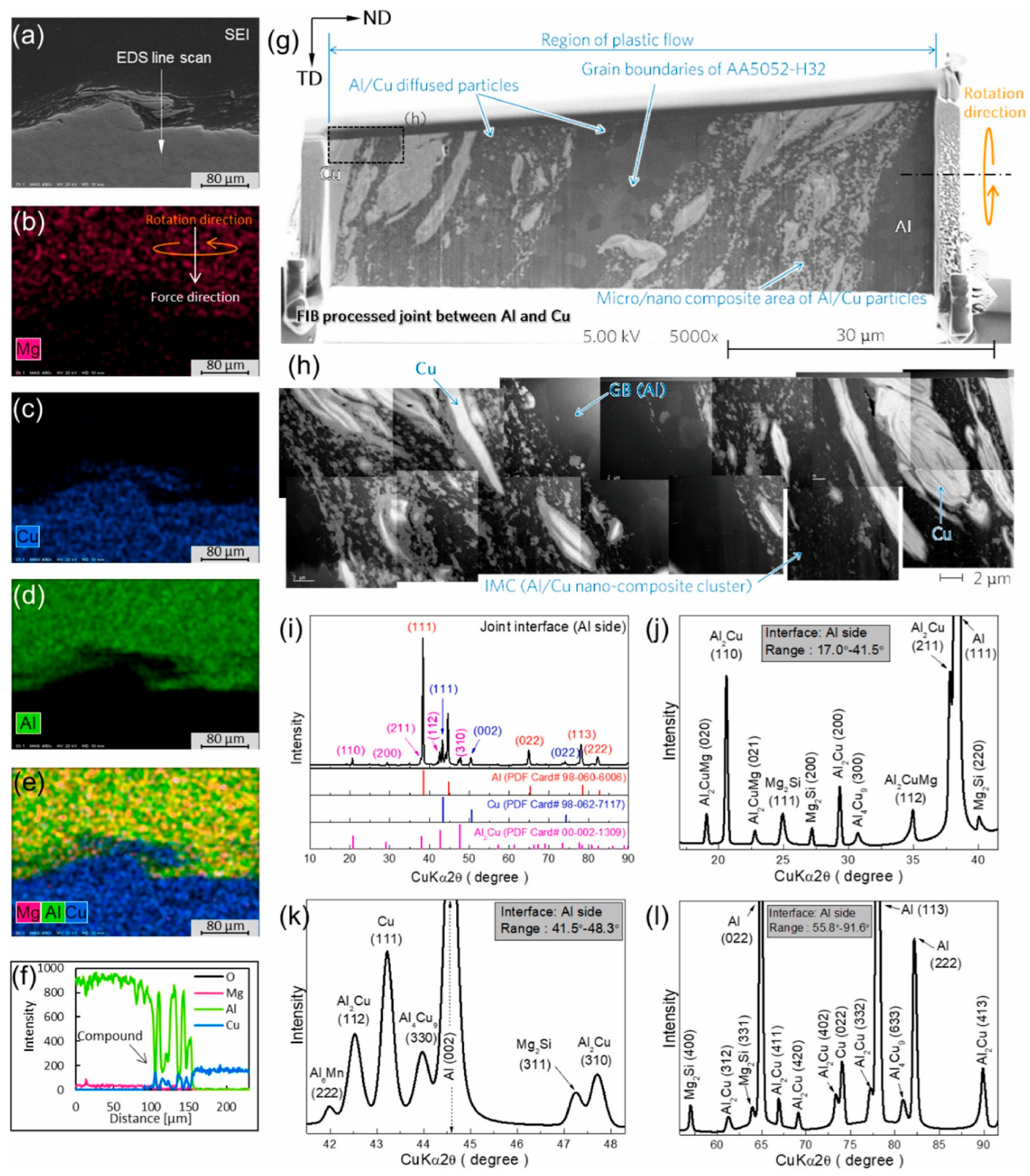

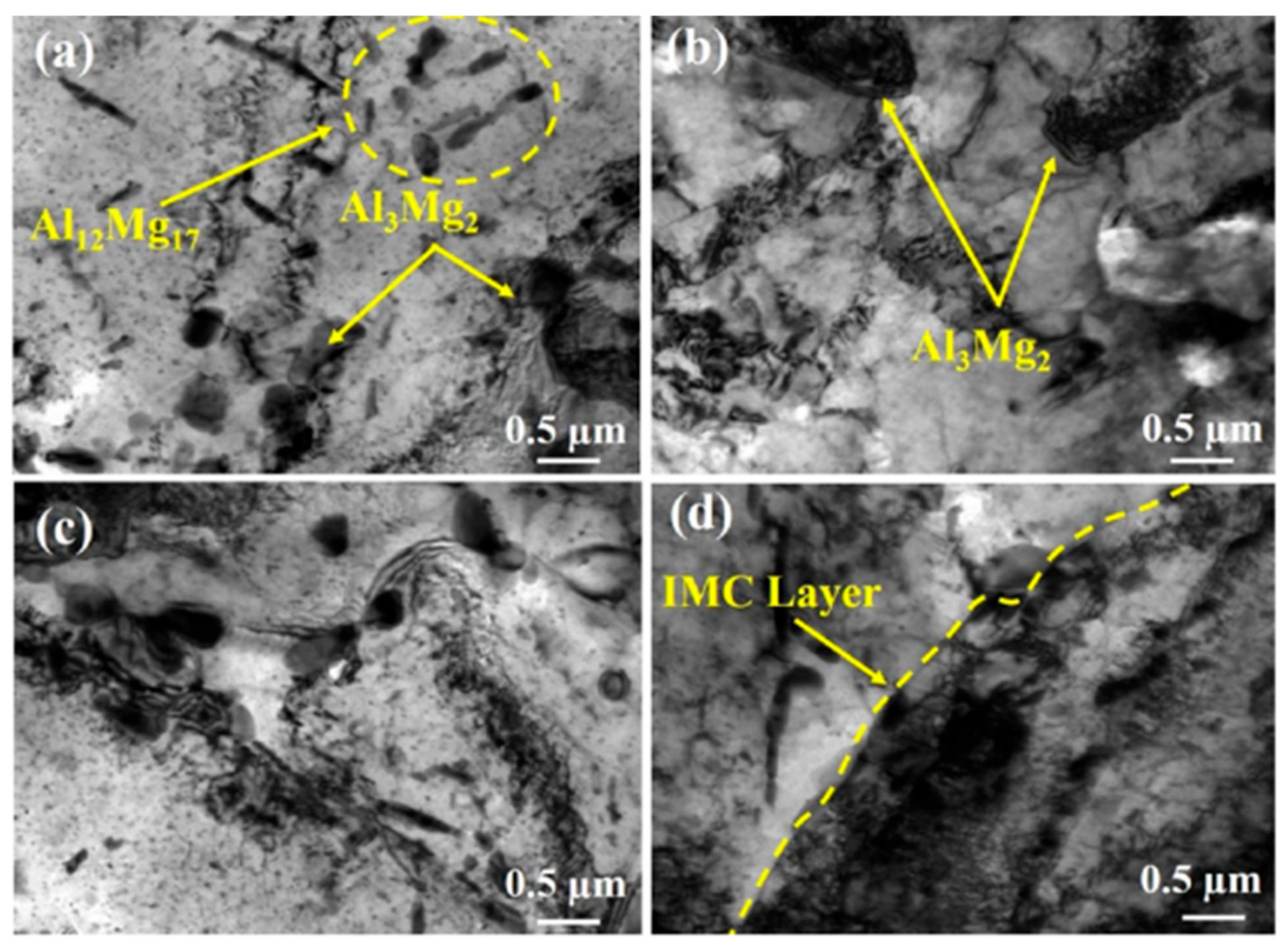

5. Microstructure

6. Design Rules and Code Comparisons for FSSW of Aluminum Alloys

7. Summary

- It can be seen that a wide range of tool materials are being used; H13 is the most widely used, other popular ones are HSS, C40, CBN, etc.

- From the study, it can be concluded that the peak welding temperatures vary from 280 °C to 450 °C and there is an increase in temperature with an increase in RPM; however, it depends upon the aluminum grade.

- Most of the researchers have performed the Vicker’s hardness study for all the similar Al FSSW welding ranges of 50–160 HV, where HV at the Stir Zone of the upper plate has the highest hardness value.

- For achieving the highest load-bearing capacity, the dwell time should be kept minimum and the load-bearing capacity can be slightly improved using a pinless tool.

- Numerous researchers have conducted tensile testing of the FSSW joints, Al 6XXX series seems to show the maximum load-bearing capacity.

- From the studies, it is evident that the thermal history has a critical influence on the final mechanical behavior.

- Studies have been conducted to analyze the design standards, and it was found that currently there is no defined standard for the FSSW process, at present only AWS has a specific standard for the friction stir welding.

8. Future Directions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Su, J.Q.; Nelson, T.W.; Mishra, R.; Mahoney, M. Microstructural investigation of friction stir welded 7050-T651 aluminium. Acta Mater. 2003, 51, 713–729. [Google Scholar] [CrossRef]

- Mubiayi, M.P.; Akinlabi, E.T.; Makhatha, M.E. Current state of friction stir spot welding between aluminium and copper. Mater. Today Proc. 2018, 5, 18633–18640. [Google Scholar] [CrossRef]

- Çam, G.; Mistikoglu, S. Recent developments in friction stir welding of al-Alloys. J. Mater. Eng. Perform. 2014, 23, 1936–1953. [Google Scholar] [CrossRef]

- Lin, Y.C.; Liu, J.J.; Chen, J.N. Material flow tracking for various tool geometries during the friction stir spot welding process. J. Mater. Eng. Perform. 2013, 22, 3674–3683. [Google Scholar] [CrossRef]

- Shen, Z.; Ding, Y.; Gerlich, A.P. Advances in friction stir spot welding. Crit. Rev. Solid State Mater. Sci. 2019, 45, 457–534. [Google Scholar] [CrossRef]

- Hsu, T.I.; Wu, L.T.; Tsai, M.H. Resistance and friction stir spot welding of dual-phase (DP 780)—A comparative study. Int. J. Adv. Manuf. Technol. 2018, 97, 2293–2299. [Google Scholar] [CrossRef]

- Yang, X.W.; Fu, T.; Li, W.Y. Friction stir spot welding: A review on joint macro- and microstructure, property, and process modelling. Adv. Mater. Sci. Eng. 2014, 2014, 697170. [Google Scholar] [CrossRef]

- Andalib, H.; Farahani, M.; Enami, M. Study on the new friction stir spot weld joint reinforcement technique on 5754 aluminum alloy. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci 2018, 232, 2976–2986. [Google Scholar] [CrossRef]

- Venukumar, S.; Muthukumaran, S.; Swaroop, Y. Microstructure and mechanical properties of refilled friction stir spot welding of commercial pure aluminium. Mater. Sci. Forum 2013, 765, 776–780. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; EI-Sayed Seleman, M.M.; Fydrych, D.; Çam, G. Friction Stir Welding of Aluminum in the Aerospace Industry: The Current Progress and State-of-the-Art Review. Materials 2023, 16, 2971. [Google Scholar] [CrossRef]

- Sengupta, K.; Chowdhury, I.; Banerjee, A.; Mondal, A.K.; Bose, D. Analysis of suitability of WC tool for joining Inconel 601 alloy by electric assisted friction stir welding. Mater. Today Proc. 2022, 60, 2093–2098. [Google Scholar] [CrossRef]

- Sengupta, K.; Mondal, A.K.; Bose, D.; Chowdhury, I. Experimental Investigation on Metallurgical Properties on Effect of Dual Hybridization by Ultrasonic and Electric Energy in Friction Stir Welding for Joining Inconel 625 to Stainless Steel 304. Trans. Indian Inst. Met. 2024, 77, 941–953. [Google Scholar] [CrossRef]

- Chowdhury, I.D.; Sengupta, K.; Singh, D.K.; Maji, K.K.; Roy, S.; Ghosal, S.; Mondal, A.K. Investigation of mechanical properties of dissimilar joint of 6063 aluminium and C26000 copper alloy by friction stir welding. Mater. Today Proc. 2021, 44, 4039–4047. [Google Scholar] [CrossRef]

- Sengupta, K.; Singh, D.K.; Mondal, A.K.; Bose, D.; Patra, D.; Dhar, A. Characterization of tool wear in similar and dissimilar joints of MS and SS using EAFSW. Mater. Today Proc. 2021, 44, 3967–3975. [Google Scholar] [CrossRef]

- Shen, Z.; Ding, Y.; Guo, W.; Hou, W.; Liu, X.; Chen, H.; Liu, F.; Li, W.; Gerlich, A. Refill Friction Stir Spot Welding Al Alloy to Copper via Pure Metallurgical Joining Mechanism. Chin. J. Mech. Eng. 2021, 34, 75. [Google Scholar] [CrossRef]

- Myśliwiec, P.; Kubit, A.; Szawara, P. Optimization of 2024-T3 Aluminum Alloy Friction Stir Welding Using Random Forest, XGBoost, and MLP Machine Learning Techniques. Materials 2024, 17, 1452. [Google Scholar] [CrossRef]

- Mehdi, H.; Singh, J.; Mouria, P.K.; Mishra, S.; Prakash, C. Effect of Tool Pin Profile on Mechanical and Metallurgical Properties of the Friction Stir Welded Joint of AA6061 and AZ91D. J. Mater. Eng. Perform. 2025, 34, 7976–7990. [Google Scholar] [CrossRef]

- Mehdi, H.; Singh, B.; Salah, A.N.; Dubey, M.K.; Mishra, S.; Kumar, S. Effect of PWHT on metallurgical and mechanical characterization of dissimilar welded joint of P91 and P92 steels. J. Adhes. Sci. Technol. 2024, 38, 1395–1412. [Google Scholar] [CrossRef]

- Reyaz, M.S.B.; Sinha, A.N.; Mehdi, H.; Murtaza, Q. Effect of Pulsed TIG Welding Parameters on the Microstructural Evolution and Mechanical Properties of Dissimilar AA6061-T6 and AA7075-T6 Weldments. Arab. J. Sci. Eng. 2024, 49, 10891–10911. [Google Scholar] [CrossRef]

- Kumar, J.; Kumar, G.; Mehdi, H.; Kumar, M. Optimization of FSW parameters on mechanical properties of different aluminum alloys of AA6082 and AA7050 by response surface methodology. Int. J. Interact. Des. Manuf. 2024, 18, 1359–1371. [Google Scholar] [CrossRef]

- Mehdi, H.; Batra, L.; Singh, A.P.; Malla, C. Multi-response optimization of FSW process parameters of dissimilar aluminum alloys of AA2014 and AA6061 by response surface methodology (RSM). Int. J. Interact. Des. Manuf. 2024, 18, 1507–1522. [Google Scholar] [CrossRef]

- Jain, S.; Mishra, R.S.; Mehdi, H.; Gupta, R.; Dubey, A.K. Optimization of processing variables of friction stir welded dissimilar composite joints of AA6061 and AA7075 using response surface methodology. J. Adhes. Sci. Technol. 2024, 38, 949–968. [Google Scholar] [CrossRef]

- Msomi, V.; Mabuwa, S.; Ngonda, T.; Mehdi, H.; Saxena, K.K. Microstructure and mechanical properties of tungsten inert gas welded dissimilar aluminum alloys joint subjected to normal multi-pass friction stir process. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2023, 235, 2531–2546. [Google Scholar] [CrossRef]

- Mehdi, H.; Jain, S.; Salah, A.N.; Singh, A.P.; Chawla, S. Effect of friction stir welding parameters on microstructure and mechanical properties of the dissimilar alloys of AZ91D and AA7075. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2023, 239. [Google Scholar] [CrossRef]

- Mehdi, H.; Jain, S.; Msomi, V.; Mabuwa, S.; Malla, C. Effect of Intermetallic Compounds on Mechanical and Microstructural Properties of Dissimilar Alloys Al-7Si/AZ91D. J. Mater. Eng. Perform. 2023, 33, 4781–4793. [Google Scholar] [CrossRef]

- Jain, S.; Mishra, R.S.; Mehdi, H. Influence of SiC Microparticles and Multi-Pass FSW on Weld Quality of the AA6082 and AA5083 Dissimilar Joints. Silicon 2023, 15, 6185–6197. [Google Scholar] [CrossRef]

- Boldsaikhan, E.; Fukada, S.; Fujimoto, M.; Kamimuki, K.; Okada, H. Refill friction stir spot welding of surface-treated aerospace aluminum alloys with faying-surface sealant. J. Manuf. Process. 2019, 42, 113–120. [Google Scholar] [CrossRef]

- Yuan, W. Friction Stir Spot Welding of Aluminum Alloys. Master’s Thesis, Missouri University of Science and Technology, Rolla, MO, USA, 2008. Available online: https://scholarsmine.mst.edu/masters_theses/5429/ (accessed on 11 July 2025).

- Kah, P.; Rajan, R.; Martikainen, J.; Suoranta, R. Investigation of weld defects in friction-stir welding and fusion welding of aluminium alloys. Int. J. Mech. Mater. Eng. 2015, 10, 26. [Google Scholar] [CrossRef]

- Yang, Q.; Mironov, S.; Sato, Y.S.; Okamoto, K. Material flow during friction stir spot welding. Mater. Sci. Eng. A 2010, 527, 4389–4398. [Google Scholar] [CrossRef]

- Bakavos, D.; Chen, Y.; Babout, L.; Prangnell, P. Material interactions in a novel pinless tool approach to friction stir spot welding thin aluminum sheet. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2011, 42, 1266–1282. [Google Scholar] [CrossRef]

- Yazdi, S.R.; Beidokhti, B.; Haddad-Sabzevar, M. Pinless tool for FSSW of AA 6061-T6 aluminum alloy. J. Mater. Process. Technol. 2019, 267, 44–51. [Google Scholar] [CrossRef]

- Garg, A.; Bhattacharya, A. Strength and failure analysis of similar and dissimilar friction stir spot welds: Influence of different tools and pin geometries. Mater. Des. 2017, 127, 272–286. [Google Scholar] [CrossRef]

- Vacchi, G.S.; Silva, R.; Plaine, A.H.; Suhuddin, U.F.H.; Alcântara, N.G.; Sordi, V.L.; Rovere, C.A.D. Refill friction stir spot welded AA5754-H22/Ti-6Al-4V joints: Microstructural characterization and electrochemical corrosion behavior of aluminum surfaces. Mater. Today Commun. 2020, 22, 100759. [Google Scholar] [CrossRef]

- Shin, H.S.; De Leon, M. Weldability assessment of friction stir spot welded lightweight alloys using pin and pinless tools. Sci. Technol. Weld. Join. 2016, 21, 99–105. [Google Scholar] [CrossRef]

- Cox, C.D.; Gibson, B.T.; Delapp, D.R.; Strauss, A.M.; Cook, G.E. A method for double-sided friction stir spot welding. J. Manuf. Process. 2014, 16, 241–247. [Google Scholar] [CrossRef]

- Cox, C.D.; Gibson, B.T.; Strauss, A.M.; Cook, G.E. Energy input during friction stir spot welding. J. Manuf. Process. 2014, 16, 479–484. [Google Scholar] [CrossRef]

- Hirasawa, S.; Badarinarayan, H.; Okamoto, K.; Tomimura, T.; Kawanami, T.; Hirano, S. Analysis of Temperature and Plastic Flow during Friction Stir Spot Welding Using Particle Method. J. Therm. Sci. Technol. 2009, 4, 260–271. [Google Scholar] [CrossRef]

- Membala, S.B.; Sutresman, O.S.; Arsyad, H.; Syahid, M.; Widyianto, A. Metallurgical Characterization of Micro Friction Stir Spot Welding (μFSSW) Parameters on Similar Materials AA1100. J. Phys. Conf. Ser. 2024, 2739, 012043. [Google Scholar] [CrossRef]

- Safitri, L.A.; Fakhrurrozi, I.F.; Amat, M.A.; Baskoro, A.S.; Rupajati, P.; Kiswanto, G. Effect of Tool Profile on Mechanical Properties, Temperature, and RPM Using Micro Friction Stir Spot Welding (mFSSW) on Aluminum Alloy AA1100. J. Phys. Conf. Ser. 2024, 2739, 012024. [Google Scholar] [CrossRef]

- Li, W.; Li, J.; Zhang, Z.; Gao, D.; Wang, W.; Dong, C. Improving mechanical properties of pinless friction stir spot welded joints by eliminating hook defect. Mater. Des. 2014, 62, 247–254. [Google Scholar] [CrossRef]

- Rai, R.; De, A.; Bhadeshia, H.K.D.H.; DebRoy, T. Review: Friction stir welding tools. Sci. Technol. Weld. Join. 2011, 16, 325–342. [Google Scholar] [CrossRef]

- Zhang, Y.N.; Cao, X.; Larose, S.; Wanjara, P. Review of tools for friction stir welding and processing. Can. Metall. Q. 2012, 51, 250–261. [Google Scholar] [CrossRef]

- Chiteka, K. Friction Stir Welding/Processing Tool Materials and Selection. Int. J. Eng. Res. Technol. 2013, 2, 8–18. [Google Scholar]

- Mishra, R.S.; Ma, Z.Y. Friction stir welding and processing. Mater. Sci. Eng. R Rep. 2005, 50, 1–78. [Google Scholar] [CrossRef]

- Meilinger, A.; Torok, I. The Importance of Friction Stir Welding Tool. Prod. Process. Syst. 2013, 6, 25–34. [Google Scholar]

- Prado, R.A.; Murr, L.E.; Shindo, D.J.; Soto, K.F. Tool wear in the friction-stir welding of aluminum alloy 6061+20% Al2O3: A preliminary study. Scr. Mater. 2001, 45, 75–80. [Google Scholar] [CrossRef]

- Prado, R.A.; Murr, L.E.; Soto, K.F.; McClure, J.C. Self-optimization in tool wear for friction-stir welding of Al 6061+20% Al2O3 MMC. Mater. Sci. Eng. A 2003, 349, 156–165. [Google Scholar] [CrossRef]

- Singh, R.K.R.; Sharma, C.; Dwivedi, D.K.; Mehta, N.K.; Kumar, P. The microstructure and mechanical properties of friction stir welded Al-Zn-Mg alloy in as welded and heat treated conditions. Mater. Des. 2011, 32, 682–687. [Google Scholar] [CrossRef]

- Nami, H.; Adgi, H.; Sharifitabar, M.; Shamabadi, H. Microstructure and mechanical properties of friction stir welded Al/Mg2Si metal matrix cast composite. Mater. Des. 2011, 32, 976–983. [Google Scholar] [CrossRef]

- Fernandez, G.J.; Murr, L.E. Characterization of tool wear and weld optimization in the friction-stir welding of cast aluminum 359+20% SiC metal-matrix composite. Mater. Charact. 2004, 52, 65–75. [Google Scholar] [CrossRef]

- Lee, W.B.; Yeon, Y.M.; Jung, S.B. Joint properties of friction stir welded AZ31B—H24 magnesium alloy. Mater. Sci. Technol. 2003, 19, 785–790. [Google Scholar] [CrossRef]

- Rodriguez, N.A.; Almanza, E.; Alvarez, C.J.; Murr, L.E. Study of friction stir welded A319 and A413 aluminum casting alloys. J. Mater. Sci. 2005, 40, 4307–4312. [Google Scholar] [CrossRef]

- Rajakumar, S.; Muralidharan, C.; Balasubramanian, V. Influence of friction stir welding process and tool parameters on strength properties of AA7075-T6 aluminium alloy joints. Mater. Des. 2011, 32, 535–549. [Google Scholar] [CrossRef]

- Thomas, W.M.; Nicholas, E.D.; Watts, E.R.; Staines, D.G. Friction based welding technology for aluminium. Mater. Sci. Forum 2002, 396–402, 1543–1548. [Google Scholar] [CrossRef]

- Lee, C.Y.; Choi, D.H.; Yeon, Y.M.; Jung, S.B. Dissimilar friction stir spot welding of low carbon steel and Al-Mg alloy by formation of IMCs. Sci. Technol. Weld. Join. 2009, 14, 216–220. [Google Scholar] [CrossRef]

- Elrefaey, A.; Gouda, M.; Takahashi, M.; Ikeuchi, K. Characterization of aluminum/steel lap joint by friction stir welding. J. Mater. Eng. Perform. 2005, 14, 10–17. [Google Scholar] [CrossRef]

- Chen, T. Process parameters study on FSW joint of dissimilar metals for aluminum-steel. J. Mater. Sci. 2009, 44, 2573–2580. [Google Scholar] [CrossRef]

- Chen, T.P.; Lin, W.B. Optimal FSW process parameters for interface and welded zone toughness of dissimilar aluminium-steel joint. Sci. Technol. Weld. Join. 2010, 15, 279–285. [Google Scholar] [CrossRef]

- DebRoy, T.; Bhadeshia, H.K.D.H. Friction stir welding of dissimilar alloys—A perspective. Sci. Technol. Weld. Join. 2010, 15, 266–270. [Google Scholar] [CrossRef]

- Dressler, U.; Biallas, G.; Alfaro Mercado, U. Friction stir welding of titanium alloy TiAl6V4 to aluminium alloy AA2024-T3. Mater. Sci. Eng. A 2009, 526, 113–117. [Google Scholar] [CrossRef]

- Miles, M.P.; Feng, Z.; Kohkonen, K.; Weickum, B.; Steel, R.; Lev, L. Spot joining of AA 5754 and high strength steel sheets by consumable bit. Sci. Technol. Weld. Join. 2010, 15, 325–330. [Google Scholar] [CrossRef]

- Meran, C.; Kovan, V. Microstructures and mechanical properties of friction stir welded dissimilar copper/brass joints. Mater. Und Werkst. 2008, 39, 521–530. [Google Scholar] [CrossRef]

- Jiang, W.H.; Kovacevic, R. Feasibility study of friction stir welding of 6061-T6 aluminium alloy with AISI 1018 steel. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2004, 218, 1323–1331. [Google Scholar] [CrossRef]

- Karthikeyan, L.; Puviyarasan, M.; Sharath Kumar, S.; Balamugundan, B. Experimental studies on friction stir welding of AA2011 and AA6063 aluminium alloys. Int. J. Adv. Eng. Technol. 2012, 3, 144–145. [Google Scholar]

- Hariharan, V.; Elumalai, P.V.; Nambiraj, M.; Jayakar, J.; Parthasarathy, M.; Venkata Kamesh, V. Experimental investigation of friction stir welding on aluminium AA6063. Mater. Today Proc. 2021, 47, 6830–6834. [Google Scholar] [CrossRef]

- Palanivel, R.; Koshy Mathews, P. Prediction and optimization of process parameter of friction stir welded AA5083-H111 aluminum alloy using response surface methodology. J. Cent. South Univ. Technol. (English Ed.) 2012, 19, 1–8. [Google Scholar] [CrossRef]

- Cavaliere, P.; De Santis, A.; Panella, F.; Squillace, A. Effect of welding parameters on mechanical and microstructural properties of dissimilar AA6082-AA2024 joints produced by friction stir welding. Mater. Des. 2009, 30, 609–616. [Google Scholar] [CrossRef]

- Parida, B.; Mohapatra, M.M.; Biswas, P.; Mandal, N.R. Study of Mechanical and Micro-structural Properties of Friction Stir Welded Al-Alloy. Int. J. Emerg. Technol. Adv. Eng. 2012, 2, 307–312. [Google Scholar]

- Akinlabi, E.T.; Reddy, R.D.; Akinlabi, S.A. Microstructural characterizations of dissimilar friction stir welds. Lect. Notes Eng. Comput. Sci. 2012, 3, 1779–1783. [Google Scholar]

- Pathak, N.; Bandyopadhyay, K.; Sarangi, M.; Panda, S.K. Microstructure and mechanical performance of friction stir spot-welded aluminum-5754 sheets. J. Mater. Eng. Perform. 2013, 22, 131–144. [Google Scholar] [CrossRef]

- Shindo, D.J.; Rivera, A.R.; Murr, L.E. Shape optimization for tool wear in the friction-stir welding of cast Al359-20% SiC MMC. J. Mater. Sci. 2002, 37, 4999–5005. [Google Scholar] [CrossRef]

- Feizollahi, V.; Yousefi, M.; Elahifar, A.; Pourmirza, B.; Hasab, M.G.; Moghadam, A.H. Effect of shoulder diameter, tool rotation speed, and arrangement of plates on mechanical and metallurgical properties of dissimilar aluminum 2024-T3 and 7075-T6 friction stir spot welding (FSSW). Eng. Fail. Anal. 2024, 163, 108548. [Google Scholar] [CrossRef]

- Tobin, D.; O’Shaughnessy, S.; Trimble, D. Characterisation of force and torque with auxiliary heating during friction stir spot welding of AA2024-T3. Results Mater. 2024, 21, 100535. [Google Scholar] [CrossRef]

- Manohar, M.V.N.S.; Mahadevan, K.; Aravindan, A. Performance of H13 and HCHCR Tool Materials on Friction Stir Welded 6070Aluminium Alloy Plates Subjected to Different Temper Conditions. Int. J. Recent Technol. Eng. 2019, 8, 5261–5266. [Google Scholar] [CrossRef]

- Singh, K.; Khatirkar, R.K.; Sapate, S.G. Microstructure evolution and abrasive wear behavior of D2 steel. Wear 2015, 328–329, 206–216. [Google Scholar] [CrossRef]

- Zhou, X.F.; Fang, F.; Li, F.; Jiang, J.Q. Morphology and microstructure of M2C carbide formed at different cooling rates in AISI M2 high speed steel. J. Mater. Sci. 2011, 46, 1196–1202. [Google Scholar] [CrossRef]

- Vander Voort, G.F.; Lucas, G.M. Metallography and Microstructures of Stainless Steels and Maraging Steels; ASM Handbook: Materials Park, OH, USA, 2019. [Google Scholar] [CrossRef]

- Tanaka, T.; Hirata, T.; Shinomiya, N.; Shirakawa, N. Analysis of material flow in the sheet forming of friction-stir welds on alloys of mild steel and aluminum. J. Mater. Process. Technol. 2015, 226, 115–124. [Google Scholar] [CrossRef]

- Ragu Nathan, S.; Balasubramanian, V.; Malarvizhi, S.; Rao, A.G. An investigation on metallurgical characteristics of tungsten based tool materials used in friction stir welding of naval grade high strength low alloy steels. Int. J. Refract. Met. Hard Mater. 2016, 56, 18–26. [Google Scholar] [CrossRef]

- Sato, Y.S.; Yamanoi, H.; Kokawa, H.; Furuhara, T. Microstructural evolution of ultrahigh carbon steel during friction stir welding. Scr. Mater. 2007, 57, 557–560. [Google Scholar] [CrossRef]

- Ghosh, M.; Kumar, K.; Mishra, R.S. Analysis of microstructural evolution during friction stir welding of ultrahigh-strength steel. Scr. Mater. 2010, 63, 851–854. [Google Scholar] [CrossRef]

- Park, S.H.C.; Sato, Y.S.; Kokawa, H.; Okamoto, K.; Hirano, S.; Inagaki, M. Rapid formation of the sigma phase in 304 stainless steel during friction stir welding. Scr. Mater. 2003, 49, 1175–1180. [Google Scholar] [CrossRef]

- Park, S.H.C.; Sato, Y.S.; Kokawa, H.; Okamoto, K.; Hirano, S.; Inagaki, M. Microstructural characterisation of stir zone containing residual ferrite in friction stir welded 304 austenitic stainless steel. Sci. Technol. Weld. Join. 2005, 10, 550–556. [Google Scholar] [CrossRef]

- Miles, M.P.; Nelson, T.W.; Steel, R.; Olsen, E.; Gallagher, M. Effect of friction stir welding conditions on properties and microstructures of high strength automotive steel. Sci. Technol. Weld. Join. 2009, 14, 228–232. [Google Scholar] [CrossRef]

- Zhang, Y.; Sato, Y.S.; Kokawa, H.; Park, S.H.C.; Hirano, S. Stir zone microstructure of commercial purity titanium friction stir welded using PCBN tool. Mater. Sci. Eng. A 2008, 488, 25–30. [Google Scholar] [CrossRef]

- Sato, Y.S.; Nelson, T.W.; Sterling, C.J.; Steel, R.J.; Pettersson, C.O. Microstructure and mechanical properties of friction stir welded SAF 2507 super duplex stainless steel. Mater. Sci. Eng. A 2005, 397, 376–384. [Google Scholar] [CrossRef]

- Santella, M.; Hovanski, Y.; Frederick, A.; Grant, G.; Dahl, M. Friction stir spot welding of DP780 carbon steel. Sci. Technol. Weld. Join. 2010, 15, 271–278. [Google Scholar] [CrossRef]

- Park, S.H.C.; Sato, Y.S.; Kokawa, H.; Okamoto, K.; Hirano, S.; Inagaki, M. Boride formation induced by PCBN tool wear in friction-stir-welded stainless steels. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2009, 40, 625–636. [Google Scholar] [CrossRef]

- Hovanski, Y.; Santella, M.L.; Grant, G.J. Friction stir spot welding of hot-stamped boron steel. Scr. Mater. 2007, 57, 873–876. [Google Scholar] [CrossRef]

- Sumiya, H.; Uesaka, S.; Satoh, S. Mechanical properties of high purity polycrystalline CBN synthesized by direct conversion sintering method. J. Mater. Sci. 2000, 35, 1181–1186. [Google Scholar] [CrossRef]

- Sato, Y.S.; Harayama, N.; Kokawa, H.; Inoue, H.; Tadokoro, Y.; Tsuge, S. Evaluation of microstructure and properties in friction stir welded superaustenitic stainless steel. Sci. Technol. Weld. Join. 2009, 14, 202–209. [Google Scholar] [CrossRef]

- Agarwala, B.K.; Singh, B.P.; Singhal, S.K. Synthesis and characterization of polycrystalline sintered compacts of cubic boron nitride. J. Mater. Sci. 1986, 21, 1765–1768. [Google Scholar] [CrossRef]

- Giménez, S.; Van der Biest, O.; Vleugels, J. The role of chemical wear in machining iron based materials by PCD and PCBN super-hard tool materials. Diam. Relat. Mater. 2007, 16, 435–445. [Google Scholar] [CrossRef]

- Collier, M.; Steel, R.; Nelson, T.; Sorensen, C.; Packer, S. Grade development of polycrystalline cubic boron nitride for friction stir processing of ferrous alloys. Mater. Sci. Forum 2003, 426–432, 3011–3016. [Google Scholar] [CrossRef]

- D’Evelyn, M.P.; Taniguchi, T. Elastic properties of translucent polycrystalline cubic boron nitride as characterized by the dynamic resonance method. Diam. Relat. Mater. 1999, 8, 1522–1526. [Google Scholar] [CrossRef]

- Casanova, C.A.M.; Balzaretti, N.M.; Voronin, G.; Da Jornada, J.A.H. Experimental study of plastic deformation during sintering of cubic boron nitride compacts. Diam. Relat. Mater. 1999, 8, 1451–1454. [Google Scholar] [CrossRef]

- Harris, T.K.; Brookes, E.J.; Taylor, C.J. The effect of temperature on the hardness of polycrystalline cubic boron nitride cutting tool materials. Int. J. Refract. Met. Hard Mater. 2004, 22, 105–110. [Google Scholar] [CrossRef]

- König, W.; Neises, A. Wear mechanisms of ultrahard, non-metallic cutting materials. Wear 1993, 162–164, 12–21. [Google Scholar] [CrossRef]

- Hooper, R.M.; Shakib, J.I.; Brookes, C.A. Microstructure and wear of TiC-cubic BN tools. Mater. Sci. Eng. 1988, 105–106, 429–433. [Google Scholar] [CrossRef]

- Nabhani, F. Wear mechanisms of ultra-hard cutting tools materials. J. Mater. Process. Technol. 2001, 115, 402–412. [Google Scholar] [CrossRef]

- Poulachon, G.; Moisan, A.; Jawahir, I.S. Tool-wear mechanisms in hard turning with polycrystalline cubic boron nitride tools. Wear 2001, 250–251, 576–586. [Google Scholar] [CrossRef]

- Zimmermann, M.; Lahres, M.; Viens, D.V.; Laube, B.L. Investigations of the wear of cubic boron nitride cutting tools using Auger electron spectroscopy and X-ray analysis by EPMA. Wear 1997, 209, 241–246. [Google Scholar] [CrossRef]

- Nelson, T.W.; Sorensen, C.D.; Mayfield, D.W. Friction Stir Welds of HSLA steel panels for shipyard applications. In Proceedings of the 8th International Symposium on Friction Stir Welding, Hamburg, Germany, 18–20 May 2010; The Welding Institute: Hamburg, Germany. [Google Scholar]

- Mahoney, M.; Nelson, T.; Sorenson, C.; Packer, S. Friction stir welding of ferrous alloys: Current status. Mater. Sci. Forum 2010, 638–642, 41–46. [Google Scholar] [CrossRef]

- Liu, F.C.; Hovanski, Y.; Miles, M.P.; Sorensen, C.D.; Nelson, T.W. A review of friction stir welding of steels: Tool, material flow, microstructure, and properties. J. Mater. Sci. Technol. 2018, 34, 39–57. [Google Scholar] [CrossRef]

- Borah, M.; Saha, N.; Rajbongshi, S.K.; Dharam, B. Friction stir spot welding process: An innovative approach for transforming from engineering design to production. Int. J. Interact. Des. Manuf. (IJIDeM) 2023, 17, 2259–2270. [Google Scholar] [CrossRef]

- Arul, S.G.; Miller, S.F.; Kruger, G.H.; Pan, T.Y.; Mallick, P.K.; Shih, A.J. Experimental study of joint performance in spot friction welding of 6111-T4 aluminium alloy. Sci. Technol. Weld. Join. 2008, 13, 629–637. [Google Scholar] [CrossRef]

- Pandey, A.K.; Mahapatra, S.S. Investigation of weld zone obtained by friction stir spot welding (FSSW) of aluminium-6061 alloy. Mater. Today Proc. 2019, 18, 4491–4500. [Google Scholar] [CrossRef]

- Li, G.; Zhou, L.; Luo, L.; Wu, X.; Guo, N. Microstructural evolution and mechanical properties of refill friction stir spot welded alclad 2A12-T4 aluminum alloy. J. Mater. Res. Technol. 2019, 8, 4115–4129. [Google Scholar] [CrossRef]

- Kubit, A.; Trzepiecinski, T. A fully coupled thermo-mechanical numerical modelling of the refill friction stir spot welding process in Alclad 7075-T6 aluminium alloy sheets. Archiv. Civ. Mech. Eng. 2020, 20, 117. [Google Scholar] [CrossRef]

- Gerlich, A.; Avramovic-Cingara, G.; North, T.H. Stir zone microstructure and strain rate during Al 7075-T6 friction stir spot welding. Metall. Mater. Trans. A 2006, 37, 2773–2786. [Google Scholar] [CrossRef]

- Shen, Z.; Chen, Y.; Hou, J.S.C.; Yang, X.; Gerlich, A.P. Influence of processing parameters on microstructure and mechanical performance of refill friction stir spot welded 7075-T6 aluminium alloy. Sci. Technol. Weld. Join. 2015, 20, 48–57. [Google Scholar] [CrossRef]

- Janga, V.S.R.; Awang, M.; Yamin, M.F.; Suhuddin, U.F.H.; Klusemann, B.; Santos, J.F.d. Experimental and Numerical Analysis of Refill Friction Stir Spot Welding of Thin AA7075-T6 Sheets. Materials 2021, 14, 7485. [Google Scholar] [CrossRef]

- Kubit, A.; Kluz, R.; Trzepieciński, T.; Wydrzyński, D.; Bochnowski, W. Analysis of the mechanical properties and of micrographs of refill friction stir spot welded 7075-T6 aluminium sheets. Archiv. Civ. Mech. Eng. 2018, 18, 235–244. [Google Scholar] [CrossRef]

- Sarfaraz, Z.; Awan, Y.R.; Saeed, H.A.; Khan, R.; Wieczorowski, M.; Din, N.A. Residual Stress in Friction Stir Welding of Dissimilar Aluminum Alloys: A Parametric Study. Materials 2025, 18, 316. [Google Scholar] [CrossRef]

- Sun, Y.; Morisada, Y.; Fujii, H.; Tsuji, N. Ultrafine grained structure and improved mechanical properties of low temperature friction stir spot welded 6061-T6 Al alloys. Mater. Charact. 2018, 135, 124–133. [Google Scholar] [CrossRef]

- Farmanbar, N.; Mousavizade, S.M.; Ezatpour, H.R. Achieving special mechanical properties with considering dwell time of AA5052 sheets welded by a simple novel friction stir spot welding. Mar. Struct. 2019, 65, 197–214. [Google Scholar] [CrossRef]

- Badarinarayan, H.; Yang, Q.; Zhu, S. Effect of tool geometry on static strength of friction stir spot-welded aluminum alloy. Int. J. Mach. Tools Manuf. 2009, 49, 142–148. [Google Scholar] [CrossRef]

- Merzoug, M.; Mazari, M.; Berrahal, L.; Imad, A. Parametric studies of the process of friction spot stir welding of aluminium 6060-T5 alloys. Mater. Des. 2010, 31, 3023–3028. [Google Scholar] [CrossRef]

- Subramanian, S.; Natarajan, E.; Khalfallah, A.; Muthukutti, G.P.; Beygi, R.; Louhichi, B.; Sengottuvel, R.; Ang, C.K. Current Trends and Emerging Strategies in Friction Stir Spot Welding for Lightweight Structures: Innovations in Tool Design, Robotics, and Composite Reinforcement—A Review. Crystals 2025, 15, 556. [Google Scholar] [CrossRef]

- Boucherit, A.; Abdi, S.; Aissani, M.; Medhi, B.; Abib, K.; Badji, R. Weldability, microstructure, and residual stress in Al/Cu and Cu/Al friction stir spot weld joints with Zn interlayer. Int. J. Adv. Manuf. Technol. 2020, 111, 1553–1569. [Google Scholar] [CrossRef]

- Balamurugan, M.; Gopi, S.; Dhanesh, G.M. Influence of tool pin profiles on the filler added friction stir spot welded dissimilar aluminium alloy joints. Mater. Res. Express 2021, 8, 096531. [Google Scholar] [CrossRef]

- Yousefi, A.; Serjouei, A.; Hedayati, R.; Bodaghi, M. Fatigue Modeling and Numerical Analysis of Re-Filling Probe Hole of Friction Stir Spot Welded Joints in Aluminum Alloys. Materials 2021, 14, 2171. [Google Scholar] [CrossRef]

- Kubit, A.; Święch, Ł.; Trzepieciński, T.; Faes, K. Experimental Analysis of the Post-Buckling Behaviour of Compressed Stiffened Panel with Refill Friction Stir Spot Welded and Riveted Stringers. Adv. Sci. Technol. Res. J. 2022, 16, 159–167. [Google Scholar] [CrossRef]

- Kubit, A.; Drabczyk, M.; Trzepiecinski, T.; Bochnowski, W.; Kaščák, Ľ.; Slota, J. Fatigue Life Assessment of Refill Friction Stir Spot Welded Alclad 7075-T6 Aluminium Alloy Joints. Metals 2020, 10, 633. [Google Scholar] [CrossRef]

- Tier, M.D.; Rosendo, T.S.; dos Santo, J.F.; Huber, N.; Mazzaferro, J.A.; Mazzaferro, C.P.; Strohaecker, T.R. The influence of refill FSSW parameters on the microstructure and shear strength of 5042 aluminium welds. J. Mater. Process. Technol. 2013, 213, 997–1005. [Google Scholar] [CrossRef]

- Venukumar, S.; Baby, B.; Muthukumaran, S.; Kailas, S.V. Microstructural and Mechanical Properties of Walking Friction Stir Spot Welded AA 6061-T6 Sheets. Procedia Mater. Sci. 2014, 6, 656–665. [Google Scholar] [CrossRef]

- Freeney, T.A.; Sharma, S.R.; Mishra, R.S. Effect of welding parameters on properties of 5052 Al friction stir spot welds. SAE Tech. Pap. 2006, 1, 0969. [Google Scholar] [CrossRef]

- Shen, Z.; Yang, X.; Zhang, Z.; Cui, L.; Li, T. Microstructure and failure mechanisms of refill friction stir spot welded 7075-T6 aluminum alloy joints. Mater. Des. 2013, 44, 476–486. [Google Scholar] [CrossRef]

- Zhang, Z.; Yang, X.; Zhang, J.; Zhou, G.; Xu, X.; Zou, B. Effect of welding parameters on microstructure and mechanical properties of friction stir spot welded 5052 aluminum alloy. Mater. Des. 2011, 32, 4461–4470. [Google Scholar] [CrossRef]

- Rosendo, T.; Parra, B.; Tier, M.A.D.; da Silva, A.A.M.; dos Santos, J.F.; Strohaecker, T.R.; Alcântara, N.G. Mechanical and microstructural investigation of friction spot welded AA6181-T4 aluminium alloy. Mater. Des. 2011, 32, 1094–1100. [Google Scholar] [CrossRef]

- Nandan, R.; DebRoy, T.; Bhadeshia, H.K.D.H. Recent advances in friction-stir welding—Process, weldment structure and properties. Prog. Mater. Sci. 2008, 53, 980–1023. [Google Scholar] [CrossRef]

- Mofid, M.A.; Abdollah-zadeh, A.; Gür, C.H. Investigating the formation of intermetallic compounds during friction stir welding of magnesium alloy to aluminum alloy in air and under liquid nitrogen. Int. J. Adv. Manuf. Technol. 2014, 71, 1493–1499. [Google Scholar] [CrossRef]

- Lv, X.Q.; Wu, C.S.; Padhy, G.K. Diminishing intermetallic compound layer in ultrasonic vibration enhanced friction stir welding of aluminum alloy to magnesium alloy. Mater. Lett. 2017, 203, 81–84. [Google Scholar] [CrossRef]

- Baghdadi, A.H.; Sajuri, Z.; Selamat, N.F.M.; Omar, M.Z.; Miyashita, Y.; Kokabi, A.H. Effect of intermetallic compounds on the fracture behavior of dissimilar friction stir welding joints of Mg and Al alloys. Int. J. Miner. Metall. Mater. 2019, 26, 1285–1298. [Google Scholar] [CrossRef]

- Kim, D.; Baek, S.; Nishijima, M.; Lee, H.-C.; Geng, P.; Ma, N.; Zhang, Z.; Park, H.; Chen, C.; Lee, S.-J.; et al. Toward defect-less and minimized work-hardening loss implementation of Al alloy/high-purity Cu dissimilar lap joints by refill friction stir spot welding for battery tab-to-busbar applications. Mater. Sci. Eng. A 2024, 892, 146089. [Google Scholar] [CrossRef]

- EN 1999-1-1; Eurocode 9: Design of Aluminium Structures—Part 1-1: General Structural Rules. European Committee for Standardization (CEN): Brussels, Belgium, 2007.

- AWS D17.3/D17.3M:2016; Specification for Friction Stir Welding of Aluminum Alloys for Aerospace Applications. AWS: Miami, FL, USA, 2016.

- AS/NZS 1665:2004; Welding of Aluminium Structures. Standards Australia/Standards New Zealand: Sydney, Australia; Wellington, New Zealand, 2004.

- CSA S157-17; Strength Design in Aluminium. Canadian Standards Association (CSA Group): Mississauga, ON, Canada, 2017.

- AISC 360-22; Specification for Structural Steel Buildings. American Institute of Steel Construction (AISC): Chicago, IL, USA, 2022.

- Draper, J.; Fritsche, S.; de Traglia Amancio-Filho, S.; Galloway, A.; Toumpis, A. A numerical modelling approach to predict material flow and defect formation in refill friction stir spot welded joints. Int. J. Adv. Manuf. Technol. 2025, 139, 2907–2921. [Google Scholar] [CrossRef]

- Mondal, A.K.; Biswas, P.; Bag, S. Influence of tacking sequence on residual stress and distortion of single sided fillet submerged arc welded joint. J. Marine. Sci. Appl. 2015, 14, 250–260. [Google Scholar] [CrossRef]

| Materials for Joining | Thickness of the Joined Material | Tool Material |

|---|---|---|

| 6061-T6 Al and AISI 1018 mild steel [17,21,64] | 6 mm | H13 |

| AA2011 and AA6063 alloy [13,65,66] | 10 mm | HSS |

| AA5083-H111 Al alloy [67] | HCHCr | |

| AA6082 and AA2024 [26,68] | 4 mm | C40 |

| Commercial grade Al alloys [69] | 6 mm | SS310 |

| AA5754 and C11000 copper [70,71] | 3.175 mm | H13 |

| Steel Type | %C | %Ni | %Mn | %Cr | %Si | %Mo | %W | %Cu | %V |

|---|---|---|---|---|---|---|---|---|---|

| H13 | 0.45 | 0.30 | 0.50 | 5.25 | 1.20 | 1.75 | - | 0.25 | 1.20 |

| HCHCr-D2 | 1.5 | 0.45 | 12.00 | 0.30 | 0.9 | - | 1.00 | ||

| C40 | 0.37–0.44 | 0.4 | 0.5–0.8 | 0.4 | 0.4 | 0.1 | - | - | - |

| HSS | 0.87 | 0.26 | 3.99 | 4.61 | 5.83 | 1.76 | |||

| SS310 | 0.25 | 19.0–22.0 | 2.00 | 24.0–26.0 | 1.50 |

| Code/Standard | Region | Design Focus | Relevant Provisions for FSSW | Advantages | Limitations |

|---|---|---|---|---|---|

| Eurocode 9 (EN 1999-1-1) | Europe | Structural design of aluminum structures | Allows mechanical fastening and fusion welding; FSSW not explicitly included | Comprehensive structural safety checks | Lacks FSSW-specific guidance; conservative assumptions for weld strength |

| AWS D17.3/D17.3M | USA | Friction stir welding of aluminum in aerospace | Covers friction stir welding, thus indirectly applicable to FSSW | Aerospace-focused, high reliability | Limited FSSW-specific joint design parameters |

| AS/NZS 1665 | Australia/New Zealand | Welding of aluminum structures | Primarily deals with fusion welding; spot weld strength limits provided | Some design guidance can be extrapolated | Does not consider solid-state welding processes like FSSW |

| AISC Manual | USA | Structural steel/aluminum joints | Not directly applicable but useful for understanding allowable stress design | Well-established engineering principles | No mention of FSSW or aluminum-specific solid-state welding |

| CSA S157 | Canada | Strength of aluminum joints | Offers general aluminum weld joint design guidance | Includes provisions for performance-based assessment | No separate treatment of friction stir-based spot welding |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Borah, M.J.; Sarma, K.; Nirsanametla, Y.; Haldar, B.; Mondal, A.K.; Louhichi, B.; Joardar, H. A Critical Review on Friction Stir Spot Welding of Aluminium Alloys: Tool, Mechanical, and Micro-Structural Characteristics. Crystals 2025, 15, 755. https://doi.org/10.3390/cryst15090755

Borah MJ, Sarma K, Nirsanametla Y, Haldar B, Mondal AK, Louhichi B, Joardar H. A Critical Review on Friction Stir Spot Welding of Aluminium Alloys: Tool, Mechanical, and Micro-Structural Characteristics. Crystals. 2025; 15(9):755. https://doi.org/10.3390/cryst15090755

Chicago/Turabian StyleBorah, Manash J., Kanta Sarma, Yadaiah Nirsanametla, Barun Haldar, Arpan K. Mondal, Borhen Louhichi, and Hillol Joardar. 2025. "A Critical Review on Friction Stir Spot Welding of Aluminium Alloys: Tool, Mechanical, and Micro-Structural Characteristics" Crystals 15, no. 9: 755. https://doi.org/10.3390/cryst15090755

APA StyleBorah, M. J., Sarma, K., Nirsanametla, Y., Haldar, B., Mondal, A. K., Louhichi, B., & Joardar, H. (2025). A Critical Review on Friction Stir Spot Welding of Aluminium Alloys: Tool, Mechanical, and Micro-Structural Characteristics. Crystals, 15(9), 755. https://doi.org/10.3390/cryst15090755