The Effect of Heat Treatment on Yellow-Green Beryl Color and Its Enhancement Mechanism

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

3. Results and Discussion

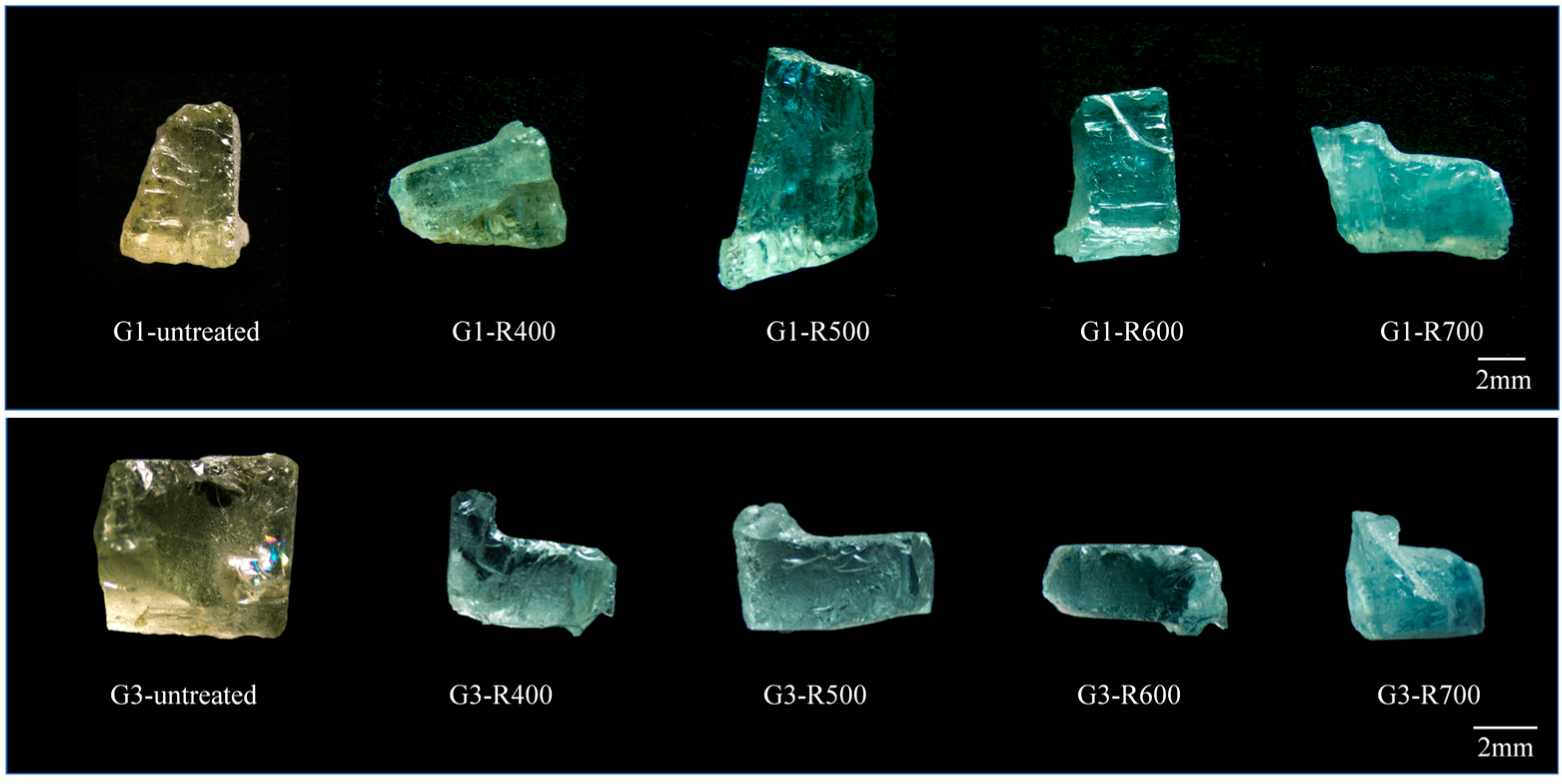

3.1. General Properties

3.2. Composition and Crystal Structure

3.2.1. Chemical Composition

3.2.2. Differential Thermal Analysis

3.2.3. Crystal Structure and Phase Analysis

3.3. Spectroscopy Properties

3.3.1. Fourier Transform Infrared Spectroscopy (FTIR)

3.3.2. Raman Spectroscopy

3.3.3. UV-Vis Spectroscopy

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Thomazo, C.; Papineau, D. Biogeochemical Cycling of Nitrogen on the Early Earth. Elements 2013, 9, 345–351. [Google Scholar] [CrossRef]

- de Almeida Sampaio Filho, H.; Sighinolfi, G.P.; Galli, E. Contribution to the Crystal Chemistry of Beryl. Contrib. Mineral. Petrol. 1973, 38, 279–290. [Google Scholar] [CrossRef]

- Minerals from Macedonia: XXIII. Spectroscopic and Structural Characterization of Schorl and Beryl Cyclosilicates. Spectrochim. Acta Part A 2009, 73, 460–467. [Google Scholar] [CrossRef]

- Hanser, C.S.; Häger, T.; Botcharnikov, R. Incorporation and Substitution of Ions and H2O in the Structure of Beryl. Eur. J. Mineral. 2024, 36, 449–472. [Google Scholar] [CrossRef]

- Henry, R.E.; Groat, L.A.; Cempírek, J.; Škoda, R.; Holá, M. Predicting the Crystal Structure of Beryl from the Chemical Composition. Can. J. Mineral. Petrol. 2023, 61, 873–897. [Google Scholar] [CrossRef]

- Charalambous, F.A.; Ram, R.; Pownceby, M.I.; Tardio, J.; Bhargava, S.K. Chemical and Microstructural Characterisation Studies on Natural and Heat Treated Brannerite Samples. Miner. Eng. 2012, 39, 276–288. [Google Scholar] [CrossRef]

- Wang, Q.; Guo, Q.; Li, N.; Cui, L.; Liao, L. Study of the Mechanism of Color Change of Prehnite after Heat Treatment. RSC Adv. 2022, 12, 3044–3054. [Google Scholar] [CrossRef]

- Song, Z.-X.; Guo, Q.-F.; Liao, L.-B. Effect of Heat Treatment on the Color of Yellow-Green Sphene and Its Color-Causing Mechanism. JOM 2025, 77, 5182–5191. [Google Scholar] [CrossRef]

- Mathew, G.; Karanth, R.V.; Rao, T.K.G.; Deshpande, R.S. Channel Constituents of Alkali-Poor Orissan Beryls: An FT-IR Spectroscopic Study. Curr. Sci. 1997, 73, 1004–1011. [Google Scholar]

- Fan, Z.-W.; Xiong, Y.-Q.; Shao, Y.-J.; Wen, C.-H. Textural and Chemical Characteristics of Beryl from the Baishawo Be-Li-Nb-Ta Pegmatite Deposit, Jiangnan Orogen: Implication for Rare Metal Pegmatite Genesis. Ore Geol. Rev. 2022, 149, 105094. [Google Scholar] [CrossRef]

- Locock, A.J. An Excel Spreadsheet to Classify Chemical Analyses of Amphiboles Following the IMA 2012 Recommendations. Comput. Geosci. 2014, 62, 1–11. [Google Scholar] [CrossRef]

- Santiago, J.S.; Souza, V.d.S.; Filgueiras, B.d.C.; Jiménez, F.A.C. Emerald from the Fazenda Bonfim Deposit, Northeastern Brazil: Chemical, Fluid Inclusions and Oxygen Isotope Data. Braz. J. Geol. 2018, 48, 457–472. [Google Scholar] [CrossRef]

- Hawthorne, F.C.; Cerny, P. The Alkali-Metal Positions in Cs-Li Beryl. Can. Mineral. 1977, 15, 414–421. [Google Scholar]

- Fukuda, J.; Shinoda, K. Water Molecules in Beryl and Cordierite: High-Temperature Vibrational Behavior, Dehydration, and Coordination to Cations. Phys. Chem. Miner. 2011, 38, 469–481. [Google Scholar] [CrossRef]

- Fukuda, J.; Shinoda, K. Coordination of Water Molecules with Na+ Cations in a Beryl Channel as Determined by Polarized IR Spectroscopy. Phys. Chem. Miner. 2008, 35, 347–357. [Google Scholar] [CrossRef]

- Bharat, V.; Durga Prasad, B.; Venkateswarlu, K. Effect of Beryl on Wear and Thermal Expansion Behavior of Al-Beryl MMCs. Mater. Today Proc. 2018, 5, 7609–7614. [Google Scholar] [CrossRef]

- Franz, G.; Morteani, G. Be-Minerals: Synthesis, Stability, and Occurrence in Metamorphic Rocks. Rev. Mineral. Geochem. 2002, 50, 551–589. [Google Scholar] [CrossRef]

- Sripoonjan, T.; Seneewong Na Ayutthaya, M. Aquamarine from Southern Ethiopia: An Update. J. Gemmol. 2019, 36, 497–499. [Google Scholar] [CrossRef]

- Aurisicchio, C.; Fioravanti, G.; Grubessi, O.; Zanazzi, P.F. Reappraisal of the Crystal Chemistry of Beryl. Am. Mineral. 1988, 73, 826–837. [Google Scholar]

- Wang, P.; Gray, T.P.; Li, Z.; Anderson, E.J.D.; Allaz, J.; Smyth, J.R.; Koenig, A.E.; Qi, L.; Zhou, Y.; Raschke, M.B. Mineralogical Classification and Crystal Water Characterisation of Beryl from the W–Sn–Be Occurrence of Xuebaoding, Sichuan Province, Western China. Mineral. Mag. 2021, 85, 172–188. [Google Scholar] [CrossRef]

- Fan, Z.-W.; Xiong, Y.-Q.; Brzozowski, M.J.; Shao, Y.-J.; Gu, X.-P.; Anwar, M.; Ghoneim, S.M. Crystallographic Insights and Crystal Fractionation Simulations of Alkali- and Water-Bearing Beryl: Implications for Magmatic–Hydrothermal Evolution and Be Enrichment Mechanisms. Ore Geol. Rev. 2024, 174, 106278. [Google Scholar] [CrossRef]

- Łodziński, M.; Sitarz, M.; Stec, K.; Kozanecki, M.; Fojud, Z.; Jurga, S. ICP, IR, Raman, NMR Investigations of Beryls from Pegmatites of the Sudety Mts. Mol. Spectrosc. Mol. Struct. 2005, 744–747, 1005–1015. [Google Scholar] [CrossRef]

- Wang, H.; Guan, Q.; Liu, Y.; Guo, Y. Effects of Transition Metal Ions on the Colour of Blue-Green Beryl. Minerals 2022, 12, 86. [Google Scholar] [CrossRef]

- Chankhantha, C.; Thanasuthipitak, P.; Kidkhunthod, P. Iron K-Edge Xanes Study of Heated Green Beryl from Madagascar. Walailak J. Sci. Technol. (WJST) 2016, 13, 977–983. [Google Scholar]

- Li, J.; Zheng, Y.; Liu, X.; Li, G.; Yu, X.; Wang, Y.; Li, H.; Liu, H.; Shan, G.; Li, T.; et al. Thermal Process of Rock Crystal: Cause of Infrared Absorption Band at 3585 Cm−1. Crystals 2021, 11, 1083. [Google Scholar] [CrossRef]

- Fridrichová, J.; Bačík, P.; Rusinová, P.; Antal, P.; Škoda, R.; Bizovská, V.; Miglierini, M. Optical and Crystal-Chemical Changes in Aquamarines and Yellow Beryls from Thanh Hoa Province, Vietnam Induced by Heat Treatment. Phys. Chem. Miner. 2015, 42, 287–302. [Google Scholar] [CrossRef]

- Nguyen, P.Q.H.; Zhang, D.; Xu, J.; Downs, R.T.; Dera, P.K. Dehydration Kinetics of Nanoconfined Water in Beryl Probed by High Temperature Single Crystal Synchrotron X-Ray Diffraction. Sci. Rep. 2024, 14, 6079. [Google Scholar] [CrossRef] [PubMed]

- Bačík, P.; Fridrichová, J.; Uher, P.; Vaculovič, T.; Bizovská, V.; Škoda, R.; Dekan, J.; Miglierini, M.; Malíčková, I. Beryl Crystal Chemistry and Trace Elements: Indicators of Pegmatite Development and Fractionation (Damara Belt, Namibia). Lithos 2021, 404–405, 106441. [Google Scholar] [CrossRef]

- Gavrilenko, E.V.; Pérez, B.C.; Bolibar, R.C.; Amo, D.G. del Emeralds from the Delbegetey Deposit (Kazakhstan): Mineralogical Characteristics and Fluid-Inclusion Study. Mineral. Mag. 2006, 70, 159–173. [Google Scholar] [CrossRef]

- Romero Ordóñez, F.H.; González-Durán, A.F.; García-Toloza, J.; Rotlewicz Cohen, J.; Cedeño Ochoa, C.J.; Alvarado González, H.R.; Angarita Sarmiento, L.G.; Romero Ordóñez, F.H.; González-Durán, A.F.; García-Toloza, J.; et al. Mineralogy and Fluid Inclusions of the Cunas Emerald Mine, Maripí—Boyacá, Colombia. Earth Sci. Res. J. 2021, 25, 139–156. [Google Scholar] [CrossRef]

- Wang, H.; Shu, T.; Chen, J.; Guo, Y. Characteristics of Channel-Water in Blue-Green Beryl and Its Influence on Colour. Crystals 2022, 12, 435. [Google Scholar] [CrossRef]

- Hu, Y.; Lu, R. Color Characteristics of Blue to Yellow Beryl from Multiple Origins. Gems Gemol. 2020, 56, 54–65. [Google Scholar] [CrossRef]

- Yu, X.; Hu, D.; Niu, X.; Kang, W. Infrared Spectroscopic Characteristics and Ionic Occupations in Crystalline Tunneling System of Yellow Beryl. JOM 2017, 69, 704–712. [Google Scholar] [CrossRef]

- Taran, M.N.; Vyshnevskyi, O.A. Be, Fe2+-Substitution in Natural Beryl: An Optical Absorption Spectroscopy Study. Phys. Chem. Miner. 2019, 46, 795–806. [Google Scholar] [CrossRef]

- Shang, Y.; Guo, Y.; Tang, J. Spectroscopy and Chromaticity Characterization of Yellow to Light-Blue Iron-Containing Beryl. Sci. Rep. 2022, 12, 10765. [Google Scholar] [CrossRef]

| Sample | SiO2 | Al2O3 | Cr2O3 | TiO2 | FeO | MnO | MgO | Na2O | K2O | NiO | F | Cl | BeO | H2O | Total |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| G2 | 65.23 | 18.27 | 0 | 0 | 0.66 | 0.03 | 0.33 | 0.37 | 0.01 | 0.02 | 0 | 0 | 12.60 | 1.65 | 99.17 |

| G3 | 65.3 | 18.3 | 0 | 0 | 0.91 | 0 | 0.49 | 0.49 | 0.03 | 0.03 | 0 | 0 | 12.24 | 1.80 | 99.60 |

| G5 | 64.77 | 18.59 | 0.02 | 0 | 0.65 | 0.01 | 0.33 | 0.42 | 0.02 | 0.01 | 0.04 | 0.01 | 12.39 | 1.72 | 98.93 |

| Sample | Si | Al | Cr | Ti | Fe | Mn | Mg | Ca | Na | K | Ni | Be |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| G2 | 6.037 | 1.993 | 0.000 | 0.000 | 0.051 | 0.002 | 0.046 | 0.000 | 0.066 | 0.001 | 0.001 | 2.802 |

| G3 | 6.047 | 1.997 | 0.000 | 0.000 | 0.070 | 0.000 | 0.068 | 0.000 | 0.088 | 0.004 | 0.002 | 2.724 |

| G5 | 6.020 | 2.036 | 0.001 | 0.000 | 0.051 | 0.001 | 0.046 | 0.000 | 0.076 | 0.002 | 0.001 | 2.766 |

| Reducing Atmosphere | Oxidizing Atmosphere | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| G3 | 400 °C | 500 °C | 600 °C | 700 °C | 400 °C | 500 °C | 600 °C | 700 °C | |

| a (Å) | 9.209 (2) | 9.217 (2) | 9.219 (2) | 9.219 (2) | 9.217 (2) | 9.220 (2) | 9.216 (2) | 9.209 (2) | 9.202 (2) |

| c (Å) | 9.166 (2) | 9.193 (2) | 9.194 (2) | 9.189 (2) | 9.191 (2) | 9.194 (2) | 9.186 (2) | 9.195 (2) | 9.183 (2) |

| c/a | 0.995 (1) | 0.997 (1) | 0.997 (1) | 0.997 (1) | 0.997 (1) | 0.997 (1) | 0.997 (1) | 0.998 (1) | 0.998 (1) |

| Å3 | 673.230 (2) | 676.280 (2) | 676.700 (2) | 676.320 (2) | 676.190 (2) | 676.840 (2) | 675.610 (2) | 675.370 (2) | 673.310 (2) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hao, B.; Zhao, S.; Guo, Q. The Effect of Heat Treatment on Yellow-Green Beryl Color and Its Enhancement Mechanism. Crystals 2025, 15, 746. https://doi.org/10.3390/cryst15080746

Hao B, Zhao S, Guo Q. The Effect of Heat Treatment on Yellow-Green Beryl Color and Its Enhancement Mechanism. Crystals. 2025; 15(8):746. https://doi.org/10.3390/cryst15080746

Chicago/Turabian StyleHao, Binru, Shuxin Zhao, and Qingfeng Guo. 2025. "The Effect of Heat Treatment on Yellow-Green Beryl Color and Its Enhancement Mechanism" Crystals 15, no. 8: 746. https://doi.org/10.3390/cryst15080746

APA StyleHao, B., Zhao, S., & Guo, Q. (2025). The Effect of Heat Treatment on Yellow-Green Beryl Color and Its Enhancement Mechanism. Crystals, 15(8), 746. https://doi.org/10.3390/cryst15080746