Abstract

Aluminium alloys are known for their high strength-to-weight-ratio offering a wide range of applications in the aerospace and automotive industries. However, challenges exist like porosity, oxidation, solidification shrinkage, hot cracking, etc., in joining aluminium alloys. To address these challenges, there is a necessity to understand the process parameters for the welding/joining of aluminium alloys. The present study aims to investigate the effect of cold metal transfer (CMT) welding process parameters (i.e., welding speed and wire feed rate) on mechanical properties for dissimilar AA6061-AA6082 alloys weld joints. Two different welding conditions viz. CMT1 (speed: 0.5 m/min with feed: 5 m/min) and CMT2 (speed: 0.3 m/min with feed: 3 m/min), were considered. The weldments were deployed for testing different mechanical properties such as tensile, impact, hardness, corrosion tests and bead profile geometries. The results reveal that CMT1 has better mechanical properties (tensile_233 MPa; impact_8 J; corrosion rate_0.01368 mm/year) than CMT2, showing the welding speed and wire feed rate play a significant role in the joint performance. The heat affected zone and fusion zone are narrow for CMT1 when compared with CMT2. The present study provides insights into the CMT process and dissimilar joining of aluminium alloys that might be helpful for additive manufacturing of dissimilar aluminium alloys as future research directions.

1. Introduction

Aluminium (Al) alloys, such as AA6061 and AA6082, are widely used in aerospace, automotive, and marine industries due to their excellent strength-to-weight ratio, corrosion resistance, and good weldability [1,2,3,4]. However, joining dissimilar Al alloys has specific challenges such as differences in thermal properties, melting points, and microstructural evolution [5,6,7,8]. The use of ER2219 filler wire, which is specifically designed for high-strength Al alloys, helps to overcome the challenges by providing a stable arc, enhancing metallurgical compatibility, and improving the welding strength of the joint [9]. This provides new prospects for lightweight high-performance structures in fields where material optimization and cost effectiveness are demanded, for example, welding dissimilar alloys such as AA6061 and AA6082.

The choice of proper welding methods is essential to produce sound, welded structures during fabrication. Fusion welding processes such as metal inert gas (MIG) and tungsten inert gas (TIG) welding are widely employed to join both similar and dissimilar aluminium alloys in order to achieve the desired mechanical and metallurgical properties [10]. TIG welding is also widely used due to its ability to produce high-quality welds, making it suitable for complex structural fabrication across various industries [11,12,13,14,15]. The difficulty with its use is its slow process and restricted penetration depth that limits high-volume industrial application. MIG welding is acknowledged to possess a higher rate of deposition [16] as well as the ability to weld thicker sections of Al effectively [17]. It faces porosity and spatter in addition to all those difficulties of its counterparts. Recent research focuses on the optimization of process parameters, including current, voltage, shielding gas composition and wire feed rate, to enhance weld integrity and mechanical properties with minimum defects [18]. Comparative studies reveal that TIG welding is excellent in precision but MIG welding is superior for structural applications, thus indicating the need for process-specific optimizations suited to Al alloy compositions and the intended applications [19].

Friction stir welding (FSW), a solid-state process, has been widely used for its efficiency in joining Al alloys [20,21], which are difficult to weld using conventional fusion methods due to problems such as porosity, cracking, and distortion [22]. FSW works below the melting point of the base material, using a rotating tool to generate frictional heat and mechanically stir the materials to create a strong, defect-free joint. This process demonstrates that FSW produces welds possessing superior mechanical properties, including higher tensile strength as well as fatigue resistance due to the fine-grained microstructure and absence of solidification-related defects [23,24]. The process can be further applied to aerospace and automotive applications where lightweight and high-strength joints are of prime importance. The effects of tool speed on the mechanical behaviour of AA6061 Al alloy welded by FSW are investigated. These experiments demonstrate that higher rotational speeds enhance the microstructural properties and hardness, and bending strength of the welds. Specifically, the best mechanical properties were found for the AA6061 alloy welded at 1800 rpm: hardness number of 73.46 HVN, and bending property of 60.56 MPa, which indicates improved performance of the material with an increase in rotational speed [25]. In another study, the influence of material and tool rotational speed on the microstructure and mechanical properties of 6061 aluminium alloy welded by the friction stir welding (FSW) technique was investigated. The results indicated that at a tool speed of 1400 rpm and a traverse speed of 600 mm/min, double-sided FSW enhanced heat input, promoted better material flow, and achieved a more uniform microstructure, leading to notable improvements in tensile strength and microhardness [26].

Recent studies have been directed toward optimizing tool design, rotational speed, and traverse rate to improve weld quality and extend its application to dissimilar Al alloys and complex geometries. Hybrid FSW methods and post-weld treatments are also being explored to further improve joint performance and broaden industrial applications. Further, the thickness of the joint to be welded in FSW is limited. CMT is an advanced version of MIG welding that exhibits low heat input and controlled metal transfer by proper modulation of welding current and wire feed [27]. The process tends to reduce thermal distortion and minimizes the heat-affected zone (HAZ), which is a very advantageous aspect in welding thin Al sheets and dissimilar materials. Even though the input heat is reduced, the CMT weld produces adequate penetration that allows for thicker plates to be welded without compromise on joint integrity. Controlled metal transfer produces smooth weld beads with less spatter, making welds aesthetically better [28]. The mechanical properties of the CMT-welded joints exhibit tensile strength and hardness equal to or higher than those obtained by conventional methods, mainly because of the improved microstructures and significantly reduced porosity [29]. The mechanical and microstructural properties of AA7475-T7351 Al alloy welded by CMT and MIG welding techniques have been studied. This evaluation shows that CMT welding results in better mechanical properties, such as higher tensile strength, yield strength, elongation, and hardness, compared to MIG welds [30]. The studies performed on AA2014-T6 weldments using the CMT welding technique found improved tensile strength and hardness, when a higher welding speed (0.5 m/min) was employed, due to less heat input, which induces microstructural homogenization and improves welding strength [31].

To summarize the existing literature, it is evident that both solid-state and fusion welding techniques have been extensively employed to join aluminium alloys. However, limitations such as high heat input in fusion welding and complex tooling in solid-state processes have restricted their broader industrial applicability. While the CMT technique offers significant advantages such as lower heat input and better control over metal deposition only a few studies have explored its application for dissimilar aluminium welds. Moreover, there is a noticeable lack of detailed analysis regarding the effect of CMT process parameters on both the mechanical and corrosion properties of such joints.

The novelty of the present work lies in investigating dissimilar weld joints between AA6061 and AA6082 alloys using ER2219 filler wire through the CMT process. This study systematically varies the key process parameters, specifically welding speed and wire feed rate, to evaluate their influence on weld microstructure, mechanical performance, and corrosion resistance. Furthermore, the results are critically correlated with the process conditions to establish clear relationships between parameter variations and property changes. These findings aim to bridge the existing gap in the literature and offer insights into optimizing CMT for high-performance dissimilar aluminium welds.

2. Materials and Methods

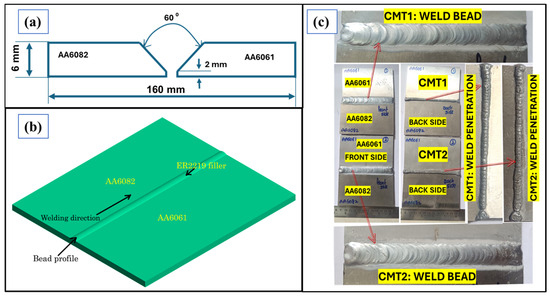

The base metals, AA6061 and AA6082, using plates of dimensions 150 × 80 × 6 mm were considered to produce dissimilar welded joints using ER2219 as a filler wire. The chemical composition of the base metals and filler wire material are represented in Table 1. The AA6061 alloy consists of Mg (1.0%) and Si (0.6%), which contribute to good corrosion resistance with moderate strength, whereas the base metal AA6082, having Mg (0.8%) and Si (1.0%), shows excellent strength along with good machinability for critical applications. The filler wire (ER2219) is selected based on the compatibility of dissimilar Al alloys. A standard butt V-groove joint was prepared with groove angle of 60° and a land face of 2 mm, with precise machining to achieve accurate groove dimensions, as shown in Figure 1a. Before welding, any abrasives or contaminants are removed from the weld area to ensure the optimal weld quality, preventing defects and enhancing the overall strength and integrity of the weld.

Table 1.

Chemical composition (wt.%) of base metals (AA6061, AA6082) and filler wire (ER2219) [25,32].

Figure 1.

(a,b) Schematics of the V-groove joint and dimensions of the dissimilar welding joint and (c) dissimilar welded joints: CMT1 and CMT2.

The welding of two dissimilar base metals, AA6061 and AA6082 was carried out using CMT process. The CMT process utilizes the controlled metal deposition of filler material (ER2219) at low heat input through filler metal retraction at short circuiting phase. Table 2 shows the welding conditions used to join the dissmilar Al alloys. The welding was performed in the flat position and progressed along the length of the base plate, as shown in Figure 1b. Both the variables play a vital role on the heat-input generation. The wire feed rate is directly proportional to current, whereas the welding speed has direct influence on the total heat input generated. The contact-tube-to-work distance (CTWD) was maintained at 8 mm, which is directly proportional to the voltage and helps stabilize the arc, resulting in consistent metal transfer during deposition. The arc is protected by argon shielding gas with a constant flow rate of 8 lpm to prevent oxidation. The experiments were carried out, and the weld joints were visually inspected on both the top and bottom sides, as shown in Figure 1c, with particular attention given to weld bead geometry and ensuring full penetration.

Table 2.

Process parameters of the CMT welding to produce dissimilar weld joints.

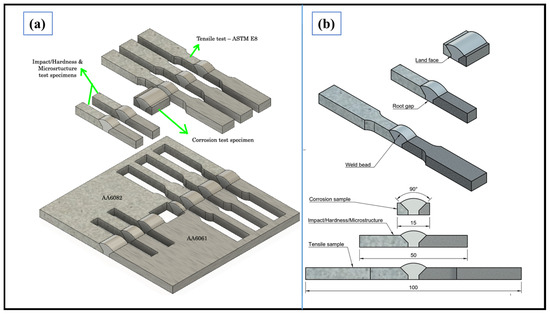

After experimentation, the dissimilar welded plates produced under two different welding conditions were subjected to wire-EDM. Standard specimens were extracted for macrostructural analysis of the weld bead geometry and for mechanical testing, including tensile, hardness, and impact tests, as shown in Figure 2a. An optical microscope, OLYMPUS model, was used to visualize the macrostructure of the weldment zones and weld bead geometry. The weld sample surfaces were polished using an emery sheet to clean the rub/slurry/blurs on the weld area and ensure a scratch-free surface. The samples are then etched to improve the contrast in microstructural features after polishing. Keller’s reagent solution was used to reveal the width, depth, and height of weld bead geometry, as well as the different weld zones (dissimilar, base metal, HAZ and weldment). The fracture modes and phases involved in the tensile and impact fracture analyses were examined using scanning electron microscopy (SEM) and energy dispersive X-ray analysis (EDAX). A cyclic sweep test in a 3.5% NaCl solution was performed on the welded samples to assess the corrosion behaviour. The test was carried out by submerging the specimens in the electrolyte and recording potentiodynamic polarization scans for measuring corrosion. The cyclic test provided insight into the passivation and pitting behaviour of the weldments, particularly the weld zone. Further, the tensile tests were carried out using a universal testing machine (UTM) [model: unitek-9400, load capacity-50 kN] that examines the strength, elongation, and fracture behaviour, according to ASTM E8 standards [21]. Microhardness testing was carried out using a Vickers hardness tester [model: VH-1MDX, testing load: 1 gf to 1 kgf], 3 mm from the root of the weld with a 500 gf load and measured across the cross section of the weld bead. Izod impact test [model: IT-30] was conducted using an impact tester to assesses the material toughness under sudden loads. Dimensions of the samples for all the tests are shown in Figure 2b.

Figure 2.

(a) Schematic 3D model cutout of the dissimilar welds. (b) Dimensions of the samples.

3. Results and Discussions

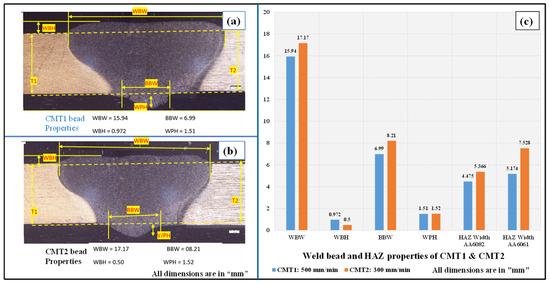

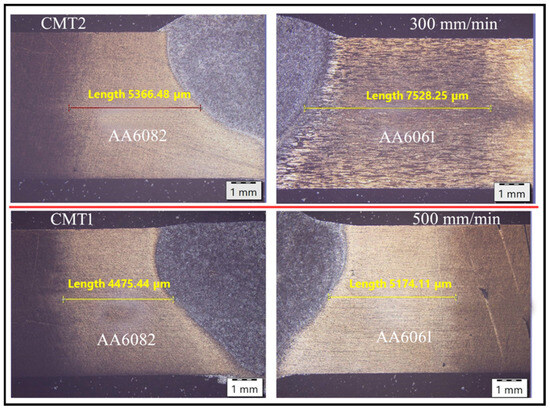

3.1. Weld Bead Geometry

The weld bead dimensions and width of the HAZ are shown in Figure 3 and Figure 4. The figure analyses the configuration of welded joints and shows dimensions and characteristics for each sample. In CMT1, the weld bead width (WBW) is 15.94 ± 2 mm, and the weld bead height (WBH) is 0.972 ± 0.2 mm. The back bead width (BBW) is 6.99 ± 0.5 mm, while the weld penetration height (WPH) is 1.51 ± 0.2 mm. The HAZ width for AA6061 is 5.174 ± 0.5 mm, and for AA6082, it is 4.4755 ± 0.5 mm. For CMT2, the WBW is 17.17 ± 2 mm, and a low WBH of 0.50 ± 0.2 mm. The BBW is 8.21 ± 0.5 mm, while the WPH is 1.52 ± 0.2 mm. The HAZ width for AA6061 is 7.528 ± 0.5 mm and for AA6082 is 5.366 ± 0.5 mm. The weld bead properties and HAZ width of dissimilar weldments under CMT1 and CMT2 conditions are presented in Figure 3a,b and tabulated in Table 3. For CMT1, the bead profile is much more refined with smaller dimensions of the beads and a narrow HAZ compared to CMT2. This is an indication of controlled heat input and more localized heating during welding, which ensures better weld quality. The narrow HAZ would mean less grain coarsening and a stable microstructure for CMT1, which is beneficial for its mechanical properties like strength and toughness [32]. On the other hand, larger bead width and height in CMT2 indicates less controlled heat input due to slower welding speed, which gives a larger HAZ, especially in AA6082, resulting in more significant grain growth, possibly lowering the mechanical performance of the material [33].

Figure 3.

Macrostructure of welded sample: (a) CMT1, (b) CMT2 and (c) weld bead properties of CMT1 and CMT2.

Figure 4.

HAZ width of dissimilar AA6082 and AA6061 welded samples.

Table 3.

Weld bead properties of dissimilar weldments.

The bead dimensions and the width of the HAZ were distinctly different for both welds and showed that higher welding speeds led to different final characteristics of the weld. At higher welding speeds, a more localized input of heat is given by the CMT1, thus smaller dimensions of beads with better control on penetration, thinner HAZ and therefore likely having a greater mechanical strength. On the other hand, a lower speed in CMT2 yields a wider bead and HAZ with more material degradation, and thus lower tensile strength and higher corrosion attack. These observations are also generally consistent with findings concerning the mechanical properties of the welds since performance is significantly better for CMT1.

3.2. Tensile Testing

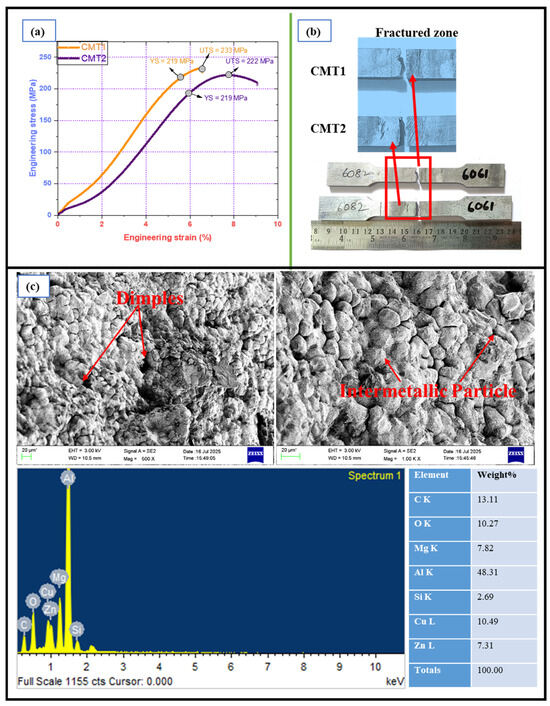

The tensile test results for the CMT welded samples are listed in Table 4 revealing differences in mechanical properties. The engineering stress and strain curves of the dissimilar welded samples are plotted in Figure 5a and the samples’ fracture locations under uni-axial loads are shown in Figure 5b. CMT1 showed a higher yield strength (YS) of 219 MPa and ultimate tensile strength (UTS) of 233 MPa but a lower elongation of 3.66% compared to CMT2, which had a YS of 194 MPa, UTS of 222 MPa, and a higher elongation of 5.98%. The higher strength in CMT1 might be related to better penetration and good weld fusion because the base metals were bonded together very strongly. Elongation values are relatively lower in CMT1, which is also a brittle weld; a phenomenon that generally occurs when the welding parameters are in favor of strength rather than ductility. On the other side, CMT2 was relatively more ductile in nature. The ratio of YS to UTS CMT1 was found to be 0.94 which is higher than CMT2, which was 0.87. This could be attributed to differences in welding parameters: a reduced feed rate or wire speed resulting in a more expansive HAZ. Similar results were witnessed in these current studies concerning earlier research findings for CMT welds [31]. According to the work of Beytullah et al. [33], Al alloys welded by CMT were found to have yield strengths in the range of 180–220 MPa, while the elongations ranged between 3.5% and 6%. The observed strength–ductility trade-off is therefore in good agreement with the results from the present work: the highest strength but a lower elongation of CMT1, while CMT2 had higher elongation but lower strength. Singh et al. [34] also reported similar trends in their CMT welding experiments, where increasing the wire feed rate improved tensile strength but reduced elongation, consistent with the results observed in CMT1.

Table 4.

Tensile stress–strain results of CMT1 and CMT2 welds.

Figure 5.

(a) Tensile stress–strain plot, (b) fracture samples under uni-axial loads and (c) fracture analysis using SEM/EDAX.

Figure 5c shows the fracture surface of the tensile specimen observed under SEM, highlighting the ductile fracture mode. The surface exhibits well-defined dimples, indicative of microvoid coalescence, which suggests significant plastic deformation before failure [35]. The presence of tear ridges and shear lips further confirms the material’s ability to absorb energy, indicating a high toughness and resilience under tensile stress. The elemental data from the EDAX analysis further corroborates the fracture mode observations [36]. The high concentration of aluminium (48.31%) is typical for Al alloys, with copper (10.49%) and zinc (7.31%) contributing to strengthening the material, enhancing both mechanical properties and fracture resistance. The presence of magnesium (7.82%) and silicon (2.69%) supports the alloy’s corrosion resistance and overall durability.

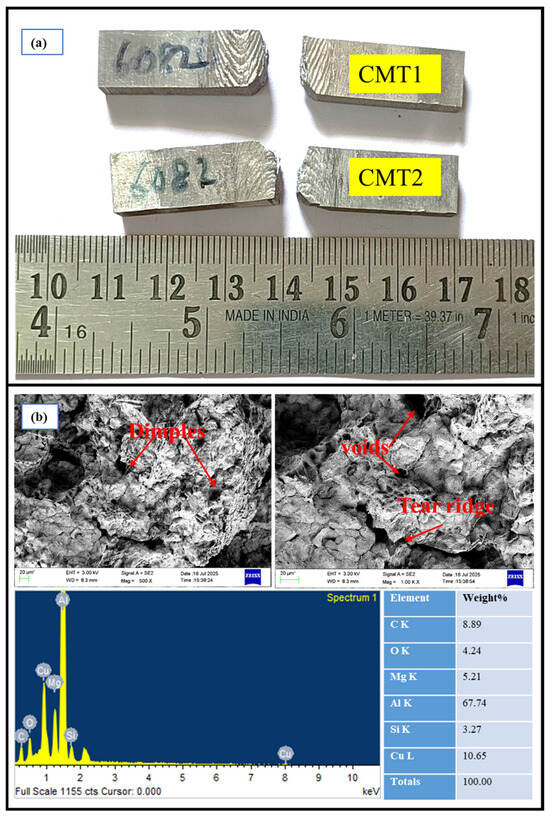

3.3. Impact Testing

The fractured impact strength results of the dissimilar welded samples are shown in Figure 6, showing that the impact strength for CMT1 and CMT2 is 8 J and 6 J, respectively. In addition, CMT2 had a more brittle fracture, consistent with its lower tensile strength and higher elongation. The higher impact strength of CMT1 may be due to its higher tensile strength, which would suggest a more robust weld with less susceptibility to sudden fractures. A relationship between tensile strength and impact toughness exists, in that materials with higher tensile strength often show better resistance to sudden impacts because they are less likely to deform plastically before failure. The difference in impact strength can also be partially attributed to the welding speed. CMT1 was welded at a faster speed, which usually results in lower heat input, minimizing the HAZ and improving the weld’s overall mechanical properties, including impact strength. In contrast, the CMT2, having a slower welding speed, must have had a larger HAZ that resulted in lower impact toughness as seen by the lower impact strength.

Figure 6.

(a) Fractured samples under sudden loads and (b) fracture analysis using SEM/EDAX.

Figure 6b shows the impact fracture analysis revealed a predominantly ductile fracture mode, characterized by large, equiaxed dimples formed due to micro-void coalescence [37]. These dimples suggest significant plastic deformation before fracture, indicating the material’s ability to absorb high energy. The fracture surface exhibited shear lips and tearing ridges, emphasizing the material’s toughness and resistance to brittle failure under dynamic loading conditions [38]. The EDAX analysis reveals a dominant presence of aluminium (67.74%), which forms the primary matrix of the alloy. Copper (10.65%) enhances the material’s strength and wear resistance, while magnesium (5.21%) improves corrosion resistance. Additionally, silicon (3.27%) contributes to the material’s thermal stability.

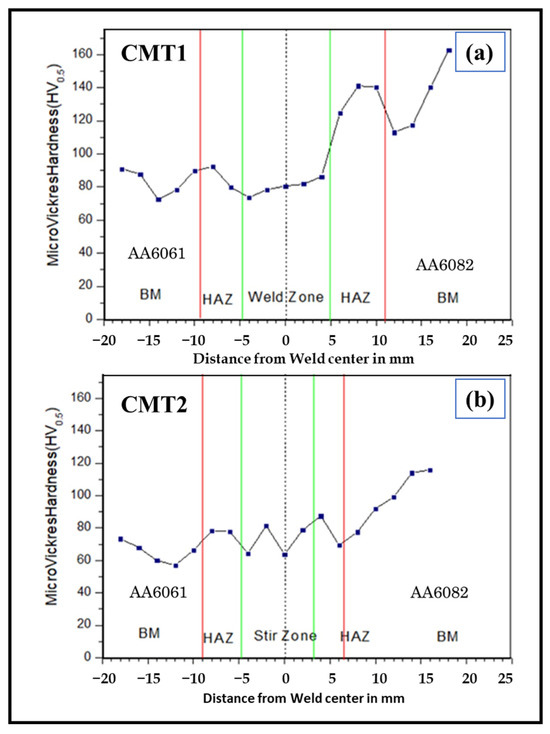

3.4. Microhardness

The microhardness of the CMT1 and CMT2 welded samples are plotted and their profiles are shown in Figure 7. For CMT1, the hardness values HAZ of AA6061 = 87 HV, HAZ of AA6082 = 134 HV, and at weld zone = 80 HV. For CMT 2, hardness values are as follows: HAZ of AA6061 = 77 HV, HAZ of AA6082 = 79 HV, and at weld centre, 72 HV. These results indicates that the hardness values for CMT1 are higher in both the HAZ and weld zone than for CMT2. The hardness in CMT1 may be attributed to the faster welding speed, resulting in a smaller HAZ and fine-grain coarsening, thus retaining higher hardness in both the HAZ and weld zone. On the other hand, CMT2 possesses lower hardness values, since the width of the HAZ is larger and it can be attributed to the lower welding speeds that produce coarse grains along with the softening of the material in these regions. Similar HAZ properties were observed in joining Al alloys using the CMT welding technique [31,33]. When compared, CMT1 shows an overall better hardness across both the HAZ and weld zone, showing a better weld quality and stronger material properties. This is also in line with the tensile and impact strength data observed wherein CMT1 performed better. These microhardness comparisons further confirm the influence of welding speed and heat input on the material’s mechanical properties and microstructural integrity. The higher hardness values in the HAZ and weld zone correspond to the controlled heat input, which contributed to better mechanical properties and resilience during fracture, while maintaining the material’s capacity to absorb energy before failure [39].

Figure 7.

Microhardness of the dissimilar welds (a) CMT1 and (b) CMT2.

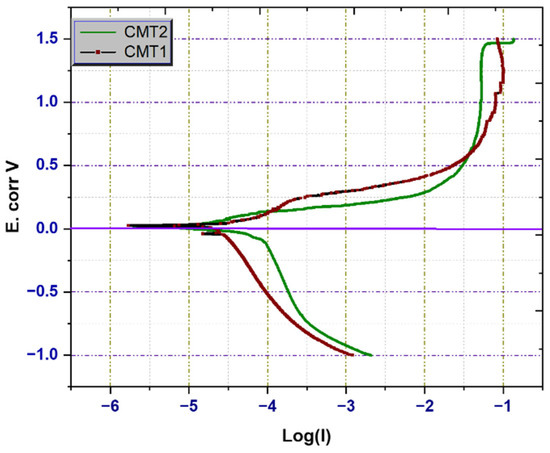

3.5. Corrosion

The corrosion plots are drawn between E. corr V and Log (I) of CMT1 and CMT2 and the profiles are shown in Figure 8. The results for the corrosion data are listed in Table 5. From the corrosion test results, it can be clearly deduced that the corrosion rates are low in CMT1 at 0.01368 mm/y while having a corrosion current of 1.21 × 10−6 A, while corrosion rates for CMT 2 are at a higher value at 0.01795 mm/y with a corrosion current of 1.61 × 10−6 A. Hence, it gives the impression that CMT1 has a higher corrosion-resistance ability. This is because the welding speed is higher in CMT1, which provides a smaller HAZ. The smaller HAZ will preserve and enhance the material’s microstructure, therefore enhancing corrosion resistance. Additionally, the mechanical properties of CMT1, including tensile strength, impact toughness, and micro-hardness, are higher, and these are responsible for the better performance in corrosive environments. CMT1 shows a lower corrosion rate, which may be attributed to its stronger and more stable surface that offers greater resistance to corrosion and surface degradation [40].

Figure 8.

Corrosion plots of dissimilar weldments.

Table 5.

Pitting potential (Epit mV) values of CMT AA6061-AA6082 weldments.

The corrosion resistance of CMT2 is lower because the slower speed led to a larger HAZ, and this reduced the tensile strength, impact toughness, and surface hardness numbers. This follows the observed mechanical properties; CMT2 presents a good correlation between strength and corrosion resistance where both are compromised due to the slower welding speed [31]. Overall, the comparison reveals the significant influence of welding speed on both the mechanical behaviour and corrosion resistance of the welded joints, indicating that the higher welding speed employed in CMT1 leads to improved and reliable performance.

4. Conclusions

In this study, dissimilar Al alloys AA6061 and AA6082 were successfully joined using the cold metal transfer (CMT) process, with ER2219 filler wire. Post-weld evaluations were carried out to understand the relationship between process parameters, macrostructure, and mechanical properties. Based on the findings, the following conclusions were drawn:

- CMT1 exhibited superior mechanical performance with a tensile strength of 233 MPa, and a higher yield-to-ultimate tensile strength ratio of 0.94, attributed to its narrower heat-affected zone (HAZ) and improved bead geometry.

- CMT2, by contrast, showed lower tensile strength (UTS = 222 MPa, YS = 184 MPa, and a ratio of 0.87), likely due to increased heat input, leading to a wider bead and larger HAZ.

- The impact toughness of CMT1 was 8 J, higher than CMT2’s 6 J, which can be linked to refined grain structures and reduced HAZ width in CMT1.

- Hardness values were also higher in CMT1 across the HAZ and weld zone, again correlated to the reduced HAZ size. CMT2 showed relatively lower hardness due to grain coarsening and broader thermal exposure.

- In terms of corrosion resistance, CMT1 demonstrated a lower corrosion rate, aligning with its better mechanical properties and more stable microstructure. CMT2, with a broader HAZ and lower mechanical strength, was more prone to corrosion.

- The findings clearly show that higher welding speeds, as used in CMT1, contribute to enhanced joint quality through better control of bead formation and thermal input. In contrast, the slower welding speed in CMT2 led to wider HAZs and compromised mechanical and corrosion properties. This study offers valuable insights for industries such as aerospace, automotive, and marine engineering, where lightweight dissimilar Al joints are critical.

Future research may explore the effects of shielding gas composition, multi-pass welding, and post-weld heat treatment on microstructure and corrosion behaviour. Additionally, the insights from this study on dissimilar Al alloy joining using the CMT process could support the development of additive manufacturing techniques for dissimilar Al materials.

Author Contributions

Conceptualization, B.Y. and M.Z.; methodology, M.Z.; software, S.Q.M. and S.P.S.I.; validation, S.Q.M. and M.F.K.; formal analysis, B.Y., S.P.S.I. and M.Z.; investigation, B.Y. and M.Z.; resources, H.A., S.Q.M. and M.F.K.; writing—original draft preparation, B.Y. and M.Z.; writing—review and editing, S.Q.M., H.A. and M.F.K.; supervision, B.Y.; project administration, B.Y. and S.P.S.I.; funding acquisition, H.A., S.Q.M. and M.F.K. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Deanship of Scientific Research, Vice Presidency for Graduate Studies and Scientific Research, King Faisal University, Saudi Arabia, [Grant No. KFU252438].

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Singh, H.; Singh, K.; Vardhan, S.; Mohan, S. Study on the wear performance of AA 6061 and AA 6082 based metal matrix composites. Mater. Today Proc. 2021, 43, 660–664. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; Seleman, M.M.E.-S.; Ahmed, E.; Reyad, H.A.; Touileb, K.; Albaijan, I. Friction Stir Spot Welding of Different Thickness Sheets of Aluminum Alloy AA6082-T6. Materials 2022, 15, 2971. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, M.M.Z.; Seleman, M.M.E.-S.; Ahmed, E.; Reyad, H.A.; Alsaleh, N.A.; Albaijan, I. A Novel Friction Stir Deposition Technique to Refill Keyhole of Friction Stir Spot Welded AA6082-T6 Dissimilar Joints of Different Sheet Thicknesses. Materials 2022, 15, 6799. [Google Scholar] [CrossRef] [PubMed]

- Alzahrani, B.; Ahmed, M.M.Z.; Habba, M.I.A.; Fouad, R.A.; Elshaghoul, Y.G.Y.; Gadallah, E.A. TIG Welding of EN AW-6082 Al Alloy: A Comparative Analysis of Filler Rods on Microstructural and Mechanical Performance. J. Manuf. Mater. Process. 2025, 9, 21. [Google Scholar] [CrossRef]

- Dada, M.; Popoola, P. Recent advances in joining technologies of aluminum alloys: A review. Discov. Mater. 2024, 4, 86. [Google Scholar] [CrossRef]

- Karrar, G.; Galloway, A.; Toumpis, A.; Li, H.; Al-Badour, F. Microstructural characterisation and mechanical properties of dissimilar AA5083-copper joints produced by friction stir welding. J. Mater. Res. Technol. 2020, 9, 11968–11979. [Google Scholar] [CrossRef]

- Nagaraja, S.; Anand, P.B.; Mariswamy, M.; Alkahtani, M.Q.; Islam, S.; Khan, M.A.; Khan, W.A.; Bhutto, J.K. “Friction stir welding of dissimilar Al–Mg alloys for aerospace applications: Prospects and future potential” Reviews on advanced materials science. Rev. Adv. Mater. Sci. 2024, 63, 20240033. [Google Scholar] [CrossRef]

- Yang, Y.; Bhowmik, A.; Tan, J.L.; Du, Z.; Zhou, W. A New Strategy for Dissimilar Material Joining between SiC and Al Alloys through Use of High-Si Al Alloys. Metals 2022, 12, 887. [Google Scholar] [CrossRef]

- Ahmed, M.; Javidani, M.; Mirakhorli, F.; Maltais, A.; Chen, X.G. Novel High-Strength Al-Si-Mg Filler Wires for Aluminum Welding. In Proceedings of the 62nd Conference of Metallurgists, COM 2023; Springer: Cham, Switzerland, 2023. [Google Scholar] [CrossRef]

- Adin, M.Ş. A parametric study on the mechanical properties of MIG and TIG welded dissimilar steel joints. J. Adhes. Sci. Technol. 2024, 38, 115–138. [Google Scholar] [CrossRef]

- Nandhakumar, S.; Kumar, K.G.; Arivazhagan, N.; Manikandan, M.; Jose, B.; Renangi, S. Technology development of novel autogenous double pulse tungsten insert gas welding technique to evaluate the depth of penetration, micro segregation via machine learning and desirability function approach. Mater. Today Commun. 2024, 40, 109614. [Google Scholar] [CrossRef]

- Yelamasetti, B.; Sushma, S.P.; Mohammed, Z.; Altammar, H.; Khan, M.F.; Moinuddin, S.Q. Synergistic Effects of Thermal Cycles and Residual Stress on Microstructural Evolution and Mechanical Properties in Monel 400 and AISI 316L Weld Joints. Metals 2025, 15, 469. [Google Scholar] [CrossRef]

- Kumar, P.; Sinha, A.N.; Hirwani, C.K.; Murugan, M.; Saravanan, A.; Singh, A.K. Effect of welding current in TIG welding 304L steel on temperature distribution, microstructure and mechanical properties. J. Braz. Soc. Mech. Sci. Eng. 2021, 43, 369. [Google Scholar] [CrossRef]

- Kumar, P.; Arif, A.; Prasad, A.C.V.; Danaiah, P.; Singh, A.K.; Patro, M.; Kishore, K.S.; Murugan, M. Study of welding process parameter in TIG joining of aluminum aolly (6061). Mater. Today Proc. 2021, 47, 4020–4025. [Google Scholar] [CrossRef]

- Vasantharaja, P.; Vasudevan, M.; Maduraimuthu, V. Effect of Arc Welding Processes on the Weld Attributes of Type 316LN Stainless Steel Weld joint. Trans. Indian Inst. Met. 2018, 71, 127–137. [Google Scholar] [CrossRef]

- Ganesh, K.C.; Balasubramanian, K.R.; Vasudevan, M.; Vasantharaja, P.; Chandrasekhar, N. Effect of Multipass TIG and Activated TIG Welding Process on the Thermo-Mechanical Behavior of 316LN Stainless Steel Weld Joints. Met. Mater. Trans. B 2016, 47, 1347–1362. [Google Scholar] [CrossRef]

- Nandan, G.; Kumar, G.; Arora, K.; Kumar, A. MIG and CMT brazing of aluminum alloys and steel: A review. Mater. Today Proc. 2022, 56 Pt 1, 481–488. [Google Scholar] [CrossRef]

- Afzal, M.S.; Wakeel, A.; Nasir, M.A.; Qazi, M.I.; Abas, M. Optimization of process parameters for shielded metal arc welding for ASTM A 572 grade 50. J. Eng. Res. 2024, 13, 1072–1088. [Google Scholar] [CrossRef]

- Abima, C.S.; Akinlabi, S.A.; Madushele, N.; Akinlabi, E.T. Comparative study between TIG-MIG Hybrid, TIG and MIG welding of 1008 steel joints for enhanced structural integrity. Sci. Afr. 2022, 17, e01329. [Google Scholar] [CrossRef]

- Saravanakumar, R.; Sirohi, S.; Pandey, S.M.; Rajasekaran, T.; Pandey, C. Attributes of FSW and UWFSW butt joints of armour grade AA5083 aluminium alloy: Impact of tool pin profile. Heliyon 2024, 10, e38351. [Google Scholar] [CrossRef] [PubMed]

- Yelamasetti, B.; Sridevi, M.; Sree, N.S.; Geetha, N.K.; Bridjesh, P.; Shelare, S.D.; Prakash, C. Comparative Studies on Mechanical Properties and Microstructural Changes of AA5052 and AA6082 Dissimilar Weldments Developed by TIG. J. Mater. Eng. Perform. 2024, 34, 9972–9985. [Google Scholar] [CrossRef]

- Verma, S.; Gupta, M.; Misra, J.P. Performance evaluation of friction stir welding using machine learning approaches. MethodsX 2018, 5, 1048–1058. [Google Scholar] [CrossRef]

- Kesharwani, R.; Jha, K.K.; Imam, M.; Sarkar, C.; Barsoum, I. Correlation of microstructure, texture, and mechanical properties of friction stir welded Joints of AA7075-T6 plates using a flat tool pin profile. Heliyon 2024, 10, e25449. [Google Scholar] [CrossRef] [PubMed]

- Pouraliakbar, H.; Jandaghi, M.R.; Ghaffari, G.; Fallah, V.; Moverare, J.; Khalaj, G. Friction stir processing of AA6061-T6/graphene nanocomposites: Unraveling the influence of tool geometry, rotation, and advancing speed on microstructure and mechanical properties. J Alloys Compd 2024, 1002, 175400. [Google Scholar] [CrossRef]

- Hilmawan, M.I.; Putri, E.D.S.; Muhayat, N.; Manurung, Y.H.; Ilhamdi; Sulardjaka; Hendrato; Triyono. Effect of tools rotational speed on the mechanical properties of one-step double-acting friction stir welded aluminum alloy AA 6061 hollow panel. Int. J. Light. Mater. Manuf. 2024, 7, 467–479. [Google Scholar] [CrossRef]

- Tang, Y.; Li, W.; Zou, Y.; Wang, W.; Xu, Y.; Vairis, A.; Çam, G. Effects of tool rotation direction on microstructure and mechanical properties of 6061 aluminum alloy joints by the synergistically double-sided friction stir welding. J. Manuf. Process. 2024, 126, 109–123. [Google Scholar] [CrossRef]

- Bellamkonda, P.N.; Dwivedy, M.; Addanki, R. Cold metal transfer technology—A review of recent research developments. Results Eng. 2024, 23, 102423. [Google Scholar] [CrossRef]

- Feng, J.; Zhang, H.; He, P. The CMT short-circuiting metal transfer process and its use in thin aluminium sheets welding. Mater. Des. 2009, 30, 1850–1852. [Google Scholar] [CrossRef]

- Shen, H.; Yu, J.; Wang, L.; Vogel, F.; Li, C.; Nagaumi, H. A comparative filling materials study on microstructure and mechanical properties of welded joints of dissimilar Al–Mg–Si alloys using CMT-laser beam oscillation hybrid welding. J. Mater. Res. Technol. 2025, 34, 1029–1044. [Google Scholar] [CrossRef]

- Shanker, H.; Wattal, R. Comparative Study of Microstructural and Mechanical Properties of Robotic Cmt and Gmaw Welded 7475-T7351 Aluminium Alloy Joints. Mater. Today Commun. 2023, 37, 106994. [Google Scholar] [CrossRef]

- Yelamasetti, B.; Devi, B.T.L.; Sree, N.S.; Vempati, S.; Sonar, T.; Kumar, A.; Rakesh, C.; Sharma, A.; Ansari, M.A. Investigations on mechanical behavior of AA2014-T6 weldments developed using CMT welding: As-weld and post weld heat treatment conditions. J. Mater. Res. Technol. 2025, 35, 1409–1418. [Google Scholar] [CrossRef]

- Yelamasetti, B.; G, V.R.; Manikyam, S.; Saxena, K.K. Multi-response Taguchi grey relational analysis of mechanical properties and weld bead dimensions of dissimilar joint of AA6082 and AA7075. Adv. Mater. Process. Technol. 2021, 8, 1474–1484. [Google Scholar] [CrossRef]

- Gungor, B.; Kaluc, E.; Taban, E.; SIK ŞŞ, A. Mechanical and microstructural properties of robotic Cold Metal Transfer (CMT) welded 5083-H111 and 6082-T651 aluminum alloys. Mater. Des. 2014, 54, 207–211. [Google Scholar] [CrossRef]

- Singh, I.J.; Murtaza, Q.; Kumar, P. Effect of CMT Welding Process Parameters on the Microstructural and Mechanical Properties of Dissimilar Aluminum Alloys of AA8011 and AA6061. Trans. Indian Inst. Met. 2025, 78, 3. [Google Scholar] [CrossRef]

- Pineau, A.; Pardoen, T. Failure of metals. In Comprehensive Structural Integrity, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2003; pp. 321–432. [Google Scholar] [CrossRef]

- Karihaloo, B.; Xiao, Q. Linear and nonlinear fracture mechanics. In Comprehensive Structural Integrity; Elsevier: Amsterdam, The Netherlands, 2003; pp. 81–212. [Google Scholar] [CrossRef]

- Carta, M.; Aydi, L.; Buonadonna, P.; Morea, D.; El Mehtedi, M. Effect of post heat treatment on microstructure and mechanical properties of hot-rolled AA2017 aluminum alloy. Heliyon 2024, 10, e40922. [Google Scholar] [CrossRef]

- Das, A. Correlation of fractographic features with tensile properties in systematically varied microstructures of a pearlitic steel. Can. Met. Q. 2025, 1–12. [Google Scholar] [CrossRef]

- Alaboodi, A.S.; Sivasankaran, S.; Ramkumar, K.; Ammar, H.R. Microstructural evolution and enhanced mechanical performance of dissimilar CoCrFeMnNi High Entropy Alloy-Duplex Stainless Steel welds using laser beam welding. J. Mater. Res. Technol. 2025, 36, 4985–4998. [Google Scholar] [CrossRef]

- Velmurugan, S.; Babu, N.; Santhosh, V. Effect of Post-Heat treatment on corrosion resistance and microstructural characteristics of CMT-WAAM Inconel 718 in 3.5% NACL solution. J. Indian Chem. Soc. 2025, 102, 101625. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).