Effect of Al-5Ti-2B on the Microstructure and Mechanical Properties of Recycled Al-7Si-0.3Mg-1Fe Alloy

Abstract

1. Introduction

2. Materials and Methods

3. Results

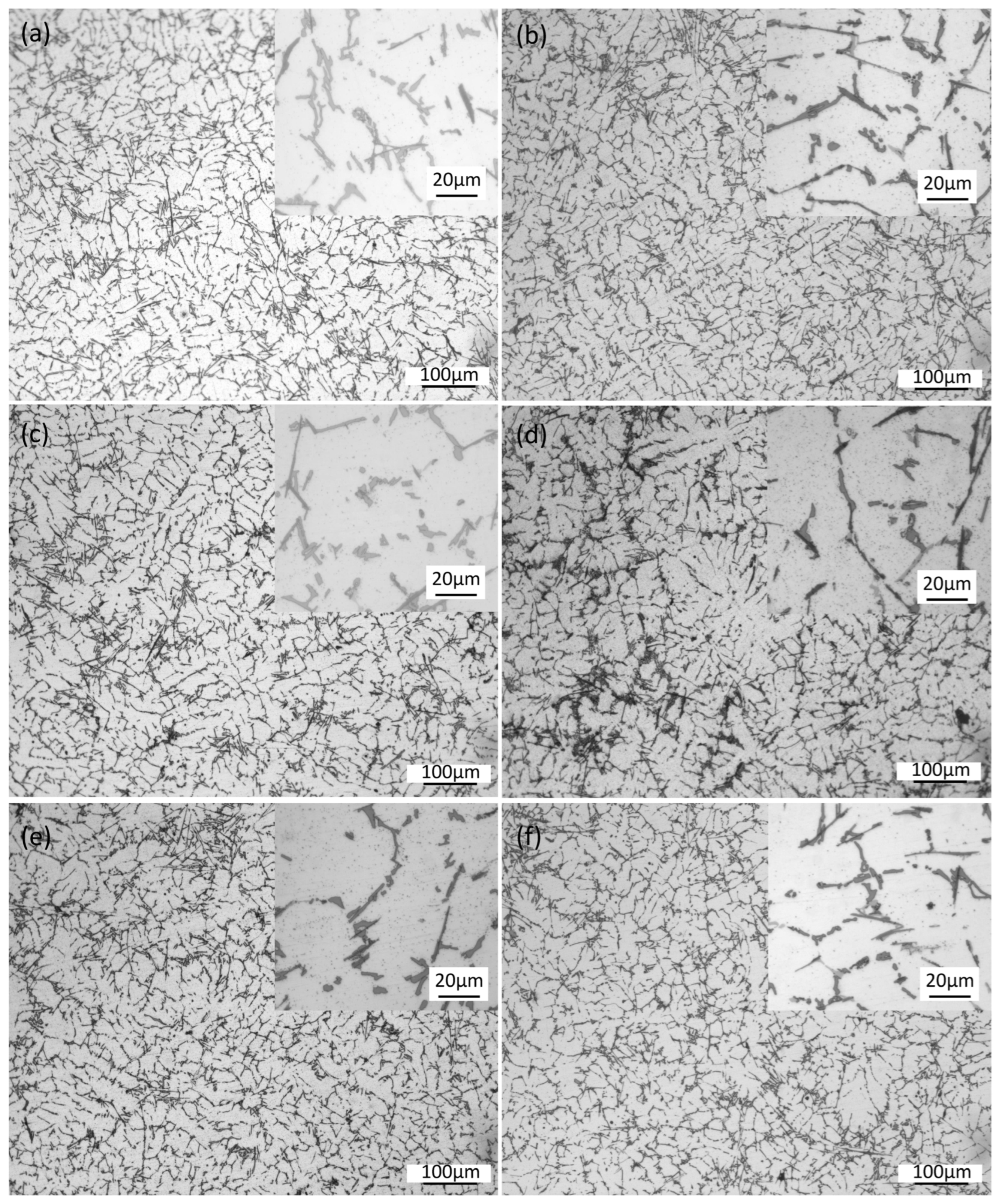

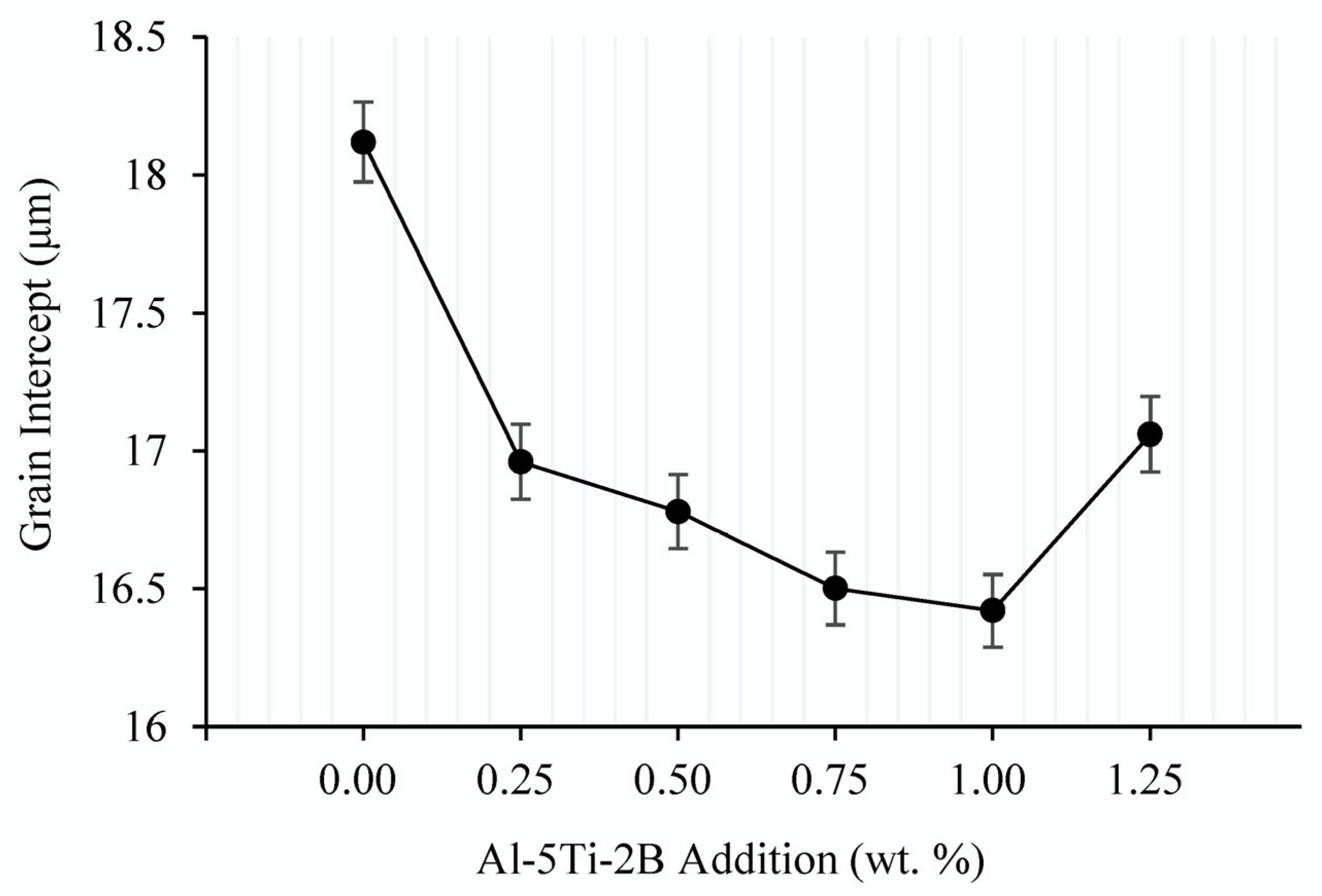

3.1. Metallographic Analysis

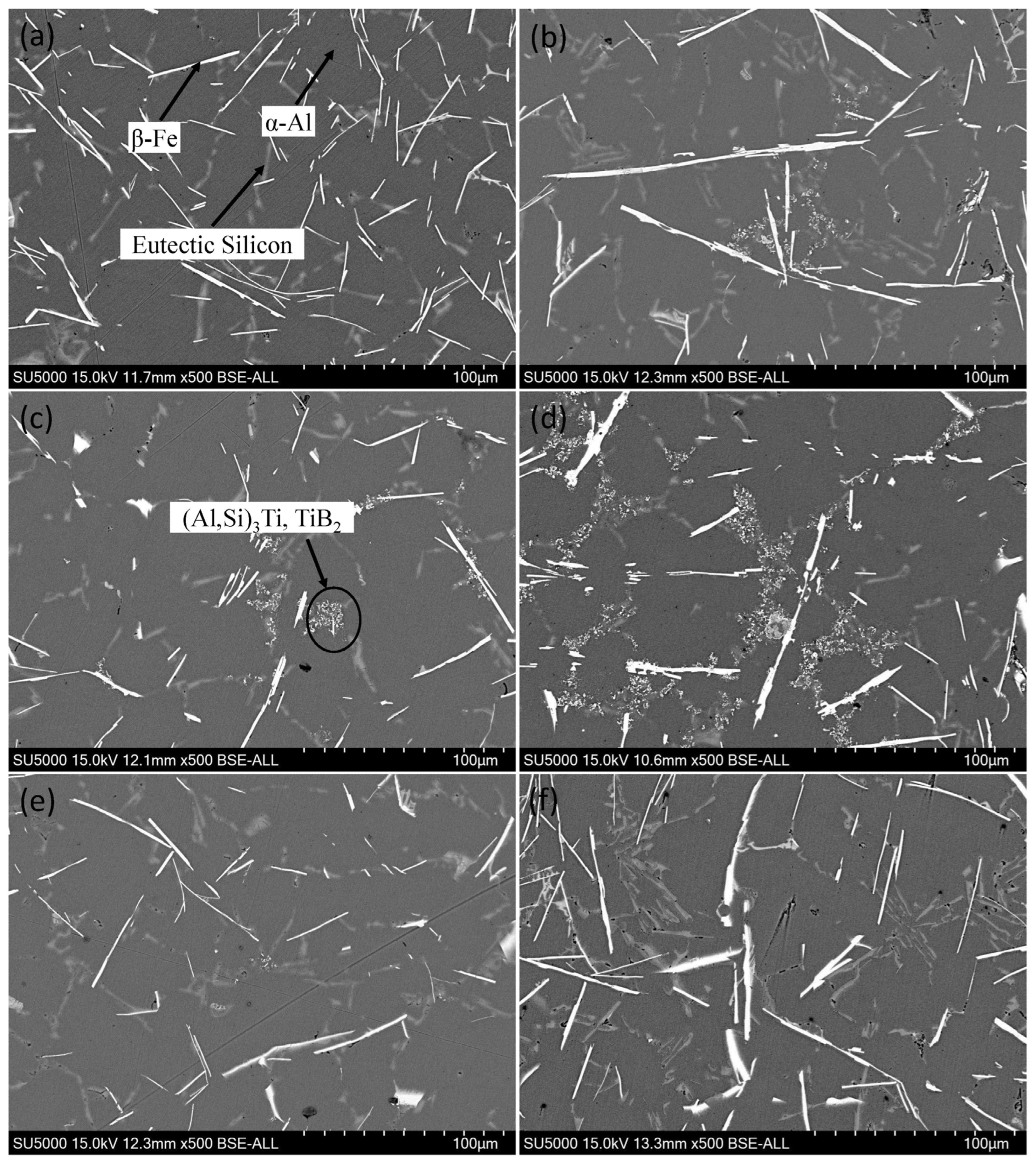

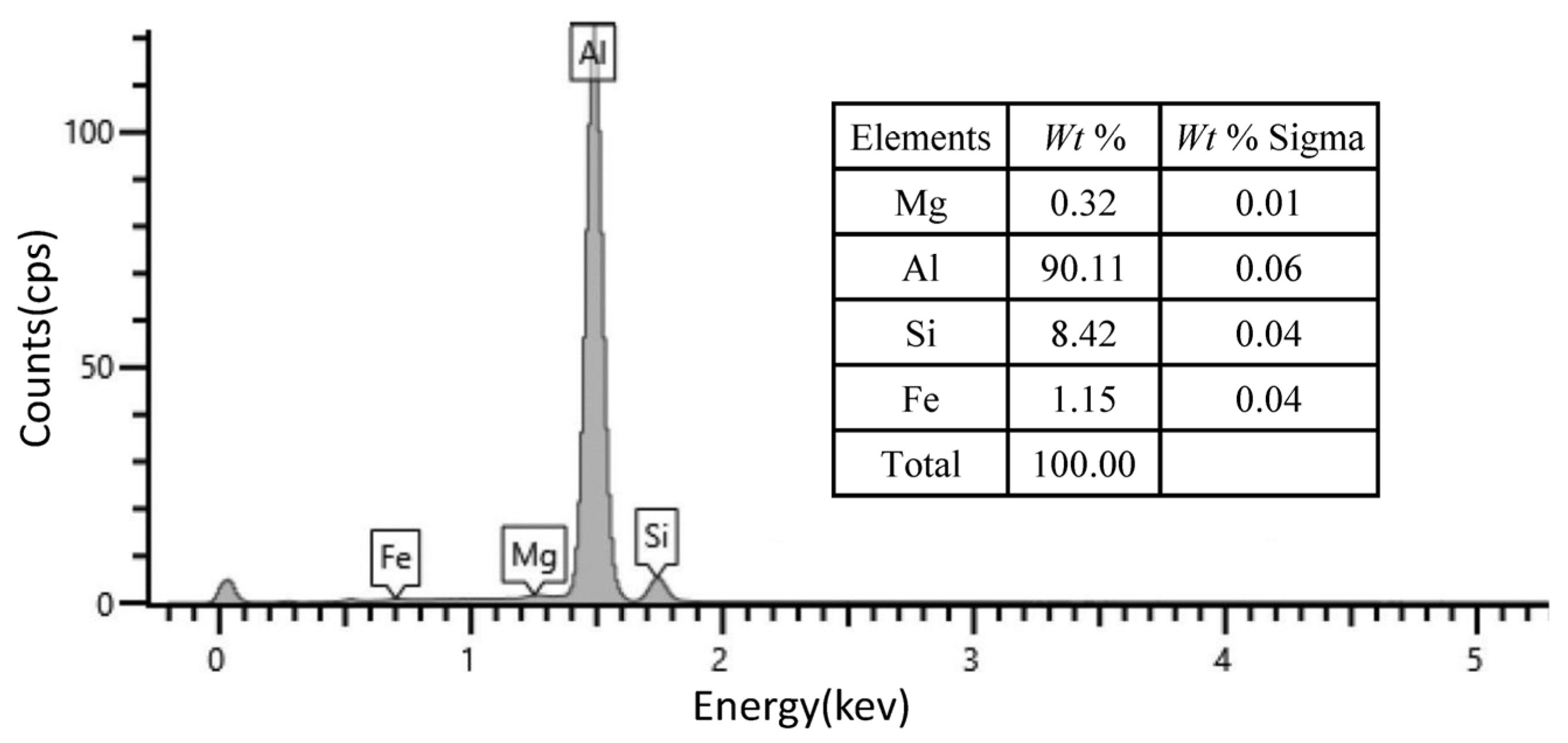

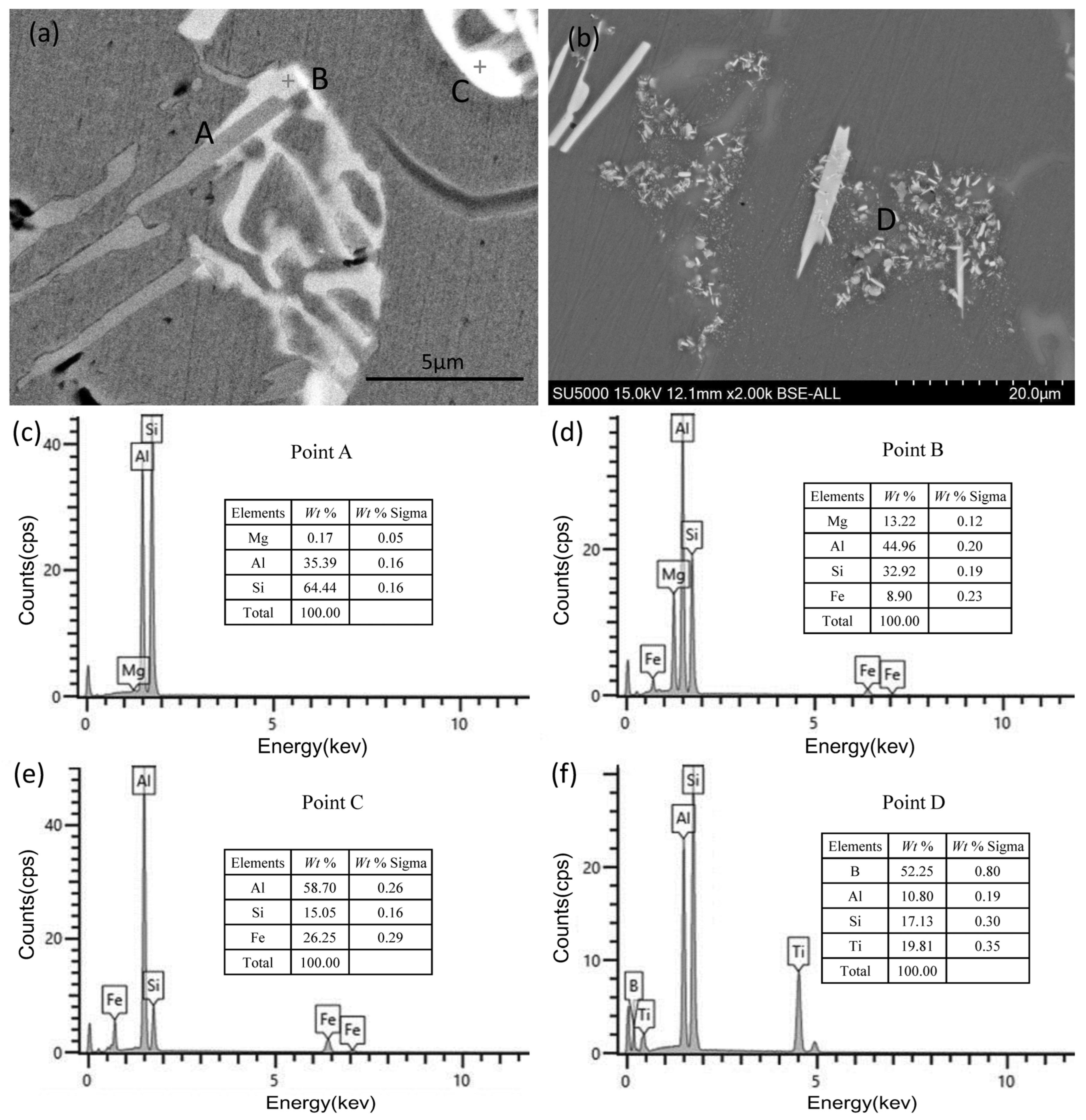

3.2. BSE Imaging and EDS Analysis

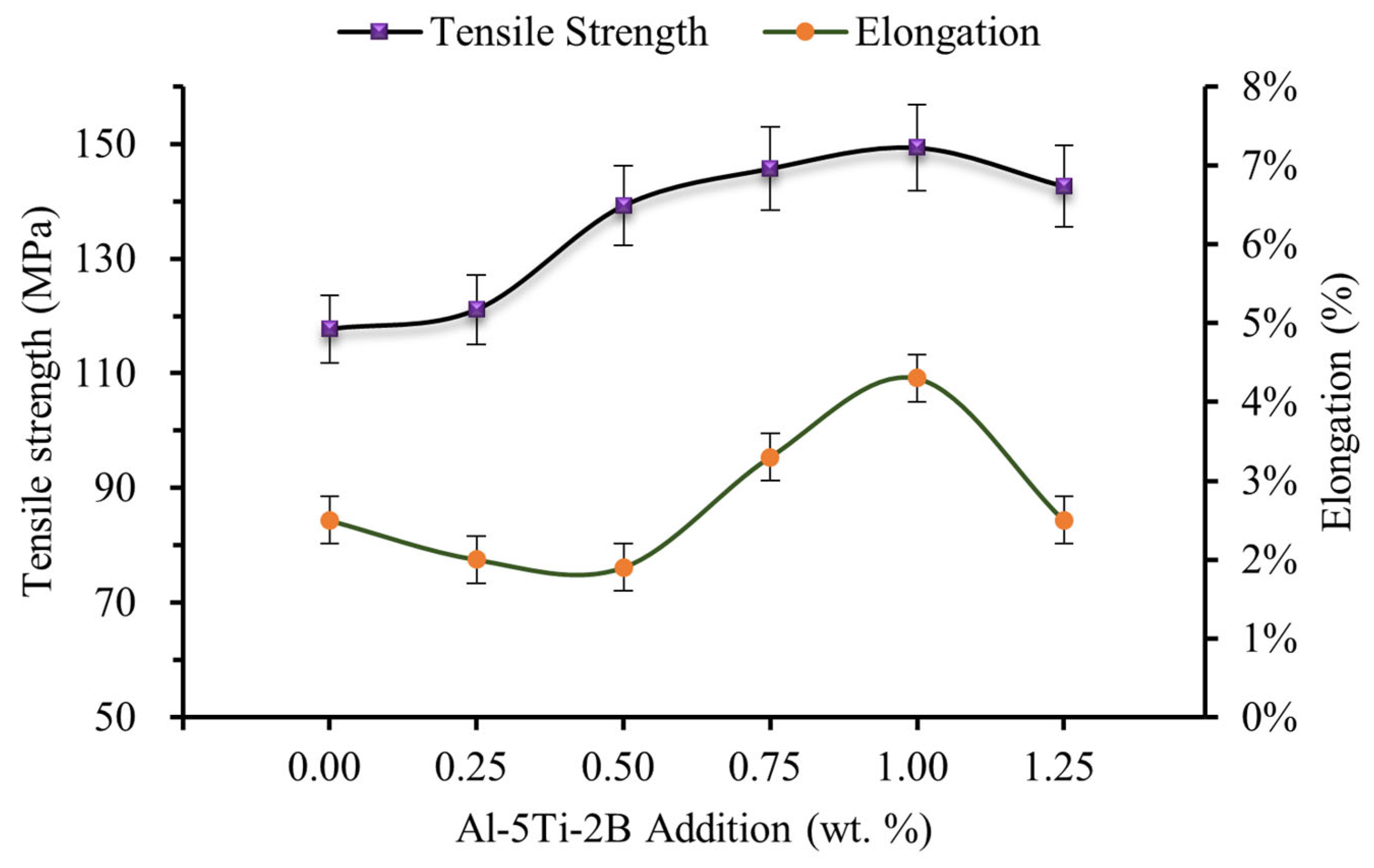

3.3. Tensile Properties Analysis

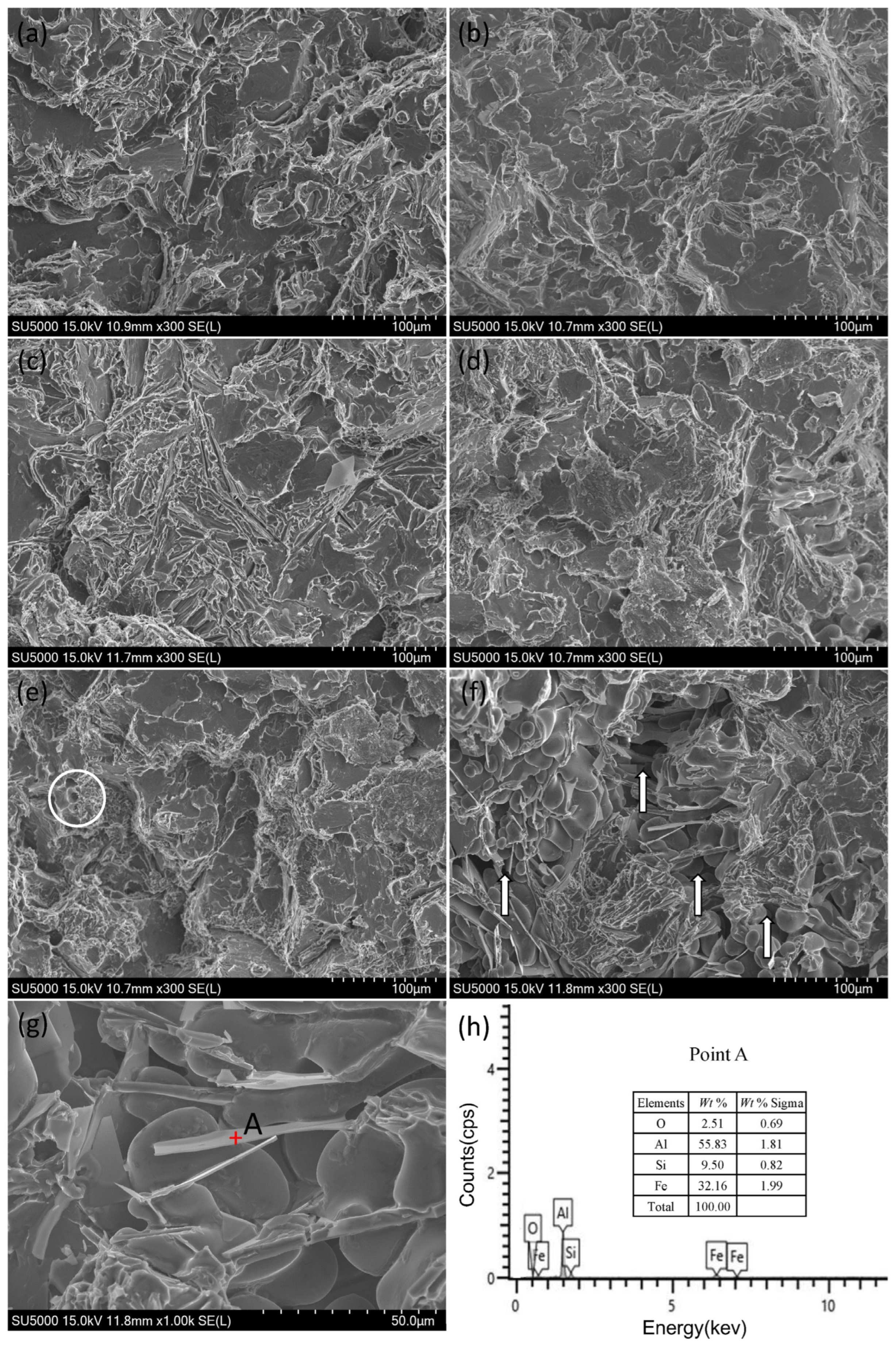

3.4. Fractography Analysis

4. Conclusions

- (1)

- In the recycled Al-7Si-0.3Mg-1Fe alloy, Fe primarily exists in the form of the β-Al5SiFe phase, appearing as coarse needle-like structures distributed around the eutectic Si, with some penetrating the entire Al-Si eutectic structure and disrupting the matrix structure. As the addition of Al-5Ti-2B increases, the α-Al primary phase and eutectic Si in the matrix alloy structure become refined, and the structure tends to homogenize. When the addition of Al-5Ti-2B reaches 1%, the alloy properties reach their optimal state, with the average grain size decreasing to 16.42 μm, tensile strength increasing to 149.4 MPa, and the elongation increasing to 4.3%. When the addition of Al-5Ti-2B continues to increase, the eutectic Si aggregates, the β-Al5SiFe phase coarsens, and micro-porosity appears in the alloy structure, leading to a decline in the alloy’s performance.

- (2)

- Iron (Fe) elements adhere to the eutectic silicon (Si), forming the β-Al5FeSi phase. Magnesium (Mg) enriches at grain boundaries, inhibiting the growth of coarse Fe phases. Simultaneously, Mg reacts with silicon to form Mg2Si, achieving solid solution strengthening and enhancing the alloy’s performance. Al-5Ti-2B serves as a grain refiner, with its effectiveness primarily dependent on TiB2 and Al3Ti, which act as nuclei for the heterogeneous nucleation of α-Al. When the addition of Al-5Ti-2B is 1%, the refinement effect on the primary α-Al phase and eutectic Si in the matrix structure is significant, but its effect on altering the morphology of the β-Al5FeSi phase is not prominent. However, after the matrix structure is refined, it inhibits the growth and distribution of the β-Al5FeSi phase, thereby mitigating the adverse effects of the β-Al5FeSi phase on the matrix alloy. When the addition of Al-5Ti-2B increases to 1.25%, eutectic Si aggregates, and the β-Al5FeSi phase regrows into coarse needle-like structures, severely impairing the alloy’s mechanical properties. Additionally, iron-rich intermetallic compounds may serve as nucleation sites for pores, increasing the porosity and leading to casting defects. Therefore, when improving the properties of iron-rich regenerated Al-Si-Mg alloys through the refinement effect of Al-5Ti-2B, the optimal addition amount is 1%.

- (3)

- Based on the relevant literature and experimental results, it is known that due to the difference in thermal expansion coefficients at the interface between the β-Al5FeSi phase and the matrix, microcracks are prone to form. Under external force, these microcracks propagate rapidly along the interface between the β-Al5FeSi phase and the α-Al matrix. Meanwhile, unmodified eutectic Si particles act as obstacles during crack propagation, causing crack deflection and branching, which severely impair the mechanical properties of the alloy. The presence of Fe elements affects the distribution of eutectic Si, thereby reducing the alloy’s casting performance. In tensile tests, the fracture surface shows no obvious yield or necking phenomena, with brittle fracture being the primary mode of failure.

5. Outlook

- (1)

- Interfacial Behavior of TiB2/Al and Fe Segregation Mechanisms

- (i)

- In situ TEM characterization of Fe segregation kinetics at TiB2/Al interfaces, particularly focusing on the atomic-scale interaction between Fe and the (0001)TiB2 nucleation substrate;

- (ii)

- Quantitative assessment of nucleation potency deterioration through interfacial energy measurements (e.g., AFM-based nanomechanical testing), establishing a predictive model correlating Fe concentration with undercooling requirements.

- (2)

- Rare-Earth-Enhanced Impurity Tolerance in Recycled Al-Si-Mg Alloys

- (i)

- The synergistic effects of Ce/La multi-component additions could mitigate Si poisoning by competitively binding with Ti (as verified by ab initio MD simulations of Ti-Si-RE cluster stability);

- (ii)

- Advanced correlative microscopy (combining APT for nanoscale Mg mapping and synchrotron μ-XRD for phase identification) is essential to quantify Mg partitioning behavior in Fe-containing systems;

- (iii)

- Phase-field modeling incorporating experimental inputs from high-throughput XRD-EBSD could elucidate the stabilization mechanism of α-Al(Fe,Mn)Si phases during solidification.

- (3)

- Thermomechanical Processing Optimization

- (i)

- The critical strain threshold for Fe-intermetallic fragmentation during multi-pass rolling, which could be determined through high-temperature EBSD coupled with crystal plasticity finite element modeling (CPFEM);

- (ii)

- The role of stored energy distribution (characterized by 3D-EBSD and TEM dislocation analyses) in governing precipitation kinetics during post-deformation aging.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Taylor, J.A. Iron-Containing Intermetallic Phases in Al-Si Based Casting Alloys. Procedia Mater. Sci. 2012, 1, 19–33. [Google Scholar] [CrossRef]

- Chen, Z.H.; Xu, C.; Hu, X.L.; Liu, Z.G.; Yamagata, H.; Ma, C.L. Effect of Iron-Rich Intermetallic and Eutectic Si Accumulation on Al-Si-Mg Alloy. Mater. Sci. Forum 2016, 848, 633–641. [Google Scholar] [CrossRef]

- Bacaicoa, I.; Luetje, M.; Wicke, M.; Geisert, A.; Zeismann, F.; Fehlbier, M.; Brueckner-Foit, A. 3D Morphology of Al5FeSi Inclusions in High Fe-Content Al-Si-Cu Alloys. Procedia Struct. Integr. 2016, 2, 2269–2276. [Google Scholar] [CrossRef]

- Ma, Z.; Samuel, A.M.; Doty, H.W.; Valtierra, S.; Samuel, F.H. Effect of Fe Content on the Fracture Behaviour of Al–Si–Cu Cast Alloys. Mater. Amp. Des. 2014, 57, 366–373. [Google Scholar] [CrossRef]

- Liu, B.; Ma, C.; Li, L.; Yang, C.; Yu, N.; Wang, W.; Gao, T. Morphologies and Compositions of α–Al15Fe3Si2-Type Intermetallics in Al–Si–Fe–Mn–Cr Alloys. Int. J. Met. 2022, 17, 1156–1164. [Google Scholar] [CrossRef]

- Hou, L.G.; Cai, Y.H.; Cui, H.; Zhang, J.S. Microstructure Modification and Related Mechanism of Spray-formed Fe-bearing Hypereutectic Al-Si Alloys. Mater. Und Werkst. 2010, 41, 613–619. [Google Scholar] [CrossRef]

- Kakitani, R.; Rodrigues, A.V.; Silva, C.; Garcia, A.; Cheung, N. The Roles of Solidification Cooling Rate and (Mn,Cr) Alloying Elements in the Modification of β-AlFeSi and Hardness Evolvements in near-Eutectic Al-Si Alloys. J. Alloys Metall. Syst. 2023, 1, 100005. [Google Scholar] [CrossRef]

- Li, C.; Liu, F.; Yu, F.; Qiao, H.; Zheng, D.; Le, Q. The Growth Mechanism and Morphology Evolution of Primary Si during Slow Cooling Solidification of High Purity Al–15Si Alloy with Cr Additions. J. Mater. Res. Technol. 2023, 23, 1204–1213. [Google Scholar] [CrossRef]

- Rajabi, M.; Vahidi, M.; Simchi, A.; Davami, P. Microstructural Evolution of Al-20Si-5Fe Alloy during Rapid Solidification and Hot Consolidation. Rare Met. 2009, 28, 639–645. [Google Scholar] [CrossRef]

- Haque, M.M.; Ismail, A.F. Effect of Superheating Temperatures on Microstructure and Properties of Strontium Modified Aluminium–Silicon Eutectic Alloy. J. Mater. Process. Technol. 2005, 162–163, 312–316. [Google Scholar] [CrossRef]

- Luo, L.; Tang, Y.; Liang, X.; Su, Y.; Zhang, Y.; Xie, H. Optimizing the Morphology and Solidification Behavior of Fe-Rich Phases in Eutectic Al-Si-Based Alloys with Different Fe Contents by Adding Mn Elements. Materials 2024, 17, 4104. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.J.; Muggerud, A.M.F.; Olsen, A.; Furu, T. Precipitation of Partially Coherent α-Al(Mn,Fe)Si Dispersoids and Their Strengthening Effect in AA 3003 Alloy. Acta Mater. 2012, 60, 1004–1014. [Google Scholar] [CrossRef]

- Zhu, X.; Ji, S. The Formation of Al6 (Fe, Mn) Phase in Die-Cast Al-Mg Alloys. IOP Conf. Ser. Mater. Sci. Eng. 2019, 529, 012011. [Google Scholar] [CrossRef]

- Shen, X.; Liu, S.; Wang, X.; Cui, C.; Gong, P.; Zhao, L.; Han, X.; Li, Z. Effect of Cooling Rate on the Microstructure Evolution and Mechanical Properties of Iron-Rich Al–Si Alloy. Materials 2022, 15, 411. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Tang, P.; Lu, J. Unveiling the Refinement Effect of the Coarse Fe-Rich Phase in Al-Si-Fe Alloy under Controlled Diffusion Solidification Treatments. J. Mater. Eng. Perform. 2024, 34, 9759–9771. [Google Scholar] [CrossRef]

- Modalavalasa, K.; Namburi, G.M.K.; Battula, S.R.S.S.; Hasan, M.; Koppula, N.R.; Ramavajjala, A.K.; Rajulapati, K.V.; Rao, A.K.P. Investigation of the Microstructure and Dry-Sliding Wear Behavior of Co Containing Al-Si-Fe Scrap Alloy. Tribol. Trans. 2024, 67, 765–774. [Google Scholar] [CrossRef]

- Gencalp Irizalp, S.; Saklakoglu, N. Effect of Fe-Rich Intermetallics on the Microstructure and Mechanical Properties of Thixoformed A380 Aluminum Alloy. Eng. Sci. Technol. Int. J. 2014, 17, 58–62. [Google Scholar] [CrossRef]

- Lin, C.-W.; Hung, F.-Y.; Lui, T.-S. Microstructure Evolution and Microstructural Characteristics of Al–Mg–Si Aluminum Alloys Fabricated by a Modified Strain-Induced Melting Activation Process. Metals 2017, 8, 3. [Google Scholar] [CrossRef]

- Lin, B.; Li, H.; Xu, R.; Shi, Y.; Xiao, H.; Zhang, W.; Liu, K. Precipitation of Iron-Rich Intermetallics and Mechanical Properties of Al–Si–Mg–Fe Alloys with Al–5Ti–B. Mater. Sci. Technol. 2018, 34, 2145–2152. [Google Scholar] [CrossRef]

- Wang, S.C.; Li, J.L.; Gan, C.L.; Zheng, K. Grain Refinement Mechanism and Effective Nucleation Phase of Al-5Ti-1B Master Alloy. Mater. Sci. Forum 2017, 898, 1231–1235. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, S.; Yang, Q.; Liu, X.; Dong, C.; Liu, L. Refinement Properties and Refinement Mechanism of a New Master Alloy Al-5Ti-1B-1RE Refiner. Coatings 2024, 14, 1485. [Google Scholar] [CrossRef]

- Lin, L.; Zhou, L.; Xie, Y.; Bai, W.; Li, F.; Xie, Y.; Lu, M.; Wang, J. Study on the Effect of Pre-Refinement and Heat Treatment on the Microstructure and Properties of Hypoeutectic Al-Si-Mg Alloy. Materials 2022, 15, 6056. [Google Scholar] [CrossRef] [PubMed]

- Qiu, K.; Wang, R.; Peng, C.; Wang, N.; Cai, Z.; Zhang, C. Effects of Mn and Sn on Microstructure of Al–7Si–Mg Alloy Modified by Sr and Al–5Ti–B. Trans. Nonferrous Met. Soc. China 2015, 25, 3546–3552. [Google Scholar] [CrossRef]

- Chowwanonthapunya, T.; Peeratatsuwan, C. The Influence of Fe on Grain Refinement of Recycled A 356 Alloy Initially Refined by Al-5Ti-1B Master Alloy. Trends Sci. 2022, 20, 6393. [Google Scholar] [CrossRef]

- Song, L.Y.; Liu, H.X.; Nie, S.N.; Yu, B.Y.; Wang, S.C.; Zheng, L.; Li, R.X. Microstructure and Fracture Behavior of Al-Si-Mg Alloy Prepared with Recycled Alloy. Mater. Und Werkst. 2019, 50, 462–470. [Google Scholar] [CrossRef]

- Doroshenko, V.; Shurkin, P.; Sviridova, T.; Fortuna, A.; Shkaley, I. Phase Composition and Microstructure of Cast Al-6%Mg-2%Ca-2%Zn Alloy with Fe and Si Additions. Metals 2023, 13, 1584. [Google Scholar] [CrossRef]

- Khan, M.H.; Das, A.; Khan, T.I.; Li, Z.; Kotadia, H.R. Microstructural Modification in an Al-Mg-Si (6082) Alloy with High Fe Content Using Inoculation and/or High-Intensity Ultrasonication. J. Alloys Compd. 2025, 1012, 178500. [Google Scholar] [CrossRef]

- Kim, J.; Kim, D. Effects of Fragmented Fe Intermetallic Compounds on Ductility in Al–Si–Mg Alloys. J. Nanosci. Nanotechnol. 2018, 18, 2137–2139. [Google Scholar] [CrossRef]

- Bogdanoff, T.; Lattanzi, L.; Merlin, M.; Ghassemali, E.; Seifeddine, S. THE Influence of Copper Addition on Crack Initiation and Propagation in an Al–Si–Mg Alloy during Cyclic Testing. Materialia 2020, 12, 100787. [Google Scholar] [CrossRef]

- Elsebaie, O.; Samuel, A.M.; Samuel, F.H.; Doty, H.W. Impact Toughness of Al–Si–Cu–Mg–Fe Cast Alloys: Effects of Minor Additives and Aging Conditions. Mater. Amp. Des. 2014, 60, 496–509. [Google Scholar] [CrossRef]

- Xia, L.; Zheng, J.; Liu, Y.; Song, J.; Jiang, B. The Influence of Heat Treatment on the Heterogenous Structure and Deformation Behavior of a High Pressure Die-Cast Al-10Si-0.5Mn-0.3Mg Alloy. Sci. Sin. Technol. 2025, 55, 617–629. [Google Scholar] [CrossRef]

- Basak, S.; Biswas, P.; Patra, S.; Roy, H.; Mondal, M.K. Effect of TiB2 and Al3Ti on the Microstructure, Mechanical Properties and Fracture Behaviour of near Eutectic Al-12.6Si Alloy. Int. J. Miner. Metall. Mater. 2021, 28, 1174–1185. [Google Scholar] [CrossRef]

- Liu, Y.; Wu, C.; Tu, H.; Lu, X.; Wang, J.; Su, X. Microstructure and Mechanical Properties of Al-10Si Alloy Modified with Al-5Ti. China Foundry 2018, 15, 405–410. [Google Scholar] [CrossRef]

| Specimen ID | Al-5Ti-2B Additions (wt.%) |

|---|---|

| 1 | 0 |

| 2 | 0.25% |

| 3 | 0.5% |

| 4 | 0.75% |

| 5 | 1% |

| 6 | 1.25% |

| Specimen Number | Tensile Strength (MPa) | Elongation (%) |

|---|---|---|

| 1 | 117.7 | 2.5 |

| 2 | 121.1 | 2.0 |

| 3 | 139.2 | 1.9 |

| 4 | 145.7 | 3.3 |

| 5 | 149.4 | 4.3 |

| 6 | 142.6 | 2.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, W.; Chen, L.; He, B.; Lu, B.; Yang, J. Effect of Al-5Ti-2B on the Microstructure and Mechanical Properties of Recycled Al-7Si-0.3Mg-1Fe Alloy. Crystals 2025, 15, 584. https://doi.org/10.3390/cryst15070584

Shi W, Chen L, He B, Lu B, Yang J. Effect of Al-5Ti-2B on the Microstructure and Mechanical Properties of Recycled Al-7Si-0.3Mg-1Fe Alloy. Crystals. 2025; 15(7):584. https://doi.org/10.3390/cryst15070584

Chicago/Turabian StyleShi, Weihe, Lin Chen, Bing He, Biwang Lu, and Jianbing Yang. 2025. "Effect of Al-5Ti-2B on the Microstructure and Mechanical Properties of Recycled Al-7Si-0.3Mg-1Fe Alloy" Crystals 15, no. 7: 584. https://doi.org/10.3390/cryst15070584

APA StyleShi, W., Chen, L., He, B., Lu, B., & Yang, J. (2025). Effect of Al-5Ti-2B on the Microstructure and Mechanical Properties of Recycled Al-7Si-0.3Mg-1Fe Alloy. Crystals, 15(7), 584. https://doi.org/10.3390/cryst15070584