Grain Size Engineering and Tuning of Magnetic Properties in Ultra-Thin NiMnGa Glass-Coated Microwires: Insights from Annealing Effects

Abstract

1. Introduction

2. Materials and Methods

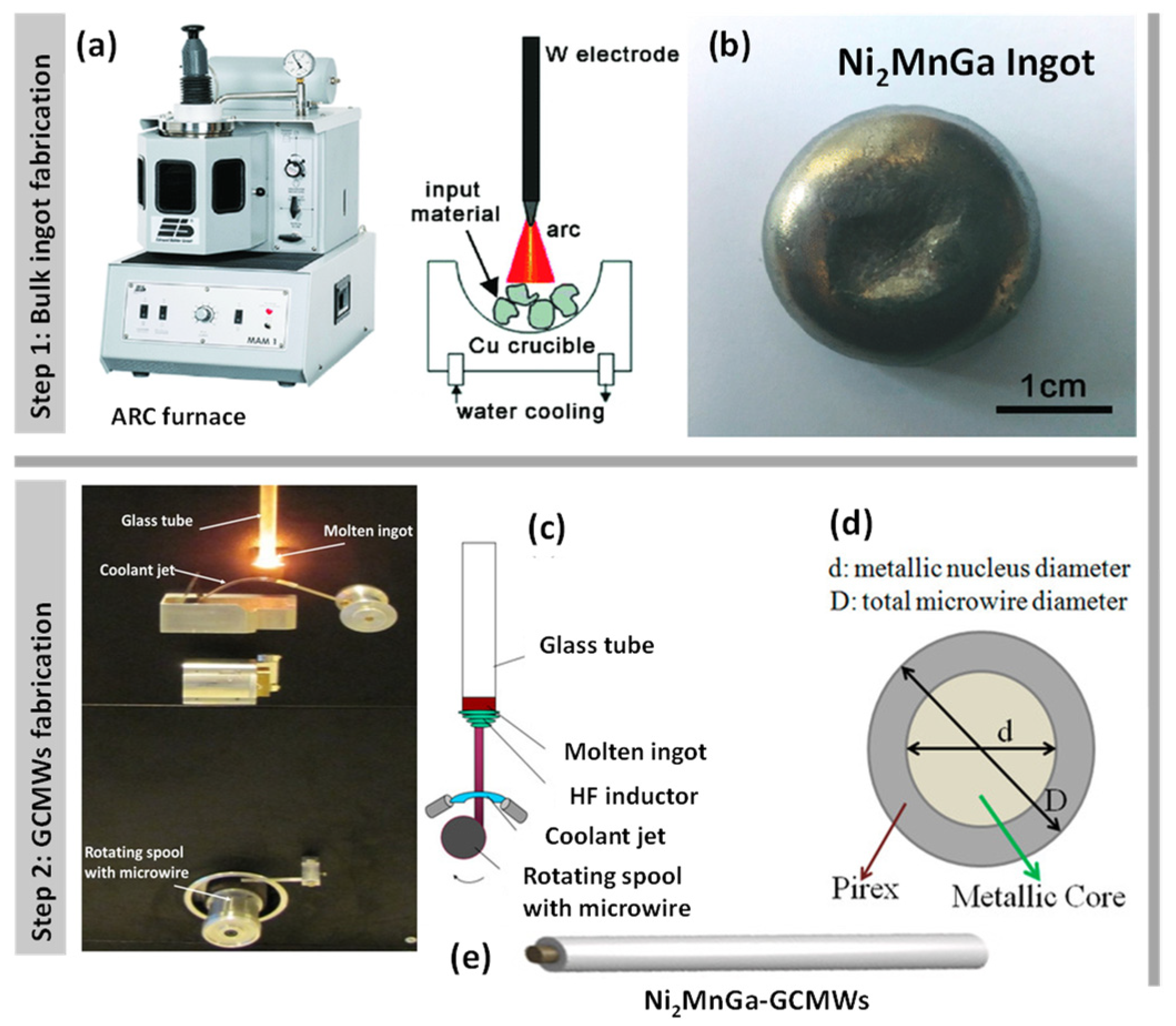

2.1. Fabrication of Bulk NiMnGa Form

2.2. Preparation of NiMnGa Glass-Coated Microwires

2.3. Structural and Magnetic Characterization Methods

- Zero-field cooling (ZFC): The sample was cooled from 400 K (paramagnetic regime) in the absence of an applied field.

- Field-cooled (FC) measurement: Upon reaching 5 K, a static magnetic field of 50 Oe was applied, and magnetization data were acquired during subsequent heating to 350 K.

- Field-heated (FH) measurement: Maintaining the applied field, data collection continued during cooling and the subsequent reheating cycles.

3. Results

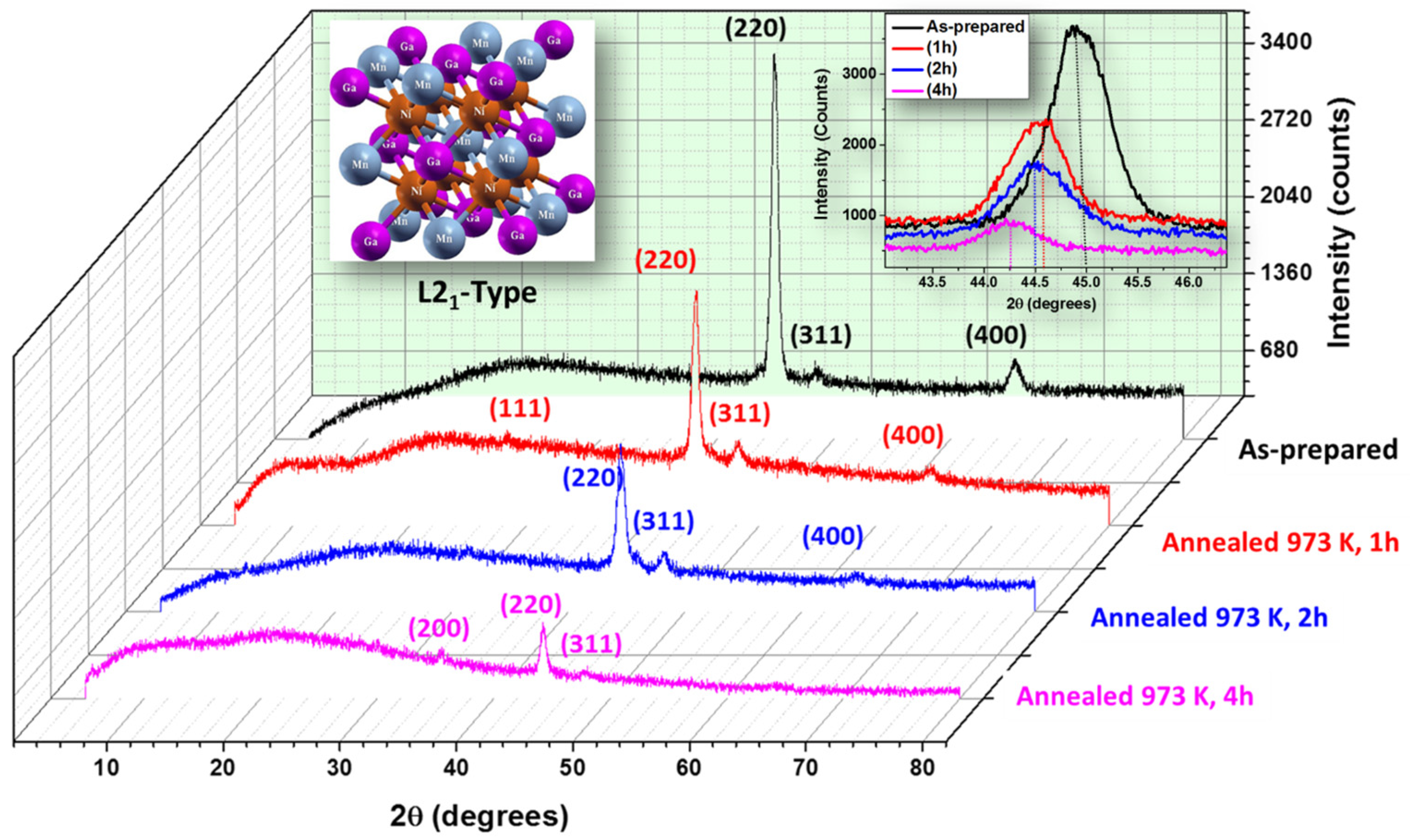

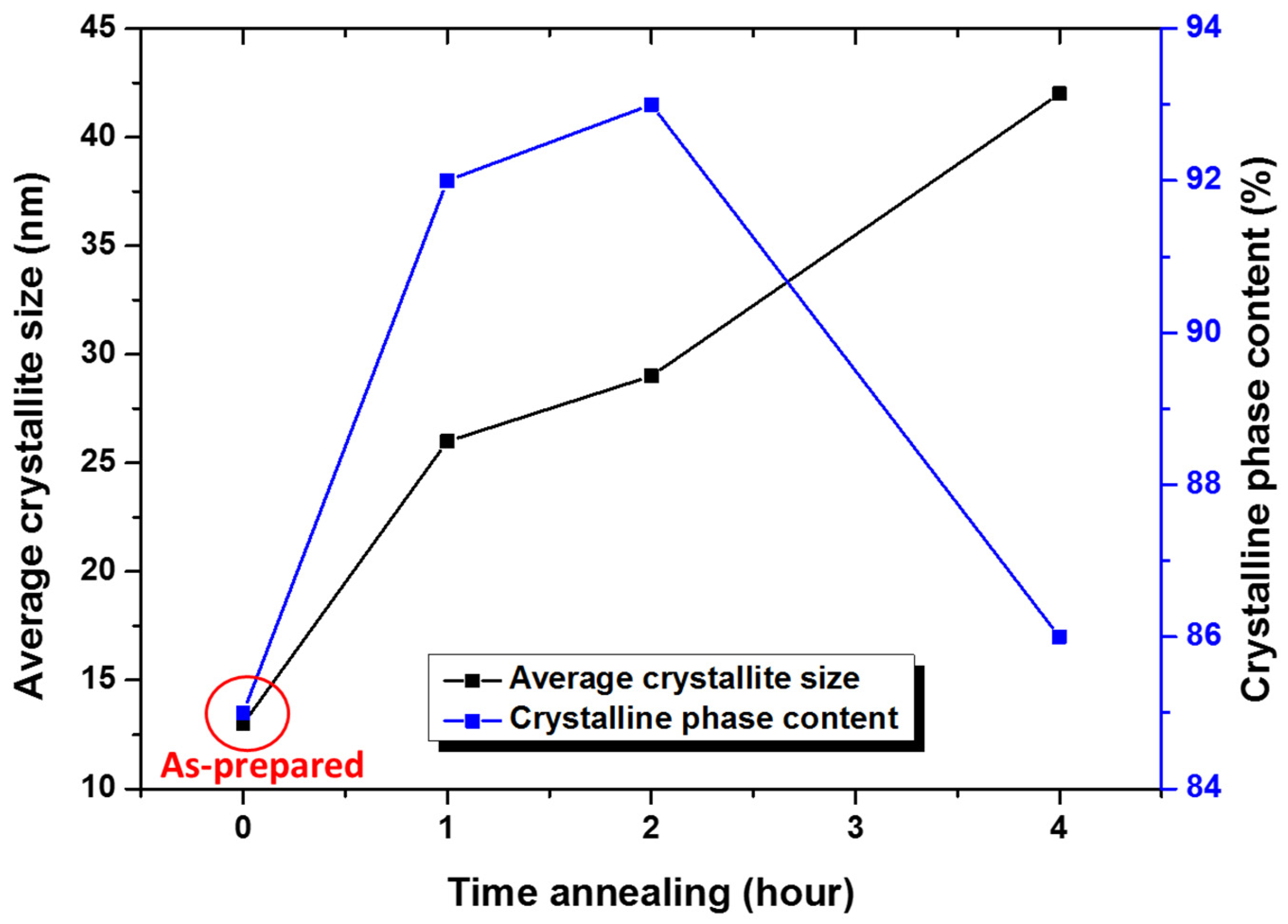

3.1. Structure Characterizations

3.2. Magnetic Properties and Martensitic Transformation Behavior

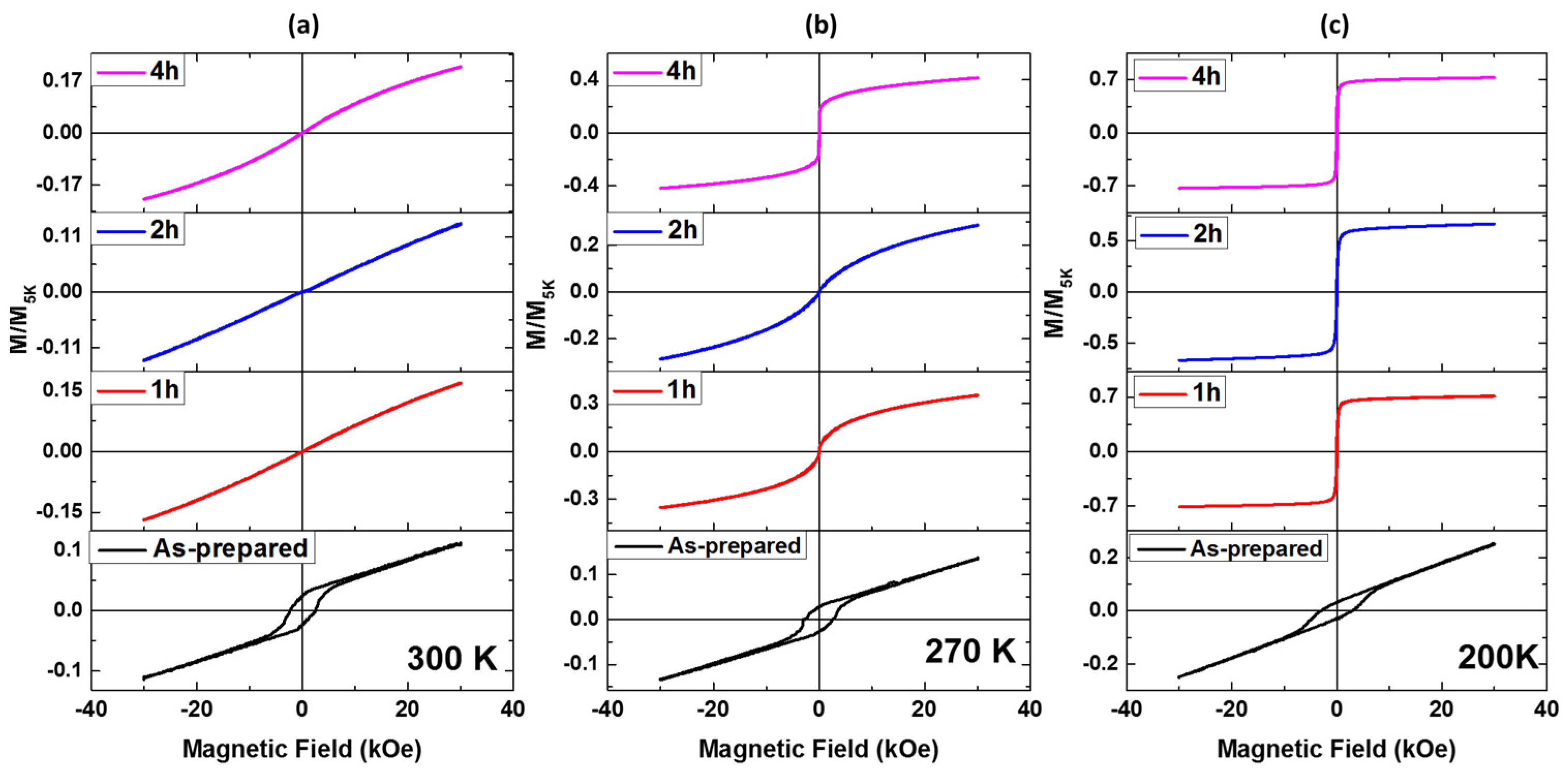

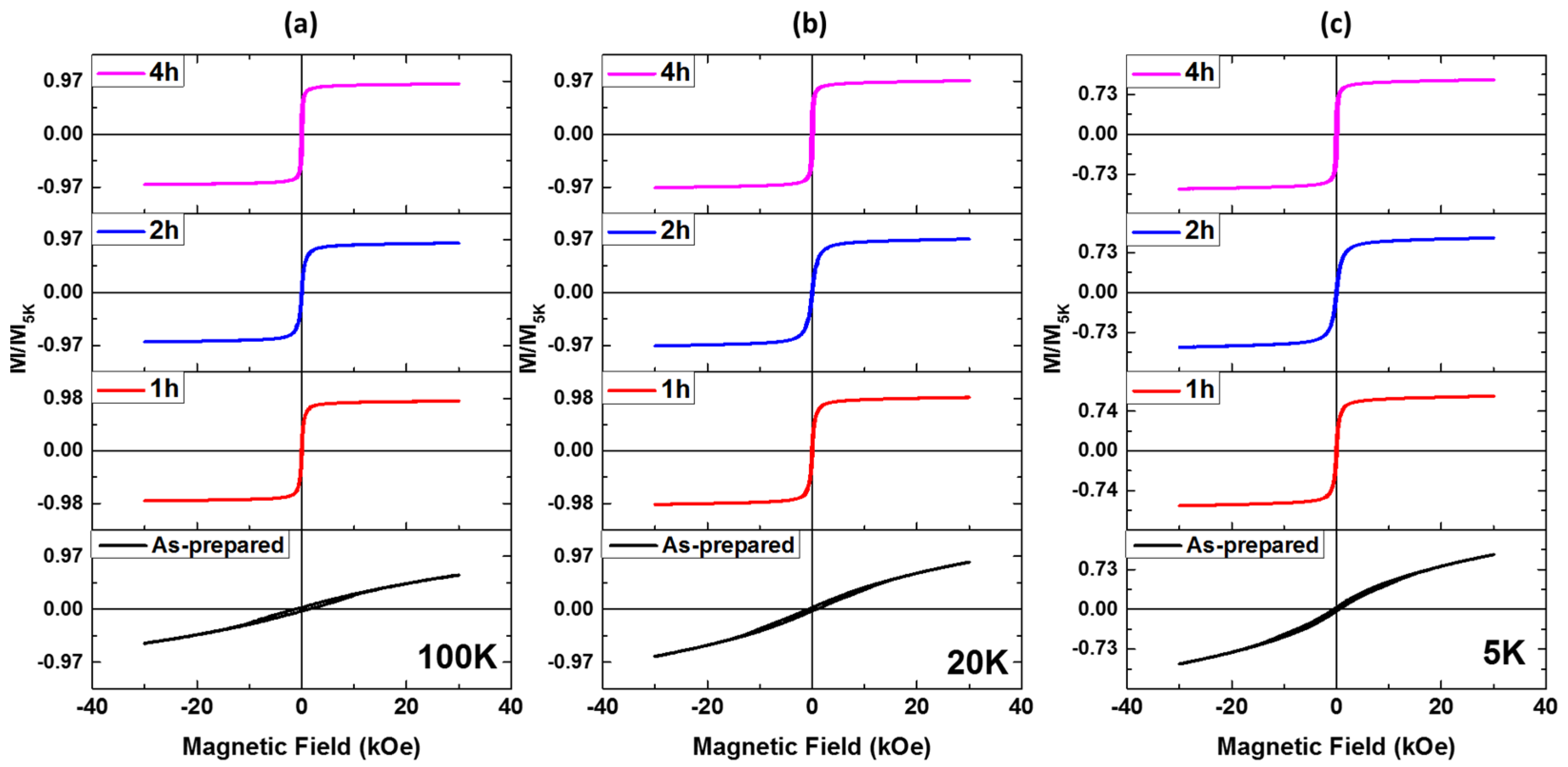

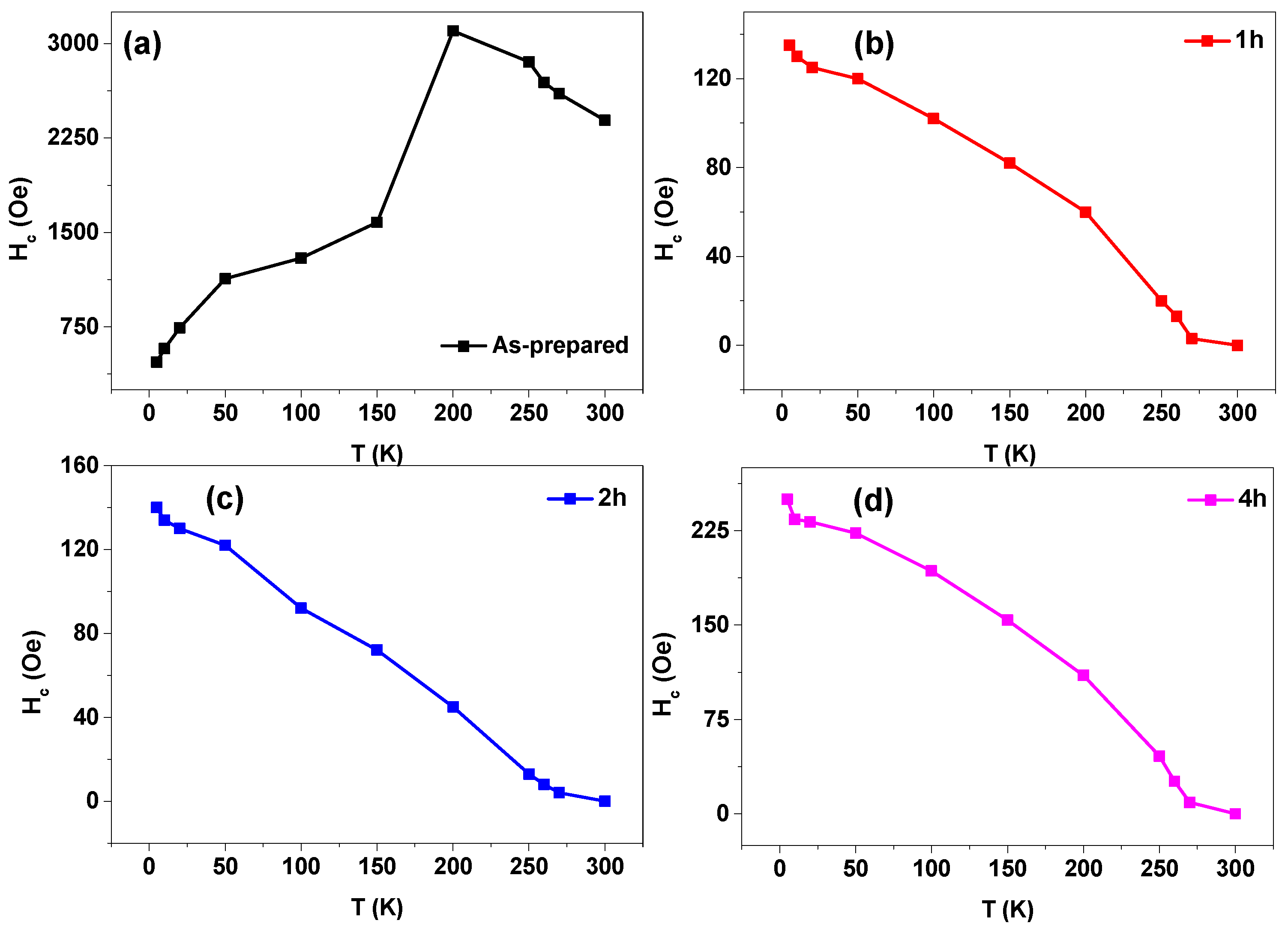

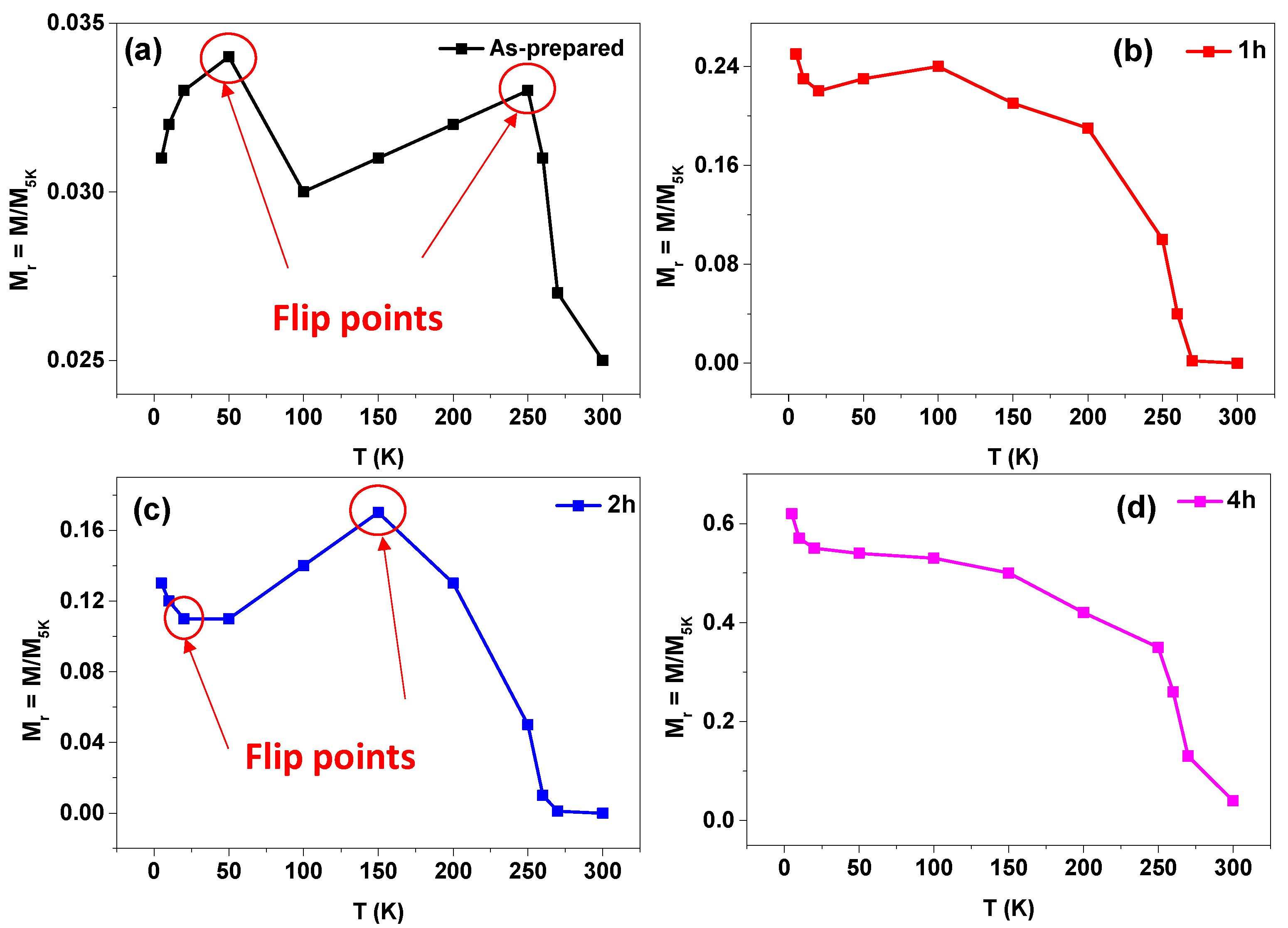

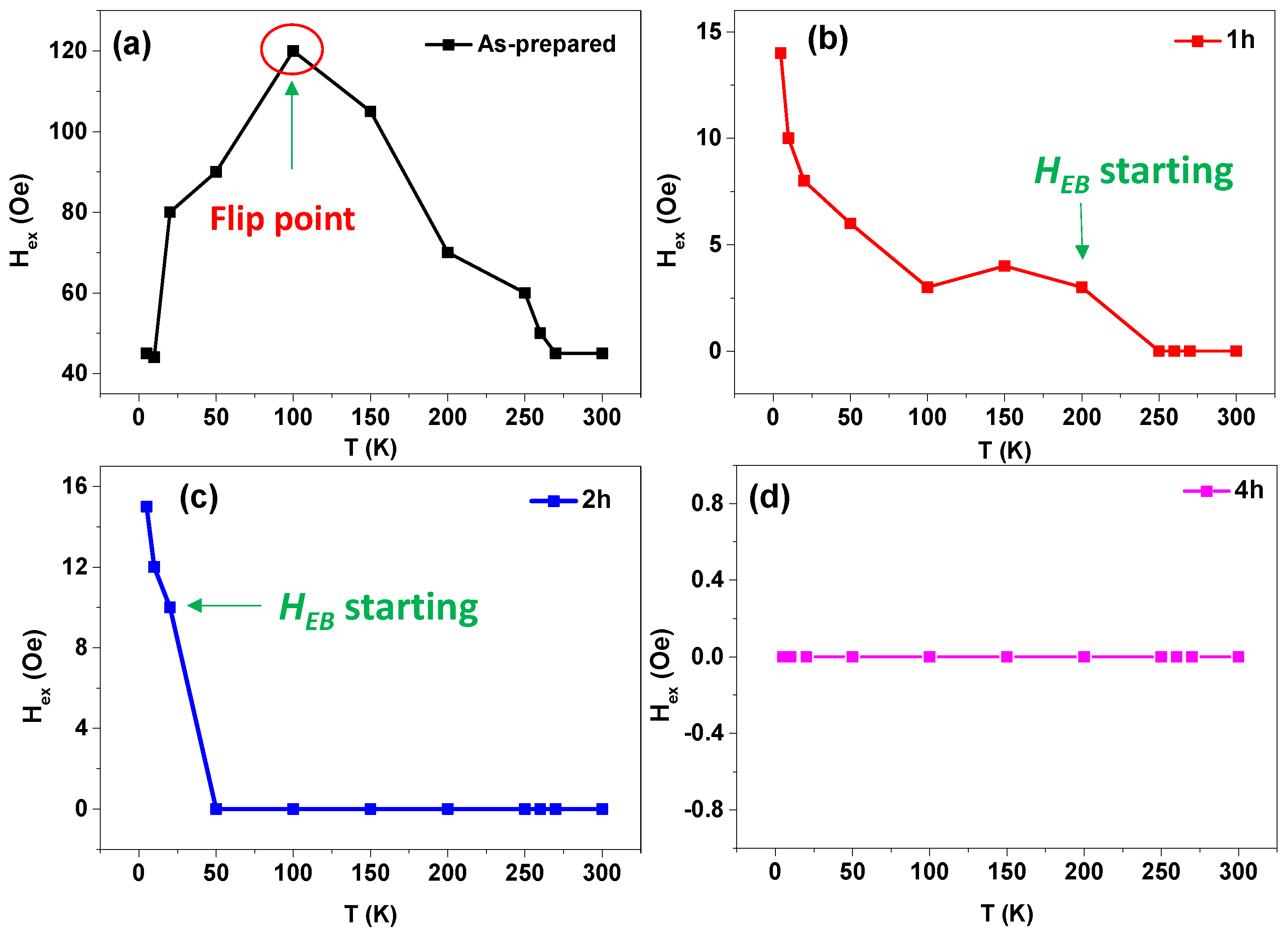

3.3. Hysteresis Loops

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Moya, X.; Kar-Narayan, S.; Mathur, N.D. Caloric materials near ferroic phase transitions. Nat. Mater. 2014, 13, 439–450. [Google Scholar] [CrossRef] [PubMed]

- Manosa, L.; Planes, A. Materials with giant mechanocaloric effects: Cooling by strength. Adv. Mater. 2017, 29, 1603607. [Google Scholar] [CrossRef]

- Tavares, S.; Yang, K.; Meyers, M.A. Heusler alloys: Past, properties, new alloys, and prospects. Prog. Mater. Sci. 2023, 132, 101017. [Google Scholar] [CrossRef]

- Guillou, F.; Porcari, G.; Yibole, H.; van Dijk, N.; Bruck, E. Taming the first-order transition in giant magnetocaloric materials. Adv. Mater. 2014, 26, 2671–2675. [Google Scholar] [CrossRef]

- Li, D.; Li, Z.; Yang, J.; Li, Z.; Yang, B.; Yan, H.; Wang, D.; Hou, L.; Li, X.; Zhang, Y.; et al. Large elastocaloric effect driven by stress-induced two-step structural transformation in a directionally solidified Ni55Mn18Ga27 alloy. Scr. Mater. 2019, 163, 116–120. [Google Scholar] [CrossRef]

- Bonnot, E.; Romero, R.; Manosa, L.; Vives, E.; Planes, A. Elastocaloric effect associated with the martensitic transition in shape-memory alloys. Phys. Rev. Lett. 2008, 100, 125901. [Google Scholar] [CrossRef] [PubMed]

- Zhukova, V.; Aliev, A.M.; Varga, R.; Aronin, A.; Abrosimova, G.; Kiselev, A.; Zhukov, A. Magnetic Properties and MCE in Heusler-Type Glass-Coated Microwires. J. Supercond. Novel Magn. 2013, 26, 1415–1419. [Google Scholar] [CrossRef]

- Tang, X.; Feng, Y.; Wang, H.; Wang, P. Enhanced elastocaloric effect and cycle stability in B and Cu co-doping Ni-Mn-In polycrystals. Appl. Phys. Lett. 2019, 114, 033901. [Google Scholar] [CrossRef]

- Salaheldeen, M.; Zhukova, V.; Gonzalez, J.; Zhukov, A. Anomalous magnetic behavior in MnFePSi glass-coated microwires. J. Alloys Compd. 2024, 1002, 175244. [Google Scholar] [CrossRef]

- Neese, B.; Chu, B.; Lu, S.G.; Wang, Y.; Furman, E.; Zhang, Q.M. Large electrocaloric effect in ferroelectric polymers near room temperature. Science 2008, 321, 821–823. [Google Scholar] [CrossRef]

- Liu, J.; Gottschall, T.; Skokov, K.P.; Moore, J.D.; Gutfleisch, O. Giant magnetocaloric effect driven by structural transitions. Nat. Mater. 2012, 11, 620–626. [Google Scholar] [CrossRef] [PubMed]

- Chernenko, V.A.; Besseghini, S.; Hagler, M.; Mullner, P.; Ohtsuka, M.; Stortiero, F. Properties of sputter-deposited Ni-Mn-Ga thin films. Mater. Sci. Eng. A 2008, 481–482, 271–274. [Google Scholar] [CrossRef]

- Ma, S.; Zhang, X.; Zheng, G.; Qian, M.; Geng, L. Toughening of Ni-Mn-Based Polycrystalline Ferromagnetic Shape Memory Alloys. Materials 2023, 16, 5725. [Google Scholar] [CrossRef]

- Cong, D.Y.; Huang, L.; Hardy, V.; Bourgault, D.; Sun, X.M.; Nie, Z.H.; Wang, M.G.; Ren, Y.; Entel, P.; Wang, Y.D. Low-field-actuated giant magnetocaloric effect and excellent mechanical properties in a NiMn-based multiferroic alloy. Acta Mater. 2018, 146, 142–151. [Google Scholar] [CrossRef]

- Hirohata, A.; Sagar, J.; Lari, L.; Fleet, L.R.; Lazarov, V.K. Heusler-alloy films for spintronic devices. Appl. Phys. A 2013, 111, 423–430. [Google Scholar] [CrossRef]

- Wojcik, A.; Chulist, R.; Czaja, P.; Kowalczyk, M.; Zackiewicz, P.; Schell, N.; Maziarz, W. Evolution of microstructure and crystallographic texture of Ni-Mn-Ga melt-spun ribbons exhibiting 1.15% magnetic field-induced strain. Acta Mater. 2021, 219, 117237. [Google Scholar] [CrossRef]

- Wu, Y.F.; Xuan, H.C.; Agarwal, S.; Xu, Y.K.; Zhang, T.; Feng, L.; Li, H.; Han, P.D.; Zhang, C.L.; Wang, D.; et al. Large magnetocaloric effect and magnetoresistance in Fe and Co co-doped Ni-Mn-Al Heusler alloys. Phys. Status Solidi A. 2018, 215, 1700843. [Google Scholar] [CrossRef]

- Franco, V.; Blázquez, J.S.; Ipus, J.J.; Law, J.Y.; Moreno-Ramírez, L.M.; Conde, A. Magnetocaloric effect: From materials research to refrigeration devices. Prog. Mater. Sci. 2018, 93, 112–232. [Google Scholar]

- Salaheldeen, M.; Zhukova, V.; Lopez Anton, R.; Zhukov, A. Dependence of Magnetic Properties of As-Prepared Nanocrystalline Ni2MnGa Glass-Coated Microwires on the Geometrical Aspect Ratio. Sensors 2024, 24, 3692. [Google Scholar] [CrossRef]

- Graf, T.; Parkin, S.S.P.; Felser, C. Heusler Compounds—A Material Class With Exceptional Properties. IEEE Tran. Magn. 2011, 47, 367–373. [Google Scholar] [CrossRef]

- Otsuka, K.; Wayman, C.M. Shape Memory Materials; Cambridge University Press: Cambridge, UK, 1999. [Google Scholar]

- Pushin, V.G. Alloys with a Termomechanical Memory: Structure, properties and application. Phys. Met. Metallogr. 2000, 90 (Suppl. S1), S68–S95. [Google Scholar]

- Cesare, E.; Pons, J.; Santamarta, R.; Segui, C.; Chernenko, V.A. Ferromagnetic Shape Memory Alloys: An Overview. Arch. Metall. Mater. 2004, 49, 779–789. [Google Scholar]

- Ilyn, M.I.; Zhukova, V.; Santos, J.D.; Sánchez, M.L.; Prida, V.M.; Hernando, B.; Larin, V.; González, J.; Tishin, A.M.; Zhukov, A. Magnetocaloric effect in nanogranular glass coated microwires. Phys. Stat. Sol. 2008, 205, 1378–1381. [Google Scholar] [CrossRef]

- Otsuka, K.; Ren, X. Physical Metallurgy of Ti-Ni-based Shape Memory Alloys. Prog. Mater. C. 2005, 50, 511–678. [Google Scholar] [CrossRef]

- Wilson, J.; Weselowsky, M. Shape Memory Alloys for Seismic Response Modification: A State-of-the-Art Review. Earthq. Spectra. 2005, 21, 569–601. [Google Scholar] [CrossRef]

- Dong, J.; Cai, C.; Okeil, A. Overview of Potential and Existing Applications of Shape Memory Alloys in Bridges. J. Bridg. Eng. 2011, 16, 305–315. [Google Scholar] [CrossRef]

- Lobodyuk, V.A.; Koval’, Y.N.; Pushin, V.G. Crystal-Structural Features of Pretransition Phenomena and Thermoelastic Martensitic Transformations in Alloys of Nonferrous Metals. Phys. Met. Metallogr. 2011, 111, 165–189. [Google Scholar] [CrossRef]

- Gomes, A.M.; Khan, M.; Stadler, S.; Ali, N.; Dubenko, I.; Takeuchi, A.Y.; Guimaraes, A.P. Magnetocaloric Properties of the Ni2Mn1−x(Cu, Co)xGa Heusler Alloys. J. Appl. Phys. 2006, 99, 08Q106. [Google Scholar] [CrossRef]

- Salaheldeen, M.; Wederni, A.; Ipatov, M.; Zhukova, V.; Zhukov, A. Preparation and Magneto-Structural Investigation of High Ordered (L21 Structure) Co2MnGe Microwires. Processes 2023, 11, 1138. [Google Scholar] [CrossRef]

- Cong, D.Y.; Xiong, W.X.; Planes, A.; Ren, Y.; Mañosa, L.; Cao, P.Y.; Nie, Z.H.; Sun, X.M.; Yang, Z.; Hong, X.F.; et al. Colossal elastocaloric effect in ferroelastic Ni-Mn-Ti alloys. Phys. Rev. Lett. 2019, 122, 255703. [Google Scholar] [CrossRef]

- Callaway, J.D.; Hamilton, R.F.; Sehitoglu, H.; Miller, N.; Maier, H.J.; Chumlyakov, Y. Shape Memory and Martensite Deformation Response of Ni2MnGa. Smart Mater. Struct. 2007, 16, S108–S114. [Google Scholar] [CrossRef]

- Pons, J.; Cesari, E.; Seguí, C.; Masdeu, F.; Santamarta, R. Ferromagnetic Shape Memory Alloys: Alternatives to Ni-Mn-Ga. Mater. Sci. Eng. A 2008, 481–482, 57–65. [Google Scholar] [CrossRef]

- de Paula, V.G.; Reis, M.S. All-d-metal full Heusler alloys: A novel class of functional materials. Chem. Mater. 2021, 33, 5483–5495. [Google Scholar] [CrossRef]

- Wei, Z.Y.; Liu, E.K.; Chen, J.H.; Li, Y.; Liu, G.D.; Luo, H.Z.; Xi, X.K.; Zhang, H.W.; Wang, W.H.; Wu, G.H. Realization of multifunctional shape-memory ferromagnets in all-d-metal Heusler phases. Appl. Phys. Lett. 2015, 107, 022406. [Google Scholar] [CrossRef]

- Bachagha, T.; Suñol, J. All-d-Metal Heusler Alloys: A Review. Metals 2023, 13, 111. [Google Scholar] [CrossRef]

- Zhang, Y.; Hughes, R.A.; Britten, J.F.; Dube, P.A.; Preston, J.S.; Botton, G.A.; Niewczas, M. Magnetocaloric effect in Ni-Mn-Ga thin films under concurrent magnetostructural and curie transitions. J. Appl. Phys. 2011, 110, 013910. [Google Scholar] [CrossRef]

- Li, Z.B.; Sánchez Llamazares, J.L.; Sánchez-Valdés, C.F.; Zhang, Y.D.; Esling, C.; Zhao, X.; Zuo, L. Microstructure and magnetocaloric effect of melt-spun Ni52Mn26Ga22 ribbon. Appl. Phys. Lett. 2012, 100, 174102. [Google Scholar] [CrossRef]

- Wang, J.; Jiang, C.; Techapiesancharoenkij, R.; Bono, D.; Allen, S.M.; O’Handley, R.C. Microstructure and magnetic properties of melt spinning Ni-Mn-Ga. Intermetallics 2013, 32, 151–155. [Google Scholar] [CrossRef]

- Zhukov, A.; Garcia, C.; Ilyn, M.; Varga, R.; del Val, J.J.; Granovsky, A.; Rodionova, V.; Ipatov, M.; Zhukova, V. Magnetic and transport properties of granular and Heusler-type glass-coated microwires. J. Magn. Magn. Mater. 2012, 324, 3558–3562. [Google Scholar] [CrossRef]

- Qian, M.F.; Zhang, X.X.; Wei, L.S.; Martin, P.; Sun, J.F.; Geng, L.; Scott, T.B.; Peng, H.X. Tunable magnetocaloric effect in Ni-Mn-Ga microwires. Sci. Rep. 2018, 8, 16574. [Google Scholar] [CrossRef]

- Qian, M.F.; Zhang, X.X.; Li, X.; Zhang, R.C.; Martin, P.G.; Sun, J.F.; Geng, L.; Scott, T.B.; Peng, H.X. Magnetocaloric effect in bamboo-grained Ni-Mn-Ga microwires over a wide working temperature interval. Mater. Des. 2020, 190, 108557. [Google Scholar] [CrossRef]

- Zheng, P.; Kucza, N.J.; Patrick, C.L.; Müllner, P.; Dunand, D.C. Mechanical and magnetic behavior of oligocrystalline Ni-Mn-Ga microwires. J. Alloys Compd. 2015, 624, 226–233. [Google Scholar] [CrossRef]

- Salaheldeen, M.; Wederni, A.; Ipatov, M.; Gonzalez, J.; Zhukova, V.; Zhukov, A. Elucidation of the strong effect of the annealing and the magnetic field on the magnetic properties of Ni2-based Heusler microwires. Crystals 2022, 12, 1755. [Google Scholar] [CrossRef]

- Ding, Z.; Zhu, J.; Zhang, X.; Liu, D.; Qi, Q.; Zhang, Y.; Cong, D. 14% recoverable strain in Ni52.87Mn23.82Ga23.32 microwires. J. Appl. Phys. D 2016, 50, 095303. [Google Scholar] [CrossRef]

- Chiriac, H.; Lupu, N.; Stoian, G.; Ababei, G.; Corodeanu, S.; Óvári, T.A. Ultrathin Nanocrystalline Magnetic Wires. Crystals 2017, 7, 48. [Google Scholar] [CrossRef]

- Cobeño, A.F.; Zhukov, A.; de Arellano-Lopez, A.R.; Elías, F.; Blanco, J.M.; Larin, V.; González, J. Physical properties of nearly zero magnetostriction Co-rich glass-coated amorphous microwires. J. Mater. Res. 1999, 14, 3775–3783. [Google Scholar] [CrossRef]

- Zhukov, A.; Gonzalez, J.; Torcunov, A.; Pina, E.; Prieto, M.J.; Cobeño, A.F.; Blanco, J.M.; Larin, V.; Baranov, S. Ferromagnetic resonance and Structure of Fe-based Glass-coated Microwires. J. Magn. Magn. Mater. 1999, 203, 238–240. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, M.; Wang, Y.D.; Lin, J.P.; Dahmen, K.A.; Wang, Z.L.; Liaw, P.K. Superelasticity and serration behavior in small-sized NiMnGa alloys. Adv. Eng. Mater. 2014, 16, 955–960. [Google Scholar] [CrossRef]

- Zhukov, A.; Ipatov, M.; Corte-León, P.; Gonzalez-Legarreta, L.; Blanco, J.M.; Zhukova, V. Soft Magnetic Microwires for Sensor Applications. J. Magn. Magn. Mater. 2020, 498, 166180. [Google Scholar] [CrossRef]

- Chiriac, H.; Ovári, T.A.; Pop, G. Internal stress distribution in glass-covered amorphous magnetic wires. Phys. Rev. B 1995, 52, 10104–10113. [Google Scholar] [CrossRef]

- Zhang, X.X.; Miao, S.P.; Sun, J.F. Magnetocaloric effect in Ni-Mn-In-Co microwires prepared by Taylor-Ulitovsky method. Trans. Nonferrous Met. Soc. China 2014, 24, 3152–3157. [Google Scholar] [CrossRef]

- Zhukov, A.; Ipatov, M.; del Val, J.J.; Taskaev, S.; Churyukanova, M.; Zhukova, V. First-order martensitic transformation in Heusler-type glass-coated microwires. Appl. Phys. Lett. 2017, 111, 242403. [Google Scholar] [CrossRef]

- Zhukov, A.; Ipatov, M.; del Val, J.J.; Corte-León, P.; Gonzalez, J.; Granovsky, A.; Zhukova, V. Effect of annealing on magnetic properties of Ni-Mn-Ga glass-coated microwires. J. Mater. Res. 2018, 33, 2148–2155. [Google Scholar] [CrossRef]

- Ulitovsky, A.V.; Maianski, I.M.; Avramenco, A.I. 1960 Method of Continuous Casting of Glass Coated Microwire. USSR Patent 128427, 6 May 1960. [Google Scholar]

- Zhukov, A.; Corte-Leon, P.; Gonzalez-Legarreta, L.; Ipatov, M.; Blanco, J.M.; Gonzalez, A.; Zhukova, V. Advanced functional magnetic microwires for technological applications. J. Phys. D Appl. Phys. 2022, 55, 253003. [Google Scholar] [CrossRef]

- Salaheldeen, M.; Zhukova, V.; Ipatov, M.; Zhukov, A. Unveiling the Magnetic and Structural Properties of (X2YZ.; X = Co and Ni, Y = Fe and Mn, and Z = Si) Full-Heusler Alloy Microwires with Fixed Geometrical Parameters. Crystals 2023, 13, 1550. [Google Scholar] [CrossRef]

- Baranov, S.A.; Larin, V.S.; Torcunov, A.V. Technology, Preparation and Properties of the Cast Glass-Coated Magnetic Microwires. Crystals 2017, 7, 136. [Google Scholar] [CrossRef]

- Salaheldeen, M.; Wederni, A.; Ipatov, M.; Zhukova, V.; Zhukov, A. Carbon-Doped Co2MnSi Heusler Alloy Microwires with Improved Thermal Characteristics of Magnetization for Multifunctional Applications. Materials 2003, 16, 5333. [Google Scholar] [CrossRef] [PubMed]

- Chernenko, V.A.; Ohtsuka, M.; Kohl, M.; Khovailo, V.V.; Takagi, T. Transformation behavior of Ni-Mn-Ga thin films. Smart Mater. Struct. 2005, 14, S245–S252. [Google Scholar] [CrossRef]

- Zhukov, A.; Ipatov, M.; del Val, J.J.; Zhukova, V.; Chernenko, V.A. Magnetic and structural properties of glass-coated Heusler-type microwires exhibiting martensitic transformation. Sci. Rep. 2018, 8, 621. [Google Scholar] [CrossRef]

- Salaheldeen, M.; Garcia-Gomez, A.; Ipatov, M.; Corte-Leon, P.; Zhukova, V.; Blanco, J.M.; Zhukov, A. Fabrication and Magneto-Structural Properties of Co2-Based Heusler Alloy Glass-Coated Microwires with High Curie Temperature. Chemosensors 2022, 10, 225. [Google Scholar] [CrossRef]

- Salaheldeen, M.; Ipatov, M.; Corte-Leon, P.; Zhukova, V.; Zhukov, A. Effect of Annealing on the Magnetic Properties of Co2MnSi-Based Heusler Alloy Glass-Coated Microwires. Metals 2023, 13, 412. [Google Scholar] [CrossRef]

- Salaheldeen, M.; Wederni, A.; Ipatov, M.; Zhukova, V.; Lopez Anton, R.; Zhukov, A. Enhancing the Squareness and Bi-Phase Magnetic Switching of Co2FeSi Microwires for Sensing Application. Sensors 2023, 23, 5109. [Google Scholar] [CrossRef]

- Cerqueira, M.F.; Stepikhova, M.; Kozanecki, A.; Andrês, G.; Alves, E. Crystal size and crystalline volume fraction effects on the erbium emission of nc-Si:Er grown by r.f. sputtering. J. Nanosci. Nanotechnol. 2010, 10, 2663–2668. [Google Scholar] [CrossRef]

- Salaheldeen, M.; Garcia, A.; Corte-Leon, P.; Ipatov, M.; Zhukova, V.; Zhukov, A. Unveiling the Effect of Annealing on Magnetic Properties of Nanocrystalline Half-Metallic Heusler Co2FeSi Alloy Glass-Coated Microwires. J. Mater. Res. Technol. 2022, 20, 4161–4172. [Google Scholar] [CrossRef]

- Cerqueira, M.F.; Andritschky, M.; Rebouta, L.; Ferreira, J.A.; da Silva, M.F. Macrocrystalline silicon thin films prepared by RF reactive magnetron sputter deposition. Vacuum 1995, 46, 1385–1390. [Google Scholar] [CrossRef]

- Zhukova, V.; Cobeño, A.F.; Zhukov, A.; Blanco, J.M.; Larin, V.; Gonzalez, J. Coercivity of glass-coated Fe73.4-xCu1Nb3.1Si13.4+xB9.1 (0 ≤ x ≤ 1.6) microwires. Nanostruct. Mater. 1999, 11, 1319–1327. [Google Scholar] [CrossRef]

- Greer, A.L. Crystallization of amorphous alloys. Metall. Mater. Trans. A 1996, 27, 549–555. [Google Scholar] [CrossRef]

- Herzer, G. Grain Size Dependence of Coercivity and Permeability in Nanocrystalline Ferromagnets. IEEE Trans. Magn. 1990, 26, 1397–1402. [Google Scholar] [CrossRef]

- Talaat, A.; Del Val, J.J.; Zhukova, V.; Ipatov, M.; Klein, P.; Varga, R.; Gonzalez, J.; Zhdanova, M.; Churyukanova, M.; Zhukov, A. Effect of annealing on magnetic properties of nanocrystalline Hitperm-type glass-coated microwires. J. Alloys Compd. 2016, 660, 297–303. [Google Scholar] [CrossRef]

- Serebryakov, A.V. Amorphization reactions and glass to crystal transformations in metallic materials. J. Non-Cryst. Solids 1993, 156–158, 594–597. [Google Scholar] [CrossRef]

- Zhukov, A.; Ipatov, M.; del Val, J.J.; Chernenko, V.A.; Zhukova, V. Tailoring of magnetic properties of Heusler-type glass-coated microwires by annealing. J. Alloys Compd. 2018, 732, 561–566. [Google Scholar] [CrossRef]

- Chernenko, V.A.; L’vov, V.A.; Zagorodnyuk, S.P.; Takagi, T. Ferromagnetism of thermoelastic martensites: Theory and experiment. Phys. Rev. B 2003, 67, 064407. [Google Scholar] [CrossRef]

- Wu, S.K.; Yang, S.T. Effect of composition on transformation temperatures of Ni-Mn-Ga shape memory alloys. Mater. Lett. 2003, 57, 4291–4296. [Google Scholar] [CrossRef]

- Chernenko, V.A. Compositional instability of β-phase in Ni-Mn-Ga alloys. Scr. Mater. 1999, 40, 523–527. [Google Scholar] [CrossRef]

- Besseghini, S.; Gambardella, A.; Chernenko, V.A.; Hagler, M.; Pohl, C.; Mullner, P.; Ohtsuka, M.; Doyle, S. Transformation behavior of Ni-Mn-Ga/Si(100) thin film composites with different film thicknesses. Eur. Phys. J. Spec. Top. 2008, 158, 179–185. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Salaheldeen, M.; Zhukova, V.; Gonzalez, J.; Zhukov, A. Grain Size Engineering and Tuning of Magnetic Properties in Ultra-Thin NiMnGa Glass-Coated Microwires: Insights from Annealing Effects. Crystals 2025, 15, 565. https://doi.org/10.3390/cryst15060565

Salaheldeen M, Zhukova V, Gonzalez J, Zhukov A. Grain Size Engineering and Tuning of Magnetic Properties in Ultra-Thin NiMnGa Glass-Coated Microwires: Insights from Annealing Effects. Crystals. 2025; 15(6):565. https://doi.org/10.3390/cryst15060565

Chicago/Turabian StyleSalaheldeen, Mohamed, Valentina Zhukova, Julian Gonzalez, and Arcady Zhukov. 2025. "Grain Size Engineering and Tuning of Magnetic Properties in Ultra-Thin NiMnGa Glass-Coated Microwires: Insights from Annealing Effects" Crystals 15, no. 6: 565. https://doi.org/10.3390/cryst15060565

APA StyleSalaheldeen, M., Zhukova, V., Gonzalez, J., & Zhukov, A. (2025). Grain Size Engineering and Tuning of Magnetic Properties in Ultra-Thin NiMnGa Glass-Coated Microwires: Insights from Annealing Effects. Crystals, 15(6), 565. https://doi.org/10.3390/cryst15060565