Improved Microstructure and Enhanced Tensile Properties of Hypoeutectic AlMg5Si2Mn Alloy Modified by Yttrium

Abstract

1. Introduction

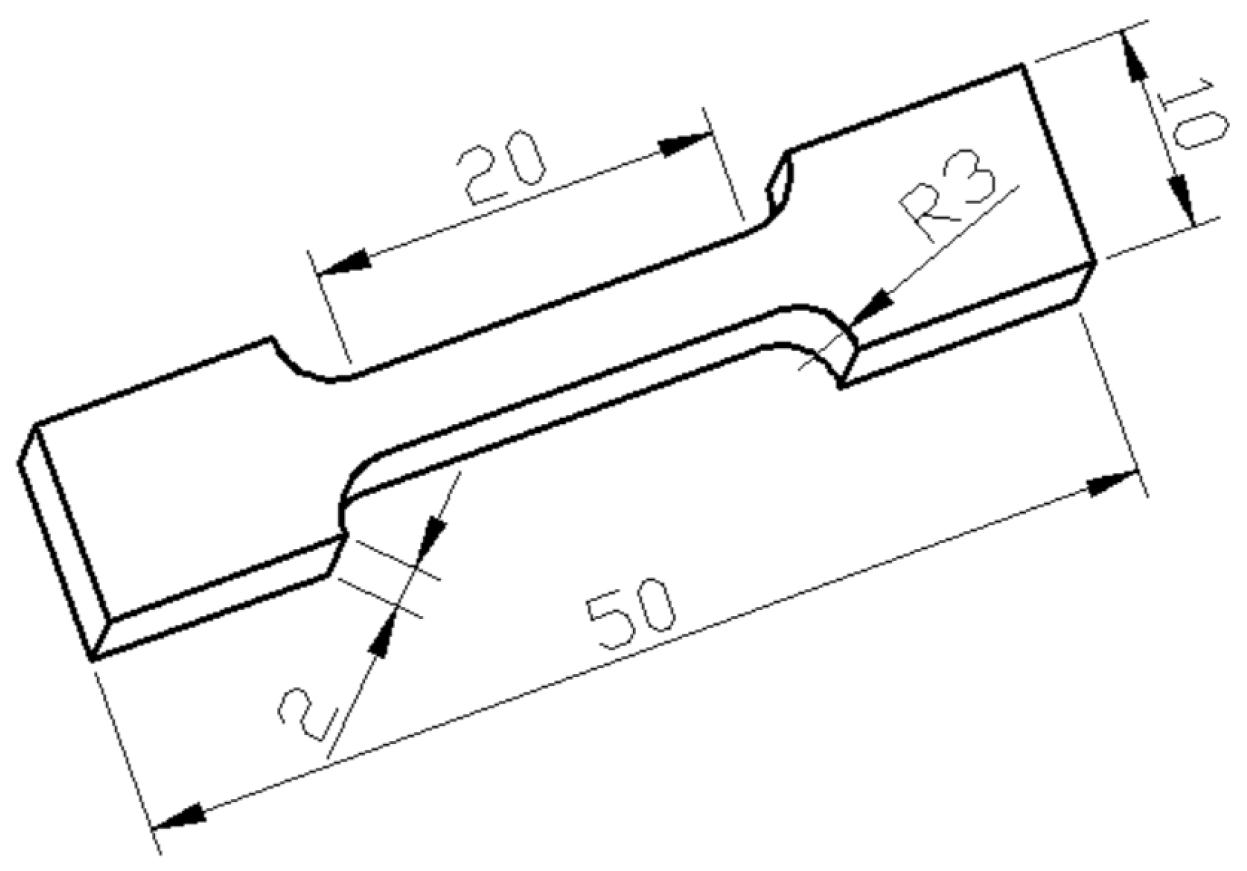

2. Experimental Methods and Procedures

3. Results

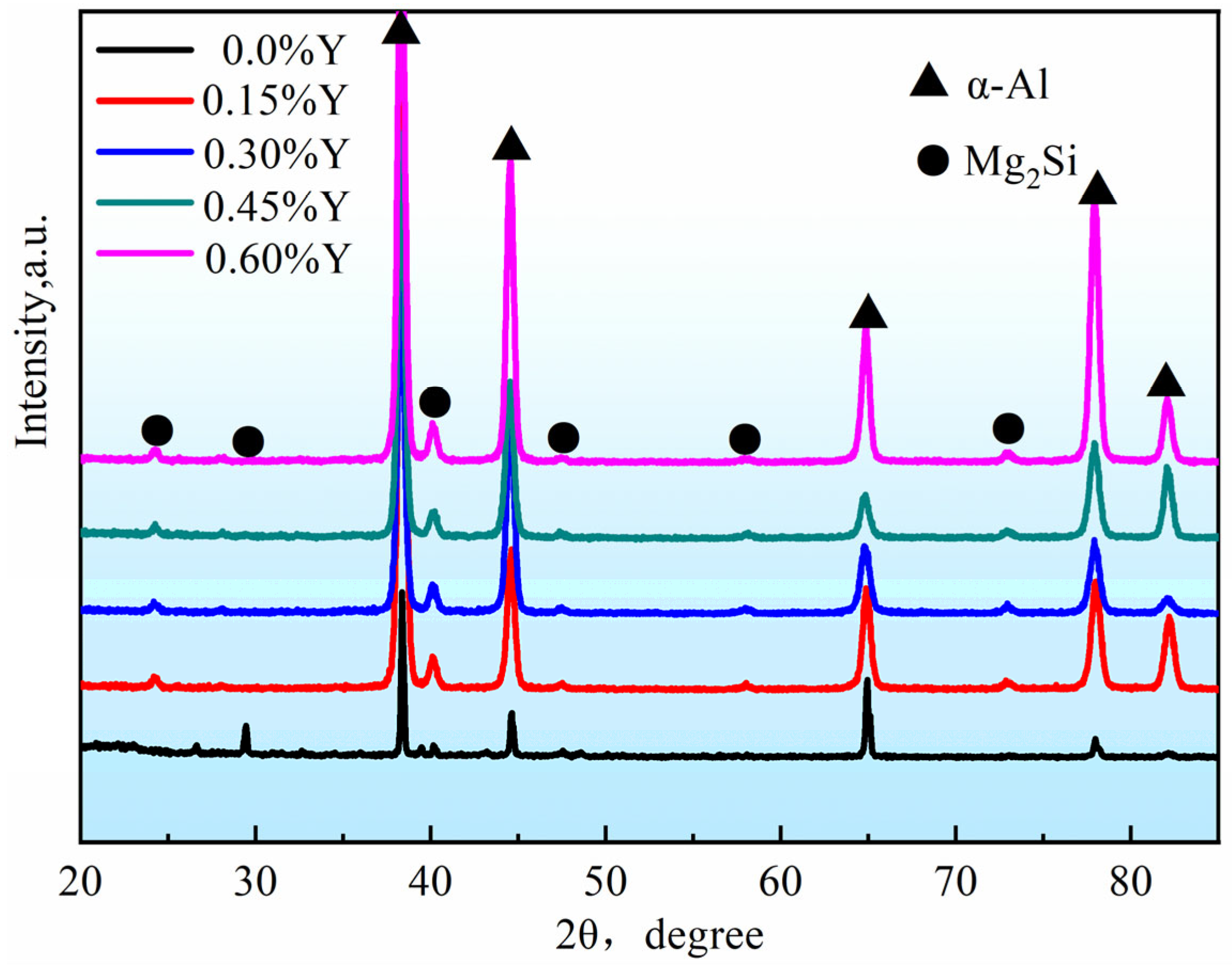

3.1. XRD Analysis

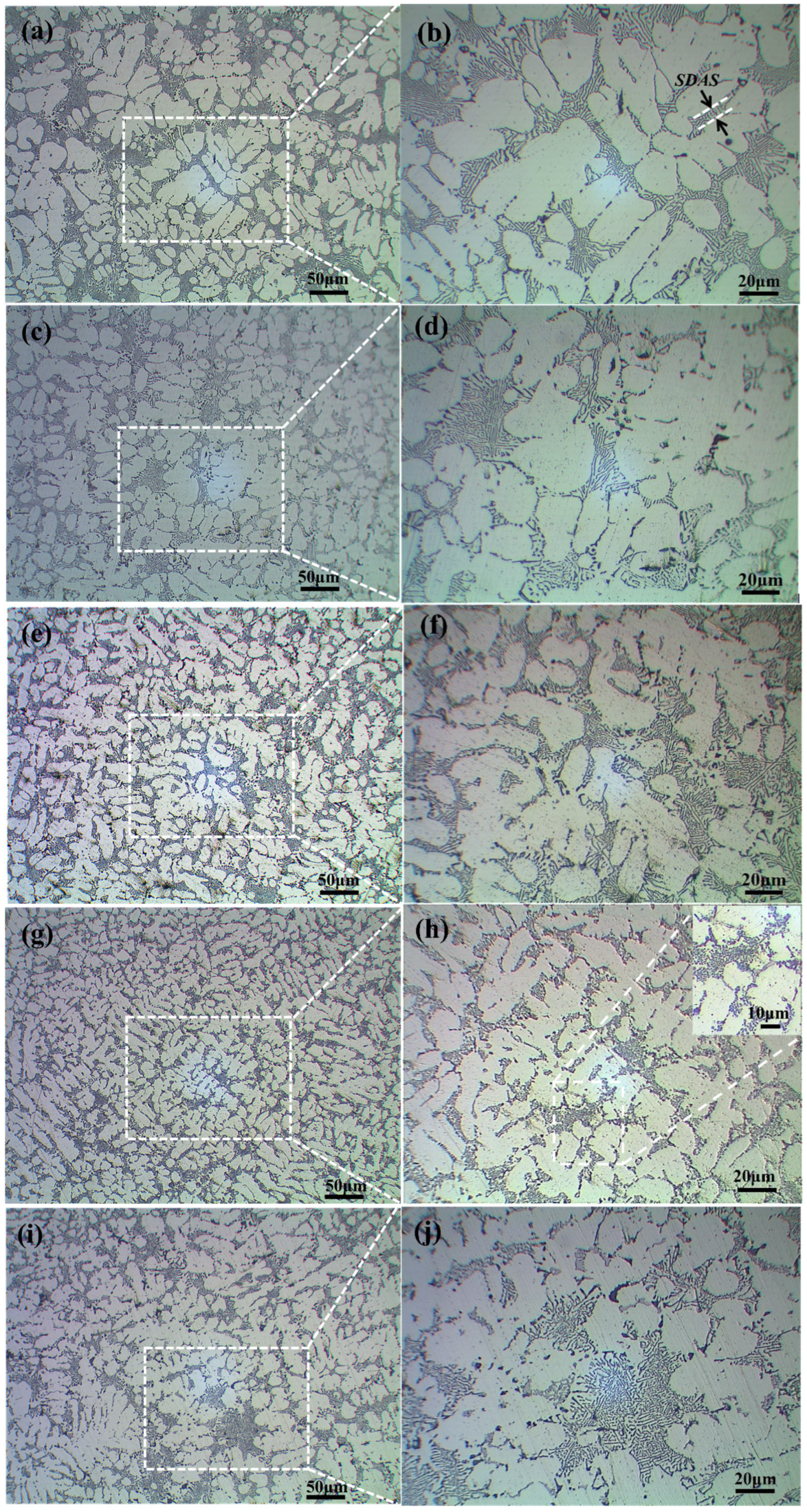

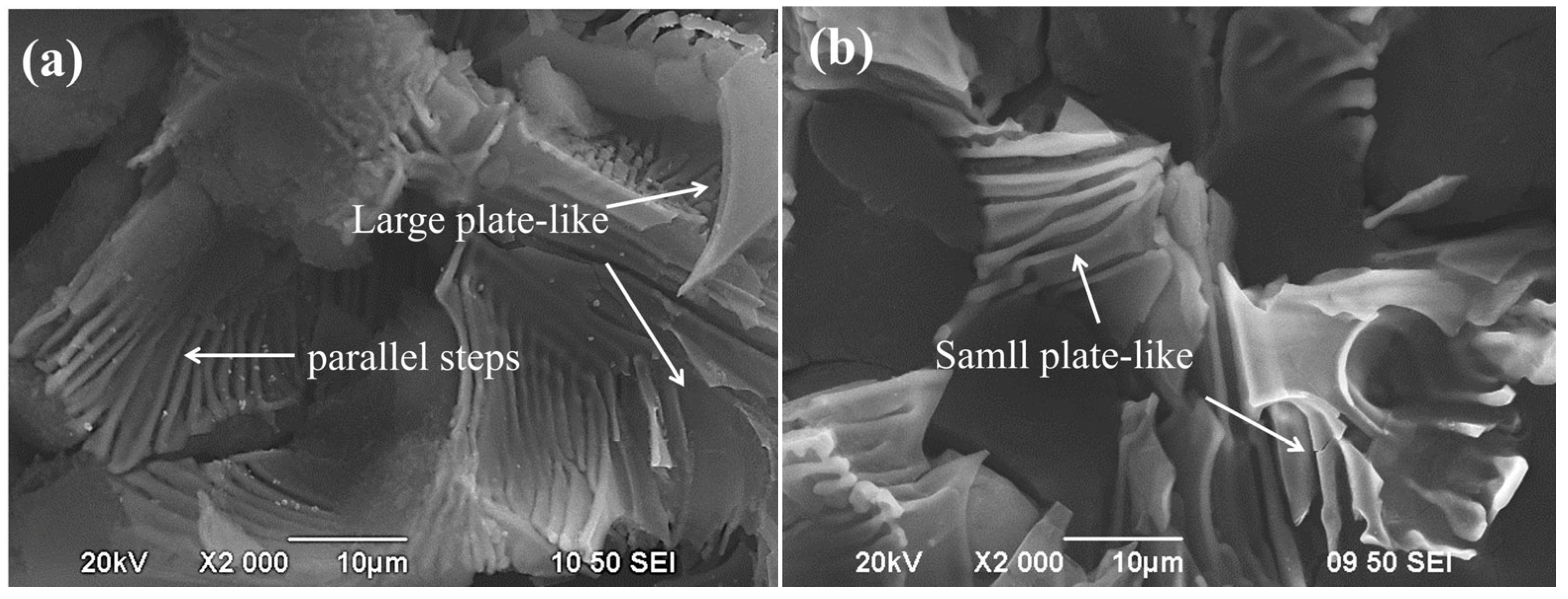

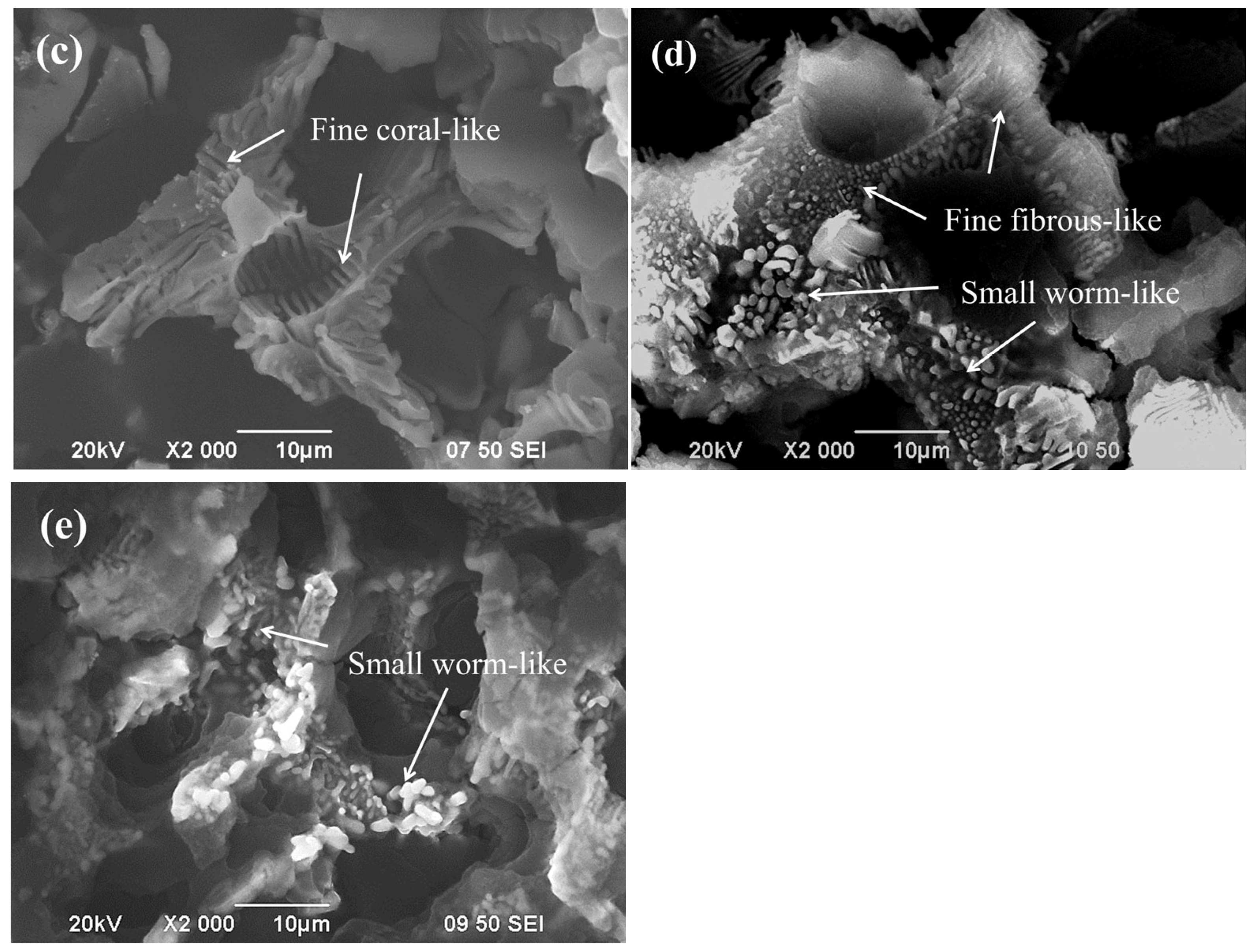

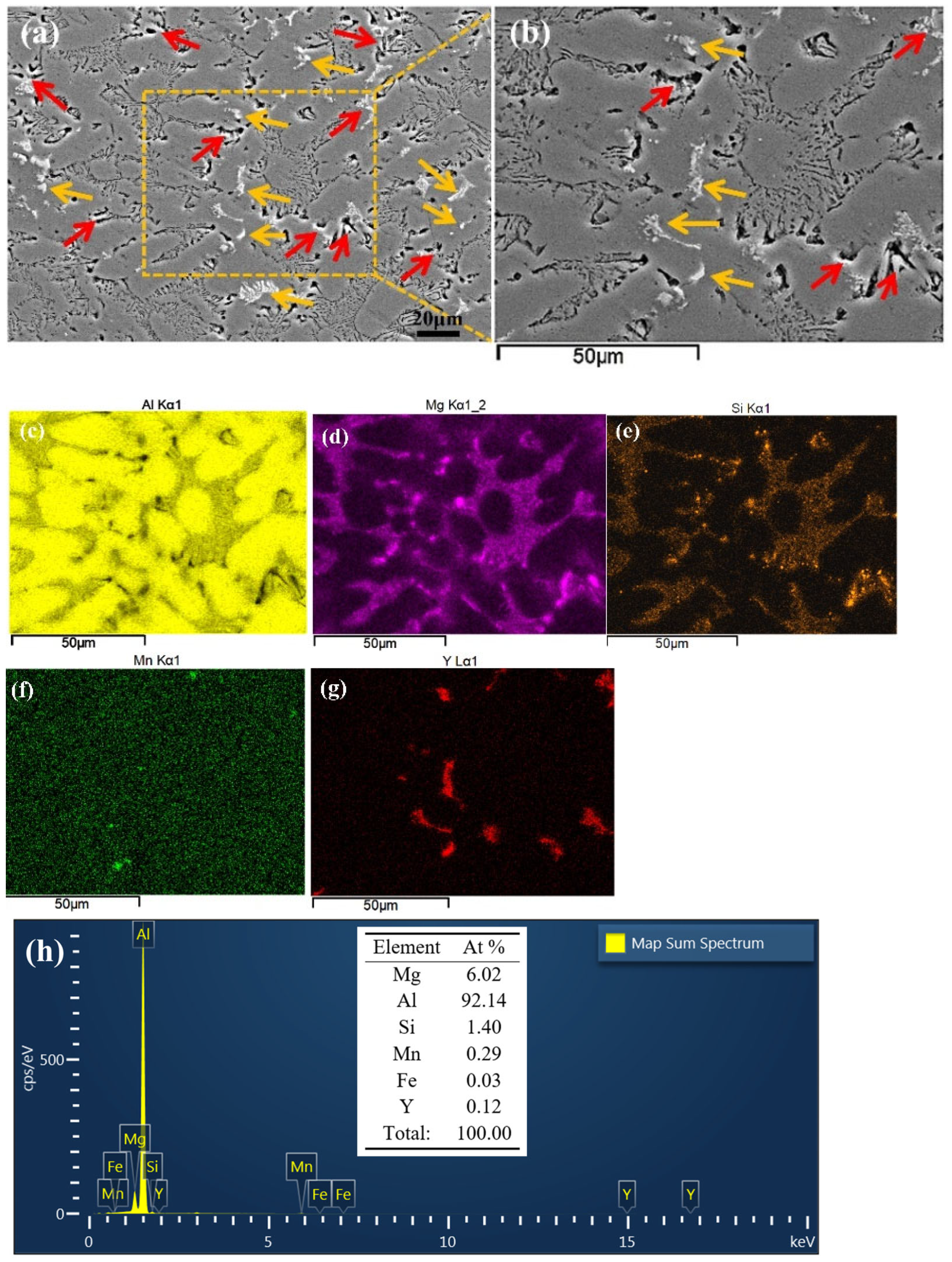

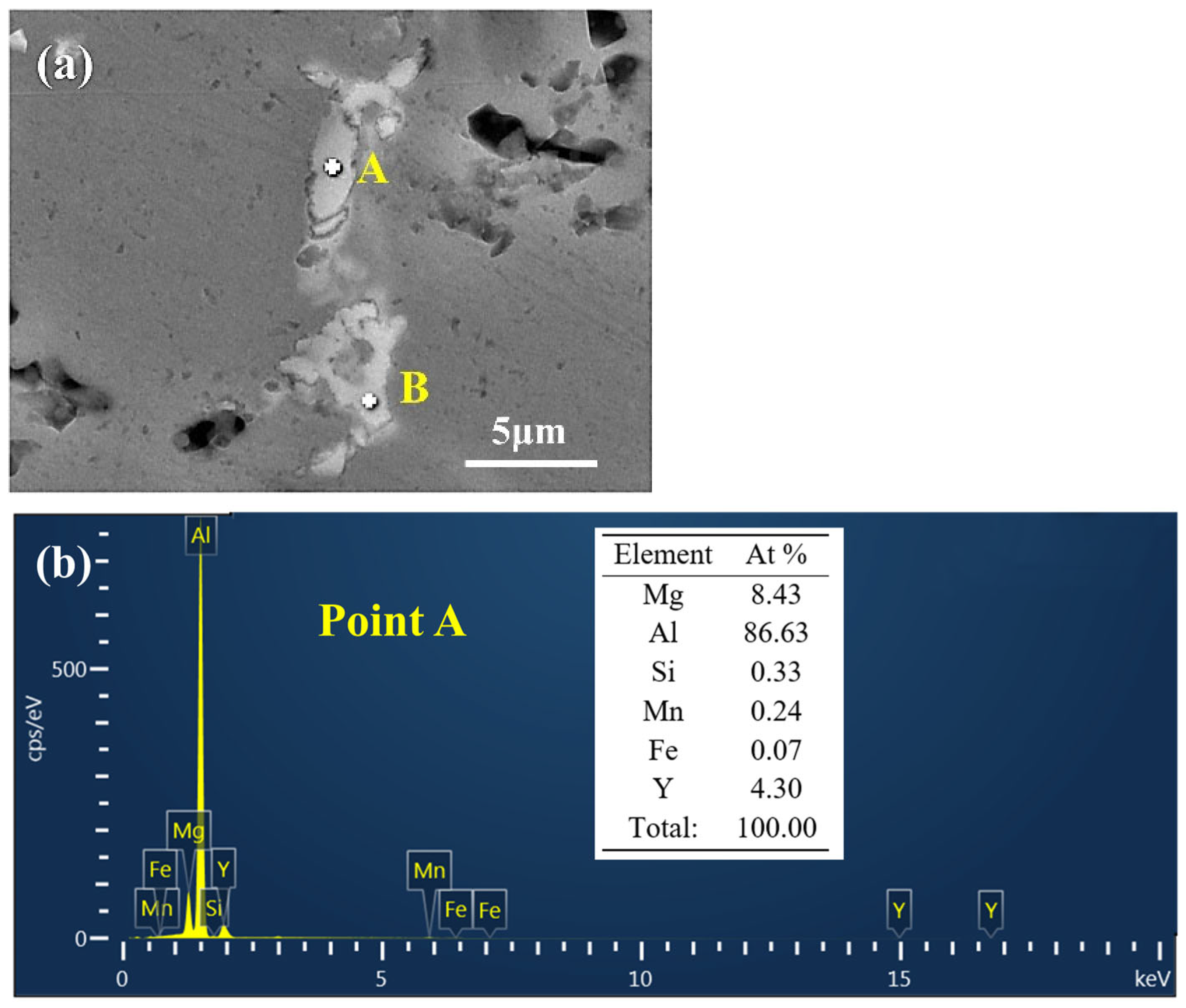

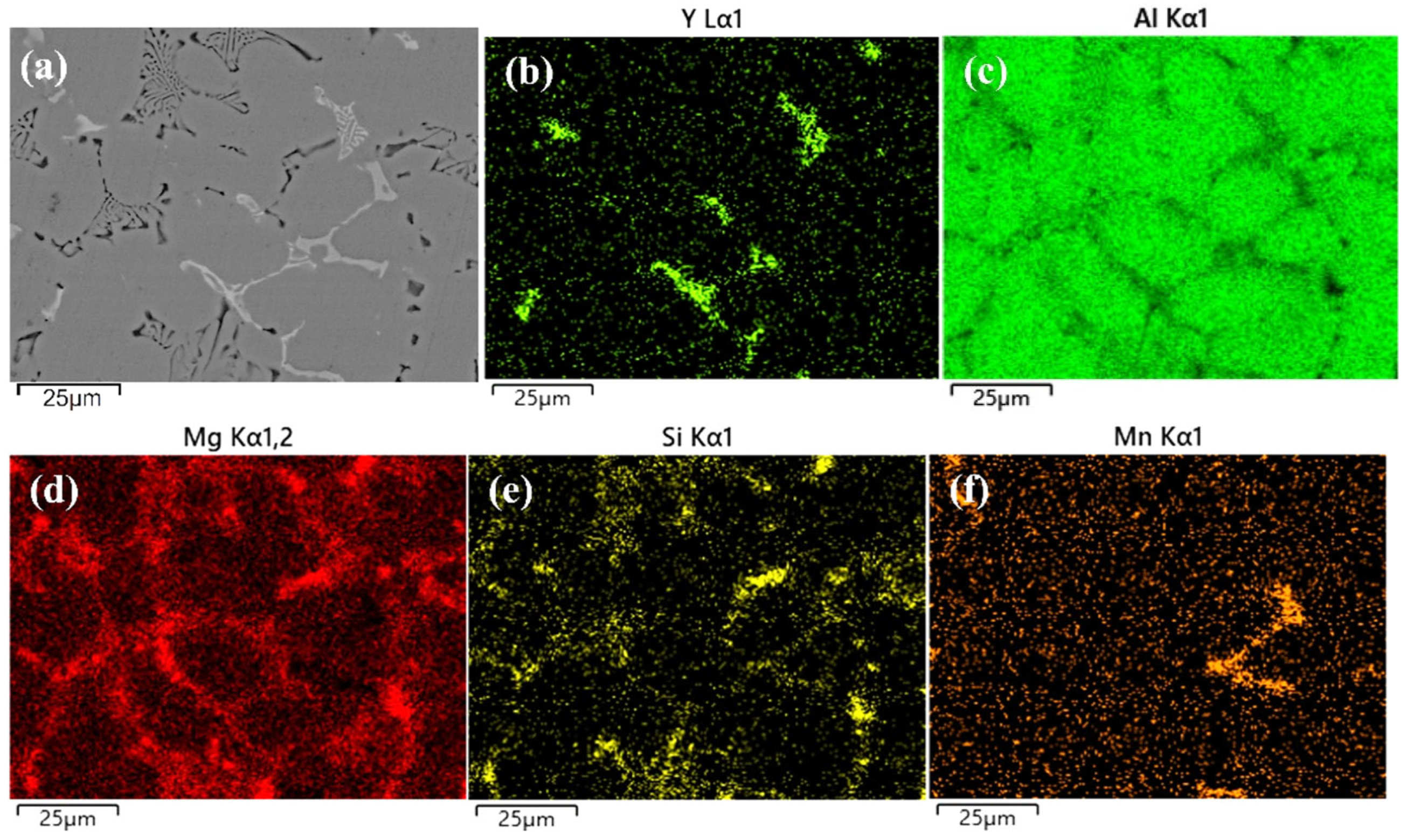

3.2. Microstructural Characteristics of the Alloy

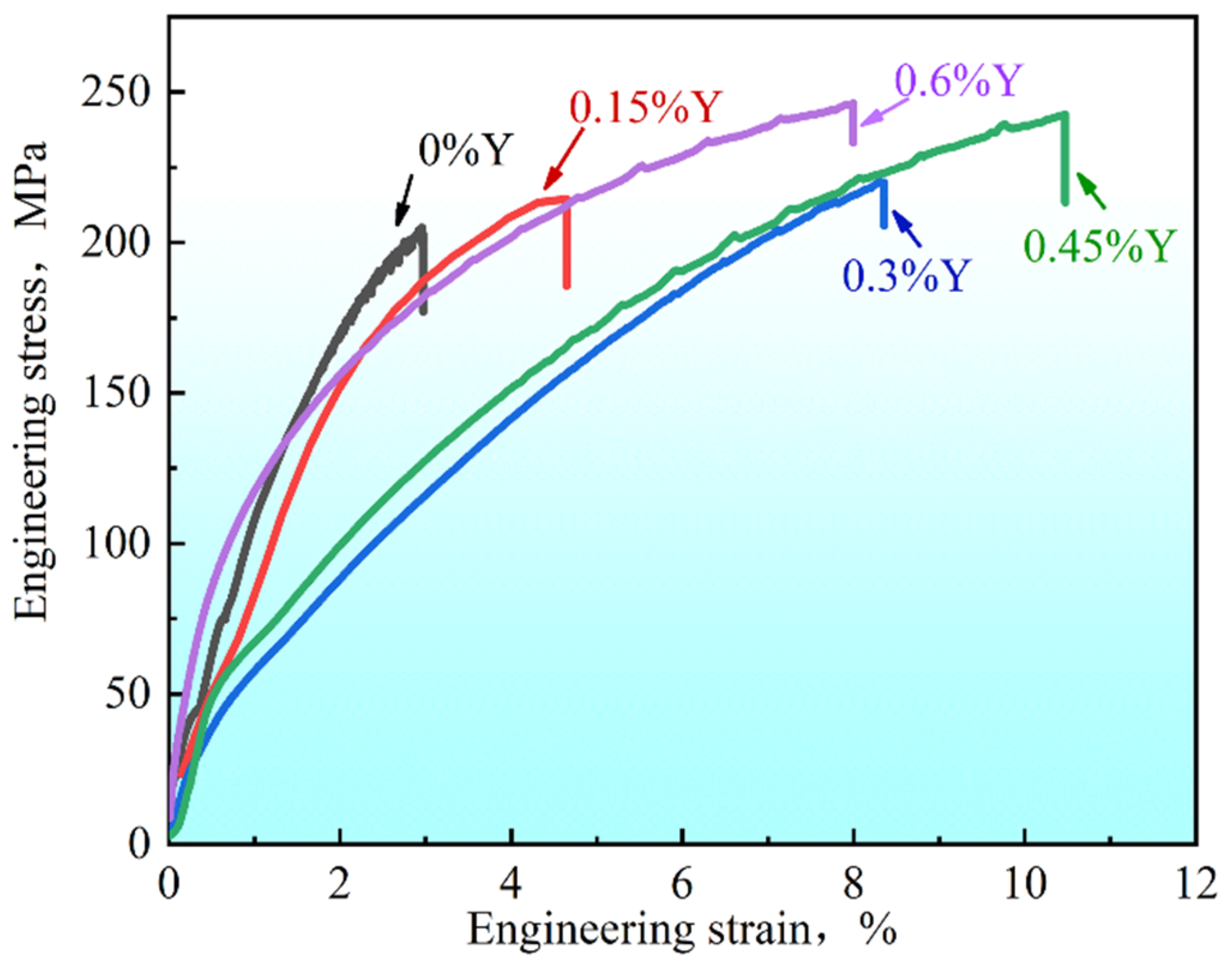

3.3. Tensile Properties of the Alloys

4. Discussion

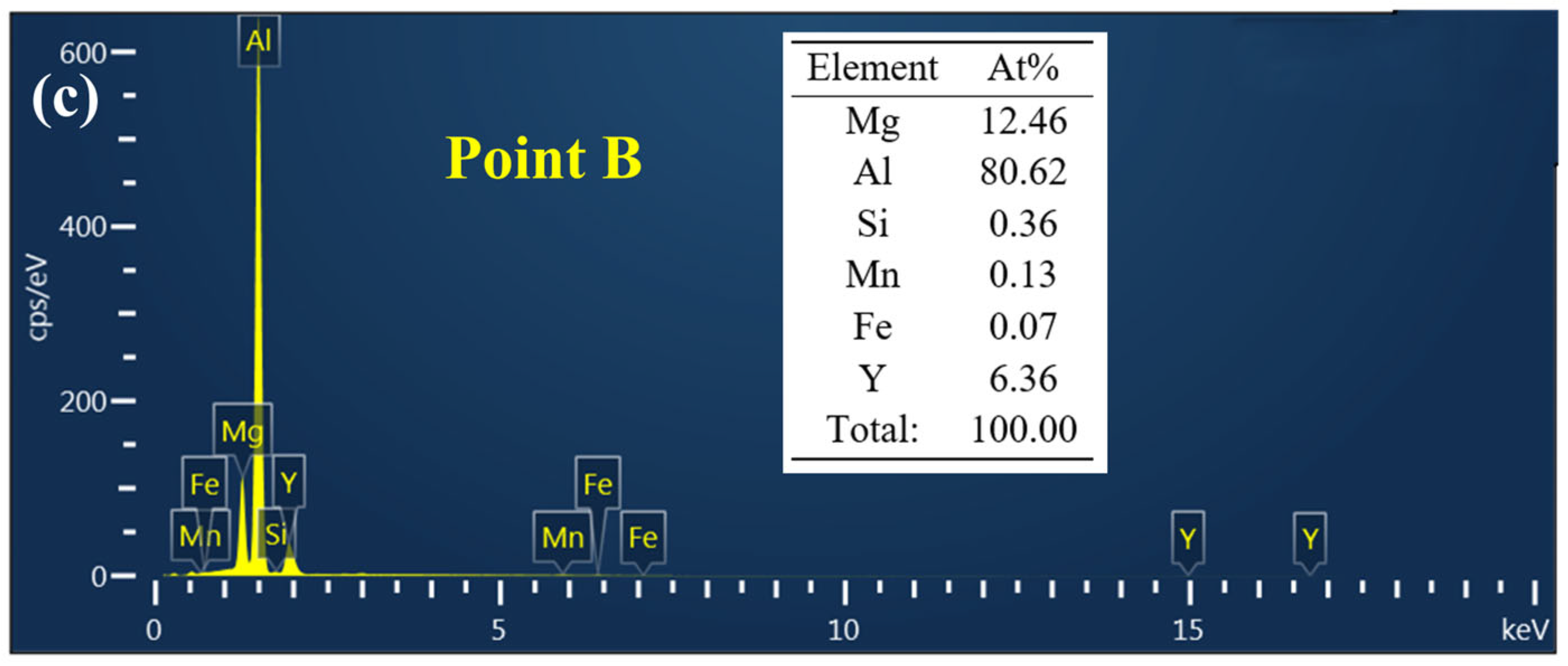

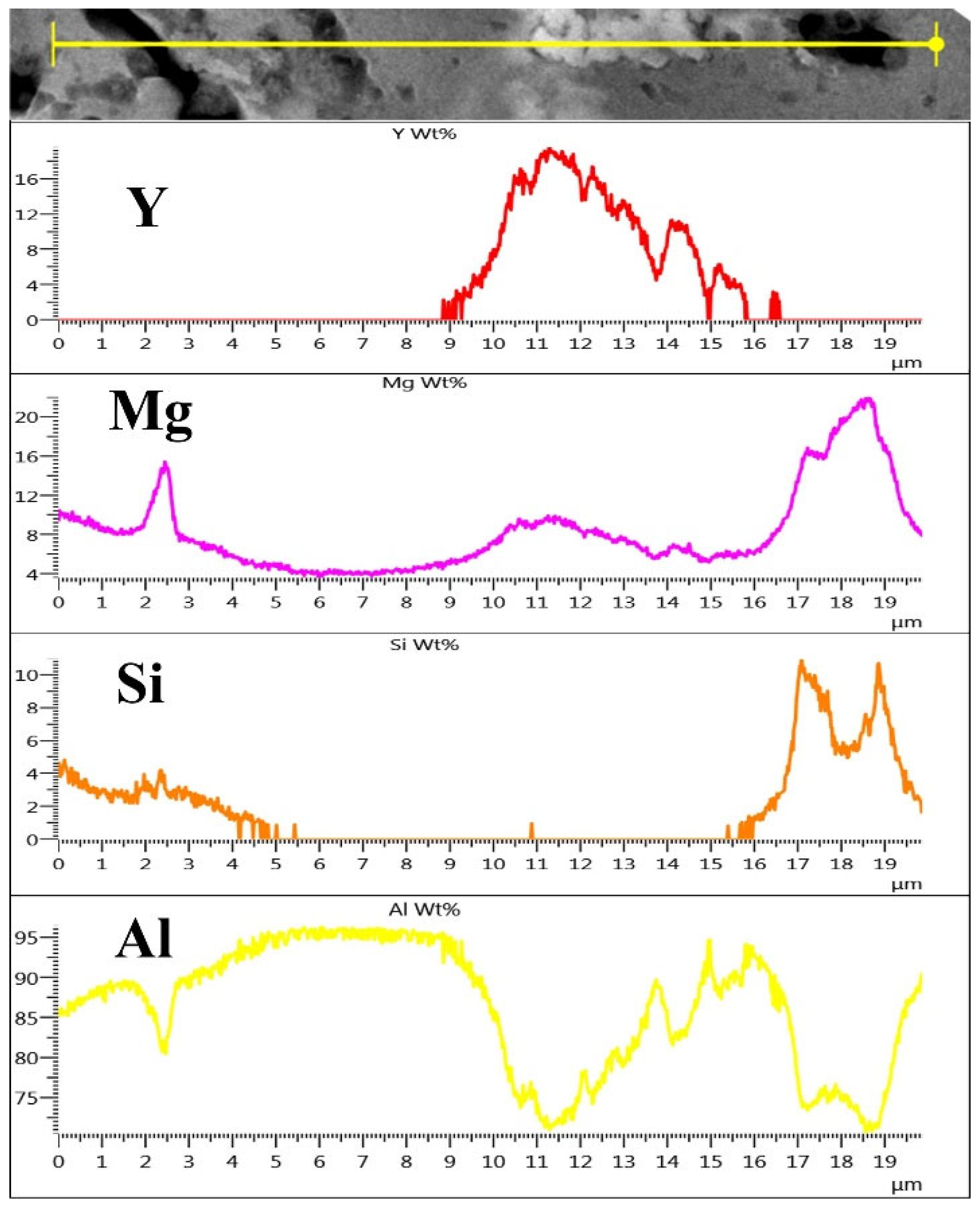

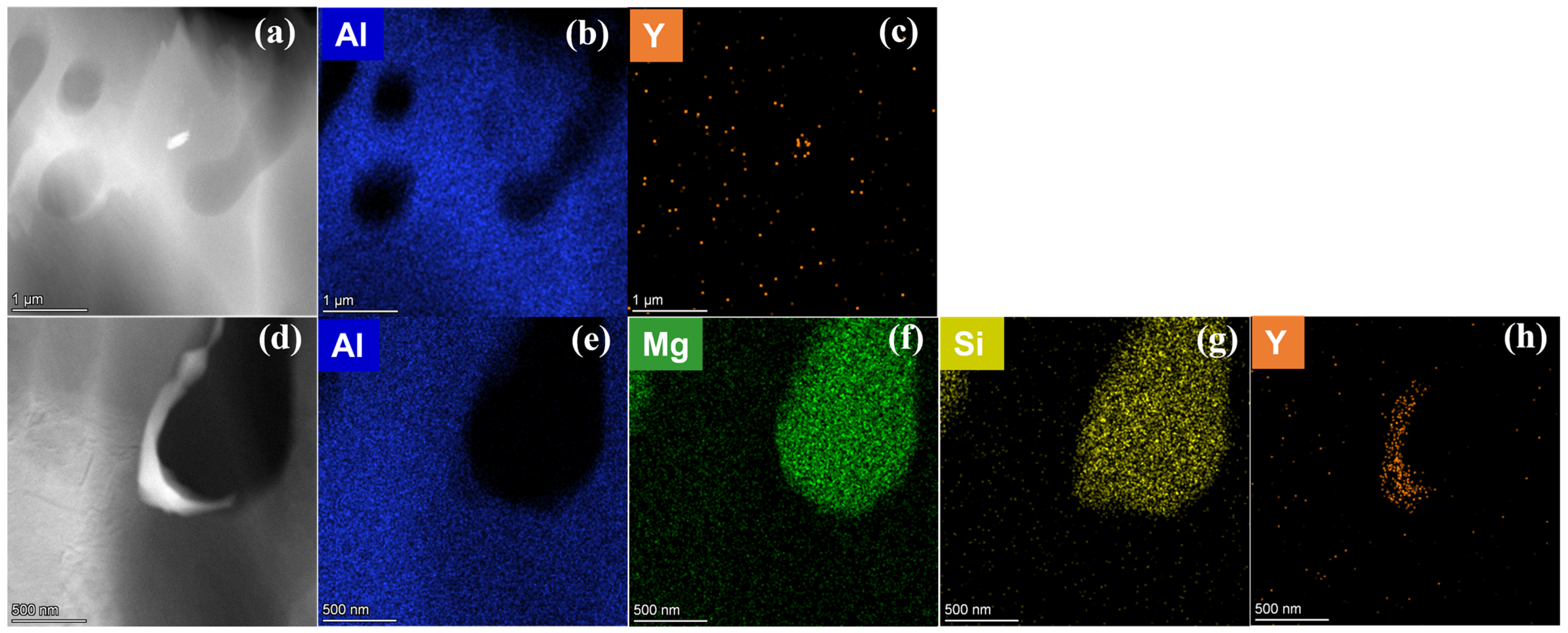

4.1. Refinement Mechanism of Alloys

4.2. Mechanical Property Enhancement Mechanisms for Alloys

5. Conclusions

- (1)

- The incorporation of Y elements in cast AlMg5Si2Mn alloys results in microstructural refinement, as indicated by a substantial reduction in the SDAS of primary α-Al dendrites, as well as significant modification of both the morphology and dimensions of the eutectic Mg2Si.

- (2)

- In Y-added AlMg5Si2Mn alloys, Al3Y particles act as effective heterogeneous nucleation sites and exhibit significant multiple strengthening effects.

- (3)

- The comprehensive mechanical properties of AlMg5Si2Mn alloys are significantly enhanced by the addition of Y.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wu, X.F.; Wang, K.Y.; Wu, F.F.; Zhao, R.D.; Chen, M.H.; Xiang, J.; Ma, S.N.; Zhang, Y. Simultaneous grain refinement and eutectic Mg2Si modification in hypoeutectic Al-11Mg2Si alloys by Sc addition. J. Alloys Compd. 2019, 791, 402–410. [Google Scholar] [CrossRef]

- Wang, K.Y.; Zhao, R.D.; Wu, F.F.; Wu, X.F.; Chen, M.H.; Xiang, J.; Chen, S.H. Improving microstructure and mechanical properties of hypoeutecticAl-Mg2Si alloy by Gd addition. J. Alloys Compd. 2020, 813, 152178. [Google Scholar] [CrossRef]

- Wu, X.F.; Wang, Y.; Wang, K.Y.; Zhao, R.D.; Wu, F.F. Enhanced mechanical properties of hypoeutectic Al-10Mg2Si cast alloys by Bi addition. J. Alloys Compd. 2018, 767, 163–172. [Google Scholar] [CrossRef]

- Wang, K.Y.; Xiang, J.; Zhao, R.D.; Bi, J.L.; Wu, X.F.; Chen, M.H.; Wu, F.F.; Eckert, J. Microstructure refinement and enhanced tensile properties of Al-11Mg2Si alloy modified by erbium. J. Alloys Compd. 2021, 860, 158421. [Google Scholar] [CrossRef]

- Jiang, F.; Qiu, K.Q.; Wang, H.D.; Xiang, Q.C.; Zhang, Y.R.; Qu, Y.D. Effects of Bi modification and ultrasonic treatment on microstructure evolution and mechanical properties of AlMg5Si2Mn alloy. J. Alloys Compd. 2022, 901, 163486. [Google Scholar] [CrossRef]

- Pan, Y.; Zhang, D.; Liu, H.; Zhuang, L.; Zhang, J. Precipitation hardening and intergranular corrosion behavior of novel Al-Mg-Zn(-Cu) alloys. J. Alloys Compd. 2020, 853, 157199. [Google Scholar] [CrossRef]

- Collot, J. Review of new process technologies in the aluminum die-casting industry. Mater. Manuf. Process. 2001, 16, 595–617. [Google Scholar] [CrossRef]

- Lee, Y.S.; Cha, J.H.; Kim, S.H.; Lim, C.Y.; Kim, H.W. Effect of pre-homogenization deformation treatment on the workability and mechanical properties of AlMg5Si2Mn alloy. Mater. Sci. Eng. A 2017, 685, 244–252. [Google Scholar] [CrossRef]

- Li, Z.; Li, C.; Liu, Y.; Yu, L.; Guo, Q.; Li, H. Effect of heat treatment on microstructure and mechanical property of Al-10%Mg2Si alloy. J. Alloys Compd. 2016, 663, 16–19. [Google Scholar] [CrossRef]

- Li, C.; Sun, J.; Li, Z.; Gao, Z.; Liu, Y.; Yu, L.; Li, H. Microstructure and corrosion behavior of Al-10%Mg2Si cast alloy after heat treatment. Mater. Charact. 2016, 122, 142–147. [Google Scholar] [CrossRef]

- Shimosaka, D.; Kumai, S.; Casarotto, F.; Watanabe, S. Effect of cooling rates during solidification of Al-5.5%Mg-2.3%Si-0.6%Mn and Al-13%Mg2Si pseudo-binary alloys on their secondary-particle morphology and tear toughness. Mater. Trans. 2011, 52, 920–927. [Google Scholar] [CrossRef]

- Kori, S.A.; Murty, B.S.; Chakraborty, M. Development of an efficient grain refiner for Al-7Si alloy and its modification with strontium. Mater. Sci. Eng. A 2000, 283, 94–104. [Google Scholar] [CrossRef]

- Snopiński, P.; Król, M.; Wróbel, T.; Matus, K.; Woźniak, A.; Tański, T.; Palček, P. Effects of modifying the hypoeutectic AlMg5Si2Mn alloy via addition of Al10Sr and/or Al5TiB. Arch. Civ. Mech. Eng. 2021, 21, 2. [Google Scholar] [CrossRef]

- Kumar, G.S.V.; Murty, B.S.; Chakraborty, M. Grain refinement response of LM25 alloy towards Al-Ti-C and Al-Ti-B grain refine. J. Alloys Compd. 2009, 472, 112–120. [Google Scholar] [CrossRef]

- Moldovan, P.; Popescu, G. The grain refinement of 6063 aluminum using Al-5Ti-1B and Al-3Ti-0.15C grain refiners. J. Alloys Compd. 2004, 56, 59–61. [Google Scholar] [CrossRef]

- Li, P.T.; Liu, S.D.; Zhang, L.L.; Liu, X.F. Grain refinement of A356 alloy by Al-Ti-B-C master alloy and its effect on mechanical properties. Mater. Des. 2013, 47, 522–528. [Google Scholar] [CrossRef]

- Khorshidi, R.; Raouf, A.H.; Emamy, M.; Campbell, J. The study of Li effect on the microstructure and tensile properties of cast Al-Mg2Si metal matrix composite. J. Alloys Compd. 2011, 509, 9026–9033. [Google Scholar] [CrossRef]

- Li, C.; Wang, C.; Yang, Z.Z.; Ma, P.K.; Ren, M.W.; Wang, H.Y. Effect of complex modification of Ca and Sb on the microstructure and mechanical properties of hypoeutectic Al-11Mg2Si alloy. J. Alloys Compd. 2021, 869, 159304. [Google Scholar] [CrossRef]

- Li, C.; Wang, C.; Yang, Z.Z.; Ma, P.K.; Ren, M.W.; Wang, H.Y. Effect of Sb modification on microstructure and mechanical properties of hypoeutectic Al-11Mg2Si alloy. Mater. Sci. Eng. A 2020, 782, 139247. [Google Scholar] [CrossRef]

- Li, B.; Wang, H.W.; Jie, J.C.; Wei, Z.J. Effects of yttrium and heat treatment on the microstructure and tensile properties of Al-7.5Si-0.5Mg alloy. Mater. Des. 2011, 32, 1617–1622. [Google Scholar] [CrossRef]

- Liu, Z.; Hu, Y.M. Effect of yttrium on the microstructure of a semi-solid A356 Al alloy. Rare Met. 2008, 27, 536–540. [Google Scholar] [CrossRef]

- Wan, B.B.; Chen, W.P.; Liu, L.S.; Cao, X.Y.; Zhou, L.; Fu, Z.Q. Effect of trace yttrium addition on the microstructure and tensile properties of recycled Al-7Si-0.3Mg-1.0Fe casting alloys. Mater. Sci. Eng. A 2016, 666, 165–175. [Google Scholar] [CrossRef]

- Mao, G.L.; Yan, H.; Zhu, C.C.; Wu, Z.; Gao, W.L. The varied mechanisms of yttrium (Y) modifying a hypoeutectic Al-Si alloy under conditions of different cooling rates. J. Alloys Compd. 2019, 806, 909–916. [Google Scholar] [CrossRef]

- Li, Q.L.; Zhu, Y.Q.; Zhao, S.; Lan, Y.F.; Liu, D.X.; Jian, G.F.; Zhang, Q.; Zhou, H.W. Influences of Fe, Mn and Y additions on microstructure and mechanical properties of hypoeutectic Al-7%Si alloy. Intermetallics 2020, 120, 106768. [Google Scholar] [CrossRef]

- GB/T 228.1-2021; Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature. General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China. Standardization Administration of the People’s Republic of China: Beijing, China, 2010.

- Tsai, Y.C.; Lee, S.L.; Lin, C.K. Effect of trace La addition on the microstructures and mechanical properties of A356 (Al-7Si-0.35Mg) aluminum alloys. J. Alloys Compd. 2009, 487, 157–162. [Google Scholar] [CrossRef]

- Li, S.; Zhao, S.; Pan, M.; Zhao, D.; Chen, X.; OM, B.; RI, B. Solidification and structural characteristics of Al-Mg2Si eutectic. Mater. Trans. JIM 1997, 38, 553–559. [Google Scholar] [CrossRef]

- Jiang, F.; Wang, H.D.; Xiang, Q.C.; Ren, Y.L.; Meng, F.X.; Qu, Y.D.; Qiu, K.Q. Effect of trace Bi addition on the microstructure and mechanical properties of hypoeutectic Al-Mg-Si-Mn alloy. Mater. Today Commun. 2024, 41, 110954. [Google Scholar] [CrossRef]

- Rao, J.; Zhang, J.; Liu, R.; Zheng, J.; Yin, D. Modification of eutectic Si and the microstructure in an Al-7Si alloy with barium addition. Mater. Sci. Eng. A 2018, 728, 72–79. [Google Scholar] [CrossRef]

- Hu, Z.; Ruan, X.; Yan, H. Effects of neodymium addition on microstructure and mechanical properties of near-eutectic Al-12Si alloys. Trans. Nonferrous Met. Soc. China 2015, 25, 3877–3885. [Google Scholar] [CrossRef]

- Xu, C.; Xiao, W.L.; Zheng, R.X.; Hanada, S.J.; Yamagata, H.S.; Ma, C.L. The synergic effects of Sc and Zr on the microstructure and mechanical properties of Al-Si-Mg alloy. Mater. Des. 2015, 88, 485–492. [Google Scholar] [CrossRef]

- Liu, S.; Du, Y.; Xu, H.; He, C.; Schuster, J.C. Experimental investigation of the Al-Y particle diagram. J. Alloys Compd. 2006, 414, 60–65. [Google Scholar] [CrossRef]

- Bramfitt, B.L. The effect of carbide and nitride additions on the heterogeneous nucleation behavior of liquid iron. Metall. Trans. 1970, 7, 1987–1995. [Google Scholar] [CrossRef]

- Zheng, L.; Chun, C.Q.; Guo, S.; Yi, L.J.; Qian, H.Q. Calculation of planar disregistries between compounds of rare earth-Al and primary α particle in A356-RE alloy and its verification. Rare Met. Mater. Eng. 2015, 44, 859–865. [Google Scholar]

- Li, J.H.; Wang, X.D.; Ludwig, T.H.; Tsunekawa, Y.; Arnberg, L.; Jiang, J.Z.; Schumacher, P. Modification of eutectic Si in Al-Si alloys with Eu addition. Acta Mater. 2015, 84, 153–163. [Google Scholar] [CrossRef]

- Huang, J.; Liu, S.; Friák, M.; Liu, Y.; Du, Y. Experimental and theoretical investigation on refining mechanism of Mg2Si by Y addition in the Mg-Al-Si alloys. J. Alloys Compd. 2024, 1002, 175432. [Google Scholar] [CrossRef]

- Li, Q.L.; Li, B.Q.; Li, J.B.; Zhu, Y.Q.; Xia, T.D. Effect of yttrium addition on the microstructures and mechanical properties of hypereutectic Al-20Si alloy. Mater. Sci. Eng. A 2018, 722, 47–57. [Google Scholar] [CrossRef]

- Li, Q.L.; Xia, T.D.; Lan, Y.F.; Zhao, W.J.; Fan, L.; Li, P.F. Effect of rare earth cerium addition on the microstructure and tensile properties of hypereutectic Al-20% Si alloy. J. Alloys Compd. 2013, 562, 25–32. [Google Scholar] [CrossRef]

- Nogita, K.; Yasuda, H.; Yoshida, M.; McDonald, S.D.; Uesugi, K.; Takeuchi, A.; Suzuki, Y. The role of trace element segregation in the eutectic modification of hypoeutectic Al-Si alloys. J. Alloys Compd. 2010, 489, 415–420. [Google Scholar] [CrossRef]

- Zhang, X.H.; Su, G.C.; Ju, C.W.; Wang, W.C.; Yan, W.L. Effect of modification treatment on the microstructure and mechanical properties of Al-0.35%Mg-7.0%Si cast alloy. Mater. Des. 2010, 31, 4408–4413. [Google Scholar] [CrossRef]

- Deng, Y.; Yin, Z.; Zhao, K.; Duan, J.; He, Z. Effects of Sc and Zr microalloying additions on the microstructure and mechanical properties of new Al-Zn-Mg alloys. J. Alloys Compd. 2012, 530, 71–80. [Google Scholar] [CrossRef]

- Wang, F.; Bhattacharyya, J.J.; Agnew, S.R. Effect of precipitate shape and orientation on Orowan strengthening of non-basal slip modes in hexagonal crystals, application to magnesium alloys. Mater. Sci. Eng. A 2016, 666, 114–122. [Google Scholar] [CrossRef]

- Curry, D.A.; Knott, J.F. Effect of microstructure on cleavage fracture toughness of quenched and tempered steels. Met. Sci. 1979, 13, 341–345. [Google Scholar] [CrossRef]

- Griffith, A.A. The phenomenon of rupture and flow in solids. Philos. Trans. R. Soc. Lond. Ser. A 1920, 221, 163–198. [Google Scholar]

| Element | Mg | Si | Mn | Fe | Ti | Cu | Al |

|---|---|---|---|---|---|---|---|

| Nominal value | 5.5 | 2 | 0.6 | <0.15 | <0.09 | <0.01 | Bal. |

| Actual value | 5.668 | 2.126 | 0.642 | 0.128 | 0.004 | 0.003 | Bal. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, F.; Wang, H.; Meng, F.; Xiang, Q.; Ren, Y.; Zhang, W.; Qiu, K. Improved Microstructure and Enhanced Tensile Properties of Hypoeutectic AlMg5Si2Mn Alloy Modified by Yttrium. Crystals 2025, 15, 535. https://doi.org/10.3390/cryst15060535

Jiang F, Wang H, Meng F, Xiang Q, Ren Y, Zhang W, Qiu K. Improved Microstructure and Enhanced Tensile Properties of Hypoeutectic AlMg5Si2Mn Alloy Modified by Yttrium. Crystals. 2025; 15(6):535. https://doi.org/10.3390/cryst15060535

Chicago/Turabian StyleJiang, Feng, Hongding Wang, Fanxu Meng, Qingchun Xiang, Yinglei Ren, Wei Zhang, and Keqiang Qiu. 2025. "Improved Microstructure and Enhanced Tensile Properties of Hypoeutectic AlMg5Si2Mn Alloy Modified by Yttrium" Crystals 15, no. 6: 535. https://doi.org/10.3390/cryst15060535

APA StyleJiang, F., Wang, H., Meng, F., Xiang, Q., Ren, Y., Zhang, W., & Qiu, K. (2025). Improved Microstructure and Enhanced Tensile Properties of Hypoeutectic AlMg5Si2Mn Alloy Modified by Yttrium. Crystals, 15(6), 535. https://doi.org/10.3390/cryst15060535