Abstract

The research and related tests aimed to investigate the effect of different heat inputs on the microstructure and properties of the joint when using laser-backing welding for X80 steel, with the purpose of guiding a reasonable adjustment of heat inputs to obtain a sound and high-quality joint, and ultimately laying the foundation for the engineering application of laser-backing welding. The fiber-laser-backing welding is performed on a 22 mm thick X80 steel, before which a groove is prepared and assembled; joints were obtained under different heat inputs (162, 180, 210, 270 J/mm) with orthogonal combinations of laser power and welding speed. The microstructure and properties of the joints were characterized by using an optical microscope, scanning electron microscope, and microhardness tester. According to this investigation, the morphology of the joint is directly affected by the heat input, and insufficient heat input (<180 J/mm) will lead to an unacceptable weld profile. The width of the weld and heat-affected zone gets bigger as the heat input increases. The hardness nephograms of the joints under different heat inputs show that the weld has the highest hardness, followed by the coarse-grain heat-affected zone and the fine-grain heat-affected zone, sequentially. The less heat input, the lower the joint hardness; when the heat input increases to 270 J/mm, the coarse-grain zone near the fusion line shows obvious hardening. In addition, heat input also affects the impact toughness of the weld. The grain size of X80 steel with a lower content of niobium easily becomes coarse under excessive heat input (270 J/mm), resulting in the degradation of the grain-boundary slip ability; hence, the impact toughness of the joint deteriorates. The optimal heat input of 210 J/mm was identified, achieving a grain size of nearly 14 µm and providing a balanced combination of lower strength and higher impact toughness.

1. Introduction

Under the global background of “carbon peak and carbon neutrality”, the transformation of cleaner energy continues to promote the demand for natural gas. The X80 steel has become the preferred choice for large-volume and high-pressure gas pipelines due to its high strength grade, good weldability, and obvious advantages in transportation efficiency. Currently, X80 steel has been introduced in the main pipelines such as the China–Russia Eastern Gas Pipeline, Fourth West–East Gas Pipeline, and Central Asian Pipeline [1]. Traditional arc welding is usually adopted to weld the long-distance X80 pipeline. However, low production efficiency and large deformation in the welding of thick plates remain issues [2,3]. For the pipeline construction and operation, higher requirements for welding efficiency, quality, safety, and economy have been put forward. It is essential to develop and apply new high-efficiency and high-quality welding techniques [4]. Laser welding plays an increasingly important role in high precision, high efficiency, and high quality, owing to its advantages in heat input concentration, easy control of the heat source, the narrow heat-affected zone, and small amount of welding stress/deformation [5].

Many researchers have carried out a large number of studies on the laser welding of high-strength steel and medium-thick plate steels (see Table 1), which are mainly concentrated in the fields of automobiles and ships [6]. Fatma et al. [7] explored how the laser-dominated zone is of particular importance regarding Charpy impact toughness; the low heat input of the laser can lead to a martensitic microstructure, causing the hardening and deterioration of impact toughness. Zhu et al. [8] discovered that degenerate upper bainite (DUB) and martensite (M) play key roles as strengthening phases, whereas granular bainite (GB) and acicular ferrite (AF) serve as primary toughening phases. Zou et al. [9] found that with the increase in welding speed, the toughness of the welded joints first increased and then decreased using laser-arc composite welding for marine high-strength steel. Yang et al. [10] determined that with the increase in laser heat input, the joint elongation decreased due to the hardening effect, whereas the tensile fracture showed ductile fracture characteristics. Yang et al. [11] studied the effect of heat input on the microstructural transformation and properties of the laser-welded joints of CP800 multiphase steel. The welded joint with the highest elongation was obtained under the high heat input of 52.5 J/mm. Jiang et al. [12] described the use of the ultra-high power density of a 10,000 W laser to obtain a weld joint with greater aspect-ratio characteristics, greatly improving the welding efficiency. Jacek [13] used the welding keyhole effect to achieve a one-time penetration connection of steel plates with a thickness of more than 4 mm, which not only improved welding efficiency but also reduced the material loss of deposited metal.

Table 1.

Summary of prior research and relevance to current study.

Suder et al. [14] found that sufficient energy and penetration force were needed to form a keyhole with balanced force throughout the entire welded thickness to obtain a smooth root profile. Ramachandran et al. [15] demonstrated that by using a certain laser power coupled with appropriate welding speed, the narrowest welded seam could be obtained. Ribic et al. [16] found that reducing the line energy of the heat input would produce a finer microstructure and improve the joint strength and toughness. Chen et al. [17] showed the higher the heat input was, the larger the range of the heat-affected zone would be. Han et al. [18] compared the effects of niobium (Nb) content in micro-alloy elements on the microstructure and properties of X80 pipeline steel under different heat input conditions. It showed that a higher Nb content would enhance the adaptability toward different welding methods and processes. In this work, the IPG LS-10000 fiber laser was introduced to weld X80 pipeline steel at a flat welding position. The effect of different heat inputs on joint forming, the microstructure, and mechanical properties was studied. We aimed to develop the two-to-one prefabrication laser welding of pipelines for the on-site construction requirements.

2. Experimental Materials and Methods

2.1. Experimental Materials

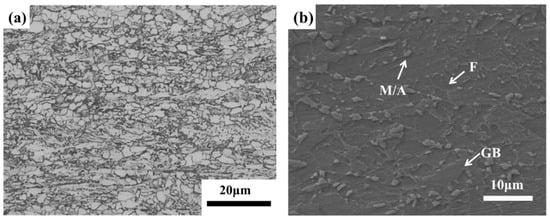

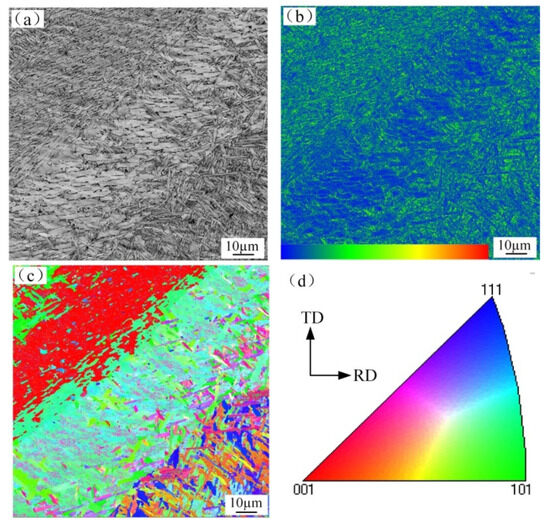

The materials used were X80 pipeline steel produced by Shengli Xianggang Steel Pipe Co., Ltd., (Xiangtan, Hunan, China) for the Sichuan-to-East Gas Transmission Project. The size of the sheet was 300 mm × 150 mm × 22 mm, produced by the Thermo Mechanical Control Process (TMCP), which is a highly optimized process that combines controlled rolling at 950 °C and accelerated cooling at a rate of up to 30 °C/s to achieve a fine-grained, high-strength microstructure; Figure 1 shows the microstructure. It was found that the materials consist of polygonal ferrite (F), granular bainite (GB) and a small amount of martensite/residual austenite (M/A). This microstructure provides excellent strength, toughness, and weldability, making X80 steel ideal for pipeline applications. The grain deformation along the rolling direction can also be observed. The welding protective gas introduced was 100% Ar.

Figure 1.

The microstructure of the X80 pipeline steel: (a) optical microscope image; (b) scanning electron microscope image.

The chemical composition of X80 pipeline steels used is listed in Table 2 [18]. The Nb content was controlled at a low level. The steels with a good toughness level had a tensile strength of 700 MPa by controlling the rolling and cooling process. The average hardness was 228 HV10. Lower niobium content reduced the pinning effect of carbonitrides (NbC/NbN) on grain boundaries during welding, making the steel more susceptible to grain coarsening at higher heat inputs. This was confirmed by microstructural analysis, which showed an obvious increase in grain size at 270 J/mm compared to 180 J/mm.

Table 2.

Chemical compositions of the X80 pipeline steel.

2.2. Experimental Methods

2.2.1. Laser Welding

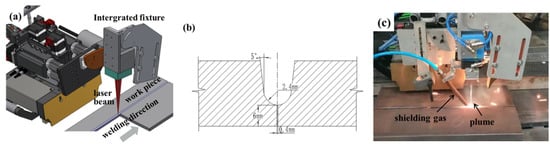

The new generation of rail-mounted laser-arc hybrid welding systems (model GWCX-LAHW01) was jointly developed by the PipeChina Engineering Technology Innovation Company and China Petroleum Research Institute. The system integrated both fiber-laser and electric-arc-welding heat sources. The laser spot diameter was 0.6 mm. The all-position laser hybrid welding and single laser welding for pipelines could be realized. First, the welding system was used to perform laser-backing welding on X80 steel plates on the welding platform. The U-shaped groove with a 6 mm root face was manufactured at the end of the steel plate. The welding process is shown in Figure 2.

Figure 2.

Laser-backing welding on X80 steel plate: (a) schematic diagram of laser welding; (b) joint design; (c) welding process.

It should be mentioned that the heat input was determined by the ratio of laser power to welding speed [19]. Most of the researchers paid more attention to the influence of laser power or welding speed on welding penetration, whereas the superimposing effect of welding speed and laser power were ignored. To investigate the combined effects of laser power and welding speed, we employed an orthogonal-design experimental approach, which could systematically evaluate the effects of multiple factors with a minimal number of experiments. The orthogonal design of laser power and welding speed was carried out in this work. The variables such as shielding-gas flow rate, groove size, and defocus amount remained constant. The influence of different heat inputs on the formation, microstructure, and properties of laser-backing welded X80 steel joints were explored. The welding parameters used are shown in Table 3. The heat inputs of 162, 180, 210, and 270 J/mm were chosen based on preliminary experiments to systematically evaluate the effects of heat input on the microstructure and mechanical properties of X80 steel welds. Preliminary experiments were conducted to identify the range of heat inputs covering both low heat input (minimizing grain coarsening) and high heat input (simulating excessive heat exposure). The defocus amount was determined to be −2 mm after considering the welding formation, spatter, and others.

Table 3.

Process parameters of laser-backing welding for X80 pipe steel.

2.2.2. Microstructure and Microhardness Distribution Test

Metallographic specimens with dimensions of 50 × 22 × 30 mm were sectioned perpendicular to the welding direction using a wire-EDM process, after which cross-sections were progressively ground using silicon carbide papers from 600 to 1200 grit and were polished using 0.1 μm alumina suspension to achieve a mirror-like surface. Finally, the polished samples were immersed in 4% nitric-acid alcohol. Immediately after etching, samples were rinsed with ethanol and dried with compressed air. After preparation, the specimens were observed using an optical microscope. (ZEISS Imager.M1m; Carl Zeiss AG, Oberkochen, Germany) and a scanning electron microscope (SEM). Microhardness (HV0.5) measurements were conducted on the polished samples across the joints for a load of 500 g and a dwell time of 12 s by an automatic Vickers microhardness tester (FLC-ARS000; Future-Tech Corporation, Tokyo, Japan). All indentations were distributed at minimum grid spacing of 0.3 mm across the joints to prevent any potential effect of strain fields caused by adjacent indentations. The results were plotted to create a hardness nephogram, which is a visual representation of the microhardness value distribution of the backing weld, heat-affected zone, and base metal.

2.2.3. Impact Toughness and Fracture Analysis

Currently, the engineering design requirements for the impact-toughness-test temperature of onshore buried pipelines are mostly −10 °C in China. Therefore, this test, measuring the impact toughness of the laser-backing weld, was set at −10 °C. An impact toughness test was conducted in accordance with ASTM E23 standards, and a group of impact specimens with V-notch configurations and dimensions of 2.5 × 10 × 55 mm was prepared at the center of the weld. Each group contained 6 parallel specimens. After the test, the fracture morphology was characterized by a field-emission scanning electron microscope.

3. Results and Discussion

3.1. Effect of Heat Input on the Weld Formation

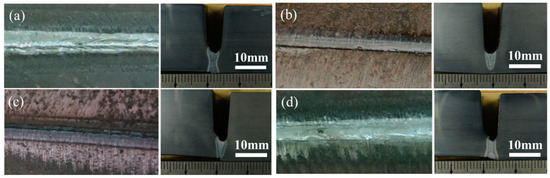

Figure 3 shows the backside weld formation of the joint and its cross-section macroscopic metallography under four different heat input conditions. When the linear energy increases from 162 J/mm to 270 J/mm, the welded joint changes from incomplete penetration to complete penetration, and the depth of the penetration increases from 4.8 mm under the heat input of 162 J/mm to approximately 6 mm under the heat input of 180 J/mm, which means it is insufficient for obtaining a stable back formation when the heat input is lower than 180 J/mm. Furthermore, the 6 mm thick root face can be completely penetrated above the heat input of 210 J/mm. With the increase in heat input, the cross-section of the weld changes from a nail shape to an hourglass shape and finally approaches a straight cylinder shape [10,20]. The welded joints have a stable and continuous formation under both laser powers at 1 m/min welding speed. Concurrent with the extended dwell time at high temperatures, the width of the weld expanded from 2.1 mm to 2.5 mm as the laser power increased from 3.5 kW to 4.5 kW. The amount of metal evaporation from the molten pool and the spatter ejected from the back of the keyhole also increases; as a result, the welding thickness decreases. Therefore, the heat input ultimately determines the welded morphology. To obtain a stable weld formation, sufficient heat input will be required. However, excessive heat input can lead to metallic loss in the welded joint, which negatively influences the production efficiency.

Figure 3.

Weld profiles and cross-section morphologies of joint with specified linear energy. (a) 210 J/mm; (b) 162 J/mm; (c) 180 J/mm; (d) 270 J/mm.

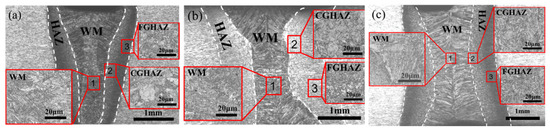

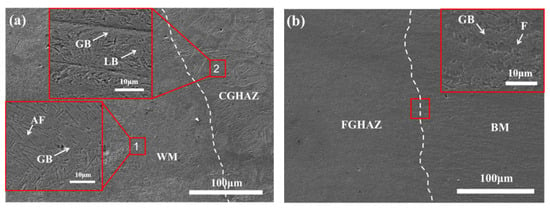

3.2. Effect of Heat Input on Microstructure

During solidification, epitaxial nucleation initiated at the solid–liquid interface of the fusion line, with columnar grains growing competitively along the maximum temperature gradient direction (corresponding to the <100> crystallographic orientation in FCC metals). This process follows the Hunt–Jackson model for columnar growth and produced columnar crystals in parallel. Subsequently, a small amount of nucleation occurred in the center of the weld, and grew and solidified into equiaxed crystals. The metallographic microscope was used to characterize the microstructure of different micro-regions of the welded joint, as shown in Figure 4. After solidification, the WM mainly consisted of acicular ferrite (AF) and granular bainite. The coarse grain heat-affected zone (CGHAZ) near the fusion line is primarily composed of granular and lath bainite (LB). The fine grain heat-affected zone (FGHAZ) away from the fusion line is mainly composed of polygonal ferrite, granular bainite, and particle cementite. When the heat input was 210 J/mm, it not only had enough linear energy to melt through the 6 mm root face but also inhibited the grain growth to a certain extent, compared with the heat input of 270 J/mm. Therefore, reducing the heat input was conducive to obtaining fine-grain structure. Hardness as well as toughness correlated strongly with the phase fractions in WM and HAZ. The WM was dominated by the phase of AF, which combines ultra-high dislocation density and fine grain size, contributing to superior strength and toughness. The HAZ was primarily composed of lath bainite and granular bainite, the ratio of which significantly affected HAZ properties. While lath bainite has higher strength due to the high density of dislocation, the granular bainite has higher toughness due to high-angle ferrite grain boundaries. When heat input increases from 180 J/mm to 270 J/mm, the CCT diagram shifts rightward with reduced cooling rates, contributing to a slight decrease in AF and LB but a more dispersed, even excessive precipitation of carbonitrides at the boundaries. As a result, hardness increases gradually, while toughness improves initially but ultimately degrades.

Figure 4.

A cross-section of the metallographic microstructure of the joint with different linear energy. (a) 180 J/mm; (b) 210 J/mm; (c) 270 J/mm.

The microstructure characterization revealed that the weld metal primarily consisted of acicular ferrite (34 ± 6 vol%), exhibiting an elongated lath morphology with a high aspect ratio and high-angle grain boundaries from15° to 55° (see Figure 5), which contributed to the tested hardness through Hall–Petch strengthening:

where the effective grain size (d) corresponds to the lath’s width. Primary δ-ferrite preferentially precipitated along the grain boundaries of the original austenite to form a network distribution. The remaining granular bainite exhibited M-A constituents due to incomplete phase transformation in bainite.

σy = σ0 + kyd−1/2

Figure 5.

EBSD of WM under heat input of 210 J/mm. (a) BC image; (b) local misorientation map; (c) IPF image; (d) color scale. Color coding: red = [001]; blue = [111]; green= [101] (BCC stereographic triangle).

A scanning electron microscope (SEM) was used to characterize the microstructure of welded joints with the heat input of 210 J/mm. Figure 6 shows that a large number of acicular ferrites of different sizes are distributed in the center of the WM, which can enhance the strength and toughness of the WM. The CGHAZ is mainly composed of granular bainite and lath bainite, while a larger grain size can be found close to the fusion line. The deformed state of the grains along the rolling direction gradually disappears when transitioning from the base metal (BM) to the FGHAZ. Through recrystallization, a large number of equiaxed grains were produced and the structure of the material gradually returned to a softened state. This process helped improve the toughness and strength of the material, thereby enhancing the overall performance of the welded joint.

Figure 6.

Microstructures of different micro-zones in welded joints characterized by SEM: (a) near the fusion line; (b) near the boundary between HAZ and BM.

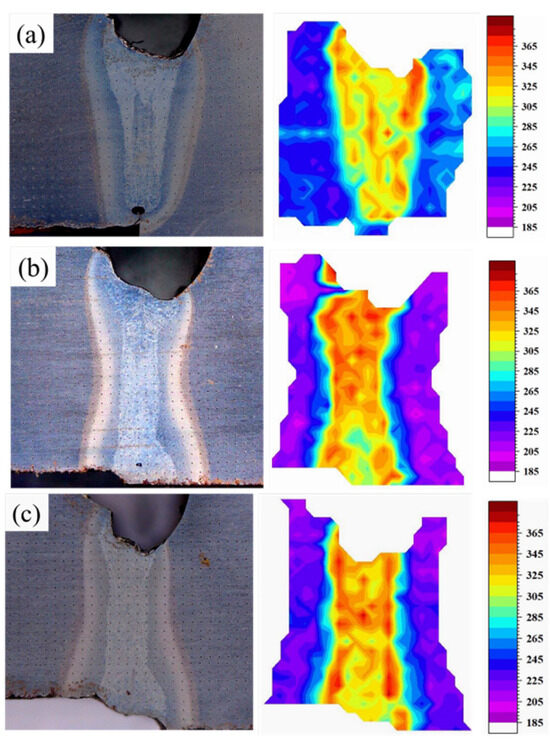

3.3. Effect of Heat Input on the Joint Hardness

The microhardness distribution of the joint is shown in Figure 7. The hardness distribution nephogram under different heat inputs indicates that the WM has the highest hardness, followed by the CGHAZ and FGHAZ. The base metal close to the FGHAZ has the lowest hardness and appears to be softened. When the heat input is 180 J/mm, the hardness of the WM is relatively low. As the heat input increases, the hardness near the weld and the fusion line has an increasing trend, and forms a large gradient distribution near the fusion line. When the heat input is 270 J/mm, the hardness of the CGHAZ near the fusion line is generally as high as 340 HV0.5 or more, showing a relatively obvious hardening feature. When the heat input is 210 J/mm, the hardness of the upper part of the WM is relatively higher than that of the lower part. The hardening level can be adjusted by repeated heat cycles with subsequent filler beads. Therefore, applying a smaller heat input would be helpful for improving the mechanical properties.

Figure 7.

Microhardness nephogram of laser-welded X80 joint with different heat inputs. (a) 180 J/mm; (b) 210 J/mm; (c) 270 J/mm.

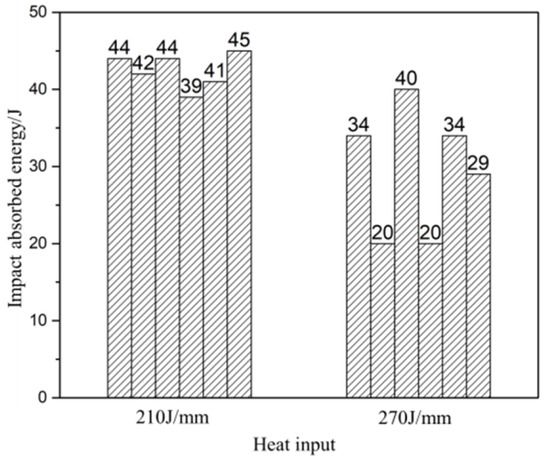

3.4. Effect of Heat Input on the Impact Toughness

When the heat input is lower than 180 J/mm, the penetration effect of a 6 mm root face is insufficient. Therefore, the impact toughness of the WM under 210 J/mm and 270 J/mm at −10 °C were tested in this work. The results show that the impact toughness of the WM is high and stable under the condition of lower heat input, as shown in Figure 8. The content of Nb in X80 steel used here was low, which decreased the inhibiting effect of grain growth. This fact was also not conducive to obtaining good toughness under the conditions of a large heat input and cooling rate. That is, the toughness of the WM was sensitive to the variations in heat input [21,22].

Figure 8.

The impact toughness of the X80 weld with two different heat inputs.

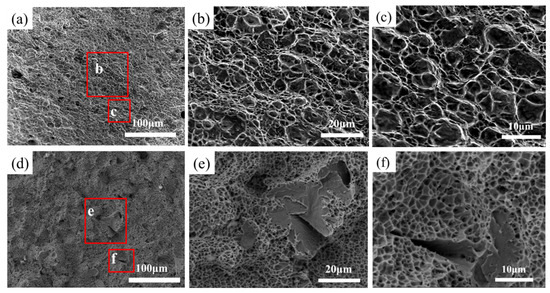

The SEM impact fracture morphologies of X80 steel when laser welding with two different heat inputs was used are presented in Figure 8. It can be seen that the microscopic fracture morphology exhibits a slight difference under the two heat inputs. When the heat input is 210 J/mm, the fracture of the specimen displays a large amount of continuously distributed cup-shaped dimples, and the dimples are relatively deep, which is an obvious toughness fracture. The specimen tested at 270 J/mm (Figure 9b) displays smaller and shallower dimples compared to specimens at the lower heat input. The fracture shows a characteristic of a pore-aggregated fracture, coupled with discontinuously distributed cleavage planes. Localized microcracks can also be observed. The degradation in toughness at a higher heat input (270 J/mm) is attributed to austenite grain coarsening and the precipitation of coarser carbide at the boundaries, resulting in a decrease in the number of grain boundaries and more brittle phases along the grain boundaries. The sliding capacity of the grain boundary was therefore suppressed, which resulted in a decrease in toughness. Therefore, the lower heat input would be conducive to obtaining a suitable impact toughness in the WM.

Figure 9.

Impact fracture morphologies of X80 laser weld with two different heat inputs. (a–c) 210 J/mm; (d–f) 270 J/mm.

4. Conclusions

(1) The joint morphology of the X80 laser-backing welding was primarily influenced by the energy of the heat input. The root face showed a lack of penetration under insufficient heat input. With the increase in heat input, the formation of the weld on the back side gradually became stable, while the width of the WM and HAZ increased. Further increasing the heat input would result in a reduction in the thickness of WM.

(2) The microstructure of the WM of the X80 laser-backing welding were primarily composed of acicular ferrite and granular bainite. The CGHAZ was mainly composed of granular bainite and lath bainite. The FGHAZ was mainly composed of polygonal ferrite, granular bainite, and granular cementite, the deformed grains in the zone during thermo-mechanical rolling gradually disappeared, culminating in softening phenomenon. With the increase in heat input, the content of AF and LB decreased slightly, but more carbonitrides precipitated at the boundaries.

(3) The hardness in the joint of X80 laser-backing welding was distributed from high to low: WM, CGHAZ, and FGHAZ. When the heat input was relatively low, the overall hardness of the joint was low. When the heat input was excessively high, the hardening and embrittlement characteristics appeared in the CGHAZ near the fusion line. With the increase in heat input, hardness increased gradually.

(4) It was essential to control the heat input when the X80 steel with a low Nb content was laser-welded. Excessively high heat input led to grain growth in the WM and CGHAZ, resulting in a reduction in scattered impact toughness. The fracture exhibited localized cleavage characteristics. With the increase in heat input, toughness improved initially but ultimately degraded.

Based on our findings, we recommend a heat input of 210 J/mm for laser welding on X80 steel with a lower niobium content, as it provides an optimal balance of strength and toughness. This parameter minimizes grain coarsening while maintaining high impact energy and tensile strength.

Author Contributions

Conceptualization, C.Y.; methodology, X.S. and C.W.; validation, G.W.; investigation, M.Y. and S.L.; resources, C.W.; writing—original draft preparation, X.S.; writing—review and editing, C.W.; visualization, F.W.; supervision, S.Z.; funding acquisition, C.W. All authors have read and agreed to the published version of the manuscript.

Funding

This work was funded by PipeChina Science and Technology Program No. SJSG202201.

Data Availability Statement

The original contributions presented in this study are included in the this article. Further inquiries can be directed to the corresponding author.

Acknowledgments

We thank Shimin Zhang (China University of Petroleum-Beijing) for their supervision and guidance. We confirm that all acknowledged individuals, including Shimin Zhang, have provided written consent for their mention in this publication.

Conflicts of Interest

Authors Changjiang Wang and Feng Wang were employed by the company PipeChina Engineering Technology Innovation Co., Ltd. Authors Xiaosong Shi, Chen Yan, Meimei Yang, and Songyang Li were employed by the company China Petroleum Pipeline Research Institute Co., Ltd. Author Gang Wei was employed by the company Construction Project Management Branch of National Petroleum and Natural Gas Pipeline Network Group Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest in connection with the work submitted.

References

- Feng, R.J.; Ji, L.K.; Li, W.W.; Liu, Y.; Huo, C. Progress and prospects of research and application of X80 pipeline steel and steel pipe in China. Oil Gas Storage Transp. 2020, 39, 612–618. [Google Scholar]

- Yang, Y.H.; Shi, L.; Xu, Z.; Lu, H.S.; Chen, X.; Wang, X. Fracture toughness of the materials in welded joint of X80 pipeline steel. Eng. Fract. Mech. 2015, 148, 337–349. [Google Scholar] [CrossRef]

- Xu, K. Comprehensive Study on Fatigue Properties of Welded Joints of X80 Welded Pipe. Ph.D. Thesis, Yanshan University, Qinhuangdao, China, 2020. [Google Scholar]

- Yan, C.Y.; Zhang, H.; Zhu, Z.J.; Zhang, K.Z.; Gu, Z.J.; Wang, B.S. Residual stress analysis of X80 pipeline steel by multi pass laser MIG hybrid welding. Trans. China Weld. Inst. 2021, 42, 28–34. [Google Scholar]

- Zhang, J.X.; Li, X.T.; Wang, J. Laser wobble welding process of SUS316 stainless steel. Appl. Laser 2022, 42, 24–32. [Google Scholar]

- Lei, Z.L.; Chen, Y.B.; Song, G.X.; Wang, Q. Weld appearance of CO2 laser-gas metal arc hybrid welding for ultra-low carbon bainitic steel. Chin. J. Lasers 2009, 36, 3068–3073. [Google Scholar]

- Akyel, F.; Üstündag, Ö.; Bakir, N.; Brunner-Schwer, C.; Gumenyuk, A.; Rethmeier, M. Influence of heat input on cooling rates and mechanical properties of laser hybridwelded thick structural steels. Weld. World 2025. [Google Scholar] [CrossRef]

- Zhu, Z.Y.; Min, L.; Xiao, B.Z.; Xue, L.; Zhao, S.Z.; Shen, J.B.; Xu, C.F. Effect of Heat Input on the Metal Microstructure and Mechanical Properties of Q960 High-Strength Steel Solid Core Welding Wire. Steel Res. Int. 2024, 95, 2400060. [Google Scholar] [CrossRef]

- Zou, D.M.; Qi, J.G.; Zhao, L.; Cao, Y. Effect of welding speed on bead appearance and low temperature impact toughness in lase-arc hybrid welding. Chin. J. Lasers 2022, 49, 0802014. [Google Scholar]

- Yang, J.W.; Chen, J.L.; Li, T.; Xiao, H.; Qiao, J. Study on microstructure and properties of QP980 high strength steel joint welded by small laser spot welding. Appl. Laser 2023, 43, 37–42. [Google Scholar]

- Zhang, Q.B.; Ren, L.N.; Lei, X.W.; Yang, J.D.; Zhang, K.; Zhang, J.X. Effect of Laser Heat Input on the Microstructures and Low-Cycle Fatigue Properties of Ti60 Laser Welded Joints. Crystals 2024, 14, 677. [Google Scholar] [CrossRef]

- Yang, L.; Wang, X.N.; Huan, P.C.; Liu, Z.G.; Zhang, M.; Chen, C.J.; Hu, Z.R. Effect of heat input on microstructure and properties of CP800 complex phase steel laser welded joints. Appl. Laser 2018, 38, 562–569. [Google Scholar]

- Jiang, B.; Huang, R.S.; Lei, Z.; Cao, H.; Sun, Q. Research status of 10kW level fiber laser welding technique of medium steel plate. Weld. Join. 2020, 2, 42–48. [Google Scholar]

- Jacek, G. Assessment of the effect of laser welding on the properties and structure of TMCP steel butt Joint. Materials 2020, 13, 1312. [Google Scholar] [CrossRef] [PubMed]

- Suder, W.; Ganguly, S.; Williams, S.; Yudodibroto, B. Root stability in hybrid laser welding. J. Laser Appl. 2017, 29, 022410. [Google Scholar] [CrossRef]

- Ramachandran, O.; Palaniyandi, K.; Natarajan, A. Metallurgical and mechanical properties of laser welded high strength low alloy steel. J. Adv. Res. 2016, 7, 463–472. [Google Scholar]

- Ribic, B.; Palmer, T.A.; Debroy, T. Problems and issues in laser-arc hybrid welding. Int. Mater. Rev. 2009, 54, 223. [Google Scholar] [CrossRef]

- Chen, T.W.; Wang, X.Y.; Xie, J.; Bai, N.; Peng, H.B.; Leng, C.; Xiong, Z.H. Laser-MIG hybrid welding of high-strength marine steel. Ordnance Mater. Sci. Eng. 2023, 46, 125–131. [Google Scholar]

- David, H.; Qi, L.H.; Huo, C.Y.; José, B.B.; Marcos, A.S.N.; Frank, J.B.; Zhang, Y.Q. X80 line pipes with several typical alloy designs and their girth welds. Pet. Tubul. GoodsInstr. 2021, 7, 55–61. [Google Scholar]

- Jin, J.D. A discussion on the heat input formula of welding. Weld. Join. 2001, 6, 42–43. [Google Scholar]

- Barbaro, F.; Zhu, Z.X.; Lenka, K.; Li, H.J.; Gray, J.M. Towards improved steel alloy designs for control of weld heat affected zone properties. In Proceedings of the 5th Baosteel Biennial Academic Conference, Shanghai, China, 4–6 June 2013; pp. 89–96. [Google Scholar]

- Liu, Q.Y. The alloy design and weldability of high performance pipeline steels. In Proceedings of the International Conference on Pipelines and Linepipe Steels, Xi’an, China, 27 April 2015. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).