Evaluation of Fracture Toughness of γ-Phase Containing Cemented Carbides by Using Through-Thickness Micronotches Shaped by Ultrashort Pulsed Laser Ablation

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Indentation Fracture Toughness

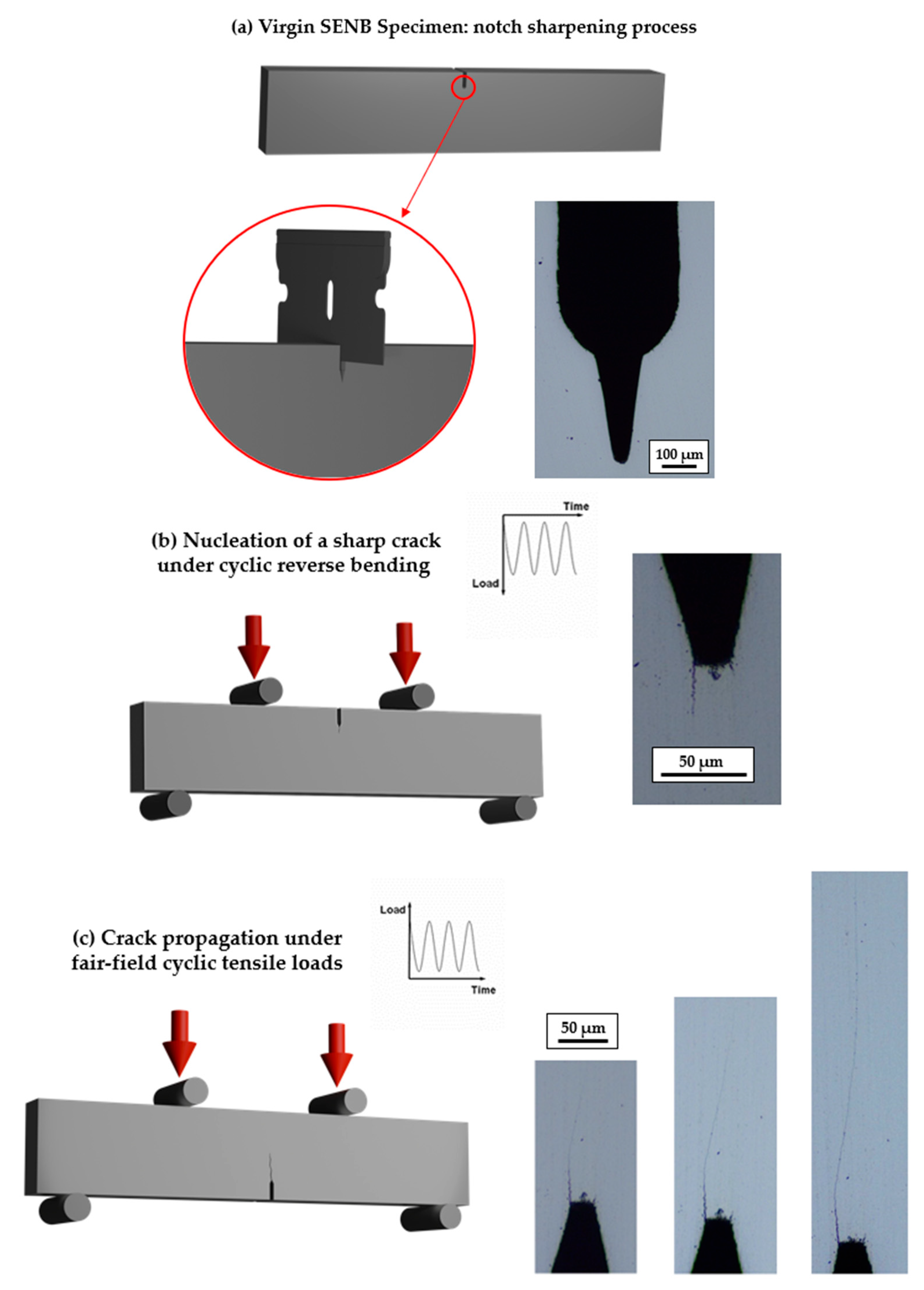

2.3. SENB Testing Procedure

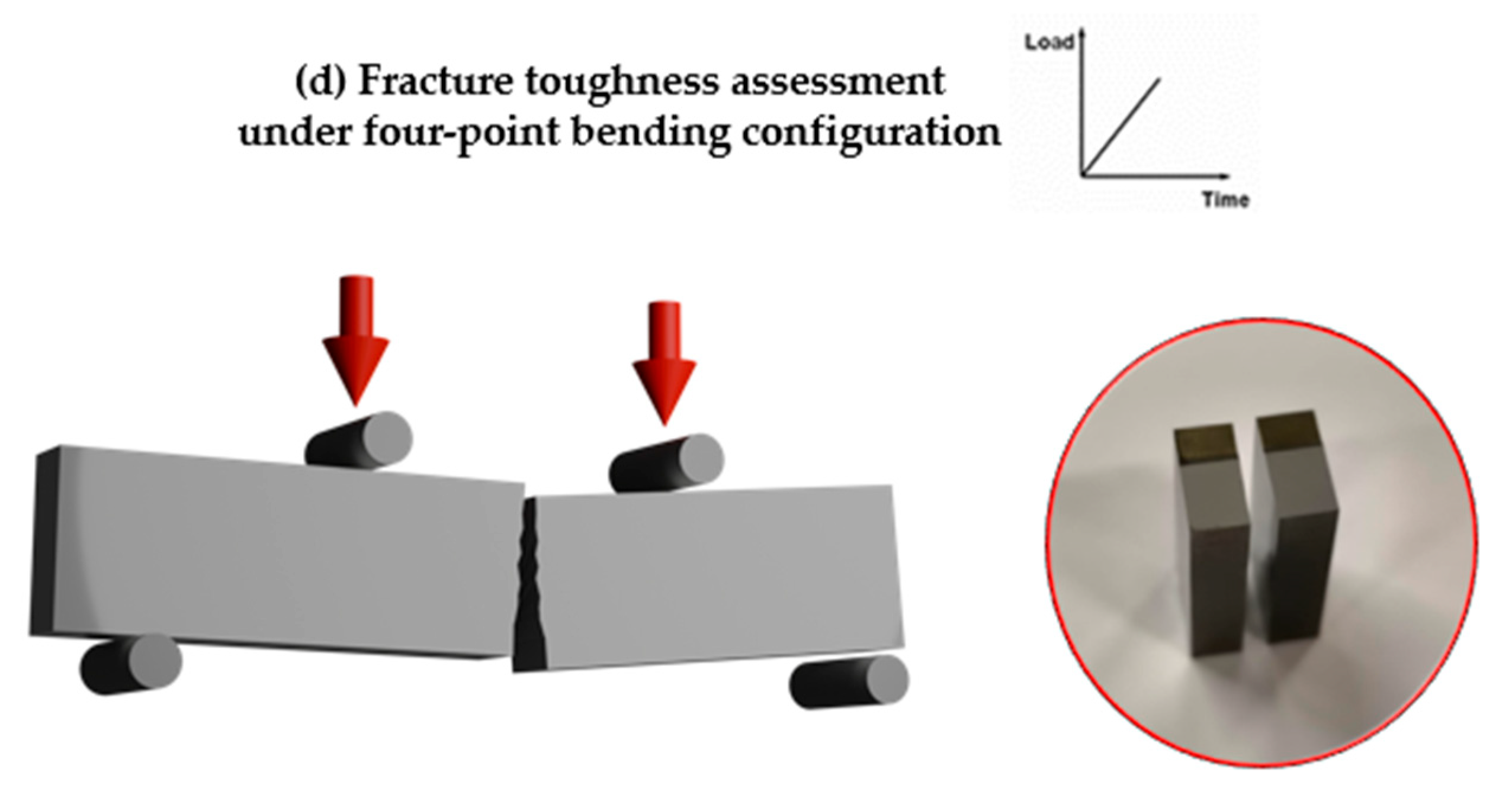

2.4. SEμNB Testing Method

3. Results and Discussion

3.1. Comparative Assessment of Methods Used for Fracture Toughness Evaluation

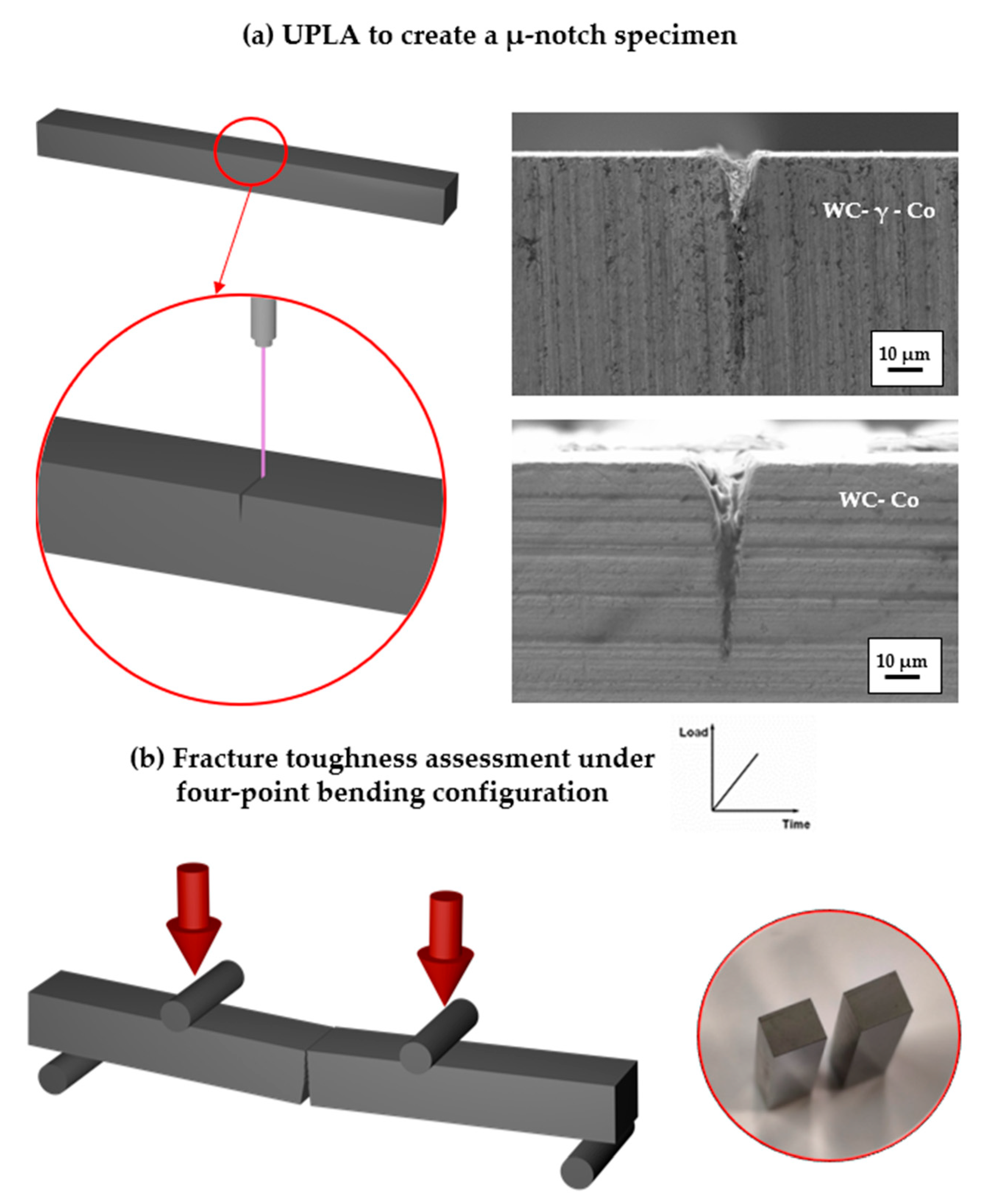

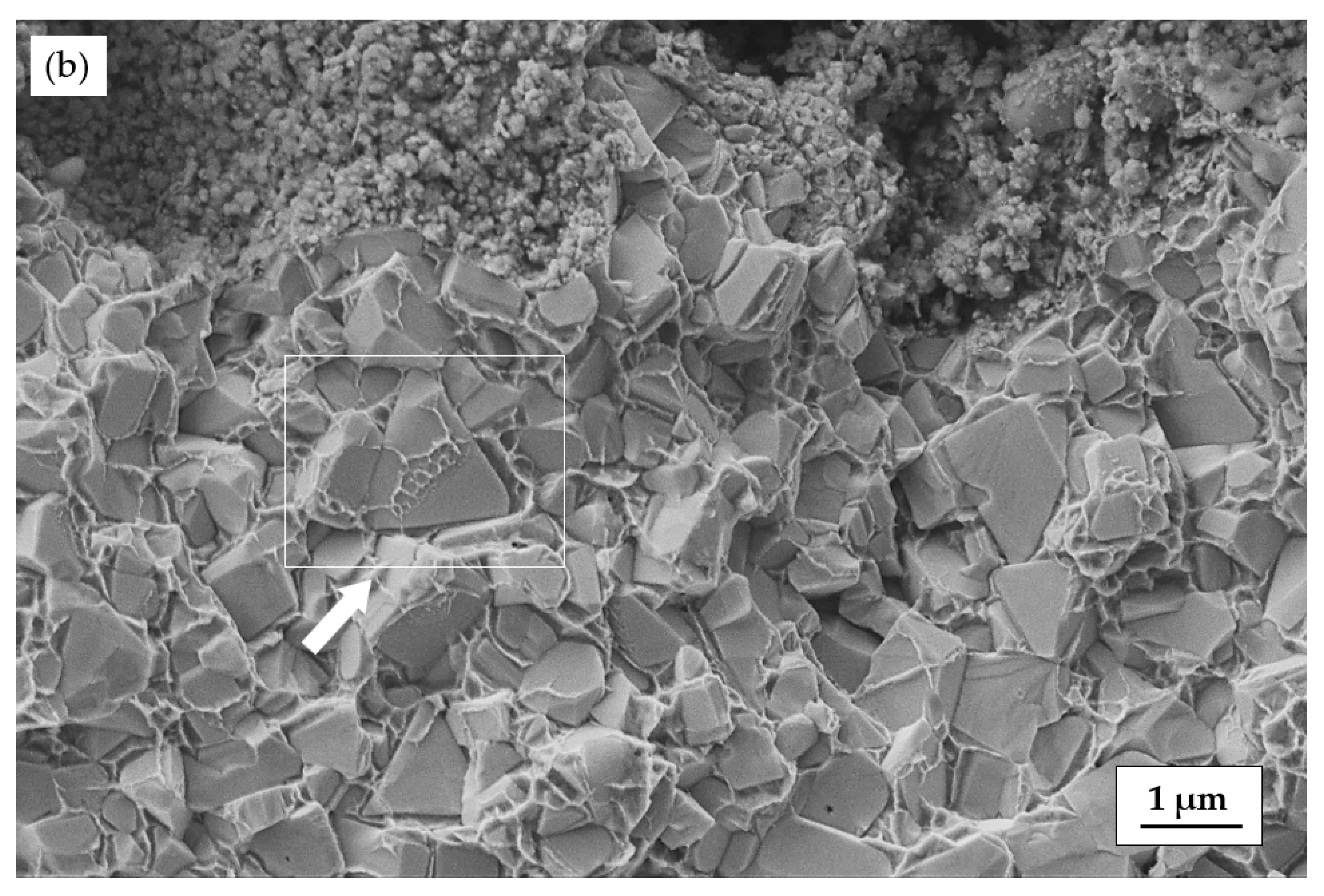

3.2. Fractographic Inspection

4. Conclusions

- (1)

- The UPLA laser μ-notching technique, combined with flexural testing, is a reliable and efficient method for evaluating fracture toughness in cemented carbides. It produces sharp, well-defined notches with minimal residual stresses, ensuring accuracy comparable to pre-cracked SENB specimens, while providing a faster and simpler fracture toughness measurement.

- (2)

- Fracture toughness values obtained from SEμNB specimens were statistically equivalent to those measured with SENB specimens, as confirmed by t-test analysis. This result validates the use of UPLA-generated notches for accurate toughness evaluation, including in γ-phase containing cemented carbide grades.

- (3)

- The fractographic analysis revealed consistent failure micromechanisms between SEμNB and pre-cracked SENB specimens. Ductile dimples observed ahead of the laser μ-notch were also found in pre-cracked SENB specimens, ahead of the crack tip. Moreover, consistency in laser notch profile and depth was evidenced across both studied materials. These findings further validate the applicability of UPLA μ-notching as a viable and reproducible technique to assess fracture toughness in both plain WC-Co and γ-phase cemented carbide grades.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Prakash, L. Fundamentals and General Applications of Hardmetals. In Comprehensive Hard Materials; Elsevier Ltd.: Amsterdam, The Netherlands, 2014; pp. 29–90. [Google Scholar] [CrossRef]

- García, J.; Collado-Ciprés, V.; Blomqvist, A.; Kaplan, B. Cemented carbide microstructures: A review. Int. J. Refract. Met. Hard Mater. 2019, 80, 40–68. [Google Scholar] [CrossRef]

- Viswanadham, R.K.; Sun, T.S.; Drake, E.F.; Peck, J.A. Quantitative fractography of WC-Co cermets by Auger spectroscopy. J. Mater. Sci. 1981, 16, 1029–1038. [Google Scholar] [CrossRef]

- Pickens, J.R.; Gurland, J. The fracture toughness of WC-Co alloys measured on single-edge notched beam specimens precracked by electron discharge machining. Mater. Sci. Eng. 1978, 33, 135–142. [Google Scholar] [CrossRef]

- Warren, P.D. Determining the fracture toughness of brittle materials by Hertzian indentation. J. Eur. Ceram. Soc. 1995, 15, 201–207. [Google Scholar] [CrossRef]

- Torres, Y.; Casellas, D.; Anglada, M.; Llanes, L. Fracture toughness evaluation of hardmetals: Influence of testing procedure. Int. J. Refract. Met. Hard Mater. 2001, 19, 27–34. [Google Scholar] [CrossRef]

- Kenny, P. The application of fracture mechanics to cemented carbides. Powder Met. 1971, 14, 22–38. [Google Scholar] [CrossRef]

- Sheikh, S.; M’Saoubi, R.; Flasar, P.; Schwind, M.; Persson, T.; Yang, J.; Llanes, L. Fracture toughness of cemented carbides: Testing method and microstructural effects. Int. J. Refract. Met. Hard Mater. 2015, 49, 153–160. [Google Scholar] [CrossRef]

- Chychko, A.; García, J.; Collado-Ciprés, V.; Holmström, E.; Blomqvist, A. HV-K Ic property charts of cemented carbides: A comprehensive data collection. Int. J. Refract. Met. Hard Mater. 2022, 103, 105763. [Google Scholar] [CrossRef]

- Shetty, D.K.; Wright, I.G.; Mincer, P.N.; Clauer, A.H. Indentation fracture of WC-Co cermets. J. Mater. Sci. 1985, 20, 1873–1882. [Google Scholar] [CrossRef]

- Fang, S.; Klein, S.; Bähre, D.; Llanes, L. Performance of laser surface textured cemented carbide tools during abrasive machining: Coating effects, surface integrity assessment and wear characterization. CIRP J. Manuf. Sci. Technol. 2020, 31, 130–139. [Google Scholar] [CrossRef]

- Hajri, M.; Börner, P.; Wegener, K. An industry-relevant method to determine material-specific parameters for ultra-short pulsed laser ablation of cemented carbide. Procedia CIRP 2018, 74, 709–713. [Google Scholar] [CrossRef]

- Turon-Vinas, M.; Morillas, J.; Moreno, P.; Anglada, M. Evaluation of damage in front of starting notches induced by ultra-short pulsed laser ablation for the determination of fracture toughness in zirconia. J. Eur. Ceram. Soc. 2017, 37, 5127–5131. [Google Scholar] [CrossRef]

- Ortiz-Membrado, L.; Liu, C.; Prada-Rodrigo, J.; Jiménez-Piqué, E.; Lin, L.L.; Moreno, P.; Wang, M.S.; Llanes, L. Assessment of fracture toughness of cemented carbides by using a shallow notch produced by ultrashort pulsed laser ablation, and a comparative study with tests employing precracked specimens. Int. J. Refract. Met. Hard Mater. 2022, 108, 105949. [Google Scholar] [CrossRef]

- Hearing, B.; Gestrich, T.; Steinborn, C.; Vornberger, A.; Pötschke, J. Influence of alternative hard and binder phase compositions in hardmetals on thermophysical and mechanical properties. Metals 2023, 13, 1803. [Google Scholar] [CrossRef]

- de Nicolás, M.; Besharatloo, H.; Alvaredo, P.; Roa, J.J.; Llanes, L.; Gordo, E. Design of alternative binders for hard materials. Int. J. Refract. Met. Hard Mater. 2020, 87, 105089. [Google Scholar] [CrossRef]

- Soria-Biurrun, T.; Navarrete-Cuadrado, J.; Lozada-Cabezas, L.; Ibarreta-Lopez, F.; Martínez-Pampliega, R.; Sánchez-Moreno, J.M. Microstructure, mechanical properties and fracture behavior of NiCoCrTiAl and FeNiCoCr new alternative binders for WC based hardmetals. Int. J. Refract. Met. Hard Mater. 2021, 103, 105748. [Google Scholar] [CrossRef]

- Grilli, M.L.; Bellezze, T.; Gamsjäger, E.; Rinaldi, A.; Novak, P.; Balos, S.; Piticescu, R.R.; Ruello, M.L. Solutions for critical raw materials under extreme conditions: A review. Materials 2017, 10, 285. [Google Scholar] [CrossRef]

- von Spalden, M.; Pötschke, J.; Michaelis, A. Novel alternative Ni-based binder systems for hardmetals. Crystals 2024, 14, 1013. [Google Scholar] [CrossRef]

- Exner, H.E. Physical and Chemical Nature of Cemented Carbides. Int. Met. Rev. 1979, 24, 149–173. [Google Scholar] [CrossRef]

- Roebuck, B.; Almond, E.A. Deformation and fracture processes and the physical metallurgy of WC–Co hardmetals. Int. Mater. Rev. 1988, 33, 90–112. [Google Scholar] [CrossRef]

- Torres, Y.; Anglada, M.; Llanes, L. Fatigue mechanics of WC–Co cemented carbides. Int. J. Refract. Met. Hard Mater. 2001, 19, 341–348. [Google Scholar] [CrossRef]

- Iizuka, H.; Tanaka, M. Fracture toughness measurement with fatigue-precracked single edge-notched beam specimens of WC-Co hard metall. J. Mater. Sci. 1991, 26, 4394–4398. [Google Scholar] [CrossRef]

- Suresh, S. The failure of hard materials in cyclic compression: Theory, experiments and applications. Mater. Sci. Eng. A 1988, 105, 323–329. [Google Scholar] [CrossRef]

- James, M.N.; Human, A.M.; Luyckx, S. Fracture toughness testing of hard metals using compression-compression precracking. J. Mater. Sci. 1990, 25, 4810–4814. [Google Scholar] [CrossRef]

- Godse, R.; Gurland, J.; Suresh, S. Effects of residual stresses in fracture toughness testing of hard metals. Mater. Sci. Eng. A 1988, 105, 383–387. [Google Scholar] [CrossRef]

- Munz, D.; Fett, T.; Properties, M.; Behaviour, F.; Selection, M. Ceramics; Springer: Berlin/Heidelberg, Germany, 1999. [Google Scholar] [CrossRef]

- Melk, L.; Turon-Vinas, M.; Roa, J.J.; Antti, M.-L.; Anglada, M. The influence of unshielded small cracks in the fracture toughness of yttria and of ceria stabilised zirconia. J. Eur. Ceram. Soc. 2016, 36, 147–153. [Google Scholar] [CrossRef]

- Turon-Vinas, M.; Anglada, M. Assessment in Si3N4 of a new method for determining the fracture toughness from a surface notch micro-machined by ultra-short pulsed laser ablation. J. Eur. Ceram. Soc. 2015, 35, 1737–1741. [Google Scholar] [CrossRef]

- Konyashin, I.; Ries, B.; Carbides, C. Cemented Carbides; Elsevier: Amsterdam, The Netherlands, 2022. [Google Scholar] [CrossRef]

- Huang, S.G.; Liu, C.; Liu, B.L.; Vleugels, J.; Huang, J.H.; Lauwers, B.; Qian, J.; Mohrbacher, H. Microstructure and mechanical properties of (Nb,W,Ti)(C,N)-Ni solid solution cermets with 6 to 20 wt% Ni. Int. J. Refract. Met. Hard Mater. 2022, 103, 105757. [Google Scholar] [CrossRef]

- Li, N.; Zhang, W.; Peng, Y.; Du, Y. Effect of the cubic phase distribution on ultrafine WC–10Co–0.5Cr–xTa cemented carbide. J. Am. Ceram. Soc. 2015, 99, 1047–1054. [Google Scholar] [CrossRef]

- Ramqvist, L. Preparation, properties and electronic structure of refractory carbides and related compounds. Jernkontoret Ann. 1969, 153, 159–179. [Google Scholar]

- Schleinkofer, U.; Sockel, H.G.; Görting, K.; Heinrich, W. Microstructural processes during subcritical crack growth in hard metals and cermets under cyclic loads. Mater. Sci. Eng. A 1996, 209, 103–110. [Google Scholar] [CrossRef]

- Llanes, L. In-depth understanding of fatigue micromechanisms in cemented carbides: Implications for optimal microstructural tailoring. Metals 2019, 9, 924. [Google Scholar] [CrossRef]

- Serra, M.; García-Marro, F.; Cinca, N.; Tarrés, E.; Jiménez-Piqué, E.; Llanes, L. Finite fatigue life behavior and fatigue crack-growth resistance of a fine-grained WC-Co cemented carbide. Int. J. Refract. Met. Hard Mater. 2025, 128, 107022. [Google Scholar] [CrossRef]

- Sigl, L.S.; Fischmeister, H.F. On the fracture toughness of cemented carbides. Acta Met. 1988, 36, 887–897. [Google Scholar] [CrossRef]

- Torres, Y.; Tarrago, J.M.; Coureaux, D.; Tarrés, E.; Roebuck, B.; Chan, P.; James, M.; Liang, B.; Tillman, M.; Viswanadham, R.K.; et al. Fracture and fatigue of rock bit cemented carbides: Mechanics and mechanisms of crack growth resistance under monotonic and cyclic loading. Int. J. Refract. Met. Hard Mater. 2014, 45, 179–188. [Google Scholar] [CrossRef]

| Grade | %vol Binder | dwc (μm) | dγ (μm) | λCo (μm) | Ccarbide | HV30 |

|---|---|---|---|---|---|---|

| WC-Co * | 16.0 | 0.5 ± 0.2 | - | 0.2 ± 0.1 | 0.5 | 1600 ± 10 |

| WC-γ-Co | 16.0 | 0.5 ± 0.3 | 1.2 ± 0.4 | 0.3 ± 0.2 | 0.6 | 1550 ± 10 |

| Grade | IFT (MPa·m1/2) | SENB (MPa·m1/2) | SEμNB (MPa·m1/2) |

|---|---|---|---|

| WC-Co | 11.4 ± 0.1 | 9.9 ± 0.3 | 8.9 ± 0.7 |

| WC-γ-Co | 10.7 ± 0.2 | 9.1 ± 0.5 | 8.5 ± 0.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Serra, M.; Batista, R.; Cinca, N.; Tarrés, E.; Jiménez-Piqué, E.; Moreno, P.; Llanes, L. Evaluation of Fracture Toughness of γ-Phase Containing Cemented Carbides by Using Through-Thickness Micronotches Shaped by Ultrashort Pulsed Laser Ablation. Crystals 2025, 15, 279. https://doi.org/10.3390/cryst15030279

Serra M, Batista R, Cinca N, Tarrés E, Jiménez-Piqué E, Moreno P, Llanes L. Evaluation of Fracture Toughness of γ-Phase Containing Cemented Carbides by Using Through-Thickness Micronotches Shaped by Ultrashort Pulsed Laser Ablation. Crystals. 2025; 15(3):279. https://doi.org/10.3390/cryst15030279

Chicago/Turabian StyleSerra, Marc, Ramon Batista, Núria Cinca, Elena Tarrés, Emilio Jiménez-Piqué, Pablo Moreno, and Luis Llanes. 2025. "Evaluation of Fracture Toughness of γ-Phase Containing Cemented Carbides by Using Through-Thickness Micronotches Shaped by Ultrashort Pulsed Laser Ablation" Crystals 15, no. 3: 279. https://doi.org/10.3390/cryst15030279

APA StyleSerra, M., Batista, R., Cinca, N., Tarrés, E., Jiménez-Piqué, E., Moreno, P., & Llanes, L. (2025). Evaluation of Fracture Toughness of γ-Phase Containing Cemented Carbides by Using Through-Thickness Micronotches Shaped by Ultrashort Pulsed Laser Ablation. Crystals, 15(3), 279. https://doi.org/10.3390/cryst15030279