Microstructure and Reciprocating Sliding Wear Resistance Evaluation on SiMo Ductile Iron Low Alloyed with Cobalt

Abstract

1. Introduction

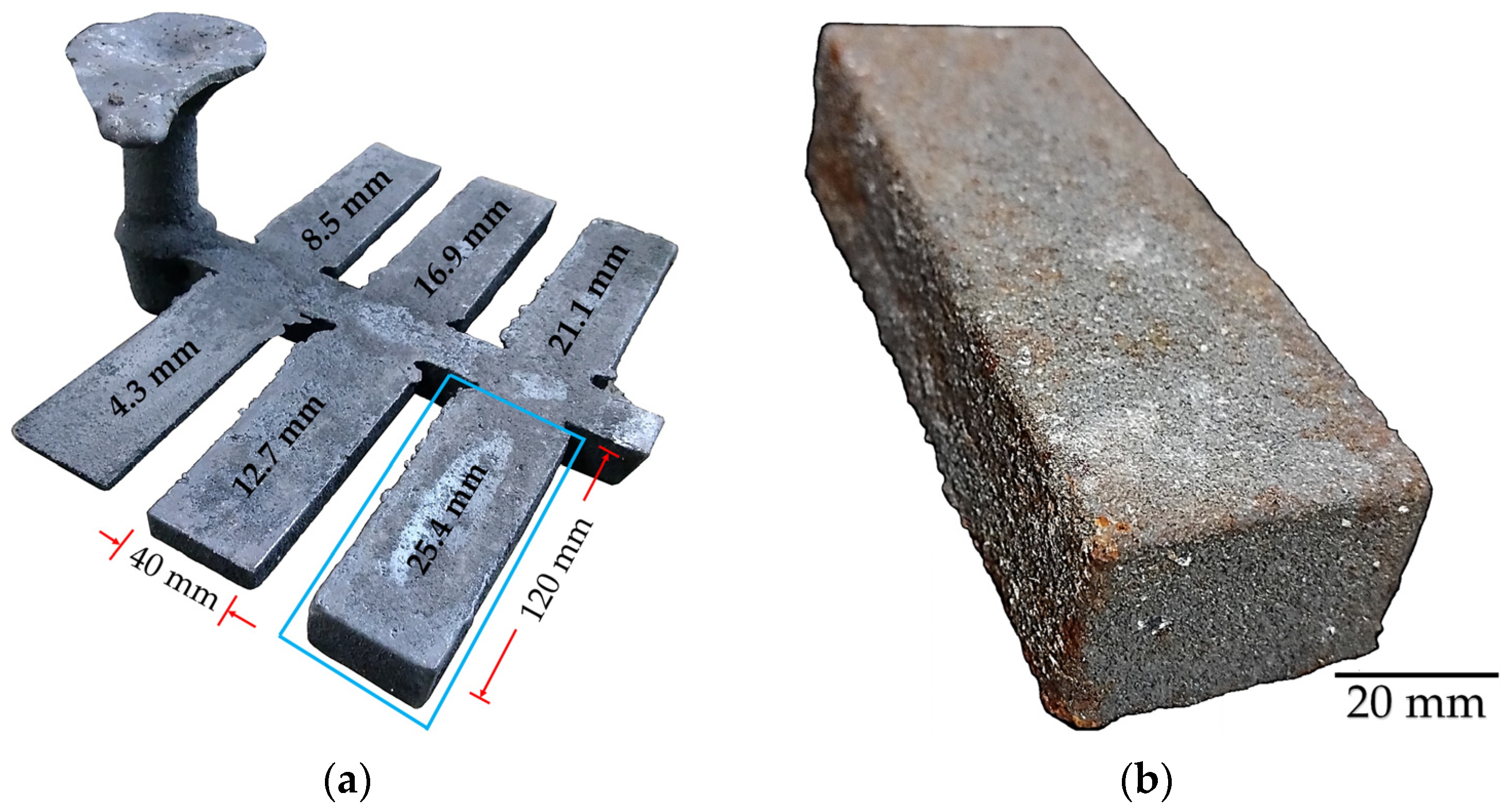

2. Materials and Methods

2.1. Microstructure of SiMo Ductile Irons

2.2. Hardness of SiMo Ductile Irons

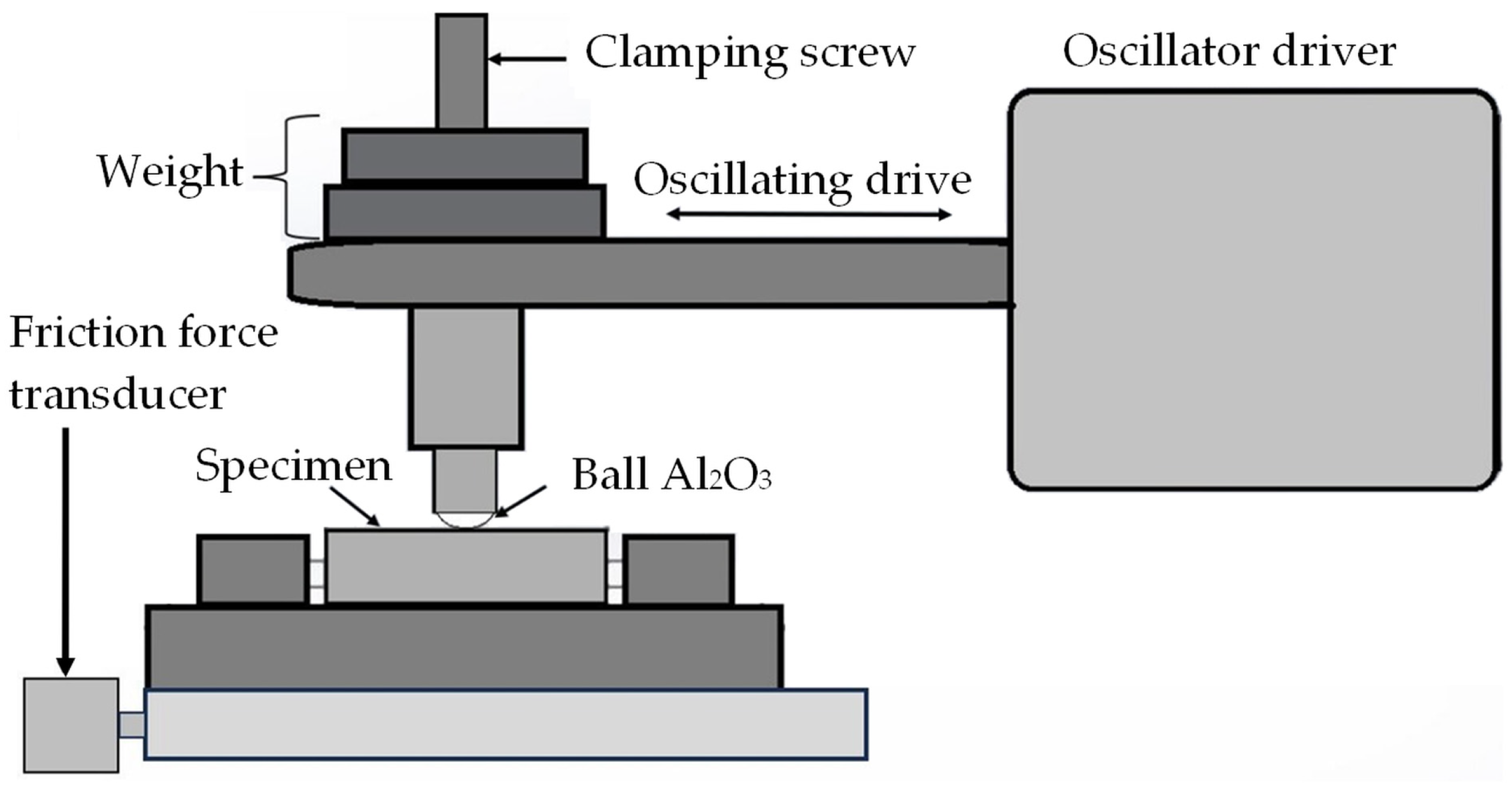

2.3. Reciprocating Sliding Wear of SiMo Ductile Irons

3. Results and Discussion

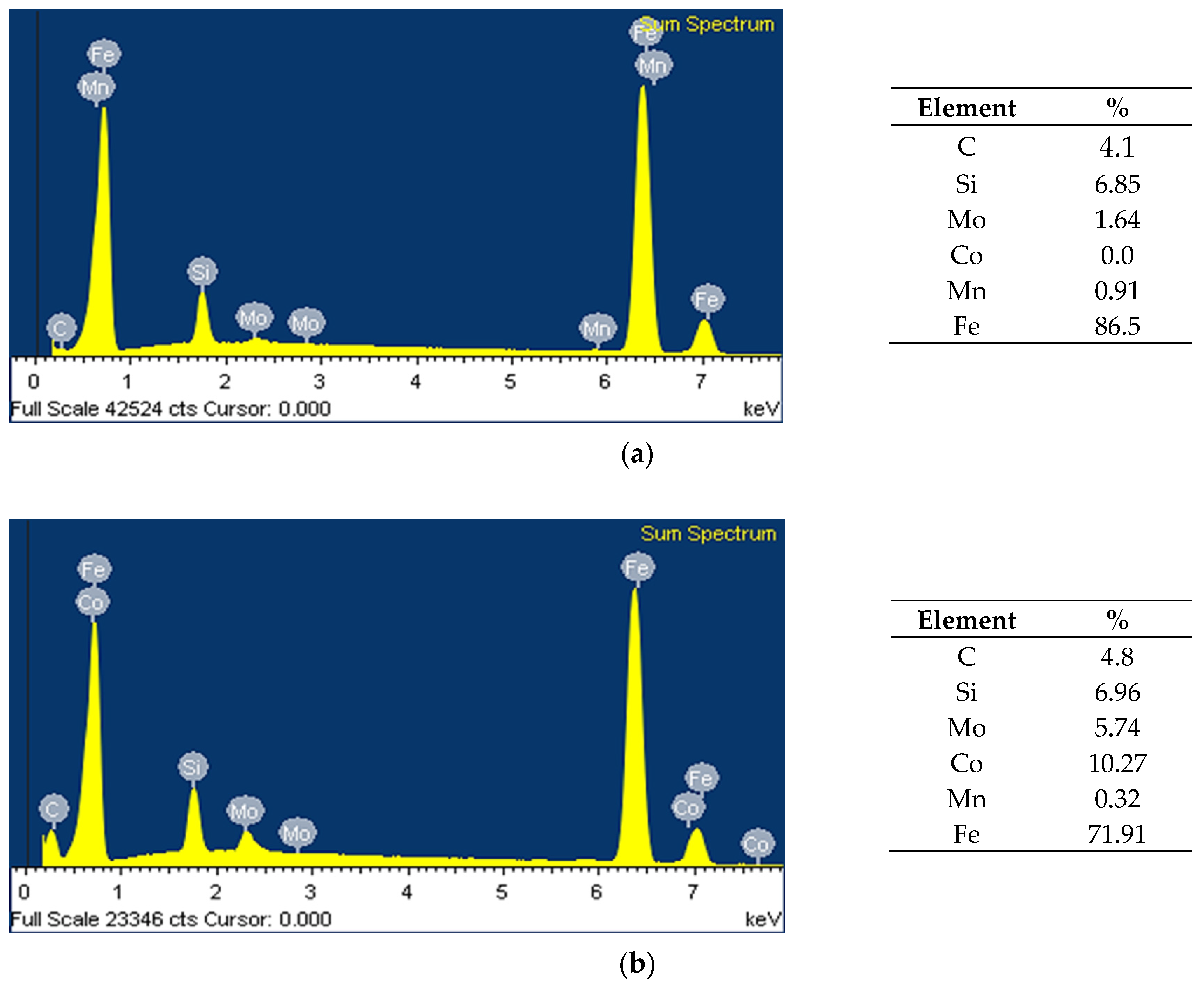

3.1. Chemical Composition of SiMo Ductile Irons

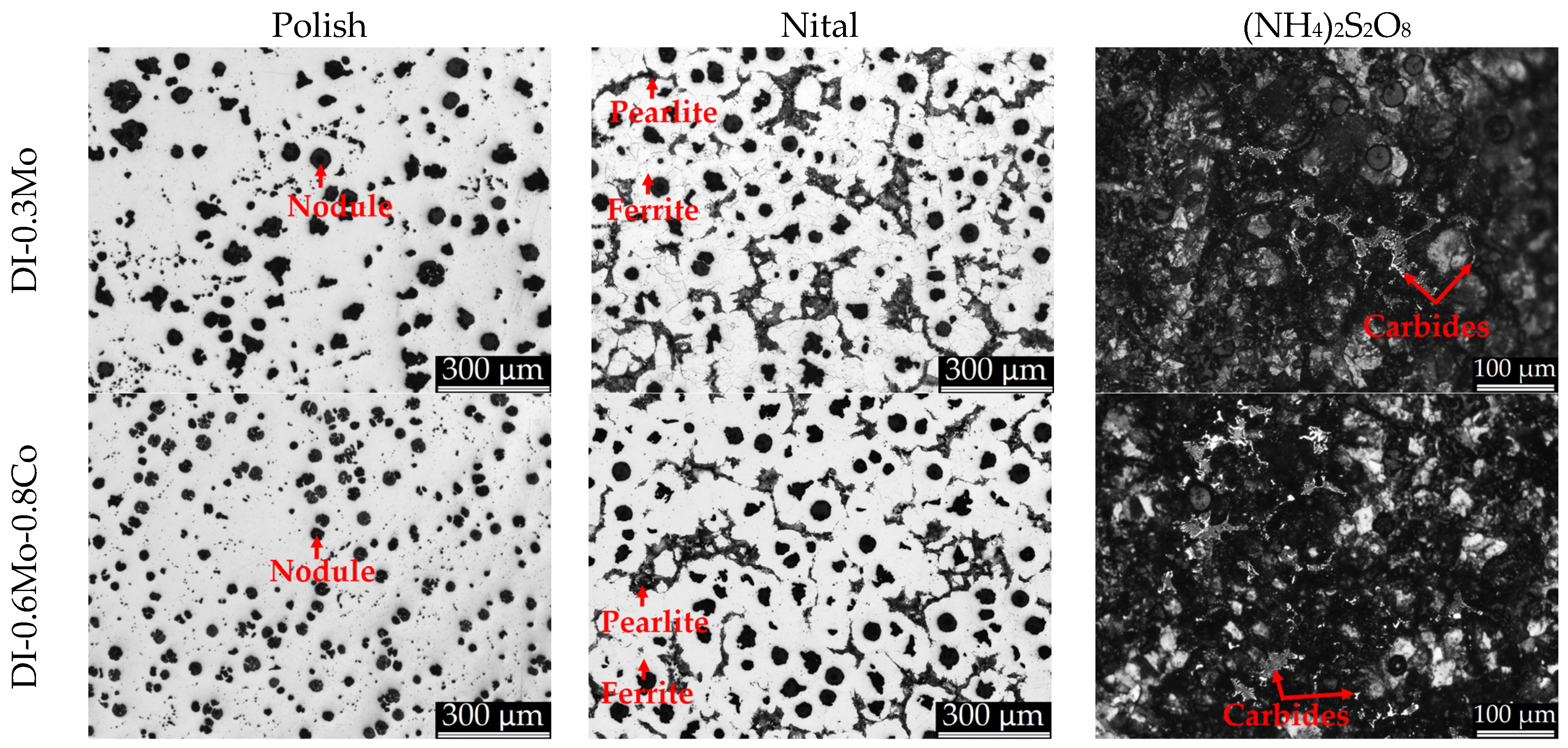

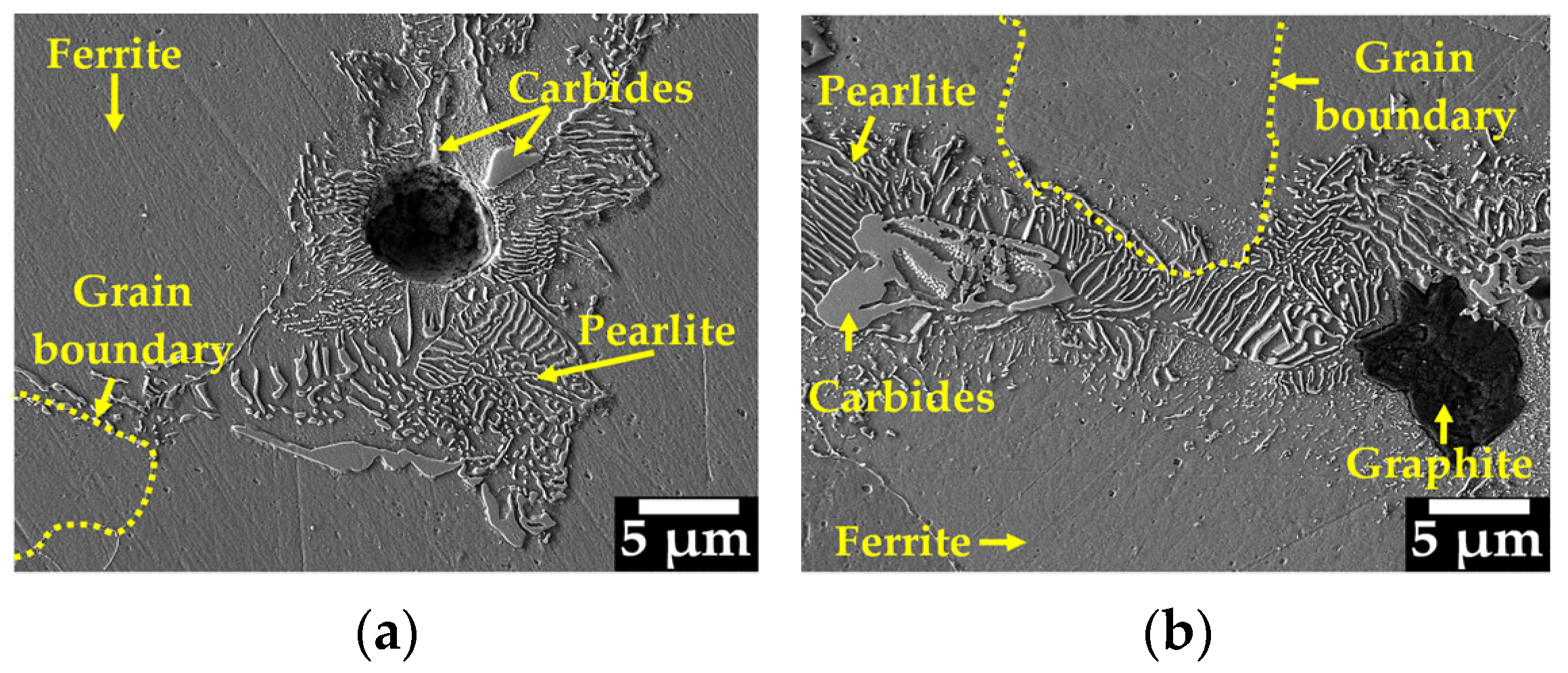

3.2. Microstructural Characterization for SiMo Ductile Irons

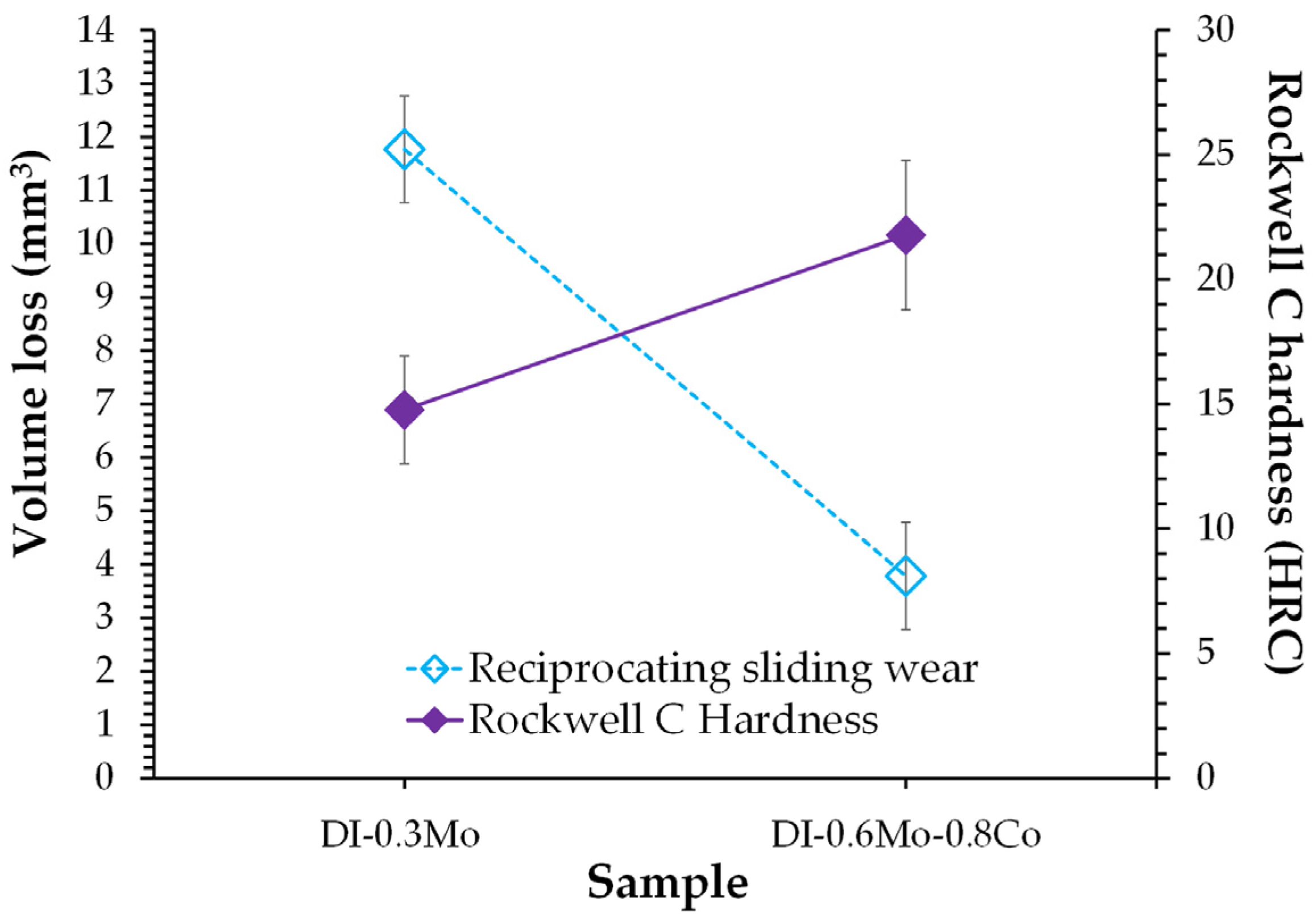

3.3. Hardness of SiMo Ductile Irons

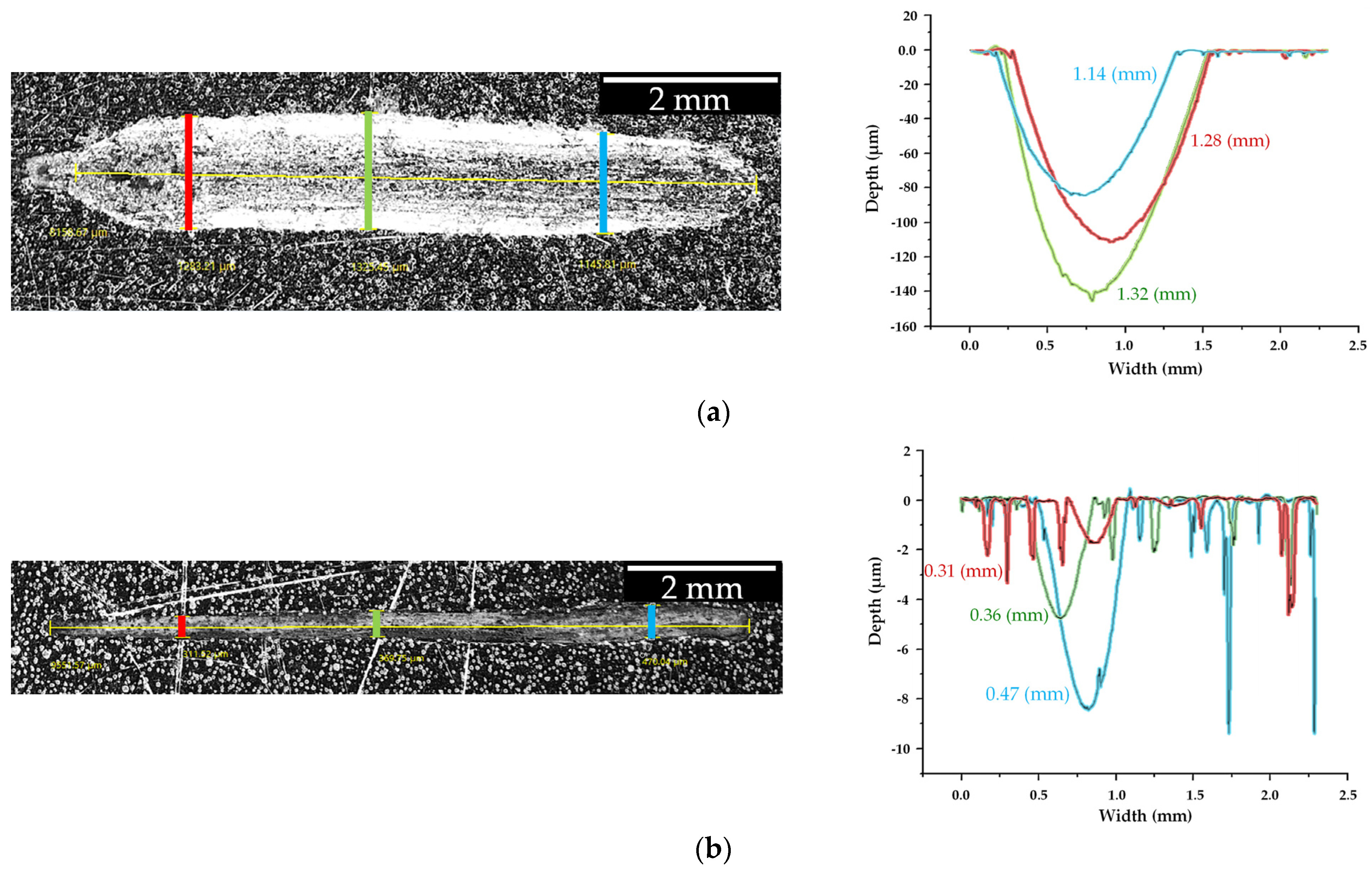

3.4. Reciprocating Sliding Wear of SiMo Ductile Irons

4. Conclusions

- The addition of 0.6% Mo and 0.8% Co in the ductile iron improves the nodule count with 247 nod/mm2, the nodule size is refined with 22.32 µm and 86.69% nodularity, and there is an increase in the volume fraction of ferrite with 78.15% and carbides of 2.1%.

- The carbides due to molybdenum addition were located in the pearlite microconstituent in the grain boundaries inside the predominantly ferritic matrix.

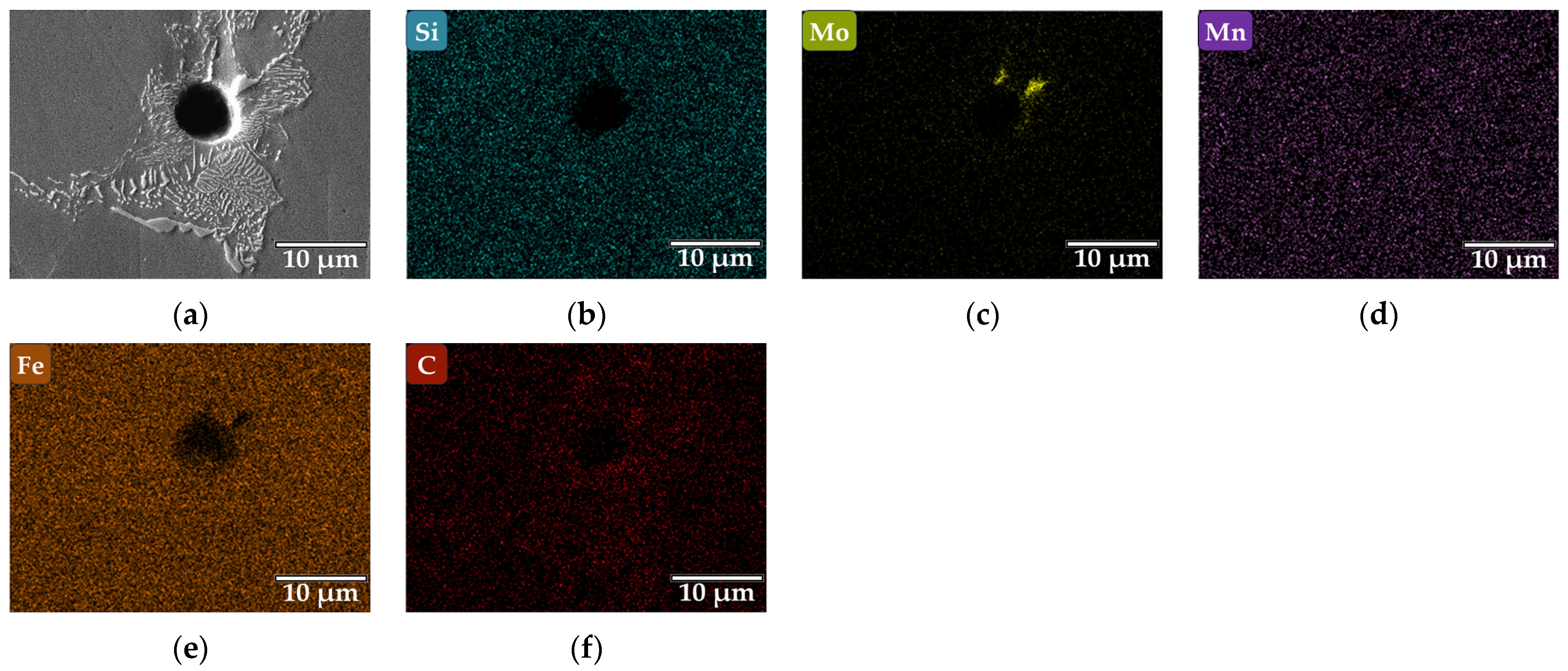

- The SiMo ductile irons were evaluated to show that molybdenum was mainly distributed in the carbides, while cobalt was distributed homogeneously in the ferritic matrix, increasing its strength.

- The highest Rockwell C hardness (21.29 HRC) was obtained for the SiMo ductile iron containing 0.6% Mo and 0.8% Co due to the highest carbide content (2.1%).

- The highest wear resistance due to the lower volume loss (3.78 mm3) and the low friction coefficient was obtained for the SiMo ductile iron containing 0.6% Mo and 0.8% Co as a result of the increased strength of the ferritic matrix by cobalt addition and high carbide content.

- The addition of 0.8% cobalt and 0.6% molybdenum in the SiMo ductile iron contributed to obtaining a higher amount of ferrite (78.15%) with high strength due to a solid-solution mechanism with Co and Mo; this last element also contributed to forming a higher volume fraction of molybdenum carbides (2.1%) with appropriate dispersion in the grain boundaries closer to pearlite regions. Both features contributed to obtaining a higher hardness (21.29 HRC) and higher wear resistance.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sirtuli, L.J.; Bermejo, J.M.B.; Windmark, C.; Norgren, S.; Ståhl, J.-E.; Boing, D. Machining of compacted graphite iron: A review. J. Mater. Proces. Tech. 2024, 332, 118553. [Google Scholar] [CrossRef]

- Chen, T.; Wang, C.; Yan, C.; Li, F.; Wang, J.; Wang, J. Study on friction and wear behavior of gray cast iron with different carbon content at different temperatures. Mater. Res. Express 2024, 11, 046505. [Google Scholar] [CrossRef]

- Hu, Z.; Liu, C.; Du, Y.; Wang, X.; Zhu, X. Effects of tempering temperature on mechanical and tribological behavior of ductile iron. Lubricants 2022, 10, 326. [Google Scholar] [CrossRef]

- Oktadinata, H.; Latifah, S.M.; Sastrawan, S. Influence of tempering time on the microstructure, hardness and impact toughness of ductile cast iron. In Proceedings of the 6th Mechanical Engineering, Science and Technology International Conference (MEST 2022), Xiamen, China, 21–23 October 2022; Atlantis Press: Paris, France, 2023. [Google Scholar]

- Machado, H.D.; García-Mateo, C.; Aristizábal-Sierra, R. Effect of intercritical austenitization and starting matrix on martensite start temperature and austenite carbon concentration in ductile iron. Inter. J. Met. 2024, 1–11. [Google Scholar] [CrossRef]

- Colin-García, E.; Cruz-Ramírez, A.; Reyes-Castellanos, G.; Romero-Serrano, J.A.; Sánchez-Alvarado, R.G.; Hernández-Chávez, M. Influence of nickel addition and casting modulus on the properties of hypo-eutectic ductile cast iron. J. Min. Metall. Sect. B-Metall. 2019, 55, 283–293. [Google Scholar] [CrossRef]

- Ješić, D.; Kovač, P.; Plavšić, M.; Šooš, L.; Sarjanović, D. Wear resistance of austempered pearlitic ductile iron. Kov. Mater. 2018, 56, 415–418. [Google Scholar]

- Hsu, G.H.; Chen, M.L.; Hu, C.J. Microstructure and mechanical properties of 4% cobalt and nickel alloyed ductile irons. Mater. Sci. Eng. A 2007, 444, 339–346. [Google Scholar] [CrossRef]

- Guerra, F.; Bedolla-Jacuinde, A.; Mejia, I.; Zuno, J.; Maldonado, C. Effects of boron addition and austempering time on microstructure, hardness and tensile properties of ductile irons. Mater. Sci. Eng. A 2015, 648, 193–201. [Google Scholar] [CrossRef]

- Hegde, A.; Anne, G.; Gowrishankar, M.C.; Sharma, S.; Karthik, B.M.; Castelino, M.R. Effect of austempering parameters and manganese content on the machinability of austempered ductile iron produced using novel method. Cogent. Eng. 2024, 11, 1–10. [Google Scholar] [CrossRef]

- Dakre, V.S.; Peshwe, D.R.; Pathak, S.U.; Likhite, A.A. Characterization of austempered ferritic ductile iron. Mater. Sci. Eng. 2018, 346, 1–10. [Google Scholar] [CrossRef]

- Abdelrahim, D.M.; Ateia, E.E.; Nofal, A.A. Effect of molybdenum contents on microstructure and high-temperature wear behavior of SiMo ductile iron. Int. J. Met. 2024, 18, 530–545. [Google Scholar] [CrossRef]

- Lekakh, S.N.; Bofah, A.; Godlewski, L.A.; Li, M. Effect of micro-structural dispersity of SiMo ductile iron on high temperature performance during static oxidation. Metals 2022, 12, 661. [Google Scholar] [CrossRef]

- Hervas, I.; Thuault, A.; Hug, E. Damage analysis of a ferritic SiMo ductile cast iron submitted to tension and compression loadings in temperature. Metals 2015, 5, 2351–2369. [Google Scholar] [CrossRef]

- Roučka, J.; Abramová, E.; Kaňa, V. Properties of type SiMo ductile irons at high temperatures. Arch. Metall. Mater. 2018, 63, 601–607. [Google Scholar] [CrossRef]

- Stawarz, M. SiMo ductile iron crystallization process. Arch. Foundry Eng. 2017, 17, 147–152. [Google Scholar] [CrossRef]

- de Magalhães, M.M.; Lemos, G.V.B.; Froehlich, A.; Piaggio, H.; Clarke, T.; Reguly, A. Microstructure and mechanical properties of SiMo ductile cast irons alloys with varied Mo and Nb contents. J. Mater. Res. Technol. 2024, 30, 6301–6308. [Google Scholar] [CrossRef]

- Stan, I.; Chisamera, M.; Lascu, R.; Cariga, C.; Stefan, E.; Stan, S.; Anca, D.; Riposan, L. High temperature oxidation of inoculated high Si/SiMo ductile cast irons in air and combustion atmospheres. China Foundry 2024, 21, 555–562. [Google Scholar] [CrossRef]

- Dyrlaga, Ł.; Zapała, R.; Morgiel, K.; Studnicki, A.; Szczęsny, A.; Kopyciński, D. Evaluation of microstructure and abrasive wear-resistance of medium alloy SiMo ductile cast iron. Materials 2024, 17, 1223. [Google Scholar] [CrossRef]

- Yazdani, S.; Bayati, H.; Elliot, R. The influence of the cobalt on the austempering reaction in ductile cast iron. Int. J. Cast. Metals Res. 2001, 13, 317–326. [Google Scholar] [CrossRef]

- Shen, X.P.; Harris, S.J.; Noble, B. Influence of small vanadium and cobalt additions on microstructure and properties of ductile iron. Mater. Sci. Tech. 1995, 11, 893–900. [Google Scholar]

- Duwe, S.; Tonn, B. Ductile cast iron with high toughness at low temperatures. Mater. Sci. Forum 2018, 925, 334–341. [Google Scholar] [CrossRef]

- González-Martínez, R.; Sertucha, R.J.; Lacaze, J. Effects of cobalt on mechanical properties of high silicon ductile irons. Mater. Sci. Technol. 2020, 36, 327–333. [Google Scholar] [CrossRef]

- Yiran, W.; Ruian, W.; Yimin, G. Effect of Co content on microstructure and mechanical properties of maraging steel. J. Mater. Res. Technol. 2023, 27, 3887–3899. [Google Scholar] [CrossRef]

- Almanza, A.; Dewald, D.; Licavoli, J.; Sanders, P.G. Influence of cobalt in the tensile properties of 1/2 inch ductile iron Y-blocks mold. Inter. Met. 2021, 15, 443–446. [Google Scholar]

- Colin-García, E.; Sánchez-Alvarado, R.G.; Cruz-Ramírez, A.; Suarez-Rosales, M.A.; Portuguez-Pardo, L.; Jiménez-Lugos, J.C. Effect of regular thicknesses on the microstructural and quantitative analysis for a hypo-eutectic ductile iron alloyed with Ni and V. J. Min. Metall. Sect. B-Met. 2024, 60, 15–31. [Google Scholar] [CrossRef]

- ASTM E 18; Standard Test Methods for Rockwell Hardness of Metallic Materials. ASTM International ASTM International: West Conshohocken, PA, USA, 2002.

- ASTM G 133; Standard Test Method for Linearly Reciprocating Ball-on-Flat Sliding Wear. ASTM International: West Conshohocken, PA, USA, 2005.

- Ortiz-Armenta, M.A.; Vera-Cárdenas, E.E.; Abundis-Fong, H.F.; Martínez-Pérez, A.I. Diseño, análisis y fabricación de una plataforma para pruebas de desgaste. In Proceedings of the XXVIII Congreso Internacional Anual de la SOMIM, Bogotá, Colombia, 22 September 2022. [Google Scholar]

- Arshad, W.; Mehmood, A.; Hashmi, M.F.; Rauf, O.U. The effect of increasing silicon on mechanical properties of ductile iron. J. Phys. Conf. Ser. 2018, 1082, 1–6. [Google Scholar] [CrossRef]

- Omran, A.M.; Abdel-Jaber, G.T.; Ali, M.M. Effect of Cu and Mn on the mechanical properties and microstructure of ductile cast iron. J. Eng. Res. Appl. 2014, 4, 90–96. [Google Scholar]

- Upadhyay, S.; Saxena, K.K. Effect of Cu and Mo addition on mechanical properties and microstructure of grey cast iron: An overview. Mater. Today Proc. 2020, 26, 2462–2470. [Google Scholar] [CrossRef]

- Chavan, S.; Khandelwal, H. Effect of Mo on micro-structural and mechanical properties of as-Cast ferritic spheroidal graphite iron. Trans. Indian Inst. Met. 2021, 74, 2703–2711. [Google Scholar] [CrossRef]

- Franzen, D.; Pustal, B.; Bührig-Polaczek, A. Mechanical properties and impact toughness of molybdenum alloyed ductile iron. Inter. Met. 2021, 15, 983–994. [Google Scholar] [CrossRef]

- Sadighzadeh, B.A. Effect of alloying elements on austempered ductile iron (ADI) properties and its process: Review. China Foundry 2015, 1, 54–70. [Google Scholar]

- Han, C.F.; Sun, Y.F.; Wu, Y.; Ma, Y.H. Effects of vanadium and austempering temperature on microstructure and properties of CADI. Metallogr. Microstruct. Anal. 2015, 4, 135–145. [Google Scholar] [CrossRef]

- Almanza, A.I. Effect of Cobalt in Thin Wall Ductile Iron and Solid Effect of Cobalt in Thin Wall Ductile Iron and Solid Solution Strengthened Ferritic Ductile Iron. Ph.D. Thesis, Michigan Technological University, Houghton, MI, USA, 2020. [Google Scholar]

- Górny, M.; Kawalec, B.M.; Gracz, B.; Tupaj, M. Influence of cooling rate on microstructure formation of Si–Mo ductile iron castings. Metals 2021, 11, 1634. [Google Scholar] [CrossRef]

- Black, B.; Burger, G.; Logan, R.; Perrin, R.; Gundlach, R. Microstructure and dimensional stability in Si-Mo ductile irons for elevated temperature applications. SAE Tech. 2002, 1, 1–18. [Google Scholar]

- Youssef, M.; Nofal, A.; Hussein, A. Influence of cooling rate on nature and morphology of intercellular precipitates in Si-Mo ductile irons. Mater. Sci. Forum 2018, 925, 231–238. [Google Scholar] [CrossRef]

- Stawarz, M. The Role of Intermetallic Phases in Silicon Cast Iron; Polish Academy of Sciences: Katowice, Poland, 2019. [Google Scholar]

- Cruz Ramírez, A.; Colin García, E.; Chávez Alcalá, J.F.; Téllez Ramírez, J.; Magaña Hernández, A. Evaluation of CADI Low Alloyed with Chromium for Camshafts Application. Metals 2022, 12, 249. [Google Scholar] [CrossRef]

- Glavas, Z.; Strkalj, A.; Stojakovic, A. The properties of silicon alloyed ferritic ductile irons. Metalurgija 2016, 55, 293–296. [Google Scholar]

- Meza-Salazar, G.; Cruz-Manjarrez, H.; Agredo-Diaz, G.D.; Ortiz-Godoy, N.; Rickards-Campbell, J.; González-Parra, R.; Valdez-Navarro, R.; Barba-Pingarrón, A. Surface modification of a ferritic ductile iron through plasma nitriding. Dyna 2021, 88, 203–209. [Google Scholar] [CrossRef]

| Test Parameter | Value |

|---|---|

| Hertz pressure (GPa) | 2.11 |

| Load (N) | 30 |

| Frequency (Hertz) | 4 |

| Amplitude (mm) | 9 |

| Total sliding distance (m) | 86.4 |

| Test duration (s) | 1800 |

| Sample | C | Si | Mn | P | S | Mg | Mo | Co | Ni | Al | Cu | Nb | V | CE |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DI-0.3Mo | 3.58 | 3.76 | 0.20 | 0.009 | 0.002 | 0.038 | 0.33 | 0.0 | 0.1 | 0.1 | 0.1 | 0.02 | 0.01 | 4.86 |

| DI-0.6Mo-0.8Co | 3.51 | 3.83 | 0.22 | 0.004 | 0.003 | 0.036 | 0.61 | 0.82 | 0.1 | 0.1 | 0.1 | 0.01 | 0.01 | 4.78 |

| Sample | Nodule Count (Nod/mm2) | Nodule Size (µm) | Nodularity (%) | Graphite (%) | Ferrite (%) | Pearlite (%) | Carbides (%) |

|---|---|---|---|---|---|---|---|

| DI-0.3Mo | 175 | 30.95 | 80.14 | 13.88 | 71.82 | 12.8 | 1.4 |

| DI-0.6Mo-0.8Co | 247 | 22.32 | 86.69 | 11.42 | 78.15 | 8.32 | 2.1 |

| Sample | Rockwell C Hardness Measurements | Average | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | ||

| DI-0.3Mo | 20.1 | 15.3 | 16.4 | 17.2 | 15.2 | 14.6 | 14.5 | 14.7 | 16.8 | 10.5 | 15.53 ± 2.45 |

| DI-0.6Mo-0.8Co | 21.6 | 20.3 | 24.5 | 37.5 | 13.4 | 29 | 15.3 | 18.4 | 14.2 | 19.7 | 21.29 ± 7.39 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Colin-García, E.; Cruz-Ramírez, A.; Moreno-Ríos, M.; Sánchez-Alvarado, R.G.; Romero-Serrano, J.A.; Jiménez-Lugos, J.C.; Martínez-Pérez, A.I.; Vera-Cárdenas, E.E. Microstructure and Reciprocating Sliding Wear Resistance Evaluation on SiMo Ductile Iron Low Alloyed with Cobalt. Crystals 2025, 15, 278. https://doi.org/10.3390/cryst15030278

Colin-García E, Cruz-Ramírez A, Moreno-Ríos M, Sánchez-Alvarado RG, Romero-Serrano JA, Jiménez-Lugos JC, Martínez-Pérez AI, Vera-Cárdenas EE. Microstructure and Reciprocating Sliding Wear Resistance Evaluation on SiMo Ductile Iron Low Alloyed with Cobalt. Crystals. 2025; 15(3):278. https://doi.org/10.3390/cryst15030278

Chicago/Turabian StyleColin-García, Eduardo, Alejandro Cruz-Ramírez, Marisa Moreno-Ríos, Ricardo Gerardo Sánchez-Alvarado, José Antonio Romero-Serrano, Juan Cancio Jiménez-Lugos, Armando Irvin Martínez-Pérez, and Edgar Ernesto Vera-Cárdenas. 2025. "Microstructure and Reciprocating Sliding Wear Resistance Evaluation on SiMo Ductile Iron Low Alloyed with Cobalt" Crystals 15, no. 3: 278. https://doi.org/10.3390/cryst15030278

APA StyleColin-García, E., Cruz-Ramírez, A., Moreno-Ríos, M., Sánchez-Alvarado, R. G., Romero-Serrano, J. A., Jiménez-Lugos, J. C., Martínez-Pérez, A. I., & Vera-Cárdenas, E. E. (2025). Microstructure and Reciprocating Sliding Wear Resistance Evaluation on SiMo Ductile Iron Low Alloyed with Cobalt. Crystals, 15(3), 278. https://doi.org/10.3390/cryst15030278