Influence of Rotational Speed on the Microstructure and Mechanical Properties of Refill Friction Stir Spot Welded Pure Copper

Abstract

1. Introduction

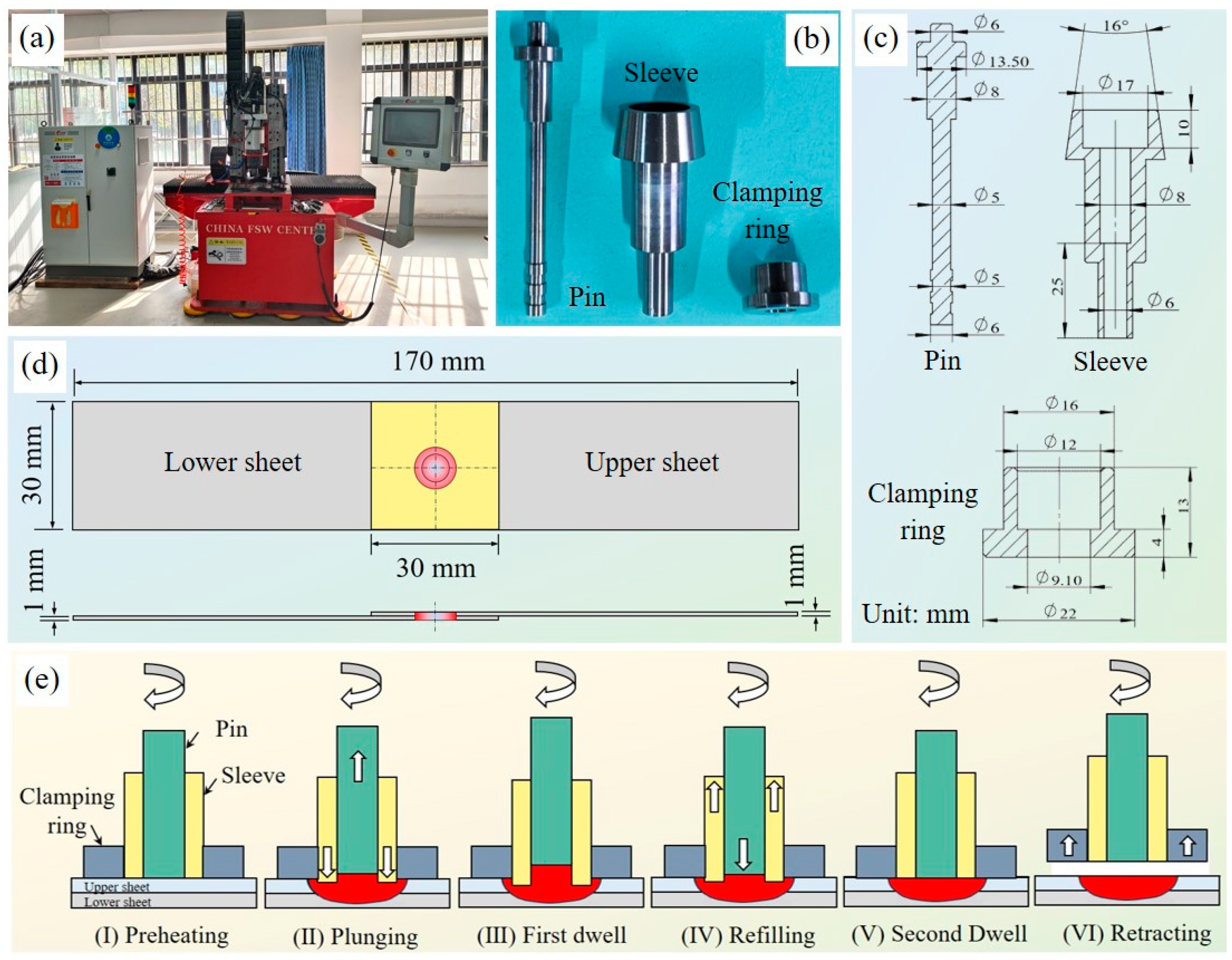

2. Materials and Methods

2.1. Experimental Materials and Equipment

2.2. Microstructure and Mechanical Properties Characterization

3. Results and Discussion

3.1. Appearance and Defects

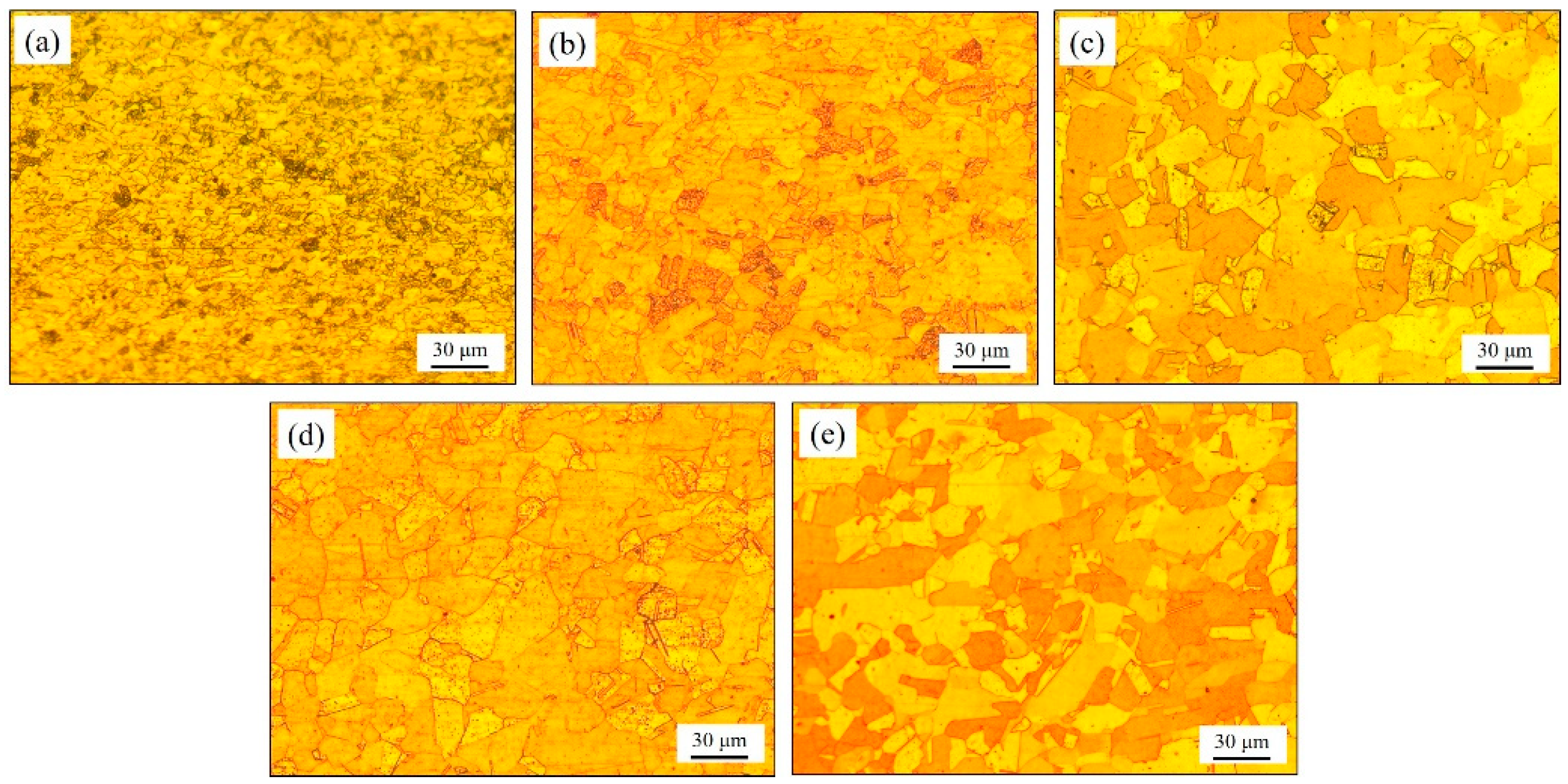

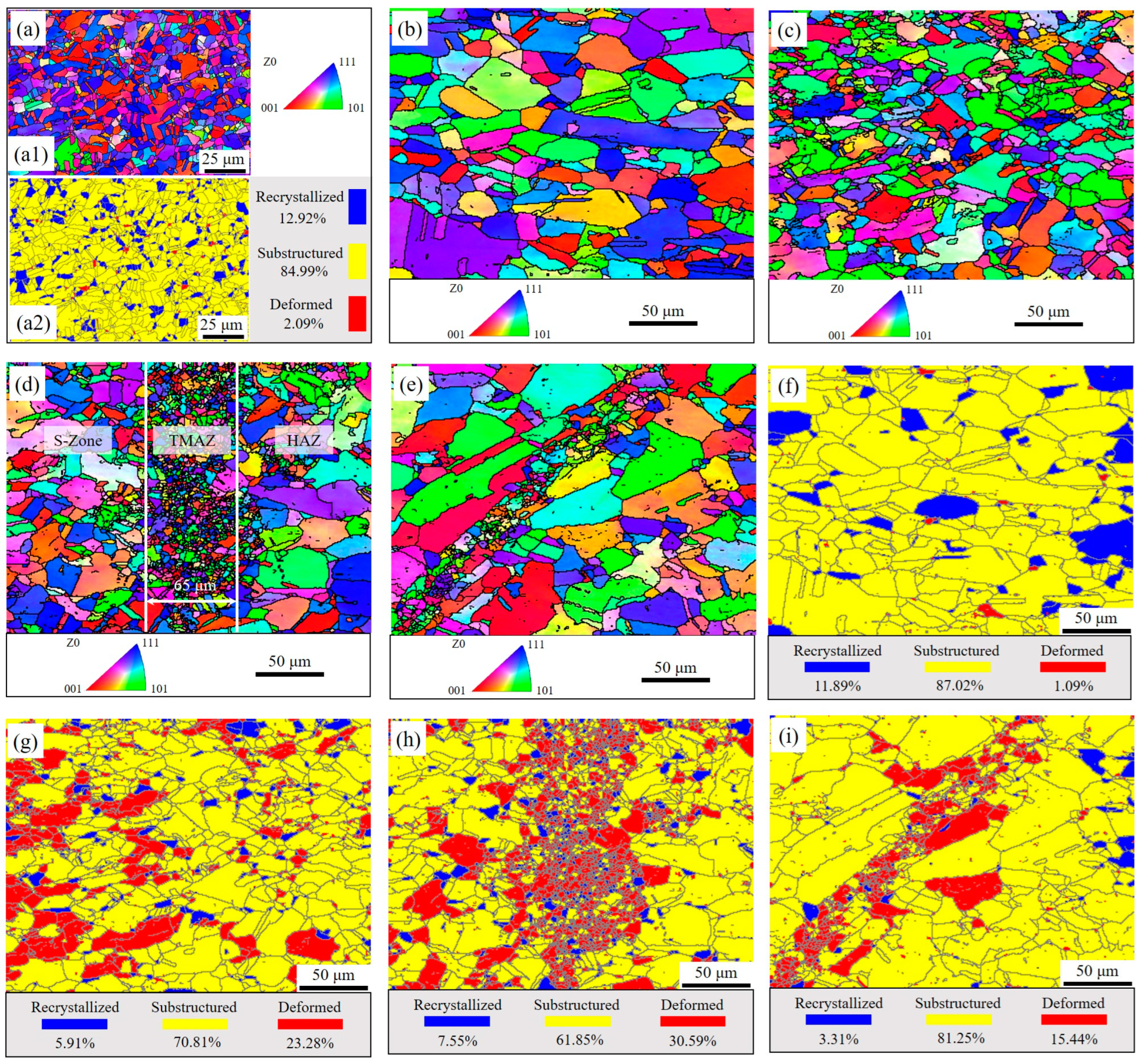

3.2. Microstructure

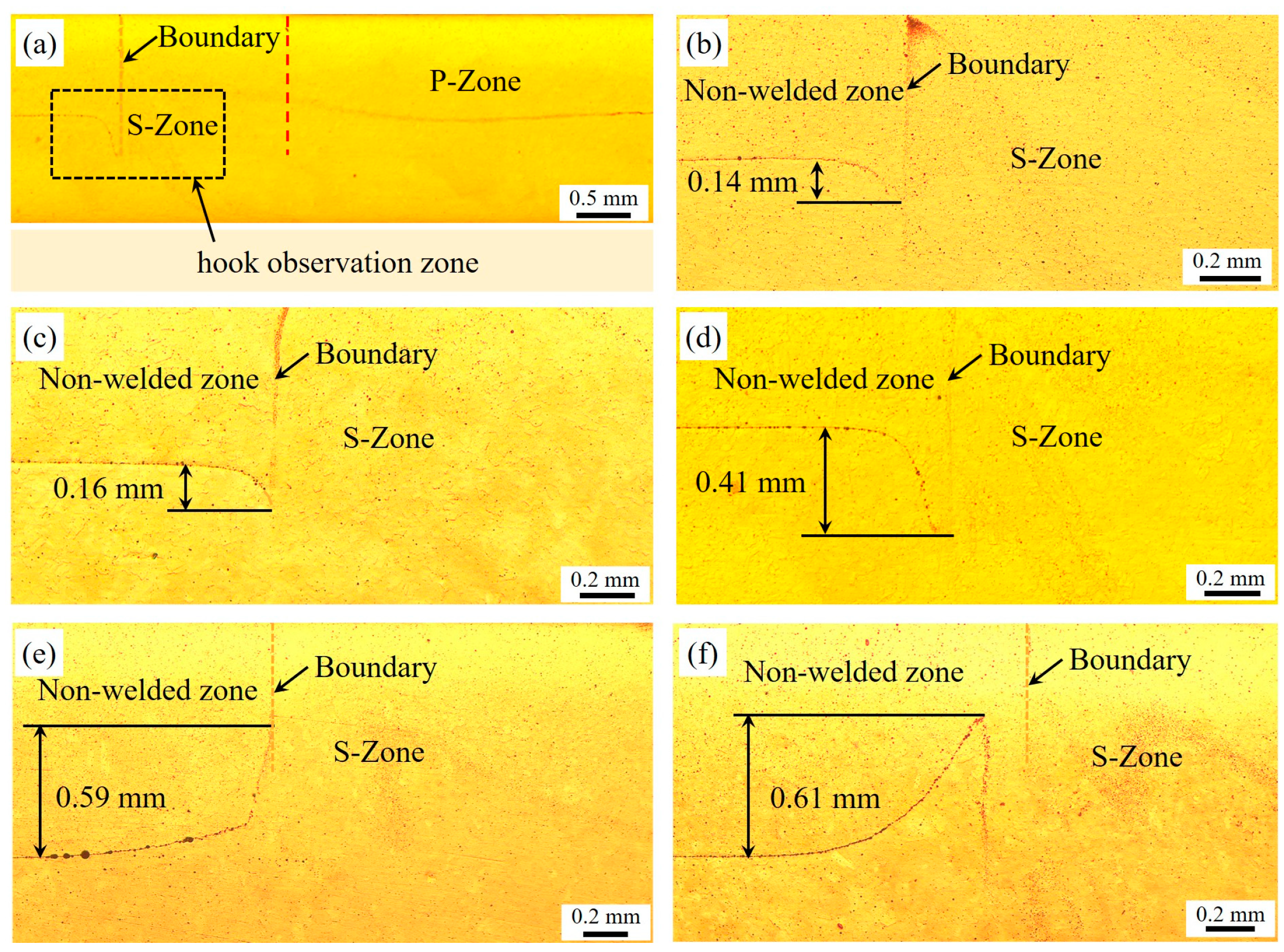

3.3. Hook Morphology

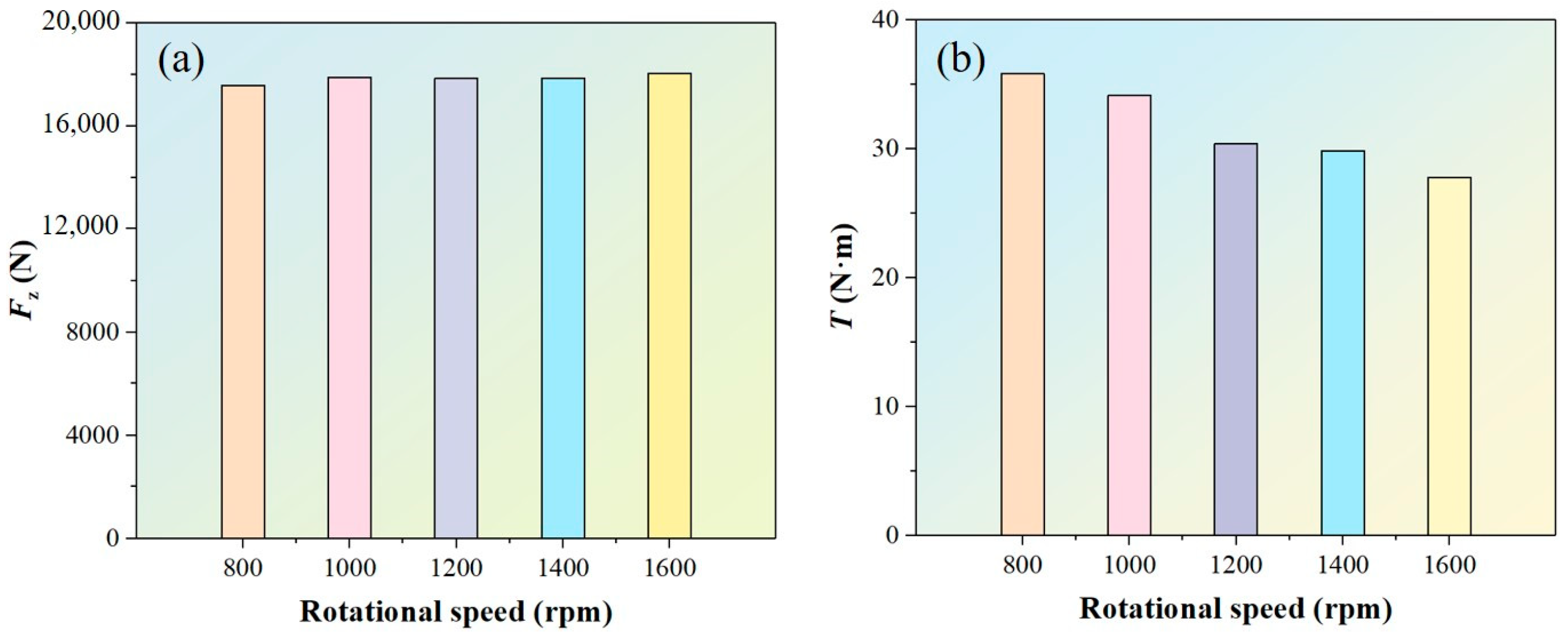

3.4. Axial Force and Torque

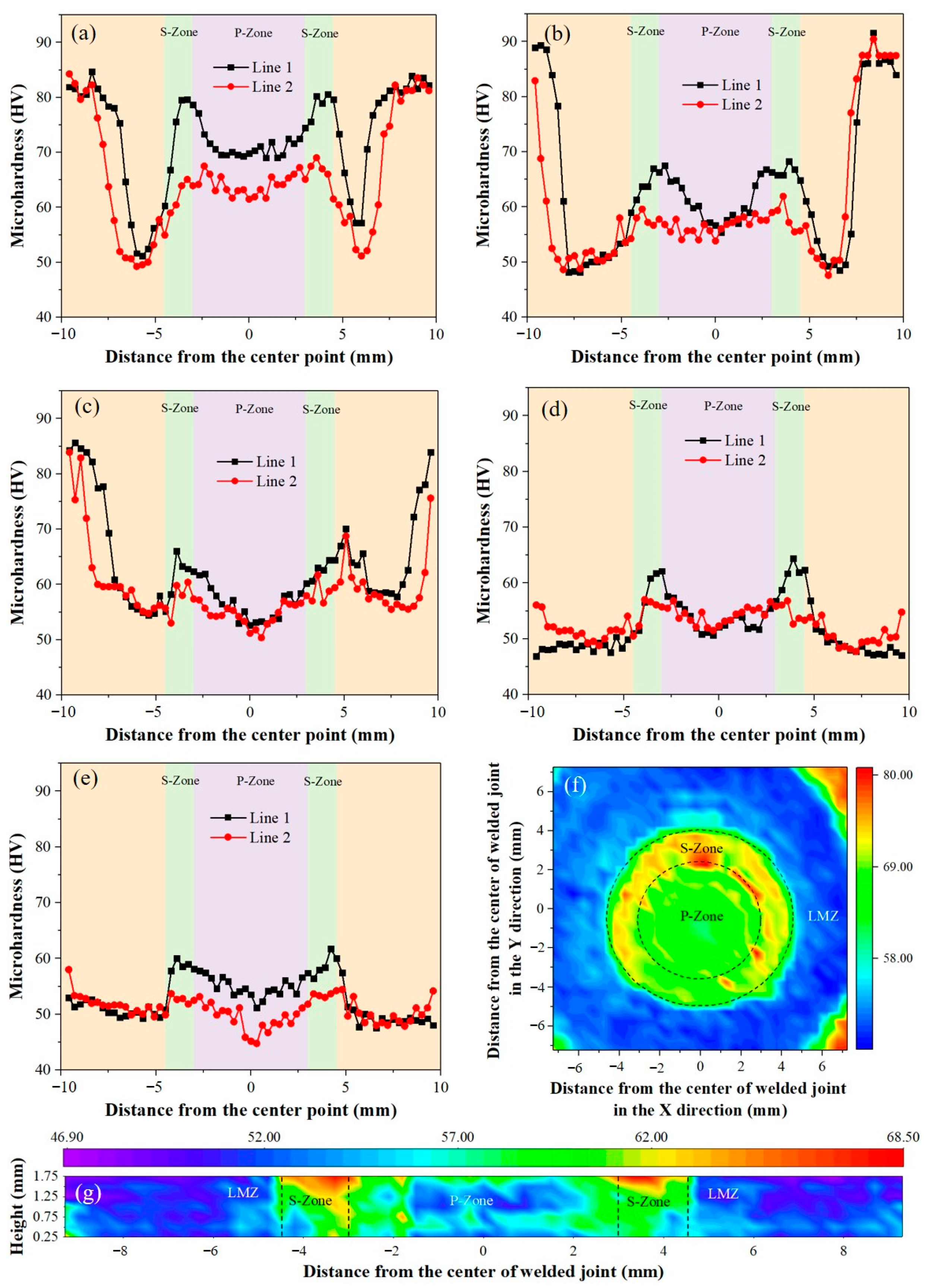

3.5. Microhardness

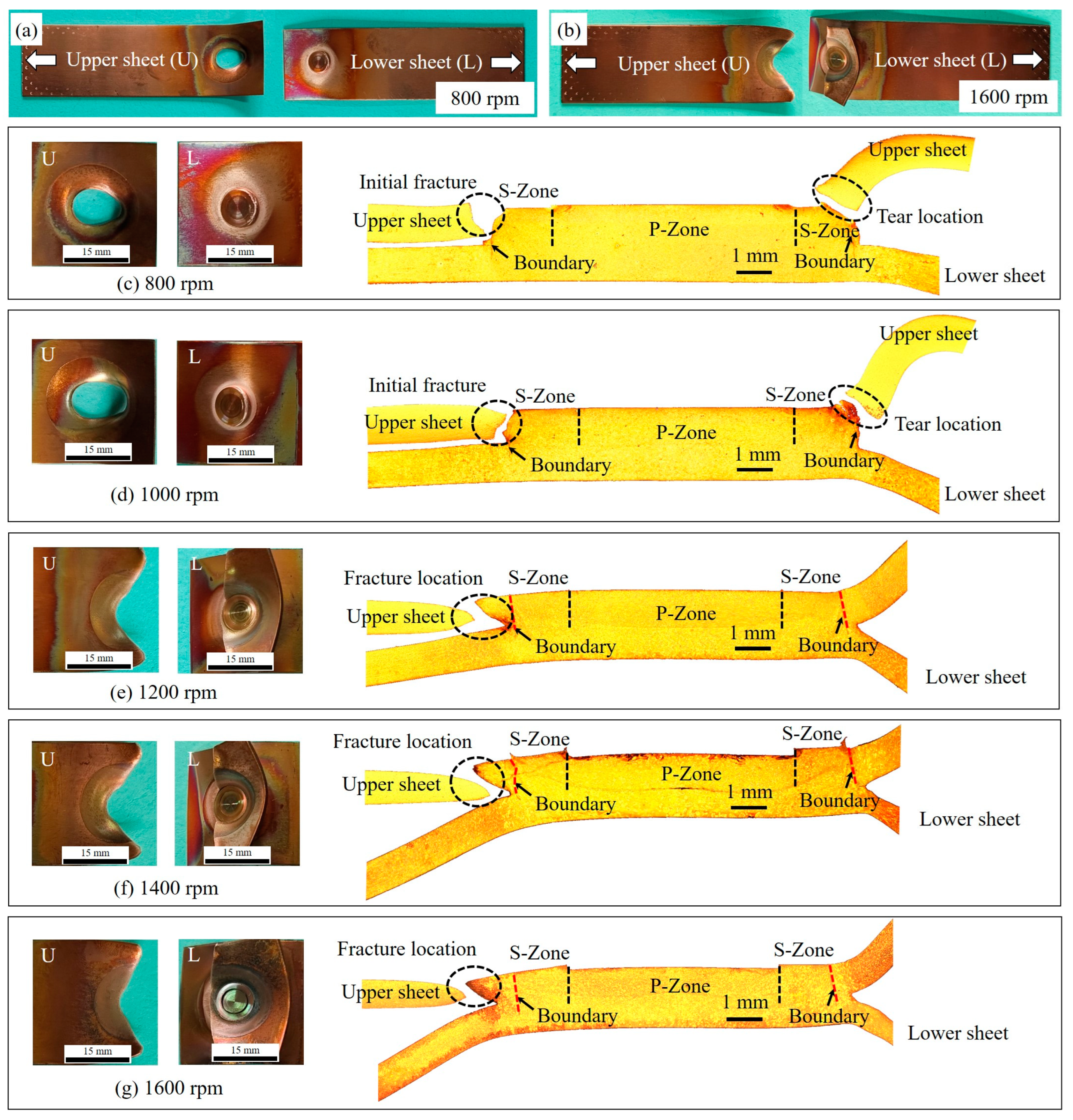

3.6. Tensile Performance

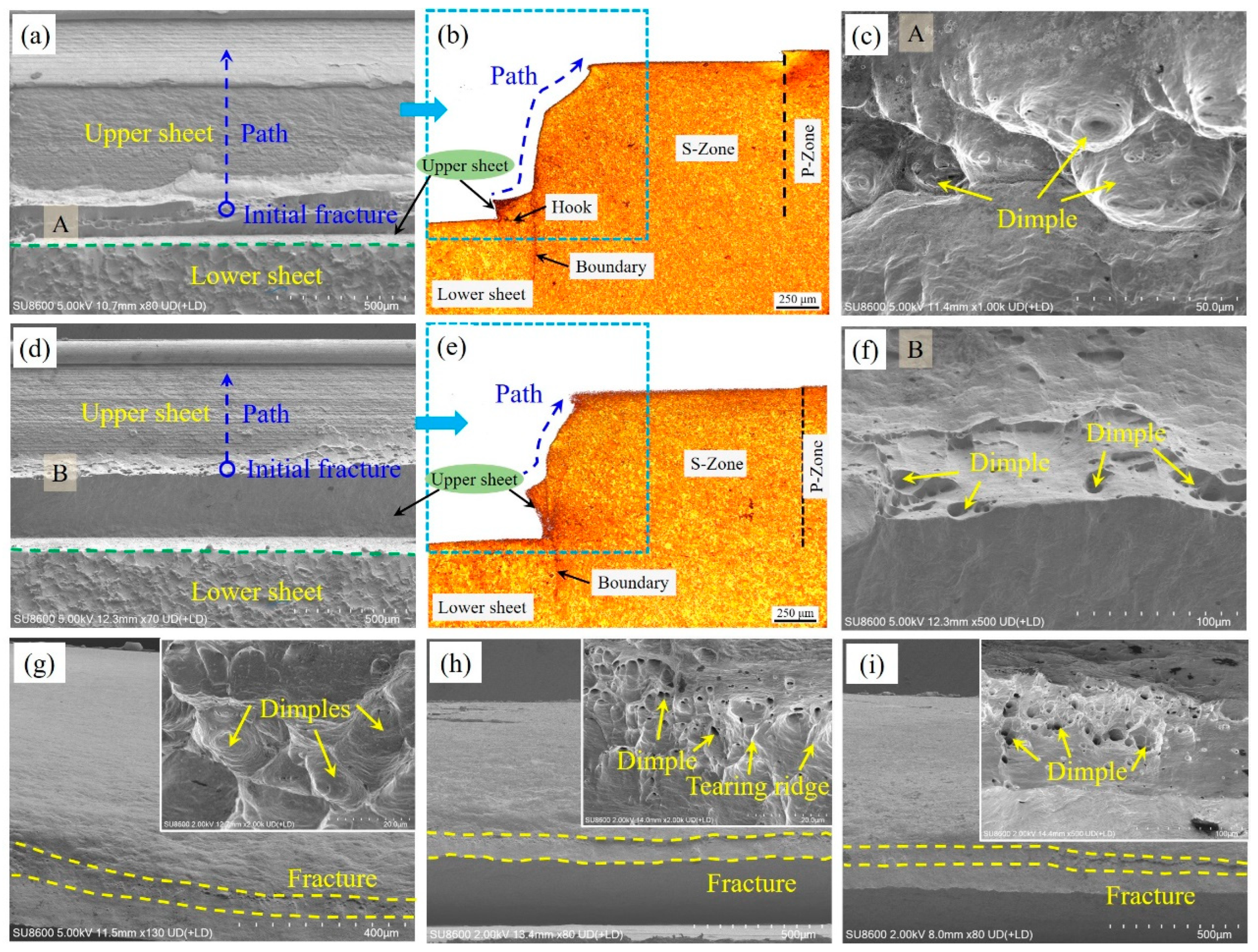

3.7. Fracture Mechanism

4. Conclusions

- (1)

- Two types of welding defects were identified: incomplete refill and surface unevenness. These defects can be mitigated by increasing the rotational speed or adjusting the relative position of the tool. The cross-sectional morphology of the welded joints at different rotational speeds exhibited similar structural features. Higher rotational speeds resulted in coarser microstructures in the stir zone. The average grain size in the S-Zone was smaller than that of the P-Zone. In the welded joints, the substructured grains are predominant. The proportion of substructured grains in the S-Zone is lower than that in the P-Zone, whereas the fraction of deformed grains in the S-Zone is higher than that in the P-Zone. With increasing rotational speed, the hook height gradually increased. During welding, the maximum axial force occurred near the second dwell stage before the welding process concluded, while the maximum torque appeared during the sleeve plunging stage.

- (2)

- The microhardness in the welded zone exhibited an M-shaped distribution, with higher microhardness at the top of the S-Zone and the lowest microhardness at the center of the P-Zone. With increasing rotational speed, the tensile-shear failure load of the welded joint initially increased and then decreased, peaking at 5229 N at a rotational speed of 1200 rpm. At rotational speeds of 800 rpm and 1000 rpm, the welded joints exhibited plug fracture. The initial fracture originated near the bottom of the upper sheet outside the boundary of the welded joint. In the rotational speed range of 1200 rpm to 1600 rpm, the fracture type shifted to upper sheet fracture. The fracture location was at an LMZ within the upper sheet, at a certain distance outside the boundary of the welded joint, coinciding with the transition zone between residual tensile stress and compressive stress.

- (3)

- This study bridges the knowledge gap in understanding the influence of rotational speed on the RFSSW joint characteristics of pure copper, a high-melting-point and high-thermal-conductivity material, which has not been fully revealed in previous research. The findings contribute to a deeper understanding of the welding characteristics of high-melting-point and high-thermal-conductivity materials. Future research should focus on investigating the effects of other process parameters such as plunge depth and welding time on the welding characteristics of pure copper, as well as developing numerical simulation models and temperature field measurements for RFSSW of pure copper to gain a more comprehensive understanding of the welding process.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Forsström, A.; Bossuyt, S.; Yagodzinskyy, Y.; Tsuzaki, K.; Hänninen, H. Strain localization in copper canister FSW welds for spent nuclear fuel disposal. J. Nucl. Mater. 2019, 523, 347–359. [Google Scholar] [CrossRef]

- Ólafsson, D.; Vilaça, P.; Vesanko, J. Multiphysical characterization of FSW of aluminum electrical busbars with copper ends. Weld. World 2020, 64, 59–71. [Google Scholar] [CrossRef]

- Zhang, H.; Jiao, K.X.; Zhang, J.L.; Liu, J. Experimental and numerical investigations of interface characteristics of copper/steel composite prepared by explosive welding. Mater. Des. 2018, 154, 140–152. [Google Scholar] [CrossRef]

- Chen, D.; Li, J.; Xiong, J.; Shi, J.; Dou, J.; Zhao, H. Enhance mechanical properties of refill friction stir spot welding joint of alclad 7050/2524 aluminum via suspension rotating process. J. Mater. Res. Technol. 2021, 12, 1243–1251. [Google Scholar] [CrossRef]

- Heidarzadeh, A.; Jabbari, M.; Esmaily, M. Prediction of grain size and mechanical properties in friction stir welded pure copper joints using a thermal model. Int. J. Adv. Manuf. Technol. 2015, 77, 1819–1829. [Google Scholar] [CrossRef]

- Barlas, Z. Effect of friction stir spot weld parameters on Cu/CuZn30 bimetal joints. Int. J. Adv. Manuf. Technol. 2015, 80, 161–170. [Google Scholar] [CrossRef]

- Zohoori-Shoar, V.; Eslami, A.; Karimzadeh, F.; Abbasi-Baharanchi, M. Resistance spot welding of ultrafine grained/nanostructured Al 6061 alloy produced by cryorolling process and evaluation of weldment properties. J. Manuf. Process. 2017, 26, 84–93. [Google Scholar] [CrossRef]

- Wang, Y.; Tao, W.; Yang, S. A method for improving joint strength of resistance spot welds of AA 5182-O aluminum alloy. J. Manuf. Process. 2019, 45, 661–669. [Google Scholar] [CrossRef]

- Li, G.; Zhou, L.; Zhou, W.; Song, X.; Huang, Y. Influence of dwell time on microstructure evolution and mechanical properties of dissimilar friction stir spot welded aluminum–copper metals. J. Mater. Res. Technol. 2019, 8, 2613–2624. [Google Scholar] [CrossRef]

- Yang, X.W.; Fu, T.; Li, W.Y. Friction stir spot welding: A review on joint macro- and microstructure, property, and process modelling. Adv. Mater. Sci. Eng. 2014, 2014, 697170. [Google Scholar] [CrossRef]

- Fu, B.; Shen, J.; Suhuddin, U.F.H.R.; Chen, T.; dos Santos, J.F.; Klusemann, B.; Rethmeier, M. Improved mechanical properties of cast Mg alloy welds via texture weakening by differential rotation refill friction stir spot welding. Scr. Mater. 2021, 203, 114113. [Google Scholar] [CrossRef]

- Suhuddin, U.F.H.R.; Mironov, S.; Sato, Y.S.; Kokawa, H.; Lee, C.W. Grain structure evolution during friction-stir welding of AZ31 magnesium alloy. Acta Mater. 2009, 57, 5406–5418. [Google Scholar] [CrossRef]

- Patel, V.K.; Bhole, S.D.; Chen, D.L. Influence of ultrasonic spot welding on microstructure in a magnesium alloy. Scr. Mater. 2011, 65, 911–914. [Google Scholar] [CrossRef]

- Zhang, Z.; Yang, X.; Zhang, J.; Zhou, G.; Xu, X.; Zou, B. Effect of welding parameters on microstructure and mechanical properties of friction stir spot welded 5052 aluminum alloy. Mater. Des. 2011, 32, 4461–4470. [Google Scholar] [CrossRef]

- Pankaj, P.; Medhi, T.; Dhara, L.N.; Tiwari, A.; Biswas, P. A route for properties enhancement by utilizing external auxiliary energy systems for FSW of aluminum-steel. CIRP J. Manuf. Sci. Technol. 2023, 46, 204–229. [Google Scholar] [CrossRef]

- Ge, X.; Jiang, D.; Song, W.; Wang, H. Effects of tool plunging path on the welded joint properties of pinless friction stir spot welding. Lubricants 2023, 11, 150. [Google Scholar] [CrossRef]

- Uematsu, Y.; Tokaji, K.; Tozaki, Y.; Kurita, T.; Murata, S. Effect of re-filling probe hole on tensile failure and fatigue behaviour of friction stir spot welded joints in Al–Mg–Si alloy. Int. J. Fatigue 2008, 30, 1956–1966. [Google Scholar] [CrossRef]

- Buffa, G.; Fratini, L.; Piacentini, M. On the influence of tool path in friction stir spot welding of aluminum alloys. J. Mater. Process. Technol. 2008, 208, 309–317. [Google Scholar] [CrossRef]

- Suresh, S.; Venkatesan, K.; Natarajan, E.; Rajesh, S.; Lim, W.H.J.M.E. Evaluating weld properties of conventional and swept friction stir spot welded 6061-T6 aluminium alloy. Mater. Express 2019, 9, 851–860. [Google Scholar] [CrossRef]

- Suresh, S.; Venkatesan, K.; Natarajan, E.; Rajesh, S. Performance analysis of nano silicon carbide reinforced swept friction stir spot weld joint in AA6061-T6 alloy. Silicon 2021, 13, 3399–3412. [Google Scholar] [CrossRef]

- Tozaki, Y.; Uematsu, Y.; Tokaji, K. A newly developed tool without probe for friction stir spot welding and its performance. J. Mater. Process. Technol. 2010, 210, 844–851. [Google Scholar] [CrossRef]

- Prangnell, P.B.; Bakavos, D. Novel approaches to friction spot welding thin aluminium automotive sheet. Mater. Sci. Forum 2010, 638–642, 1237–1242. [Google Scholar] [CrossRef]

- Yazdi, S.R.; Beidokhti, B.; Haddad-Sabzevar, M. Pinless tool for FSSW of AA 6061-T6 aluminum alloy. J. Mater. Process. Technol. 2019, 267, 44–51. [Google Scholar] [CrossRef]

- Alaeibehmand, S.; Mirsalehi, S.E.; Ranjbarnodeh, E. Pinless FSSW of DP600/Zn/AA6061 dissimilar joints. J. Mater. Res. Technol. 2021, 15, 996–1006. [Google Scholar] [CrossRef]

- Schilling, C.; dos, S.J. Method and Device for Joining at Least Two Adjoining Work Pieces by Friction Welding. US Patent US6722556B2, 20 April 2004. [Google Scholar]

- Zhao, Y.-Q.; Yang, H.-K.; Andriia, A.; Lo, H.-H.; Li, J.-X. Refill friction stir spot welding (RFSSW): A review of processing, similar/dissimilar materials joining, mechanical properties and fracture mechanism. J. Iron. Steel Res. Int. 2024, 31, 1825–1839. [Google Scholar] [CrossRef]

- Mehta, K.; Astarita, A.; Carlone, P.; Della Gatta, R.; Vyas, H.; Vilaça, P.; Tucci, F. Investigation of exit-hole repairing on dissimilar aluminum-copper friction stir welded joints. J. Mater. Res. Technol. 2021, 13, 2180–2193. [Google Scholar] [CrossRef]

- Derlatka, A.; Lacki, P. Experimental study and numerical simulation of cellular I-beam manufactured using refill friction stir spot welding technology. Thin-Walled Struct. 2024, 200, 111890. [Google Scholar] [CrossRef]

- Zhang, D.; Dong, J.; Xiong, J.; Jiang, N.; Li, J.; Guo, W. Microstructure characteristics and corrosion behavior of refill friction stir spot welded 7050 aluminum alloy. J. Mater. Res. Technol. 2022, 20, 1302–1314. [Google Scholar] [CrossRef]

- Liu, Z.; Fan, Z.; Liu, L.; Miao, S.; Lin, Z.; Wang, C.; Zhao, Y.; Xin, R.; Dong, C. Refill friction stir spot welding of AZ31 magnesium alloy sheets: Metallurgical features, microstructure, texture and mechanical properties. J. Mater. Res. Technol. 2023, 23, 3337–3350. [Google Scholar] [CrossRef]

- Li, Y.; Sun, G.; Zhang, Z.; Zhou, L.; Guo, N.; Meng, Q.; Dong, J.; Zhao, H. Texture evolution of refill friction stir spot welding in alclad 2A12-T42 aluminum alloy. Mater. Charact. 2023, 205, 113289. [Google Scholar] [CrossRef]

- Becker, N.; dos Santos, J.F.; Klusemann, B. Experimental investigation of crack propagation mechanism in refill friction stir spot joints of AA6082-T6. Eng. Fract. Mech. 2024, 300, 109963. [Google Scholar] [CrossRef]

- Gera, D.; Fu, B.; Suhuddin, U.F.H.R.; Plaine, A.; Alcantara, N.; dos Santos, J.F.; Klusemann, B. Microstructure, mechanical and functional properties of refill friction stir spot welds on multilayered aluminum foils for battery application. J. Mater. Res. Technol. 2021, 13, 2272–2286. [Google Scholar] [CrossRef]

- de Castro, C.C.; Plaine, A.H.; de Alcântara, N.G.; dos Santos, J.F. Taguchi approach for the optimization of refill friction stir spot welding parameters for AA2198-T8 aluminum alloy. Int. J. Adv. Manuf. Technol. 2018, 99, 1927–1936. [Google Scholar] [CrossRef]

- Li, S.; Xing, Y.; Liu, X. Effect of rotational speed on forming and tensile shear properties of 2060 Al-Li RFSSW joint. Trans. China Weld. Inst. 2019, 40, 156–160. [Google Scholar] [CrossRef]

- Chai, P.; Wang, Y. Effect of rotational speed on microstructure and mechanical properties of 2060 aluminum alloy RFSSW joint. Met. Mater. Int. 2019, 25, 1574–1585. [Google Scholar] [CrossRef]

- Dong, Z.; Hu, W.; Ai, X.; Lv, Z. Effect of rotation speed on intermetallic compounds and failure load of RFSSW-ed dissimilar Al/Mg. Trans. Indian Inst. Met. 2019, 72, 2249–2256. [Google Scholar] [CrossRef]

- Li, G.; Zhou, L.; Luo, L.; Wu, X.; Guo, N. Microstructural evolution and mechanical properties of refill friction stir spot welded alclad 2A12-T4 aluminum alloy. J. Mater. Res. Technol. 2019, 8, 4115–4129. [Google Scholar] [CrossRef]

- Shi, Y.; Yue, Y.; Zhang, L.; Ji, S.; Wang, Y. Refill friction stir spot welding of 2198-T8 aluminum alloy. Trans. Indian Inst. Met. 2018, 71, 139–145. [Google Scholar] [CrossRef]

- Zou, Y.; Li, W.; Chu, Q.; Shen, Z.; Wang, F.; Tang, H.; Vairis, A.; Liu, L. The impact of macro/microstructure features on the mechanical properties of refill friction stir spot–welded joints of AA2219 alloy with a large thickness ratio. Int. J. Adv. Manuf. Technol. 2021, 112, 3093–3103. [Google Scholar] [CrossRef]

- Zhou, L.; Luo, L.Y.; Zhang, T.P.; He, W.X.; Huang, Y.X.; Feng, J.C. Effect of rotation speed on microstructure and mechanical properties of refill friction stir spot welded 6061-T6 aluminum alloy. Int. J. Adv. Manuf. Technol. 2017, 92, 3425–3433. [Google Scholar] [CrossRef]

- Li, Z.; Gao, S.; Ji, S.; Yue, Y.; Chai, P. Effect of rotational speed on microstructure and mechanical properties of refill friction stir spot welded 2024 Al alloy. J. Mater. Eng. Perform. 2016, 25, 1673–1682. [Google Scholar] [CrossRef]

- Nan, X.; Zhao, H.; Jia, B.-B.; Ma, C.; Sun, G.; Zhou, L.; Wang, R.; Song, X. The effect of rotational speed on microstructure and mechanical properties of Al/Ti dissimilar joint produced by refill friction stir spot welding. J. Mater. Eng. Perform. 2024, 34, 1812–1824. [Google Scholar] [CrossRef]

- Cui, Y.; Wang, B.; Dong, W.; Li, Z.; Yan, J. Refill friction stir spot welding of an Al-Li alloy: The effects of rotating speed and welding time on joint microstructure and mechanical properties. Metals 2024, 14, 1383. [Google Scholar] [CrossRef]

- Kluz, R.; Kubit, A.; Trzepiecinski, T.; Faes, K.; Bochnowski, W. A weighting grade-based optimization method for determining refill friction stir spot welding process parameters. J. Mater. Eng. Perform. 2019, 28, 6471–6482. [Google Scholar] [CrossRef]

- Xiong, J.; Peng, X.; Shi, J.; Wang, Y.; Sun, J.; Liu, X.; Li, J. Numerical simulation of thermal cycle and void closing during friction stir spot welding of AA-2524 at different rotational speeds. Mater. Charact. 2021, 174, 110984. [Google Scholar] [CrossRef]

- Ji, S.; Li, Z.; Wang, Y.; Ma, L.; Zhang, L. Material flow behavior of refill friction stir spot welded LY12 aluminum alloy. High Temp. Mater. Process. 2017, 36, 495–504. [Google Scholar] [CrossRef]

- GB/T 3355-2014; Test Method for in-Plane Shear Response of Polymer Matrix Composite Materials. Chinese National Standard, General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China, Standardization Administration of China: Beijing, China, 2014.

- Łogin, W.; Śliwa, R.E.; Ziaja, W.; Ostrowski, R. The influence of modification of the geometry of the front surface of the RFSSW tool inner sleeve on the fatigue life of joints during joining clad sheets made of aluminum alloy 2024-T3. Arch. Civ. Mech. Eng. 2024, 25, 17. [Google Scholar] [CrossRef]

- Wu, T.; Liu, Y.; Ji, S.; Sui, X.; Li, Z. Refill friction stir spot welding of a graphene-reinforced AA 6061 aluminum alloy. JOM 2025, 77, 1280–1291. [Google Scholar] [CrossRef]

- Li, Z.; Ji, S.; Ma, Y.; Chai, P.; Yue, Y.; Gao, S. Fracture mechanism of refill friction stir spot-welded 2024-T4 aluminum alloy. Int. J. Adv. Manuf. Technol. 2016, 86, 1925–1932. [Google Scholar] [CrossRef]

- Zuo, Y.; Kong, L.; Liu, Z.; Lv, Z.; Wen, H. Process parameters optimization of refill friction stir spot welded Al/Cu joint by response surface method. Trans. Indian Inst. Met. 2020, 73, 2975–2984. [Google Scholar] [CrossRef]

- de Castro, C.C.; Plaine, A.H.; Dias, G.P.; de Alcântara, N.G.; dos Santos, J.F. Investigation of geometrical features on mechanical properties of AA2198 refill friction stir spot welds. J. Manuf. Process. 2018, 36, 330–339. [Google Scholar] [CrossRef]

- Zhao, Y.; Liu, H.; Yang, T.; Lin, Z.; Hu, Y. Study of temperature and material flow during friction spot welding of 7B04-T74 aluminum alloy. Int. J. Adv. Manuf. Technol. 2016, 83, 1467–1475. [Google Scholar] [CrossRef]

- Janga, V.S.R.; Awang, M.; Yamin, M.F.; Suhuddin, U.F.H.; Klusemann, B.; Santos, J.F.d. Experimental and numerical analysis of refill friction stir spot welding of thin AA7075-T6 sheets. Materials 2021, 14, 7485. [Google Scholar] [CrossRef]

- Marek, M.; Krzysztof Jan, K. Generalised stacking fault energies of copper alloys—Density functional theory calculations. J. Min. Metall. Sect. B 2019, 55, 271–282. [Google Scholar] [CrossRef]

- Cao, J.Y.; Wang, M.; Kong, L.; Guo, L.J. Hook formation and mechanical properties of friction spot welding in alloy 6061-T6. J. Mater. Process. Technol. 2016, 230, 254–262. [Google Scholar] [CrossRef]

- Zou, Y.; Li, W.; Yang, X.; Su, Y.; Chu, Q.; Shen, Z. Microstructure and mechanical properties of refill friction stir spot welded joints: Effects of tool size and welding parameters. J. Mater. Res. Technol. 2022, 21, 5066–5080. [Google Scholar] [CrossRef]

- Adamus, J.; Adamus, K. The analysis of reasons for defects formation in aluminum joints created using RFSSW technology. Manuf. Lett. 2019, 21, 35–40. [Google Scholar] [CrossRef]

- Kubit, A.; Faes, K.; Aghajani Derazkola, H. Refill friction stir spot welding tool plunge depth effects on shear, peel, and fatigue properties of alclad coated AA7075 aluminum joints. Int. J. Fatigue 2024, 185, 108308. [Google Scholar] [CrossRef]

- Fritsche, S.; Schindler, F.; de Carvalho, W.S.; Amancio-Filho, S.T. Wear mechanisms and failure analysis of a tool used in refill friction stir spot welding of AA6061-T6. Wear 2025, 560–561, 205610. [Google Scholar] [CrossRef]

- Silva, B.H.; Zepon, G.; Bolfarini, C.; dos Santos, J.F. Refill friction stir spot welding of AA6082-T6 alloy: Hook defect formation and its influence on the mechanical properties and fracture behavior. Mat. Sci. Eng. A 2020, 773, 138724. [Google Scholar] [CrossRef]

- Ragab, A.E.; Alsaty, A.; Alsamhan, A.; Al-Tamimi, A.A.; Dabwan, A.; Sayed, A.; Alghilan, W. Open-source real-time monitoring system of temperature and force during friction stir spot welding. J. Eng. Res. 2023, 2023, 1–13. [Google Scholar] [CrossRef]

- Badwelan, A.; Al-Samhan, A.M.; Anwar, S.; Hidri, L. Novel technique for enhancing the strength of friction stir spot welds through dynamic welding parameters. Metals 2021, 11, 280. [Google Scholar] [CrossRef]

- Liu, W.H.; Wu, Y.; He, J.Y.; Nieh, T.G.; Lu, Z.P. Grain growth and the Hall–petch relationship in a high-entropy fecrnicomn alloy. Scr. Mater. 2013, 68, 526–529. [Google Scholar] [CrossRef]

- Sun, Q.; Di, H.S.; Li, J.C.; Wu, B.Q.; Misra, R.D.K. A comparative study of the microstructure and properties of 800Mpa microalloyed C-Mn steel welded joints by laser and gas metal arc welding. Mat. Sci. Eng. A 2016, 669, 150–158. [Google Scholar] [CrossRef]

- Choi, I.-C.; Kim, Y.-J.; Wang, Y.M.; Ramamurty, U.; Jang, J.-i. Nanoindentation behavior of nanotwinned Cu: Influence of indenter angle on hardness, strain rate sensitivity and activation volume. Acta Mater. 2013, 61, 7313–7323. [Google Scholar] [CrossRef]

- Zhou, G.; Huang, T.; Su, L.; Huang, Q.; Wu, S.; Zhang, B. The microstructure and mechanical properties of deposited alcusc alloy wall structures fabricated by waam with FSP assistance. Thin-Walled Struct. 2025, 209, 112954. [Google Scholar] [CrossRef]

- Tang, H.W.; Li, W.Y.; Feng, X.S.; Cui, F.; Zou, Y.F. Microstructure and mechanical properties of refill friction stir spot welded Al–Mg-Li alloy joints. Weld. World 2023, 67, 385–393. [Google Scholar] [CrossRef]

- Rosendo, T.; Tier, M.; Mazzaferro, J.; Mazzaferro, C.; Strohaecker, T.R.; Dos Santos, J.F. Mechanical performance of AA6181 refill friction spot welds under lap shear tensile loading. Fatigue Fract. Eng. Mater. Struct. 2015, 38, 1443–1455. [Google Scholar] [CrossRef]

- Plaine, A.H.; Suhuddin, U.F.H.; Alcântara, N.G.; dos Santos, J.F. Microstructure and mechanical behavior of friction spot welded AA6181-T4/Ti6Al4V dissimilar joints. Int. J. Adv. Manuf. Technol. 2017, 92, 3703–3714. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ge, X.; Kolupaev, I.N.; Jiang, D.; Song, W.; Wang, H. Influence of Rotational Speed on the Microstructure and Mechanical Properties of Refill Friction Stir Spot Welded Pure Copper. Crystals 2025, 15, 268. https://doi.org/10.3390/cryst15030268

Ge X, Kolupaev IN, Jiang D, Song W, Wang H. Influence of Rotational Speed on the Microstructure and Mechanical Properties of Refill Friction Stir Spot Welded Pure Copper. Crystals. 2025; 15(3):268. https://doi.org/10.3390/cryst15030268

Chicago/Turabian StyleGe, Xiaole, I. N. Kolupaev, Di Jiang, Weiwei Song, and Hongfeng Wang. 2025. "Influence of Rotational Speed on the Microstructure and Mechanical Properties of Refill Friction Stir Spot Welded Pure Copper" Crystals 15, no. 3: 268. https://doi.org/10.3390/cryst15030268

APA StyleGe, X., Kolupaev, I. N., Jiang, D., Song, W., & Wang, H. (2025). Influence of Rotational Speed on the Microstructure and Mechanical Properties of Refill Friction Stir Spot Welded Pure Copper. Crystals, 15(3), 268. https://doi.org/10.3390/cryst15030268