Abstract

Laser welding–brazing experiments with 6061 aluminum alloy and Q235 steel were conducted using AlSi12 and ZnAl22 as filler metals. The macroscopic morphologies and microstructures of welding–brazing joints were analyzed by optical microscopy (OM) and scanning electron microscopy (SEM). The effects of Si and Zn elements in filler wires on the macroscopic morphologies, interfacial microstructures, tensile properties, and corrosion resistances of joints were studied. The results show that the wettability of ZnAl22-filler wire was better than that of AlSi12-filler wire. The fusion zone of the joint welded with AlSi12-filler wire consisted of α–Al solid solution and Al–Si eutectic mixture, while the interfacial reaction zone was composed of η-Fe2(Al, Si)5 and τ5-Fe1.8Al7.2Si. The fusion zone of the joint formed using AlZn22-filler wire consisted of α–Al solid solution, η-Zn solid solution, and ZnAl eutectic structure. The joint welded with AlSi12-filler wire showed better tensile strength and corrosion resistance compared to that welded with ZnAl22-filler wire.

1. Introduction

Al–steel joining is widely utilized in the automotive and aerospace industries due to its significant weight-saving advantages [1,2]. Due to the significant differences in thermal conductivity, coefficient of linear expansion, weldability, etc. between Al and steel, which are dissimilar metals, defects such as pores and cracks tend to occur in the weld zone. This results in a weld seam that has inferior mechanical properties, making the welding of Al to steel a current research hotspot [3,4,5]. Laser welding is an automated welding process that utilizes a laser as the heat source; it is characterized by its higher welding speed, reduced post-welding deformation, and more accurate keyhole positioning [6,7,8]. Owing to the significant disparity in melting points between Al and steel, simultaneous melting and adequate elemental diffusion cannot be achieved. To address these challenges, scholars have integrated laser technology with brazing, resulting in the innovative laser welding–brazing process [9]. The laser welding–brazing process not only solves the issue of excessively rapid Al melting but also enhances the spreading performance of Al on the steel surface.

Due to the differences in physical and chemical properties between Al and steel, welding these dissimilar materials can lead to the formation of a considerable amount of brittle intermetallic compounds (IMC), which can greatly compromise the performance of the welded joint [10,11,12]. Numerous studies have demonstrated that the addition of various elements to the Al/steel-welding process can effectively impede the diffusion metallurgical reaction between Al and Fe [13,14,15,16], thus enhancing the mechanical properties of the welded joint. Dong et al. [13] examined the influence of Si, Cu, and Zn as alloying elements on the microstructure and tensile strength of lap joints between Al and steel using gas tungsten arc welding with various filler wires. The results showed that adding Si to the weld suppressed Fe diffusion from the base metal, reduced IMC thickness, and improved joint tensile strength. Yang et al. [14] found that adding alloying elements such as Si and Zn into pure Al to form Al–Si or Al–Zn filler wires can increase the fracture load of Al/steel joints. Yu et al. [15] explored the welding characteristics of Al–5052/Q235 galvanized steel joints using various filler wires, including pure Al, AlSi5, AlMg5, AlCu6, and ZnAl2, through a laser welding–brazing process. They found that the Si element markedly inhibits the formation of IMCs and that the joints welded with AlSi5 filler wire demonstrated superior load-bearing and fracture strengths compared to other joints. Further investigation showed that adding Si changed the interface microstructure from brittle Fe–Al IMCs to ductile Fe-Al–Si IMCs, inhibiting crack propagation and ensuring sufficient joint strength [16].

Control of heat input during Al/steel welding is crucial for reducing the formation of brittle Al–Fe IMCs [17]. Su et al. [18] found that the fracture load of laser fusion-welded Al/steel joints initially increased and subsequently decreased as the laser power increased. These changes can be primarily attributed to the alterations in interfacial phase morphology and bonding length induced by variations in laser power. Yu et al. [19] showed that unbeveled Al/steel joints can be effectively welded using the laser-arc hybrid welding–brazing process. The tensile strength of the joint initially increased and then decreased as the welding speed or wire feed speed increased. Narsimhachary et al. [20] indicated that the welding performance and corrosion resistance of laser welded–brazed Al/steel joints are influenced by the wire-deposition rate. Li et al. [21] examined the influence of groove shape on the formation performance of Al/steel joints produced through the laser welding–brazing process. The results showed that the half-V-shaped groove had the smallest temperature gradient across the steel interface, leading to the most uniform IMC thickness and highest tensile strength compared to square and half-Y-shaped grooves. Additionally, Li et al. [22] improved the reliability of laser welded–brazed Al/steel joints by using a novel surface-texturing technique that modifies reaction behavior and strain-stress distribution, thus enhancing line load capacity. Jiang et al. [23] achieved reliable joining between Al and steel through the application of a porous high-entropy alloy coating. In this case, the results indicated that the joint wettability improved as the defocused distance decreased, with optimal wettability achieved at 0 mm defocused distance, which yielded a wetting length of 5.57 mm and a contact angle of 59.8°. There is evidence suggesting that using HEAs as a transient layer or filler metal can help reduce the formation of brittle IMCs caused by reactions between Al and steel [24,25]. This, in turn, enhances the strength of welded joints.

In addition, Mohammadpour et al. [26] demonstrated the superiority of the double-beam laser welding–brazing process in joining dissimilar Al–6022 and galvanized steels. Yuan et al. [27] employed dual-beam laser welding–brazing to regulate the wetting angle, wetting distance, and the thickness of the IMC layer, thereby achieving successful formation of Al/steel lap joints without the use of filler material. Xia et al. [28] investigated weld formation via laser welding–brazing between Al and steel using single laser beams, as well as cross and in-line dual laser beams. The results demonstrated that the dual-laser-beam technique positively contributed to reducing the IMC thickness and promoting a more uniform interfacial IMC morphology. Moreover, the interface exhibiting the most homogeneous IMC and the joint demonstrating the highest tensile strength were achieved using the cross dual laser beams. Meng et al. [29] used a laser-beam-oscillation technique to optimize the uniformity of the IMC layer. The results indicated that as the optimized laser offset increased from 0.4 to 0.8 mm, the IMC thickness variance from top to bottom decreased from 105.14 to 0.0022, enhancing the ultimate tensile strength of the joint from 77 to 160 MPa.

It can be seen that the addition of alloy elements or modifications to the welding process can lead to changes in the joint’s performance. Therefore, this study conducted experimental investigations on the laser welding–brazing of 6061 aluminum alloy and Q235 steel utilizing AlSi12- and ZnAl22-filler wires. The influence of Si and Zn elements on the macroscopic morphology, microstructural constitution, mechanical properties, and corrosion resistance of the welded joints was investigated.

2. Materials and Methods

6061 aluminum alloy and Q235 mild steel with the same dimensions (150 mm × 80 mm × 2 mm) were used as base metals in this study. The filler wires were a 1.6 mm diameter AlSi12-filler wire and a ZnAl22-filler wire with a flux composition of No-clock flux (97% KAlF4, 3% CsAlF4). The chemical compositions of the base metal and welding material are presented in Table 1.

Table 1.

Chemical compositions and properties of base metals and filler wires.

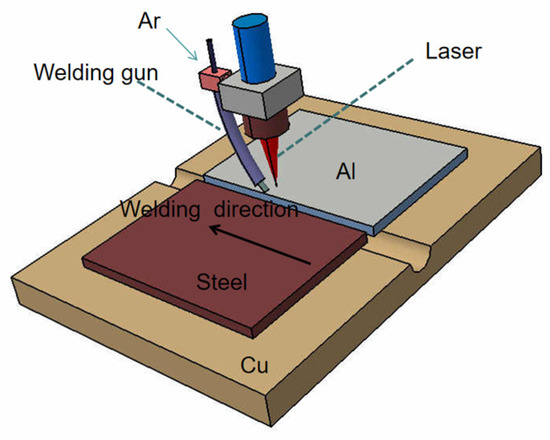

Laser welding–brazing was performed on 6061 aluminum alloy and steel using AlSi12-filler wire and ZnAl22-filler wire, respectively. Figure 1 illustrates the schematic diagram of the laser-brazing process. The base metal was assembled in the form of a butt joint, and a copper substrate was placed under the base material. By utilizing the high thermal conductivity of copper, the heat generated during welding can be eliminated, thereby reducing the growth of IMCs. The laser was tilted 10° away from the vertical direction to prevent laser reflection from damaging the laser head. The specific parameters of the welding process are shown in Table 2.

Figure 1.

Laser welding–brazing assembly diagram.

Table 2.

Laser welding–brazing parameters.

Metallographic samples and tensile specimens from the weld seams were extracted perpendicular to the welding direction. After grinding, polishing, and etching, the morphologies of the cross-sectional microstructures of the steel/welded seam interfaces were characterized by scanning electron microscopy (SEM) and the chemical compositions were identified by energy dispersive spectrometry (EDS). The tensile properties of Al/steel joints were evaluated by preparing three specimens for each joint and determining the average test results. Additionally, electrochemical and X-ray photoelectron spectroscopy (XPS) analyses were conducted on metallographic specimens to investigate their corrosion resistance.

3. Results and Discussion

3.1. The Macroscopic Morphology of Different Al/Steel Joints

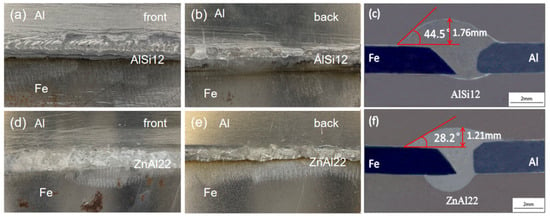

Figure 2 depicts the macroscopic morphology of Al/steel welded joints achieved by employing AlSi12- and ZnAl22-filler wires. As shown in Figure 2a, the front surface of the joint welded with AlSi12-filler wire exhibited a fish-scale-like weld seam, indicating good formation. However, the formation of the back surface was suboptimal, with welding defects such as a biting edge observed. Additionally, the wettability of the back surface was also unsatisfactory. Figure 2b shows the macroscopic morphology of the joint welded with ZnAl22-filler wire. Despite the favorable wettability and spreadability of the joint, the morphology suggests that the formation of the joint was suboptimal. The front surface of the weld seam did not exhibit any fish-scale-like patterns. Moreover, a large number of slag inclusions were generated on the surface of the joint. The wetting angles and weld reinforcements of the joints formed utilizing AlSi12- and ZnAl22-filler materials were measured as 44.5°, 1.76 mm and 28.2°, 1.21 mm, respectively. The wettability of the joint formed using ZnAl22-filler wire was significantly enhanced compared to that of the joint made with AlSi12-filler wire, resulting in a more continuous formation at the back. However, the overall formation of the joint prepared with Zn-based filler material was inferior to that of the joint made with Al-based filler material, which could significantly impact the mechanical properties of the welded joint. In fact, the spattering of ZnAl22-filler wire during welding contributed to the formation of welding slag, which adhered to the surface of the welded joint. Furthermore, the melting point of ZnAl22 (420–480 °C) is much lower than that of AlSi12 (595–625 °C), resulting in a higher heat input during welding with ZnAl22-filler wire, which led to the collapse of the weld joint.

Figure 2.

Macroscopic morphology of Al/steel joints welded using (a–c) AlSi12- and (d–f) ZnAl22-filler wires, respectively.

3.2. Interfacial Microstructure of Al/Steel Joints

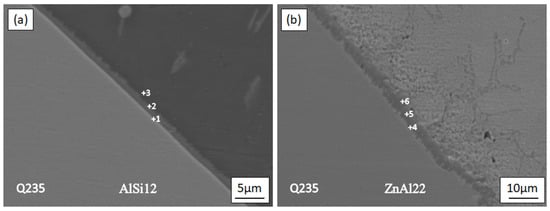

Figure 3 shows the SEM image of the interfacial microstructure of the brazing zone at the steel-side interface. The EDS results for different points (point 1–6, as shown in Figure 3) within the IMC layer are presented in Table 3. The IMC layer near the steel matrix in the joint using AlSi12-filler wire, identified as τ5-Fe1.8Al7.2Si, exhibited a zigzag-like morphology (referred to as I layer), while the IMC layer near the weld displayed a continuous planar shape and was identified as η-Fe2(Al, Si)5 (referred to as II layer), as shown in Figure 3a. The IMC layer formed in the joint using ZnAl22-filler wire exhibited a continuous planar shape (identified as Fe2Al5-xZnx) near the weld, while a zigzag-like layer (identified as FeZn10) was present closer to the steel matrix, as shown in Figure 3b.

Figure 3.

SEM morphology of brazing zones within joints made with (a) AlSi12- and (b) ZnAl22-filler wires, respectively.

Table 3.

The EDS results for points 1–6 (see Figure 3).

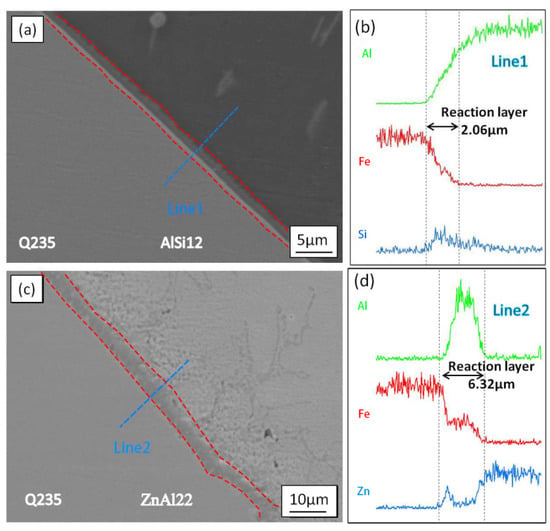

Figure 4 shows the EDS line-scanning results for brazing zones within joints made with AlSi12- and ZnAl22-filler wires. The thickness of the IMC layer formed in the joint welded with AlSi12-filler wire was 2.06 μm, as shown in Figure 4a,b. Variation in the content of Al, Fe, and Si elements can be observed in the transition from the steel-side base metal to the weld, as depicted in Figure 4b. The concentration of Al decreased progressively with increasing distance from the steel side, while the concentration of Fe exhibited a gradual increase. Segregation of Si elements was observed at the interface between the steel and the weld seam. The IMC layer formed within the joint using ZnAl22-filler wire is depicted in Figure 4c and exhibited a thickness of 6.32 μm. The concentration of Al in the IMC layer exhibited an initial increase, which was followed by a subsequent decrease. The Fe content gradually decreased from left to right, reaching a certain value before further declining upon achieving dynamic stability. Additionally, the segregation of Si elements was also observed at the interface on the steel side. It can be seen that, in comparison with Zn, Si can better inhibit the growth of IMC, a finding in agreement with the results reported in previous studies [10,12].

Figure 4.

EDS line scanning of steel-side brazing zones within joints using (a,b) AlSi12 or (c,d) ZnAl22.

3.3. Mechanical Properties of Al/Steel Joints

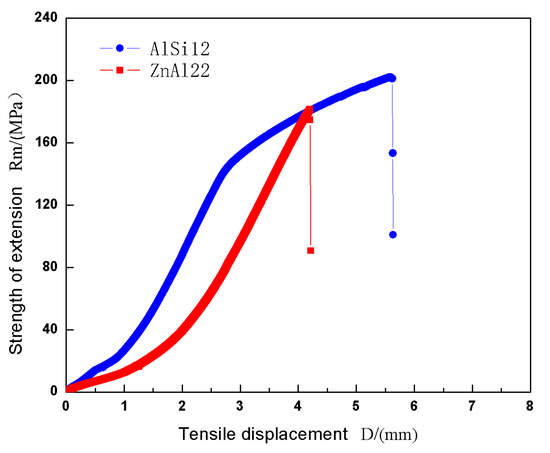

Figure 5 illustrates the tensile strength and displacement curves of the joints welded using AlSi12- and ZnAl22-filler wires. The tensile strength of the joint welded with AlSi12-filler wire was observed to be 203 MPa, with a corresponding tensile displacement of 5.8 mm. The tensile strength of the joint using ZnAl22-filler wire was 186 MPa, and the tensile displacement measured 4.5 mm. Despite the superior wetting properties exhibited by ZnAl22-filler wire, its mechanical characteristics were found to be less favorable compared to those of AlSi12-filler wire. The reason is that Si can diffuse into the vacancies of Fe2Al5, thereby reducing the direct reaction between Fe and Al and decreasing the formation of IMCs such as brittle Fe2Al5 [16]. The addition of Si can also decrease the activation energy required for Fe to diffuse in Al, facilitating the diffusion of Fe. The affinity of Si for Al is greater than that of Fe, facilitating the formation of Al–Fe–Si IMC. According to the Al–Zn phase diagram, Al and Zn can dissolve in each other indefinitely and exhibit a strong ability to interact with one another. Additionally, Zn can form Al–Fe–Zn IMCs with Fe and Al, as well as an Al–Zn solid solution [15]. The mechanical properties of the joint, however, were compromised as a result of the excessive thickness of the IMC layer. However, an excessive amount of Zn will lead to the formation of an overly thick IMC interface layer, thereby degrading the mechanical properties of the joint.

Figure 5.

Tensile strength and displacement curves of joints welded with AlSi12- and ZnAl22-filler wire.

3.4. The Corrosion Property of Al/Steel Joints

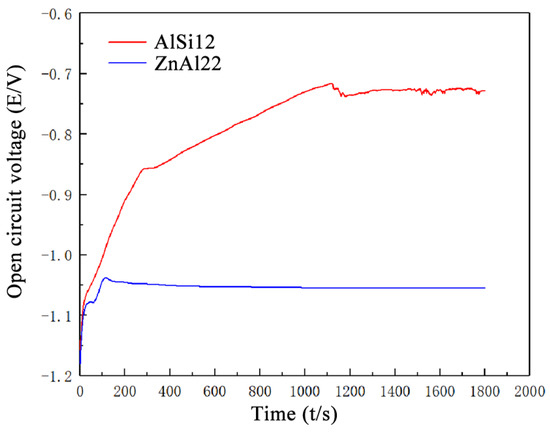

The open-circuit voltage-variation diagram of the joints welded with AlSi12- and ZnAl22-filler wire is illustrated in Figure 6. The open-circuit potentials of the joints welded with AlSi12- and ZnAl22-filler wire are presented in Table 4. The open-circuit potential of the joint welded with AlSi12-filler wire was −0.730 V, while that of the joint welded with ZnAl22-filler wire was −1.055 V. The higher open-circuit potential indicates that the joint welded with AlSi12 filler exhibited improved electrochemical stability and a reduced susceptibility to corrosion. The weld seam of the joint welded with AlSi12-filler wire primarily consisted of α–Al and Al–Si eutectic, facilitating the formation of a compact aluminum oxide film during the corrosion. The dense aluminum-containing oxide film covering the weld surface could play a role in isolating the corrosive liquid, resulting in increased potential and passivation of corrosion resistance. The dense oxide film containing aluminum on the surface of the weld could effectively isolate corrosive liquids, leading to an increased potential and enhanced resistance to corrosion.

Figure 6.

Open-circuit voltage-variation diagram of joints welded with AlSi12- and ZnAl22-filler wire.

Table 4.

Open-circuit potential of joints welded with AlSi12- and ZnAl22-filler wire.

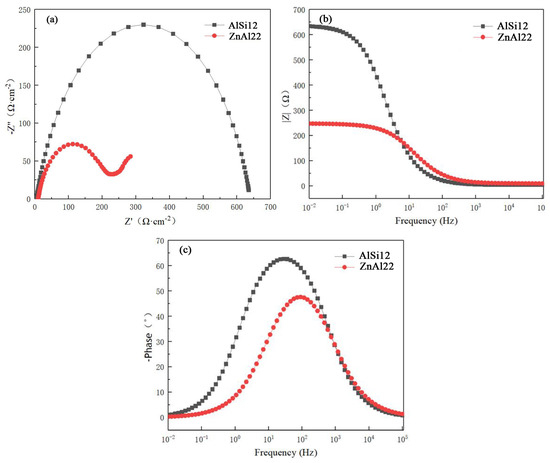

Figure 7 shows the alternating current (AC) impedance spectroscopy of the joints welded with AlSi12 and ZnAl22-filler wires. The AC impedance spectra of both joints exhibit a semicircular shape, as illustrated in Figure 7a. The radius of the AC impedance spectrum was larger for the AlSi12-welded joint than for the ZnAl22-welded joint, indicating that the AlSi12-welded joint exhibited better corrosion resistance. The thickness of Al/steel interface layer obtained from ZnAl22 welding was much higher than that obtained with AlSi12 welding. The excessive formation of IMC can result in galvanic corrosion at the joint, which may further compromise its resistance to corrosion. Sravanthi et al. [30] also found that the formation of IMC enhanced the galvanic corrosion of an Al/steel welded joint and significantly reduced the corrosion resistance of the hybrid structure. In addition, the ZnAl22-welded joint also displayed a linear tail at an angle of 45°. The appearance of such a curve on the Nyquist plot signifies an inhibition of diffusion of a corrosive substance towards the interface between the matrix and film. This also indicates that the corrosion layer on the joint surface was dense enough to prevent diffusion from occurring.

Figure 7.

AC impedance diagram of AlSi12 and ZnAl22-filler wire-welded joints. (a) Nyquist diagram; (b) Mode-frequency Bode diagram; (c) Phase angle-frequency Bode diagram.

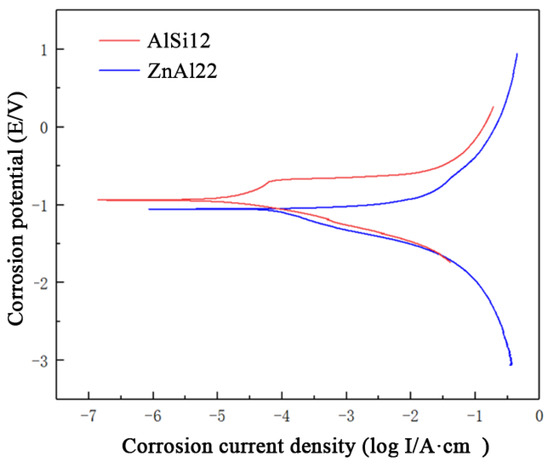

Figure 8 shows the polarization curves of the joints welded with AlSi12- and ZnAl22-filler wires. Table 5 shows the self-corrosion current density and self-corrosion potential of the test joints, as calculated using Tafel extrapolation [31]. The self-corrosion potential of the joint welded with AlSi12-filler wire (Ecorr–AlSi12) was −0.93788 V, while that of the joint welded with ZnAl22-filler wire (Ecorr–ZnAl22) was −1.0536 V. The self-corrosion current density of the joint welded with AlSi12-filler wire (Icorr–AlSi12) was 3.3578 × 10−5 A·cm−2, and the self-corrosion current density of the joint welded with ZnAl22-filler wire (Icorr–ZnAl22) was 1.7668 × 10−4 A·cm−2. A smaller self-corrosion current means slower corrosion, while a higher self-corrosion potential indicates stronger corrosion resistance [32]. Ecorr–AlSi12 was greater than Ecorr–ZnAl22, indicating that the joint welded with ZnAl22-filler wire was more susceptible to self-corrosion behavior. Additionally, the higher self-corrosion current density indicates that the joint welded with AlZn22-filler wire would corrode faster and had poorer corrosion resistance. Therefore, the joints welded using AlSi12-filler wire exhibited superior corrosion resistance.

Figure 8.

Polarization curves of joints welded with AlSi12- and ZnAl22-filler wire.

Table 5.

The self-corrosion current densities and the self-corrosion potentials of tested joints.

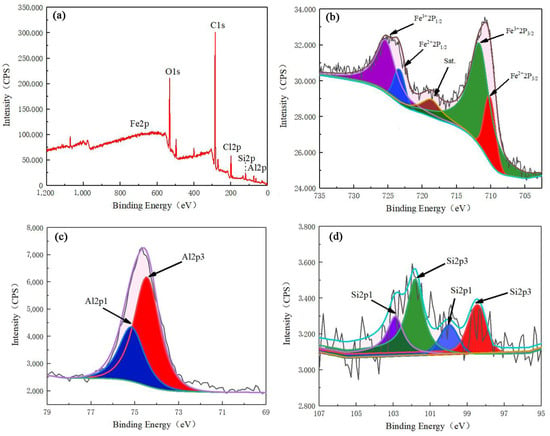

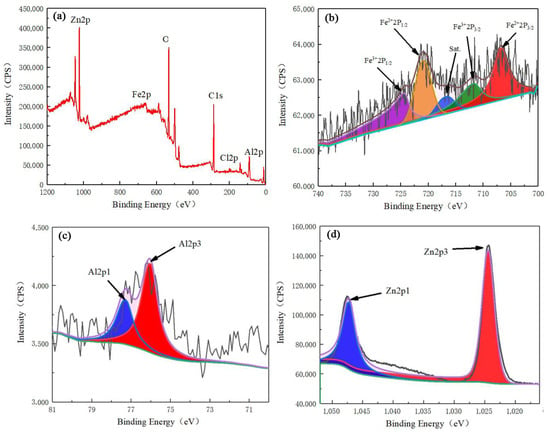

Figure 9 and Figure 10 present the XPS spectra of the passivation films formed on the surfaces of the joints welded using AlSi12- and ZnAl22-filler wires, respectively. As illustrated in Figure 9a, spectrum peaks corresponding to the elements Fe, O, C, Si, and Al were observed. It can be inferred that the passivation film was mainly constituted by elements Fe, Al, Si, and O. Meanwhile, the spectrum peaks shown in Figure 10a indicate that the passivation film that developed on the surface of the joint welded with the ZnAl22-filler wire was primarily composed of Fe, Al, Zn, and O. The iron profiles displayed in Figure 9b and Figure 10b suggest that Fe2+ and Fe3+ are the main forms of iron in the passive films. The fine spectra of the Al2p spectrum of both joints are shown in Figure 9b and Figure 10b, where two peaks in the Al2p orbitals can be observed. Al easily reacts with O to form Al2O3, enhancing the corrosion resistance of the Al/steel joint [33,34,35]. Figure 9d and Figure 10d show the fitting results of the Si2p and Zn2p orbitals for the joints welded with Al–Si12 and Zn–Al22-filler wire, respectively. This indicates that silicon oxides and zinc oxides formed in the passive films of different joints. Moreover, in conjunction with the aforementioned results (see Figure 8), these results show that the addition of the Si element is more effective in enhancing corrosion resistance.

Figure 9.

XPS spectra of passivation film on the surface of the joint welded with AlSi12-filler wire: (a) total spectrum, (b) Fe2p, (c) Al2p, and (d) Si2p.

Figure 10.

XPS spectra of passive film on the surface of the joint welded with ZnAl22-filler wire: (a) total spectrum, (b) Fe2p, (c) Al2p, and (d) Zn2p.

4. Conclusions

In this study, the effects of the alloying elements Si and Zn on weld morphology, microstructural constitution, mechanical property, and corrosion resistance were systematically investigated. The main conclusions can be summarized as follows:

- (1)

- The wetting properties of ZnAl22-filler wire were better than those of AlSi12-filler wire, but the overall aesthetics of the welded joint were not as good as those obtained with AlSi12.

- (2)

- Both Si and Zn elements can inhibit the formation of IMC. The thickness of the IMC in the joint welded with AlSi12-filler wire was 2.06 μm, while that in the joint welded with ZnAl22-filler wire was 6.32 μm.

- (3)

- The tensile strength of the joint welded with AlSi12-filler wire was 203 MPa, and the displacement measured 5.8 mm. The joint welded with ZnAl22-filler wire had a tensile strength of 186 MPa, with a displacement measuring 4.5 mm.

- (4)

- The joint welded with AlSi12-filler wire exhibited better corrosion resistance compared to the joint welded with ZnAl22-filler wire.

Author Contributions

Conceptualization, W.G. and L.T.; methodology, W.G.; software, W.G.; validation, W.G., M.W. and L.T.; formal analysis, L.T.; investigation, W.G. and L.T.; resources, W.G.; data curation, W.G.; writing—original draft preparation, W.G. and L.T.; writing—review and editing, M.W., L.L. and H.W.; visualization, M.W.; supervision, M.W. and H.W.; project administration, M.W. and H.W.; funding acquisition, H.W. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Taizhou Science and Technology Support Plan Project, grant number TS202503, the sixteenth “Six talent peaks” of high-level talent selection and a training project of Jiangsu Province, grant number XCL-265; the Natural Science Foundation of the Jiangsu Higher Education Institutions of China, grant number 21KJB430016.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Kaushik, P.; Dwivedi, D.K. Al-steel dissimilar joining: Challenges and opportunities. Mater. Today Proc. 2022, 62, 6884–6899. [Google Scholar] [CrossRef]

- Yang, Y.; Luo, Z.; Zhang, Y.; Su, J. Dissimilar welding of aluminium to steel: A review. J. Manuf. Process. 2024, 110, 376–397. [Google Scholar] [CrossRef]

- Li, B.; Hu, T.; Zhou, J.; Pan, H.; Ding, K.; Wu, T.; Gao, Y. Interfacial microstructure characteristics and failure mechanism of the laser welding-brazing steel-Al joints with various welding parameters. J. Mater. Res. Technol. 2024, 31, 2498–2507. [Google Scholar] [CrossRef]

- Beygi, R.; Galvão, I.; Akhavan-Safar, A.; Pouraliakbar, H.; Fallah, V.; da Silva, L.F. Effect of alloying elements on intermetallic formation during friction stir welding of dissimilar metals: A critical review on aluminum/steel. Metals 2023, 13, 768. [Google Scholar] [CrossRef]

- Li, M.; Tao, W.; Zhang, J.; Wang, Y.; Yang, S. Hybrid resistance-laser spot welding of aluminum to steel dissimilar materials: Microstructure and mechanical properties. Mater. Des. 2022, 221, 111022. [Google Scholar] [CrossRef]

- Huang, Y.W.; Gao, X.D.; Gao, P.P.; Ma, B.; Zhang, Y.X. Laser welding monitoring techniques based on optical diagnosis and artificial intelligence: A review. Adv. Manuf. 2024, 1–25. [Google Scholar] [CrossRef]

- Park, S.J.; Heogh, W.; Yang, J.; Kang, S.; Jeong, W.; Lee, H.; Jang, T.; Jung, H.; Jahazi, M.; Han, S.C.; et al. Meta-structure of amorphous-inspired 65.1Co28.2Cr5.3Mo lattices augmented by artificial intelligence. Adv. Compos. Hybrid Mater. 2024, 7, 224. [Google Scholar] [CrossRef]

- Ali, S.; Shin, J. Improvement in weld quality of Al and Cu joints using dual-beam laser welding. J. Manuf. Process. 2024, 119, 499–510. [Google Scholar] [CrossRef]

- Du, W.; Huang, X.; Zheng, M.; Xiao, R.; Xu, J.; Huang, T. Hybrid laser welding and brazing for controlling intermetallic compounds in Al/Cu dissimilar joint. Opt. Laser Technol. 2025, 180, 111559. [Google Scholar] [CrossRef]

- Wallerstein, D.; Solla, E.L.; Lusquiños, F.; Comesaña, R.; del Val, J.; Riveiro, A.; Pou, J. Advanced characterization of intermetallic compounds in dissimilar aluminum-steel joints obtained by laser welding-brazing with AlSi filler metals. Mater. Charact. 2021, 179, 111345. [Google Scholar] [CrossRef]

- Wang, J.; Fu, X.; Zhang, L.; Zhang, Z.; Liu, J.; Chen, S. A short review on laser welding/brazing of aluminum alloy to steel. Int. J. Adv. Manuf. Technol. 2021, 112, 2399–2411. [Google Scholar] [CrossRef]

- Wallerstein, D.; Salminen, A.; Lusquinos, F.; Comesana, R.; García, J.D.V.; Rodríguez, A.R.; Aida, B.; Pou, J. Recent developments in laser welding of aluminum alloys to steel. Metals 2021, 11, 622. [Google Scholar] [CrossRef]

- Dong, H.; Hu, W.; Duan, Y.; Wang, X.; Dong, C. Dissimilar metal joining of aluminum alloy to galvanized steel with Al–Si, Al–Cu, Al–Si–Cu and Zn–Al filler wires. J. Mater. Process. Technol. 2012, 212, 458–464. [Google Scholar] [CrossRef]

- Yang, J.; Yu, Z.; Li, Y.; Zhang, H.; Guo, W.; Zhou, N. Influence of alloy elements on microstructure and mechanical properties of Al/steel dissimilar joint by laser welding/brazing. Weld. World 2018, 62, 427–433. [Google Scholar] [CrossRef]

- Yu, G.; Chen, S.; Zhao, Z.; Wen, Z.; Huang, J.; Yang, J.; Chen, S. Comparative study of laser welding-brazing of aluminum alloy to galvanized steel butted joints using five different filler wires. Opt. Laser Technol. 2022, 147, 107618. [Google Scholar] [CrossRef]

- Li, B.; Zhou, J.; Hu, R.; Hu, T.; Pan, H.; Wu, T.; Gao, Y. Role of Si element in the IMC formation and tensile-shear property of the laser welding-brazing steel-Al dissimilar joints. Mater. Lett. 2024, 375, 137274. [Google Scholar] [CrossRef]

- Xue, J.; Li, Y.; Chen, H.; Zhu, Z. Effects of heat input on wettability, interface microstructure and properties of Al/steel butt joint in laser-metal inert-gas hybrid welding-brazing. J. Mater. Process. Technol. 2018, 255, 47–54. [Google Scholar] [CrossRef]

- Su, J.; Yang, J.; Li, Y.; Yu, Z.; Chen, J.; Zhao, W.; Liu, H.; Tan, C. Microstructure and mechanical properties of laser fusion welded Al/steel joints using a Zn-based filler wire. Opt. Laser Technol. 2020, 122, 105882. [Google Scholar] [CrossRef]

- Yu, G.; Nie, X.; Li, L.; Chen, S.; Wang, Y. Dissimilar unbeveled aluminum to steel butt joint achieved by laser-arc hybrid welding-brazing. J. Mater. Res. Technol. 2024, 33, 6980–6989. [Google Scholar] [CrossRef]

- Narsimhachary, D.; Lavakumar, A.; Katiyar, P.K.; Shariff, S.M.; Basu, A. Effect of wire deposition rate on macro and microscopic characteristics of laser weld-brazed AA5083 aluminum alloy to galvanized steel joints and their corrosion response. Adv. Mater. Process. Technol. 2024, 1–22. [Google Scholar] [CrossRef]

- Li, L.; Xia, H.; Tan, C.; Ma, N. Effect of groove shape on laser welding-brazing Al to steel. J. Mater. Process. Technol. 2018, 252, 573–581. [Google Scholar] [CrossRef]

- Li, H.; Xia, H.; Li, L.; Li, L.; Su, X.; Peng, J.; Ma, Y.; Tan, C.; Song, X.; Wu, T. Enhancing the reliability of laser welded-brazed aluminum/stainless steel joints via laser-chemical hybrid surface texturing. Thin-Walled Struct. 2024, 199, 111780. [Google Scholar] [CrossRef]

- Jiang, J.; Oliveira, J.P.; Yang, J.; Zheng, M.; Li, H.; Xu, W.; Dou, T.; Wang, R.; Tan, C.; Li, Y. Effect of defocusing distance on interfacial reaction and mechanical properties of dissimilar laser Al/steel joints with a porous high entropy alloy coating. Mater. Charact. 2024, 210, 113751. [Google Scholar] [CrossRef]

- Yan, H.; Cai, D.; Gao, S.; Dong, Y.; Zhou, H.; Luo, Z. Application of high entropy alloy in aluminum/steel (Al/Fe) dissimilar welding. J. Phys. Conf. Ser. 2025, 2954, 012001. [Google Scholar] [CrossRef]

- Zeng, Y.; He, Y.; Dou, T.; Yang, J.; Li, J.; Jiang, J.; Ying, C.; Zheng, M.; Tan, C.; Zhang, H. Dissimilar laser joining of aluminum to steel via a porous FeCoCrNi high entropy alloy coating: Interfacial microstructure, wettability, and mechanical properties. Applied Surface Science 2025, 694, 162809. [Google Scholar] [CrossRef]

- Mohammadpour, M.; Yazdian, N.; Yang, G.; Wang, H.P.; Carlson, B.; Kovacevic, R. Effect of dual laser beam on dissimilar welding-brazing of aluminum to galvanized steel. Opt. Laser Technol. 2018, 98, 214–228. [Google Scholar] [CrossRef]

- Yuan, R.; Deng, S.; Cui, H.; Chen, Y.; Lu, F. Interface characterization and mechanical properties of dual beam laser welding-brazing Al/steel dissimilar metals. J. Manuf. Process. 2019, 40, 37–45. [Google Scholar] [CrossRef]

- Xia, H.; Tao, W.; Li, L.; Tan, C.; Zhang, K.; Ma, N. Effect of laser beam models on laser welding–brazing Al to steel. Opt. Laser Technol. 2022, 122, 105845. [Google Scholar] [CrossRef]

- Meng, Y.; Gong, M.; Zhang, S.; Zhang, Y.; Gao, M. Effects of oscillating laser offset on microstructure and properties of dissimilar Al/steel butt-joint. Opt. Lasers Eng. 2020, 128, 106037. [Google Scholar] [CrossRef]

- Sravanthi, S.S.; Acharyya, S.G.; Prabhakar, K.P.; Joardar, J. Effect of varying weld speed on corrosion resistance and mechanical behavior of Aluminium-steel welds fabricated by cold metal transfer technique. Mater. Manuf. Process. 2019, 34, 1627–1637. [Google Scholar] [CrossRef]

- Gong, Z.; Zhang, T.; Chen, Y.; Lu, J.; Ding, X.; Zhang, S.; Lan, M.; Shen, Y.; Wang, S. Effect of laser shock peening on stress corrosion cracking of TC4/2A14 dissimilar metal friction stir welding joints. J. Mater. Res. Technol. 2024, 30, 1716–1725. [Google Scholar] [CrossRef]

- Li, T.; Shi, J.; Li, R.; Qi, K.; Liu, Z.; Zhang, X.; Qiao, L. Interfacial microstructure and corrosion behaviors of TC4/DP780 steel joints by laser welding with H62 interlayer. J. Mater. Res. Technol. 2024, 29, 4470–4479. [Google Scholar] [CrossRef]

- Zhang, C.; Du, D.; Wu, Z.; Sun, Y.; Wang, X.; Long, W.; Pu, J. Effect of an Ultrasonic Vibration on the Microstructure and Properties of Al Alloy/Steel Laser Welding-Brazing Joints. Coatings 2024, 14, 1219. [Google Scholar] [CrossRef]

- Liu, H.; Pu, J.; Wu, M.; Zhang, C.; Rao, J.; Long, W.; Shen, Y. Research on the Microstructure and Properties of Al Alloy/Steel CMT Welding-Brazing Joints with Al–Si Flux-Cored Welding Wires. Coatings 2023, 13, 1590. [Google Scholar] [CrossRef]

- Pu, J.; Chen, T.; Rao, J.; Sun, Y.; Chen, Y.; Jiang, C.; Sun, H. Study on the Microstructure and Properties of Al Alloy/Steel CMT Welding–Brazing Joints Under Different Pulse Magnetic Field Intensities. Coatings 2024, 14, 1515. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).