Abrasive Wear Characteristics of High-Cr Multicomponent White Cast Irons at Elevated Temperatures

Abstract

1. Introduction

2. Experimental Procedures

2.1. Material Preparation

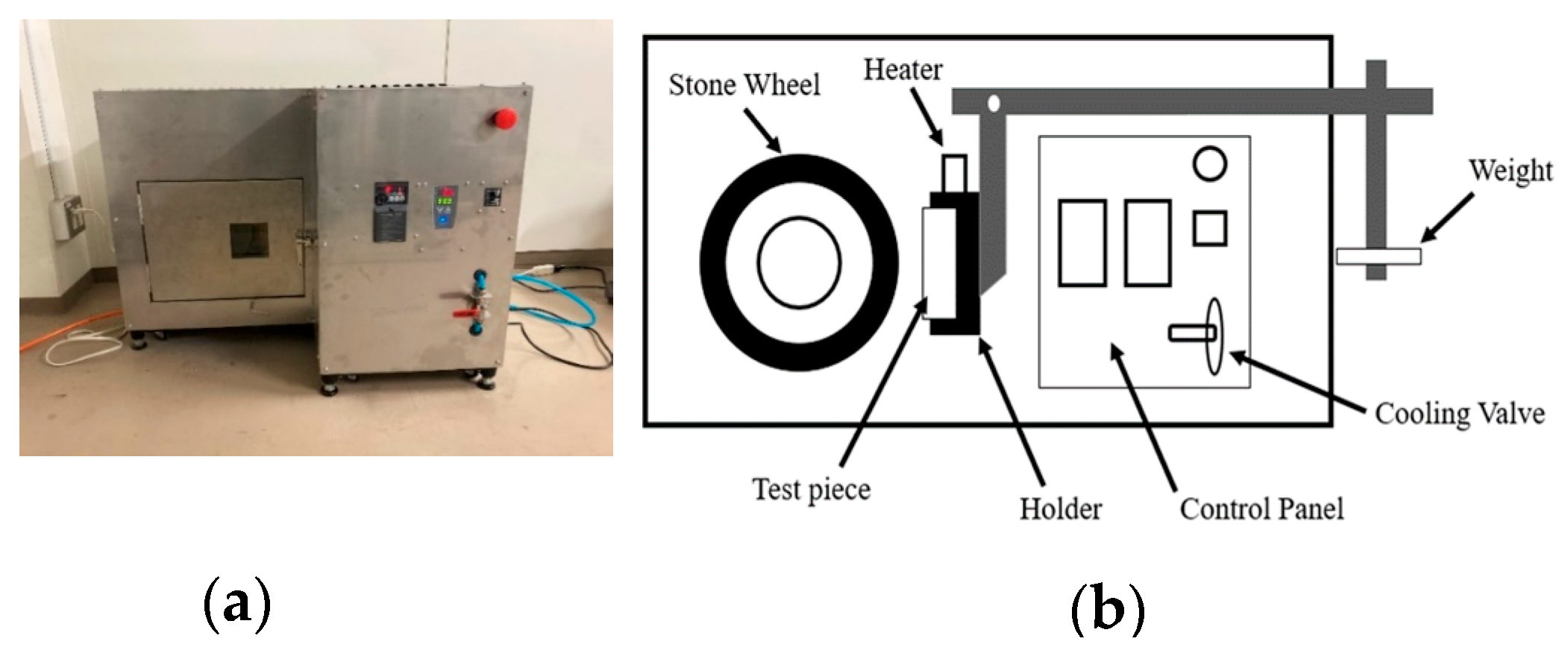

2.2. High-Temperature Abrasive Wear Testing

2.3. High-Temperature Vickers Hardness Test

3. Results and Discussion

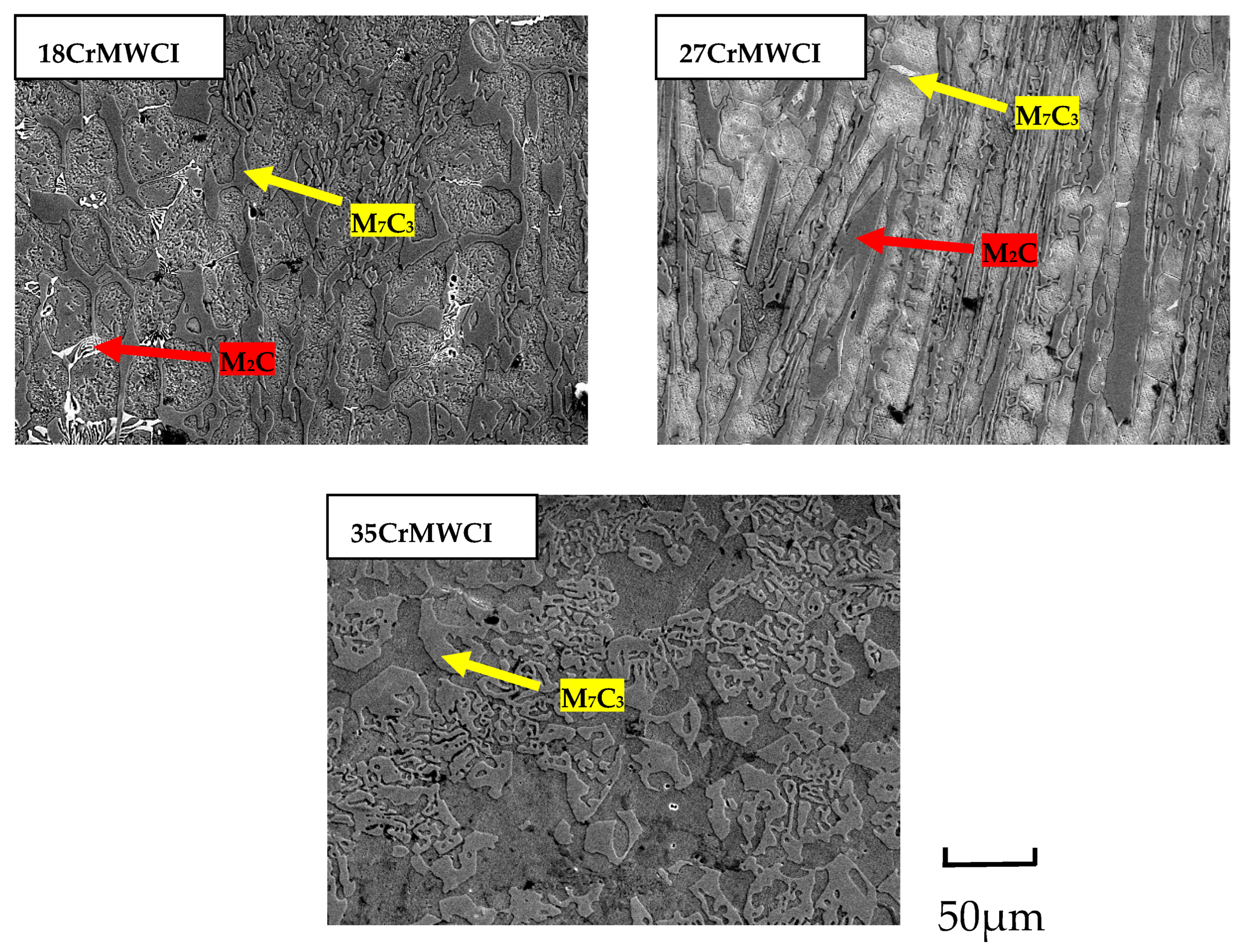

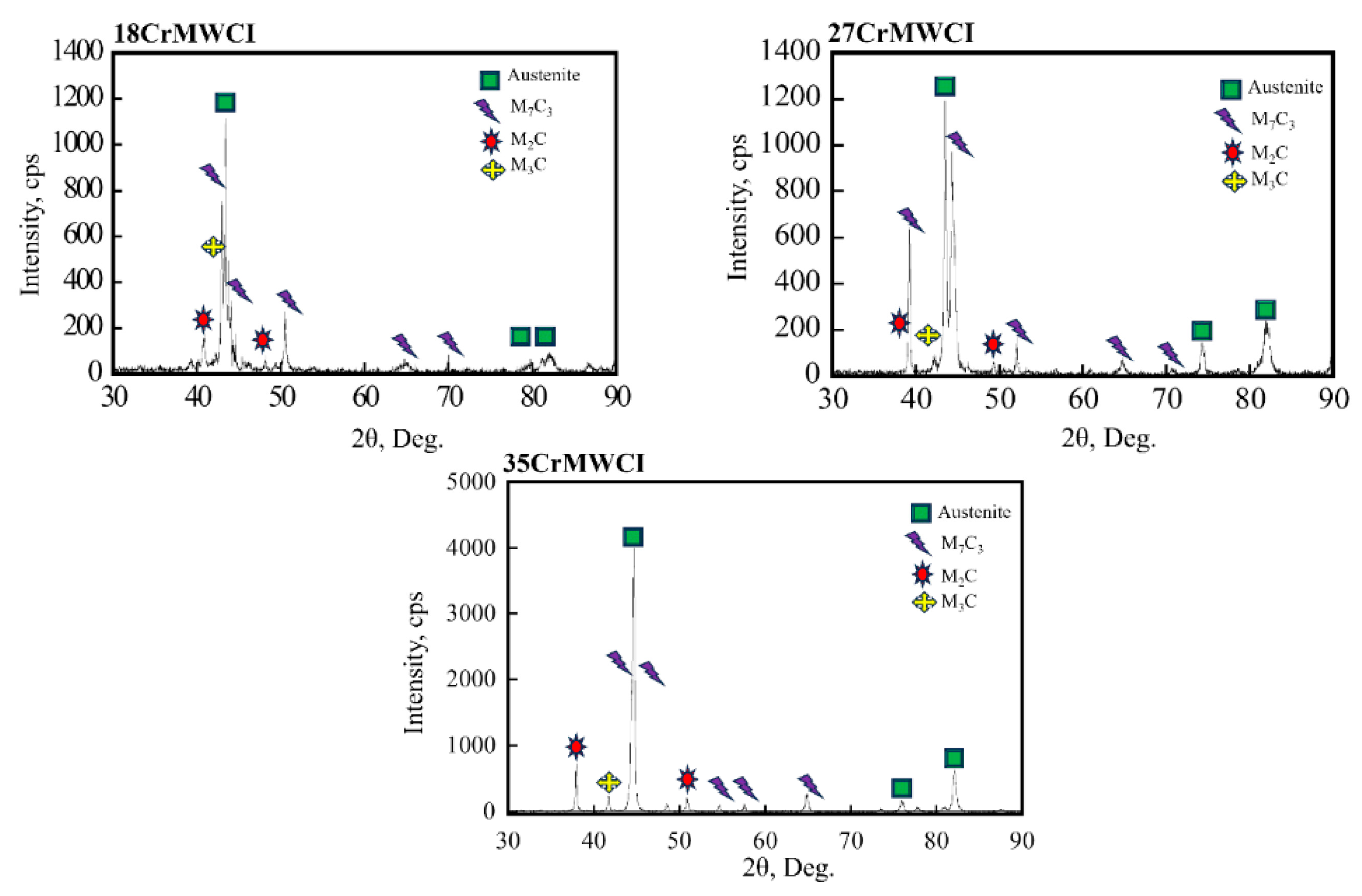

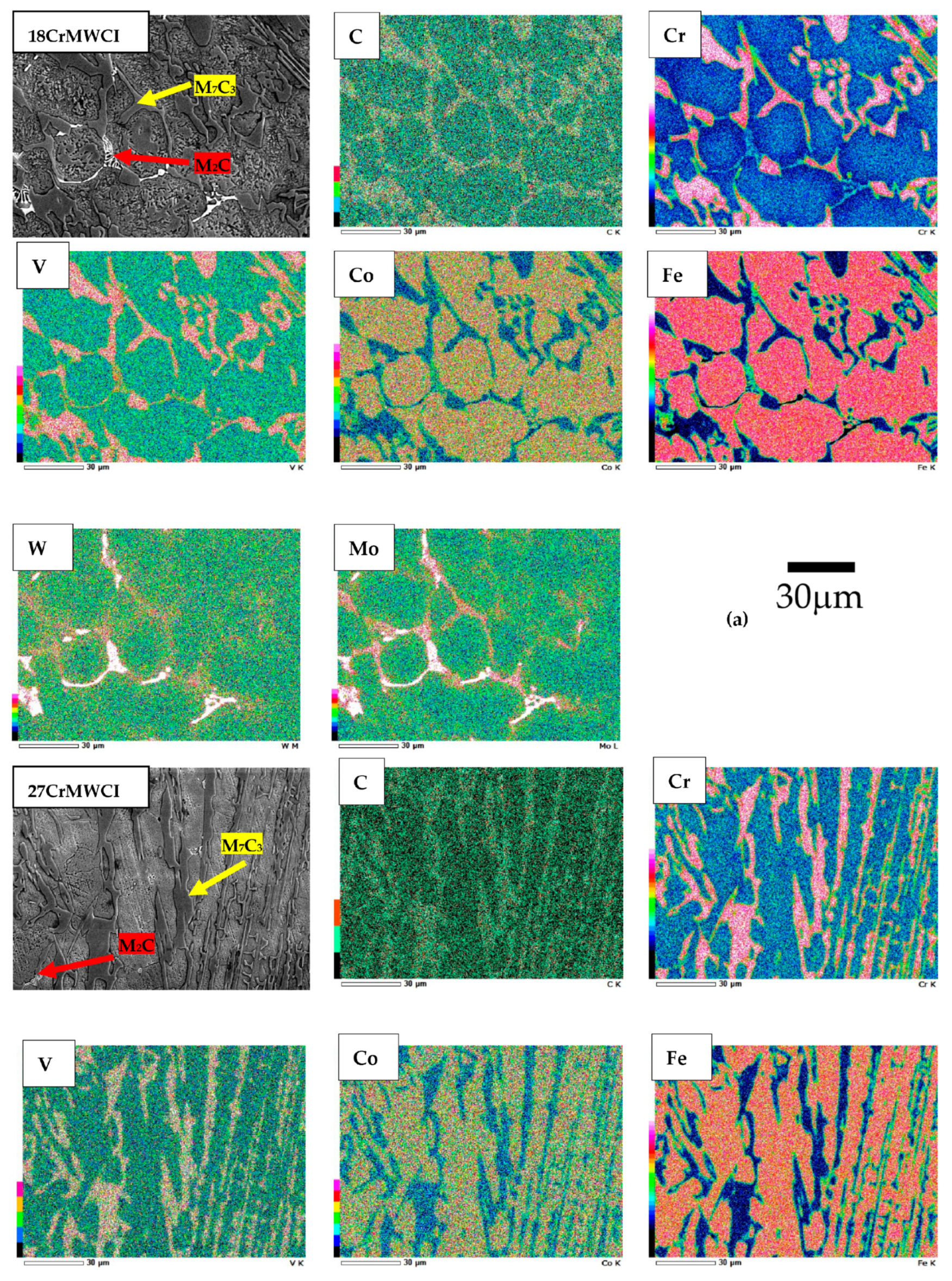

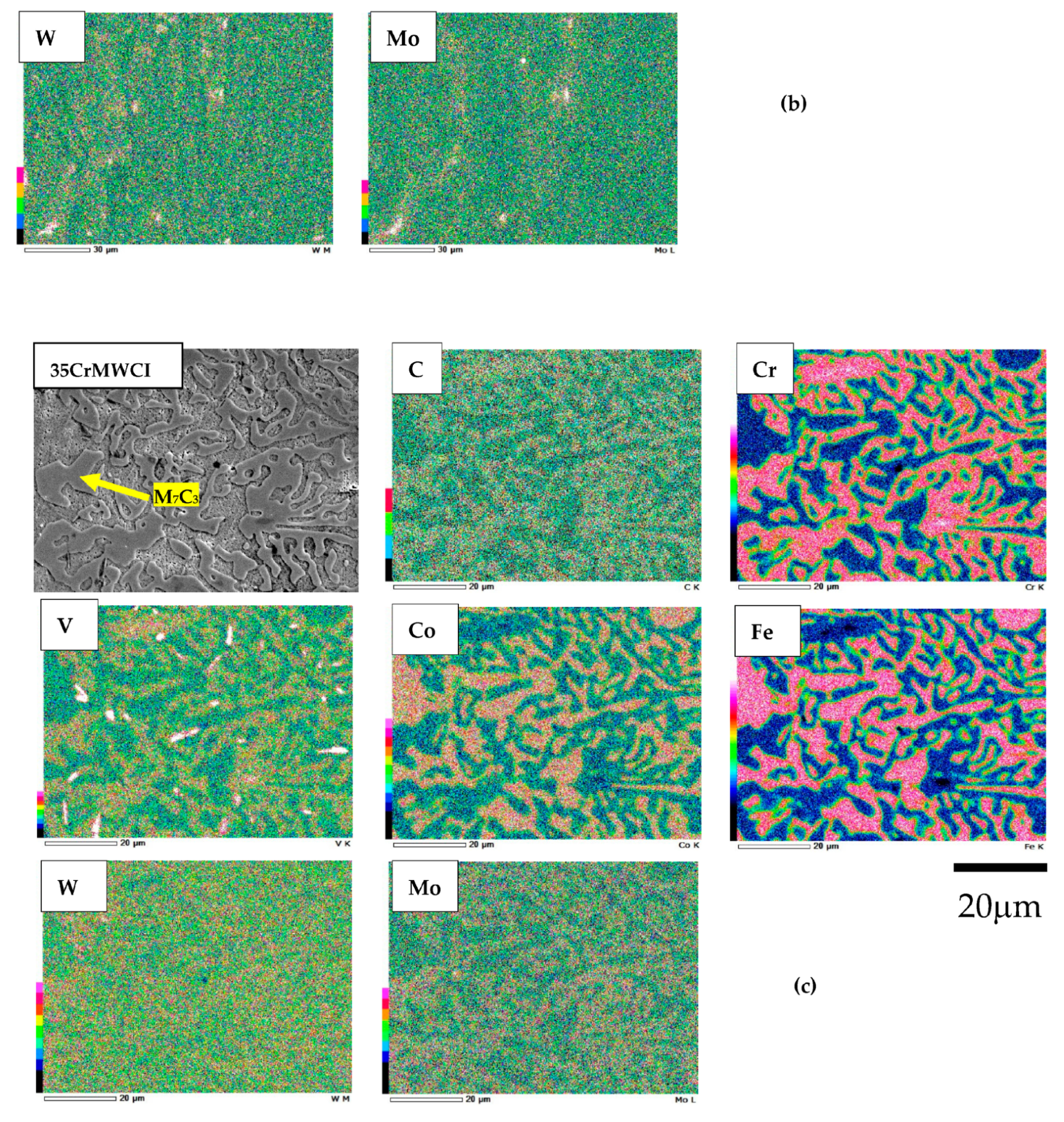

3.1. Metallographic Observation

3.2. High-Temperature Vickers Hardness

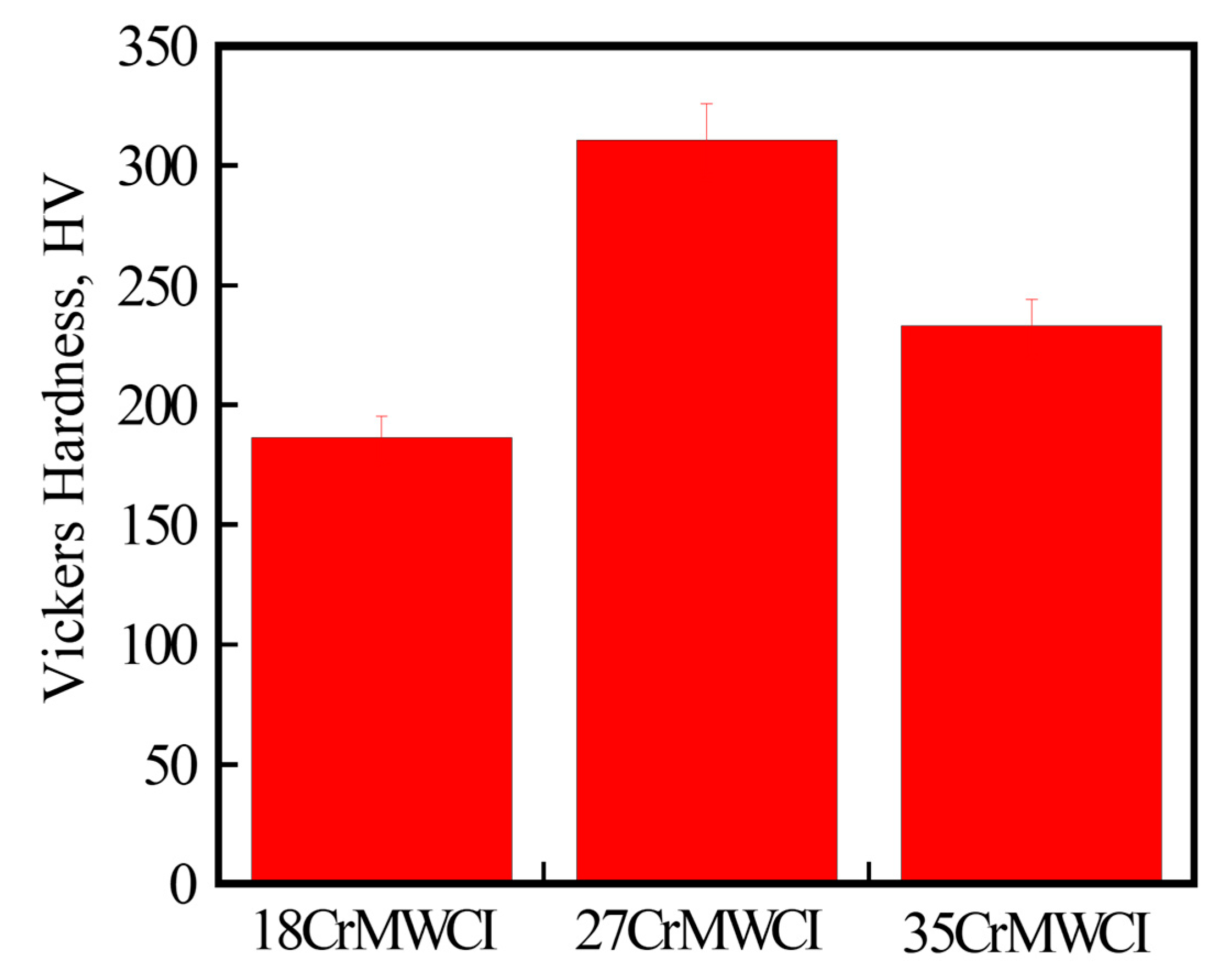

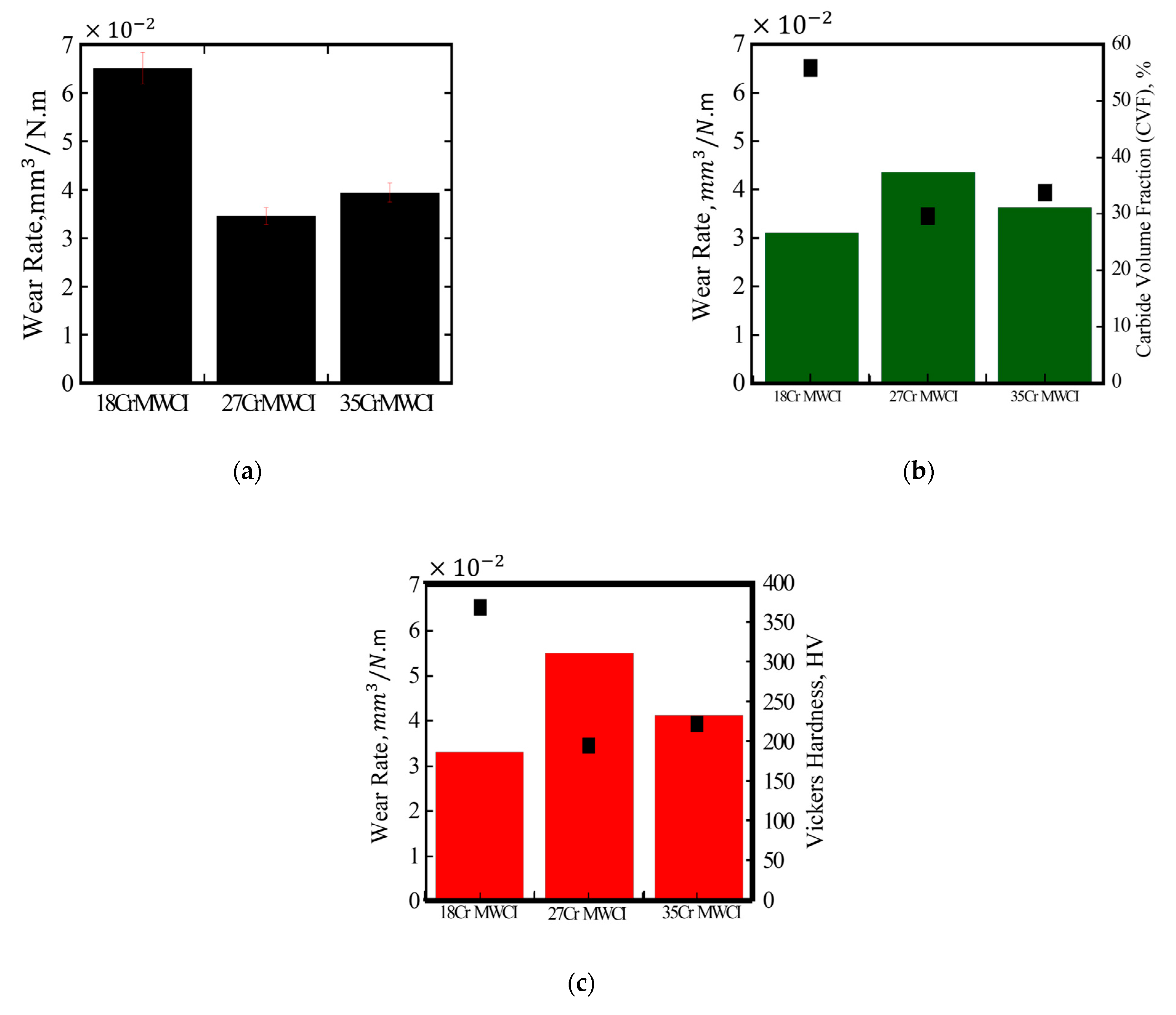

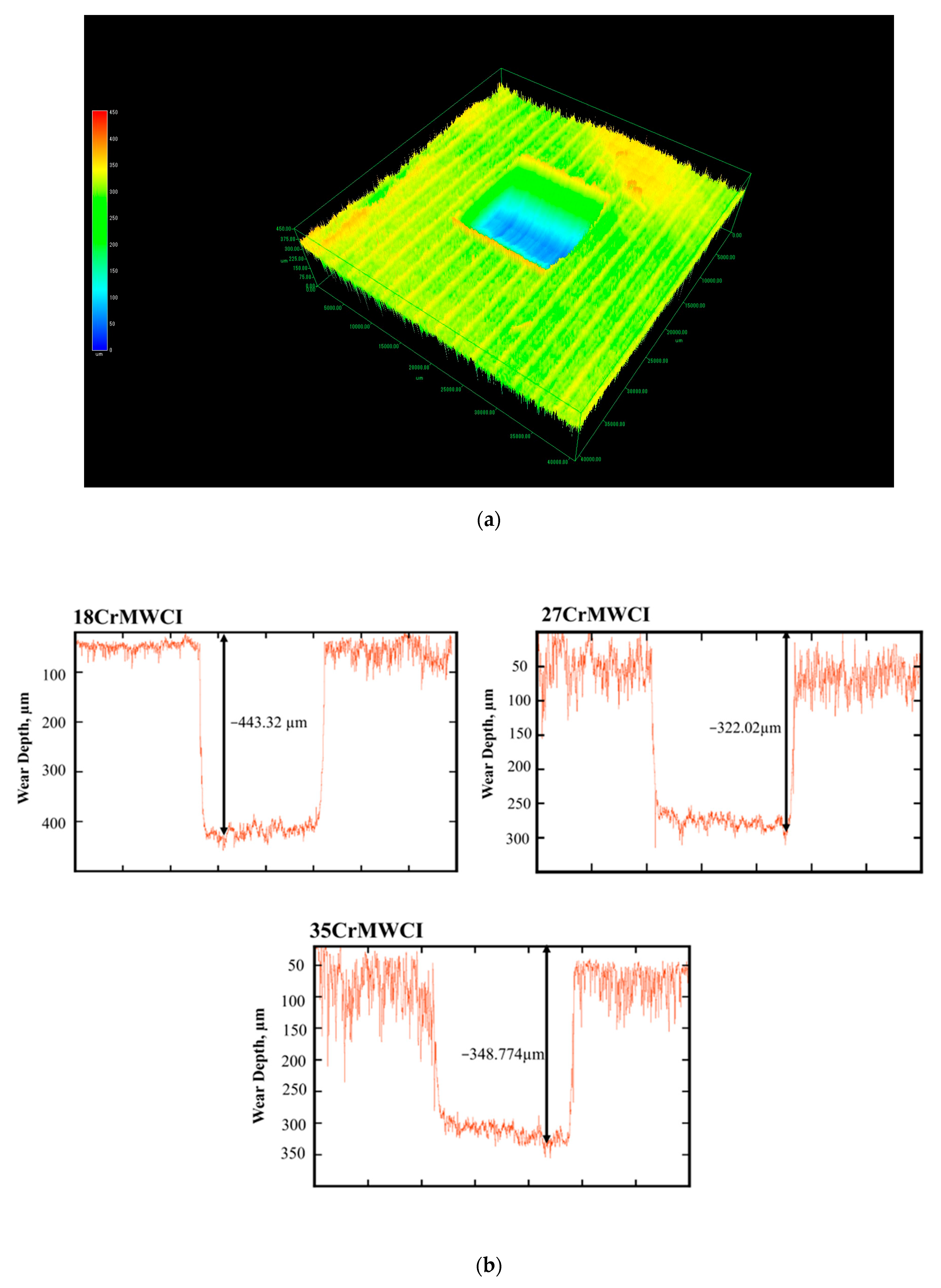

3.3. High-Temperature Abrasive Wear Performance

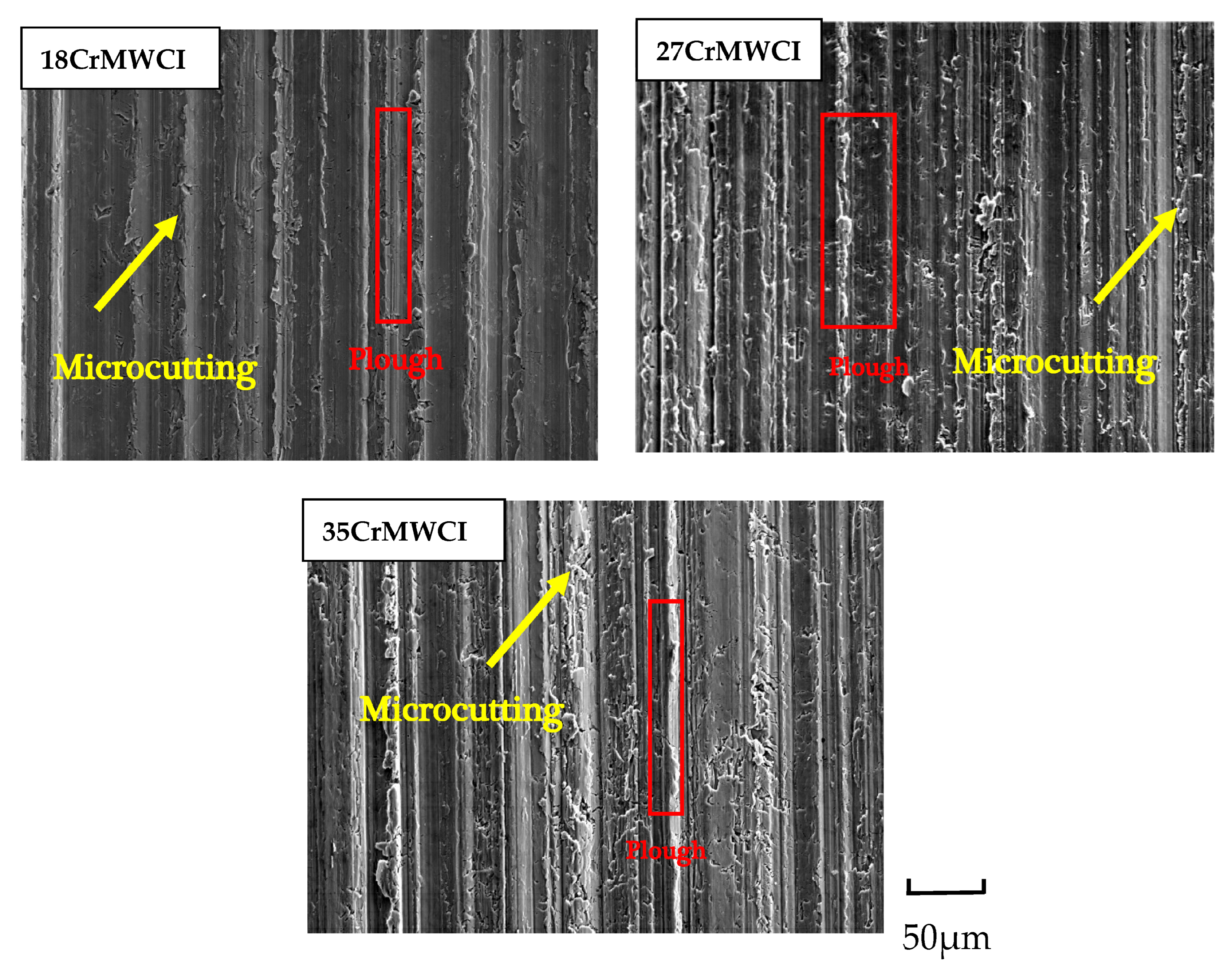

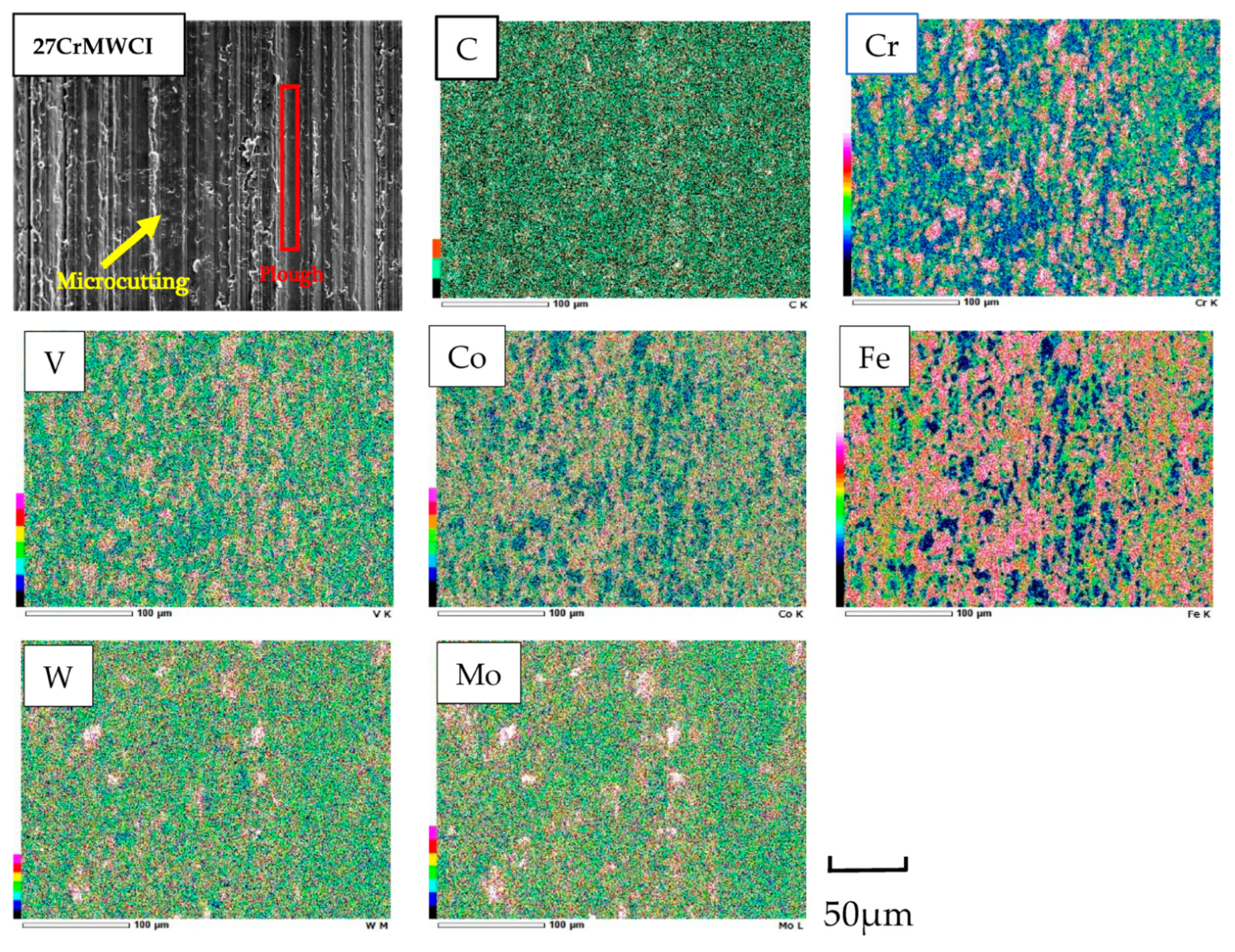

3.4. Worn Surface Analysis

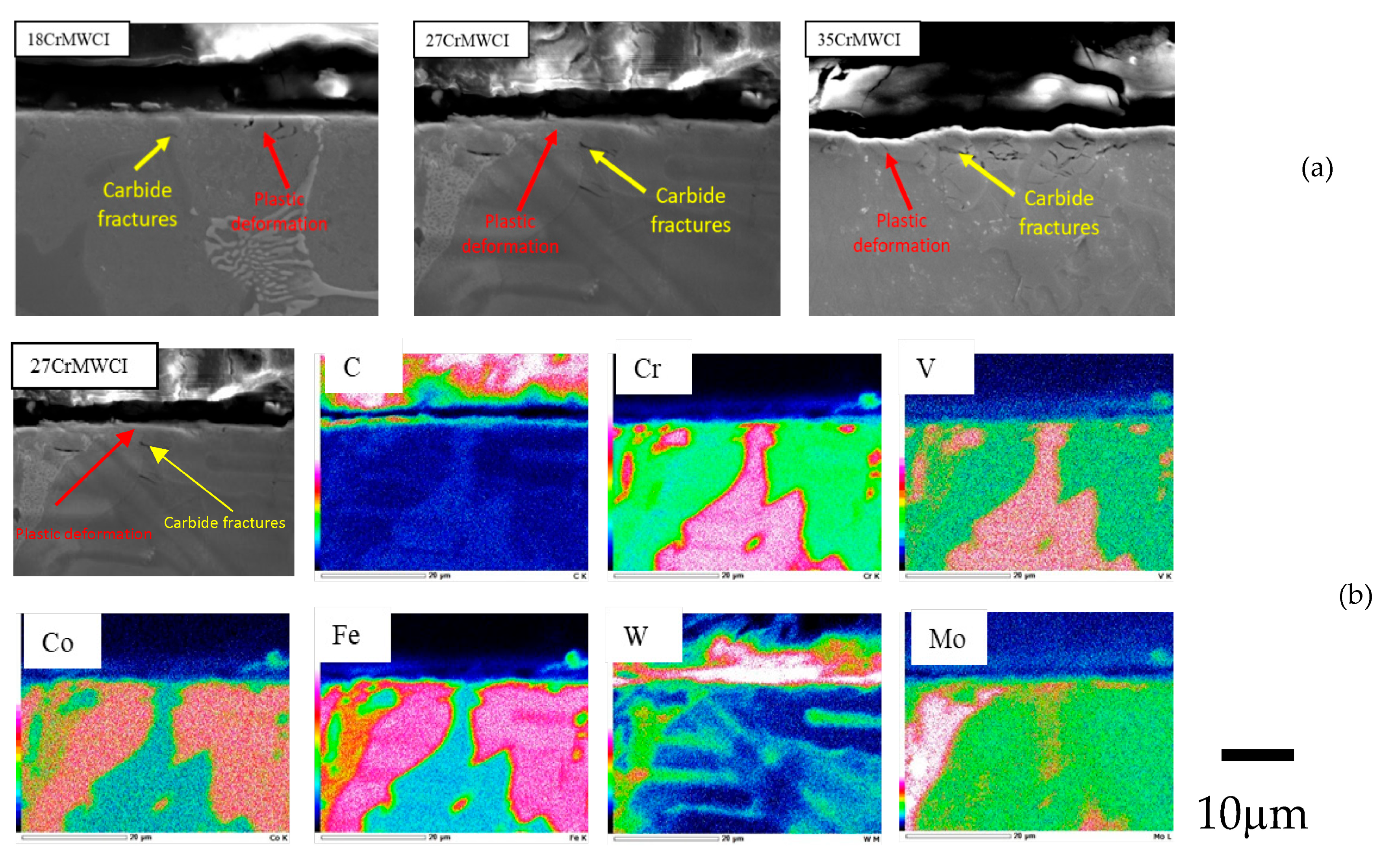

3.5. Worn Surface Analysis Through Cross-Section

4. Conclusions

- Adding Cr leads to the precipitation of various carbides, especially M7C3 carbides, which precipitate densely. This increase in Cr content leads to a higher CVF, where 27CrMWCI showed the highest CVF; however, the specimen with the highest percentage of Cr showed a decline in the CVF (35CrMWCI).

- The hardness of the specimens is significantly influenced by the CVF. The 27CrMWCI specimen showed the highest hardness, while the 18CMWCI specimen showed the lowest. This decline in hardness was the result of a lack of carbides, and lower hardness contributes to a higher wear rate, which is in agreement with several previous studies.

- The abrasive wear mechanism at high temperatures can be briefly explained as follows: In the 27CrMWCI specimen, the higher percentage of carbides provided better safety against wear by guarding the softer matrix from abrasive particles. In the 18CrMWCI and 35CrMWCI specimens, less carbides left the matrix uncovered, leading to a higher wear rate.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Pintaude, G. An Overview of the Hardness Differential Required for Abrasion. J. Tribol. 2010, 132, 034502. [Google Scholar] [CrossRef]

- Huq, M.J.; Shimizu, K.; Kusumoto, K.; Purba, R.H. Three-Body Abrasive Wear Performance of High Chromium White Cast Iron with Different Ti and C Content. Lubricants 2022, 10, 348. [Google Scholar] [CrossRef]

- Gong, L.; Fu, H.; Zhi, X. Corrosion Wear of Hypereutectic High Chromium Cast Iron: A Review. Metals 2023, 13, 308. [Google Scholar] [CrossRef]

- Fashu, S.; Trabadelo, V. Development and Performance of High Chromium White Cast Irons (HCWCIs) for Wear–Corrosive Environments: A Critical Review. Metals 2023, 13, 1831. [Google Scholar] [CrossRef]

- Ono, Y.; Murai, M.; Ogi, K. Partition Coefficients of Alloying Elements to Primary Austenite and Eutectic Phases of Chromium Irons of Rolls. ISIJ Int. 1992, 32, 1150. [Google Scholar] [CrossRef]

- Laird, G. Microstructures of Ni-Hard I, Ni-Hard IV, and High Cr White Cast Irons. AFS Trans. 1991, 99, 339. [Google Scholar]

- Todaka, T.; Shimizu, K.; Kusumoto, K.; Purba, R.H.; Gaqi, Y. Effect of Carbon Content on Three-body Abrasive Wear Characteristics of 28Cr-3Ni Cast Alloys. ISIJ Int. 2021, 61, 2274–2283. [Google Scholar] [CrossRef]

- Bedolla-Jacuinde, A.; Correa, R.; Quezada, J.G.; Maldonado, C. Effect of titanium on the as-cast microstructure of a 16% chromium white iron. Mater. Sci. Eng. A 2005, 398, 297. [Google Scholar] [CrossRef]

- Bedolla-Jacuinde, A.; Guerra, F.V.; Mejía, I.; Zuno-Silva, J.; Rainforth, M. Abrasive wear of V-Nb-Ti alloyed high-chromium white irons. Wear 2015, 332–333, 1006. [Google Scholar] [CrossRef]

- Mihailović, M.; Patarić, A.; Jordović, B. Heat Treatment Featuring the Key-Parameters of High Chromium White Cast Iron Microstructure. Met. Mater. Data 2023, 1, 81–83. [Google Scholar] [CrossRef]

- Elkassas, A.A.; Elkassas, A.M.; Rashad, R.M. Study the Influence of Destabilization and Tempering Heat Treatments on the Microstructure of High Chromium White Cast Iron by Observing the Resulted Hardness and Abrasive Wear Conduct. Eng. Sci. Mil. Technol. 2023, 6, 73–85. [Google Scholar] [CrossRef]

- Zhang, S.; Xing, J.; Peng, H.; Li, D. Effects of a Destabilization Heat Treatment on the Microstructure and Abrasive Wear Behavior of High-Chromium White Cast Iron Investigated Using Different Characterization Techniques. Metall. Mater. Trans. A 2013, 44, 4993–5005. [Google Scholar]

- Higuera-Cobos, Ó.F.; Dumitru, F.; Mesa-Grajales, D.H. Improvement of Abrasive Wear Resistance of the High Chromium Cast Iron ASTM A-532 through Thermal Treatment Cycles. Rev. Fac. Ing. 2016, 25, 93–103. [Google Scholar] [CrossRef]

- Bedolla-Jacuinde, A. Microstructure of vanadium-, niobium and titanium-alloyed high-chromium white cast irons. Int. J. Cast Met. Res. 2001, 13, 343–361. [Google Scholar] [CrossRef]

- Wu, X.; Xing, J.; Fu, H.; Zhi, X. Effect of titanium on the morphology of primary M7C3 carbides in hypereutectic high chromium white iron. Mater. Sci. Eng. A 2007, 457, 180–185. [Google Scholar] [CrossRef]

- Prayogo, R.S.; Setyana, L.D. The Improvement of Wear and Impact Resistance of High Chromium White Cast Iron for Crusher. J. Mater. Process. Charact. 2020, 1, 96–102. [Google Scholar] [CrossRef]

- Anijdan, S.M.; Bahrami, A.; Varahram, N.; Davami, P. Effect of tungsten on erosion-corrosion behavior of high chromium white cast iron. Mater Sci. Eng. 2007, 454–455, 623–628. [Google Scholar] [CrossRef]

- Shimizu, K.; Kusumoto, K.; Year, X.; Yao, Z.; Shirai, M. Effect of Mo content on erosive wear characteristics of high chromium cast iron at 1073 K. Wear 2017, 376–377, 542–548. [Google Scholar] [CrossRef]

- Bouhamla, K.; Hadji, A.; Maouche, H.; Mentouri, Z.; Remili, S. Effect of Manganese and Molybdenum on the Microstructure, the Shape of Secondary Precipitation, and the Wear Behavior of a High Chromium Cast Iron. Int. J. Met. 2024, 18, 1062–1074. [Google Scholar] [CrossRef]

- Schneider, C.; Rasband, W.; Eliceiri, K. NIH Image to ImageJ: 25 years of image analysis. Nat. Methods 2012, 9, 671–675. [Google Scholar] [CrossRef]

- Lecomte-Beckers, J.; Tchuindjang, J.T.; Pirard, E.; Breyer, J.-P. Physical Metallurgy of a HSS Material for Hot Rolling Mill Rolls. Available online: https://orbi.uliege.be/bitstream/2268/4890/1/C39%20PHYSICAL%20METALLURGY%20OF%20A%20HSS%20MATERIAL%20FOR%20HOT%20ROLLING%20MILL%20ROLLS.pdf (accessed on 11 January 2025).

- Abdel-Aziz, K.; El-Shennawy, M.; Omar, A.A. Microstructural Characteristics and Mechanical Properties of Heat Treated High-Cr White Cast Iron Alloys. Int. J. Appl. Eng. Res. 2017, 12, 4675–4686, ISSN 0973-4562. [Google Scholar]

- Chen, J.; Liu, Y.; Wang, Y.; Xu, R.; Shi, Q.; Chen, J.; Wu, Y. Design and Optimization of Heat Treatment Process Parameters for High-Molybdenum-Vanadium High-Speed Steel for Rolls. Materials 2023, 16, 7103. [Google Scholar] [CrossRef]

| Test Material | C | Cr | Mo | W | V | Co | Mn | Si | S | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| 18Cr MWCI | 2.91 | 17.01 | 2.84 | 2.61 | 2.85 | 2.71 | 0.24 | 1.39 | 0.03 | Bal. |

| 27Cr MWCI | 2.93 | 26.59 | 2.64 | 2.78 | 2.93 | 2.62 | 0.20 | 1.10 | 0.05 | Bal. |

| 35Cr MWCI | 1.93 | 34.39 | 2.79 | 2.81 | 2.89 | 2.66 | 0.17 | 0.82 | 0.01 | Bal. |

| Alloy | Carbide Type | Carbide Compound | Shape | Carbide Structure |

|---|---|---|---|---|

| 18CrMWCI | MC | - | - | - |

| M2C | (Fe59.77Mo2.17W0.49)C5.41 | Fishbone-like | Hexagonal | |

| M7C3 | (Fe59.89Cr25.19V1.86)C5.27 | Hexagonal rod-like plate | Hexagonal | |

| 27CrMWCI | MC | - | - | - |

| M2C | (Fe51.28Mo2.38W0.47)C5.95 | Fishbone-like | Hexagonal | |

| M7C3 | (Fe51.60Cr33.67V1.17)C5.30 | Hexagonal rod-like plate | Hexagonal | |

| 35CrMWCI | MC | - | - | - |

| M2C | (Fe47.33Mo1.82W0.38)C4.16 | Fishbone-like | Hexagonal | |

| M7C3 | (Fe47.48Cr40.10V1.19)C3.91 | Hexagonal plate-like | Hexagonal |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huq, M.J.; Shimizu, K.; Kusumoto, K. Abrasive Wear Characteristics of High-Cr Multicomponent White Cast Irons at Elevated Temperatures. Crystals 2025, 15, 113. https://doi.org/10.3390/cryst15020113

Huq MJ, Shimizu K, Kusumoto K. Abrasive Wear Characteristics of High-Cr Multicomponent White Cast Irons at Elevated Temperatures. Crystals. 2025; 15(2):113. https://doi.org/10.3390/cryst15020113

Chicago/Turabian StyleHuq, Mohammad Jobayer, Kazumichi Shimizu, and Kenta Kusumoto. 2025. "Abrasive Wear Characteristics of High-Cr Multicomponent White Cast Irons at Elevated Temperatures" Crystals 15, no. 2: 113. https://doi.org/10.3390/cryst15020113

APA StyleHuq, M. J., Shimizu, K., & Kusumoto, K. (2025). Abrasive Wear Characteristics of High-Cr Multicomponent White Cast Irons at Elevated Temperatures. Crystals, 15(2), 113. https://doi.org/10.3390/cryst15020113