Abstract

AlxGa1-xN layers with up to 53% Al composition and 1.3 µm total thicknesses were grown utilizing step-graded layers on dense arrays of 10 × 10 µm2 GaN tiles. While the layers were fully relaxed and crack-free, the higher Al composition sample showed increased X-ray line width, which did not correlate with a lack of increased dislocation density (as measured by TEM).

1. Introduction

AlGaN has a wide tunable bandgap range from 3.4 eV for GaN to 6.1 eV for AlN. While utilizing the full bandgap range is challenging, even an Al content of 0.7 provides a large bandgap of 5.1 eV [1,2,3]. This can be used to obtain light emitting diodes (LEDs) and laser diodes (LDs) across the ultraviolet (UV) wavelength range [4,5,6,7,8,9,10], as well as to fabricate high-power, high-frequency, and power switching devices [11,12]. The large bandgap also makes it viable for use in high-resolution optical lithography [13,14]. It is also being explored for use in UV photonics systems for potential on-chip optical communication [15,16,17,18,19].

AlGaN epilayers with low dislocation densities are necessary for these applications, especially when moving to high Al content. The first challenge is to obtain good-quality, large-area AlGaN substrates, which, at present, are not readily available. As such, various techniques are being developed, utilizing either GaN or AlN as the starting substrate. Lateral overgrowth of buried cracks was used to plastically relax AlGaN layers with 20% Al composition on GaN templates [20], while overgrowth on serrated GaN templates yielded AlGaN layers with up to 25% Al composition [21]. Sidewall growth of AlGaN on porous GaN and AlN base layers resulted in an air bridged structure with reduced dislocation densities with Al composition of 24% [22] and 98% [23], respectively, as did AlGaN layers grown via epitaxial lateral overgrowth on deep-grooved SiC substrates [24]. AlN on Sapphire [25] and SiC substrates are used to obtain AlGaN epilayers. These were used to grow UV LEDs [26,27], while LDs were demonstrated on sapphire substrates using a semipolar orientation [28]. Several research groups are also using a sacrificial AlGaN layer with up to 50% Al composition for flip chip UV LEDs [29,30].

Previously, we have had success using porous GaN pseudo-substrates (PSs) to grow crack-free, elastically relaxed AlGaN [31,32]. In this work, we have extended the growth method and deposited AlGaN directly on tiled GaN templates in an attempt to demonstrate a simpler method of obtaining relaxed AlGaN.

2. Materials and Methods

All layers in this study were grown epitaxially utilizing metal–organic chemical vapor deposition (MOCVD) using standard precursors trimethylgallium (TMGa), trimethylaluminum (TMAl), and ammonia (NH3) in a single wafer Thomas Swan (Aixtron) close-coupled showerhead reactor. Initially, 2.8 µm thick GaN was grown on c-plane sapphire substrates using standard template growth conditions [33]. The samples were first patterned and dry etched with a 100 W BCl3/Cl2 etch for 600 nm, generating 10 × 10 µm2 square tiles 2 µm apart, resulting in tiled substrates with a fill factor of ~83%. The mutually orthogonal GaN [1-100] and GaN [11-20] were identified by substrate orientation (and verified later with x-ray diffraction), and the sidewalls of the tiles were aligned along them for easier characterization.

On top of the tile arrays, AlGaN layers were grown by MOCVD at a temperature of 1155 °C, in a predominantly hydrogen ambient environment at a pressure of 100 Torr and a NH3 flow rate of 45 mmol/min. Metalorganic flow rates were set based on prior-grown fully strained AlGaN on GaN calibration samples with TMGa between 8.8 and 14.6 µmol/min and TMAl in the range of 1.0–2.4 µmol/min, respectively. The regrowth conditions were mostly similar to the optimized parameters from our previous work on porous GaN pseudo-substrates [32].

The AlGaN layers were regrown in steps, and the samples were characterized after every regrowth step. Between each regrowth, the samples were cleaned with acetone and isopropanol to remove contaminants, which was followed by a buffered HF dip to remove the oxide layer and finished with a deionized water rinse. The surface morphology was characterized using an Asylum MFP-3D atomic force microscope (AFM) from Oxford Instruments. High-resolution x-ray diffraction (XRD) measurements were performed in a X’Pert MRD diffractometer equipped with a Pixcel3D detector (Panalytical) to obtain rocking curves to evaluate the film quality [34]. Area scans were also taken to generate reciprocal space maps (RSMs) around the GaN (11–24) reflection to determine composition and relaxation [35]. In addition, the samples were characterized by transmission electron microscopy. The TEM samples were first prepared via the Focus Ion Beam (FIB) technique using a Helios Dualbeam Nanolan 600 instrument (FEI); then, measurements were performed at 200 kV in the ThermoFisher Talos G2 200X system.

3. Experiment and Results

The schematic of the full epitaxial layer structure of the first samples grown on the tiled GaN is shown in Figure 1a. The first regrowth consisted of a 10 nm GaN transition layer, followed by an 180 nm thick step-graded AlGaN layer, with each grade being 30 nm thick and with nominal Al compositions (xAl) of 0.05, 0.09, 0.13, 0.17, 0.21, and 0.25, respectively. The regrowth was continued with a 330 nm thick AlGaN with nominal xAl = 0.30. Two further regrowths were performed, each with 400 nm AlGaN and with a decreased nominal xAl = 0.28 for easier relaxation, bringing the total thickness of the AlGaN layer to 1.3 µm.

Figure 1.

(a) Schematic of the first AlGaN structure grown on tiled GaN. The vertical arrow represents the growth direction, and the dashed lines indicate regrowth interfaces. The xAl values are nominal derived from the growth of strained AlGaN on GaN test samples. (b) RSM obtained from the XRD of the final structure, with the GaN and AlGaN peaks marked.

The final samples were crack-free. RSM evaluation of the first regrown ~500 nm thick AlGaN stack showed ~35% Al composition, with a relaxation of ~82%. The measured Al composition was higher than the nominal xAl of 0.30, likely due to the composition pulling effect (the increased Al or In uptake from the gas phase with decreasing lattice mismatch) [36,37,38]. After depositing another 400 nm AlGaN, which brought the total regrowth thickness to ~900 nm, the AlGaN was ~90% relaxed with a composition of ~32% Al. The final regrowth resulting in a total ~1.3 µm thick AlGaN structure caused the layer to be fully relaxed with Al composition, staying the same at ~32% (Figure 1b) due to the enhanced Al uptake from the gas phase on the 90% relaxed Al0.32Ga0.68N.

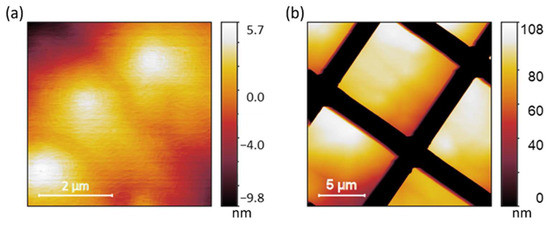

Rocking curve measurements with pseudo-Voigt fitting were used to obtain the ω-FWHM of the (0002) and (2-201) reflexes, which were 436 and 554 arc seconds, respectively. This is on par with good quality hetero-epitaxial growth of AlN on SiC [39]. The surface morphology was smooth after the first regrowth step, with a root mean square (RMS) roughness of 1.5 nm, as observed with AFM (Figure 2). The further regrowth steps increased the roughness to 2.3 and 2.7 nm, respectively. The rms increase resulted from the formation of growth spirals, a process which has also been observed for fully planar AlGaN layers [40,41].

Figure 2.

(a) 5 × 5 µm2 AFM height image of the AlGaN layer stack after final regrowth. (b) 20 × 20 µm2 AFM image shows minimal sidewall growth on the tiles. The Al composition in the top layer was 32%.

With tiled GaN templates working well to grow relaxed AlGaN with a composition of 32%, a higher Al composition was attempted. As before, a step-graded layer was utilized, this time with a steeper grading to obtain higher Al content. The layer consisted of 7 steps of 25 nm each, with nominal xAl = 0.05, 0.11, 0.17, 0.23, 0.29, 0.35, and 0.41, respectively. It was followed by a 325 nm AlGaN layer with a nominal xAl of 0.47 (Figure 3a). Two further regrowths were performed with an adjusted xAl of 0.44 of 400 nm, each bringing the total AlGaN stack thickness to almost 1.3 µm. Evaluation of RSMs was promising, with the first stack showing 88% relaxation and 58% Al content. After the second regrowth the AlGaN was fully relaxed and stayed so after a further regrowth, with a composition of ~53% Al (Figure 3b). As observed for the first sample, a significant increase in the Al incorporation was observed on the relaxed tiles.

Figure 3.

(a) Schematic of the higher Al content structure grown on tiled GaN. The vertical arrow represents the growth direction, and the dashed lines indicate regrowth interfaces. The xAl values are nominal, derived from the growth of strained AlGaN on GaN test samples. (b) RSM obtained from XRD of the final structure with the GaN and AlGaN peaks marked.

Rocking curve measurements showed ω-FWHM values of 432 and 1008 arc seconds for the (0002) and (2-201) reflexes, respectively. In comparison with the previous sample, with a final Al content of 32%, a sharp increase in the off-axis value was observed. Again, the layers remained crack-free. AFM images showed the RMS roughness increasing from 1.2 nm for the first regrowth to 2.3 and 2.5 nm for the subsequent regrowth steps (Figure 4), similar to the observations made for the lower Al composition samples. As seen for the Al0.32Ga0.68N sample, the Al0.53Ga0.47N growth preferentially occurred on the top surface of the mesa, and no significant sidewall deposition was observed.

Figure 4.

(a) 5 × 5 µm2 AFM height image of the AlGaN layer after final regrowth. (b) 20 × 20 µm2 AFM image showing preferential regrowth on top only. The Al composition in the top layer was 53%.

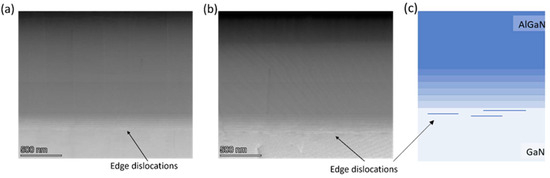

To better understand the origin of the increased (2-201) ω-FWHM of the higher Al composition sample, high-angle annular dark field (HAADF) scanning transmission electron microscopy (STEM) observation was performed. The visible vertical lines observed in the STEM images are not related to dislocations and originate from the curtaining effect when performing cross-sectional milling. Horizontal white lines are visible at the base of the step-graded layer, which were associated with pure edge component dislocations (Figure 5). A few of these planar pure edge component dislocations were also observed in our work on partially relaxed InGaN grown by molecular beam epitaxy (MBE) on tiled porous GaN pseudo-substrates [42]. Plane-view TEM was also performed to obtain a count of dislocation density. Starting with the assumption that the dislocations go straight upward to the surface of the prepared sample and finding the dislocations per unit area gave us a dislocation density of 0.9–1.1 × 109 cm−2 for both the samples.

Figure 5.

HAADF-STEM images showing edge dislocations in the GaN below the AlGaN stack for sample with (a) 32% Al content and (b) sample with 53% Al content. (c) Schematic showing the presence of edge dislocations in the GaN template at the AlGaN/GaN interface.

The results of the TEM investigation suggest that the increased (2-201) ω-FWHM of the higher Al composition sample is caused by reasons other than a higher dislocation density. It could be due to composition fluctuations across the tile [43], resulting from different rates of relaxation when comparing center to edge. Further investigations are needed to understand these findings. Moreover, in the experiments discussed here, the thickness of the graded AlGaN layer was held constant, leading to a steeper grade for the higher Al composition sample. Further optimization of the thickness of the graded AlGaN layer, as well as other process parameters, is expected to result in improved properties of the regrown AlGaN.

4. Conclusions

Fully relaxed, crack-free 1.3 µm thick AlGaN layers with 32% and 53% Al content were formed on dense 10 × 10 µm2 GaN tile arrays. The epilayers were smooth, with a reasonable dislocation density of ~109 cm−2. The results show the potential of using dense tile arrays for the epitaxy of lattice mismatched materials.

Author Contributions

Investigation, N.H., H.C., E.K., and F.W.; Resources, U.K.M.; Writing—original draft, N.H.; Writing—review and editing, S.K.; Supervision, S.K. and U.K.M. All authors have read and agreed to the published version of the manuscript.

Funding

This work was funded by the Office of Naval Research (supervised by Dr. Paul Maki).

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Marcinkevičius, S.; Jain, R.; Shatalov, M.; Yang, J.; Shur, M.; Gaska, R. High spectral uniformity of AlGaN with a high Al content evidenced by scanning near-field photoluminescence spectroscopy. Appl. Phys. Lett. 2014, 105, 241108. [Google Scholar] [CrossRef]

- Liu, X.; Lv, Z.; Liao, Z.; Sun, Y.; Zhang, Z.; Sun, K.; Zhou, Q.; Tang, B.; Geng, H.; Qi, S.; et al. Highly efficient AlGaN-based deep-ultraviolet light-emitting diodes: From bandgap engineering to device craft. Microsyst. Nanoeng. 2024, 10, 110. [Google Scholar] [CrossRef]

- Li, C.; Bao, X.; Xu, J.; Zhang, Y.; Li, X. Optical characterization of GaN/AlGaN bilayer by transmission and reflection spectra. J. Appl. Phys. 2010, 108, 063104. [Google Scholar] [CrossRef]

- Moustakas, T.D.; Paiella, R. Optoelectronic device physics and technology of nitride semiconductors from the UV to the terahertz. Rep. Prog. Phys. 2017, 80, 106501. [Google Scholar] [CrossRef] [PubMed]

- Kneissl, M.; Seong, T.Y.; Han, J.; Amano, H. The emergence and prospects of deep-ultraviolet light-emitting diode technologies. Nat. Photon. 2019, 13, 233–244. [Google Scholar] [CrossRef]

- Song, K.; Mohseni, M.; Taghipour, F. Application of ultraviolet light-emitting diodes (UV-LEDs) for water disinfection: A review. Water Res. 2016, 94, 341–349. [Google Scholar] [CrossRef]

- Yao, Y.; Zollner, C.J.; Wang, M.; Iza, M.; Speck, J.S.; DenBaars, S.P.; Nakamura, S. Polarization-Enhanced p-AlGaN Superlattice Optimization for GUV LED. IEEE J. Quantum Electron. 2022, 58, 1–9. [Google Scholar] [CrossRef]

- Sakai, T.; Kushimoto, M.; Zhang, Z.; Sugiyama, N.; Schowalter, L.J.; Honda, Y.; Sasaoka, C.; Amano, H. On-wafer fabrication of etched-mirror UV-C laser diodes with the ALD-deposited DBR. Appl. Phys. Lett. 2020, 116, 122101. [Google Scholar] [CrossRef]

- Alkhazragi, O.; Hu, F.; Zou, P.; Ha, Y.; Kang, C.H.; Mao, Y.; Ng, T.K.; Chi, N.; Ooi, B.S. Gbit/s ultraviolet-C diffuse-line-of-sight communication based on probabilistically shaped DMT and diversity reception. Optic. Express 2020, 28, 9111–9122. [Google Scholar] [CrossRef]

- Rass, J.; Cho, H.K.; Guttmann, M.; Prasai, D.; Ruschel, J.; Kolbe, T.; Einfeldt, S. Enhanced light extraction efficiency of far-ultraviolet-C LEDs by micro-LED array design. Appl. Phys. Lett. 2023, 122, 263508. [Google Scholar] [CrossRef]

- Kaplar, R.J.; Allerman, A.A.; Armstrong, A.M.; Crawford, M.H.; Dickerson, J.R.; Fischer, A.J.; Baca, A.G.; Douglas, E.A. Review—Ultra-Wide-Bandgap AlGaN Power Electronic Devices. ECS J. Solid State Sci. Technol. 2017, 6, Q3061. [Google Scholar] [CrossRef]

- Liang, Y.C.; Samudra, G.S.; Huang, H.; Huang, C.-F.; Chang, T.-F. AlGaN/GaN power HEMT devices for future energy conversion applications. In Proceedings of the 2013 International Symposium on Next-Generation Electronics, Kaohsiung, Taiwan, 25–26 February 2013. [Google Scholar] [CrossRef]

- Okazaki, S. Resolution limits of optical lithography. J. Vac. Sci. Technol. B 1991, 9, 2829–2833. [Google Scholar] [CrossRef]

- Feng, F.; Liu, Y.; Zhang, K.; Yang, H.; Hyun, B.-R.; Xu, K.; Kwok, H.-S.; Liu, Z. High-power AlGaN deep-ultraviolet micro-light-emitting diode displays for maskless photolithography. Nat. Photon. 2025, 19, 101–108. [Google Scholar] [CrossRef]

- Floyd, R.; Hussain, K.; Mamun, A.; Gaevski, M.; Simin, G.; Chandrashekhar, M.V.S.; Khan, A. Photonics integrated circuits using AlxGa1-xN based UVC light-emitting diodes, photodetectors and waveguides. Appl. Phys. Expr. 2020, 13, 022003. [Google Scholar] [CrossRef]

- Liu, C.; Cai, Y.; Jiang, H.; Lau, K.M. Monolithic integration of III-nitride voltage controlled light emitters with dual-wavelength photodiodes by selective-area epitaxy. Opt. Lett. 2018, 43, 3401–3404. [Google Scholar] [CrossRef] [PubMed]

- He, R.; Liu, N.; Gao, Y.; Chen, R.; Zhang, S.; Yuan, H.; Duo, Y.; Xu, J.; Ji, X.; Yan, J.; et al. Monolithically integrated UVC AlGaN-based multiple quantum wells structure and photonic chips for solar-blind communications. Nano Energy 2023, 106, 108038. [Google Scholar] [CrossRef]

- Gündoğdu, S.; Pregnolato, T.; Kolbe, T.; Hagedorn, S.; Pazzagli, S.; Weyers, M. Fabrication of AlGaN Integrated Photonic Devices. In Proceedings of the 2023 Conference on Lasers and Electro-Optics Europe & European Quantum Electronics Conference (CLEO/Europe-EQEC), Munich, Germany, 26–30 June 2023; p. 1. [Google Scholar] [CrossRef]

- Chen, D.; Liu, Z.; Lu, X.; Wan, L.; Li, R.; Yang, Z.; Li, G. Efficiency improved by monolithic integration of HEMT with vertical-structure LEDs and Mg doping on dry etched GaN. J. Mater. Chem. C 2019, 7, 2823–2828. [Google Scholar] [CrossRef]

- Bethoux, J.-M.; Vennéguès, P.; Natali, F.; Feltin, E.; Tottereau, O.; Nataf, G.; De Mierry, P.; Semond, F. Growth of high quality crack-free AlGaN films on GaN templates using plastic relaxation through buried cracks. J. Appl. Phys. 2003, 94, 6499. [Google Scholar] [CrossRef]

- Liu, R.; Bell, A.; Ponce, F.A.; Amano, H.; Akasaki, I.; Cherns, D. Thick crack-free AlGaN films deposited by facet-controlled epitaxial lateral overgrowth. Phys. Stat. Sol. (c) 2003, 7, 2136–2140. [Google Scholar] [CrossRef]

- Qhalid Fareed, R.S.; Adivarahan, V.; Chen, C.Q.; Rai, S.; Kuokstis, E.; Yang, J.W.; Khan, M.A.; Caissie, J.; Molnar, R.J. Air-bridged lateral growth of crack-free Al0.24Ga0.76N on highly relaxed porous GaN. Appl. Phys. Lett. 2004, 84, 696. [Google Scholar] [CrossRef]

- Wang, T.; Bai, J.; Parbrook, P.J.; Cullis, A.G. Air-bridged lateral growth of an Al0.98Ga0.02N layer by introduction of porosity in an AlN buffer. Appl. Phys. Lett. 2005, 87, 151906. [Google Scholar] [CrossRef]

- Heikman, S.; Keller, S.; Newman, S.; Wu, Y.; Moe, C.; Moran, B.; Schmidt, M.; Mishra, U.K.; Speck, J.S.; DenBaars, S.P. Epitaxial Lateral Overgrowth of High Al Composition AlGaN Alloys on Deep Grooved SiC Substrates. Jpn. J. Appl. Phys. 2005, 44, L405. [Google Scholar] [CrossRef]

- Sena, H.; Thurston, M.L.S.; Meng, C.; Chowdhury, S. Systematic investigation of AlGaN channels on AlN/sapphire substrates using metal–organic chemical vapor deposition (MOCVD): Toward higher crystallinity and lower surface roughness. APL Mater. 2025, 13, 051111. [Google Scholar] [CrossRef]

- Yao, Y.; Li, H.; Li, P.; Zollner, C.J.; Wang, M.; Iza, M.; Speck, J.S.; DenBaars, S.P.; Nakamura, S. Size dependent characteristics of AlGaN-based ultraviolet micro-LEDs. In Proceedings of the 2023 Device Research Conference (DRC), Santa Barbara, CA, USA, 25–28 June 2023; pp. 1–2. [Google Scholar] [CrossRef]

- Nagasawa, Y.; Hirano, A. A Review of AlGaN-Based Deep-Ultraviolet Light-Emitting Diodes on Sapphire. Appl. Sci. 2018, 8, 1264. [Google Scholar] [CrossRef]

- Khoury, M.; Li, H.; Zhang, H.; Bonef, B.; Wong, M.S.; Wu, F.; Cohen, D.; Mierry, P.D.; Vennéguès, P.; Speck, J.S.; et al. Demonstration of Electrically Injected Semipolar Laser Diodes Grown on Low-Cost and Scalable Sapphire Substrates. ACS Appl. Mater. Interfaces 2019, 11, 47106–47111. [Google Scholar] [CrossRef] [PubMed]

- Bergmann, M.A.; Enslin, J.; Yapparov, R.; Hjort, F.; Wickman, B.; Mercinkevičius, S.; Wernicke, T.; Kneissl, M.; Haglund, Å. Electrochemical etching of AlGaN for the realization of thin-film devices. Appl. Phys. Lett. 2019, 115, 182103. [Google Scholar] [CrossRef]

- Zhang, G.; Wang, B.; Jia, T.; Chu, C.; Fan, C.; Zhang, Y.; Zhang, X.; Liu, N.; Zhang, Z.-H.; Yan, J. Improving the performance for flip-chip AlGaN-based deep ultraviolet light-emitting diodes using surface textured Ga-face n-AlGaN. Opt. Express 2022, 30, 17781–17788. [Google Scholar] [CrossRef]

- Pasayat, S.S.; Hatui, N.; Li, W.; Gupta, C.; Nakamura, S.; DenBaars, S.P.; Keller, S.; Mishra, U.K. Method of growing elastically relaxed crack-free AlGaN on GaN as substrates for ultra-wide bandgap devices using porous GaN. Appl. Phys. Lett. 2020, 117, 062102. [Google Scholar] [CrossRef]

- Hatui, N.; Collins, H.; Kayede, E.; Pasayat, S.S.; Li, W.; Keller, S.; Mishra, U.K. Fully Relaxed, Crack-Free AlGaN with upto 50% Al Composition Grown on Porous GaN Pseudo-Substrate. Crystals 2022, 12, 989. [Google Scholar] [CrossRef]

- Keller, S.; Wu, Y.-F.; Parish, G.; Ziang, N.; Xu, J.J.; Keller, B.P.; DenBaars, S.P.; Mishra, U.K. Gallium nitride based high power heterojunction field effect transistors: Process development and present status at UCSB. IEEE Trans. Electron Devices 2001, 48, 552–559. [Google Scholar] [CrossRef]

- Moram, V.E.; Vickers, M.E. X-ray diffraction of III-nitrides. Rep. Prog. Phys. 2009, 72, 036502. [Google Scholar] [CrossRef]

- Pereira, S.; Correia, M.R.; Pereira, E.; O’Donnell, K.P.; Alves, E.; Sequeira, A.D.; Franco, N.; Watson, I.M.; Deatcher, C.J. Strain and composition distributions in wurtzite InGaN/GaN layers extracted from X-ray reciprocal space mapping. Appl. Phys. Lett. 2002, 80, 3913. [Google Scholar] [CrossRef]

- Tsai, Y.-L.; Wang, C.-L.; Lin, P.-H.; Liao, W.-T.; Gong, J.-R. Observation of compositional pulling phenomenon in AlxGa1-xN (0.4 < x < 1.0) films grown on (0001) sapphire substrates. Appl. Phys. Lett. 2003, 82, 31. [Google Scholar]

- Chen, Z.; Pei, Y.; Newman, S.; Brown, D.; Chung, R.; Keller, S.; DenBaars, S.P.; Nakamura, S.; Mishra, U.K. Growth of AlGaN/GaN/AlGaN double heterojunction field-effect transistors and the observation of a compositional pulling effect. Appl. Phys. Lett. 2009, 94, 171117. [Google Scholar] [CrossRef]

- Touré, A.; Halidou, I.; Benzarti, Z.; Fouzri, A.; Bchetnia, A.; El Jani, B. Characterization of low Al content AlxGa1−xN epitaxial films grown by atmospheric-pressure MOVPE. Phys. Status Solidi A 2012, 209, 977–983. [Google Scholar] [CrossRef]

- Zollner, C.J.; Almogbel, A.; Yao, Y.; SaifAddin, B.K.; Wu, F.; Iza, M.; DenBaars, S.P.; Speck, J.S.; Nakamura, S. Reduced dislocation density and residual tension in AlN grown on SiC by metalorganic chemical vapor deposition. Appl. Phys. Lett. 2019, 115, 161101. [Google Scholar] [CrossRef]

- Bryan, I.; Bryan, Z.; Mita, S.; Rice, A.; Hussey, L.; Shelton, C.; Tweedie, J.; Maria, J.-P.; Collazo, R.; Sitar, Z. The role of surface kinetics on composition and quality of AlGaN. J. Cryst. Growth 2016, 451, 65. [Google Scholar] [CrossRef]

- Uesugi, K.; Shojiki, K.; Tezen, Y.; Hayashi, Y.; Miyake, H. Suppression of dislocation-induced spiral hillocks in MOVPE-grown AlGaN on face-to-face annealed sputter deposited AlN template. Appl. Phys. Lett. 2020, 116, 062101. [Google Scholar] [CrossRef]

- Wurm, C.; Collins, H.; Hatui, N.; Li, W.; Pasayat, S.; Hamwey, R.; Sun, K.; Sayed, I.; Khan, K.; Ahmadi, E.; et al. Demonstration of device-quality 60% relaxed In0.2Ga0.8N on porous GaN pseudo-substrates grown by PAMBE. J. Appl. Phys. 2022, 131, 015701. [Google Scholar] [CrossRef]

- Li, X.; Sundaram, S.; Disseix, P.; Le Gac, G.; Bouchoule, S.; Patriarche, G.; Réveret, F.; Leymarie, J.; El Gmili, Y.; Moudakir, T.; et al. AlGaN-based MQWs grown on a thick relaxed AlGaN buffer on AlN templates emitting at 285 nm. Opt. Mater. Express 2015, 5, 380–392. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).