Ligament-Size Effects on the Mechanical Behavior of Au/Cu Dual-Phase Spinodoid Nanocubes

Abstract

1. Introduction

2. Material and Methodology

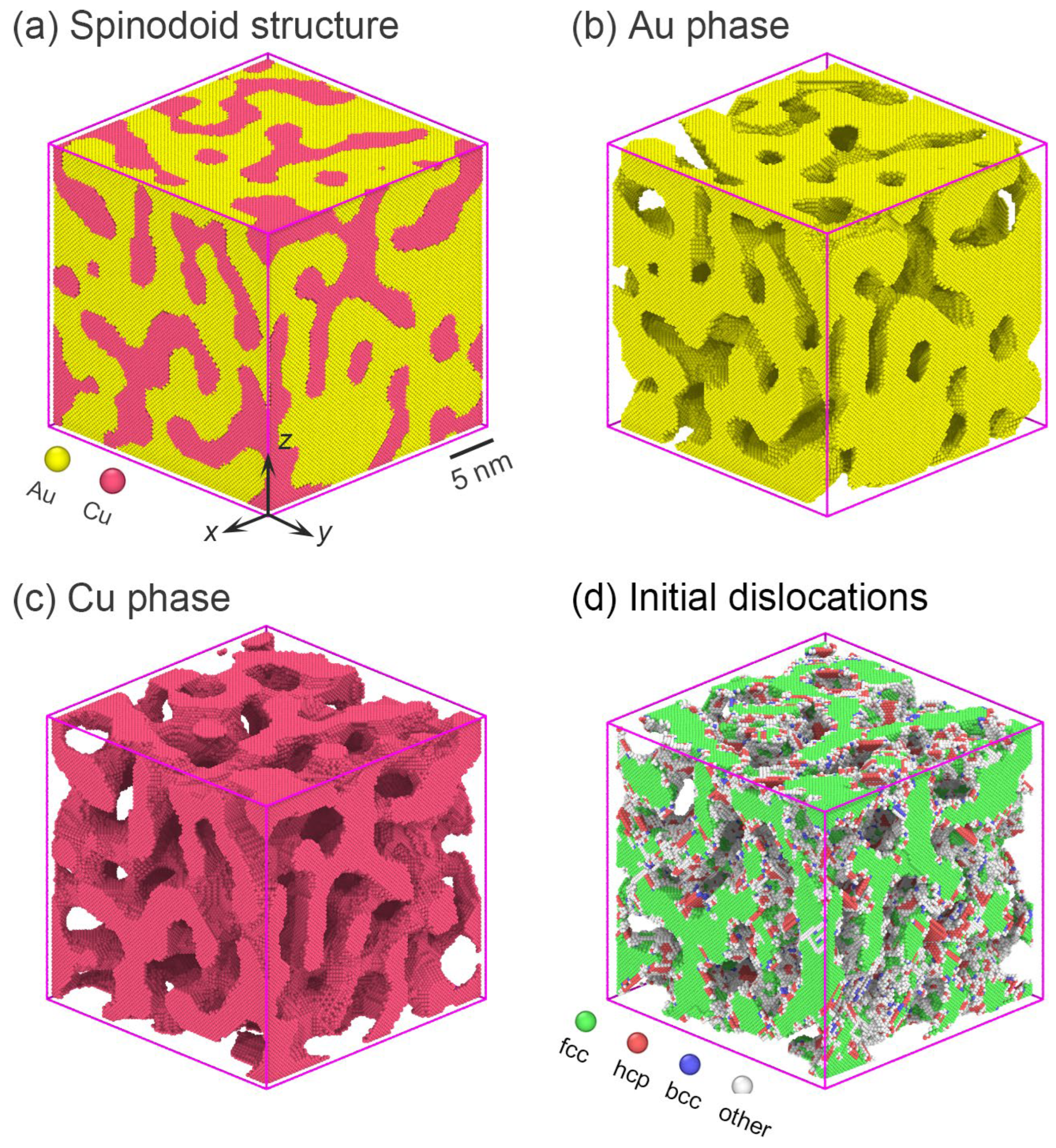

2.1. Construction of Spinodoid Structure

2.2. Materials and Setups in MD Simulations

3. Results and Discussions

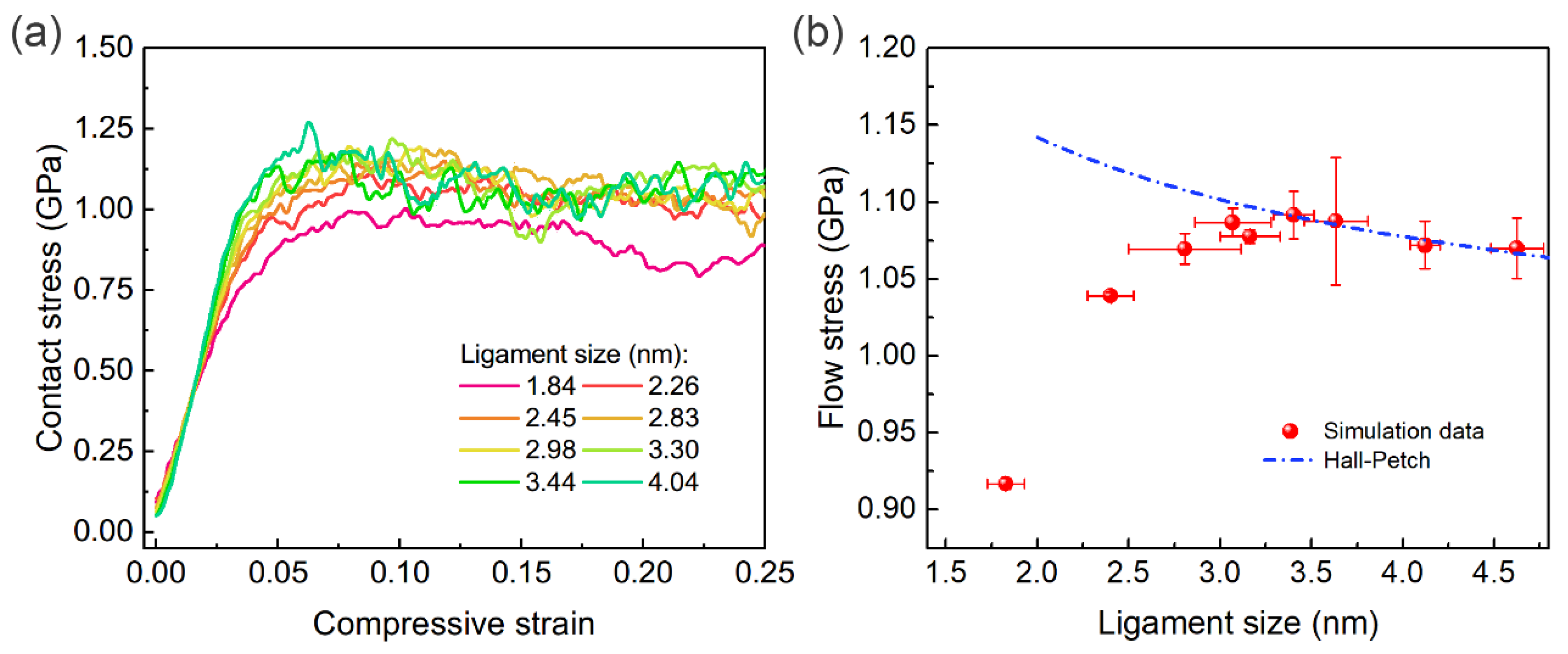

3.1. Contact Stress–Strain Curves

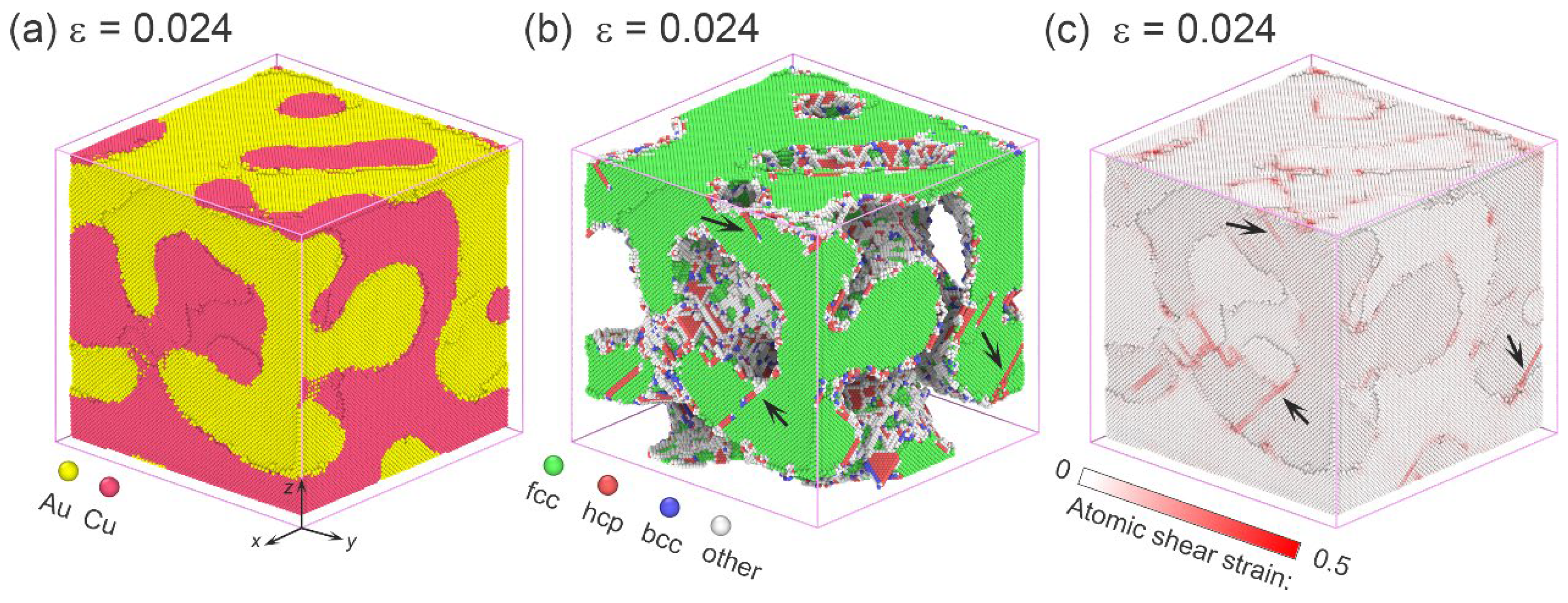

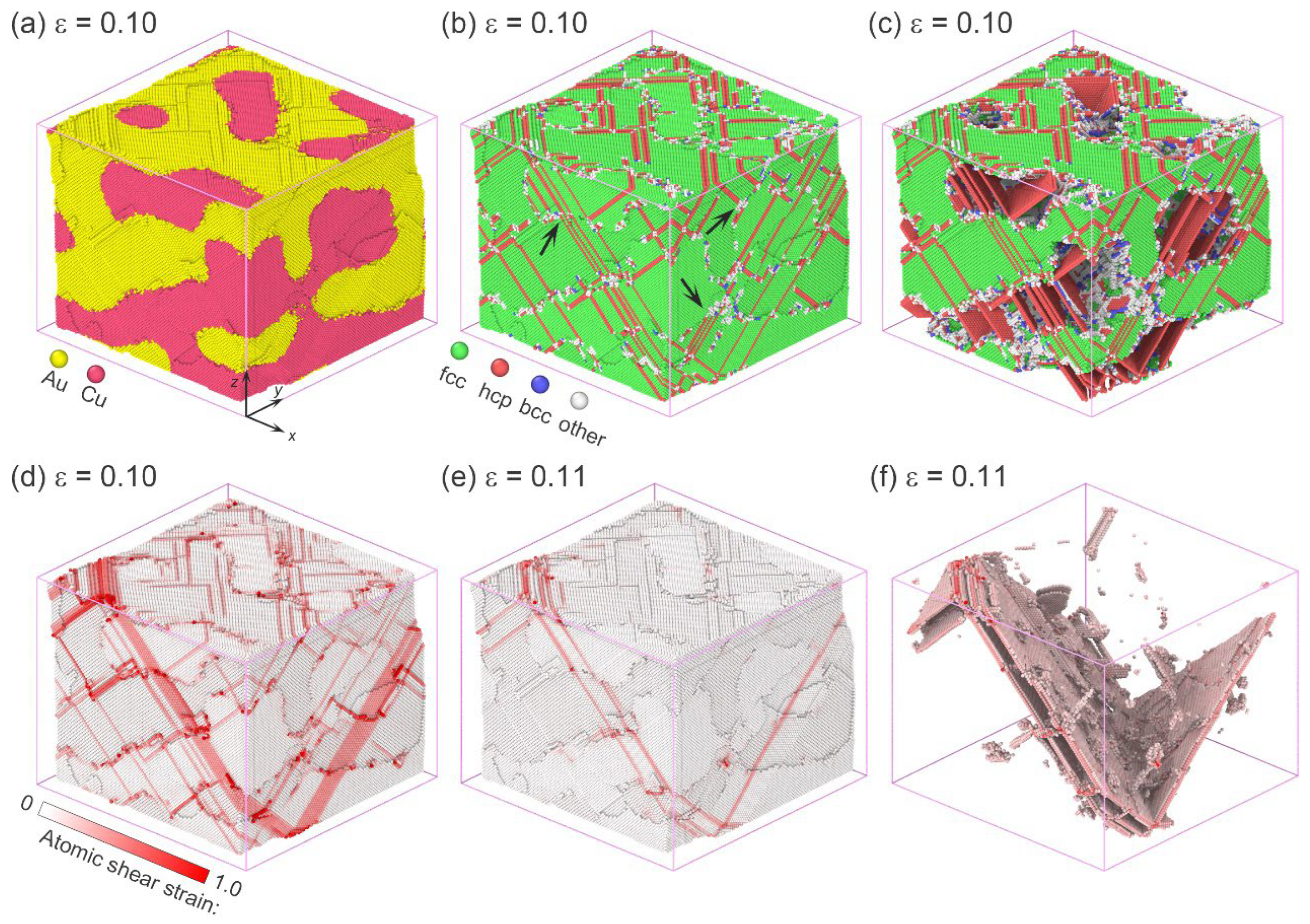

3.2. Atomic Deformation Mechanisms

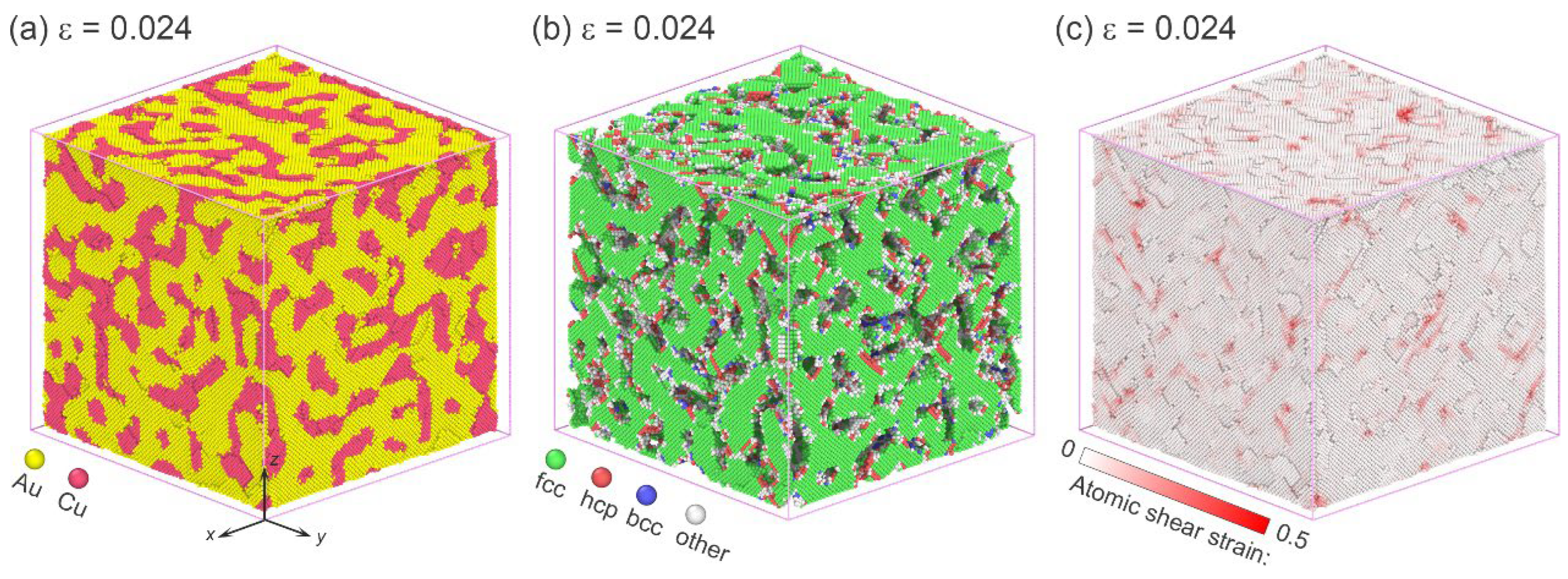

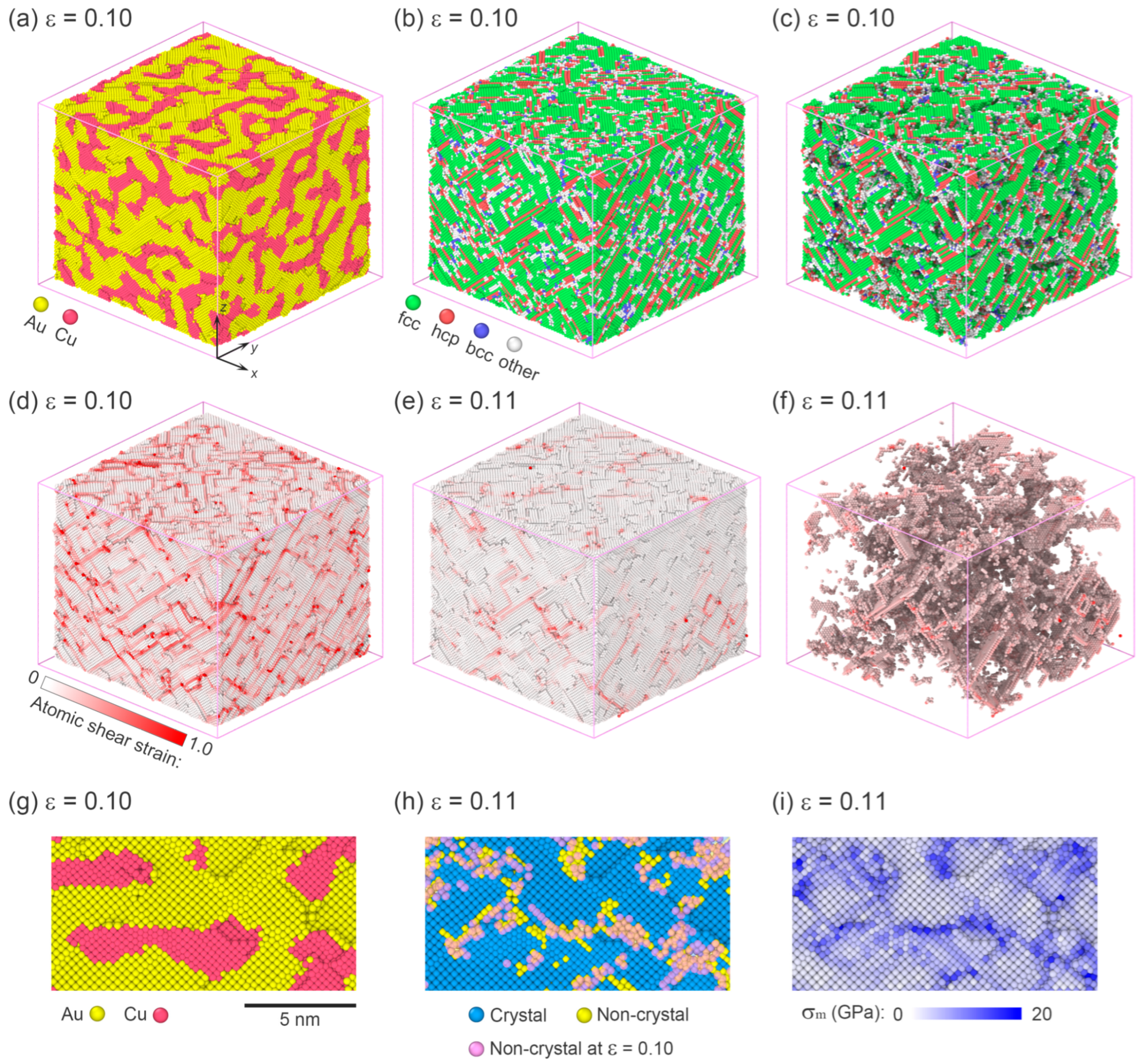

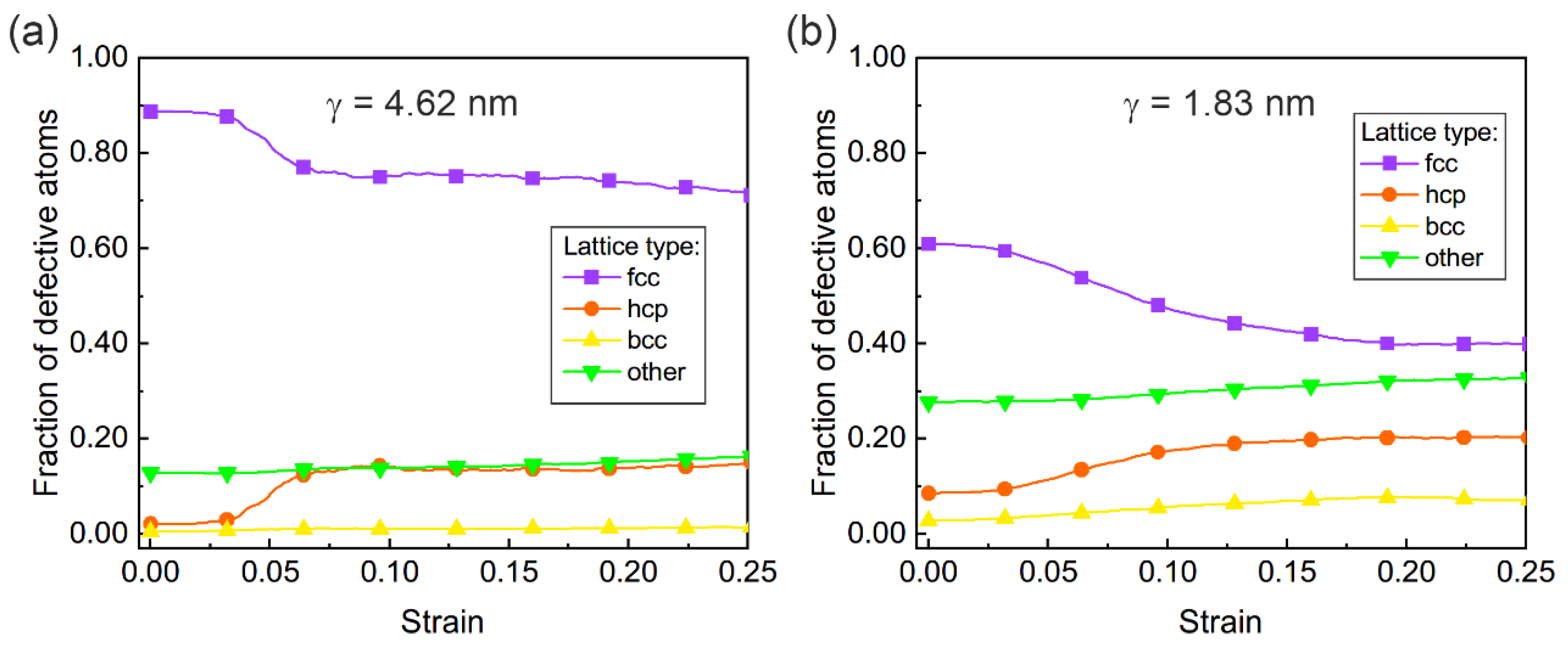

3.2.1. Deformation in Nanocube with a Larger Ligament Size (λ = 4.62 nm)

3.2.2. Deformation in Nanocube with a Smaller Ligament Size (λ = 1.83 nm)

3.3. Ligament-Size-Dependent Strengthening Effects

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Amodeo, J.; Pizzagalli, L. Modeling the mechanical properties of nanoparticles: A review. Comptes. Rendus. Phys. 2021, 22, 35–66. [Google Scholar] [CrossRef]

- Guo, D.; Xie, G.; Luo, J. Mechanical properties of nanoparticles: Basics and applications. J. Phys. D Appl. Phys. 2014, 47, 013001. [Google Scholar] [CrossRef]

- Kim, T.; Myung, S.; Kim, T.H.; Hong, S. Robust single-nanoparticle probe for contact-mode analysis and dip-pen nanolithography. Small 2008, 4, 1072–1075. [Google Scholar] [CrossRef] [PubMed]

- Yao, Y.; McDowell, M.T.; Ryu, I.; Wu, H.; Liu, N.; Hu, L.; Nix, W.D.; Cui, Y. Interconnected silicon hollow nanospheres for lithium-ion battery anodes with long cycle life. Nano Lett. 2011, 11, 2949. [Google Scholar] [CrossRef] [PubMed]

- Pizzagalli, L.; Godet, J.; Durinck, J.; Brochard, S.; Furstoss, J.; Valencia, F. Twinning and amorphization as plasticity mechanisms in ultra small tungsten nanoparticles. Comp. Mater. Sci. 2025, 258, 114077. [Google Scholar] [CrossRef]

- Armstrong, P.; Peukert, W. Size effects in the elastic deformation behavior of metallic nanoparticles. J. Nanopart. Res. 2012, 14, 1288. [Google Scholar] [CrossRef]

- Espinosa, I.M.P.; Jacobs, T.D.B.; Martini, A. Atomistic simulations of the elastic compression of platinum nanoparticles. Nanoscale Res. Lett. 2022, 17, 96. [Google Scholar] [CrossRef]

- Erbi, M.; Amara, H.; Gatti, R. Tuning elastic properties of metallic nanoparticles by shape controlling: From atomistic to continuous models. Small 2023, 19, 2302116. [Google Scholar] [CrossRef]

- Mordehai, D.; Lee, S.; Backes, B.; Srolovitz, D.J.; Nix, W.D.; Rabkin, E. Size effect in compression of single-crystal gold microparticles. Acta Mater. 2011, 59, 5202–5215. [Google Scholar] [CrossRef]

- Sharma, A.; Hickman, J.; Gazit, N.; Mishin, E.R.Y. Nickel nanoparticles set a new record of strength. Nat. Commun. 2018, 9, 4102. [Google Scholar] [CrossRef]

- Yang, L.; Bian, J.J.; Wang, G.F. Impact of atomic-scale surface morphology on the size-dependency yield stress of gold nanoparticles. J. Phys. D Appl. Phys. 2017, 50, 245302. [Google Scholar] [CrossRef]

- Bian, J.J.; Wang, G.F. Atomistic deformation mechanisms in copper nanoparticles. J. Comput. Theor. Nanosci. 2013, 10, 2299–2303. [Google Scholar] [CrossRef]

- Salah, S.B.H.; Gerard, C.; Pizzagalli, L. Influence of surface atomic structure on the mechanical response of aluminum nanospheres under compression. Comput. Mater. Sci. 2017, 129, 273–278. [Google Scholar] [CrossRef]

- Bian, J.; Zhang, H.; Niu, X.; Wang, G. Anisotropic deformation in the compressions of single crystalline copper nanoparticles. Crystals 2018, 8, 116. [Google Scholar] [CrossRef]

- Han, W.Z.; Huang, L.; Ogata, S.; Kimizuka, H.; Yang, Z.C.; Weinberger, C.; Li, Q.J.; Liu, B.Y.; Zhang, X.X.; Li, J.; et al. From ‘smaller is stronger’ to ‘size-independent strength plateau’: Towards measuring the ideal strength of iron. Adv. Mater. 2015, 27, 3385–3390. [Google Scholar] [CrossRef] [PubMed]

- Bian, J.J.; Yang, L.; Xin, X.R.; Wang, G.F. Orientation-dependent deformation mechanisms of bcc niobium nanoparticles. Philos. Mag. 2018, 98, 1848–1864. [Google Scholar] [CrossRef]

- Kositski, R.; Mordehai, D. Depinning-controlled plastic deformation during nanoindentation of BCC iron thin films and nanoparticles. Acta Mater. 2015, 90, 370–379. [Google Scholar] [CrossRef]

- Carlton, C.E.; Ferreira, P.J. In situ TEM nanoindentation of nanoparticles. Micron 2012, 43, 1134–1139. [Google Scholar] [CrossRef]

- Mordehai, D.; Rabkin, E. Pseudoelastic deformation during nanoscale adhesive contact formation. Phys. Rev. Lett. 2011, 107, 449. [Google Scholar] [CrossRef]

- Bian, J.; Yang, L.; Yuan, W.; Wang, G. Influence of hydrogenation on the mechanical properties of Pd nanoparticles. RSC Adv. 2021, 11, 3115. [Google Scholar] [CrossRef]

- Goryaeva, A.M.; Fusco, C.; Bugnet, M.; Amodeo, J. Influence of an amorphous surface layer on the mechanical properties of metallic nanoparticles under compression. Phys. Rev. Mater. 2019, 3, 033606. [Google Scholar] [CrossRef]

- Sharma, A.; Amodeo, J.; Gazit, N.; Qi, Y.; Thomas, Q.; Rabkin, E. When more is less: Plastic weakening of single crystalline Ag nanoparticles by the polycrystalline Au shell. ACS Nano 2021, 15, 14061–14070. [Google Scholar] [CrossRef] [PubMed]

- Bian, J.; Yuan, W.; Ni, N.; Shao, Z.; Wang, G. Tunable mechanical properties of high-entropy alloy nanoparticles with core-shell structure. Mater. Today Commun. 2025, 49, 113839. [Google Scholar] [CrossRef]

- Casillas, G.; Palomares-Baez, J.P.; Rodrıguez-Lopez, J.L.; Luo, J.; Ponce, A.; Esparza, R.; Velazquez-Salazar, J.J.; Hurtado-Macias, A.; Gonzalez-Hernandez, J.; Jose-Yacaman, M. In situ TEM study of mechanical behavior of twinned nanoparticles. Philos. Mag. 2012, 92, 4437–4453. [Google Scholar] [CrossRef]

- Valencia, F.J.; Ramirez, M.; Varas, A.; Rogan, J. Understanding the stability of hollow nanoparticles with polycrystalline shells. J. Phys. Chem. C 2020, 124, 10143–10149. [Google Scholar] [CrossRef]

- Valencia, F.J.; Pinto, B.; Kiwi, M.; Ruestes, C.J.; Bringa, E.M.; Rogan, J. Nanoindentation of polycrystalline Pd hollow nanoparticles: Grain size role. Compu. Mater. Sci. 2020, 179, 109642. [Google Scholar] [CrossRef]

- Kiani, M.T.; Wang, Y.; Bertin, N.; Cai, W.; Gu, X.W. Strengthening mechanism of a single precipitate in a metallic nanocube. Nano Lett. 2019, 19, 255–260. [Google Scholar] [CrossRef]

- Xin, T.; Zhao, Y.; Mahjoub, R.; Jiang, J.; Yadav, A.; Nomoto, K.; Niu, R.; Tang, S.; Ji, F.; Quadir, Z.; et al. Ultrahigh specific strength in a magnesium alloy strengthened by spinodal decomposition. Sci. Adv. 2021, 7, 3039. [Google Scholar] [CrossRef]

- Guan, H.; Xie, H.; Luo, Z.; Bao, W.; You, Z.; Jin, Z.; Jin, H. Ultrastrong spinodoid alloys enabled by electrochemical dealloying and refilling. Proc. Nat. Acad. Sci. USA 2023, 120, e221477312. [Google Scholar] [CrossRef]

- Cahn, J.W.; Hillard, J.E. Free Energy of a nonuniform system. I. interfacial free energy. J. Chem. Phys. 1958, 28, 258–267. [Google Scholar] [CrossRef]

- Zhou, X.; Johnson, R.; Wadley, H. Misfit-energy-increasing dislocations in vapor-deposited CoFe/NiFe multilayers. Phys. Rev. B 2004, 69, 144113. [Google Scholar] [CrossRef]

- Nosé, S.A. A unified formulation of the constant temperature molecular dynamics methods. J. Chem. Phys. 1984, 81, 511–519. [Google Scholar] [CrossRef]

- Hoover, W.G. Canonical dynamics: Equilibrium phase-space distributions. Phys. Rev. A 1985, 31, 1695–1697. [Google Scholar] [CrossRef]

- Bian, J.; Yuan, W.; Yang, L.; Ding, Y.; Yu, X.; Shao, Z.; Zhang, H.; Wang, G. Influence of planar defects on the mechanical behaviors of spherical metallic nanoparticles. Phys. Scr. 2025, 100, 015921. [Google Scholar] [CrossRef]

- Tsuzuki, H.; Branicio, P.S.; Rino, J.P. Structural characterization of deformed crystals by analysis of common atomic neighborhood. Comput. Phys. Commun. 2007, 177, 518. [Google Scholar] [CrossRef]

- Stukowski, A. Structure identification method for atomistic simulations of crystalline materials. Model. Simul. Mater. Sci. 2012, 20, 045021. [Google Scholar] [CrossRef]

- Plimpton, S. Fast parallel algorithms for short-range molecular dynamics. J. Comput. Phys. 1995, 117, 1–19. [Google Scholar] [CrossRef]

- Stukowski, A. Visualization and analysis of atomistic simulation data with OVITO-the open visualization tool Modelling Simul. Mater. Sci. Eng. 2010, 18, 015012. [Google Scholar]

- Abu-Oden, A.; Allaparti, T.; Asta, M. Structure and glide of Lomer and Lomer-Cottrell dislocations: Atomistic simulations for model concentrated alloy solid solutions. Phys. Rev. Mater. 2022, 6, 103603. [Google Scholar] [CrossRef]

- Pizzagalli, L.; Gatti, R.; Amodeo, J.; Godet, J.; Durinck, J.; Brochard, S. Relation between strength and local stresses in nanostructures as a function of their size and shape. J. Mech. Phys. Solids 2025, 205, 106306. [Google Scholar] [CrossRef]

- Amodeo, J.; Lizoul, K. Mechanical properties and dislocation nucleation in nanocrystals with blunt edges. Mater. Des. 2017, 135, 223–231. [Google Scholar] [CrossRef]

- Li, X.; Wei, Y.; Yang, W.; Gao, H. Competing grain-boundary- and dislocation-mediated mechanisms in plastic strain recovery in nanocrystalline aluminum. Proc. Nat. Acad. Sci. USA 2009, 106, 16108–16113. [Google Scholar] [CrossRef]

- Schiotz, J.; Jacobsen, K.W. A maximum in the strength of nanocrystalline copper. Science 2002, 301, 1357–1359. [Google Scholar] [CrossRef] [PubMed]

- Schiotz, J.; Di Tolla, F.D.; Jacobsen, K.W. Softening of nanocrystalline metals at very small grain sizes. Nature 1998, 391, 561–563. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Wei, Y.; Lu, L.; Lu, K.; Gao, H. Dislocation nucleation governed softening and maximum strength in nano-twinned metals. Nature 2010, 464, 877–880. [Google Scholar] [CrossRef] [PubMed]

- Chokshi, A.H.; Rosen, A.; Karch, J.; Gleiter, H. On the validity of the Hall-Petch relationship in nanocrystalline materials. Scr. Metall. 1989, 23, 1679–1684. [Google Scholar] [CrossRef]

- Naik, S.N.; Walley, S.M. The Hall–Petch and inverse Hall–Petch relations and the hardness of nanocrystalline metals. J. Mater. Sci. 2020, 55, 2661–2681. [Google Scholar] [CrossRef]

- Wang, Y.M.; Ma, E. Temperature and strain rate effects on the strength and ductility of nanostructured copper. Appl. Phys. Lett. 2003, 83, 3165. [Google Scholar] [CrossRef]

- Campbell, J.D.; Ferguson, W.G. The temperature and strain-rate dependence of the shear strength of mild steel. Philos. Mag. 1970, 21, 63–82. [Google Scholar] [CrossRef]

- Smirnov, B.I. Temperature dependence of the Peierls-Nabarro forces in body-centered cubic metals. Mater. Sci. 1967, 3, 366–367. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bian, J.; Yang, L. Ligament-Size Effects on the Mechanical Behavior of Au/Cu Dual-Phase Spinodoid Nanocubes. Crystals 2025, 15, 957. https://doi.org/10.3390/cryst15110957

Bian J, Yang L. Ligament-Size Effects on the Mechanical Behavior of Au/Cu Dual-Phase Spinodoid Nanocubes. Crystals. 2025; 15(11):957. https://doi.org/10.3390/cryst15110957

Chicago/Turabian StyleBian, Jianjun, and Liang Yang. 2025. "Ligament-Size Effects on the Mechanical Behavior of Au/Cu Dual-Phase Spinodoid Nanocubes" Crystals 15, no. 11: 957. https://doi.org/10.3390/cryst15110957

APA StyleBian, J., & Yang, L. (2025). Ligament-Size Effects on the Mechanical Behavior of Au/Cu Dual-Phase Spinodoid Nanocubes. Crystals, 15(11), 957. https://doi.org/10.3390/cryst15110957