Seed-Layer-Assisted Liquid-Phase Epitaxial Growth of YIG Films on Single-Crystal Yttrium Aluminum Garnet Substrates: Evidence for Enhancement in Strain-Induced Anisotropy

Abstract

1. Introduction

2. Experiment

2.1. Deposition and Characterization of Seed Layer of YIG on YAG

2.2. Liquid-Phase Epitaxial Growth of YIG Films and Characterization

3. Results

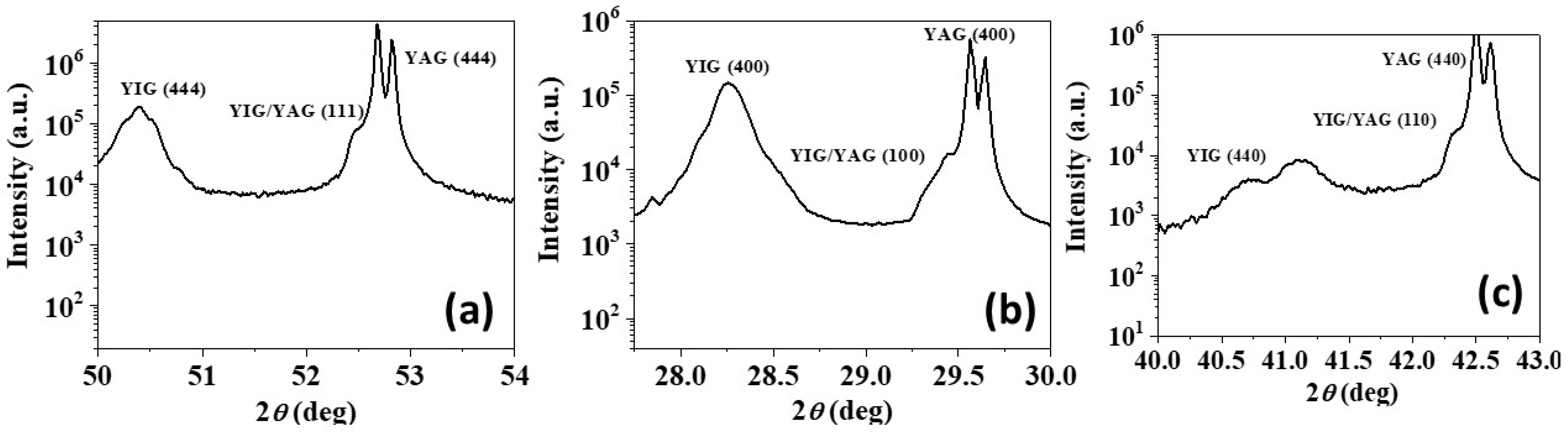

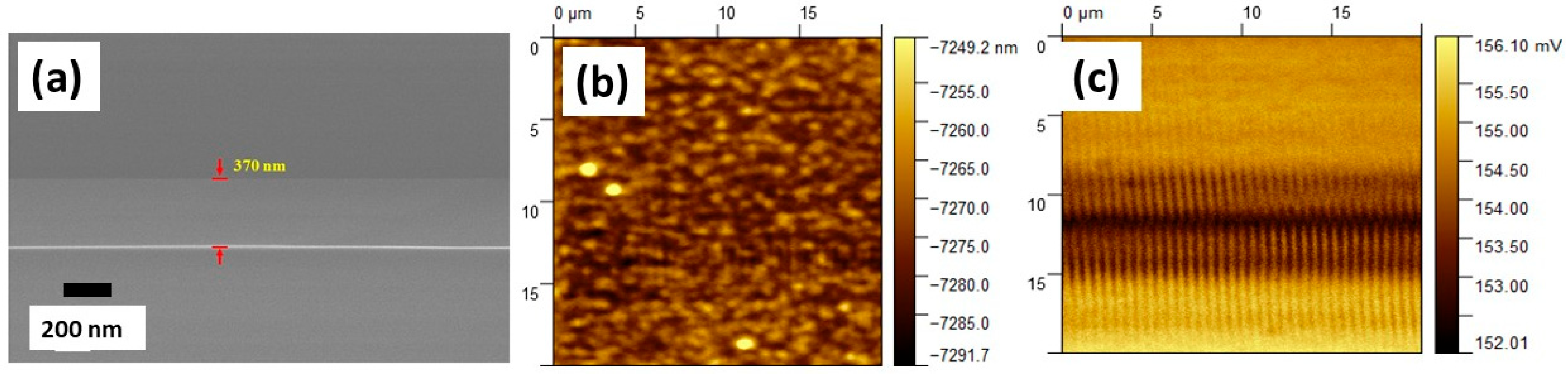

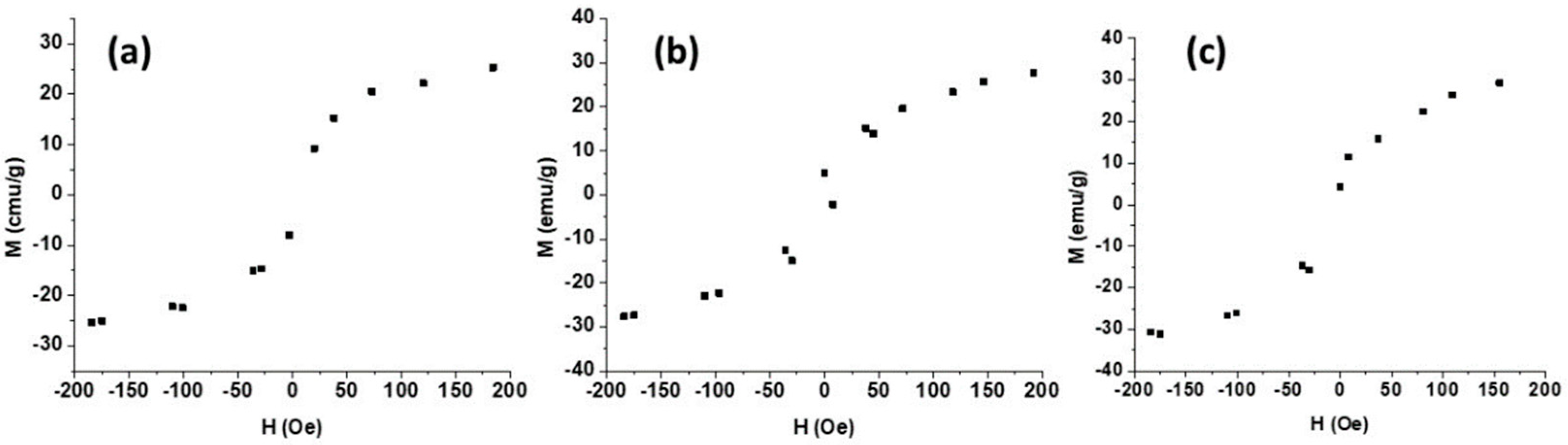

3.1. Seed Layers of YIG on YAG Substrates

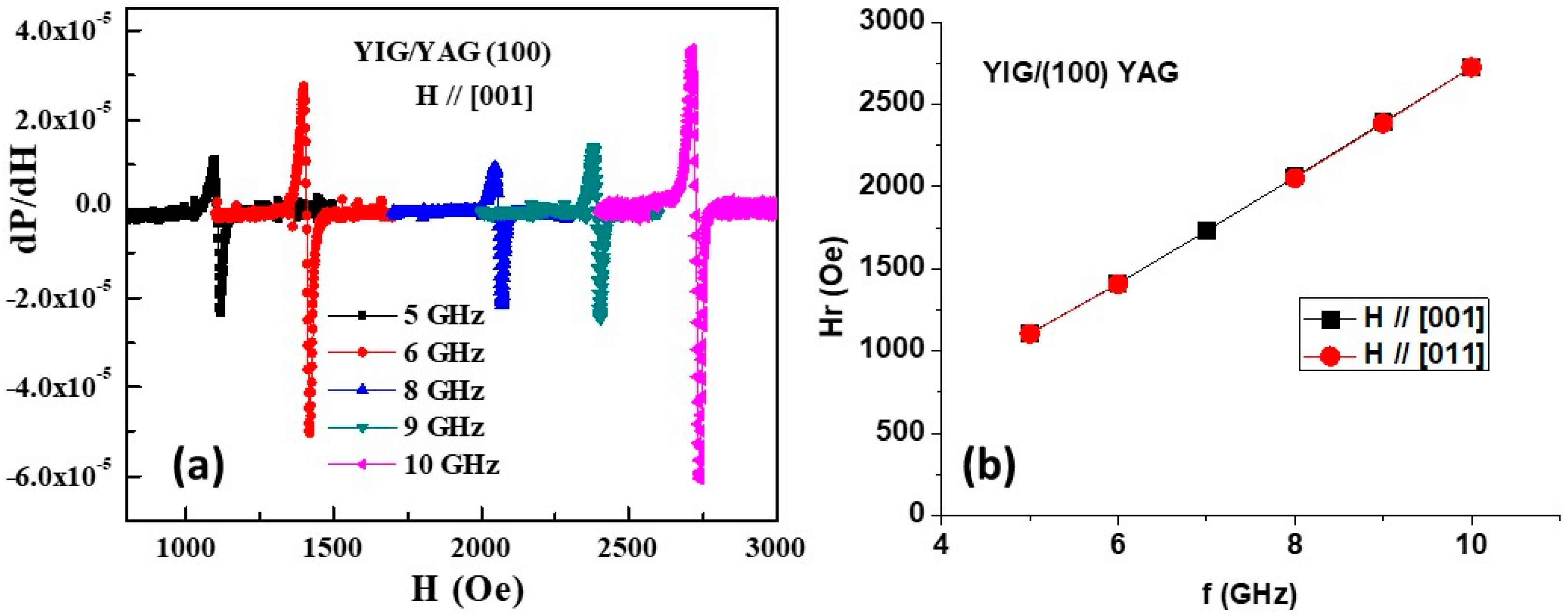

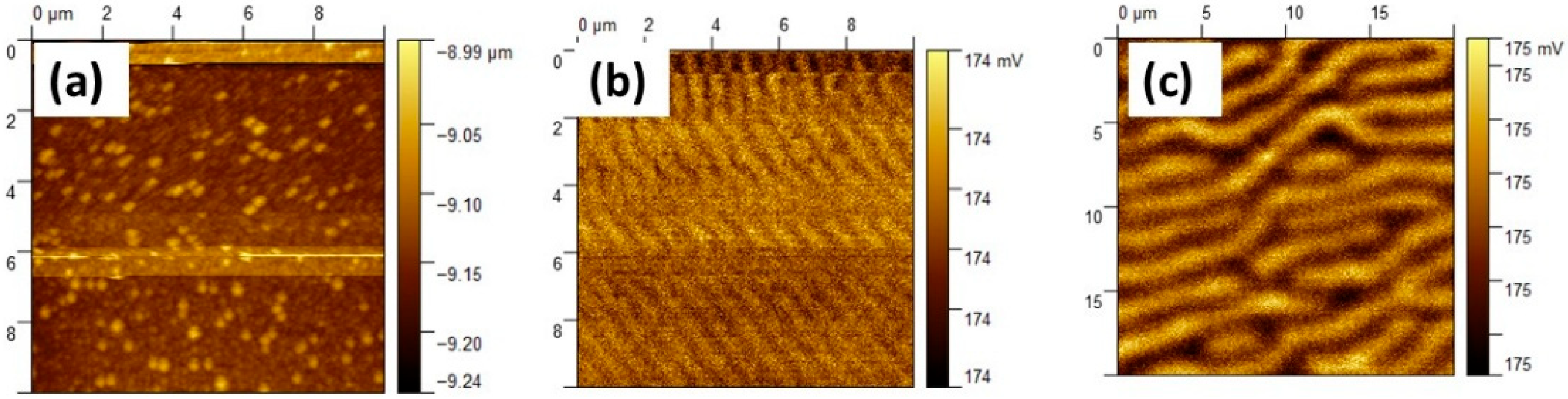

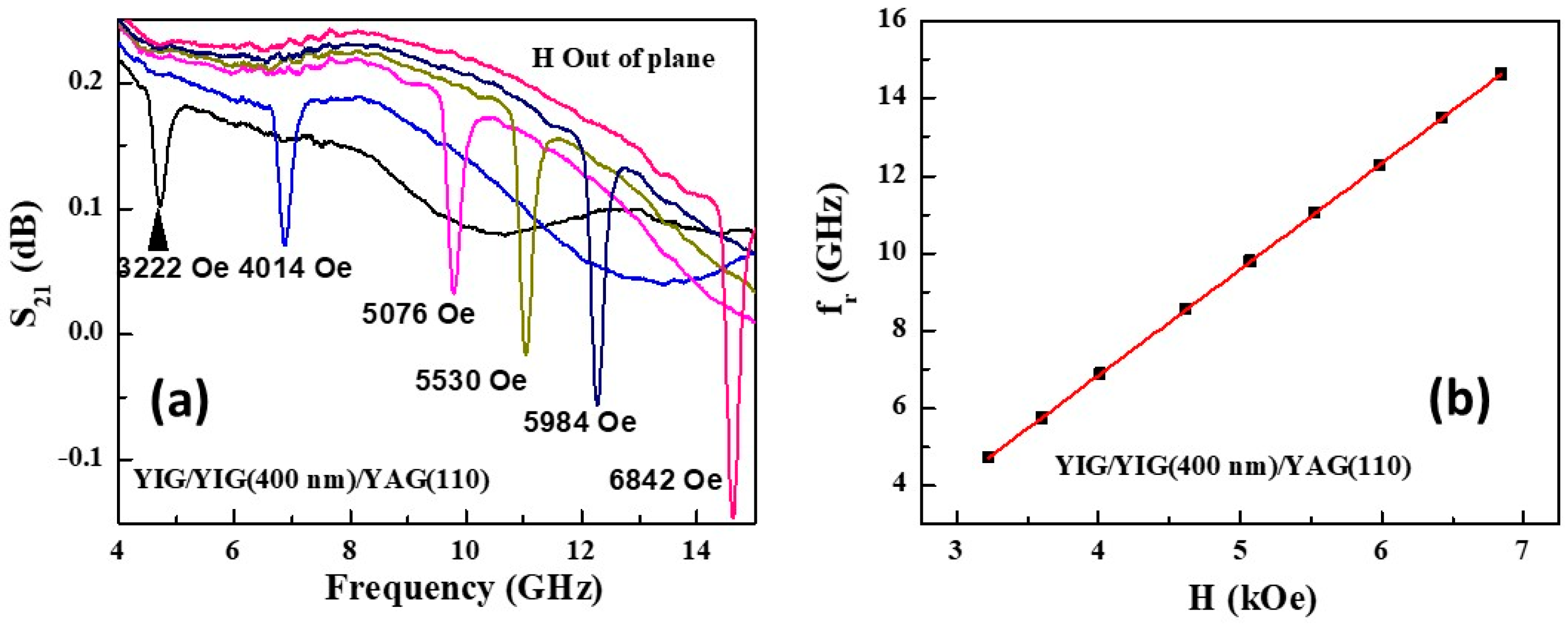

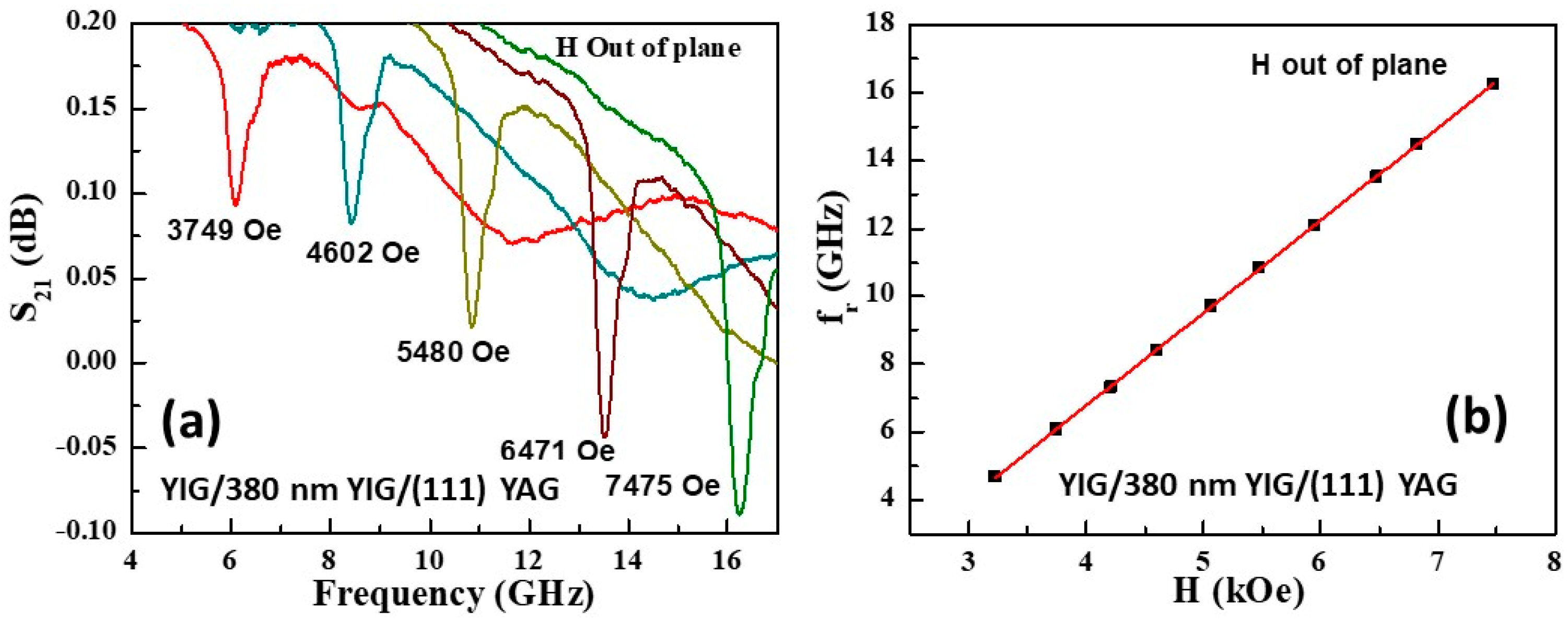

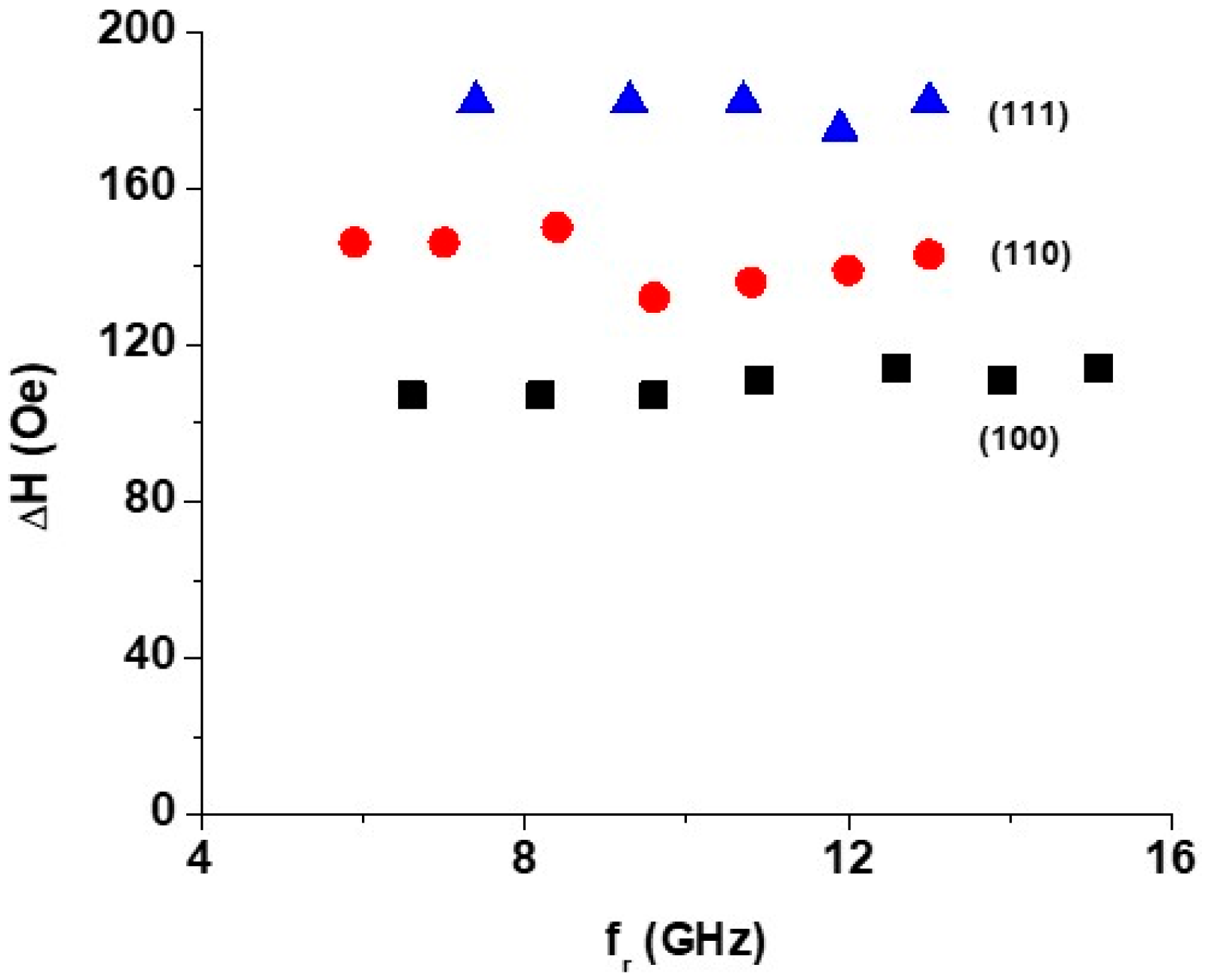

3.2. LPE YIG Films on YAG with Seed Layer of YIG

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Mallmann, E.J.J.; Sombra, A.S.B.; Goes, J.C.; Fechine, P.B.A. Yttrium iron garnet: Properties and applications review. Solid State Phenom. 2013, 202, 65–96. [Google Scholar]

- Arsad, A.Z.; Zuhdi, A.W.M.; Ibrahim, N.B.Y.; Hannan, M.A. Recent advances in yttrium iron garnet films: Methodologies, characterization, properties, applications, and bibliometric analysis for future research directions. Appl. Sci. 2023, 13, 1218. [Google Scholar] [CrossRef]

- Schmidt, G.; Hauser, C.; Trempler, P.; Paleschke, M.; Papaioannou, E.T. Ultra thin films of yttrium iron garnet with very low damping: A review. Phys. Status Solidi (b) 2020, 257, 1900644. [Google Scholar] [CrossRef]

- Wigen, P.E. Microwave properties of magnetic garnet thin films. Thin Solid Film. 1984, 114, 135–186. [Google Scholar] [CrossRef]

- Serga, A.A.; Chumak, A.V.; Hillebrands, B. YIG magnonics. J. Phys. D Appl. Phys. 2010, 43, 264002. [Google Scholar] [CrossRef]

- Sheng, L.; Chen, J.; Wang, H.; Yu, H. Magnonics based on thin-film iron garnets. J. Phys. Soc. Jpn. 2021, 90, 081005. [Google Scholar] [CrossRef]

- Zeyfang, R. Stresses in Epitaxially Grown Single-Crystal Films: YIG on YAG. J. Appl. Phys. 1970, 41, 3718–3721. [Google Scholar] [CrossRef]

- Aida, H.; Watanuki, R.; Ito, A. High-speed epitaxial growth of Y3Fe5O12 thick film with high magnetization on (4 2 0) Y3Al5O12 substrate using metal-organic chemical vapor deposition. Mater. Lett. 2020, 276, 128228. [Google Scholar] [CrossRef]

- Cooper, J.F.K.; Kinane, C.J.; Langridge, S.; Ali, M.; Hickey, B.J.; Niizeki, T.; Uchida, K.; Saitoh, E.; Ambaye, H.; Glavic, A. Unexpected structural and magnetic depth dependence of YIG thin films. Phys. Rev. B 2017, 96, 104404. [Google Scholar] [CrossRef]

- Yoshihara, Y.; Ishiyama, K.; Watanabe, T.; Lim, P.B.; Inoue, M.; Ross, C.A.; Goto, T. Growth of magnetooptical cerium-substituted yttrium iron garnet on yttrium aluminum garnet using ion beam sputtering. Appl. Phys. Lett. 2023, 123, 112404. [Google Scholar] [CrossRef]

- Sposito, A.; May-Smith, T.C.; Stenning, G.B.G.; De Groot, P.A.J.; Eason, R.W. Pulsed laser deposition of high-quality μm-thick YIG films on YAG. Opt. Mater. Express 2013, 3, 624–632. [Google Scholar] [CrossRef]

- Sailler, S.; Skobjin, G.; Schlörb, H.; Boehm, B.; Hellwig, O.; Thomas, A.; Goennenwein, S.T.; Lammel, M. Crystallization dynamics of amorphous yttrium iron garnet thin films. Phys. Rev. Mater. 2024, 8, 043402. [Google Scholar] [CrossRef]

- Sato, Y.; Taira, T.; Takemasa, T. Comprehensive thermal properties of Y3Al5O12 from 160 K to 500 K. Opt. Express 2025, 33, 9479–9488. [Google Scholar] [CrossRef] [PubMed]

- Geller, S.; Espinosa, G.P.; Crandall, P.B. Thermal expansion of yttrium and gadolinium iron, gallium and aluminum garnets. J. Appl. Crystallogr. 1969, 2, 86. [Google Scholar] [CrossRef]

- Vértesy, G.; Tomáš, I.; Kadlecová, J.; Metlov, K. Temperature changes of coercivity in garnets. J. Phys. IV 1998, 8, Pr2-303. [Google Scholar] [CrossRef]

- Liu, S.Y.; Lin, Z.Y.; Chang, Y.R.; Liao, Y.T.; Wu, P.H.; Huang, S.Y.; Lin, W.C.; Lo, F.Y. Strain-induced magnetic anisotropy of REIG thin films grown on YAG (111) substrates by pulsed laser deposition. J. Alloys Compd. 2022, 922, 166217. [Google Scholar] [CrossRef]

- Krysztofik, A.; Özoğlu, S.; McMichael, R.D.; Coy, E. Effect of strain-induced anisotropy on magnetization dynamics in Y3Fe5O12 films recrystallized on a lattice-mismatched substrate. Sci. Rep. 2021, 11, 14011. [Google Scholar] [CrossRef]

- Zaki, A.M.; Blythe, H.J.; Heald, S.M.; Fox, A.M.; Gehring, G.A. Growth of high quality yttrium iron garnet films using standard pulsed laser deposition technique. J. Magn. Magn. Mater. 2018, 453, 254–257. [Google Scholar] [CrossRef]

- Liu, Y.; Zhou, P.; Bidthanapally, R.; Zhang, J.; Zhang, W.; Page, M.R.; Zhang, T.; Srinivasan, G. Strain Control of Magnetic Anisotropy in Yttrium Iron Garnet Films in a Composite Structure with Yttrium Aluminum Garnet Substrate. J. Compos. Sci. 2022, 6, 203. [Google Scholar] [CrossRef]

- Krupka, J.; Salski, B.; Kopyt, P.; Gwarek, W. Electrodynamic study of YIG filters and resonators. Sci. Rep. 2016, 6, 34739. [Google Scholar] [CrossRef] [PubMed]

- Costa, J.D.; Figeys, B.; Sun, X.; Van Hoovels, N.; Tilmans, H.A.; Ciubotaru, F.; Adelmann, C. Compact tunable YIG-based RF resonators. Appl. Phys. Lett. 2021, 118, 162406. [Google Scholar] [CrossRef]

- Glass, H.L. Growth of thick single-crystal layers of yttrium iron garnet by liquid phase epitaxy. J. Cryst. Growth 1976, 33, 183–184. [Google Scholar] [CrossRef]

- Glass, H.L.; Elliott, M.T. Accommodation of Pb in yttrium iron garnet films grown by liquid phase epitaxy. J. Cryst. Growth 1974, 27, 253–260. [Google Scholar] [CrossRef]

- Adam, J.D.; Owens, J.M.; Collins, J.H. Ferromagnetic-resonance linewidth of thick yttrium–iron-garnet films grown by liquid-phase epitaxy. Electron. Lett. 1973, 9, 325. [Google Scholar] [CrossRef]

- Aichele, T.; Lorenz, A.; Hergt, R.; Görnert, P. Garnet layers prepared by liquid phase epitaxy for microwave and magneto-optical applications–a review. Cryst. Res. Technol. J. Exp. Ind. Crystallogr. 2003, 38, 575–587. [Google Scholar] [CrossRef]

- Rao, Y.H.; Zhang, H.W.; Yang, Q.H.; Zhang, D.N.; Jin, L.C.; Ma, B.; Wu, Y.J. Liquid phase epitaxy magnetic garnet films and their applications. Chin. Phys. B 2018, 27, 086701. [Google Scholar] [CrossRef]

- Dubs, C.; Surzhenko, O.; Thomas, R.; Osten, J.; Schneider, T.; Lenz, K.; Grenzer, J.; Hübner, R.; Wendler, E. Low damping and microstructural perfection of sub-40nm-thin yttrium iron garnet films grown by liquid phase epitaxy. Phys. Rev. Mater. 2020, 4, 024416. [Google Scholar] [CrossRef]

- Blank, S.L.; Nielsen, J.W. The growth of magnetic garnets by liquid phase epitaxy. J. Cryst. Growth 1972, 17, 302–311. [Google Scholar] [CrossRef]

- Nielsen, J.W.; Dearborn, E.F. The growth of single crystals of magnetic garnets. J. Phys. Chem. Solids 1958, 5, 202–207. [Google Scholar] [CrossRef]

- Özgür, Ü.; Alivov, Y.; Morkoç, H. Microwave ferrites, part 1: Fundamental properties. J. Mater. Sci. Mater. Electron. 2009, 20, 789–834. [Google Scholar] [CrossRef]

- Görnert, P.; Hergt, R.; Sinn, E.; Wendt, M.; Keszei, B.; Vandlik, J. Growth kinetics and some properties of thick lpe yig layers. J. Cryst. Growth 1988, 87, 331–337. [Google Scholar] [CrossRef]

- Shone, M. The technology of YIG film growth. Circuits Syst. Signal Process. 1985, 4, 89–103. [Google Scholar] [CrossRef]

- Beaulieu, N.; Kervarec, N.; Thiery, N.; Klein, O.; Naletov, V.; Hurdequint, H.; De Loubens, G.; Youssef, J.B.; Vukadinovic, N. Temperature dependence of magnetic properties of a ultrathin yttrium-iron garnet film grown by liquid phase epitaxy: Effect of a Pt overlayer. IEEE Magn. Lett. 2018, 9, 3706005. [Google Scholar] [CrossRef]

- Syvorotka, I.I.; Sugak, D.; Yakhnevych, U.; Buryy, O.; Włodarczyk, D.; Pieniążek, A.; Zhydachevskyy, Y.; Levintant-Zayonts, N.; Savytskyy, H.; Bonchyk, O.; et al. Investigation of the interface of Y3Fe5O12/Gd3Ga5O12 structure obtained by the liquid phase epitaxy. Cryst. Res. Technol. 2022, 57, 2100180. [Google Scholar] [CrossRef]

- Von Aulock, W.H. Handbook of Microwave Ferrite Materials; Academic Press: London, UK, 1965. [Google Scholar]

- Chen, L.F.; Ong, C.K.; Neo, C.P.; Varadan, V.V.; Varadan, V.K. Microwave Electronics: Measurement and Materials Characterization; John Wiley & Sons: Hoboken, NJ, USA, 2004. [Google Scholar]

- Anane, A.; Bernard, R.; Ben Youssef, J.; Hahn, C.; Molpeceres, A.H.; Carrétéro, C.; Jacquet, E.; Deranlot, C.; Bortolotti, P.; Lebourgeois, R.; et al. Inverse spin Hall effect in nanometer-thick yttrium iron garnet/Pt system. Appl. Phys. Lett. 2013, 103, 082408. [Google Scholar]

- Gallagher, J.C.; Yang, A.S.; Brangham, J.T.; Esser, B.D.; White, S.P.; Page, M.R.; Meng, K.Y.; Yu, S.; Adur, R.; Ruane, W.; et al. Exceptionally high magnetization of stoichiometric Y3Fe5O12 epitaxial films grown on Gd3Ga5O12. Appl. Phys. Lett. 2016, 109, 072401. [Google Scholar] [CrossRef]

| Flux Component | Mole % | Amount in g |

|---|---|---|

| PbO | 84.63 | 377.18 |

| B2O3 | 5.39 | 7.50 |

| Fe2O3 | 9.51 | 30.38 |

| Y2O3 | 0.48 | 2.16 |

| Substrate Orientation | Film Thickness (nm) | 4πMs (kG) | 4πMeff (kG) | γ (GHz/kOe) | Ha (kOe) | ΔH (Oe) and H Direction |

|---|---|---|---|---|---|---|

| (100) | 370 | 1.95 | 1.52 | 2.94 | −0.43 | 20–25 [001] 32–36 [011] |

| (110) | 400 | 1.84 | 1.57 | 2.93 | −0.27 | 83–86 [001] 82–86 [1, −1, 0] 74–82 [1, −1, 1] |

| (111) | 380 | 1.87 | 1.68 | 2.89 | −0.19 | 55–61 |

| Substrate Orientation | LPE-Film Thickness (μm) | 4πMs (kG) | 4πMeff (kG) | γ (GHz/kOe) | Ha (kOe) | ΔH (Oe) |

|---|---|---|---|---|---|---|

| (100) | 8.4 | 1.92 | 1.65 | 2.74 | −0.27 | 125–140 |

| (110) | 4.0 | 2.27 | 1.50 | 2.74 | −0.77 | 85–90 |

| (111) | 4.1 | 2.31 | 1.51 | 2.73 | −0.80 | 140–160 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kshirsagar, C.; Bidthanapally, R.; Liu, Y.; Zhou, P.; Mukund, S.; Bidthanapally, A.; Qu, H.; Xavier, D.; Samantaray, S.; Subramanian, V.; et al. Seed-Layer-Assisted Liquid-Phase Epitaxial Growth of YIG Films on Single-Crystal Yttrium Aluminum Garnet Substrates: Evidence for Enhancement in Strain-Induced Anisotropy. Crystals 2025, 15, 953. https://doi.org/10.3390/cryst15110953

Kshirsagar C, Bidthanapally R, Liu Y, Zhou P, Mukund S, Bidthanapally A, Qu H, Xavier D, Samantaray S, Subramanian V, et al. Seed-Layer-Assisted Liquid-Phase Epitaxial Growth of YIG Films on Single-Crystal Yttrium Aluminum Garnet Substrates: Evidence for Enhancement in Strain-Induced Anisotropy. Crystals. 2025; 15(11):953. https://doi.org/10.3390/cryst15110953

Chicago/Turabian StyleKshirsagar, Chaitrali, Rao Bidthanapally, Ying Liu, Peng Zhou, Sahana Mukund, Aruna Bidthanapally, Hongwei Qu, Deepa Xavier, Subhabrat Samantaray, Venkatachalam Subramanian, and et al. 2025. "Seed-Layer-Assisted Liquid-Phase Epitaxial Growth of YIG Films on Single-Crystal Yttrium Aluminum Garnet Substrates: Evidence for Enhancement in Strain-Induced Anisotropy" Crystals 15, no. 11: 953. https://doi.org/10.3390/cryst15110953

APA StyleKshirsagar, C., Bidthanapally, R., Liu, Y., Zhou, P., Mukund, S., Bidthanapally, A., Qu, H., Xavier, D., Samantaray, S., Subramanian, V., Page, M. R., & Srinivasan, G. (2025). Seed-Layer-Assisted Liquid-Phase Epitaxial Growth of YIG Films on Single-Crystal Yttrium Aluminum Garnet Substrates: Evidence for Enhancement in Strain-Induced Anisotropy. Crystals, 15(11), 953. https://doi.org/10.3390/cryst15110953