What Is the Limit of Quantification for the Minor Phase in Time-of-Flight Neutron Diffraction? A Case Study on Fe and Ni Powder Mixtures at VULCAN

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample Preparation

2.2. Powder Neutron Diffraction Measurement

2.3. Rietveld Refinement of Neutron Diffraction

3. Results and Discussion

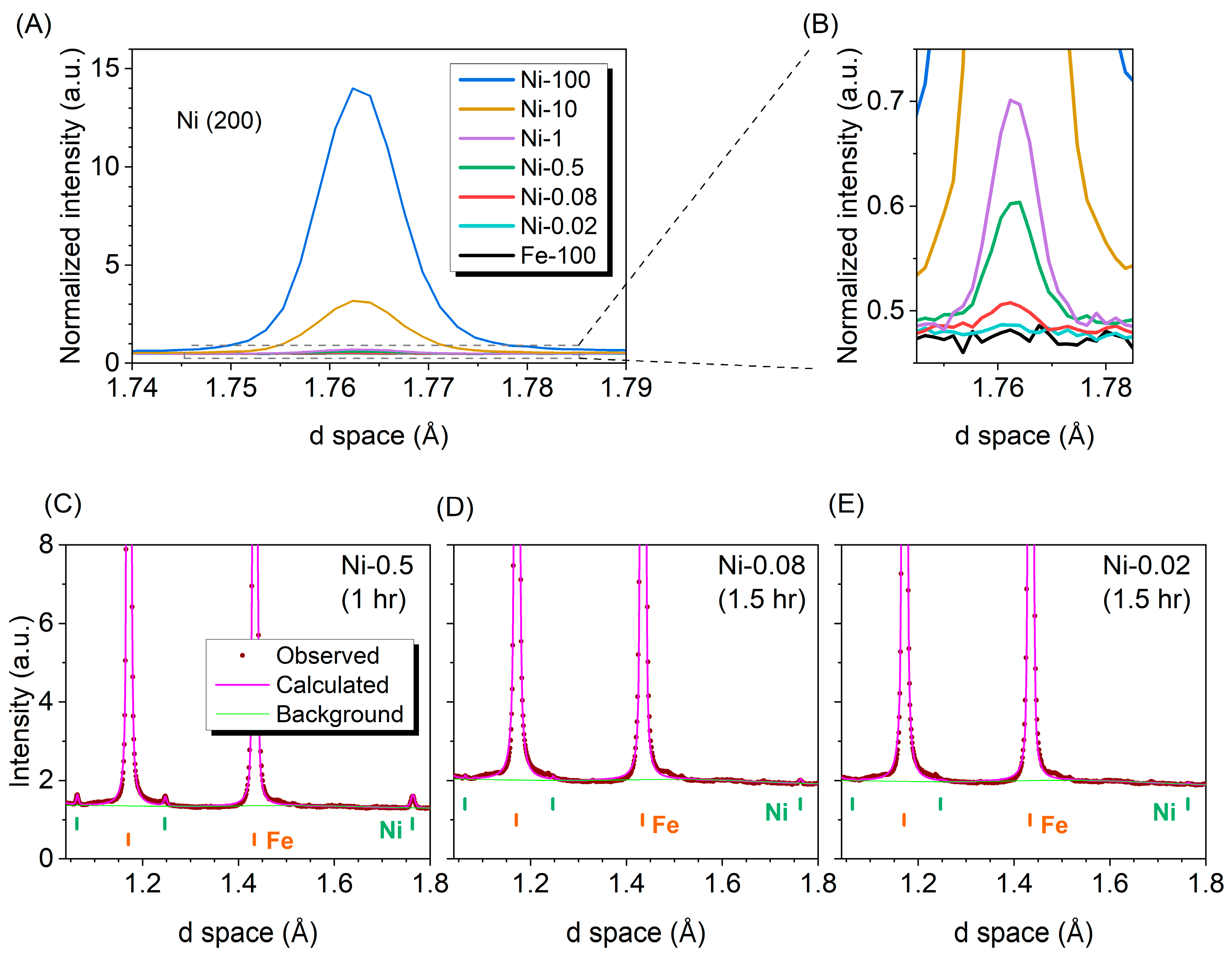

3.1. Diffraction Signal of Minor Ni Phase

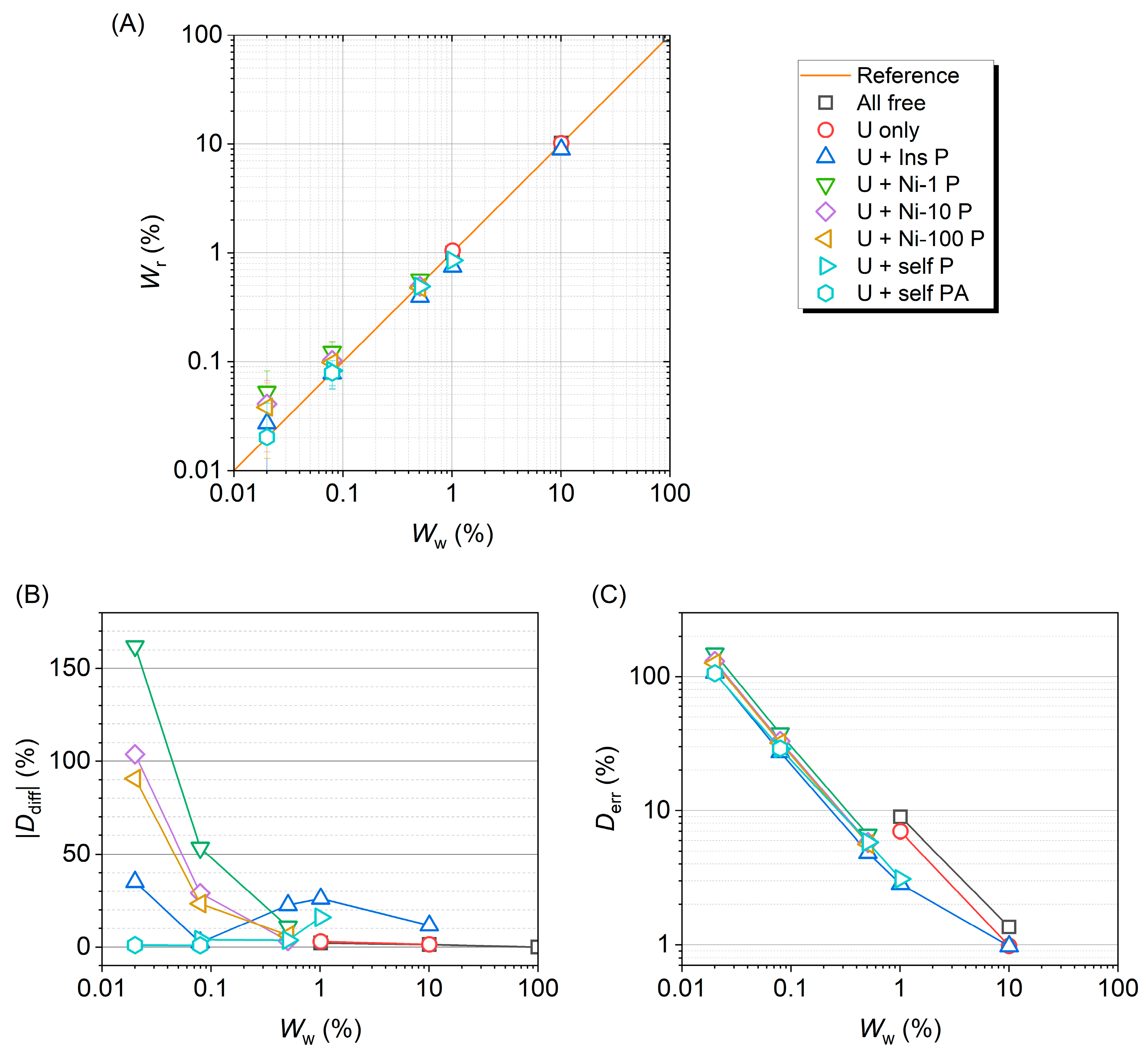

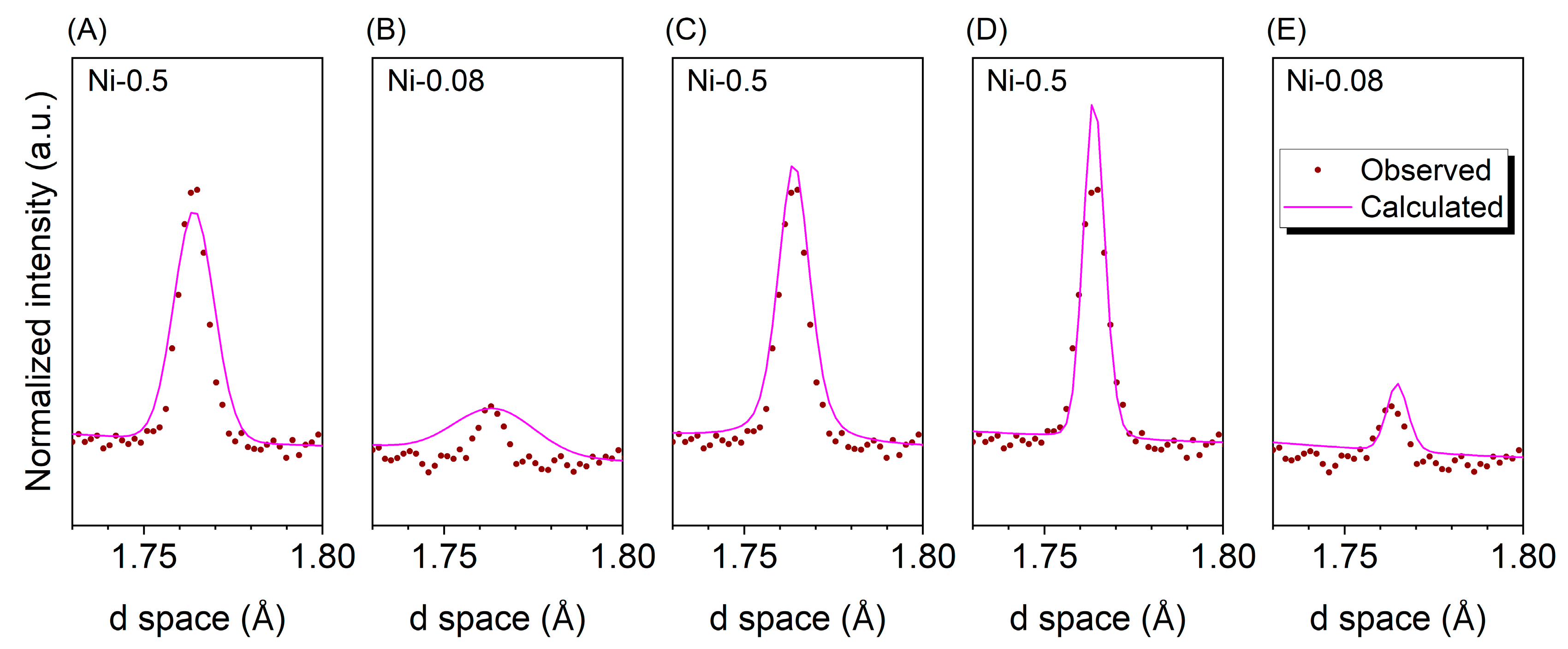

3.2. Phase Quantification with Refinement Parameter Controls

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| TOF | time-of-flight |

| SNS | Spallation Neutron Source |

Appendix A

| Element | Coh b | Inc b | Coh xs | Inc xs | Scatt xs | Abs xs |

|---|---|---|---|---|---|---|

| Fe | 9.45 | --- | 11.22 | 0.4 | 11.62 | 2.56 |

| Ni | 10.3 | --- | 13.3 | 5.2 | 18.5 | 4.49 |

| Cr | 3.635 | --- | 1.66 | 1.83 | 2.54 | 3.05 |

| Ti | −3.438 | --- | 1.485 | 2.87 | 4.35 | 6.09 |

| Sample | Ww (%) | Control | Wr (%) | wRp/Rp/χ2/Variables | Ddiff (%) |

|---|---|---|---|---|---|

| Fe-100 | 0 | All free | 0 | 0.0508/0.0407/20.73/19 | |

| Ni-100 | 100 | All free | 100 | 0.0320/0.0229/7.758/19 | |

| Ni-10 | 10.057 | All free | 10.19 (14) | 0.0401/0.0331/13.82/25 | +1.29 |

| U only | 10.20 (10) | 0.0401/0.0331/13.81/24 | +1.39 | ||

| U + Ins P | 8.89 (9) | 0.0541/0.0407/25.11/21 | −11.63 | ||

| Ni-1 | 1.0143 | All free | 0.993 (91) | 0.0430/0.0394/29.43/25 | −2.09 |

| U only | 1.044 (71) | 0.0430/0.0395/29.43/24 | +2.96 | ||

| U + Ins P | 0.750 (29) | 0.0437/0.0398/30.28/21 | −26.07 | ||

| U + Self P | 0.906 (33) | 0.0432/0.0394/29.58/21 | −16.00 | ||

| Ni-0.5 | 0.5098 | U + Ins P1 | 0.497 (35) | 0.0400/0.0389/34.32/23 | −2.47 |

| U + Ins P | 0.395 (25) | 0.0403/0.0392/34.71/21 | −22.55 | ||

| U + Ni-1 P | 0.565 (33) | 0.0400/0.0389/34.19/21 | +10.87 | ||

| U + Ni-10 P | 0.493 (30) | 0.0401/0.0390/34.32/21 | −3.32 | ||

| U + Ni-100 P | 0.478 (29) | 0.0401/0.0390/34.36/21 | −6.30 | ||

| U + Self P | 0.491 (30) | 0.0402/0.0391/34.54/21 | −3.71 | ||

| Ni-0.08 | 0.0798 | U + Ins P2 | 0.194 (53) | 0.0396/0.0397/38.14/22 | +142.64 |

| U + Ins P | 0.078 (22) | 0.0397/0.0396/38.28/21 | −2.43 | ||

| U + Ins PA | 0.076 (22) | 0.0397/0.0396/38.28/20 | −5.26 | ||

| U + Ni-1 P | 0.122 (30) | 0.0397/0.0395/38.18/21 | +53.37 | ||

| U + Ni-1 PA | 0.119 (30) | 0.0397/0.0395/38.19/20 | +48.80 | ||

| U + Ni-10 P | 0.103 (26) | 0.0397/0.0396/38.23/21 | +29.00 | ||

| U + Ni-10 PA | 0.100 (26) | 0.0397/0.0396/38.23/20 | +25.12 | ||

| U + Ni-100 P | 0.098 (26) | 0.0397/0.0396/38.24/21 | +23.34 | ||

| U + Ni-100 PA | 0.096 (26) | 0.0397/0.0396/38.24/20 | +20.20 | ||

| U + Self P | 0.083 (23) | 0.0399/0.0398/38.53/21 | +3.94 | ||

| U + Self PA | 0.079 (23) | 0.0399/0.0398/38.53/20 | −0.89 | ||

| Ni-0.02 | 0.0201 | U + Ins PA | 0.027 (22) | 0.0391/0.0392/36.91/20 | +35.12 |

| U + Ni-1 PA | 0.053 (30) | 0.0391/0.0391/38.19/20 | +161.88 | ||

| U + Ni-10 PA | 0.041 (26) | 0.0391/0.0392/38.23/20 | +103.71 | ||

| U + Ni-100 PA | 0.038 (25) | 0.0391/0.0392/38.24/20 | +90.60 | ||

| U + Self PA | 0.020 (21) | 0.0393/0.0394/38.53/20 | +1.00 |

References

- Pecharsky, V.K.; Zavalij, P.Y. Fundamentals of Powder Diffraction and Structural Characterization of Materials; Springer: Boston, MA, USA, 2003. [Google Scholar]

- Börner, H.; Brown, J.; Carlile, C.J.; Cubitt, R.; Currat, R.; Dianoux, A.J.; Farago, B.; Hewat, A.W.; Kulda, J.; Lelièvre-Berna, E.; et al. Neutron Data Booklet, 2nd ed.; Dianoux, A., Lander, G., Eds.; OCP Science: Philadelphia, PA, USA, 2003. [Google Scholar]

- Dronskowski, R.; Brückel, T.; Kohlmann, H.; Avdeev, M.; Houben, A.; Meven, M.; Hofmann, M.; Kamiyama, T.; Zobel, M.; Schweika, W.; et al. Neutron diffraction: A primer. Z. Kristallogr. Cryst. Mater. 2024, 239, 139–166. [Google Scholar] [CrossRef]

- Sears, V.F. Neutron scattering lengths and cross sections. Neutron News 1992, 3, 26–37. [Google Scholar] [CrossRef]

- Kameda, Y.; Mimuro, T.; Kondo, S.I.; Honda, T.; Otomo, T. Structure of Ion Pair Receptor Combined with Li+ Cl–in Concentrated Acetonitrile Solutions Studied by Neutron Diffraction with 6Li/7Li Isotopic Substitution Method. J. Phys. Chem. B 2024, 128, 12533–12539. [Google Scholar] [CrossRef] [PubMed]

- Komatsu, K.; Hattori, T.; Klotz, S.; Machida, S.; Yamashita, K.; Ito, H.; Kobayashi, H.; Irifune, T.; Shinmei, T.; Sano-Furukawa, A.; et al. Hydrogen bond symmetrisation in D2O ice observed by neutron diffraction. Nat. Commun. 2024, 15, 5100. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Gasparrini, C.; White, J.T.; Johnson, K.; Lopes, D.A.; Peterson, V.K.; Studer, A.; Griffiths, G.J.; Lumpkin, G.R.; Wenman, M.R.; et al. Thermal expansion and steam oxidation of uranium mononitride analysed via in situ neutron diffraction. J. Nucl. Mater. 2023, 575, 154215. [Google Scholar] [CrossRef]

- An, K.; Chen, Y.; Stoica, A.D. VULCAN: A “hammer” for high-temperature materials research. MRS Bull. 2019, 44, 878–885. [Google Scholar] [CrossRef]

- Ganesh Jangam, R.; Thamizhavel, A.; Knotko, A.V.; Yapaskurt, V.O.; Morozkin, A.V. Magnetic structure of rare earth intermetallic compound Er6MnTe2: Neutron diffraction and magnetization study. AIP Adv. 2025, 15, 035113. [Google Scholar] [CrossRef]

- Tanji, A.; Fan, X.; Sakidja, R.; Liaw, P.K.; Hermawan, H. Niobium addition improves the corrosion resistance of TiHfZrNbx high-entropy alloys in Hanks’ solution. Electrochim. Acta 2022, 424, 140651. [Google Scholar] [CrossRef]

- Zhang, Q.; Arnold, W.; Hood, Z.D.; Li, Y.; DeWees, R.; Chi, M.; Chen, Z.; Chen, Y.; Wang, H. Li0.625Al0.125H0.25Cl0.75O0.25 Superionic Conductor with Disordered Rock-Salt Structure. ACS Appl. Energy Mater. 2021, 4, 7674–7680. [Google Scholar] [CrossRef]

- Zhomartova, A.Z.; Abdurakhimov, B.A.; Talmațchi, C.; Kichanov, S.E.; Kozlenko, D.P.; Bǎlǎșoiu, M.; Talmațchi, G.; Șova, C.; Belc, M.C. The systematic structural studies of some Byzantine ceramic fragments from Dobrudja region of Romania: Raman spectroscopy, neutron diffraction, and imaging data. Archaeometry 2024, 66, 787–802. [Google Scholar] [CrossRef]

- Zhou, H.; Shen, Y.; Cao, Y.; Yang, W.; Sun, X.; Yu, C.; Lin, K.; Xing, X. A Kagome Metallic Composite Realizes Mechanically Axial Zero Thermal Expansion up to 800 K. Adv. Mater. 2025, 37, 2502030. [Google Scholar] [CrossRef]

- Xie, D.; Lyu, Z.; Fan, M.; Chew, H.B.; Liaw, P.K.; Bei, H.; Zhang, Z.; Gao, Y. Micromechanical origin of the enhanced ductility in twinless duplex Mg–Li alloy. Mater. Sci. Eng. A 2021, 815, 141305. [Google Scholar] [CrossRef]

- Yu, D.; Huang, L.; Chen, Y.; Komolwit, P.; An, K. Real-Time In Situ Neutron Diffraction Investigation of Phase-Specific Load Sharing in a Cold-Rolled TRIP Sheet Steel. JOM 2018, 70, 1576–1586. [Google Scholar] [CrossRef]

- Park, K.; Iftikhar, H.; Shin, S.; Jung, Y.; Lee, K.; Lee, C.; Song, G. Balanced mechanical properties of Al0. 5CoCrFeNiTi0. 1 high entropy alloy under extreme environments from cryogenic temperature to 800° C. J. Alloys Compd. 2025, 1010, 178199. [Google Scholar] [CrossRef]

- Gu, G.H.; Ha, H.; Harjo, S.; Gong, W.; Louzguine-Luzgin, D.V.; Kim, H.S. Mechanistic insights into deformation, load redistribution, and stress partitioning in high-strength dual-phase medium-entropy alloys. Mater. Sci. Eng. A 2025, 943, 148818. [Google Scholar] [CrossRef]

- Jiang, S.; Lin Peng, R.; Zhao, X.; Zuo, L.; Jia, N. Deformation incompatibility enables hetero-deformation induced strengthening in Ti/Nb laminates. Mater. Res. Lett. 2023, 11, 126–133. [Google Scholar] [CrossRef]

- Wang, X.; Fu, Y.; Wu, Y.; Wang, J.; Fan, J.; Zhang, F.; Ruan, H.; Wu, Y. Crystalline-amorphous-crystalline two-step phase transformation and the resulting supra-nano structure in a metastable iron-based alloy. Acta Mater. 2024, 266, 119690. [Google Scholar] [CrossRef]

- Lychagina, T.; Zisman, A.; Yashina, E.; Nikolayev, D. Directly verifiable neutron diffraction technique to determine retained austenite in steel. Adv. Eng. Mater. 2018, 20, 1700559. [Google Scholar] [CrossRef]

- Gnäupel-Herold, T.; Creuziger, A. Diffraction study of the retained austenite content in TRIP steels. Mater. Sci. Eng. A 2011, 528, 3594–3600. [Google Scholar] [CrossRef]

- Kozakevich, J.R.; Sediako, D.; Weiss, D.; Vogel, S.C. A Quantitative Phase Analysis by Neutron Diffraction of Conventional and Advanced Aluminum Alloys Thermally Conditioned for Elevated-Temperature Applications. Mater. 2024, 17, 4311. [Google Scholar] [CrossRef]

- Chen, Y.; Rangasamy, E.; dela Cruz, C.; Liang, C.; An, K. A Study of Suppressed Formation of Low-Conductive Phases in Doped Li7La3Zr2O12 Garnets by in-situ Neutron Diffraction. J. Mater. Chem. A 2015, 3, 22868–22876. [Google Scholar] [CrossRef]

- Yu, D.; Chen, Y.; Huang, L.; An, K. Tracing Phase Transformation and Lattice Evolution in a TRIP Sheet Steel under High-Temperature Annealing by Real-Time In Situ Neutron Diffraction. Crystals 2018, 8, 360. [Google Scholar] [CrossRef]

- Hua, Y.; Huang, Z.; Li, S.; Chen, S.; He, X.; Liu, H.; Feng, J. Unraveling the correlation between the synthesis time and electrochemical performance of transition metal layered oxides by in situ neutron powder diffraction. ACS Appl. Energy Mater. 2023, 6, 6563–6571. [Google Scholar] [CrossRef]

- Nisar, U.; Klein, F.; Pfeifer, C.; Wohlfahrt-Mehrens, M.; Hölzle, M.; Axmann, P. Elucidating the nature of secondary phases in LiNi0.5Mn1.5O4 cathode materials using correlative Raman-SEM microscopy. Energy Storage Mater. 2025, 74, 103905. [Google Scholar] [CrossRef]

- Chen, T.C.; Tsay, L.W.; Chou, C.C.; Hsu, S.C. Enhancing the corrosion–wear resistance of HVOF-sprayed inconel 625 coatings via micro-shot peening. Surf. Coat. Technol. 2025, 517, 132801. [Google Scholar] [CrossRef]

- Magagnosc, D.J.; Field, D.M.; Meredith, C.S.; Walter, T.R.; Limmer, K.R.; Lloyd, J.T. Superior strength and ductility in a low density duplex steel studied by in situ neutron diffraction. Mater. Sci. Eng. A 2021, 799, 140252. [Google Scholar] [CrossRef]

- Berry, K.D.; Bailey, K.M.; Beal, J.; Diawara, Y.; Funk, L.; Hicks, J.S.; Jones, A.B.; Littrell, K.C.; Pingali, S.V.; Summers, P.R.; et al. Characterization of the neutron detector upgrade to the GP-SANS and Bio-SANS instruments at HFIR. Nucl. Instrum. Methods Phys. Res. Sect. A 2012, 693, 179–185. [Google Scholar] [CrossRef]

- Larson, A.C.; Von Dreele, R.B. General Structure Analysis System (GSAS). Los Alamos National Laboratory Report LAURM. 2004; pp. 86–748. Available online: https://subversion.xray.aps.anl.gov/EXPGUI/gsas/all/GSAS%20Manual.pdf (accessed on 30 September 2025).

- Toby, B.H. EXPGUI, a graphical user interface for GSAS. J. Appl. Crystallogr. 2001, 34, 210–213. [Google Scholar] [CrossRef]

- Harmer, C.P.; Kamali, S.; Lebedev, O.I.; Lee, S.J.; Ribeiro, R.A.; Canfield, P.C.; Kovnir, K. Pseudo-polymorphism in layered FeS intercalates: A competition between charged and neutral guest species. Chem. Mater. 2022, 34, 5397–5408. [Google Scholar] [CrossRef]

- Mondal, S.; Dutta, S.; Mal, S.; Pati, S.K.; Bhattacharyya, S. Lattice Mismatch Guided Nickel-Indium Heterogeneous Alloy Electrocatalysts for Promoting the Alkaline Hydrogen Evolution. Angew. Chem. Int. Ed. 2023, 62, 202301269. [Google Scholar] [CrossRef]

- Yu, D.; Chen, Y.; Conner, D.; Berry, K.D.; Skorpenske, H.D.; An, K. Effect of Collimation on Diffraction Signal-to-Background Ratios at a Neutron Diffractometer. Quantum Beam Sci. 2024, 8, 14. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Y.; Yu, D.; An, K. What Is the Limit of Quantification for the Minor Phase in Time-of-Flight Neutron Diffraction? A Case Study on Fe and Ni Powder Mixtures at VULCAN. Crystals 2025, 15, 934. https://doi.org/10.3390/cryst15110934

Chen Y, Yu D, An K. What Is the Limit of Quantification for the Minor Phase in Time-of-Flight Neutron Diffraction? A Case Study on Fe and Ni Powder Mixtures at VULCAN. Crystals. 2025; 15(11):934. https://doi.org/10.3390/cryst15110934

Chicago/Turabian StyleChen, Yan, Dunji Yu, and Ke An. 2025. "What Is the Limit of Quantification for the Minor Phase in Time-of-Flight Neutron Diffraction? A Case Study on Fe and Ni Powder Mixtures at VULCAN" Crystals 15, no. 11: 934. https://doi.org/10.3390/cryst15110934

APA StyleChen, Y., Yu, D., & An, K. (2025). What Is the Limit of Quantification for the Minor Phase in Time-of-Flight Neutron Diffraction? A Case Study on Fe and Ni Powder Mixtures at VULCAN. Crystals, 15(11), 934. https://doi.org/10.3390/cryst15110934