Outcome of Hall Current and Mechanical Load on a Fiber-Reinforced Thermoelastic Medium per the Hypothesis of One Thermal Relaxation Time

Abstract

1. Introduction

2. Description of the Problem and the Fundamental Relations

- (i)

- The constitutive relations

- (ii)

- The equations of motion

- (iii)

- The equation of heat conduction after Lord and Shulman [4]

- (iv)

- Hall current as follows Zakaria [18]

3. The Analytical Method

4. The Resolution of the Differential Equation via a Vector Matrix

5. Boundary Conditions

- (a)

- The condition of the thermal boundary is that the surface corresponds to an isothermal boundary

- (b)

- The condition of the mechanical boundary is that the surface corresponds to an inclined load

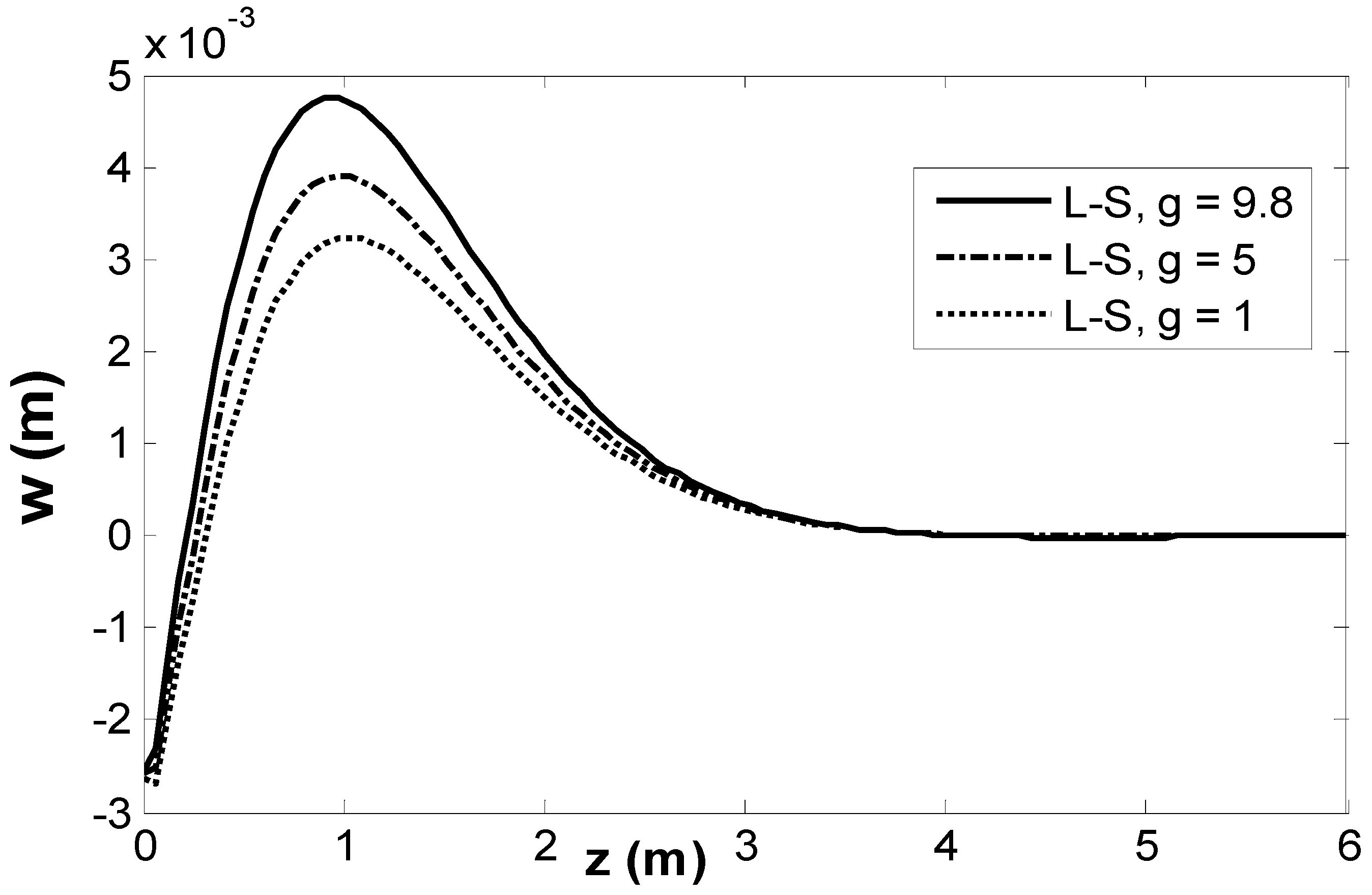

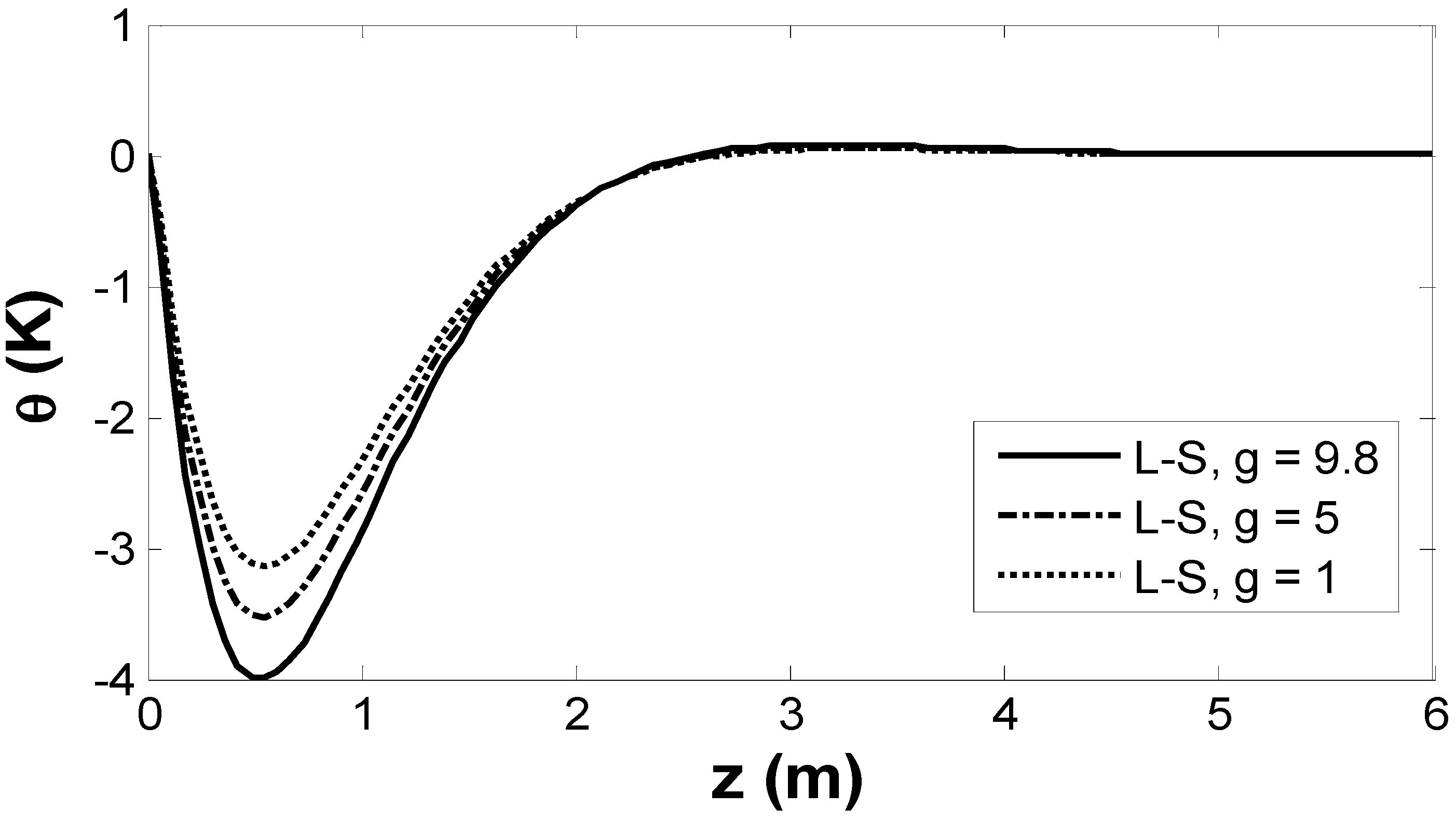

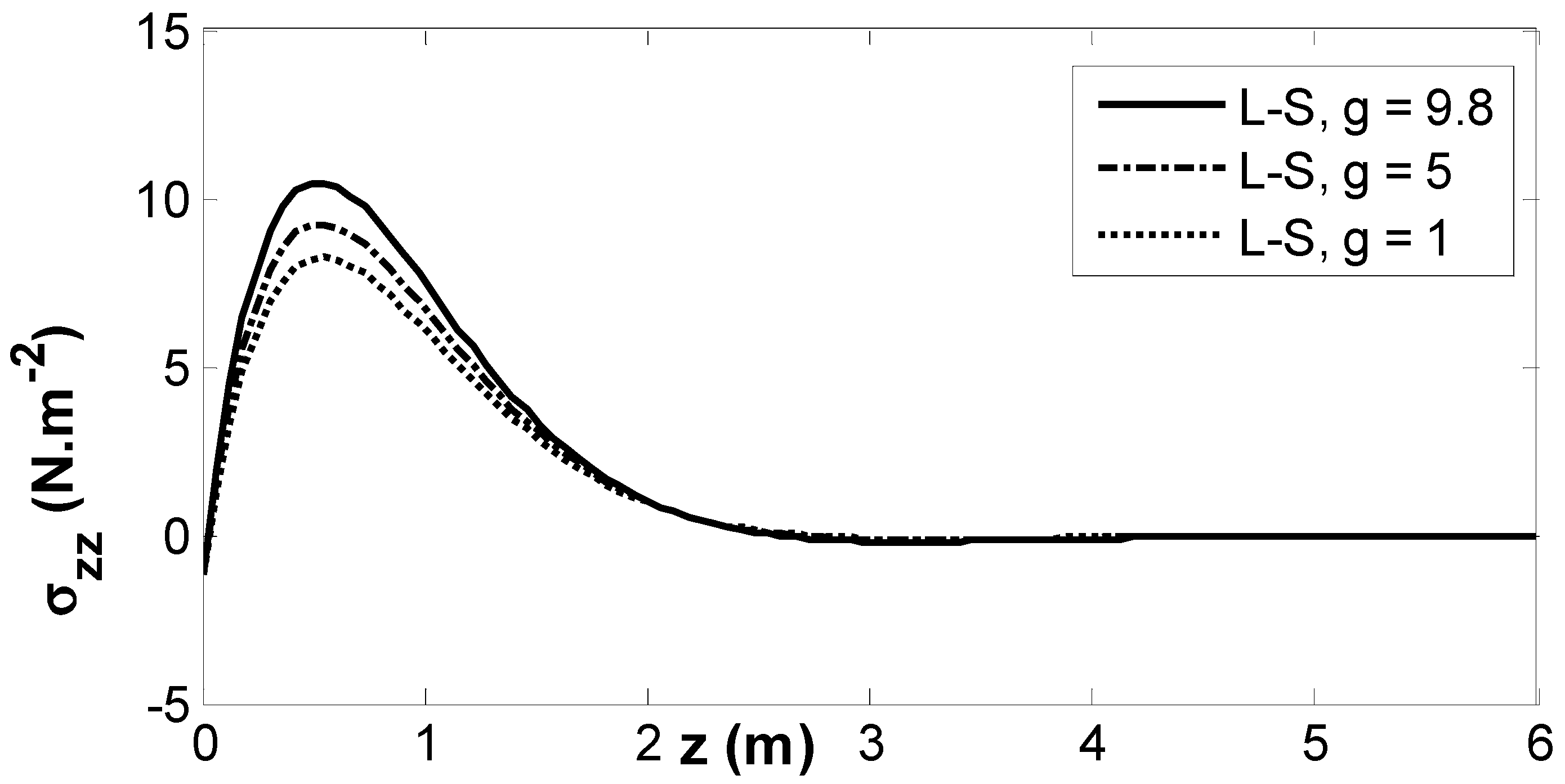

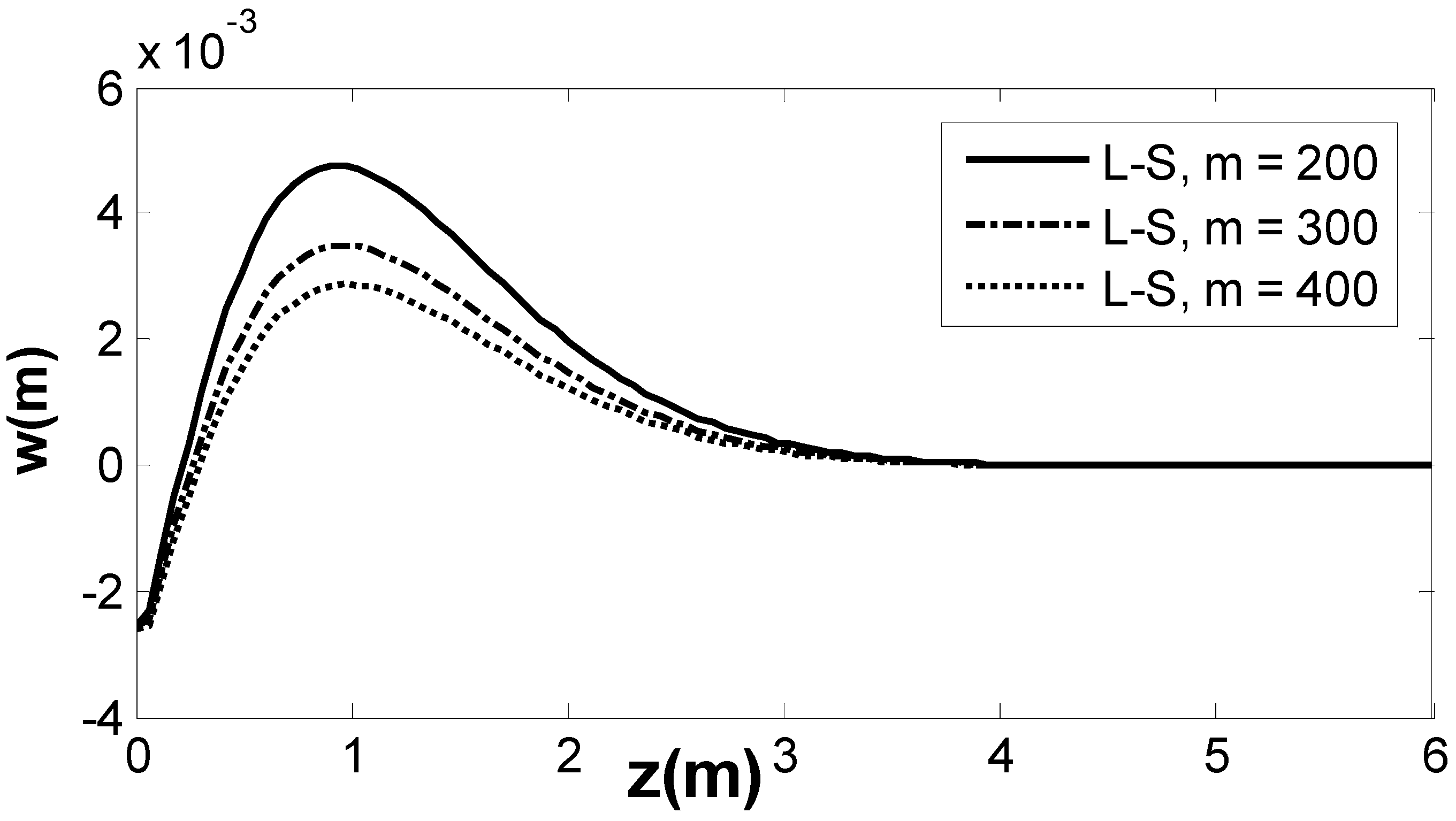

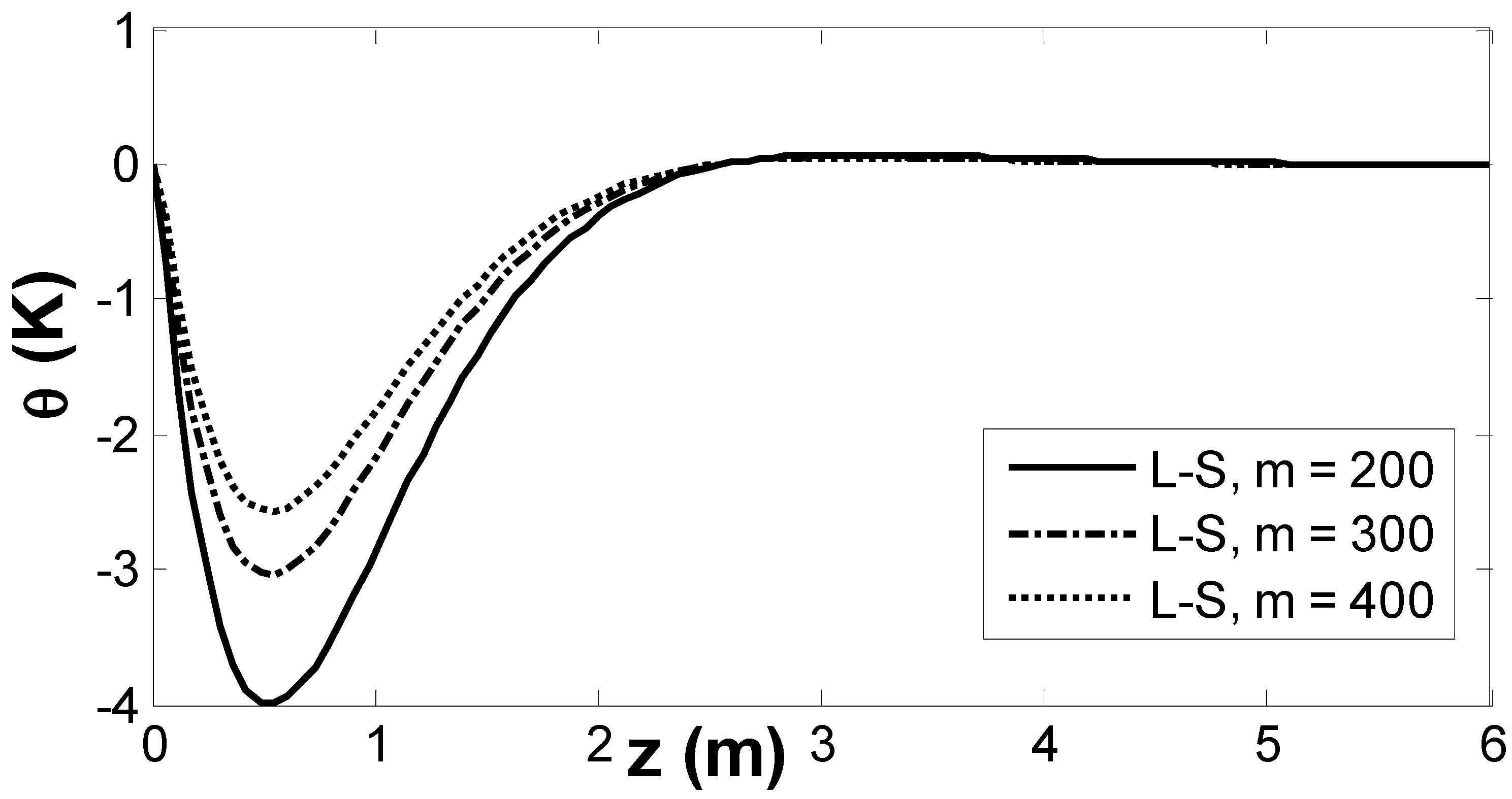

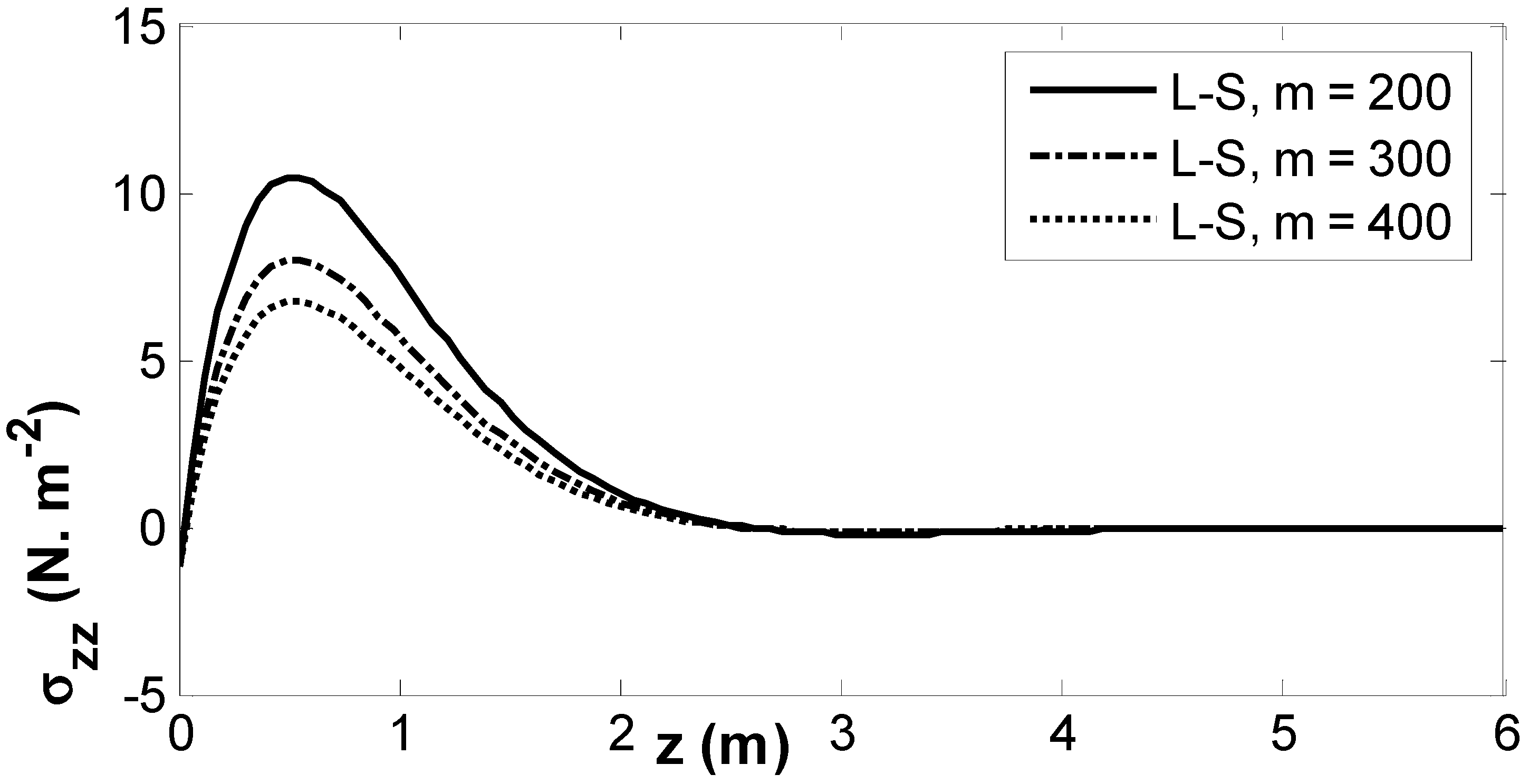

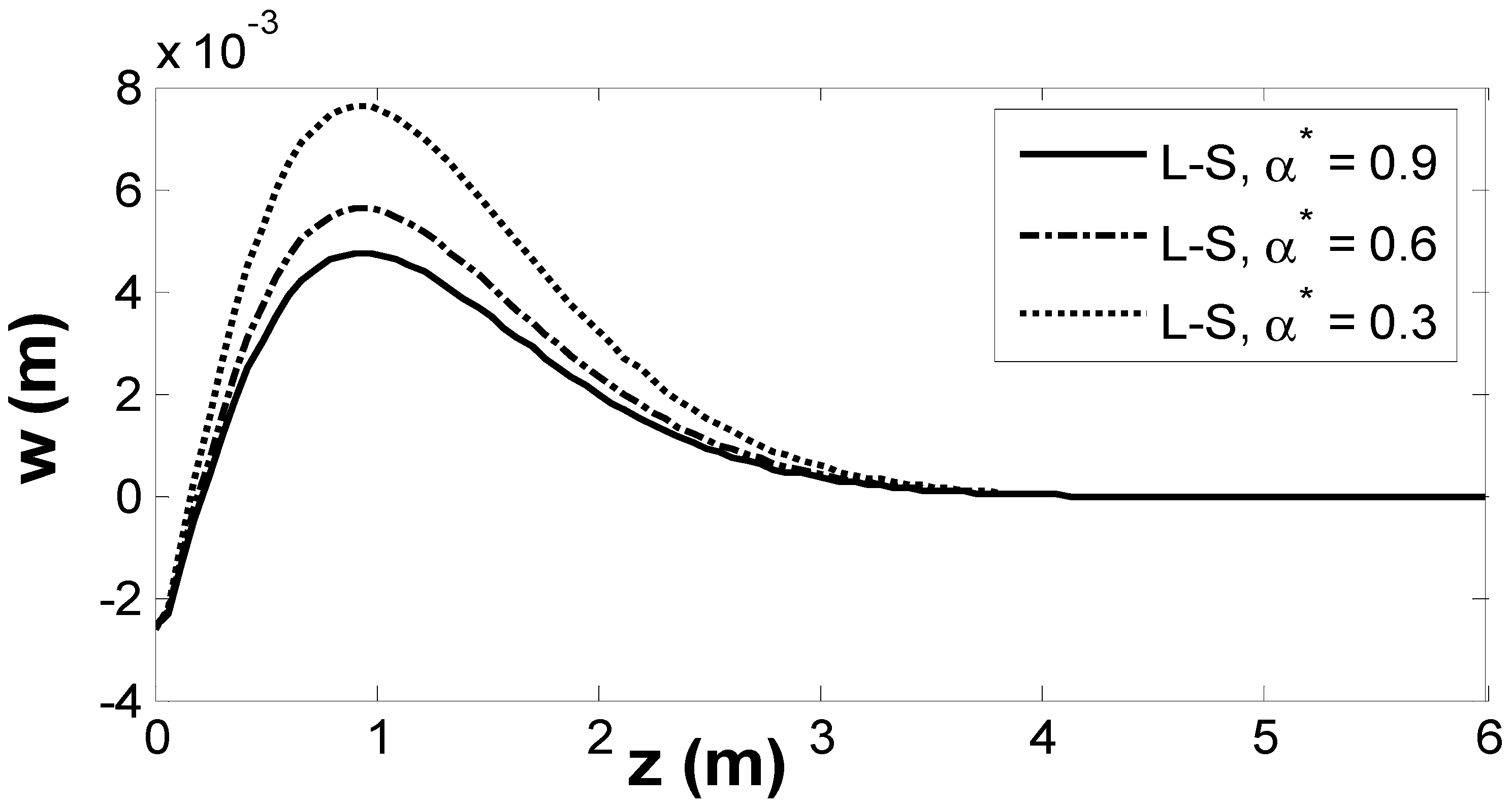

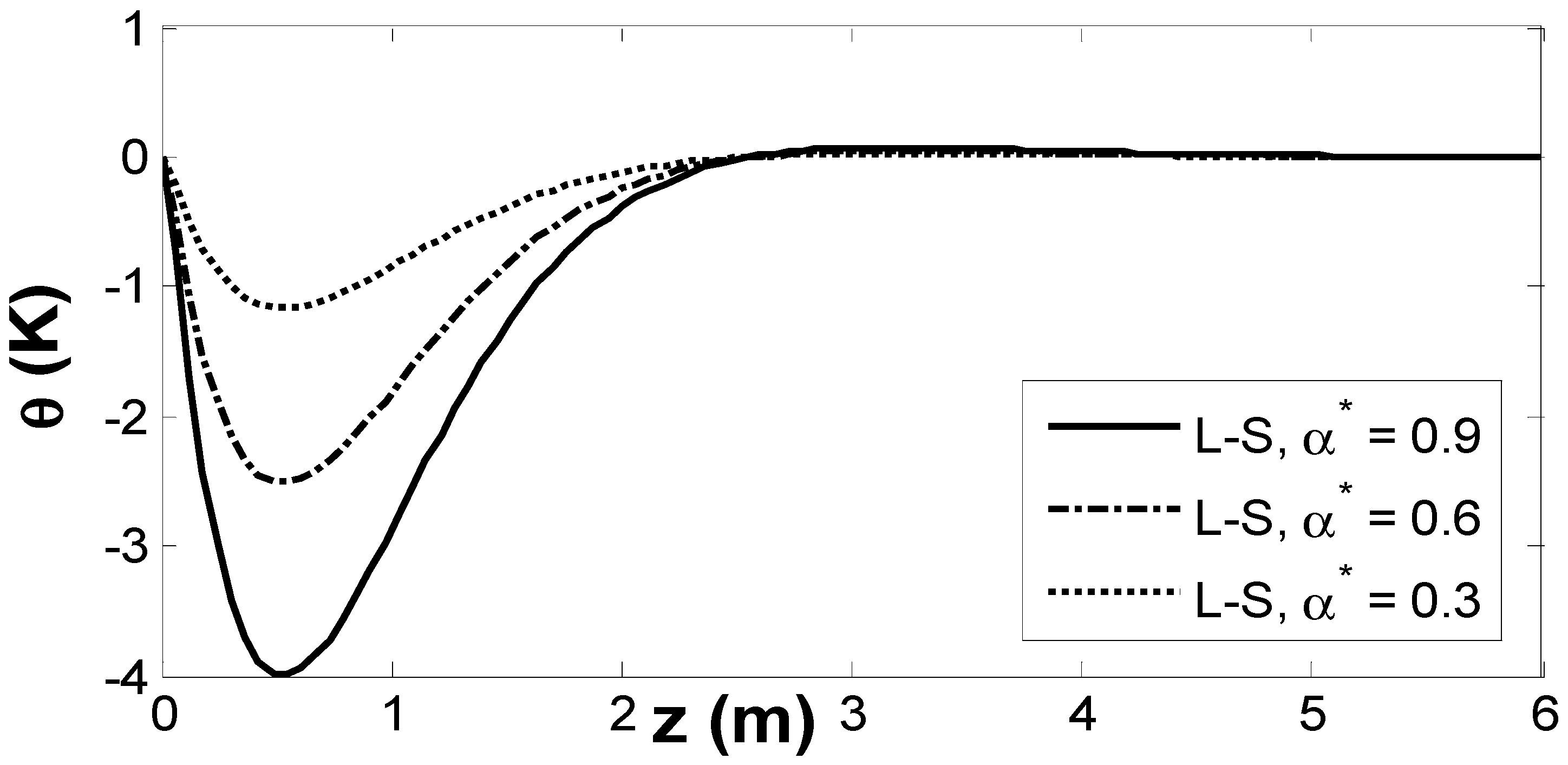

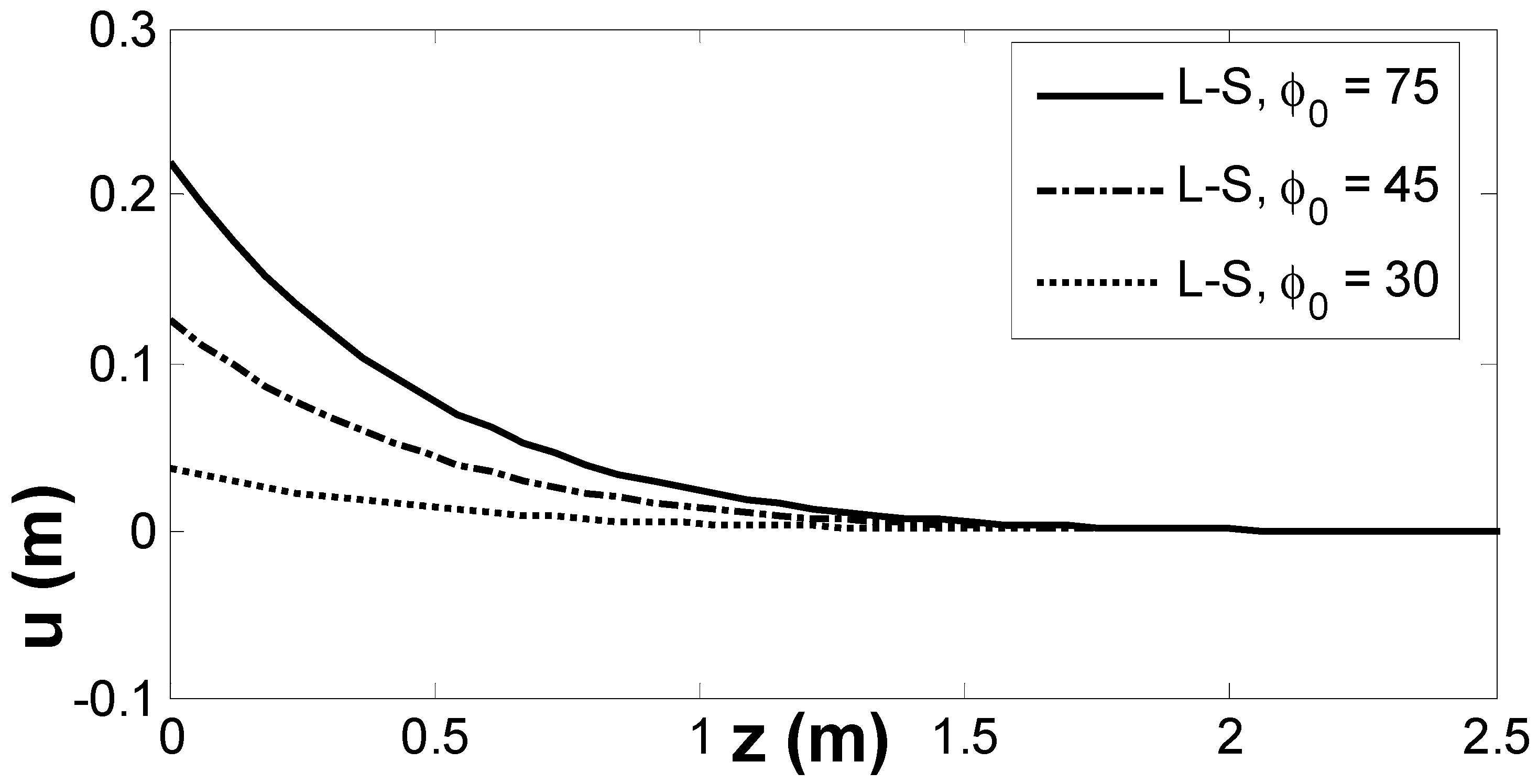

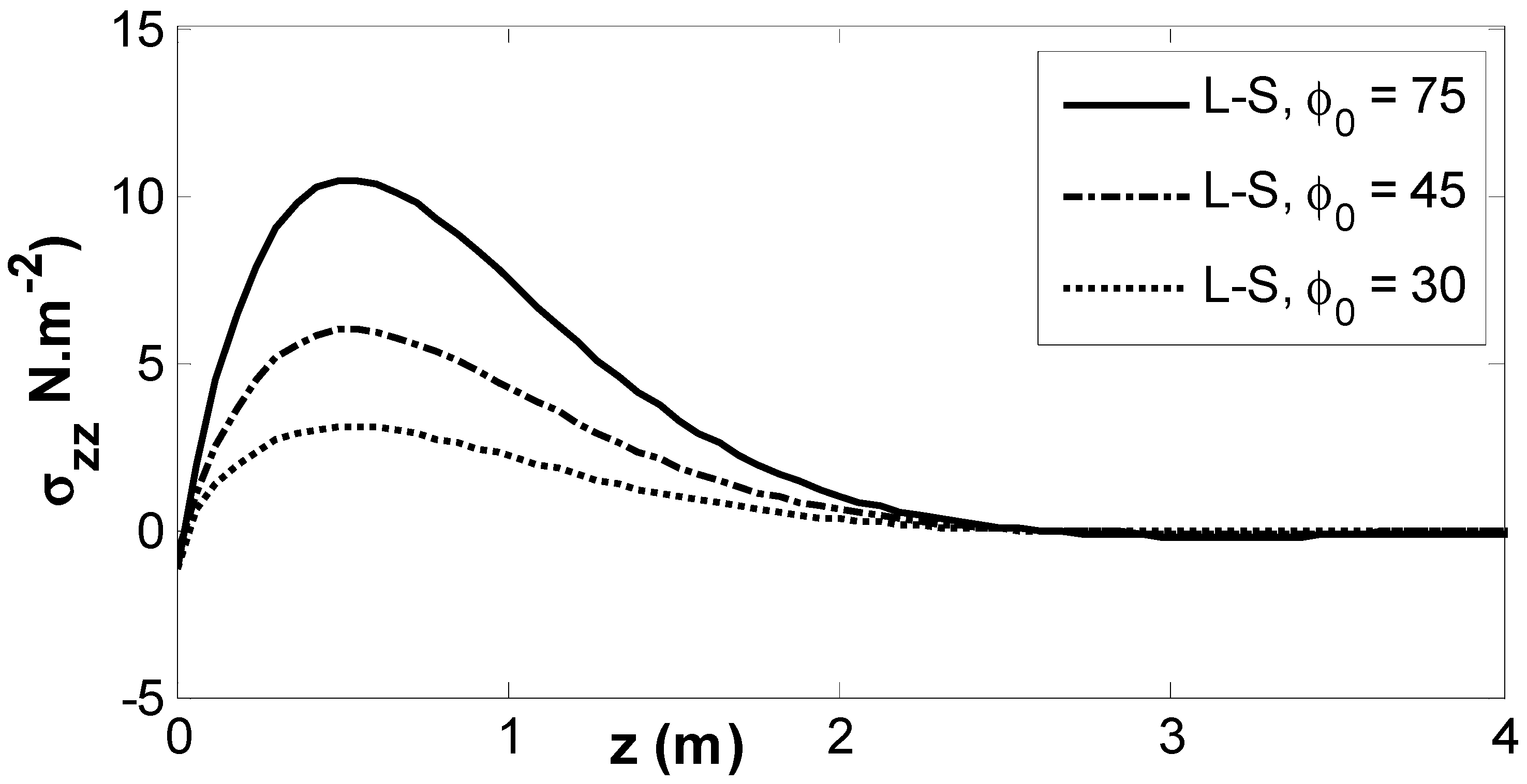

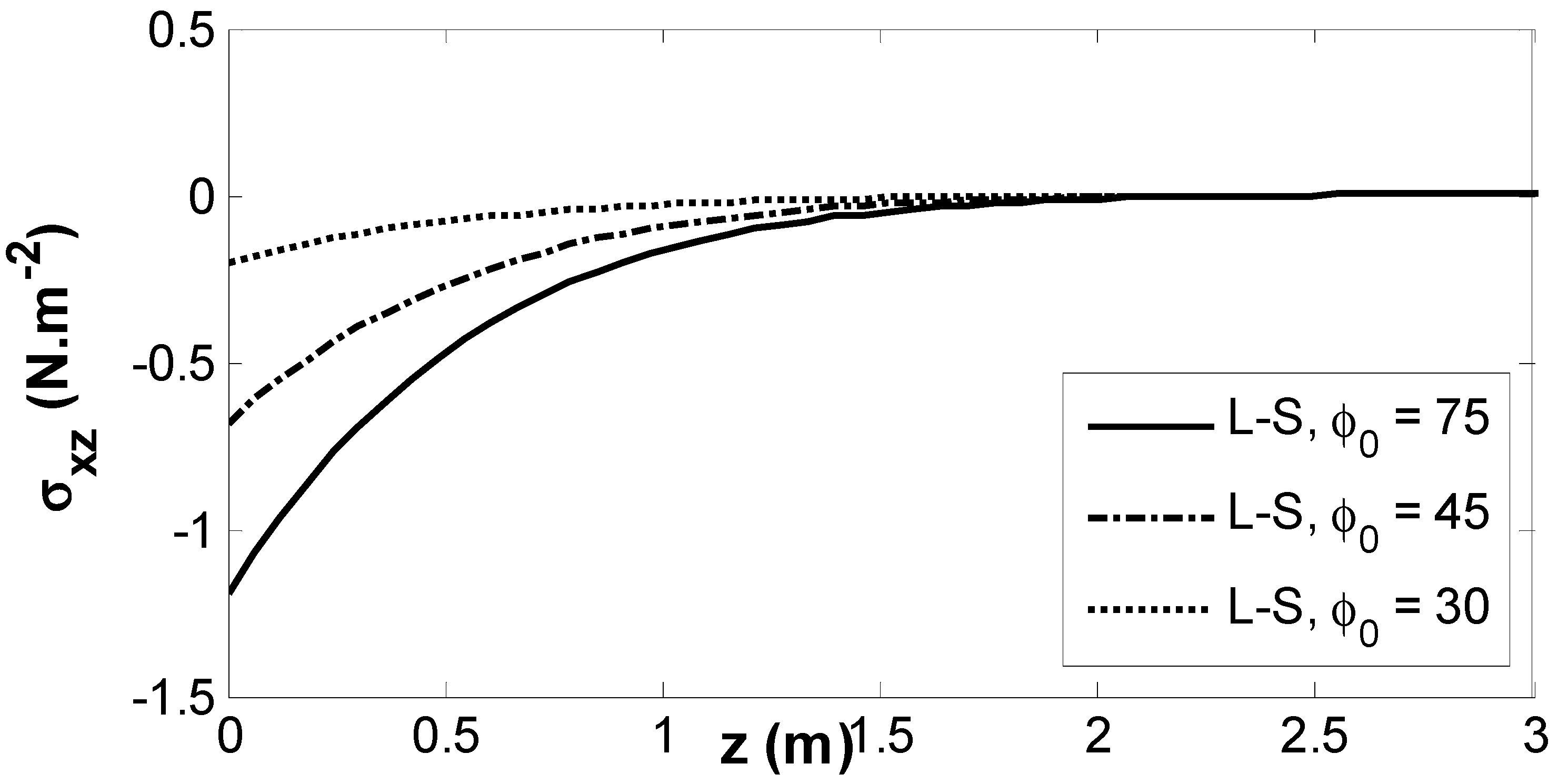

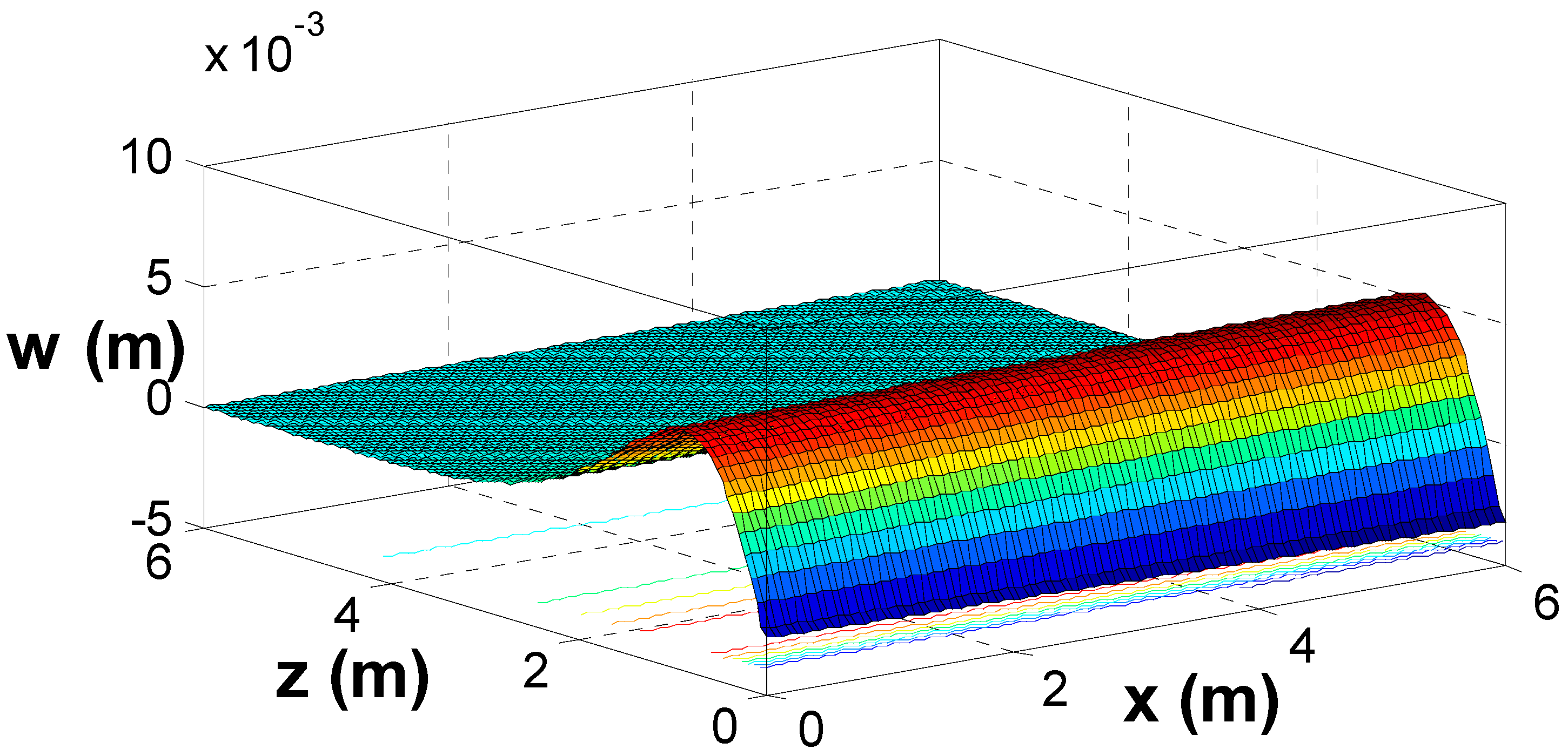

6. Results and Numerical Discussion

7. Conclusions

- The gravity field significantly impacts the magnitudes of the physical fields.

- The inclined load has a considerable effect on the magnitudes of physical fields.

- All physical fields are subject to alteration, and are significantly impacted by the empirical solid constant.

- All physical field variations approach a zero value with growing distance of , and all physical fields are continuous.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| stress tensor | magnetic field with constant intensity | ||

| dilation | thermal relaxation time | ||

| strain tensor | fiber-direction as , | ||

| Kronecker delta | thermal temperature | ||

| mass density | reference temperature, , | ||

| specific heat at constant strain | linear thermal expansion coefficient, | ||

| elastic constants | constants of material | ||

| time | an empirical material constant | ||

| the displacement vector | the function amplitude | ||

| thermal conductivity | complex constant | ||

| a wave number in -direction | permeability of magnetic field | ||

| parameters of reinforcement | permeability of electric field | ||

| vector of current density | velocity of the medium | ||

| Hall parameter | electron relaxation time | ||

| cyclotron frequency | induction of magnetic field | ||

| charge of electron | mass of electron | ||

| density of electron number | |||

| the electrical conductivity |

References

- Duhamel, J. Some memoire sur les phenomenes thermo-mechanique. J. l’École Polytech. 1837, 15, 1–31. [Google Scholar]

- Neumann, F. Vorlesungen über die Theorie der Elasticität; BG Teubner: Leipzig, Germany, 1885. [Google Scholar]

- Biot, M.A. Mechanics of Incremental Deformation; Wiley: New York, NY, USA, 1965. [Google Scholar]

- Lord, H.; Shulman, Y. A generalized dynamical theory of thermoelasticity. J. Mech. Phys. Solid 1967, 15, 299–309. [Google Scholar] [CrossRef]

- Ignaczak, J.; Bialy, J. Domain of influence in thermoelasticity with one relaxation time. J. Therm. Stress. 1980, 3, 391–399. [Google Scholar] [CrossRef]

- Sherief, H. State space formulation for generalized thermoelasticity with one relaxation time including heat sources. J. Therm. Stress. 1993, 16, 163–176. [Google Scholar] [CrossRef]

- He, T.; Cao, L. A problem of generalized magneto-thermoelastic thin slim strip subjected to a moving heat source. Math. Comp. Model. 2009, 49, 1710–1720. [Google Scholar] [CrossRef]

- Abo-Dahab, S.M.; Abbas, I.A. LS model on thermal shock problem of generalized magneto-thermoelasticity for an infinitely long annular cylinder with variable thermal conductivity. Appl. Math. Model. 2011, 35, 3759–3768. [Google Scholar] [CrossRef]

- Heydarpour, Y.; Malekzadeh, P.; Gholipour, F. Thermoelastic analysis of FG-GPLRC spherical shells under thermo-mechanical loadings based on Lord-Shulman theory. Compos. B Eng. 2019, 164, 400–424. [Google Scholar] [CrossRef]

- Sobhy, M.; Zenkour, A.M. Refined Lord-Shulman theory for 1D response of skin tissue under Ramp-type heat. Materials 2022, 15, 6292. [Google Scholar] [CrossRef]

- Abouelregal, A.E.; Askar, S.S.; Marin, M.; Mohamed, B. The theory of thermoelasticity with a memory-dependent dynamic response for a thermo-piezoelectric functionally graded rotating rod. Sci. Rep. 2023, 13, 9052. [Google Scholar] [CrossRef] [PubMed]

- Zenkour, A.M.; El-Shahrany, H.D.; El-Mekawy, H.F. Magneto-photo-thermoelastic influences on a semiconductor hollow cylinder via a series-one-relaxation model. Commun. Nonliner Sci. Numer. Simul. 2024, 139, 108295. [Google Scholar] [CrossRef]

- Said, S.M. Influence of gravitational on a rotating nonlocal thermoelastic medium with thermal variable conductivity. J. Comput. Appl. Math. 2025, 454, 116180. [Google Scholar] [CrossRef]

- Hall, E.H. On a new action of the magnet on electric currents. Am. J. Math. 1879, 2, 287–292. [Google Scholar] [CrossRef]

- Cowling, T.G. Magneto Hydrodynamics; Wiley Inter Science: New York, NY, USA, 1957. [Google Scholar]

- Salem, A.M. Hall-current effects on MHD flow of a power-law fluid over a rotating disk. J. Korean Phys. Soc. 2007, 50, 28–33. [Google Scholar] [CrossRef]

- Reddy, P.B.; Rao, A.J. Radiation and thermal diffusion effects on an unsteady MHD free convection mass transfer flow past an infinite vertical porous plate with Hall current and heat source. J. Eng. Phys. Thermophys. 2011, 84, 1369–1378. [Google Scholar] [CrossRef]

- Zakaria, M. Effects of Hall current and rotation on magneto micropolar generalized thermoelasticity due to ramp-type heating. Int. J. Electr. Appl. 2012, 2, 24–32. [Google Scholar] [CrossRef]

- Kumar, R.; Vohra, R. Effect of Hall current in thermoelastic materials with double porosity structure. Int. J. Appl. Mech. Eng. 2017, 22, 303–319. [Google Scholar] [CrossRef]

- Bhatti, M.M.; Ellahi, R.; Zeeshan, A.; Marin, M.; Ijaz, N. Numerical study of heat transfer and Hall current impact on peristaltic propulsion of particle-fluid suspension with compliant wall properties. Mod. Phys. Lett. B 2019, 33, 1950439. [Google Scholar] [CrossRef]

- Kaur, I.; Singh, K. Plane wave in non-local semiconducting rotating media with Hall effect and three-phase lag fractional order heat transfer. Int. J. Mech. Mater. Eng. 2021, 16, 14. [Google Scholar] [CrossRef]

- Deswal, S.; Sheokand, P.; Punia, B.S. Interactions due to Hall current and photothermal effect in a magneto-thermoelastic medium with diffusion and gravity. Acta Mech. 2024, 235, 235–254. [Google Scholar] [CrossRef]

- Noda, N. Thermal stresses in materials with temperature-dependent properties. In Thermal Stresses I; Hetnarski, R.B., Ed.; North-Holland: Amsterdam, The Netherlands, 1986. [Google Scholar]

- Roy Choudhuri, S.K.; Chatterjee Roy, G. Temperature-rate dependent magnetothermoelastic waves in a finitely conducting elastic half-space. Comput. Math. Appl. 1990, 19, 85–93. [Google Scholar] [CrossRef]

- Szuecs, F.; Werner, M.; Sussmann, R.S.; Pickles, C.S.J.; Fecht, H.J. Temperature dependence of Young’s modulus and degradation of chemical vapor deposited diamond. J. Appl. Phys. 1999, 86, 6010–6017. [Google Scholar] [CrossRef]

- Aouadi, M. Generalized thermo-piezoelectric problems with temperature-dependent properties. Int. J. Solids Struct. 2006, 43, 6347–6358. [Google Scholar] [CrossRef]

- Othman, M.I.A.; Kumar, R. Reflection of magneto-thermoelasticity waves with temperature dependent properties in generalized thermoelasticity. Int. Commun. Heat Mass Transf. 2009, 36, 513–520. [Google Scholar] [CrossRef]

- Abbas, I.A. Eigenvalue approach in a three-dimensional generalized thermoelastic interactions with temperature-dependent material properties. Comp. Math. Appl. 2014, 68, 2036–2056. [Google Scholar] [CrossRef]

- Li, X.; Li, C.; Xue, Z.; Tian, X. Investigation of transient thermo-mechanical responses on the triple-layered skin tissue with temperature dependent blood perfusion rate. Int. J. Therm. Sci. 2019, 139, 339–349. [Google Scholar] [CrossRef]

- Said, S.M. Effects of phase-lags, rotation, and temperature-dependent properties on plane waves in a magneto-microstretch thermoelastic medium. Mech. Basic Des. Struct. Mach. 2021, 49, 534–552. [Google Scholar] [CrossRef]

- Das, N.; De, S.; Sarkar, N. Reflection of temperature rate-dependent coupled thermoelastic waves on a non-local elastic half-space. Math. Mech. Solids 2023, 28, 1232–1254. [Google Scholar] [CrossRef]

- Deswal, S.; Kalkal, K.K.; Dhankhar, P.; Poonia, R. Reflection of plane waves in a nonlocal transversely isotropic micropolar thermoelastic medium with temperature-dependent properties. J. Vib. Eng. Technol. 2024, 12, 8595–8612. [Google Scholar] [CrossRef]

- Said, S.M.; Othman, M.I.A.; Eldemerdash, M.G. Effect of temperature-dependent properties and gravity on a nonlocal poro-thermoelastic medium with MDD via G-L model. J. Vib. Eng. Technol. 2025, 13, 116. [Google Scholar] [CrossRef]

- Belfield, A.J.; Rogers, T.G.; Spencer, A.J.M. Stress in elastic plates reinforced by fiber lying in concentric circles. J. Mech. Phys. Solid 1983, 31, 25–54. [Google Scholar] [CrossRef]

- Said, S.M. Eigenvalue approach on a problem of magneto-thermoelastic rotating medium with variable thermal conductivity: Comparisons of three theories. Waves Random Complex Media 2021, 31, 1322–1339. [Google Scholar] [CrossRef]

- Othman, M.I.A.; Said, S.M.; Marin, M. A novel model of plane waves of two-temperature fiber-reinforced thermoelastic medium under the effect of gravity with three-phase lag model. Int. J. Numer. Methods Heat Fluid Flow 2019, 29, 4788–4806. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Said, S.M.; Jaradat, E.K.; Gafel, H.S.; Abo-Dahab, S.M. Outcome of Hall Current and Mechanical Load on a Fiber-Reinforced Thermoelastic Medium per the Hypothesis of One Thermal Relaxation Time. Crystals 2025, 15, 924. https://doi.org/10.3390/cryst15110924

Said SM, Jaradat EK, Gafel HS, Abo-Dahab SM. Outcome of Hall Current and Mechanical Load on a Fiber-Reinforced Thermoelastic Medium per the Hypothesis of One Thermal Relaxation Time. Crystals. 2025; 15(11):924. https://doi.org/10.3390/cryst15110924

Chicago/Turabian StyleSaid, Samia M., Emad K. Jaradat, Hanan S. Gafel, and Sayed M. Abo-Dahab. 2025. "Outcome of Hall Current and Mechanical Load on a Fiber-Reinforced Thermoelastic Medium per the Hypothesis of One Thermal Relaxation Time" Crystals 15, no. 11: 924. https://doi.org/10.3390/cryst15110924

APA StyleSaid, S. M., Jaradat, E. K., Gafel, H. S., & Abo-Dahab, S. M. (2025). Outcome of Hall Current and Mechanical Load on a Fiber-Reinforced Thermoelastic Medium per the Hypothesis of One Thermal Relaxation Time. Crystals, 15(11), 924. https://doi.org/10.3390/cryst15110924