Aluminium-Silicon Lightweight Thermal Management Alloys with Controlled Thermal Expansion

Abstract

1. Introduction

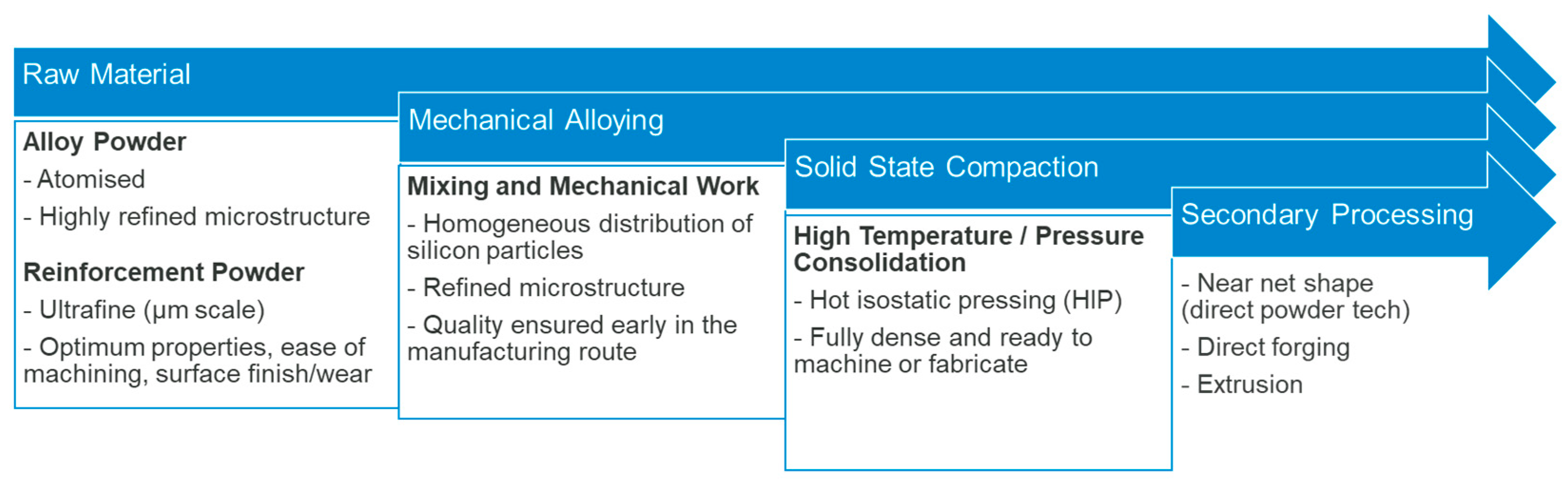

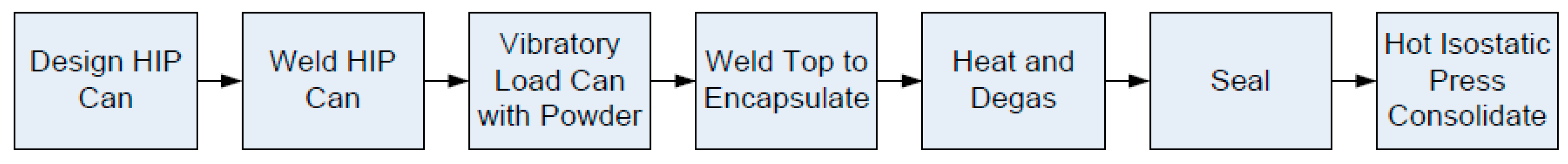

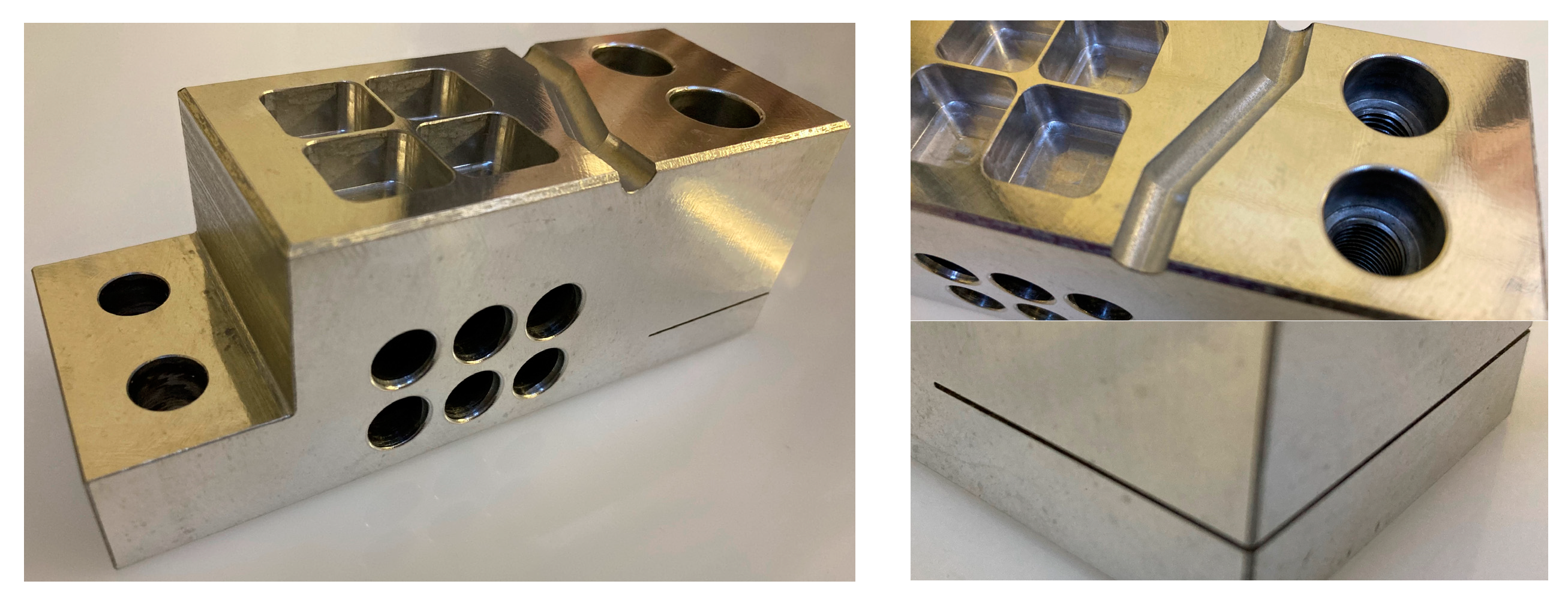

2. Materials and Methods

3. Results

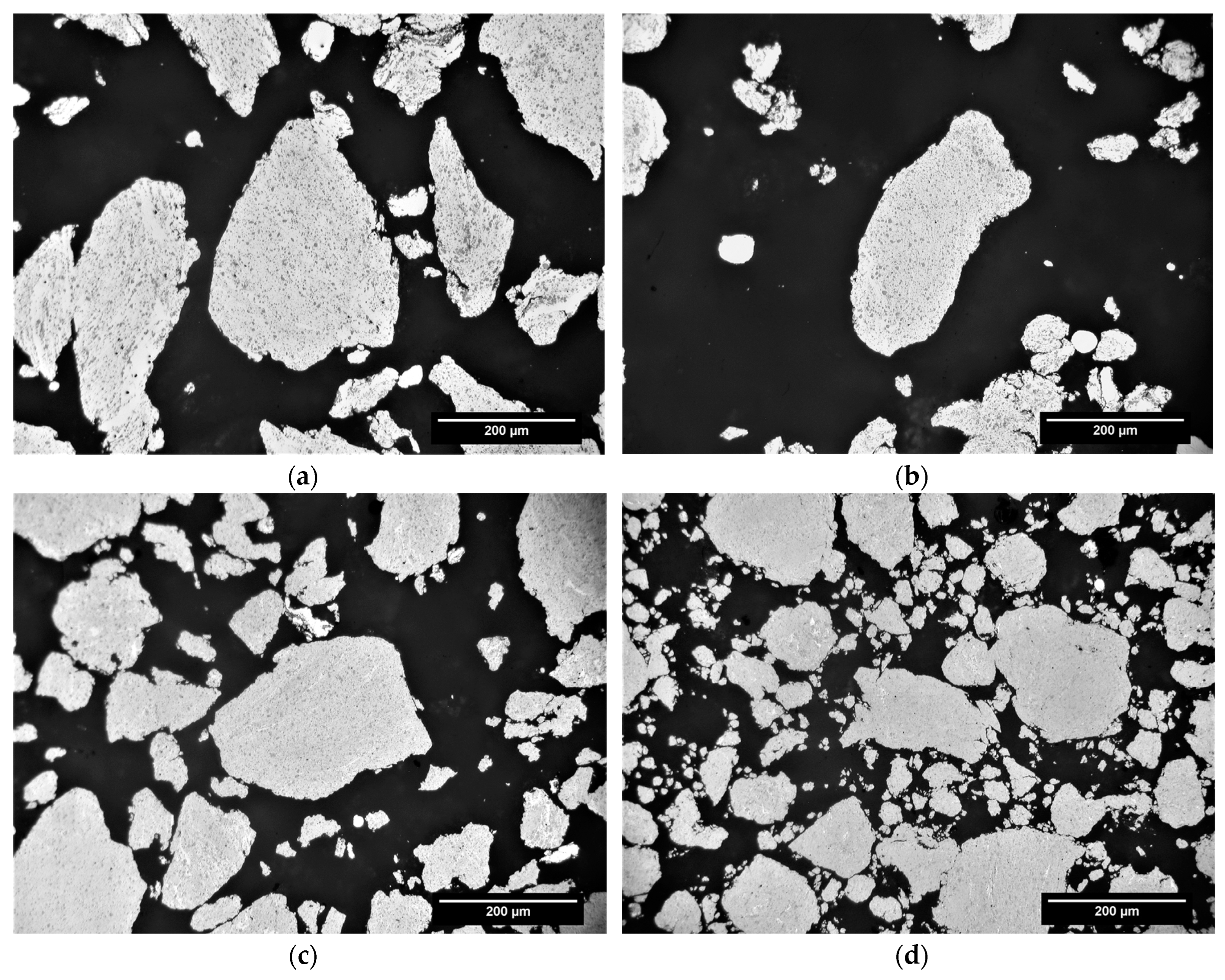

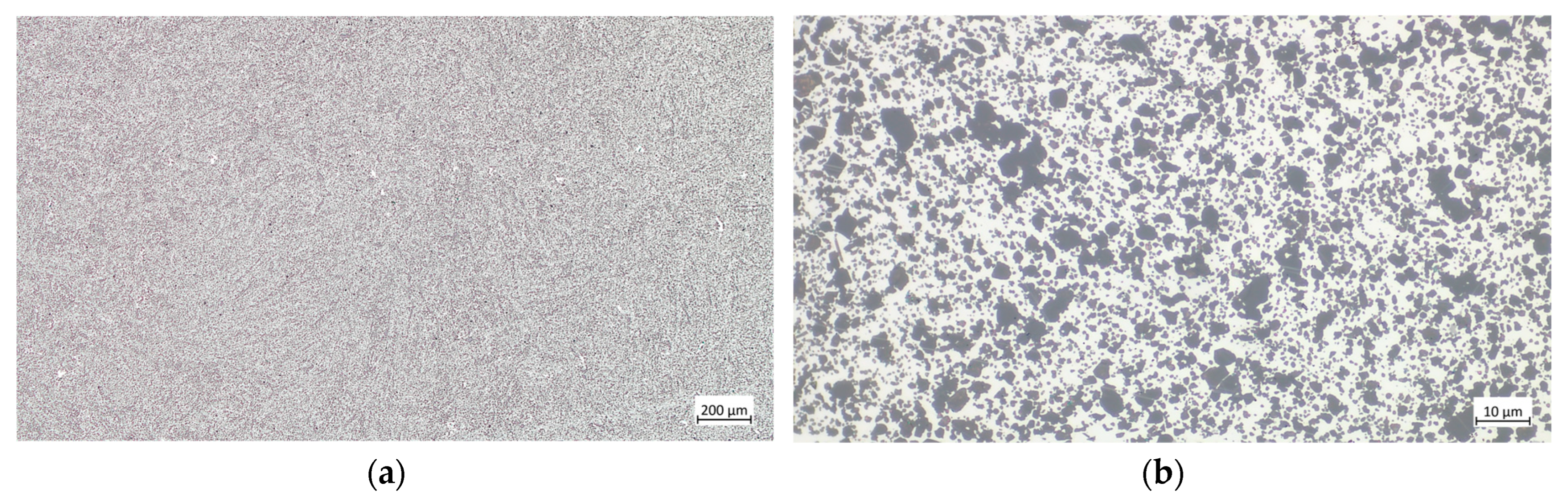

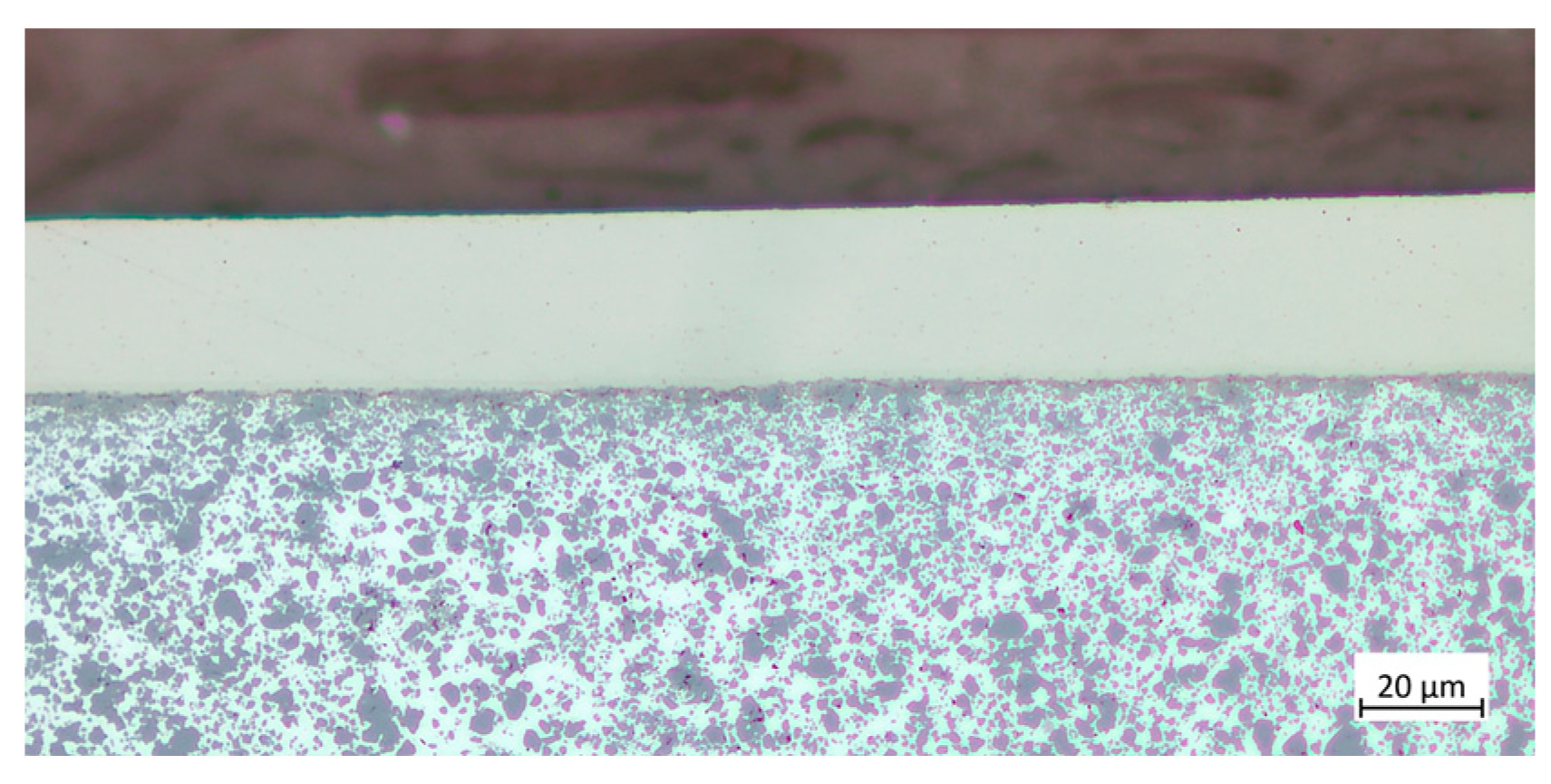

3.1. Microstructure

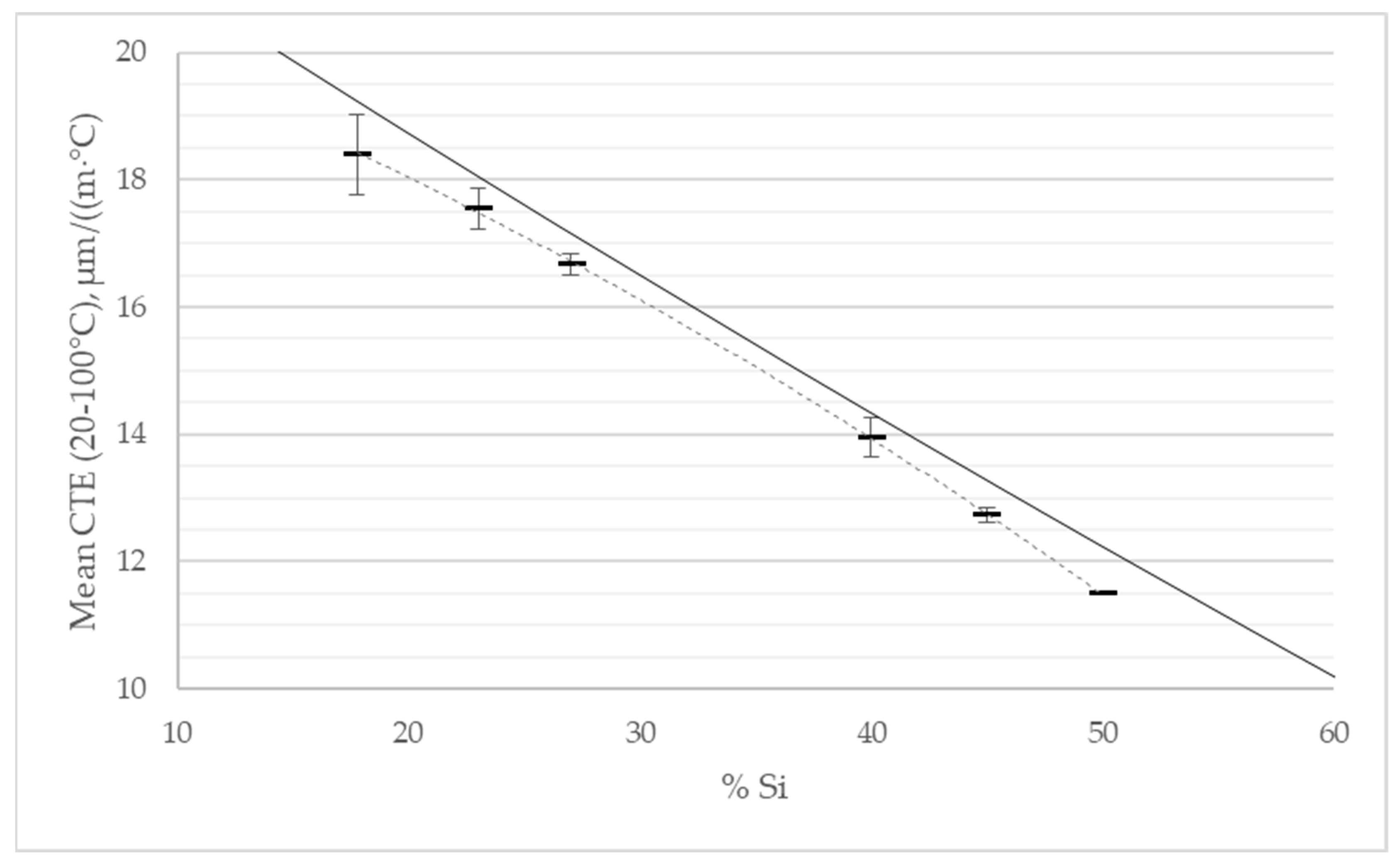

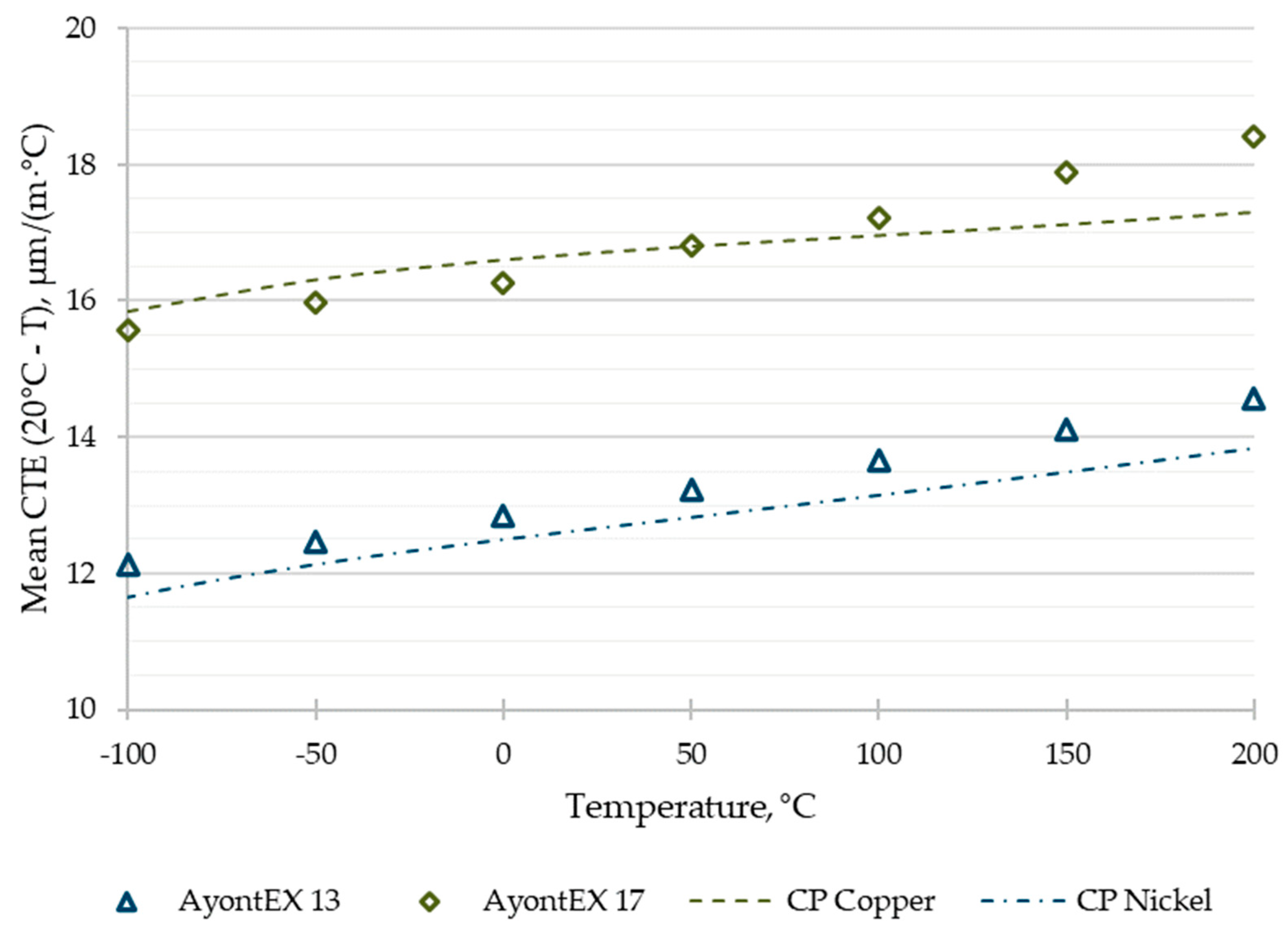

3.2. Coefficient of Thermal Expansion

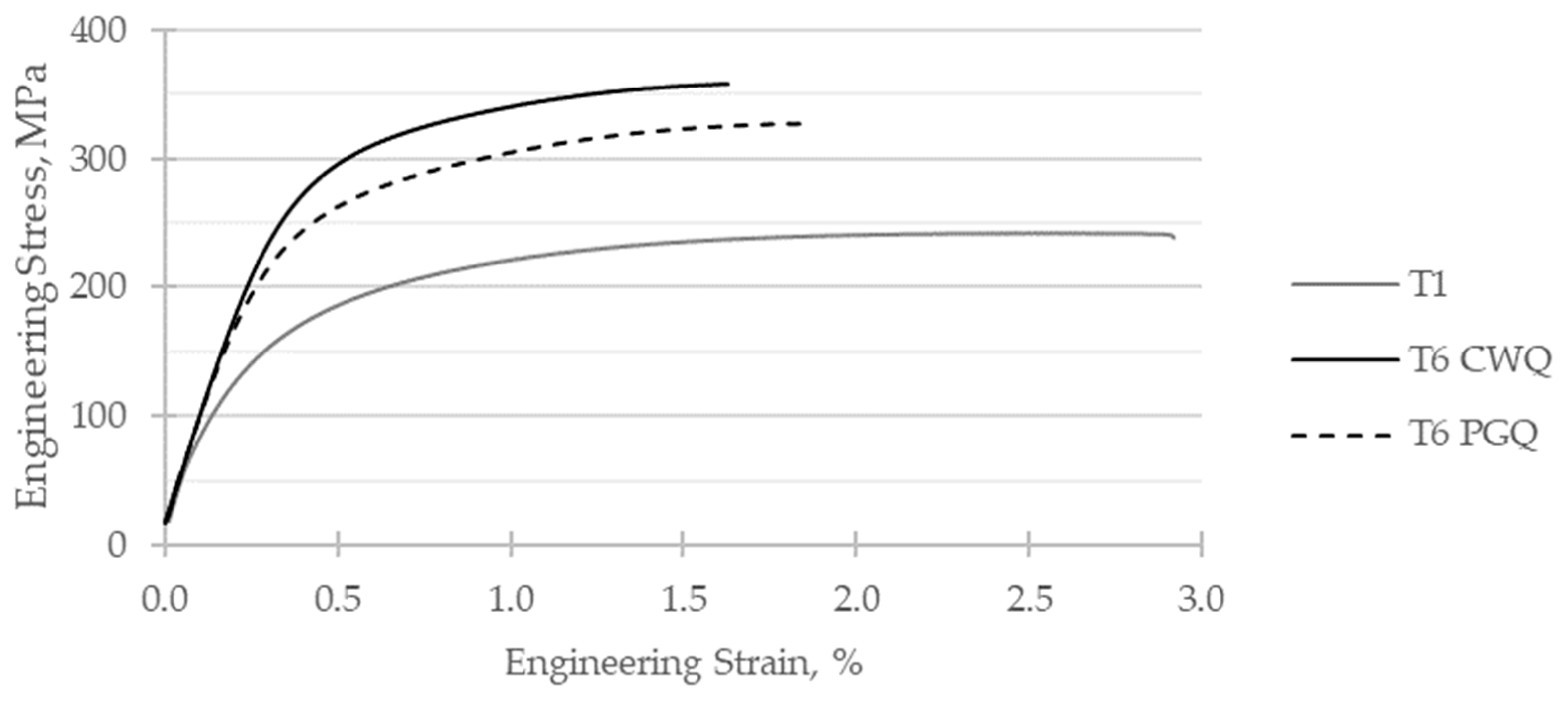

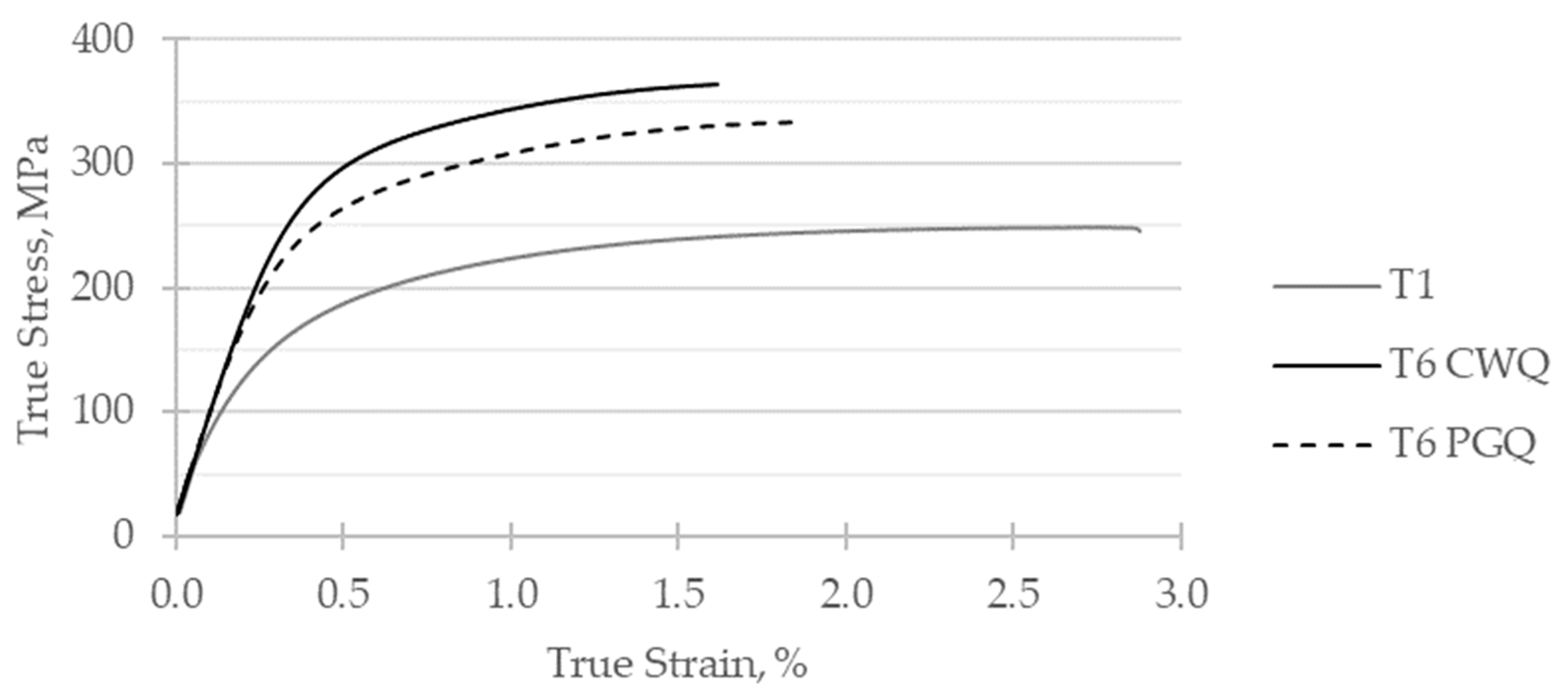

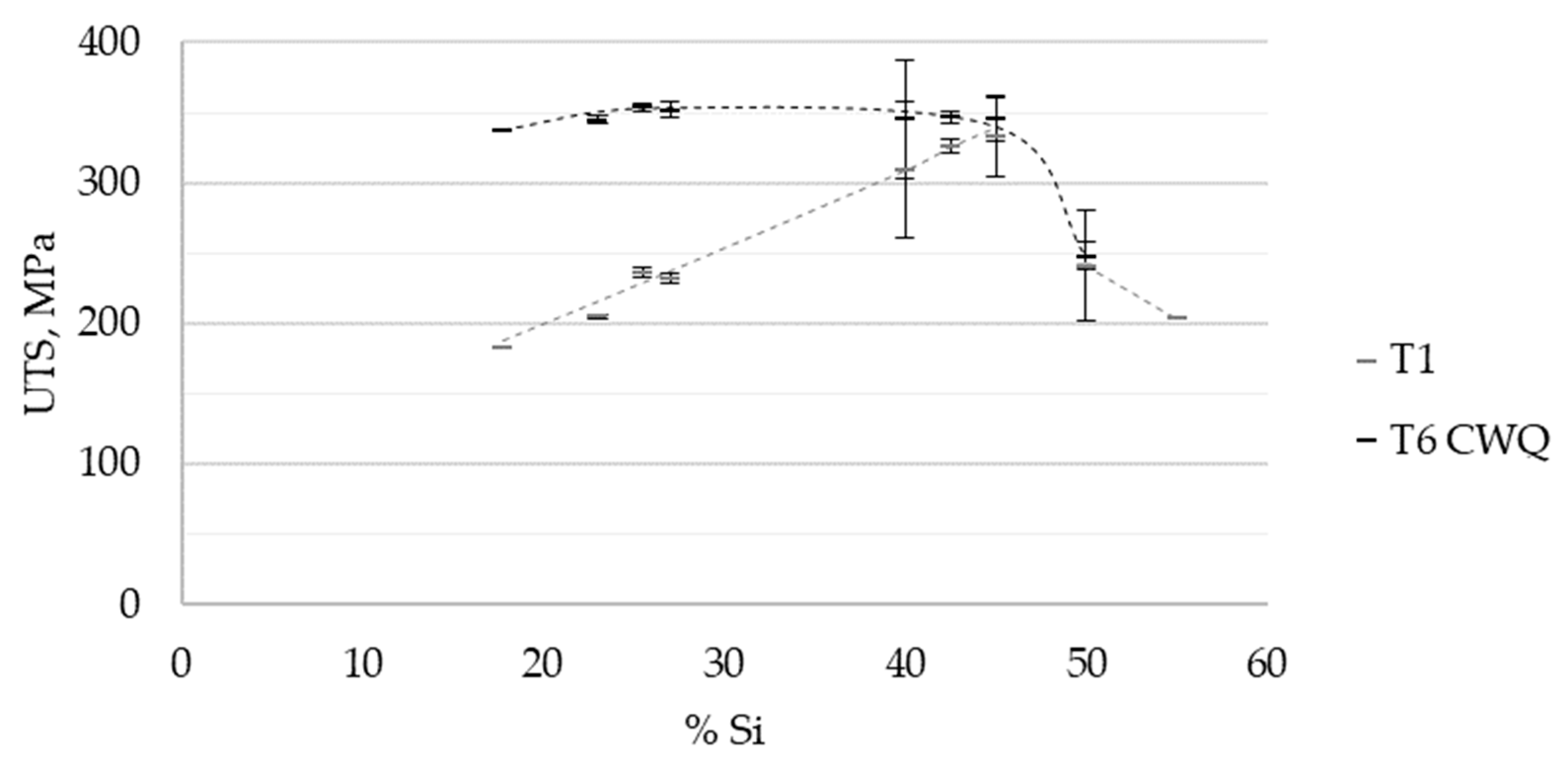

3.3. Additional Physical and Mechanical Properties

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Acreman, M.; Lewis; Farrah, N. Advanced Materials for Defense Applications-Part 2: Thermal Management. 2022. Available online: https://www.materion.com/en/insights/blog/advanced-materials-for-defense-applications-part-2-thermal-management (accessed on 7 May 2024).

- Hibbard, D.L. Electroless Nickel for Optical Applications. Adv. Mater. Opt. Precis. Struct. A Crit. Rev. 1997, 10289, 173–199. [Google Scholar]

- Rohloff, R.-R.; Gebhardt, A.; SchÃjnherr, V.; Risse, S.; Kinast, J.; Scheiding, S.; Peschel, T. A novel athermal approach for high-performance cryogenic metal optics. In Proceedings of the SPIE 7739, Modern Technologies in Space- and Ground-Based Telescopes and Instrumentation, San Diego, CA, USA, 20 July 2010. [Google Scholar]

- Kinast, J.; Grabowski, K.; Gebhardt, A.; Rohloff, R.-R.; Risse, S.; Tünnermann, A. Dimensional Stability of Metal Optics on Nickel Plate AlSi40. In Proceedings of the SPIE 10563 International Conference on Space Optics, Tenerife, Spain, 6–10 October 2014. [Google Scholar]

- Kinast, J.; Tünnermann, A.; Undisz, A. Dimensional Stability of Mirror Substrates Made of Silicon Particle Reinforced Aluminum. Materials 2022, 15, 2998. [Google Scholar] [CrossRef] [PubMed]

- Zhang, R.; Zou, C.; Wei, Z.; Wang, H. Effect of High Pressure and Temperature on the Evolution of Si Phase and Eutectic Spacing in Al-20Si Alloys. Crystals 2021, 11, 705. [Google Scholar] [CrossRef]

- Mostafa, A.; Alshabatat, N. Microstructural, Mechanical and Wear Properties of Al–1.3%Si Alloy as Compared to Hypo/Hyper–Eutectic Compositions in Al–Si Alloy System. Crystals 2022, 12, 719. [Google Scholar] [CrossRef]

- Jiandon, P.; Talangkun, S. Microstructural Modification Hardness and Surface Roughness of Hypereutectic Al–Si Alloys by a Combination of Bismuth and Phosphorus. Crystals 2022, 12, 1026. [Google Scholar] [CrossRef]

- Rosso, M. Ceramic and Metal Matrix Composites: Route and Properties. J. Mater. Process. Technol. 2006, 175, 364–375. [Google Scholar] [CrossRef]

- Ujah, C.O.; Kallon, D.V.V. Trends in Aluminium Matrix Composite Development. Crystals 2022, 12, 1357. [Google Scholar] [CrossRef]

- Kruzhanov, V.; Arnhold, V. Energy Consumption in Powder Metallurgical Manufacturing. Powder Metall. 2012, 55, 14–21. [Google Scholar] [CrossRef]

- Vine, W.J.; Goodwin, P.S. Feasibility of Synthesising Lightweight Nanophase Al Materials by Mechanical Alloying. Mater. Sci. Forum 2000, 331–337, 1145–1150. [Google Scholar] [CrossRef]

- Benjamin, J.S. Mechanical Alloying. Sci. Am. 1976, 234, 40–48. [Google Scholar] [CrossRef]

- Suryanarayana, C.; Al-Aqeeli, N. Mechanically alloyed nanocomposites. Prog. Mater. Sci. 2012, 58, 383–502. [Google Scholar] [CrossRef]

- Narayan, S.; Rajeshkannan, A. Workability behavior of powder metallurgy carbide reinforced aluminum composites during hot forging. Mater. Manuf. Process. 2015, 30, 1196–1201. [Google Scholar] [CrossRef][Green Version]

- Zhou, H.; Zhang, C.; Han, B.; Qiu, J.; Qin, S.; Gao, K.; Liu, J.; Sun, S.; Zhang, H. Microstructures and Mechanical Properties of Nanocrystalline AZ31 Magnesium Alloy Powders with Submicron TiB2 Additions Prepared by Mechanical Milling. Crystals 2020, 10, 550. [Google Scholar] [CrossRef]

- Umeda, J.; Nishimura, N.; Fujii, H.; Jia, L.; Kondoh, K. In-Situ Formed Al3Zr Compounds Reinforced Al Composites and Tribological Application. Crystals 2021, 11, 227. [Google Scholar] [CrossRef]

- Wu, Y.; Luo, S.; Wu, J.; Guo, B.; Wu, Z.; Chen, B.; Yu, Z.; Zhang, Z.; Li, W. Development and Characterization of CrCoNi Medium Entropy Alloy Particles Reinforced Aluminum Matrix Composite. Crystals 2022, 12, 1452. [Google Scholar] [CrossRef]

- Arora, G.S.; Saxena, K.K.; Mohammed, K.A.; Prakash, C.; Dixit, S. Manufacturing Techniques for Mg-Based Metal Matrix Composite with Different Reinforcements. Crystals 2022, 12, 945. [Google Scholar] [CrossRef]

- Ariff, A.M.M.; Lin, O.J.; Jung, D.-W.; Tahir, S.M.; Sulaiman, M.H. Rice Husk Ash as Pore Former and Reinforcement on the Porosity, Microstructure, and Tensile Strength of Aluminum MMC Fabricated via the Powder Metallurgy Method. Crystals 2022, 12, 1100. [Google Scholar] [CrossRef]

- Fan, M.; Zhao, F.; Liu, Y.; Yin, S.; Peng, S.; Zhang, Z. Zinc Matrix Composites Reinforced with Partially Unzipped Carbon Nanotubes as Biodegradable Implant Materials. Crystals 2022, 12, 1110. [Google Scholar] [CrossRef]

- Kushwaha, A.K.; Misra, M.; Menezes, P.L. Effect of Magnesium Dopant on the Grain Boundary Stability of Nanocrystalline Aluminum Powders during Cryomilling. Crystals 2023, 13, 541. [Google Scholar] [CrossRef]

- Sübütay, H.; Şavklıyıldız, İ. Effect of High-Energy Ball Milling in Ternary Material System of (Mg-Sn-Na). Crystals 2023, 13, 1230. [Google Scholar] [CrossRef]

- Yan, Q.; Chen, B.; Zhou, X.; Kondoh, K.; Li, J. Effect of Metal Powder Characteristics on Structural Defects of Graphene Nanosheets in Metal Composite Powders Dispersed by Ball Milling. Crystals 2021, 11, 260. [Google Scholar] [CrossRef]

- Nava-Dino, C.G.; Flores-De los Ríos, J.P.; Maldonado-Orozco, M.C.; Sánchez-Carrillo, M.; Bautista-Margulis, R.G.; Delgado AD, L.C.; Almeraya-Calderón, F. Electrochemical Noise Response of Cr2Nb Powders Applying Mechanical Alloying. Crystals 2022, 12, 482. [Google Scholar] [CrossRef]

- Gharsallah, H.I.; Azabou, M.; Khitouni, M.; Daza, J.; Suñol, J.-J. Study of the Microstructural, Thermal, and Magnetic Properties of High-Energy Ball-Milled Nanocrystalline Fe(Al). Crystals 2022, 12, 1430. [Google Scholar] [CrossRef]

- ASM International. Milling of Brittle and Ductile Materials. In ASM Handbook, Volume 7 Powder Metallurgy; ASM International: Detroit, MI, USA, 2015; pp. 77–87. [Google Scholar]

- Trautmann, M.; Ahmad, H.; Wagner, G. Influencing the Size and Shape of High-Energy Ball Milled Particle Reinforced Aluminum Alloy Powder. Materials 2022, 15, 3022. [Google Scholar] [CrossRef]

- Raducanu, D.; Cojocaru, V.D.; Nocivin, A.; Hendea, R.E.; Ivanescu, S.; Stanciu, D.; Trisca-Rusu, C.; Serban, N.; Drob, S.I.; Campian, R.S. Microstructure Evolution during Mechanical Alloying of a Biodegradable Magnesium Alloy. Crystals 2022, 12, 1641. [Google Scholar] [CrossRef]

- Hashiguchi, D.; Tricker, D.; Tarrant, A. Mechanically Alloyed Aluminum Metal Matrix Composites. In Proceedings of the SPIE 10372 Material Technologies and Applications to Optics Structures Components and Sub-Systems III, San Diego, CA, USA, 5 September 2017. [Google Scholar]

- Frehn, A.; Lewis; Tarrant, A. Partikelverstärkte Aluminium-Werkstoffe für Hochleistungsanwendungen. In Proceedings of the Tagungsband 40. Hagener Symposium, Pulvermetallurgie—Vielfältige Prozesse und Werkstoffe, Hagen, Germany, 25 November 2022; pp. 309–336. [Google Scholar]

- Hashiguchi, D.; Tricker, D.; Tarrant, A.; Campbell, J.; Pokross, C. Discontinuously reinforced aluminum MMC extrusions. Met. Powder Rep. 2017, 72, 252–258. [Google Scholar] [CrossRef]

- Reiff-Musgrove, R.; Gaiser-Porter, M.; Gu, W.; Campbell, J.; Lewis; Frehn, A.; Tarrant, A.; Tang, Y.; Burley, M.; Clyne, T.W. Indentation Plastometry of Particulate Metal Matrix Composites, Highlighting Effects of Microstructural Scale. Adv. Eng. Mater. 2023, 25, 2201479. [Google Scholar] [CrossRef]

- Winter, L.; Hockauf, K.; Lampke, T. Temperature and Particle Size Influence on the High Cycle Fatigue Behavior of the SiC Reinforced 2124 Aluminum Alloy. Metals 2018, 8, 43. [Google Scholar] [CrossRef]

- ASTM International. Standard Test Method for Thermal Diffusivity by the Flash Method, E1461-13. In ASTM Volume 14.01: Quality and Statistics; Hazard Potential of Chemicals; Thermal Measurements; Manufacture of Pharmaceutical and Biopharmaceutical Products; Healthcare Informatics; ASTM International: West Conshohocken, PA, USA, 2022. [Google Scholar]

- Nix, F.C.; MacNair, D. The Thermal Expansion of Pure Metals: Copper, Gold, Aluminum, Nickel and Iron. Phys. Rev. 1941, 60, 597–605. [Google Scholar] [CrossRef]

- Hidnert, P. Thermal Expansion of Copper and Some of its Important Industrial Alloys. Sci. Pap. Bur. Stand. 1921, 17, 91–159. [Google Scholar] [CrossRef]

- Hidnert, P. Thermal Expansion of Some Nickel Alloys. J. Res. Natl. Bur. Stand. 1957, 58, 89–92. [Google Scholar] [CrossRef]

- Bennett, S.J. The thermal expansion of copper between 300 and 700 K. J. Phys. D Appl. Phys. 1978, 11, 777–780. [Google Scholar] [CrossRef]

- Morrell, R. Thermal Properties of Composite Materials-Measurements, Models and Thermal Exposure Derived Changes in MMCs and CMCs; NPL Report CMMT (A) 6; National Physical Laboratory Management Ltd.: Teddington, UK, 1995. [Google Scholar]

- Sergo, V.; Meriani, S. Thermal Expansion and Percolation in a SiC Whisker-Reinforced Ceramic Composite. Mater. Sci. Lett. 1991, 10, 855–857. [Google Scholar] [CrossRef]

- Few, A.; Echols, J. Aluminium metal matrix composites: A capable low-cost mirror substrate. In Proceedings of the SPIE 12677 Astronomical Optics: Design, Manufacture, and Test of Space and Ground Systems IV, San Diego, CA, USA, 4 October 2023. [Google Scholar]

- Sweeney, M.; Colling, S.; Schmidt, J.; Few, A.; Echols, J.; Reardon, P.; Douthit, D.; Farrah, N.; Lewis, P.; Tarrant, A.; et al. Application and Testing of SupremEX® 640XA and AyontEX™ 13 for Mirrors and Precision Structures, In Proceedings of the SPIE 13042 Advanced Optics for Imaging Applications: UV through LWIR IX, National Harbor, MD, USA, 23 April 2024.

- Zhang, K.; Hemeng, Q.; Guan, H.; Zhang, J.; Zhang, X.; Xiaolin, X.; Yan, L.; Wang, C. Design and Fabrication Technology of Metal Mirrors Based on Additive Manufacturing: A Review. Appl. Sci. 2021, 11, 10630. [Google Scholar] [CrossRef]

- Zhang, K.; Xie, X.; Wang, C.; Wang, H.; Xu, F.; Wang, H.; Zhang, X.; Guan, H.; Qu, H.; Zhang, J. Optomechanical Performances of Advanced Lightweight Mirrors Based on Additive Manufacturing. Mircomachines 2022, 13, 1334. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Wang, C.; Qu, H.; Guan, H.; Wang, H.; Zhang, X.; Xie, X.; Wang, H.; Zhang, K.; Li, L. Design and Fabrication of an Additively Manufactured Aluminum Mirror with Compound Surfaces. Materials 2022, 15, 7050. [Google Scholar] [CrossRef] [PubMed]

- Fujimori, Y.; Shimizu, M.; Kurashina, T.; Arai, S. Substrate Thermal Expansion Coefficient Effect on Cracks Induced by the High-heat Treatment of Electroplated Ni-P Films for Power Devices. Mater. Lett. 2023, 350, 134869. [Google Scholar] [CrossRef]

- Murphy, A.; Howard, S.; Clyne, T. Characterisation of severity of particle clustering and its effect on fracture of particulate MMCs. Mater. Sci. Technol. 1998, 14, 959. [Google Scholar] [CrossRef]

- Österreicher, J.; Arnoldt, A.; Gneiger, S.; Kunschert, G. Tolerance of Al–Mg–Si Wrought Alloys for High Fe Contents: The Role of Effective Si. Metall. Mater. Trans. A 2023, 54A, 4472–4480. [Google Scholar] [CrossRef]

| Property | Unit | AyontEX 17 | AyontEX 13 | |

|---|---|---|---|---|

| Composition | - | 6063 + 28% Si | 6063 + 42% Si | |

| Density | g/cm3 | 2.60 | 2.54 | |

| Elastic Modulus | GPa | 87 | 103 | |

| Specific Stiffness | Gpa/g/cm3 | 33 | 41 | |

| Mean CTE | (−100–20 °C) | μm/(m·°C) | 15.6 | 12.1 |

| (20–50 °C) | 16.8 | 13.2 | ||

| (20–100 °C) | 17.2 | 13.7 | ||

| (20–200 °C) | 18.4 | 14.6 | ||

| Thermal Conductivity | W/mK | 160–170 | 134 | |

| Specific Heat Capacity | J/g/K | 0.88 | 0.85 | |

| 0.2% Proof Strength | Mpa | 170–300 | 300–340 | |

| Ultimate Tensile Strength | Mpa | 240–355 | 325–345 | |

| Specific Strength | Mpa/g/cm3 | 92–137 | 128–136 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lewis, P.; Tarrant, A.; Frehn, A.; Grensing, F.; Nicholson, J.; Farrah, N.; Acreman, M. Aluminium-Silicon Lightweight Thermal Management Alloys with Controlled Thermal Expansion. Crystals 2024, 14, 455. https://doi.org/10.3390/cryst14050455

Lewis P, Tarrant A, Frehn A, Grensing F, Nicholson J, Farrah N, Acreman M. Aluminium-Silicon Lightweight Thermal Management Alloys with Controlled Thermal Expansion. Crystals. 2024; 14(5):455. https://doi.org/10.3390/cryst14050455

Chicago/Turabian StyleLewis, Peter, Andrew Tarrant, Andreas Frehn, Fritz Grensing, James Nicholson, Nick Farrah, and Martyn Acreman. 2024. "Aluminium-Silicon Lightweight Thermal Management Alloys with Controlled Thermal Expansion" Crystals 14, no. 5: 455. https://doi.org/10.3390/cryst14050455

APA StyleLewis, P., Tarrant, A., Frehn, A., Grensing, F., Nicholson, J., Farrah, N., & Acreman, M. (2024). Aluminium-Silicon Lightweight Thermal Management Alloys with Controlled Thermal Expansion. Crystals, 14(5), 455. https://doi.org/10.3390/cryst14050455