Abstract

The article outlines findings from a comparative analysis of the effectiveness of doping CeO2 ceramics with a stabilizing additive Y2O3 on alterations in the strength and thermophysical parameters of ceramics under high-temperature irradiation with heavy ions comparable in energy to fission fragments of nuclear fuel, which allows, during high-temperature irradiation, to simulate radiation damage that is as similar as possible to the fission processes of nuclear fuel. During the studies, it was found that the addition of a stabilizing additive Y2O3 to the composition of CeO2 ceramics in the case of high-temperature irradiation causes an increase in stability to swelling and softening because of a decrease in the thermal expansion of the crystal lattice by 3–8 times in comparison with unstabilized CeO2 ceramics. It has been determined that the addition of a stabilizing additive Y2O3 leads not only to a rise in the resistance of the crystal structure to deformation distortions and swelling, but also to a decrease in the effect of thermal expansion of the crystal structure, which has an adverse effect on the structural ordering of CeO2 ceramics exposed to irradiation at high temperatures.

1. Introduction

There is a growing interest in research concerning the advancement of novel forms of nuclear fuel, such as dispersed nuclear fuel, which is based on the technology of placing fissile nuclear material in an inert matrix. This is primarily due to the possibility of expanding methods for processing weapons-grade plutonium, reserves of which are still sufficient in the world today, and its processing is one of the most important and strategic tasks in the field of nuclear energy and the use of atomic energy for peaceful purposes [1,2,3]. The transition to dispersed nuclear fuel will first allow increasing the efficiency of nuclear fuel burnup without the risk of embrittlement of fuel element materials, which is one of the key problems in modern nuclear energy, since traditional alloys and steels do not withstand high-dose loads during long-term operation [4,5]. Also, the use of refractory oxide ceramic materials as a basis for dispersed nuclear fuel is poised to elevate the temperature within the nuclear reactor core, thereby enhancing energy production efficiency and augmenting nuclear fuel productivity. Exploring solutions in the realm of developing materials for dispersed nuclear fuel, along with conducting an extensive investigation into the kinetics of radiation damage and the mechanisms of destruction accompanying the interaction of ionizing radiation with inert matrix materials, stands as a pivotal focus for advancing the nuclear industry [6,7,8]. Solving issues related to increasing the efficiency of nuclear fuel use, reducing the amount of accumulated radioactive waste in the fuel cycle, and expanding the possibilities of using plutonium as nuclear fuel are key tasks in nuclear energy for the coming decades. At the same time, much attention in nuclear energy in recent years has been directed to examination of the radiation damage mechanisms in materials that are candidates for use as inert matrices of dispersed nuclear fuel [9,10].

In turn, studying the stability of these materials, as well as the search for increasing their stability to radiation damage, is the key to expanding new directions in nuclear energy in the field of electricity production using alternative energy sources. The main goal of this work is to determine the mechanisms of radiation damage in inert matrices of dispersed nuclear fuel based on cerium dioxide [11,12], which is considered to be one of the candidate materials in this direction, as well as to determine the proposed mechanisms for increasing the resistance of these ceramics against radiation damage during high-temperature irradiation through the use of stabilizing additives like yttrium oxide (Y2O3), the use of which makes it possible to increase the operating efficiency of inert matrices by reducing the degree of radiation damage under high-dose irradiation [13,14,15]. As is known, cerium dioxide (CeO2) is often used in ceramic materials due to its excellent properties such as high chemical stability, high density, and thermal conductivity. In the context of nuclear power, these properties make it potentially suitable for use as an inert matrix of dispersed nuclear fuel, which consists of small particles of nuclear material (for example, uranium or plutonium oxide) dispersed in an inert matrix [16,17,18]. This helps to increase the safety of nuclear fuel, since the matrix helps prevent diffusion of radioactive products and heat release into the environment. Ceramic inert matrices based on cerium dioxide can be especially useful in this case, since they are highly resistant to radiation damage and chemical corrosion, which makes them attractive for use under conditions of extreme radiation exposure in nuclear reactors, including irradiation with heavy ions akin to fission fragments [19,20,21,22].

2. Materials and Methods

CeO2 ceramics doped with Y2O3 at a concentration of 0.15 M were chosen as objects for study, the selection of which was based on a potential to achieve a well-crystallized phase [23]. All initial reagents used to obtain microparticles were purchased from Sigma Aldrich, St. Louis, MO, USA, with a chemical purity of 99.95%. The selected synthesis method involved solid-phase synthesis coupled with thermal annealing. The reagents were ground in a specific stoichiometric ratio in a planetary mill using a tungsten carbide beaker. Grinding took place for 1 h at a speed of 500 rpm, chosen experimentally to ensure homogeneous structures. Subsequently, the resulting powders underwent annealing in a muffle furnace at 1100 °C in an oxygen-containing atmosphere for 8 h, followed by cooling to room temperature over 24 h with the furnace. The ceramic samples used for irradiation were prepared as tablets with diameters of 10 mm and a thickness of about 15 μm in order to conduct irradiation experiments in such a way as to achieve the maximum effect of structural changes in the damaged layer comparable to the thickness of the samples, as well as to avoid the contribution of a large proportion of the non-irradiated sample to the determined values of swelling and alterations in strength and thermophysical parameters.

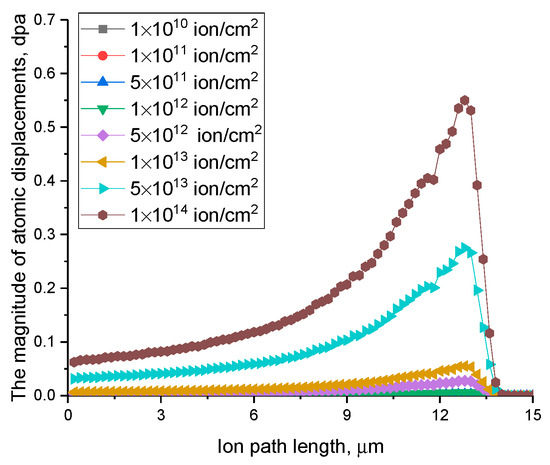

The study of the radiation resistance of CeO2 ceramics stabilized with Y2O3 was carried out with Xe22+ ions with fluences from 1010 to 1014 ion/cm2 at temperatures of 500, 700, and 1000 K. The maximum irradiation time at a fluence of 1014 ion/cm2 was about 200 h. Irradiation of the samples was carried out at the heavy ion accelerator DC-60, located in the Astana branch of the Institute of Nuclear Physics of the Ministry of Energy of the Republic of Kazakhstan. Irradiation was carried out with Xe22+ ions with an energy of about 230 MeV (1.75 MeV/nucleon). The charge of the ions was controlled by selecting optimal acceleration parameters (magnetic field strength), based on determining the type of accelerated ions using mass spectroscopy. Radiation dose monitoring was carried out using a recording system based on the use of Faraday cups. Using the SRIM Pro software code-2013, it was found that the maximum ion path length in the selected ceramic types was about 13–15 μm, and the ionization loss values during the interaction of ions with electron shells (dE/dxelectron) was about 23–23.5 keV/nm, and nuclei (dE/dxnuclear) was about 1.1–1.2 keV/nm. When calculating the simulation of the values of ionization losses of binding energy, about 25 eV were chosen for the Ce and Y elements, and about 28 eV for the O element. These values were selected based on tabular data in the SRIM Pro program. Taking into account the fact that the values of ionization losses are quite large, and the binding energies in the structure are of the order of 25–28 eV, during the interaction of incident ions, effects associated with the displacement of atoms from their positions are possible. The choice of irradiation conditions was determined by the ability to simulate conditions closely resembling the actual operating conditions of ceramics in the nuclear reactor core. At the same time, the irradiation fluences were chosen, taking into account the possibility of simulation of the radiation-induced damage formation processes in ceramics, both in the case of the formation of single damaged areas that arise when incident ions pass through the material at low fluences, and when these areas overlap in the case of high-dose irradiation. For the purpose of possible comparison of the observed changes caused by irradiation with heavy ions with other types of irradiation (for example, neutron irradiation), all changes are presented as dependences on the magnitude of atomic displacements (dpa). The value was calculated according to the method proposed in [22], in which the authors, using calculated data from the SRIM Pro program code, calculated the dependence of the change in the magnitude of atomic displacements along the ion motion trajectory, alongside contingent upon the irradiation fluence. The assessment results are revealed in Figure 1. To analyze variations in structural, strength, and thermophysical parameters, the maximum dpa value was used.

Figure 1.

Dependence of changes in the atomic displacement values upon irradiation with heavy Xe22+ ions along the trajectory of ion motion.

High-temperature irradiation of samples was conducted by placing the samples on a special holder equipped with a thermocouple to control the temperature of the sample, as well as heating elements, with the help of which the samples are heated before irradiation and subsequently maintain the selected temperature regime during the entire irradiation. The process of high-temperature irradiation itself consists of placing the sample on a holder, evacuating the irradiation chamber, heating the sample to a given temperature, stabilizing the sample in order to establish a constant temperature, irradiating the sample under constant heating at a given temperature, and cooling the sample for 15–20 h after irradiation together with the chamber under vacuum, in order to avoid sudden oxidation processes when removing heated samples to air. The heating time of the samples depended on the final temperature to which it was necessary to heat the samples (500, 700, and 1000 K) and was controlled with the heating rate, which was 20 K/min. The temperature of 500, 700, or 1000 K was maintained using a heater during the entire irradiation time, which made it possible to combine the influence of temperature exposure and radiation damage caused by irradiation on changes in the properties of the samples. Cooling of the samples after irradiation was carried out identically for all samples together with the irradiation chamber, without access to the atmosphere, until the temperature in the chamber reached room temperature. This procedure was performed to exclude the effects of possible oxidation processes during the interaction of heated samples with the atmosphere.

Ceramic strength tests were conducted using the indentation method, utilizing a LECO LM700 microhardness tester (LECO, Tokyo, Japan). Hardness values were determined using a Vickers diamond pyramid, applying a load of 1 kN. To ensure measurement accuracy and assess error margins, tests were performed consecutively, ranging from 15 to 20 consecutive tests, to determine hardness values and the geometry of resultant indenter prints. Simultaneously, measurements were taken at intervals exceeding 10 microns from each other to mitigate the influence of cracking and deformation distortions near the prints.

Determination of the degree of softening of ceramic samples depending on the degree of radiation damage accumulation in the near-surface layer when irradiation conditions changed was conducted by comparing alterations in the hardness values of ceramics before and after irradiation, followed by calculating their ratio as a percentage (the percentage of decrease in hardness during irradiation of the samples).

The determination of thermophysical parameters and their alterations was carried out applying the method of measuring longitudinal heat flow in the temperature range of 25–700 °C, based on alterations in which the thermal conductivity coefficient was determined. These measurements were performed using the KIT-800 device (Teplofon LLP, Novomoskovsk, Russia). This method is based on measuring changes in the thermal conductivity values of the material on both sides of the sample using thermocouples, which make it possible to evaluate heat transfer mechanisms, and, as a result, determine the kinetics of changes in the thermophysical parameters of the studied ceramics exposed to irradiation.

Based on the obtained values of changes in the thermal conductivity coefficient depending on variations in irradiation conditions, the values of heat losses were calculated, reflecting the deterioration of the thermal conductivity properties of ceramics depending on structural damage and their accumulation with increasing irradiation fluence.

3. Results and Discussion

One crucial criterion regarding the applicability of oxide ceramics as materials for dispersed nuclear fuel inert matrices is their resistance to high-temperature irradiation, which is typical for fuel operating conditions in real conditions. In this case, the processes of accumulation of radiation damage are influenced not only by deformation processes occurring while incident ions interact with the crystal lattice of the ceramic material, but also by factors associated with the thermal expansion effect of the crystal lattice, which are caused by alterations in the thermal vibration amplitude of atoms. The combination of these changes can lead to a significant change in the kinetics of softening processes and destructive changes in the properties of ceramics under high-dose irradiation. Also, these effects should be considered when assessing the applicability of these types of ceramics and determining their threshold values at which these ceramics are not able to be used in the future. Also, an important role in changing resistance to external influences during high-temperature irradiation is played by stabilizing additives, the addition of which is primarily due to the need to reduce the effects of thermal expansion and destabilization of the crystal structure under external influences. In this context, to investigate the radiation damage accumulation mechanisms in ceramics and to assess the impact of a stabilizing additive on radiation damage resistance under heavy Xe22+ ion irradiation, the following experiments were conducted.

Ceramics samples were irradiated with Xe22+ ions with an energy of 230 MeV and fluences from 1010 to 1014 ion/cm2 at temperatures of 500, 700, and 1000 K, the selection of which was based on the ability to simulate radiation damage processes under conditions closely resembling the operating conditions of nuclear fuel; the type of ions is due to the ability to simulate radiation damage akin to the effects of fission fragments from nuclear fuel. As ceramic samples, in order to determine the effect of a stabilizing additive on radiation damage resistance when irradiation conditions change, samples of CeO2 and CeO2 stabilized with 0.15 M Y2O3 obtained using mechanochemical grinding were selected. The choice of the concentration of the stabilizing additive was determined by the results of previous studies presented in [23], according to which the use of this concentration of 0.15 M led to maximum efficiency in increasing the ceramics’ strength properties, alongside maintaining their strength properties.

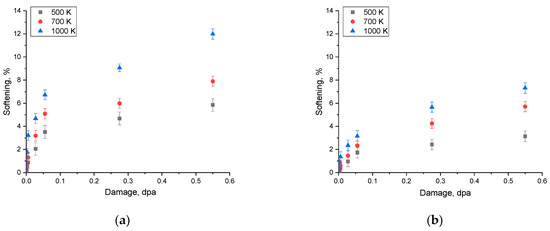

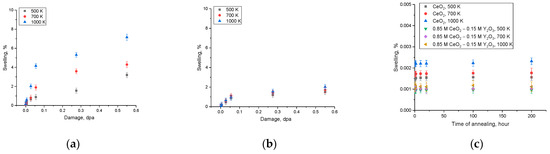

Figure 2 demonstrates the results of changes in the hardness of ceramics in the case of irradiation with heavy Xe22+ ions with a variation in the irradiation fluence, as well as varying the irradiation temperature. The data are presented in the form of a dependence of hardness on the magnitude of atomic displacements (displacements), reflecting the degree of accumulation of radiation-induced damage in the near-surface layer. Hardness measurement data were carried out in the form of serial measurements (at least 10 measurements per sample) covering the entire surface of the ceramics in different places in order to determine the uniformity of strength changes. Based on the obtained values, measurement errors and standard deviations were determined.

Figure 2.

Results of alterations in strength characteristics with varying irradiation conditions (temperature and fluence): (a) CeO2 ceramics; (b) 0.85 M CeO2–0.15 M Y2O3 ceramics. (c) Results of changes in the hardness of samples of CeO2 and 0.85 M CeO2–0.15 M Y2O3 ceramics, obtained during thermal annealing, for a time characteristic of the irradiation time with different fluences.

The overall appearance of the provided dependences of hardness value alterations of ceramic samples depending on variations in irradiation conditions indicates a significant influence of changes in irradiation temperature on a decline in the hardness of samples, especially with high-dose irradiation (in the case of displacement values of more than 0.01 dpa). At low irradiation fluences, the change in hardness is practically not observed for irradiation temperatures of 500 K and 700 K and is more pronounced at temperatures of 1000 K, which indicates a higher rate of degradation of ceramics at elevated temperatures.

It should also be noted that in the case of ceramics with the addition of a stabilizing additive, changes in hardness are less pronounced, which indicates a positive effect of the stabilizer on increasing resistance to softening. However, it should also be noted that in the case of 0.85 M CeO2–0.15 M Y2O3 ceramics, an increase in irradiation temperature from 500 K to 700 K has a more pronounced effect on the change in hardness than in the case of un-doped CeO2 ceramics. This difference can be explained by thermal effects associated with alterations in the structural characteristics of ceramics, alongside variations in the mobility of point and vacancy defects in the structure of the damaged layer when irradiation conditions change. In turn, the absence of notable alterations in hardness at irradiation fluences of 1010–1012 ion/cm2 indicates that softening is most influenced by the cumulative effect of structural distortions, which manifests itself in the event of the formation of overlapping defective areas in the damaged layer structure (generally, similar effects are observed at fluences higher than 1012 ion/cm2). Changes in hardness observed at fluences above 1012 ion/cm2 are due to the effects of accumulation of structural distortions and deformation stresses arising in the structure of the damaged layer due to the formation of point and vacancy defects, an increase in the density of which results in crystal lattice deformation swelling, and, as a consequence, deformation of the entire damaged layer through the occurrence of additional tensile residual mechanical stresses. It should also be noted that the most pronounced changes in hardness associated with the processes of softening and destabilization of strength properties are observed with irradiation temperature growth. It follows from this that the main effect on the deterioration of strength properties is exerted by the temperature effect during irradiation. At the same time, the data presented in Figure 2c, reflecting the change in hardness of samples of non-irradiated ceramics subjected to thermal annealing at temperatures of 500–1000 K for a time comparable to the irradiation time, show that the change in hardness is of the order of 0.1–0.2% for CeO2 ceramics and 0.06–0.17 for 0.85 M CeO2–0.15 Y2O3 ceramics after 200 h of thermal annealing (the time corresponding to the maximum irradiation time). The obtained values of changes in hardness for non-irradiated samples indicate that the thermal effect on samples without radiation exposure (irradiation with heavy ions) does not have a significant effect on the softening of ceramics, and also indicates a fairly high resistance of the selected oxide ceramics to thermal annealing. From this, we can conclude that irradiation with heavy ions, and, as a consequence, the accumulation of deformation damage and distortions associated with the interaction of ions with the crystal lattice, is the main factor influencing the deterioration of the strength properties of ceramics. At the same time, a more pronounced manifestation of the softening effects (the decrease in hardness) of samples during irradiation at high temperatures can be explained by the influence of a combination of factors including thermal broadening of the crystal structure, leading to more intense damage.

In this case, the explanation for the softening effect can be explained by thermal effects associated with a variation in the vibration amplitude of crystal lattice atoms during heating, alongside an increase in their mobility, which, under external deformation influences, leads to large structural changes, as well as distortions of the crystal lattice. Such effects can be more pronounced when the effects of overlapping structurally altered defective areas are achieved, an increase in the concentration of which leads to accelerated destruction of the damaged layer.

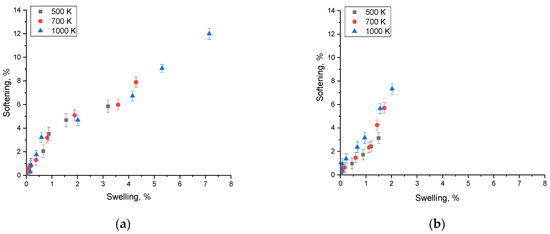

Figure 3 reveals the evaluation results of softening value alteration, reflecting changes in hardness values with varying irradiation conditions (temperature and irradiation fluence).

Figure 3.

Assessment results of the ceramics’ softening value with varying irradiation conditions (temperature and fluence): (a) CeO2 ceramics; (b) 0.85 M CeO2–0.15 M Y2O3 ceramics.

The general appearance of the presented dependences of the change in the value of softening indicates two factors influencing the change in strength characteristics: (1) the accumulation effect of structurally deformed inclusions in the damaged layer, and (2) the temperature effect associated with an increase in the mobility of defects in the structure of the damaged layer and acceleration of the processes of destruction and disorder. Moreover, comparing the presented dependences of alterations in softening values and hardness values for two types of ceramics, CeO2 and 0.85 M CeO2–0.15 M Y2O3, we can conclude that the addition of a stabilizing additive leads not only to an increase in hardness in the initial state, but also a more than 1.5–2-fold softening resistance growth with varying irradiation conditions (changes in temperature and irradiation fluence).

A general analysis of the presented dependences of changes in the value of softening (variations in the surface layer hardness and strength) indicates that the most pronounced changes are observed in the event of high-dose irradiation (at fluences more than 1012 ion/cm2), which, as stated above, is characteristic of the formation of overlap effects of structurally deformed areas during irradiation. In this case, we can conclude that at low irradiation fluences (1010–1012 ion/cm2), the isolation of structurally deformed inclusions in the damaged ceramic layer does not have a notable effect on the variation in strength properties, both due to its isolation and due to the low concentration of point and vacancy defects, which, if isolated, cannot form more complex structural defects. When structurally deformed inclusions come closer together due to an increase in irradiation density, these defects can begin to interact with each other, which leads to an increase in structural distortions and deformations in the damaged ceramic layer; additionally, due to the effect of thermal expansion (occurring with increasing irradiation temperature), these structural distortions become more pronounced. At the same time, for 0.85 M CeO2–0.15 M Y2O3 ceramics, the degree of softening in comparison with CeO2 ceramics is significantly less (more than 1.5–2 times at maximum irradiation fluences), which indicates not only a higher resistance of ceramics to softening, but also an increase in stability to temperature effects leading to deformation swelling.

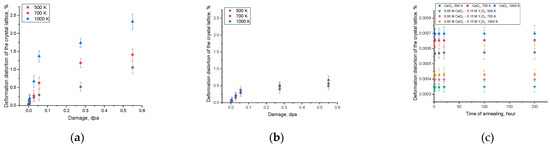

One of the factors responsible for the softening of ceramics is deformation distortion of the crystal lattice, causing an alteration in its volume as a result of the radiation damage accumulation, and, as a consequence, increases the occurrence of deformation distortions, of which the processes of partial amorphization can be initiated when at a high concentration. Strain distortions caused by irradiation, as a rule, are tensile in nature (tensile deformations), the appearance of which is associated with distortion of the crystal lattice as a result of the formation of primary knocked-out atoms, the migration of which leads to penetration into interstices, as well as the formation of additional vacancies. The assessment of the deformation distortion of the crystal lattice, in the case of a cubic type, is determined by the change in the parameter of the crystal lattice in comparison with the initial values, and the nature of the crystal lattice deformation distortion is considered isotropic in all directions (since the cubic type of crystal lattice is characterized by changes in one parameter). Moreover, in contrast to changes in strength parameters, which are most pronounced in the case of high-dose irradiation, deformation distortion of the crystal lattice can be determined both in the case of low fluences (which are characterized by the formation of structurally isolated defective inclusions) and in the case of high-dose irradiation, which leads to the formation of overlapping effects of structurally distorted defective inclusions. The assessment results of the structural deformation distortions of the crystal lattice contingent upon the irradiation fluence (the atomic displacement values arising during irradiation) are presented in Figure 4. Also, Figure 4c presents measurement data of deformation distortions of unirradiated ceramic samples subjected to thermal annealing for a time characteristic of irradiation with heavy ions with different irradiation fluences. According to the data obtained, changes in the magnitude of the deformation distortion of the crystal lattice have a small dependence on the annealing temperature (i.e., a slight increase in the deformation of the structure under thermal influence is observed). At the same time, the value of the crystal lattice deformation as a result of thermal exposure without irradiation, in comparison with changes caused by irradiation, is less than 0.1%, which indicates that the main deformation distortions are caused by radiation exposure.

Figure 4.

Results of deformation distortions of the crystal lattice with increasing irradiation fluence and irradiation temperature: (a) CeO2 ceramics; (b) 0.85 M CeO2–0.15 M Y2O3 ceramics. (c) Results of deformation distortion of the crystal structure of CeO2 and 0.85 M CeO2–0.15 M Y2O3 ceramics, obtained during thermal annealing for a time characteristic of irradiation time with different fluences.

As is evident from the presented data on changes in the magnitude of deformation distortions of the crystal lattice for the studied samples of CeO2 and 0.85 M CeO2–0.15 M Y2O3 ceramics, the general trend of changes in the value of deformation distortions indicates the occurrence of tensile deformation stresses in the composition of the ceramics, the concentration of which increases in the damaged layer with increasing irradiation fluence. Moreover, in the case of CeO2 ceramics, these deformation distortions become most pronounced at fluences above 1012 ion/cm2, which are characterized by the formation of areas of overlapping defects in the structure of the damaged layer. For low irradiation fluences, deformation distortions amount to less than 0.3%, signifying a considerable resistance of CeO2 ceramics to low-dose irradiation associated with the formation of isolated structural changes. Moreover, the change in irradiation conditions associated with variations in irradiation temperature is most pronounced at a temperature of 1000 K, in which case the value of deformation distortion at high irradiation fluences is about 1.5–2.5%, which indicates a strong structural distortion of the crystal lattice, as well as pronounced deformation swelling. This increase can be explained by the temperature effects of thermal expansion of the crystal lattice, which is accompanied by a change in the amplitude of vibrations of atoms in the lattice, which leads to an increase in their mobility and, in the case of external deformation distortions and additional thermal effects associated with transformation processes of the transferred kinetic energy of ions into thermal energy, to additional structural distortions of the crystal structure.

In the case of 0.85 M CeO2–0.15 M Y2O3 ceramics, the alteration in crystal lattice deformation distortions is no more than 0.5–0.6% at the maximum irradiation fluence, which is more than 2–3 times less than for unstabilized CeO2 ceramics, which in turn indicates a high structural resistance to deformation due to the stabilizing additive.

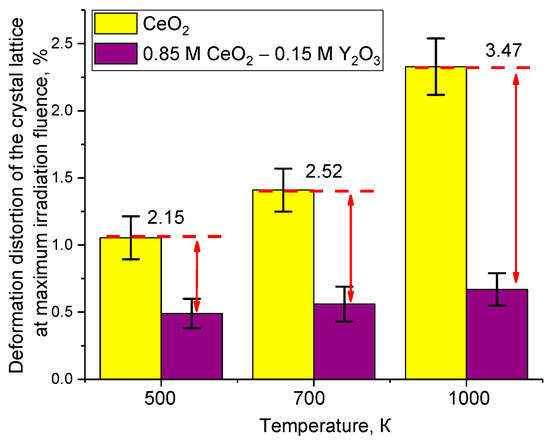

Figure 5 reveals the findings from a comparison of the crystal lattice deformation distortion values at maximum irradiation fluence for two types of ceramics, which reflects the effectiveness of increasing the resistance to deformation of the crystalline structure of ceramics when a stabilizing additive Y2O3 is added to them.

Figure 5.

Results of a comparative analysis of changes in the deformation distortion of the crystal lattice at maximum irradiation fluence (dotted lines and lines with arrows indicate the difference in changes in the crystal lattice deformation distortion value of the samples (numbers above the dotted lines) in comparison between CeO2 and 0.85 M CeO2–0.15 Y2O3 ceramics).

As is evident from a comparative analysis of the maximum value of crystal lattice deformation distortions, a rise in the irradiation temperature from 500 to 1000 K leads to an increase in the resistance of ceramics with the addition of a stabilizing additive Y2O3 to deformation and disorder [24]. This is expressed in the difference in deformation distortion, which is more than 2.1 times for irradiation temperatures of 500 K, 2.5 times for irradiation temperatures of 700 K, and more than 3.4 times for temperatures of 1000 K. It should be noted that the differences in the maximum crystal lattice deformation distortion value, in the case of CeO2 ceramics when changing irradiation conditions (irradiation temperature), are much more pronounced than for 0.85 M CeO2–0.15 M Y2O3 ceramics, for which an increase in irradiation temperature leads to a slight increase in deformation distortions. This increase in deformation distortions for 0.85 M CeO2–0.15 M Y2O3 ceramics is about 10–25%, while for CeO2 ceramics, this increase is about 30% when the temperature increases from 500 to 700 K, and more than 120% for a temperature of 1000 K compared to irradiation at a temperature of 500 K. Based on the obtained data on changes in the value of strain distortion for two types of ceramics, CeO2 and 0.85 M CeO2–0.15 M Y2O3, we can conclude that the addition of a stabilizing additive, Y2O3, to the composition of ceramics not only leads to a reduction in strain distortion by more than 2 times compared to the values for unstabilized CeO2 ceramics, but also leads to an increase in stability to the thermal effects of disorder, which most clearly manifest themselves at irradiation temperatures of 1000 K.

The assessment results of variations in the crystal lattice volume of ceramic samples under study which are contingent upon variations in irradiation conditions (temperature and fluence) are presented in Figure 6. The assessment of changes in the swelling value of ceramics was determined using a comparative analysis of the alteration in the crystal lattice volume before and after irradiation, which made it possible to determine not only the swelling value, but also the type of deformation distortion of the crystal structure.

Figure 6.

Results of changes in volumetric swelling of the crystal lattice of ceramics depending on variations in irradiation conditions (changes in fluence and irradiation temperature): (a) CeO2 ceramics; (b) 0.85 M CeO2–0.15 M Y2O3 ceramics. (c) Results of swelling of samples of CeO2 and 0.85 M CeO2–0.15 M Y2O3 ceramics, obtained during thermal annealing for a time characteristic of the irradiation time with different fluences.

The general appearance of the presented dependences of crystal lattice swelling, calculated on changes in its volume depending on the atomic displacement value, implies deformation distortion of the crystal structure of CeO2 ceramics at high irradiation doses. Moreover, a change in irradiation conditions, i.e., an increase in the irradiation temperature, results in a sharp increase in the swelling of the crystal structure, which indicates thermal instability of the crystal lattice, associated both with deformation distortions during irradiation and thermal expansion, and an increase in the amplitude of vibrations of atoms in the crystal lattice. Moreover, in the case of CeO2 stabilized ceramics, swelling is more than 2.5–3 times less, and changes in irradiation temperature do not lead to significant differences in the swelling values of the crystal structure. At the same time, the data presented in Figure 6c on the change in the amount of swelling of the crystal structure of non-irradiated ceramic samples during thermal annealing for a time characteristic of irradiation indicate a small influence, less than 1%, of the thermal effect on the volumetric change in the crystal lattice in comparison with the initial values.

The very effect of volumetric swelling of the crystal structure, which manifests itself at high doses of radiation, especially for unstabilized CeO2 ceramics irradiated at a temperature of 1000 K, can be explained as follows [25,26]. In the case of low irradiation fluences, structurally isolated defective areas do not have significant changes in the volumetric increase of the crystal lattice, since they are presented in low concentration, and their sizes are on the order of 5–10 nm in diameter (according to the assessment of the radii of damaged areas that arise when heavy ions pass through the material) [27,28]. In this case, the presence of such inclusions in the total volume of the irradiated layer, at low irradiation fluences, does not have seriously significant changes on the volume of the crystal lattice, which in turn is characterized by insignificant changes in the amount of swelling. With a rise in irradiation fluence, and as a consequence, the convergence of structurally isolated defective areas associated with an increase in their density in the damaged layer, the effect of overlapping of similar areas occurs, which in turn leads to the formation of more complex defects, including clusters, dislocation loops, as well as inclusions in the form of amorphous disordered regions. An increase in the concentration of such radiation-induced damage leads to an increase in deformation tensile stresses exerting pressure on the crystal lattice, which subsequently leads to an increase in its volume and the displacement of excess volume in the form of voids inside the damaged layer and hillock-like formations on the surface of the ceramic. In this regard, an increase in the concentration of crystal structure deformation distortions results in the emergence of metastable regions saturated with deformation stresses, which, under external influences, can lead to destructive destruction and deterioration of strength properties.

A stabilizing additive in the form of Y2O3 [24], according to the data obtained, results in a reduction in the crystal lattice swelling value, and, as shown in Figure 5, to a significant increase in resistance to swelling and destruction with the accumulation of deformation distortions. This effect can be explained by the fact that the addition of Y2O3 leads to partial replacement of cerium by yttrium ions, which, according to the assessment of structural parameters, leads to a decrease in its volume and, as a consequence, higher structural order of the crystal lattice in the initial state, as well as a decrease in the number of vacancy defects in the composition of ceramics that are filled with yttrium. In this case, deformation distortions of the crystal structure for stabilized ceramics are less pronounced, and the temperature effect is less pronounced for high-dose irradiation.

To determine the influence of the factors of the effect of thermal expansion of the crystal lattice, which occurs during thermal heating of samples, on the change in structural characteristics and softening of samples as a result of the radiation damage accumulation, a number of experimental works were carried out. These experimental works consisted of determining changes in structural parameters (in particular, changes in the volume of the crystal lattice of the samples) under long-term thermal exposure, the time of which corresponded to the time of irradiation of the samples when the maximum irradiation fluence was reached (about 200 h). The thermal annealing temperature was chosen according to the irradiation conditions of the samples. Annealing was carried out in a vacuum in order to avoid the effects of oxidation and oxygen diffusion when ceramics interact with the atmosphere during annealing.

Determination of the coefficient of volumetric thermal expansion () due to prolonged thermal heating at various annealing temperatures for both types of samples under study was performed using Equation (1) [29]:

where:

- Vinitial—the crystal lattice volume in the original state before heating;

- ∆V—the crystal lattice volume alteration as a result of thermal expansion when heated to a certain temperature;

- ∆T—temperature difference during heating.

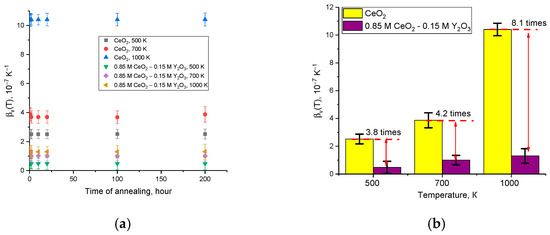

Figure 7 demonstrates the calculation results of the value for two types of ceramics in the initial state after thermal annealing in the range of times characteristic of irradiation with heavy ions with different irradiation fluences. The choice of sample heating time is determined by the irradiation time with the maximum irradiation fluence, during which the samples are exposed to both temperature and irradiation. At the same time, test experiments, determining the change in the value depending on time, comparable to the irradiation times, revealed the absence of any significant alterations in the value when changing the annealing time. The main changes in the value are comparable both after 1 h of annealing and after 200 h (see data in Figure 7a).

Figure 7.

(a) Results of changes in the value depending on the time of thermal annealing. (b) Results of evaluation of the of value after thermal annealing for about 200 h at different temperatures.

As is evident from the presented data on the value obtained at different annealing temperatures, for CeO2 ceramics, an elevation in the annealing temperature results in a substantial growth in the coefficient , the change of which is more than four times when the temperature increases from 500 K to 1000 K. In the case of stabilized ceramics, the change in the with growing annealing temperature is insignificant, and is less than 1.5 times when the annealing temperature changes from 500 to 1000 K. At the same time, a comparative analysis of data for two ceramics depending on the annealing temperature indicates a growth in stability to thermal volumetric expansion of the crystal structure of stabilized ceramics in comparison with CeO2 ceramics that do not contain a stabilizing additive. These values of indicate a clear influence of thermal expansion of the crystal lattice on the kinetics of deformation distortions resulting from irradiation, especially for unstabilized CeO2 ceramics, which leads to a significant change in the concentration of deformation distortions and swelling of the crystal lattice, which is most pronounced at high irradiation temperatures.

One of the explanations for the strong softening of ceramics with the radiation damage accumulation for high-temperature irradiation may be a sharp increase in the deformation distortion concentration leading to crystal lattice swelling in the damaged layer. Figure 8 presents data from a comparative analysis of alterations in the amount of softening of the near-surface layer of ceramics (based on the results of variations in the hardness of irradiated samples) from the amount of structural swelling (the crystal lattice volume growth). This dependence reflects the influence of structural swelling and associated deformation processes in the crystal structure, caused by irradiation and the radiation damage accumulation, on alterations in the strength characteristics of ceramics in the event of varying irradiation conditions.

Figure 8.

Results of a comparative analysis of variations in the value of softening depending on the structural swelling of the crystal lattice of ceramics with varying irradiation conditions (changes in fluence and irradiation temperature): (a) CeO2 ceramics; (b) 0.85 M CeO2–0.15 M Y2O3 ceramics.

As is evident from the data presented, the general trend of alterations in the softening degree (hardness) of ceramics has a clear dependence on the volumetric swelling of the crystal lattice, which is most pronounced for unstabilized CeO2 ceramics. At low irradiation fluences, which are characterized by the formation of locally isolated structural distortions, and as a consequence of small variations in the crystal lattice volume, the effect on the softening of ceramics is weakly expressed. In the case of an increase in irradiation fluence leading to the accumulation of structurally deformed inclusions in the damaged layer, and, consequently, the formation of metastable inclusions containing a high concentration of deformation distortions, leading to an increase in volumetric swelling, the change in hardness becomes maximum. Moreover, this effect is most pronounced at high irradiation temperatures (700 and 1000 K), for which, as was shown above, the influence of thermal expansion of the crystal lattice because of a rise in the temperature of the sample is characteristic.

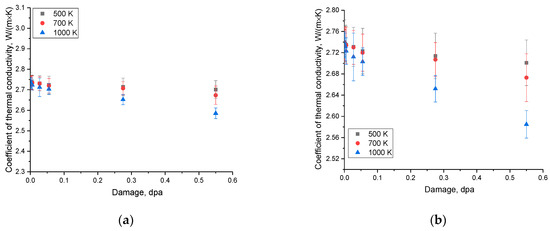

As is known, despite the great prospects for using CeO2 ceramics as a basis for creating dispersed nuclear fuel, in its pure form (without adding stabilizing additives), these types of ceramics have fairly low thermal conductivity, the increase of which, as a rule, uses various additives that have higher thermal conductivity and thermal diffusivity. In this regard, the addition of Y2O3 can affect not only strengthening, but also can be considered one of the ways to increase the thermophysical parameters of these ceramics. Figure 9 shows the results of a comparative analysis of changes in the thermal conductivity of ceramics depending on variations in irradiation conditions (fluence and irradiation temperature); the general trends of their changes indicate the negative impact of an increase in the concentration of structural distortions on changes in the thermophysical parameters of irradiated ceramics.

Figure 9.

Results of changes in the thermal conductivity of ceramics with varying irradiation conditions (changes in fluence and irradiation temperature): (a) CeO2 ceramics; (b) 0.85 M CeO2–0.15 M Y2O3 ceramics.

Analysis of the obtained changes in the thermal conductivity of CeO2 ceramics in comparison with stabilized ceramics showed an increase in the thermal conductivity coefficient from 2.74 W/(m × K) to 3.16 W/(m × K), which indicates that when a stabilizing additive is added to the ceramic composition, there is an increase not only in strength, but also in the thermophysical characteristics of the studied ceramics. In turn, a rise in the thermal conductivity of ceramics due to a stabilizing additive can have a positive effect on maintaining the stability of thermophysical properties during the radiation damage accumulation.

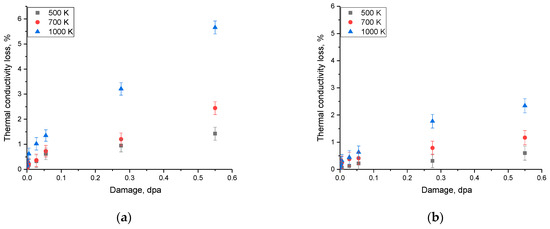

The general appearance of the presented changes in the thermal conductivity coefficient of ceramics depending on the magnitude of atomic displacements (irradiation fluence) indicates a similar nature of changes in thermophysical properties with changes in the strength characteristics of irradiated samples. This behavior indicates that both cases (variations in strength and thermophysical parameters) are due to structural changes stemming from the radiation damage accumulation in the samples, as well as subsequent deformation swelling of the crystal structure. In this case, as in the case of changes in strength and structural characteristics, the decrease in the thermal conductivity coefficient and, consequently, the increase in heat losses (see data in Figure 10) during measurements in irradiated samples is higher for unstabilized CeO2 ceramics.

Figure 10.

Results of heat losses in ceramics with varying irradiation conditions (changes in fluence and irradiation temperature): (a) CeO2 ceramics; (b) 0.85 M CeO2–0.15 M Y2O3 ceramics.

In the case of unstabilized CeO2 ceramics, an elevation in the irradiation temperature from 700 to 1000 K leads to a sharp increase in thermal losses and a decrease in thermal conductivity at high irradiation fluences (above 1013 ion/cm2), which is due to the effects of disordering and swelling of the crystal lattice [14,16,30]. The decrease in thermal conductivity for irradiated samples due to their dielectric nature is due to the creation of barrier obstacles in the path of phonons, which are the main heat carriers in ceramics. Here, an elevation in the concentration of defects in the damaged layer results in the appearance of additional scattering centers, which reduces the phonon velocity, and thereby reduces the thermal conductivity.

At the same time, for CeO2-stabilized ceramics, the decrease in thermal conductivity, even in cases of high-dose irradiation, is 1.5–2 times less than for unstabilized CeO2 ceramics, which indicates the positive effect of the stabilizing additive on maintaining the stability of thermophysical parameters. Comparison of these changes in heat losses with the data of changes in strength parameters indicates that the use of the stabilizing additive Y2O3 has a positive effect on both increasing the resistance to destruction of strength properties and also maintaining the stability of the thermophysical characteristics of ceramics.

4. Conclusions

In the course of the conducted studies on the effect of irradiation conditions (changes in fluence and irradiation temperature), it was found that the addition of 0.15 M Y2O3 to the CeO2 ceramics’ composition results in an enhancement of resistance to softening under high-temperature irradiation, which is due to a decrease in the volumetric thermal expansion coefficient in 0.85 M CeO2–0.15 M Y2O3 ceramics, and, as a consequence, a decrease in the influence of thermal effects on structural disorder at high irradiation temperatures, which are most pronounced in the case of irradiation of ceramics at temperatures of 1000 K. Analysis of structural alterations associated with crystal lattice deformation distortion and swelling showed that the addition of a stabilizing additive not only leads to a decrease in deformation distortion by 2–3 times compared to unstabilized CeO2 ceramics, but also increases the stability of the crystal structure to high-temperature irradiation by reducing the effect of thermal expansion of the crystal lattice.

Analyzing the data obtained, it was determined that the use of Y2O3-stabilizing additives to modify CeO2 ceramics in order to enhance their resistance to external influences, including radiation damage, is one of the promising ways to increase the radiation resistance of these types of ceramics, which has great potential for use as materials for inert matrices of dispersed nuclear fuel.

The established dependences of the effect of the Y2O3 dopant on resistance to radiation-induced structural disorder associated with thermal and radiation effects of crystal lattice expansion can be used in the future as one of the criteria for the possibility of using stabilizing additives in order to increase resistance to radiation damage during high-temperature irradiation, comparable to actual operating conditions in high temperature operating mode.

Author Contributions

Conceptualization: M.V.Z., R.M.R., S.G.G., A.L.K., D.I.S. and D.B.B.; methodology: D.B.B., R.M.R., S.G.G., M.V.Z., A.L.K. and D.I.S.; formal analysis: A.L.K., D.I.S. and D.B.B.; investigation: A.L.K., R.M.R. and S.G.G.; resources, writing—original draft preparation, writing—review and editing: A.L.K., R.M.R., S.G.G. and M.V.Z.; visualization: R.M.R., S.G.G., D.I.S. and A.L.K.; supervision: A.L.K. and D.B.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Ministry of Energy of the Republic of Kazakhstan (No. BR20081011).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Rieth, M.; Dudarev, S.; de Vicente, S.G.; Aktaa, J.; Ahlgren, T.; Antusch, S.; Armstrong, D.; Balden, M.; Baluc, N.; Barthe, M.-F.; et al. Recent progress in research on tungsten materials for nuclear fusion applications in Europe. J. Nucl. Mater. 2013, 432, 482–500. [Google Scholar] [CrossRef]

- Bradshaw, A.M.; Hamacher, T.; Fischer, U. Is nuclear fusion a sustainable energy form? Fusion Eng. Des. 2011, 86, 2770–2773. [Google Scholar] [CrossRef]

- Petrescu, R.V.; Aversa, R.; Kozaitis, S.; Apicella, A.; Petrescu, F.I. Some basic reactions in nuclear fusion. Am. J. Eng. Appl. Sci. 2017, 10, 709–716. [Google Scholar] [CrossRef][Green Version]

- Braams, C.M.; Peter, E.; Stott, P. Nuclear Fusion: Half a Century of Magnetic Confinement Fusion Research; CRC Press: Boca Raton, FL, USA, 2002. [Google Scholar]

- Keskar, M.; Kasar, U.M.; Mudher, K.D.; Venugopal, V. Solid state reactions of CeO2, PuO2,(U, Ce) O2 and (U, Pu) O2 with K2S2O8. J. Nucl. Mater. 2004, 334, 207–213. [Google Scholar] [CrossRef]

- Aidhy, D.S.; Wolf, D.; El-Azab, A. Comparison of point-defect clustering in irradiated CeO2 and UO2: A unified view from molecular dynamics simulations and experiments. Scr. Mater. 2011, 65, 867–870. [Google Scholar] [CrossRef]

- Mudher, K.S.; Keskar, M.; Venugopal, V. Solid state reactions of CeO2, ThO2 and PuO2 with ammonium sulphate. J. Nucl. Mater. 1999, 265, 146–153. [Google Scholar] [CrossRef]

- Konings, R.; Bakker, K.; Boshoven, J.; Conrad, R.; Hein, H. The influence of neutron irradiation on the microstructure of Al2O3, MgAl2O4, Y3Al5O12 and CeO2. J. Nucl. Mater. 1998, 254, 135–142. [Google Scholar] [CrossRef]

- Li, Y.; Ran, G.; Wu, L.; Huang, X.; Mo, H.; Cao, Z.; Wu, X.; Wang, Z. The evolution and interaction of irradiation defects in CeO2 during H2+ & He+ dual-beam synergistic irradiation investigated by in-situ TEM. J. Nucl. Mater. 2022, 570, 153957. [Google Scholar]

- Zhu, H.; Wang, F.; Liao, Q.; Wang, Y.; Zhu, Y. Effect of CeO2 and Nd2O3 on phases, microstructure and aqueous chemical durability of borosilicate glass-ceramics for nuclear waste immobilization. Mater. Chem. Phys. 2020, 249, 122936. [Google Scholar] [CrossRef]

- Kato, M.; Watanabe, M.; Hirooka, S.; Vauchy, R. Oxygen diffusion in the fluorite-type oxides CeO2, ThO2, UO2, PuO2, and (U, Pu) O2. Front. Nucl. Eng. 2023, 1, 1081473. [Google Scholar] [CrossRef]

- Chang, Y.; Guo, Y.; Li, M.; Wang, K.; Lv, L.; Liu, D. Effects of crystal quality, grain-size and oxygen vacancy of nanocrystalline CeO2 films under 1.5 MeV Au ion irradiation. J. Nucl. Mater. 2019, 518, 41–47. [Google Scholar] [CrossRef]

- Chen, W.-Y.; Wen, J.; Kirk, M.A.; Miao, Y.; Ye, B.; Kleinfeldt, B.R.; Oaks, A.J.; Stubbins, J.F. Characterization of dislocation loops in CeO2 irradiated with high energy Krypton and Xenon. Philos. Mag. 2013, 93, 4569–4581. [Google Scholar] [CrossRef]

- Cureton, W.F.; Palomares, R.I.; Tracy, C.L.; O’Quinn, E.C.; Walters, J.; Zdorovets, M.; Ewing, R.C.; Toulemonde, M.; Lang, M. Effects of irradiation temperature on the response of CeO2, ThO2, and UO2 to highly ionizing radiation. J. Nucl. Mater. 2019, 525, 83–91. [Google Scholar] [CrossRef]

- Yasuda, K.; Etoh, M.; Sawada, K.; Yamamoto, T.; Yasunaga, K.; Matsumura, S.; Ishikawa, N. Defect formation and accumulation in CeO2 irradiated with swift heavy ions. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2013, 314, 185–190. [Google Scholar] [CrossRef]

- Costantini, J.M.; Gutierrez, G.; Lelong, G.; Guillaumet, M.; Seo, P.; Yasuda, K. Radiation damage in ion-irradiated CeO2 and (Ce, Gd) O2 sinters: Effect of the Gd content. J. Nucl. Mater. 2022, 564, 153667. [Google Scholar] [CrossRef]

- Yasunaga, K.; Yasuda, K.; Matsumura, S.; Sonoda, T. Nucleation and growth of defect clusters in CeO2 irradiated with electrons. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2006, 250, 114–118. [Google Scholar] [CrossRef]

- Ishikawa, N.; Okubo, N.; Taguchi, T. Experimental evidence of crystalline hillocks created by irradiation of CeO2 with swift heavy ions: TEM study. Nanotechnology 2015, 26, 355701. [Google Scholar] [CrossRef] [PubMed]

- Seo, P.; Yasuda, K.; Matsumura, S.; Ishikawa, N.; Gutierrez, G.; Costantini, J.-M. Microstructure evolution in 200-MeV Xe ion irradiated CeO2 doped with Gd2O3. J. Appl. Phys. 2022, 132, 235902. [Google Scholar] [CrossRef]

- Cao, Z.; He, K.; Ran, G.; Qiu, X.; Sun, D.; Li, Y.; Xin, Y. Influence of thermal effect on dislocation loop evolution in Fe+-irradiated CeO2 during in-situ annealing. Ceram. Int. 2022, 48, 32022–32026. [Google Scholar] [CrossRef]

- Song, M.; Weiguo, W.; Chu, F.; Yang, X.; Mitsuishi, K.; Furuya, K.; Yasuda, H. Structure and chemical changes of CeO2 irradiated with hydrogen ions. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2002, 191, 586–590. [Google Scholar] [CrossRef]

- Cao, Z.; Ran, G.; Wang, Z.; Li, Y.; Wu, X.; Wu, L.; Huang, X.; Mo, H. In-situ TEM study on the evolution of dislocation loops and bubbles in CeO2 during Kr+ single-beam and Kr+-H2+ dual-beam synergetic irradiation. J. Mater. Sci. Technol. 2022, 123, 49–59. [Google Scholar] [CrossRef]

- Ivanov, I.A.; Rspayev, R.M.; Sapar, A.D.; Mustafin, D.A.; Zdorovets, M.V.; Kozlovskiy, A.L. Study of the Effect of Y2O3 Doping on the Resistance to Radiation Damage of CeO2 Microparticles under Irradiation with Heavy Xe22+ Ions. Crystals 2021, 11, 1459. [Google Scholar] [CrossRef]

- Zhao, H.; Li, X.; Ju, F.; Pal, U. Effects of particle size of 8 mol% Y2O3 stabilized ZrO2 (YSZ) and additive Ta2O5 on the phase composition and the microstructure of sintered YSZ electrolyte. J. Mater. Process. Technol. 2008, 200, 199–204. [Google Scholar] [CrossRef]

- Clark, D.; Zinkle, S.; Patel, M.; Parish, C. High temperature ion irradiation effects in MAX phase ceramics. Acta Mater. 2016, 105, 130–146. [Google Scholar] [CrossRef]

- Snead, L.; Katoh, Y.; Connery, S. Swelling of SiC at intermediate and high irradiation temperatures. J. Nucl. Mater. 2007, 367, 677–684. [Google Scholar] [CrossRef]

- Van Vuuren, A.J.; Saifulin, M.; Skuratov, V.; O’Connell, J.; Aralbayeva, G.; Dauletbekova, A.; Zdorovets, M. The influence of stopping power and temperature on latent track formation in YAP and YAG. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2019, 460, 67–73. [Google Scholar] [CrossRef]

- Moll, S.; Sattonnay, G.; Thomé, L.; Jagielski, J.; Legros, C.; Monnet, I. Swift heavy ion irradiation of pyrochlore oxides: Electronic energy loss threshold for latent track formation. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2010, 268, 2933–2936. [Google Scholar] [CrossRef]

- Nayak, A.K.; Singh, R.K.; Kulkarni, P.P. Measurement of volumetric thermal expansion coefficient of various nanofluids. Tech. Phys. Lett. 2010, 36, 696–698. [Google Scholar] [CrossRef]

- Graham, J.T.; Zhang, Y.; Weber, W.J. Irradiation-induced defect formation and damage accumulation in single crystal CeO2. J. Nucl. Mater. 2018, 498, 400–408. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).