Influence of TiC Particles on Mechanical and Tribological Characteristics of Advanced Aluminium Matrix Composites Fabricated through Ultrasonic-Assisted Stir Casting

Abstract

1. Introduction

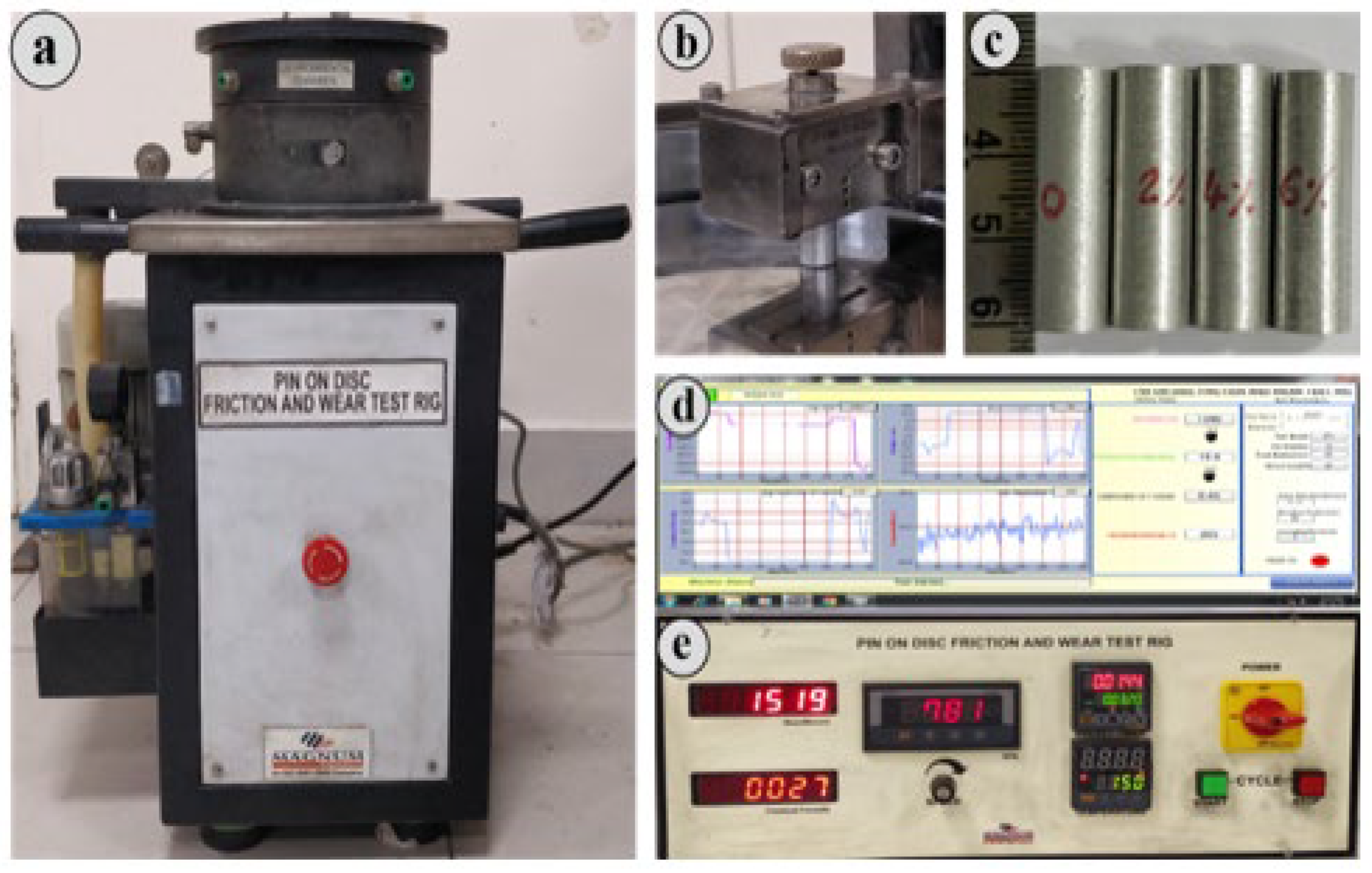

2. Materials and Methods

2.1. Materials

2.2. Fabrication of the AA8011-TiC Composites

3. Results

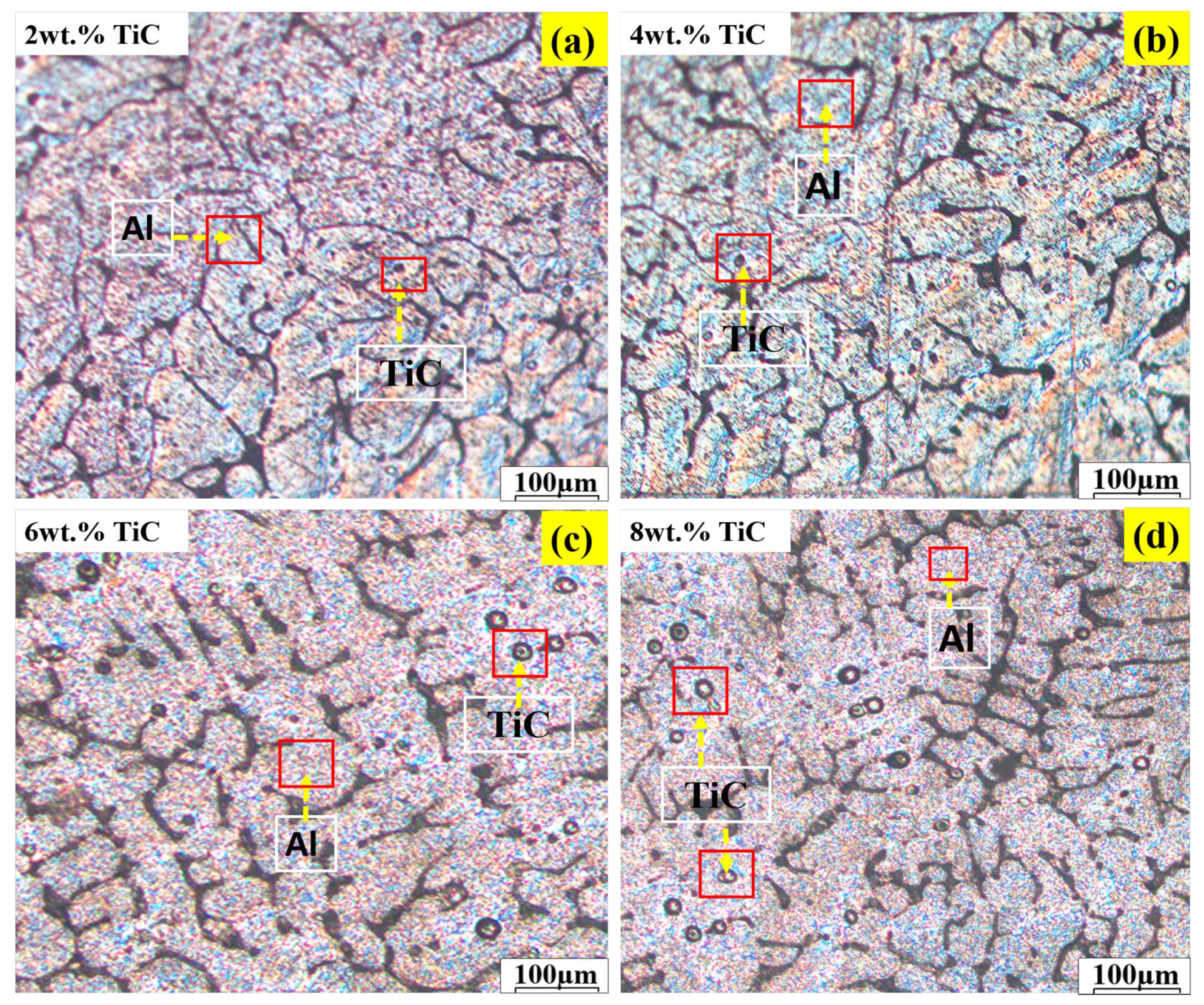

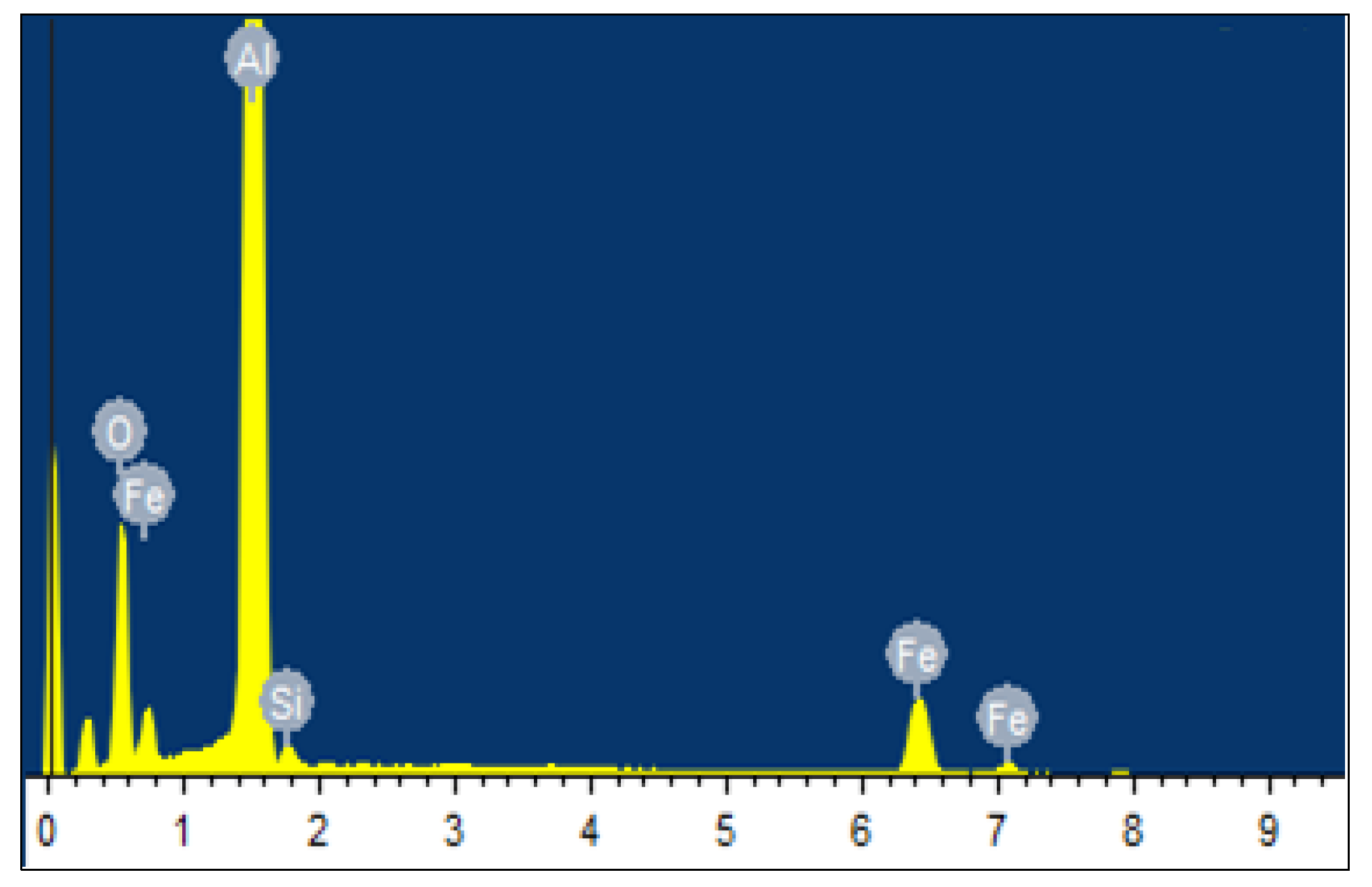

3.1. Microstructure Analysis of AA8011-TiC Composite

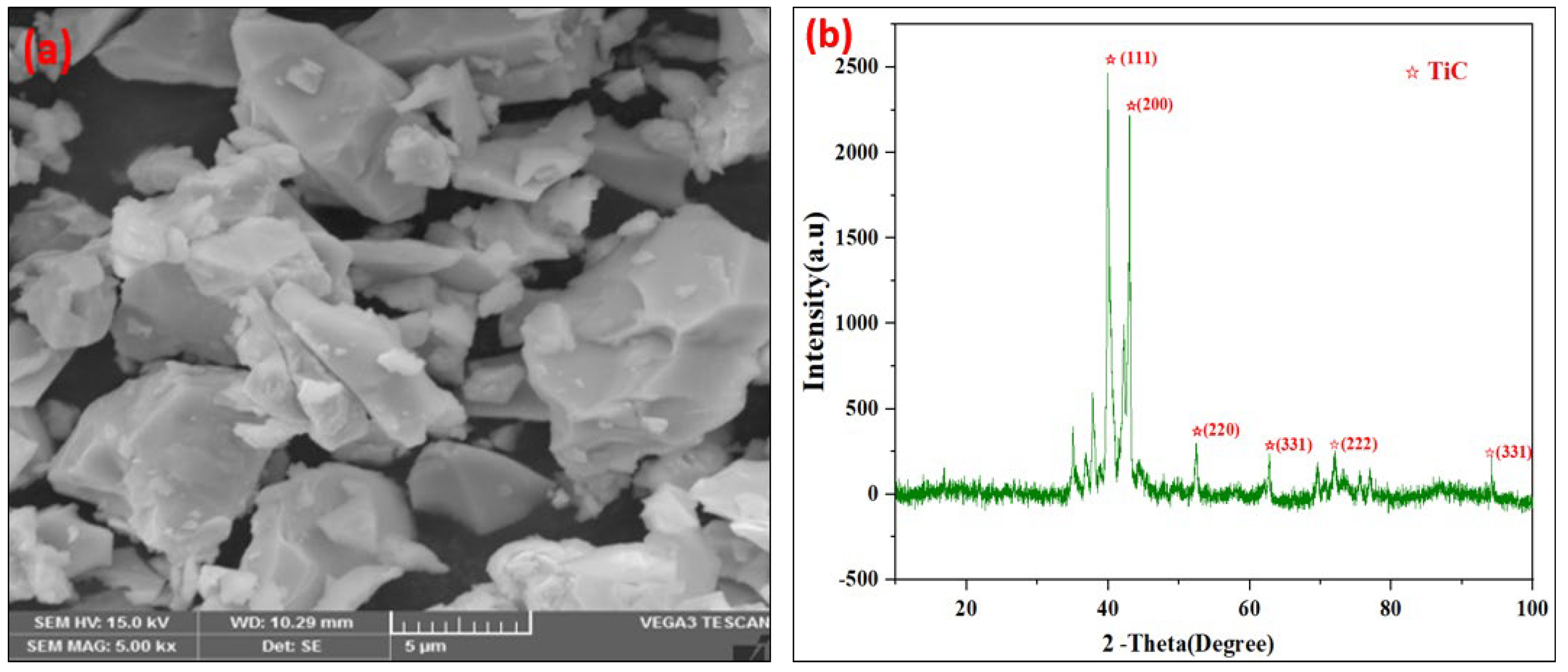

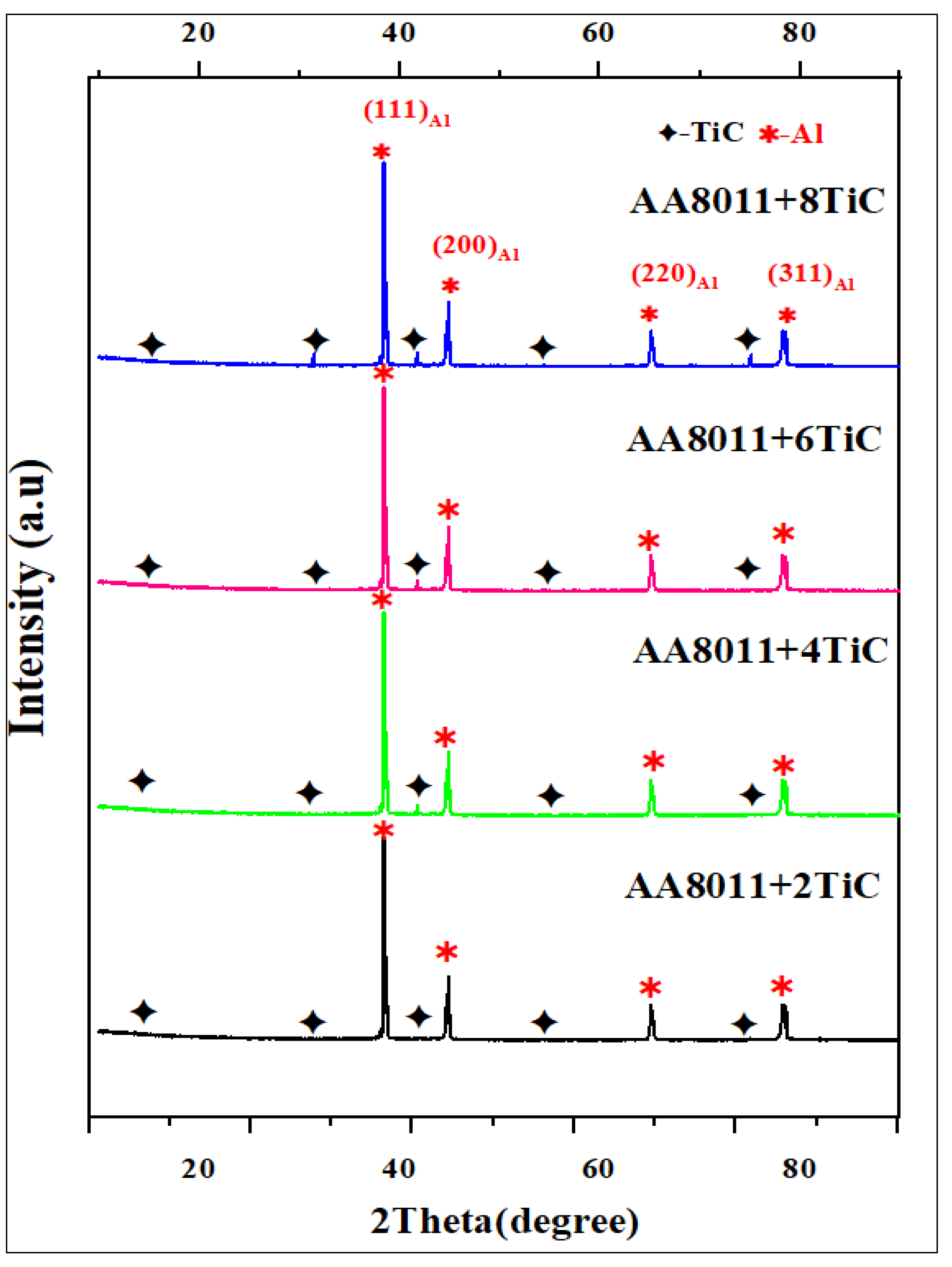

3.2. Analysis of AA8011-TiC Composite Materials Using X-ray Diffraction

3.3. Micro−Hardness

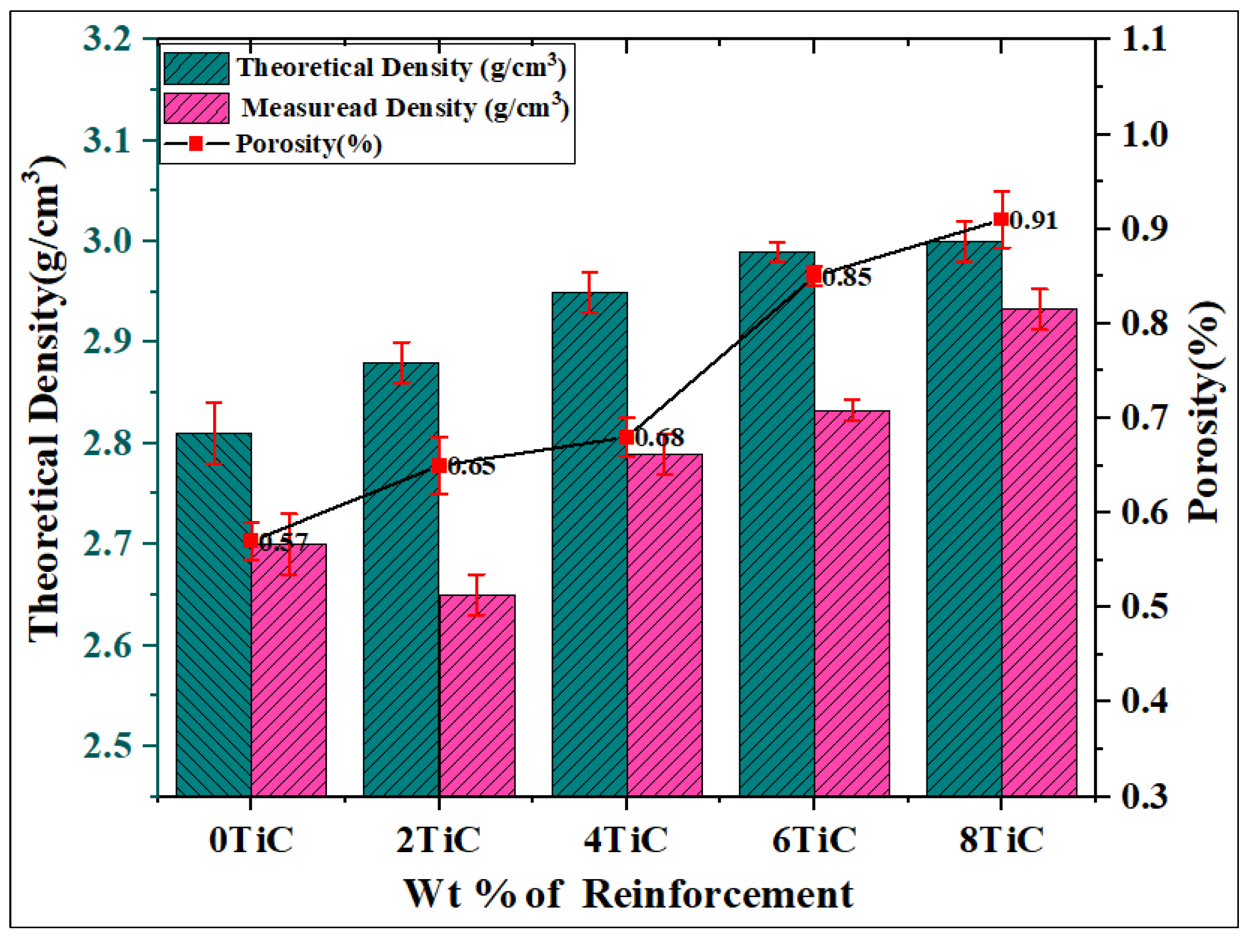

3.4. Density and Porosity

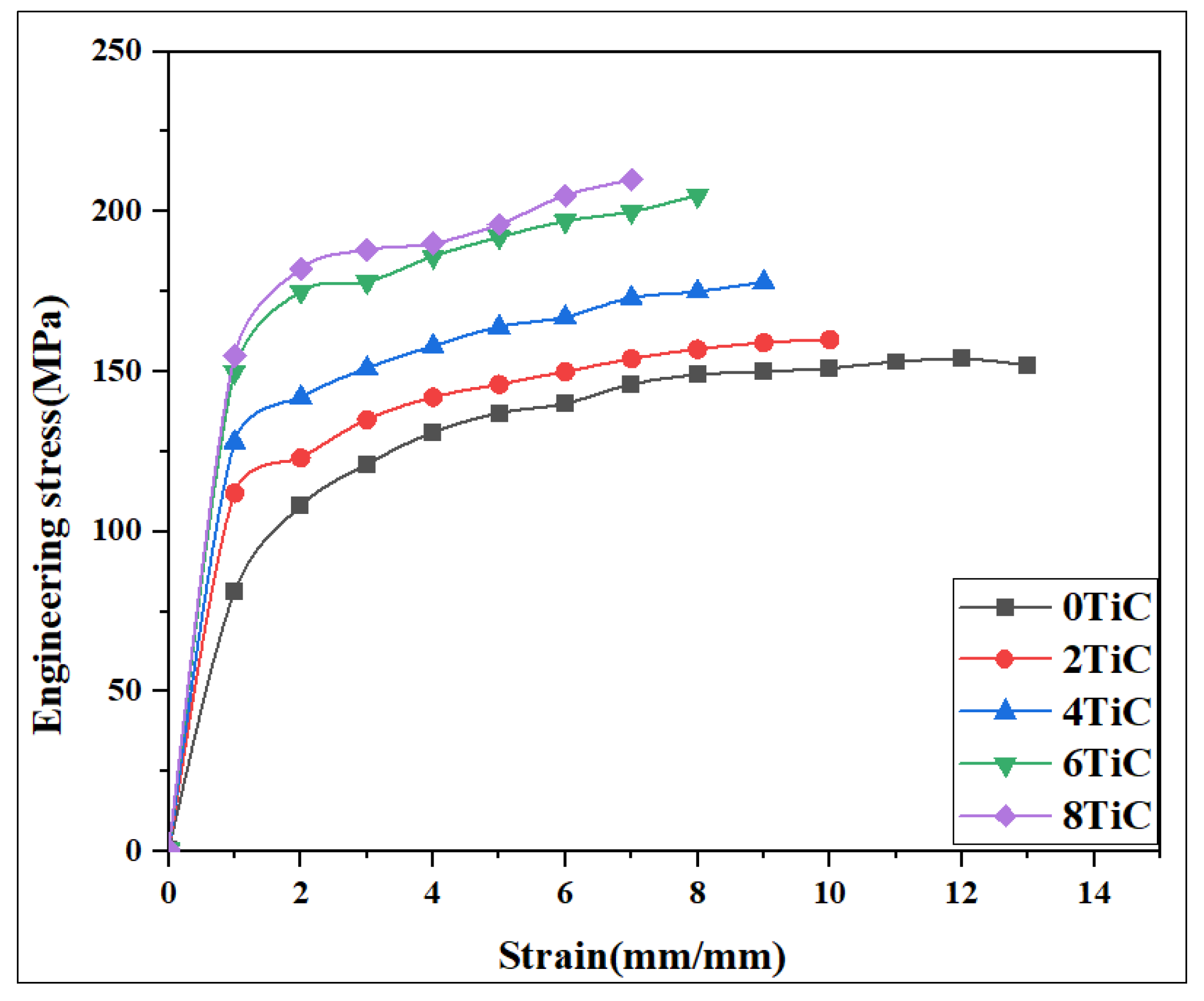

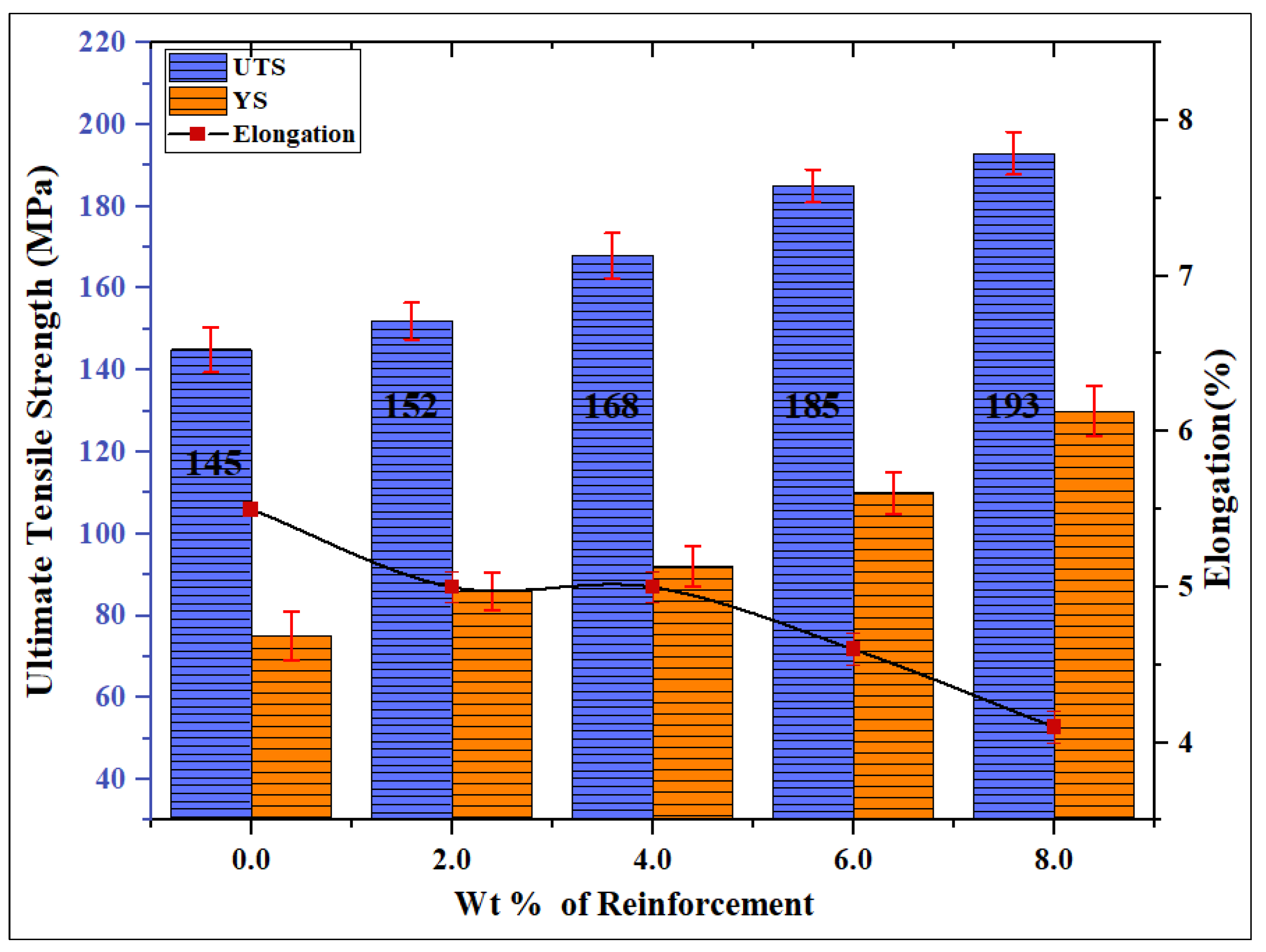

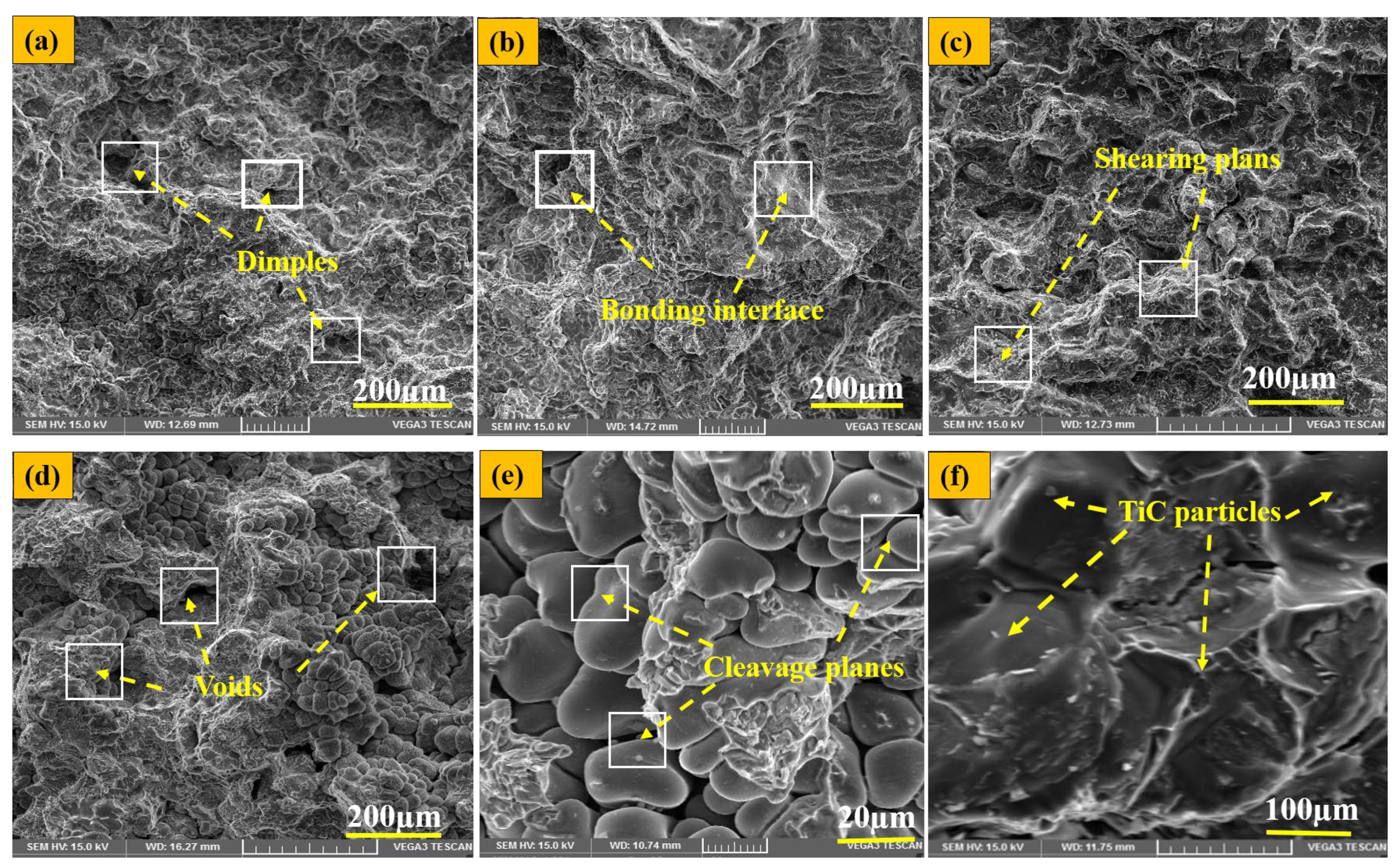

3.5. Ultimate Tensile Strength and Elongation

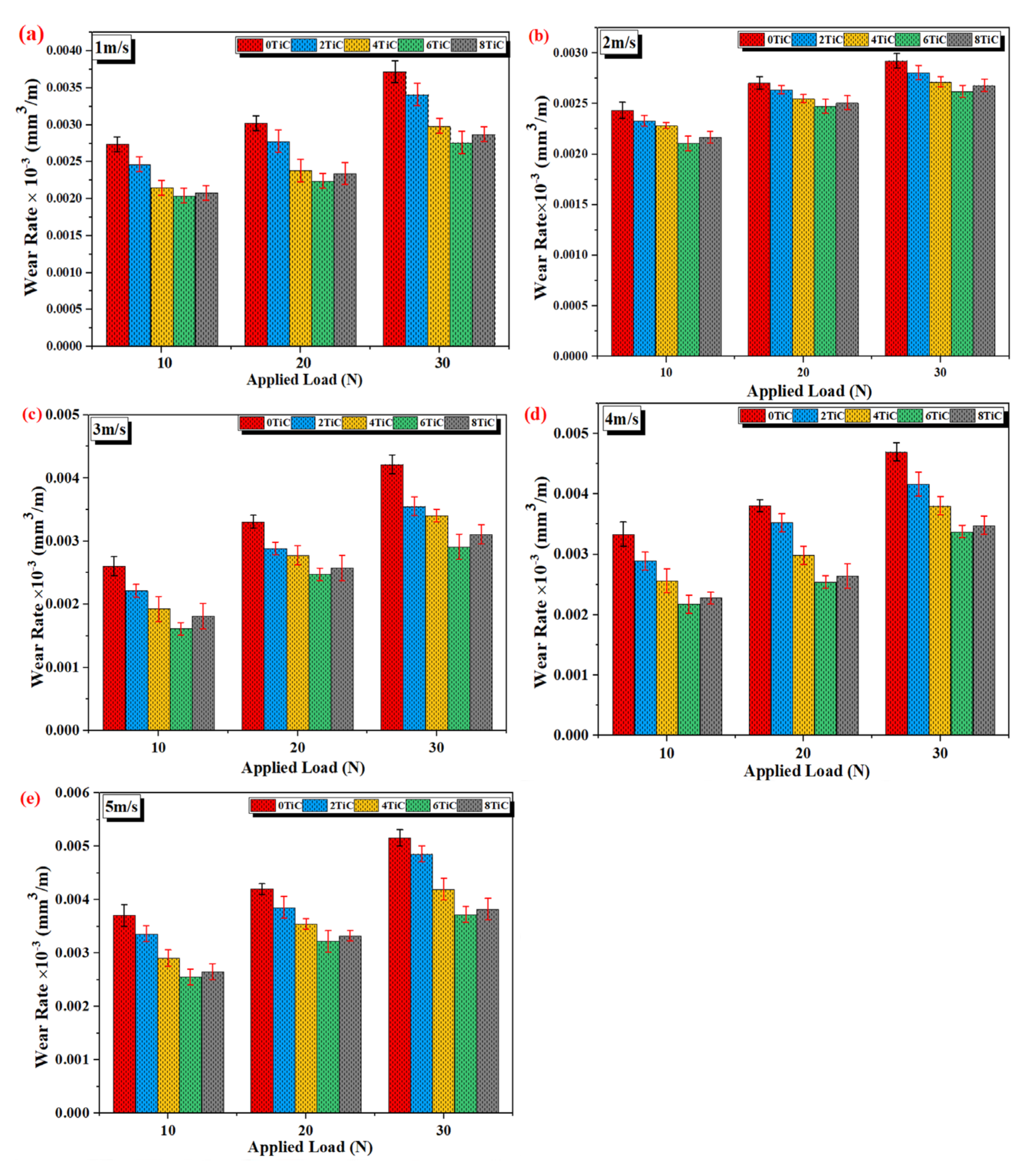

4. Wear Rate

4.1. Coefficient of Friction

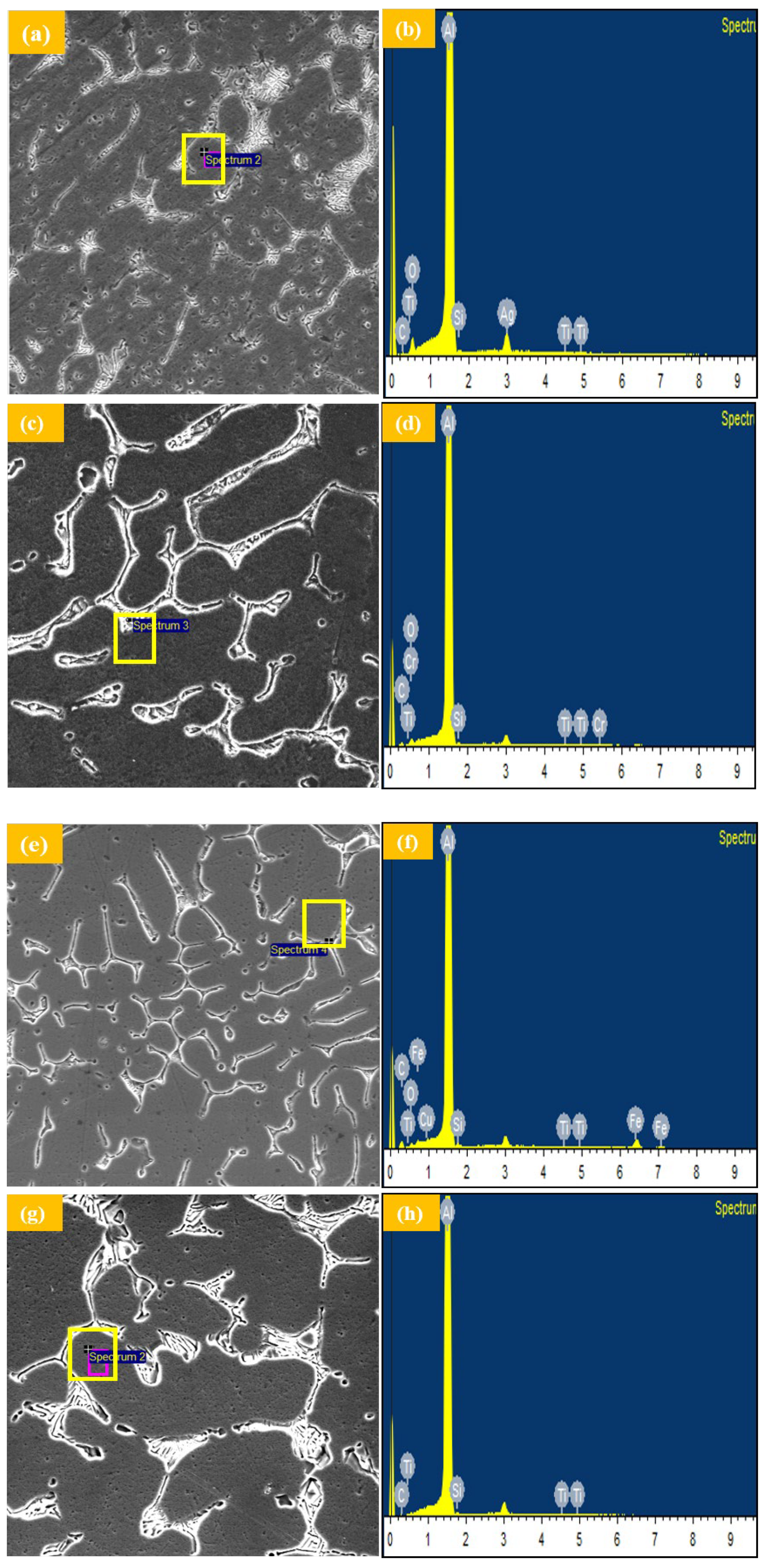

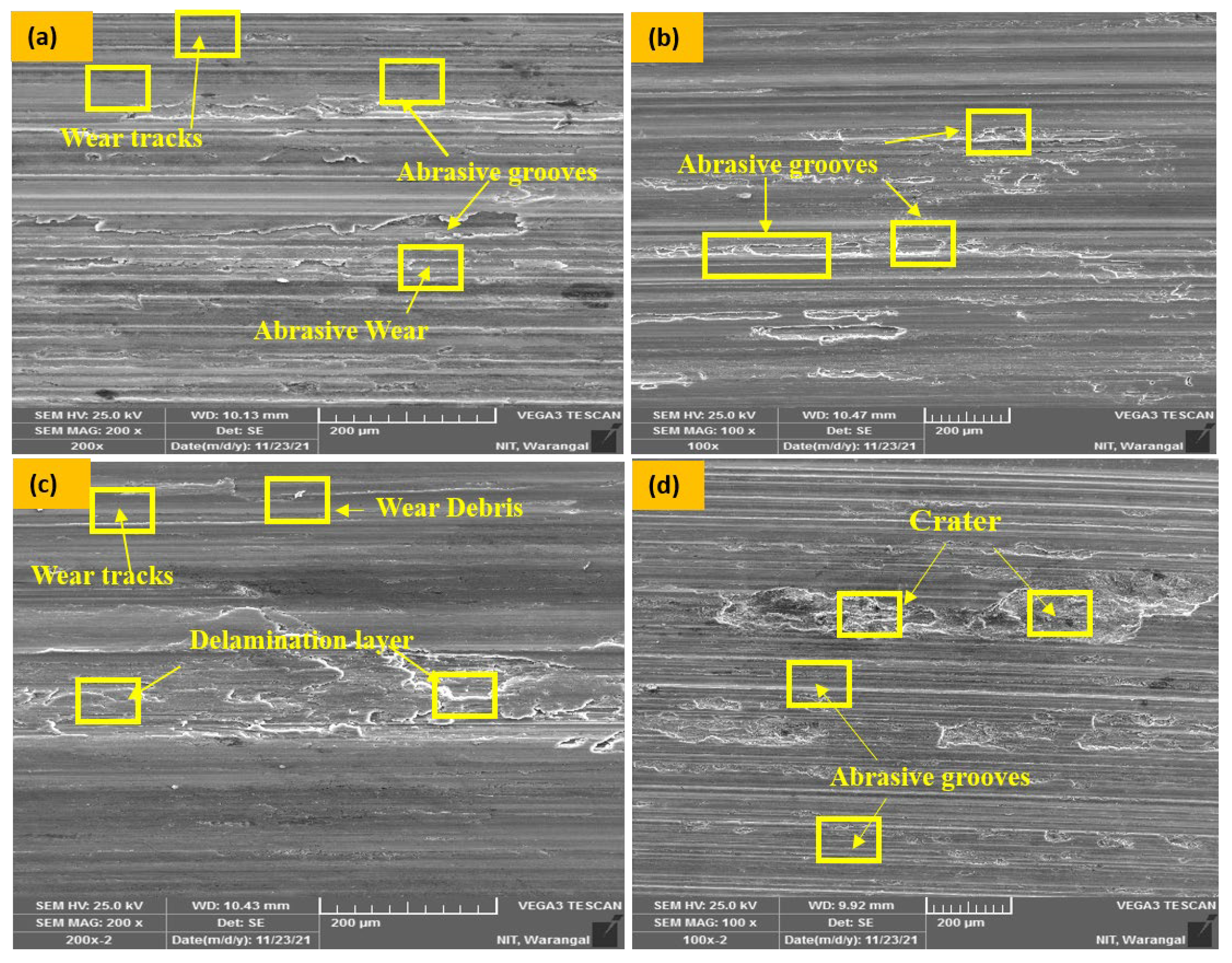

4.2. Worn Pin Surface Analysis

5. Conclusions

- A stir casting technique with ultrasonic assistance was employed to fabricate composites with a uniform dispersion of TiC. The manufactured composite exhibits a higher density in comparison to the matrix, primarily due to the high density of TiC particles within its structure.

- TiC particle-reinforced composites were found to possess greater hardness compared to the unreinforced alloy. Among the composites reinforced with TiC particles, those containing 6% exhibited the highest hardness, measured at 61.5%.

- Incorporating TiC particles into the aluminium matrix improves the material’s wear resistance. Under high load (30 N) and high-speed (5 m/s) conditions, composites containing 6% TiC particles achieved a maximum wear resistance of 32%.

- Incorporation of TiC particles into the aluminium matrix leads to a decrease in the friction coefficient. Notably, the inclusion of 6 wt.% TiC particles resulted in a significantly low coefficient of friction (0.266) under high load and speed conditions.

- Following a detailed examination of the worn surfaces, it was determined that the base alloy was worn predominantly due to abrasion and delamination. On the other hand, the AA8011 composite samples exhibited oxidation as the dominant wear mechanism.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Moorthy, C.V.K.N.S.N.; Kumar, G.N.; Srinivas, V.; Kumar, M.A.; Reddy, K.R.R.M.; Vasundhara, D.N.; Sabri, M.F.M.; Said, S.M. Metallography, Microstructure, and Wear Analysis of AA 6063/TiC Composites for Augmented Dry Sliding Property at Room Temperature. Metallogr. Microstruct. Anal. 2020, 9, 140–151. [Google Scholar] [CrossRef]

- Idrisi, A.H.; Mourad, A.H.I. Conventional Stir Casting versus Ultrasonic Assisted Stir Casting Process: Mechanical and Physical Characteristics of AMCs. J. Alloys Compd. 2019, 805, 502–508. [Google Scholar] [CrossRef]

- Liu, S.; Wang, Y.; Muthuramalingam, T.; Anbuchezhiyan, G. Effect of B4C and MOS2 Reinforcement on Micro Structure and Wear Properties of Aluminum Hybrid Composite for Automotive Applications. Compos. Part B Eng. 2019, 176, 107329. [Google Scholar] [CrossRef]

- Mavhungu, S.T.; Akinlabi, E.T.; Onitiri, M.A.; Varachia, F.M. Aluminum Matrix Composites for Industrial Use: Advances and Trends. Procedia Manuf. 2017, 7, 178–182. [Google Scholar] [CrossRef]

- Bulei, C.; Stojanovic, B.; Utu, D. Developments of Discontinuously Reinforced Aluminium Matrix Composites: Solving the Needs for the Matrix. J. Phys. Conf. Ser. 2022, 2212, 012029. [Google Scholar] [CrossRef]

- Kaushik, N.C.; Rao, R.N. Effect of Grit Size on Two Body Abrasive Wear of Al 6082 Hybrid Composites Produced by Stir Casting Method. Tribol. Int. 2016, 102, 52–60. [Google Scholar] [CrossRef]

- Sunar, T.; Özyürek, D. Effect of Al2O3Nanoparticles as Reinforcement on the Wear Properties of A356/Al2O3Nanocomposites Produced by Powder Metallurgy. J. Tribol. 2022, 144, 081701. [Google Scholar] [CrossRef]

- Imran Rizwi, M.; Mandal, D.; Show, B.K. Development of Wear Resistant Aluminum Based Nano-Composite Reinforced With Nano-AlN. J. Tribol. 2023, 145, 021702. [Google Scholar] [CrossRef]

- Rao, R.N.; Das, S. Effect of SiC Content and Sliding Speed on the Wear Behaviour of Aluminium Matrix Composites. Mater. Des. 2011, 32, 1066–1071. [Google Scholar] [CrossRef]

- Chandrasekar, P.; Natarajan, S.; Ramkumar, K.R. Influence of Carbide Reinforcements on Accumulative Roll Bonded Al 8011 Composites. Mater. Manuf. Process. 2019, 34, 889–897. [Google Scholar] [CrossRef]

- Sam, M.; Radhika, N. Effect of Heat Treatment on Mechanical and Tribological Properties of Centrifugally Cast Functionally Graded Cu/Al2O3 Composite. J. Tribol. 2018, 140, 021606. [Google Scholar] [CrossRef]

- Samal, P.; Vundavilli, P.R.; Meher, A.; Mahapatra, M.M. Influence of TiC on Dry Sliding Wear and Mechanical Properties of in Situ Synthesized AA5052 Metal Matrix Composites. J. Compos. Mater. 2019, 53, 4323–4336. [Google Scholar] [CrossRef]

- Umanath, K.; Palanikumar, K.; Selvamani, S.T. Composites: Part B Analysis of Dry Sliding Wear Behaviour of Al6061/SiC/Al2O3 Hybrid Metal Matrix Composites. Compos. Part B 2013, 53, 159–168. [Google Scholar] [CrossRef]

- Moustafa, E.B.; Melaibari, A.; Basha, M. Wear and Microhardness Behaviors of AA7075/SiC-BN Hybrid Nanocomposite Surfaces Fabricated by Friction Stir Processing. Ceram. Int. 2020, 46, 16938–16943. [Google Scholar] [CrossRef]

- Venkatesh, V.S.S.; Rao, R.N.; Patnaik, L. Effect of Spark Plasma Sintering Temperature on Phase Evaluation and Mechanical Behaviour of Cu- 4 Wt% SiC Composite. Silicon 2023. [Google Scholar] [CrossRef]

- Pc, E.; Radhakrishnan, G.; Emarose, S. Investigation into Physical, Microstructural and Mechanical Behaviour of Titanium Dioxide Nanoparticulate Reinforced Magnesium Composite. Mater. Technol. 2021, 36, 575–584. [Google Scholar] [CrossRef]

- Fayomi, J.; Popoola, A.P.I.; Popoola, O.M.; Oladijo, O.P.; Fayomi, O.S.I. Results in Physics Tribological and Microstructural Investigation of Hybrid AA8011/ZrB2-Si3N4 Nanomaterials for Service Life Improvement. Results Phys. 2019, 14, 102469. [Google Scholar] [CrossRef]

- Kumaran, S.T.; Uthayakumar, M.; Aravindan, S.; Rajesh, S. Dry Sliding Wear Behavior of SiC and B4C-Reinforced AA6351 Metal Matrix Composite Produced by Stir Casting Process. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2016, 230, 484–491. [Google Scholar] [CrossRef]

- Sivaprasad, K.; Babu, S.P.K.; Natarajan, S.; Narayanasamy, R.; Kumar, B.A.; Dinesh, G. Study on Abrasive and Erosive Wear Behaviour of Al 6063/TiB2 in Situ Composites. Mater. Sci. Eng. A 2008, 498, 495–500. [Google Scholar] [CrossRef]

- Khorasani, M.; Leary, M.; Downing, D.; Rogers, J.; Ghasemi, A.; Gibson, I.; Brudler, S.; Rolfe, B.; Brandt, M.; Bateman, S. Numerical and Experimental Investigations on Manufacturability of Al–Si–10Mg Thin Wall Structures Made by LB-PBF. Thin-Walled Struct. 2023, 188, 110814. [Google Scholar] [CrossRef]

- Ding, Y.; Muñiz-Lerma, J.A.; Trask, M.; Chou, S.; Walker, A.; Brochu, M. Microstructure and Mechanical Property Considerations in Additive Manufacturing of Aluminum Alloys. MRS Bull. 2016, 41, 745–751. [Google Scholar] [CrossRef]

- Sabry, I.; Ghafaar, M.A.; Mourad, A.H.I.; Idrisi, A.H. Stir Casted SiC-Gr/Al6061 Hybrid Composite Tribological and Mechanical Properties. SN Appl. Sci. 2020, 2, 1–8. [Google Scholar] [CrossRef]

- Anand Sekhar, R.; Rakesh Pillai, R.; Mubarak Ali, M.; Shyam Kumar, C. Enhanced Mechanical and Wear Properties of Aluminium-Based Composites Reinforced with a Unique Blend of Granite Particles and Boron Carbide for Sustainable Material Recycling. J. Alloys Compd. 2023, 963, 171165. [Google Scholar] [CrossRef]

- Yadav, M.; Kumaraswamidhas, L.A.; Singh, S.K. Investigation of Solid Particle Erosion Behavior of Al-Al2O3 and Al-ZrO2 Metal Matrix Composites Fabricated through Powder Metallurgy Technique. Tribol. Int. 2022, 172, 107636. [Google Scholar] [CrossRef]

- Bera, T.; Prakash, V.; Acharya, S.K. Erosion Wear Behaviour of A357/Fly Ash Composites. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2022, 236, 284–291. [Google Scholar] [CrossRef]

- Rokni, M.R.; Widener, C.A.; Ozdemir, O.C.; Crawford, G.A. Microstructure and Mechanical Properties of Cold Sprayed 6061 Al in As-Sprayed and Heat Treated Condition. Surf. Coat. Technol. 2017, 309, 641–650. [Google Scholar] [CrossRef]

- Balamurugan, K.; Shanmugam, V.; Palani, G.; Sundarakannan, R.; Sathish, T.; Linul, E.; Khan, S.A.; Asif, M. Effect of TiC/RHA on Solid Particle Erosion of Al6061 Hybrid Composites Fabricated through a 2-Step Ultrasonic-Assisted Stir Casting Process. J. Mater. Res. Technol. 2023, 25, 4888–4900. [Google Scholar] [CrossRef]

- Sakthivelu, S.; Sethusundaram, P.P.; Ravichandran, M.; Meignanamoorthy, M. Experimental Investigation and Analysis of Properties and Dry Sliding Wear Behavior of Al-Fe-Si Alloy Matrix Composites. Silicon 2021, 13, 1285–1294. [Google Scholar] [CrossRef]

- Siddharthan, B.; Bala, Y.V.; Mani, M.B.; Chandresh, A. Experimental Investigation of Tribological Behaviour of Aluminium Alloy Based Metal Matrix Composites. Bull. Sci. Res. 2019, 1, 10–16. [Google Scholar] [CrossRef][Green Version]

- Fayomi, J.; Popoola, A.P.I.; Popoola, O.M.; Oladijo, O.P.; Fayomi, O.S.I. Understanding the Microstructural Evolution, Mechanical Properties, and Tribological Behavior of AA8011-Reinforced Nano-Si3N4 for Automobile Application. Int. J. Adv. Manuf. Technol. 2020, 111, 53–62. [Google Scholar] [CrossRef]

- Keerthivasan, N.; Anandakrishnan, V. Effect of Recycled TiC Addition in the Compaction and Sintering Behavior of Al-Mg-Cu-Zn+r-TiC Powder Metallurgy Composites. Part. Sci. Technol. 2022, 41, 392–401. [Google Scholar] [CrossRef]

- Baskaran, S.; Anandakrishnan, V.; Duraiselvam, M. Investigations on Dry Sliding Wear Behavior of in Situ Casted AA7075–TiC Metal Matrix Composites by Using Taguchi Technique. J. Mater. 2014, 60, 184–192. [Google Scholar] [CrossRef]

- Siddappa, P.N.; Shivakumar, B.P.; Yogesha, K.B.; Mruthunjaya, M.; Girish, D.P. The Effect of TiC Particulate Reinforcement on Dry Sliding Wear Behaviour of Al Based Composites. Proc. Mater. Today 2019, 22, 2291–2299. [Google Scholar] [CrossRef]

- Maleki, K.; Alizadeh, A.; Hajizamani, M. Compressive Strength and Wear Properties of SiC/Al6061 Composites Reinforced with High Contents of SiC Fabricated by Pressure-Assisted Infiltration. Ceram. Int. 2021, 47, 2406–2413. [Google Scholar] [CrossRef]

- Kumar, R.; Dhiman, S. A Study of Sliding Wear Behaviors of Al-7075 Alloy and Al-7075 Hybrid Composite by Response Surface Methodology Analysis. Mater. Des. 2013, 50, 351–359. [Google Scholar] [CrossRef]

- Rao, R.N.; Das, S. Effect of Applied Pressure on the Tribological Behaviour of SiCp Reinforced AA2024 Alloy. Tribol. Int. 2011, 44, 454–462. [Google Scholar] [CrossRef]

- Kumar, H.G.P.; Xavior, M.A. Assessment of Mechanical and Tribological Properties of Al 2024- SiC—Graphene Hybrid Composites. Procedia Eng. 2017, 174, 992–999. [Google Scholar] [CrossRef]

- Prasad Reddy, A.; Vamsi Krishna, P.; Rao, R.N. Two-Body Abrasive Wear Behaviour of AA6061-2SiC-2Gr Hybrid Nanocomposite Fabricated through Ultrasonically Assisted Stir Casting. J. Compos. Mater. 2019, 53, 2165–2180. [Google Scholar] [CrossRef]

- Prasad Reddy, A.; Vamsi Krishna, P.; Rao, R.N. Tribological Behaviour of Al6061–2SiC-XGr Hybrid Metal Matrix Nanocomposites Fabricated through Ultrasonically Assisted Stir Casting Technique. Silicon 2019, 11, 2853–2871. [Google Scholar] [CrossRef]

- Liu, Z.; Han, Q.; Li, J. Ultrasound Assisted in Situ Technique for the Synthesis of Particulate Reinforced Aluminum Matrix Composites. Compos. Part B Eng. 2011, 42, 2080–2084. [Google Scholar] [CrossRef]

- Jeyasimman, D.; Narayanasamy, R.; Ponalagusamy, R.; Anandakrishnan, V.; Kamaraj, M. The Effects of Various Reinforcements on Dry Sliding Wear Behaviour of AA 6061 Nanocomposites. Mater. Des. 2014, 64, 783–793. [Google Scholar] [CrossRef]

- Pasha, M.B.; Sharma, R.C.; Rao, R.N.; Ismail, S.; Gupta, M. Sliding Wear Characteristics of Mg/Si3N4 Nanocomposites at Room and Elevated Temperatures. Mater. Lett. 2022, 329, 133186. [Google Scholar] [CrossRef]

- Rao, R.N.; Das, S. Effect of Matrix Alloy and Influence of SiC Particle on the Sliding Wear Characteristics of Aluminium Alloy Composites. Mater. Des. 2010, 31, 1200–1207. [Google Scholar] [CrossRef]

- Bharat, N.; Bose, P.S.C. Influence of Nano-TiO2 Particles on the Microstructure, Mechanical and Wear Behaviour of AA7178 Alloy Matrix Fabricated by Stir Casting Technique. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2022, 237, 753–766. [Google Scholar] [CrossRef]

- Li, Y.; Ramesh, K.T.; Chin, E.S.C. Comparison of the Plastic Deformation and Failure of A359/SiC and 6061-T6/Al2O3 Metal Matrix Composites under Dynamic Tension. Mater. Sci. Eng. A 2004, 371, 359–370. [Google Scholar] [CrossRef]

- Lijay, K.J.; Selvam, J.D.R.; Dinaharan, I.; Vijay, S.J. Microstructure and Mechanical Properties Characterization of AA6061/TiC Aluminum Matrix Composites Synthesized by in Situ Reaction of Silicon Carbide and Potassium Fluotitanate. Trans. Nonferrous Met. Soc. China 2016, 26, 1791–1800. [Google Scholar] [CrossRef]

- Thangarasu, A.; Murugan, N.; Dinaharan, I. Production and Wear Characterization of AA6082-TiC Surface Composites by Friction Stir Processing. Procedia Eng. 2014, 97, 590–597. [Google Scholar] [CrossRef]

- Wang, F.; Liu, H.; Yang, B. Effect of In-Situ TiC Particulate on the Wear Resistance of Spray-Deposited 7075 Al Matrix Composite. Mater. Charact. 2005, 54, 446–450. [Google Scholar] [CrossRef]

- Salur, E.; Acarer, M.; Şavkliyildiz, İ. Improving Mechanical Properties of Nano-Sized TiC Particle Reinforced AA7075 Al Alloy Composites Produced by Ball Milling and Hot Pressing. Mater. Today Commun. 2021, 27, 102202. [Google Scholar] [CrossRef]

- Ramakoteswara Rao, V.; Ramanaiah, N.; Sarcar, M.M.M. Dry Sliding Wear Behavior of TiC -AA7075 Metal Matrix Composites. Int. J. Appl. Sci. Eng. 2016, 14, 27–37. [Google Scholar] [CrossRef]

- Pasha, M.B.; Rao, R.N.; Ismail, S.; Özcan, M.; Prasad, P.S.; Gupta, M. Assessing Mg/Si3N4 Biodegradable Nanocomposites for Osteosynthesis Implants with a Focus on Microstructural, Mechanical, in Vitro Corrosion and Bioactivity Aspects. J. Mater. Res. Technol. 2022, 19, 3803–3817. [Google Scholar] [CrossRef]

- Yang, Y.; Liu, Z.; Jiang, R.; Li, R.; Li, X. Microstructural Evolution and Mechanical Properties of the AA2219/TiC Nanocomposite Manufactured by Ultrasonic Solidification. J. Alloys Compd. 2019, 811, 151991. [Google Scholar] [CrossRef]

- Xi, H.; Xiao, W.; Li, H.; Fu, Y.; Yi, G.; Qie, J.; Ma, X. Effects of Submicron-Sized TiC Particles on the Microstructure Modification and Mechanical Properties of Al-Si-Mg Alloy. J. Alloys Compd. 2023, 968, 171963. [Google Scholar] [CrossRef]

- Ravi Kumar, K.; Kiran, K.; Sreebalaji, V.S. Micro Structural Characteristics and Mechanical Behaviour of Aluminium Matrix Composites Reinforced with Titanium Carbide. J. Alloys Compd. 2017, 723, 795–801. [Google Scholar] [CrossRef]

- Li, B.; Chen, X.; Jiang, M.; Ma, S.; Wang, Z.; Lei, Z.; Chen, Y. Microstructure and Mechanical Properties of TiC Nanoparticles Reinforced 7075 Aluminium Alloy Fabricated by Oscillating Laser-Arc Hybrid Additive Manufacturing. Sci. Technol. Weld. Join. 2023, 28, 495–505. [Google Scholar] [CrossRef]

- Munivenkatappan, M.S.B.; Shanmugam, S.; Veeramani, A. Synthesis and Characterization of In-Situ AA8011-TiB2 Composites Produced by Flux Assisted Synthesis. Ann. Chim. Sci. Mater. 2020, 44, 333–338. [Google Scholar] [CrossRef]

- Kumar, A.; Gautam, R.K.; Tyagi, R. Dry Sliding Wear Characteristics of in Situ Synthesized Al-TiC Composites. Compos. Interfaces 2016, 23, 469–480. [Google Scholar] [CrossRef]

- Archard, J.F. Contact and Rubbing of Flat Surfaces. J. Appl. Phys. 1953, 24, 981–988. [Google Scholar] [CrossRef]

- Baradeswaran, A.; Elaya Perumal, A. Influence of B4C on the Tribological and Mechanical Properties of Al 7075-B4C Composites. Compos. Part B Eng. 2013, 54, 146–152. [Google Scholar] [CrossRef]

- Ul Haq, M.I.; Anand, A. Dry Sliding Friction and Wear Behavior of AA7075-Si3N4 Composite. Silicon 2018, 10, 1819–1829. [Google Scholar] [CrossRef]

- Rao, R.N.; Das, S. Effect of Sliding Distance on the Wear and Friction Behavior of as Cast and Heat-Treated Al-SiCp Composites. Mater. Des. 2011, 32, 3051–3058. [Google Scholar] [CrossRef]

- Ul Haq, M.I.; Anand, A. Friction and Wear Behavior of AA 7075- Si3N4 Composites Under Dry Conditions: Effect of Sliding Speed. Silicon 2019, 11, 1047–1053. [Google Scholar] [CrossRef]

- Khan, M.M.; Nisar, M. Effect of in Situ TiC Reinforcement and Applied Load on the High-Stress Abrasive Wear Behaviour of Zinc–Aluminum Alloy. Wear 2022, 488–489, 204082. [Google Scholar] [CrossRef]

- Vinoth, B.; Alagarsamy, S.V.; Meignanamoorthy, M.; Ravichandran, M. Prediction of Tribological Performance of AA8011/Wt.%ZrO2 Based Composites Fabricated by Stir Casting Route. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2022, 236, 2420–2433. [Google Scholar] [CrossRef]

| Element | Si | Fe | Ag | Mn | Cu | Mg | Ti | Zn | Al |

|---|---|---|---|---|---|---|---|---|---|

| AA8011 | 0.624 | 0.721 | 0.45 | 0.04 | 0.23 | 0.30 | 0.003 | 0.002 | Bal |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Golla, C.B.; Babar Pasha, M.; Rao, R.N.; Ismail, S.; Gupta, M. Influence of TiC Particles on Mechanical and Tribological Characteristics of Advanced Aluminium Matrix Composites Fabricated through Ultrasonic-Assisted Stir Casting. Crystals 2023, 13, 1360. https://doi.org/10.3390/cryst13091360

Golla CB, Babar Pasha M, Rao RN, Ismail S, Gupta M. Influence of TiC Particles on Mechanical and Tribological Characteristics of Advanced Aluminium Matrix Composites Fabricated through Ultrasonic-Assisted Stir Casting. Crystals. 2023; 13(9):1360. https://doi.org/10.3390/cryst13091360

Chicago/Turabian StyleGolla, Chitti Babu, Mahammod Babar Pasha, Rajamalla Narasimha Rao, Syed Ismail, and Manoj Gupta. 2023. "Influence of TiC Particles on Mechanical and Tribological Characteristics of Advanced Aluminium Matrix Composites Fabricated through Ultrasonic-Assisted Stir Casting" Crystals 13, no. 9: 1360. https://doi.org/10.3390/cryst13091360

APA StyleGolla, C. B., Babar Pasha, M., Rao, R. N., Ismail, S., & Gupta, M. (2023). Influence of TiC Particles on Mechanical and Tribological Characteristics of Advanced Aluminium Matrix Composites Fabricated through Ultrasonic-Assisted Stir Casting. Crystals, 13(9), 1360. https://doi.org/10.3390/cryst13091360