Bulk Polystyrene-BaF2 Composite Scintillators for Highly Efficient Radiation Detection

Abstract

:1. Introduction

2. Experimental Process

2.1. Preparation of Composite Scintillators

2.2. Characterization Methods

3. Results

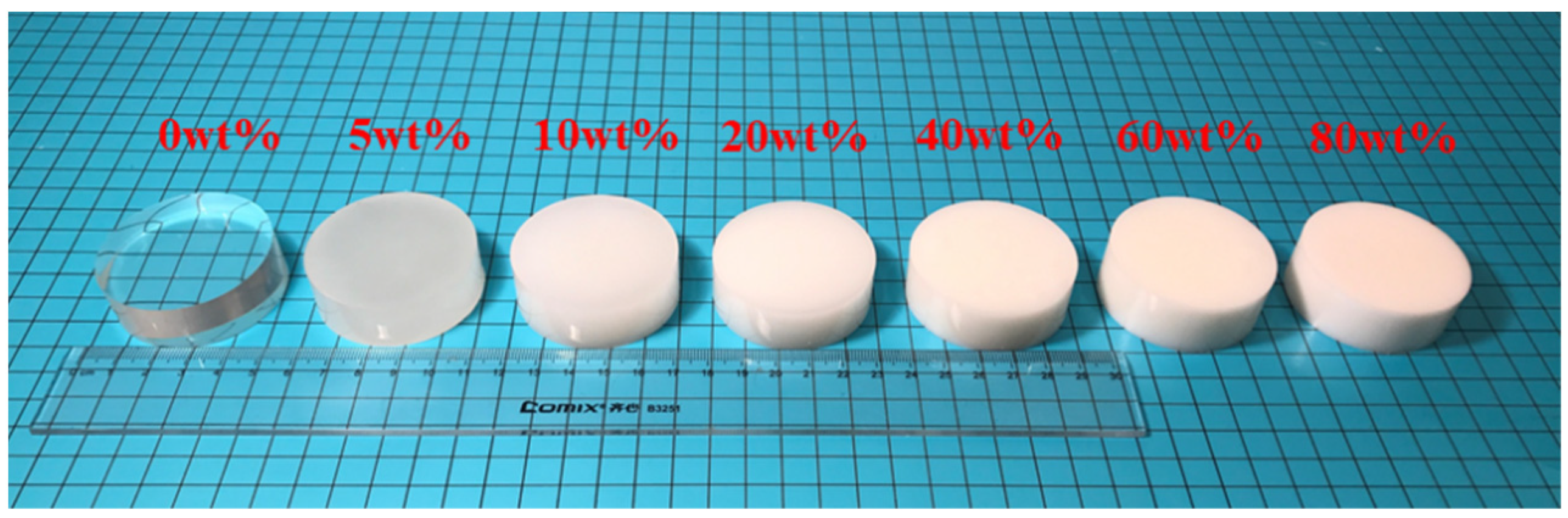

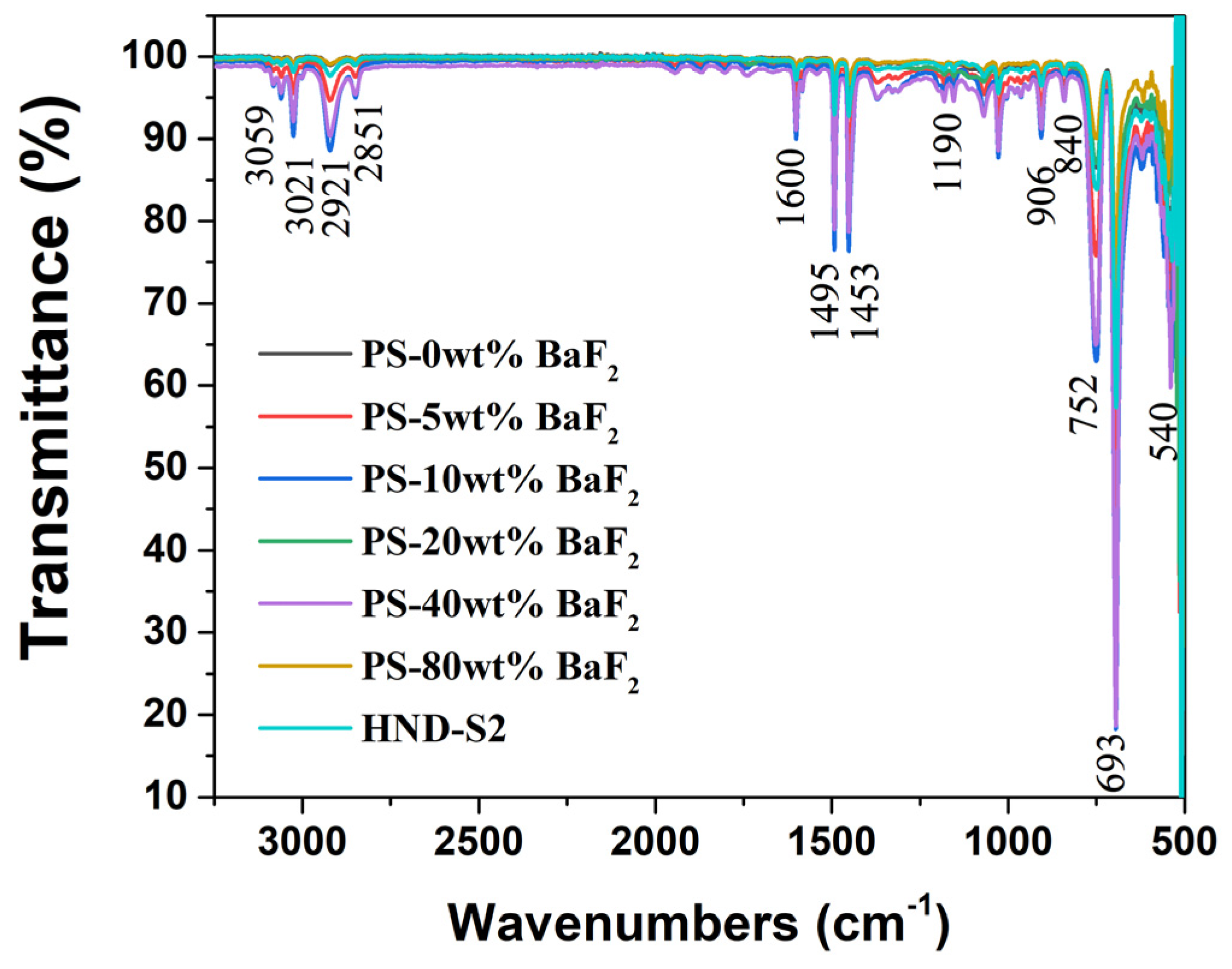

3.1. Composite Scintillators

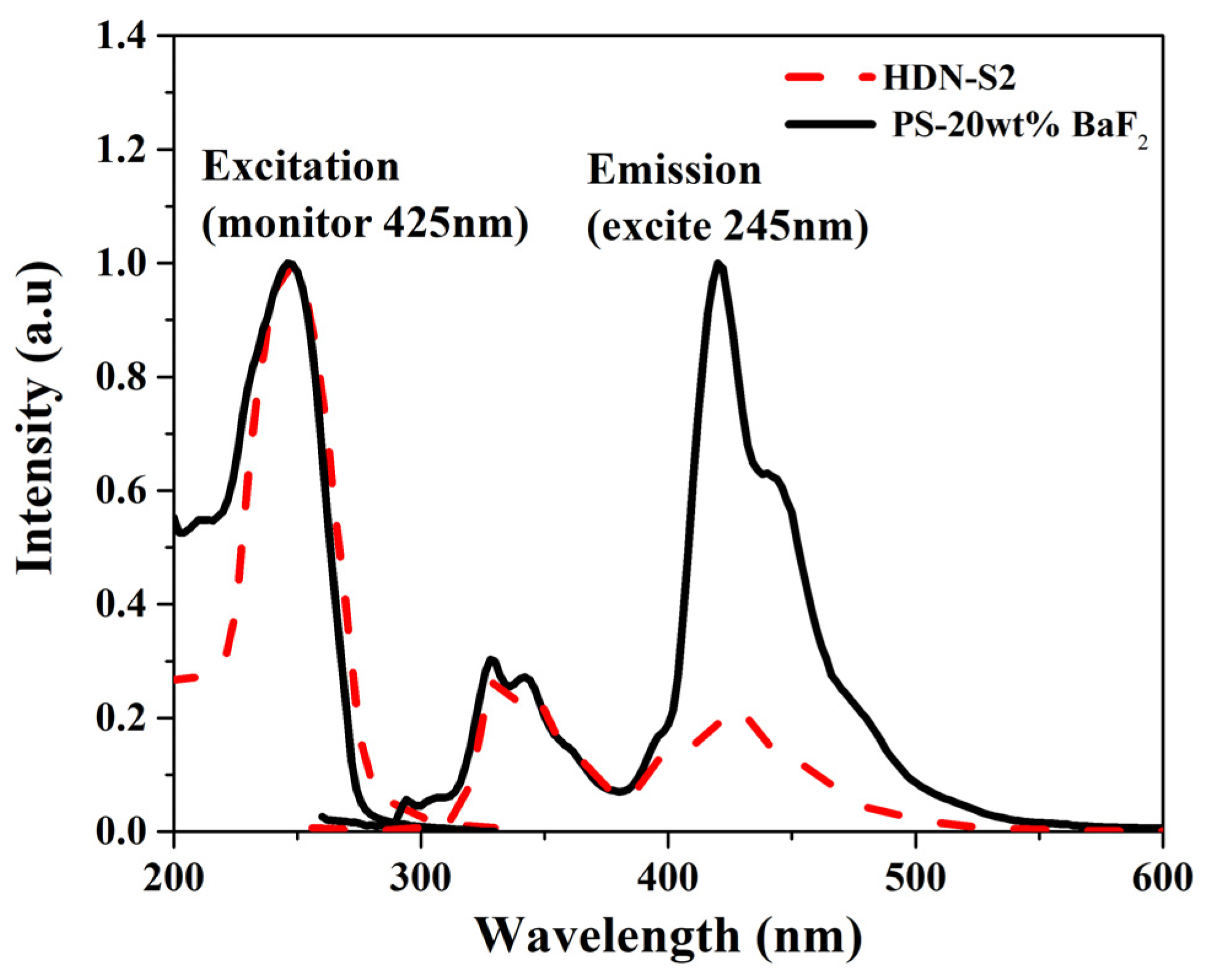

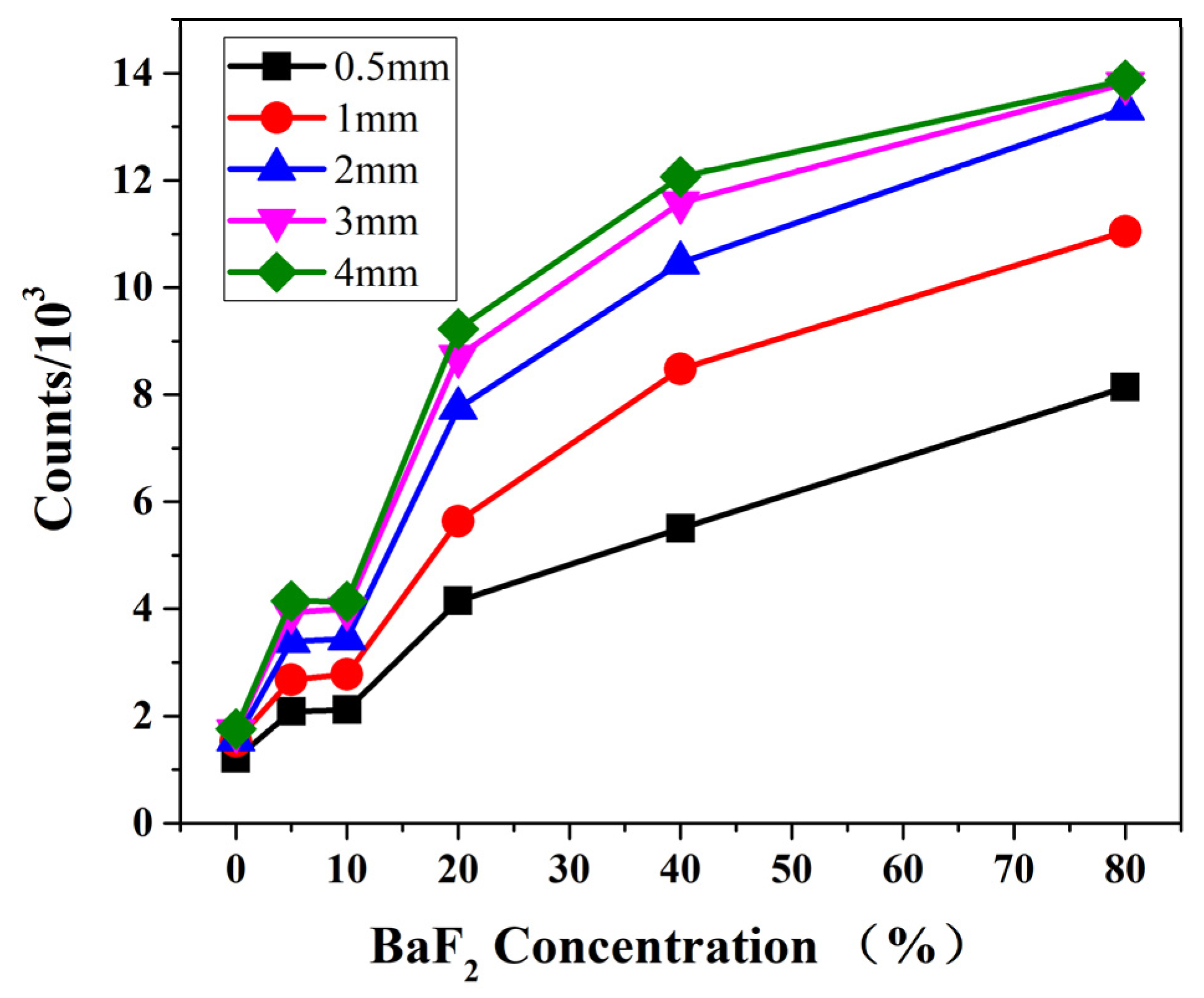

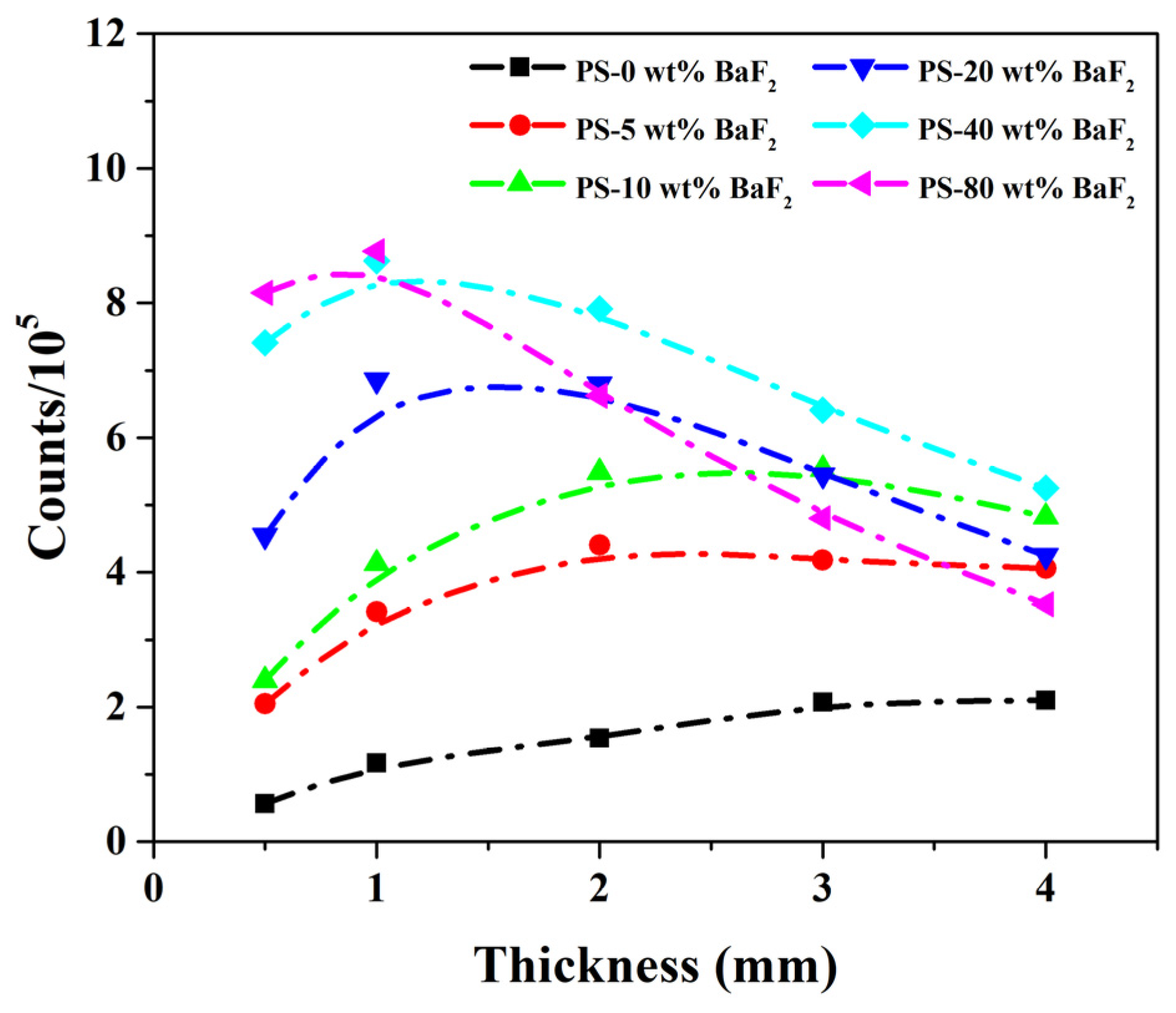

3.2. Luminescence Properties

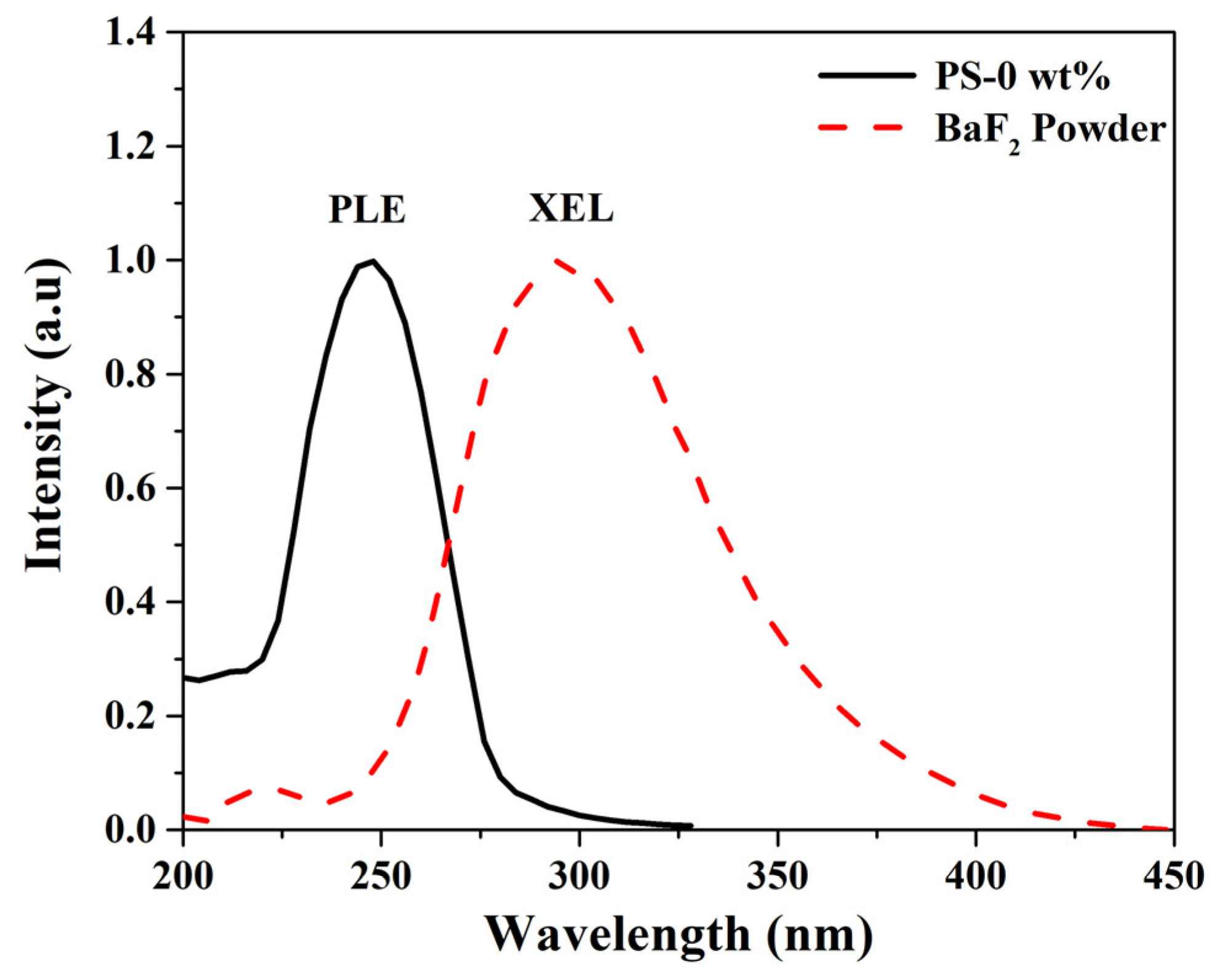

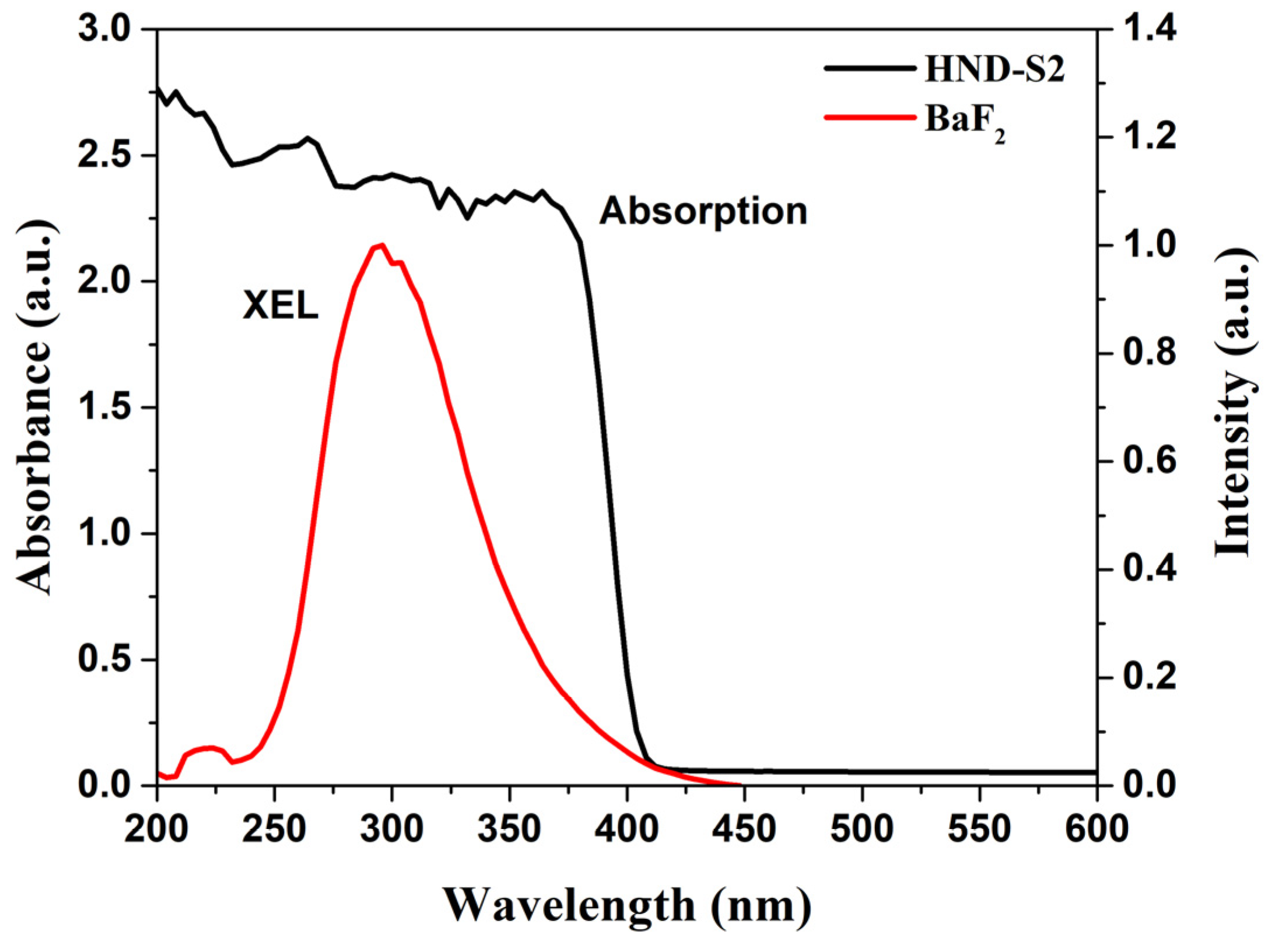

3.3. Mechanism of Luminescence Enhancement

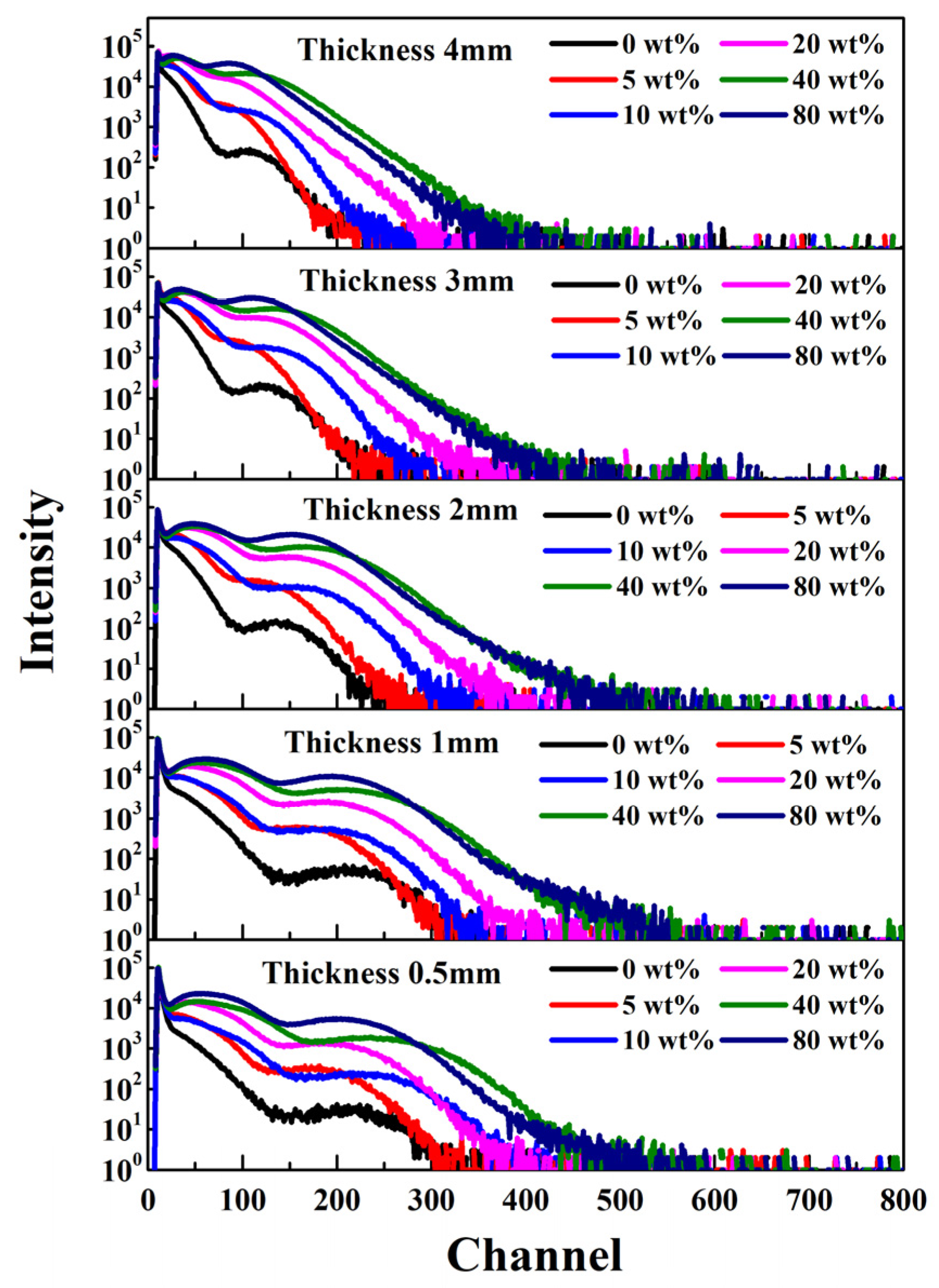

3.4. Scintillation Kinetics

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Weber, M.J. Inorganic scintillators: Today and tomorrow. J. Lumin. 2002, 100, 35–45. [Google Scholar] [CrossRef]

- Chen, X.; Lu, H.; Gu, Q.; Zhang, N.; Wang, S.; Wu, S. Terbium-doped LiYbF4 nanomaterial-based scintillator responding to X-rays with high-resolution imaging applications. CrystEngComm 2022, 24, 2551–2557. [Google Scholar] [CrossRef]

- Novais, S.M.V.; Monteiro, T.J.; Andrade, A.B.; Gomes, M.A.; Dias, C.S.B.; Valerio, M.E.G.; Macedo, Z.S. Development of CdWO4-polystyrene scintillator composites for X-ray detection in imaging systems. Nucl. Instrum. Methods Phys. Res. Sect. A 2022, 1025, 166196. [Google Scholar] [CrossRef]

- Oliveira, J.; Martins, P.M.; Martins, P.; Correia, V.; Rocha, J.G.; Lanceros-Mendez, S. Gd2O3:Eu3+/PPO/POPOP/PS composites for digital imaging radiation detectors. Process. Appl. Phys. A 2015, 121, 581–587. [Google Scholar] [CrossRef]

- Sen, S.; Tyagi, M.; Sharma, K.; Sarkar, P.S.; Sarkar, S.; Basak, C.B.; Pitale, S.; Ghosh, M.; Gadkari, S.C. Organic−Inorganic composite Films based on Gd3Ga3Al2O12:Ce scintillator nanoparticles for X-ray Imaging applications. ACS Appl. Mater. Interfaces 2017, 9, 37310–37320. [Google Scholar] [CrossRef] [PubMed]

- Novais, S.M.V.; Monteiro, T.J.; Teixeira, V.C.; Gomes, M.A.; Valerio, M.E.G.; Macedo, Z.S.; Barbosa, L.B. Hydrothermal synthesis of CdWO4 for scintillator-polymer composite films development. J. Lumin. 2018, 199, 225–231. [Google Scholar] [CrossRef]

- Wang, B.; Yang, X.; Chen, S.; Lu, S.; Zhao, S.; Qian, Q.; Cai, W.; Wang, S.; Zang, Z. Flexible perovskite scintillators and detectors for X-ray detection. iScience 2022, 25, 105593. [Google Scholar] [CrossRef]

- Komendo, I.; Bondarev, A.; Fedorov, A.; Dosovitskiy, G.; Gurinovich, V.; Kazlou, D.; Kozhemyakin, V.; Mechinsky, V.; Mikhlin, A.; Retivov, V.; et al. New scintillator 6Li2CaSiO4:Eu2+ for neutron sensitive screens. Nucl. Instrum. Methods Phys. Res. Sect. A 2023, 1045, 167637. [Google Scholar] [CrossRef]

- Oliveira, J.; Correia, V.; Costa, P.; Francesko, A.; Rocha, G.; Lanceros-Mendez, S. Stretchable scintillator composites for indirect X-ray detectors. Compos. Part B-Eng. 2018, 133, 226–231. [Google Scholar] [CrossRef]

- Cai, W.; Wang, A.; Fu, L.; Hu, J.; Rao, T.; Wang, J.; Zhong, J.; Xiang, W. Preparation and luminescent properties of GdOF:Ce, Tb nanoparticles and their transparent PMMA nanocomposites. Opt. Mater. 2015, 43, 36–41. [Google Scholar] [CrossRef]

- Sahi, S.; Chen, W.; Jiang, K. Luminescence enhancement of PPO/PVT scintillators by CeF3 nanoparticles. J. Lumin. 2015, 159, 105–109. [Google Scholar] [CrossRef]

- Boyarintsev, A.Y.; Nepokupnaya, T.A.; Onufriyev, Y.D.; Tarasov, V.A. Composite Scintillator. In Proceedings of the Engineering of Scintillation Materials and Radiation Technologies, Minsk, Belarus, 26–30 January 2016. [Google Scholar]

- McKigney, E.A.; Del Sesto, R.E.; Jacobsohn, L.G.; Santi, P.A.; Muenchausen, R.E.; Ott, K.C.; McCleskey, T.M.; Bennett, B.L.; Smith, J.F.; Cooke, D.W. Nanocomposite scintillators for radiation detection and nuclear spectroscopy. Nucl. Instrum. Methods Phys. Res. Sect. A 2007, 579, 15–18. [Google Scholar] [CrossRef]

- Ouyang, X.; Liu, B.; Xiang, X.; Chen, L.; Xu, M.; Song, X.; Ruan, J.; Liu, L.; Liu, J.; Chen, C.; et al. CsI(Na) micron-scale particles-based composite material for fast pulsed X-ray detection. Nucl. Instrum. Methods Phys. Res. Sect. A 2020, 953, 163120. [Google Scholar] [CrossRef]

- Ziluei, H.; Azimirad, R.; Larijani, M.M.; Ziaie, F. Preparation and optimization of CdWO4-polymer nano-composite film as an alpha particle counter. Nucl. Instrum. Methods Phys. Res. Sect. A 2017, 852, 85–90. [Google Scholar] [CrossRef]

- Sun, Y.; Koshimizu, M.; Yahaba, N.; Nishikido, F.; Kishimoto, S.; Haruki, R.; Asai, K. High-energy X-ray detection by hafnium-doped organic-inorganic hybrid scintillators prepared by sol-gel method. Appl. Phys. Lett. 2014, 104, 174104. [Google Scholar] [CrossRef]

- Liu, C.; Hajagos, T.J.; Kishpaugh, D.; Jin, Y.; Hu, W.; Chen, Q.; Pei, Q. Facile single-precursor synthesis and surface modification of hafnium oxide nanoparticles for nanocomposite γ-ray scintillators. Adv. Funct. Mater. 2015, 25, 4607–4616. [Google Scholar] [CrossRef]

- Hamroun, M.S.E.; Bachari, K.; Guerbous, L.; Berrayah, A.; Mechernene, L. Structural and optical properties of LSO scintillator-polymer composite films. Optik 2019, 187, 111–116. [Google Scholar] [CrossRef]

- Vistovskyy, V.V.; Zhyshkovych, A.V.; Halyatkin, O.O.; Mitina, N.E.; Zaichenko, A.S.; Rodnyi, P.A.; Vasil’ev, A.N.; Gektin, A.V.; Voloshinovskii, A.S. The luminescence of BaF2 nanoparticles upon high-energy excitation. J. Appl. Phys. 2014, 116, 054308. [Google Scholar] [CrossRef]

- Demkiv, T.M.; Halyatkin, O.O.; Vistovskyy, V.V.; Gektin, A.V.; Voloshinovskii, A.S. X-ray excited luminescence of polystyrene-based scintillator loaded with LaPO4-Pr nanoparticles. J. Appl. Phys. 2016, 120, 144301. [Google Scholar] [CrossRef]

- Demkiv, T.M.; Vistovskyy, V.V.; Halyatkin, O.O.; Malyi, T.; Yakibchuk, P.M.; Gektin, A.V.; Voloshinovskii, A.S. Luminescence of polystyrene composites loaded with CeF3 nanoparticles. Nucl. Instrum. Methods Phys. Res. Sect. A 2018, 908, 309–312. [Google Scholar] [CrossRef]

- Demkiv, T.M.; Halyatkin, O.O.; Vistovskyy, V.V.; Hevyk, V.B.; Yakibehuk, P.M.; Gektin, A.V.; Voloshinovskii, A.S. X-ray excited luminescence of polystyrene composites loaded with SrF2 nanoparticles. Nucl. Instrum. Methods Phys. Res. Sect. A 2017, 847, 47–51. [Google Scholar] [CrossRef]

- Demkiv, T.M.; Halyatkin, O.O.; Vistovskyy, V.V.; Gektin, A.V.; Voloshinovskii, A.S. Luminescent and kinetic properties of the polystyrene composites based on BaF2 nanoparticles. Nucl. Instrum. Methods Phys. Res. Sect. A 2016, 810, 1–5. [Google Scholar] [CrossRef]

- Rajakrishna, K.; Dhanasekaran, A.; Yuvaraj, N.; Ajoy, K.C.; Venkatraman, B.; Jose, M.T. Thermal neutron sensitive inorganic compound loaded thin-film composite plastic scintillators. Appl. Radiat. Isot. 2022, 181, 110115. [Google Scholar] [CrossRef] [PubMed]

- Cai, W.; Chen, Q.; Cherepy, N.; Dooraghi, A.; Kishpaugh, D.; Chatziioannou, A.; Payne, S.; Xiang, W.; Pei, Q. Synthesis of bulk-size transparent gadolinium oxide-polymer nanocomposites for gamma ray spectroscopy. J. Mater. Chem. C 2013, 1, 1970–1976. [Google Scholar] [CrossRef] [PubMed]

- Gerasymov, I.; Nepokupnaya, T.; Boyarintsev, A.; Sidletskiy, O.; Kurtsev, D.; Voloshyna, O.; Trubaieva, O.; Boyarintseva, Y.; Sibilieva, T.; Shaposhnyk, A.; et al. GAGG:Ce composite scintillator for X-ray imaging. Opt. Mater. 2020, 109, 110305. [Google Scholar] [CrossRef]

- Feller, R.K.; Purdy, G.M.; Ortiz-Acosta, D.; Stange, S.; Li, A.; McKigney, E.A.; Esch, E.I.; Muenchausen, R.E.; Gilbertson, R.; Bacrania, M.; et al. Large-scale synthesis of CexLa1−xF3 nanocomposite scintillator materials. J. Mater. Chem. 2011, 21, 5716–5722. [Google Scholar] [CrossRef]

- Shevelev, V.S.; Ishchenko, A.V.; Vanetsev, A.S.; Nagirnyi, V.; Omelkov, S.I. Ultrafast hybrid nanocomposite scintillators: A review. J. Lumin. 2022, 242, 118534. [Google Scholar] [CrossRef]

- Athulya, P.A.; Chandrasekaran, N. Interactions of natural colloids with microplastics in aquatic environment and its impact on FTIR characterization of polyethylene and polystyrene microplastics. J. Mol. Liq. 2023, 369, 120950. [Google Scholar] [CrossRef]

- Chen, J.; Yang, F.; Zhang, L.; Zhu, R.-Y.; Du, Y.; Wang, S.; Sun, S.; Li, X. Slow scintillation suppression in yttrium doped BaF2 crystals. IEEE Trans. Nucl. Sci. 2018, 65, 2147–2151. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Deng, M.; Shi, Y.; Qi, X.; Wang, S.; Lu, Y.; Du, Y.; Chen, J. Bulk Polystyrene-BaF2 Composite Scintillators for Highly Efficient Radiation Detection. Crystals 2023, 13, 1334. https://doi.org/10.3390/cryst13091334

Li X, Deng M, Shi Y, Qi X, Wang S, Lu Y, Du Y, Chen J. Bulk Polystyrene-BaF2 Composite Scintillators for Highly Efficient Radiation Detection. Crystals. 2023; 13(9):1334. https://doi.org/10.3390/cryst13091334

Chicago/Turabian StyleLi, Xiang, Mingxue Deng, Yun Shi, Xuejun Qi, Shaohan Wang, Yugui Lu, Yong Du, and Junfeng Chen. 2023. "Bulk Polystyrene-BaF2 Composite Scintillators for Highly Efficient Radiation Detection" Crystals 13, no. 9: 1334. https://doi.org/10.3390/cryst13091334

APA StyleLi, X., Deng, M., Shi, Y., Qi, X., Wang, S., Lu, Y., Du, Y., & Chen, J. (2023). Bulk Polystyrene-BaF2 Composite Scintillators for Highly Efficient Radiation Detection. Crystals, 13(9), 1334. https://doi.org/10.3390/cryst13091334