Abstract

Jian tea bowls are greatly appreciated not only due to their thick and lustrous black glazes, but also their exquisite streaked and mottled patterns. Researches on the firing process and colouring mechanism of typical hare’s fur and oil spot Jian glazes have continuously been carried out in the past decades; however, there are few reports about other scarce types of black-glazed porcelains excavated from the Jian kiln site. In this work, we report on a multi-technique analysis of the surface and cross-sectional structure, phase, morphology and chemical composition of three rare types of Jian tea bowls (tea-dust-glazed ware, grey-glazed ware and pearl-glazed ware) combining optical and spectroscopic methods such as optical coherence tomography (OCT), optical microscopy (OM), Portable energy dispersive X-ray fluorescence spectrometry (XRF), laser-Raman spectroscopy (LRS) and scanning electron microscopy coupled with an X-ray energy dispersive spectrometer (SEM-EDS). Results revealed that the tea dust glaze was one high-temperature iron-based crystalline glaze, and its glaze was characterized by a transparent glass matrix; irregular pits completely or partially filled by TiO2; and that ε-Fe2O3 and residual quartz were randomly distributed all over the surface, which produced the appearance of tea-dust. The grey-glazed porcelain was fired at a lower temperature in the dragon kiln than that of the traditional hare’s fur and oil spot samples, its glaze contained some residual quartz, and anorthite crystals showed a serried distribution along the thickness. The pearl-glazed porcelain was fired through a secondary glazing process via artificial stippling quartz powder. This work provides guidance for the firing process of three rare types of Jian wares and has not only scientific but also cultural profound significance, which reveals the features of their historical heritage.

1. Introduction

The Jian kiln series in the southwestern region of ancient China, which was a large-scale comprehensive kiln, is located in the present-day Jianyang country of Fujian province. The Jian kiln had a long manufacturing history; it started in the Tang Dynasty (618–907 A.D), flourished in the Southern Song Dynasty (1127–1279 A.D.), declined gradually and closed down at the end of the Yuan Dynasty (1271–1368 A.D.) [1]. Due to the prevailing trend of tea-tasting and competition during the Song period, craftsmen began to produce large quantities of black-glazed porcelains [2,3]. Jian tea bowls are greatly appreciated not only due to thick and lustrous black glaze, but also for the exquisite streaked and mottled textural patterns in the glaze [4].

According to the difference of firing schedules in the dragon kiln, black-glazed porcelains fired can be classified into two types: the first type is typically formed by a one-time glazing technique along with the naturally colorful and changeable patterns, such as “hare’s fur (HF)”, “oil spot (OS)”, “partridge feather (PF)”, “tiger stripe (TS)” and “tortoise shell (TS)” [5,6,7]. Among them, HF patterns are recognized by fine radical fur-like streaks and are encountered in the amazing and shining black glaze showing gold, yellowish-brown or silver colors, which are known as the aesthetic values in highlighting the color sparkling effects of tea soup due to the intensive color comparison [8,9]. OS Jian wares are acknowledged as the most characteristic representatives and are decorated with spots; their mottled patterns resemble the drops of oil in water and can differentiate in color from silvery white to the red or rust on the glaze surfaces [10,11]. The black glaze of Jian bowls marked with patterns (streaks or spots) are believed to originate from the phase separation of glaze melt and the crystallization of iron oxides [12]. This type also incorporates some samples fired at higher or lower temperatures in the dragon kiln, such as “persimmon red glazed porcelain”, “tea-dust-glazed porcelain” and “grey-glazed porcelain”. As is known, persimmon red-glazed tea bowls are overfired, (compared with the hare’s fur and oil spotted glazed wares); tea-dust-glazed tea bowls are produced due to the higher or lower temperature; and grey-glazed porcelain is burned at a lower temperature. The other type is featured by artificial stippling through a secondary glazing process, and glaze patterns are not the conventional precipitated iron oxide crystals, such as “pearl-glazed porcelain” [13,14]. These types of unique patterns are inevitably derived from local raw materials and the firing process. In a nutshell, different glaze-decoration effects can be achieved by changing process parameters or firing schedules to modify the crystallization behavior and microstructure of the glazes [15,16,17].

For Jian wares, existing reports have mainly focused on the forming cause and growth mechanism of HF and OS glazes with their distinguishing structures. There is a lack of comprehensive and in-depth studies on the microstructure and composition of other types of tea bowls, and their crystallographic nature is also worth researching. In this work, we paid attention to three rare types of Jian wares (tea-dust-glazed porcelain, grey-glazed porcelain and pearl-glazed porcelain), and conducted a detailed investigation on the cross-sectional structure, morphology, phase component, chemical composition and microstructure through a series of characterization methods.

2. Materials and Methods

2.1. Sample Preparation

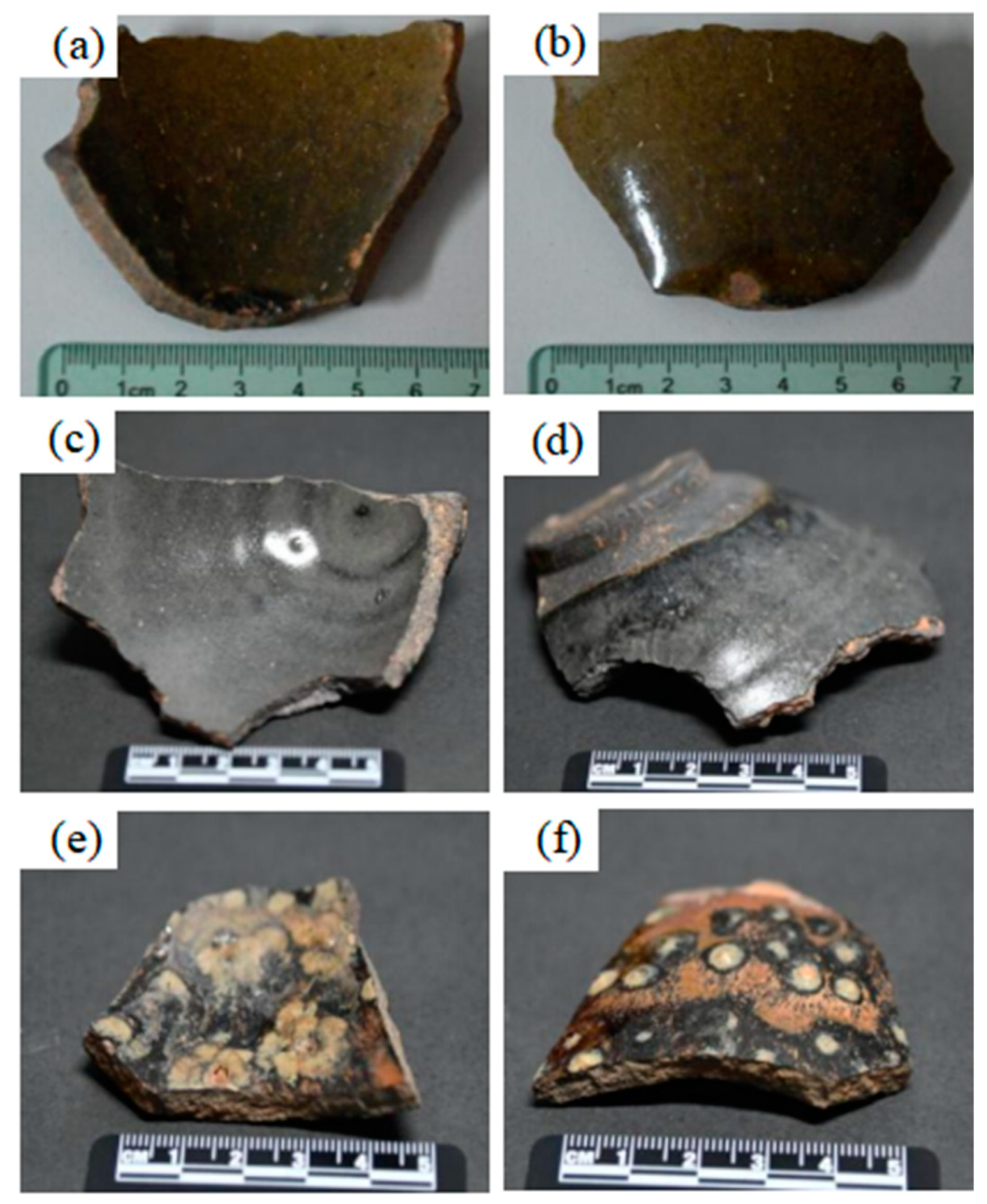

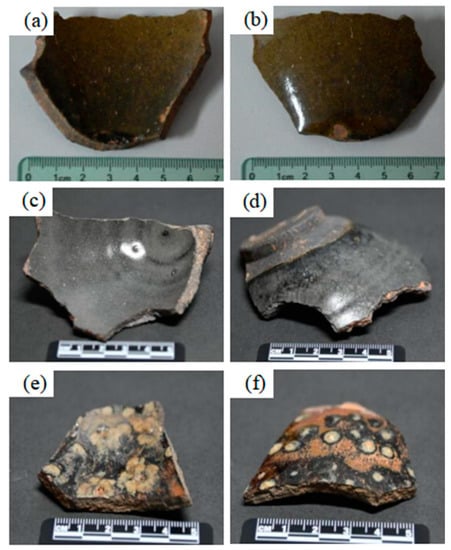

Archaeological fragments of three rare types of Jian tea bowls (tea-dust-glazed porcelain, JZ-07; grey-glazed porcelain, JZ-16; pearl-glazed porcelain, JZ-14) found in the Jian kiln relics (Jianyang District, Nanping City, Fujian Province, China) were obtained for the scientific investigation, as displayed in Figure 1. All porcelain samples could date back to the Song dynasty (960–1279 A.D.) according to their archaeological background. The tested zones of the porcelain samples were cut by a diamond-cutting machine into small pieces to conduct the following experiments. Some specimens provided for the observation of the cross-sections needed to be impregnated with epoxy resin, and then finely polished by routine metallographic methods.

Figure 1.

Practical photos of the three analyzed samples: (a,b) JZ-07, tea-dust-glazed porcelain; (c,d) JZ-16, grey-glazed porcelain; (e,f) JZ-14, pearl-glazed porcelain.

2.2. Characterization Techniques

The chemical composition of both the porcelain glaze and body were examined by portable energy-dispersive X-ray fluorescence spectrometer (EDXRF, OURSTEX 100FA, OURSTEX, Osaka, Japan). The EDXRF technology uses palladium (Pd) as excitation tube and works continuously in three different modes, effectively measuring the major elements (15 KV, 1 mA), trace elements (40 KV, 0.5 mA) and weight elements (40 KV, 1 mA), respectively. This spectrometer used a silicon drift detector (SDD) with an active area of 5 mm2 equipped with one polymer window (MOXTEK AP 3.3 film). Combined with the introduction of a low-vacuum sample chamber, which can effectively reduce the absorption of characteristic spectra of light elements (like Na and Mg), such equipment had already been applied successfully in chemical composition analysis of ancient porcelains and ceramics [18,19,20].

The cross-sectional structure of three groups of glaze layers was studied by optical coherence tomography (OCT, HSL-2100, Santec, Aichi, Japan), which typically consist of a swept light source with central wavelength around 1315–1340 nm, the imaging range was 0–20 mm and imaging depth was 3–3.5 mm. During the testing of silicate materials with a 1.5 refractive index, the transverse and longitudinal spatial resolution was 2.4 μm/pixel and 5.3 μm/pixel, respectively. This technology has been successfully applied in the study of ancient Chinese ceramics and porcelains [21,22,23].

The morphology observations on both the porcelain glaze and body were carried out by optical microscopy (OM, VHX-50000, Keyence, Osaka, Japan). The microstructure and elemental analyses of the porcelain glaze and body (both surfaces and cross-sections) were conducted by scanning electron microscope (SEM) fixed with energy-dispersive X-ray spectrometer (EDS) operated in the back-scattered electron-image mode (TM3000, HITACHI, Tokyo, Japan).

The confocal micro-Raman spectrometer (LRS, LabRAM XploRA, Horiba, Palaiseau, France) was performed on the glaze surface to identify the phase constituents and a diode near-infrared (NIR) (532 nm) laser was applied for the excitation. The laser power was a 300 mW, the confocal pinhole diameter was 300 µm, the slit width was 100 µm, the grating groove per millimeter was 1800 T, the spectral acquisition and imaging acquisition time was 20 s, and the signal acquisition integration times were 2.

3. Results and Discussion

3.1. Chemical Composition Analysis by XRF

The composition difference of the glaze and body is the main reason for the distinguished decorative effects of black-glazed porcelains. To achieve a comprehensive understanding of the chemical compositions, major and minor components, three rare groups of Jian samples were examined by EDXRF. In Table 1, it can be seen that the tea-dust porcelain possessed higher Fe2O3 concentration in glaze (8.08 wt.%) and body (11.52 wt.%) than that of other two samples, and this tea-dust glaze exhibited relatively higher content in fluxing agents such as CaO. For grey-glazed porcelain, this consisted of the lowest Al2O3 and highest SiO2 in the glaze, typically with much more alkali oxide (K2O) as flux than that of the tea-dust-glazed sample. Pearl-glazed porcelain behaved similarly in its chemical composition with grey-glazed porcelain. To our knowledge, Jian glazes were traditional Chinese high-temperature calcium-iron oxide-aluminosilicate glazes, and the unique black glaze provided a glass network (SiO2 as main component), which served as nucleation sites for the formation of iron oxide crystals. Fe elements primarily exist in the network structure of a glassy phase in the form of Fe3+ ions or Fe3+-O-Fe2+ atomic groups [24]. Meanwhile, the silicate matrix contributes to the presence of Fe3+ ions and principally forms a four-coordinate structure [FeO4] with O2− ions [25]. Under these circumstances, Fe3+ ions have a strong capability in their colorings, therefore making the porcelain glaze brownish [26]. Other network modifiers such as MgO and Na2O were found at lower concentrations.

Table 1.

Chemical composition data (wt.%) of the glaze and body carried out using PXRF on the three porcelain samples.

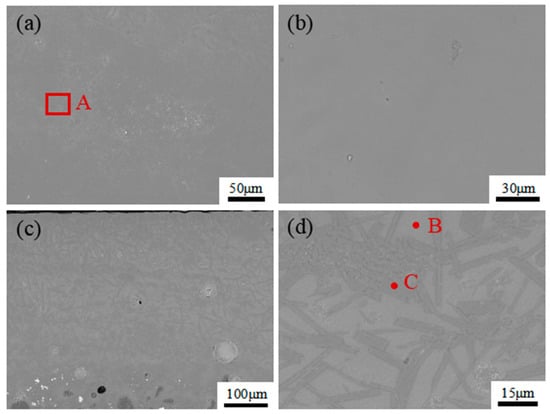

3.2. Cross-Section Structure Analysis by OCT

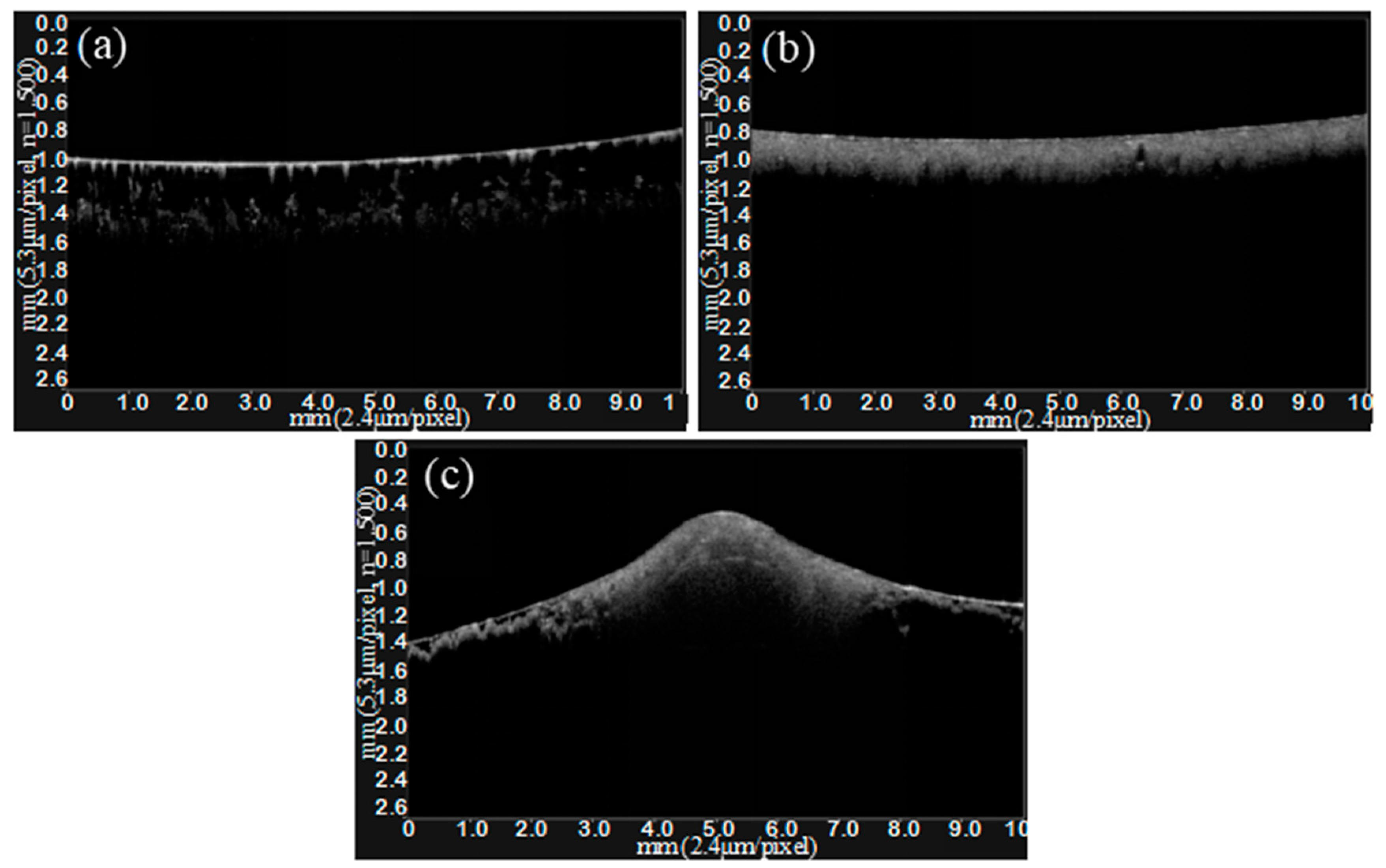

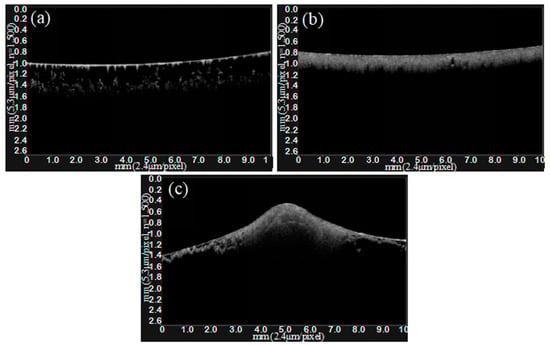

OCT is a new non-destructive imaging technology based on confocal microscopy and the Michelson interference principle, and can provide a quick and easy view of internal physical structure and uniformity. The characteristics about the size and distribution of bubbles, strong scattering particles, the uniformity, stratification and transmittance of glaze surface in the cross-sections can be acquired from the OCT gray images without destroying the structure, which also provides some guidance for the subsequent analysis like SEM-EDS.

As displayed in Figure 2, it can be seen that the structure of three types of glaze layers showed obviously different uniformity, stratification and transmissivity. Tea-dust glaze with high transparency embraced a strong capacity of light absorption, and this type of porcelain glaze was characterized by a glassy phase, but combined with a small number of scattering particles, which exhibited as some bright raised dots on the white line. The opaque grey-glazed porcelain, was dominated by a uniform scattering phase, and the glaze/body interface was invisible; The pearl-glazed porcelain had artificially decorated white patterns and possessed ra elatively stronger scattering to the detection light. On the contrary, non-stippling regions showed a higher capacity for light absorption, and some scattering particles were distributed in the glaze. The distinguished cross-sectional structures revealed that there were significant differences in the firing processes or raw materials of the tea-dust porcelain, grey-glazed porcelain and pearl-glazed porcelain, even though they were all fired at Jian kiln site of Song Dynasty.

Figure 2.

OCT gray images for three samples: (a) JZ-07 the glaze layer of tea-dust-glazed porcelain; (b) JZ-16 the glaze layer of grey-glazed porcelain; and (c) JZ-14, the glaze layer of pearl-glazed porcelain.

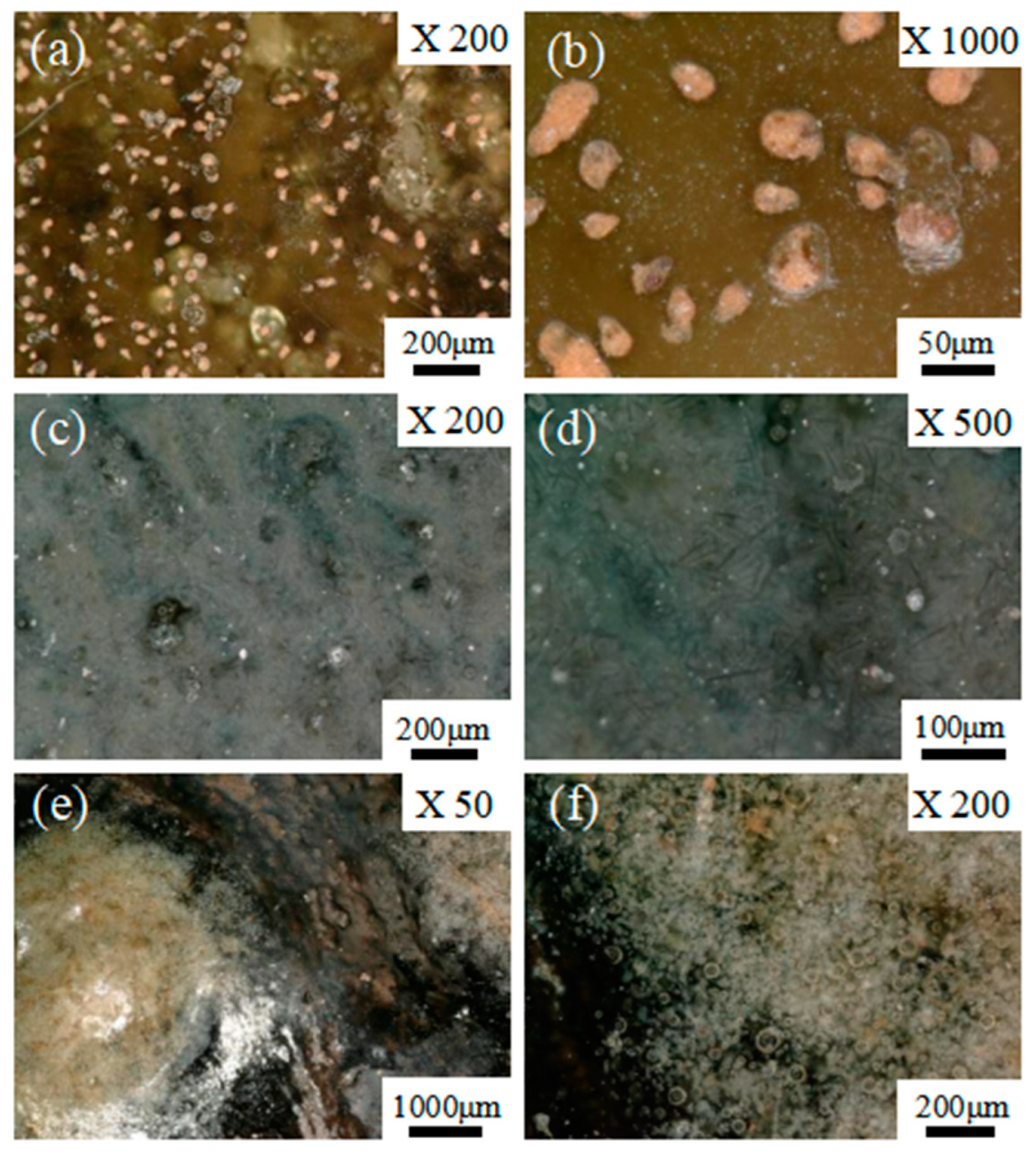

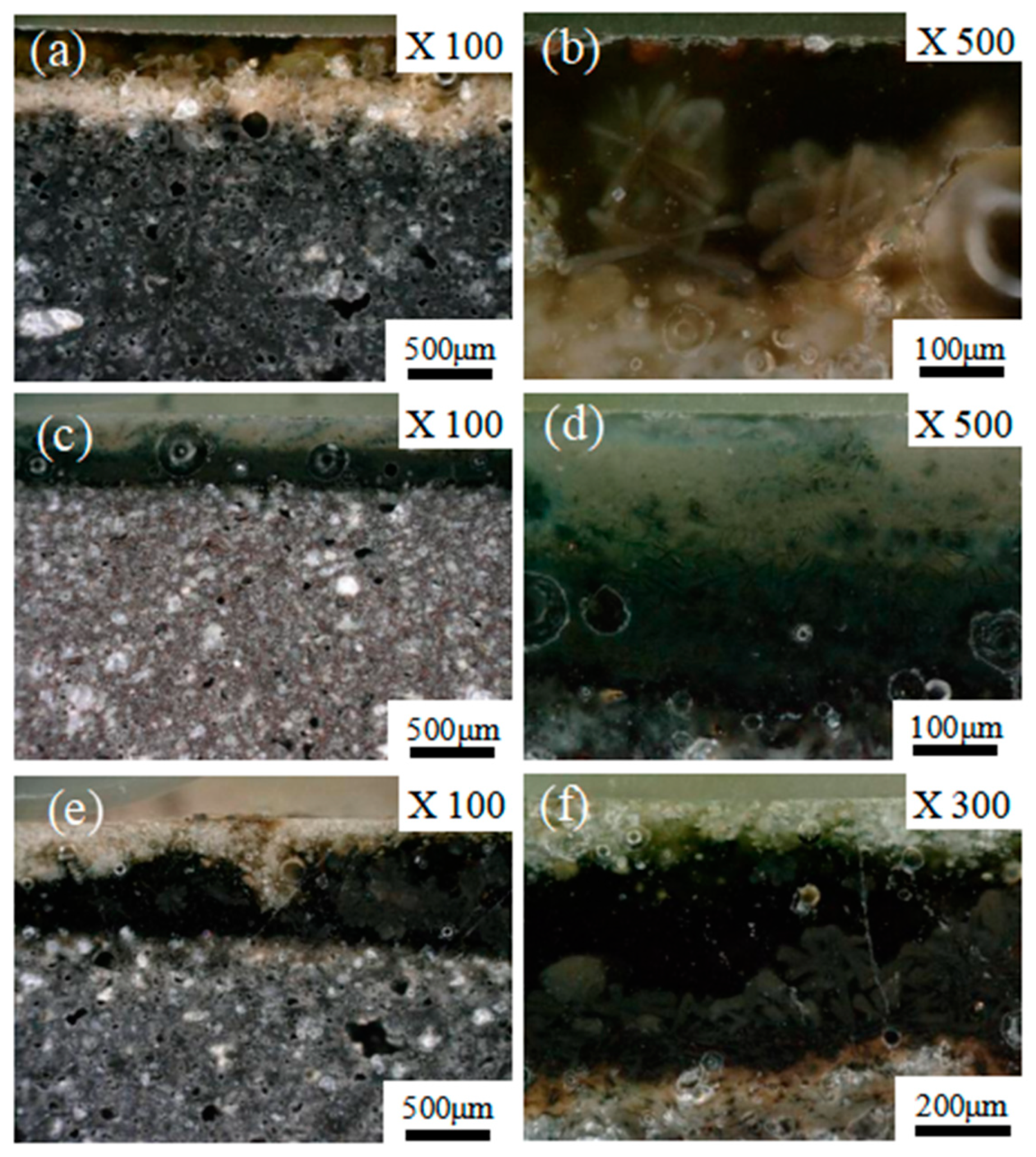

3.3. Microstructure Analysis by OM

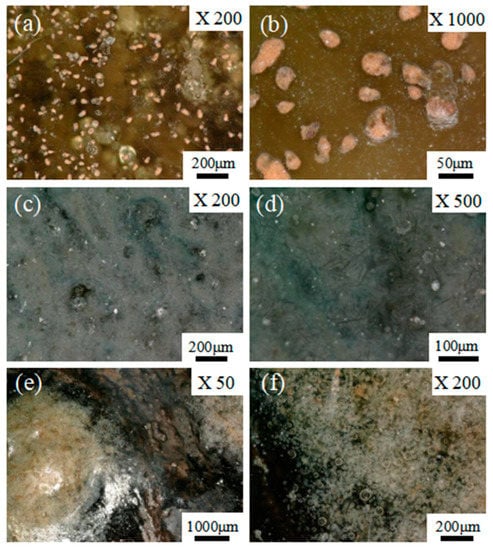

The optical microscopic observation of surface and cross-sections was examined by OM technology equipped with an ultra-depth-of-field system, since it displays the images’ information and colour characteristics, which reflects the authenticity of porcelain samples on the macro scale. As revealed in Figure 3 and Figure 4, tea-dust-glazed porcelain was characterized by a yellow translucent surface with an admixture of green, dots sprinkled on ground resembled the dust of tea leaves. One white alteration layer about 200 μm thick was located at the body-glaze interface due to the interaction and diffusion during firing. Grey-glazed porcelain kept a unique milky texture, and there were plenty of particles randomly distributed over the surface, one underlying greyish white emulsion layer could also be observed. Moreover, white patterns of pearl-glazed porcelain were featured by a transparent glassy matrix. It was worth noting that the crimson body of grey-glazed porcelain was much coarser than that of the two samples, which comprised a large number of pores, quartz particles and impurity inclusions inside.

Figure 3.

Surface morphology of three analyzed samples glaze: (a,b) JZ-07 tea-dust-glazed porcelain; (c,d) JZ-16, grey-glazed porcelain; and (e,f) JZ-14, pearl-glazed porcelain.

Figure 4.

The cross-sections of three analyzed samples: (a,b) JZ-07 tea-dust-glazed porcelain; (c,d) JZ-16 grey-glazed porcelain; and (e,f) JZ-14 pearl-glazed porcelain.

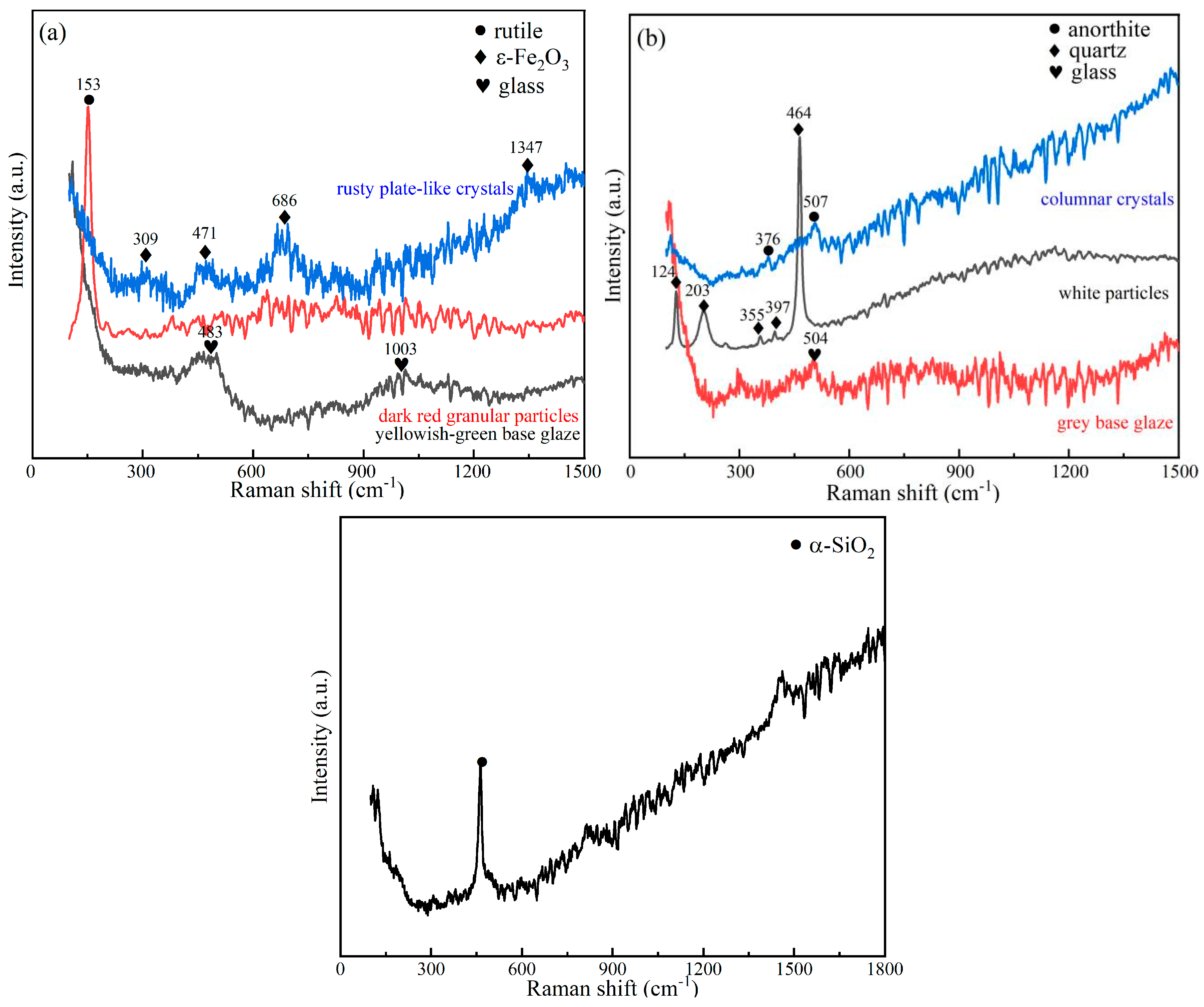

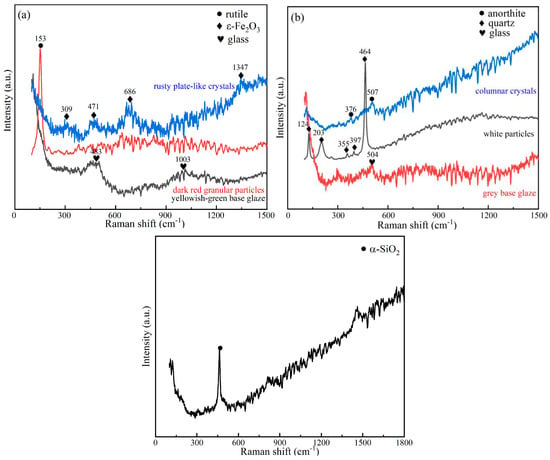

3.4. Phase Composition Analysis by RS

With the purpose of precisely recognizing the phase composition of crystals and base glaze, non-destructive RS measurements were carried out on the glaze surfaces of three types of specimens, exhibited in Figure 5. For tea-dust-glazed porcelain, the homogeneous yellowish-green glaze was characterized by a glass phase; however, inside the tea-dust spots, spectra collected at dark red granular particles were identified to the rultile phase (TiO2), and spectra taken at rusty flaky or plate-like crystals were well matched with the iron oxide phase (ε-Fe2O3). In terms of the grey-glazed porcelain, there were plenty of residual quartz particles (α-SiO2) dispersed over the glaze surface. In addition, some anorthite crystals with columnar or tabular morphology existed in the grey base glaze. The RS results disclosed that this porcelain glaze was generally featured by a glassy matrix. As for the pearl-glazed porcelain fired by intentionally stippling process, the main crystalline phase of decorated white patterns corresponded to the quartz phase, it can be inferred that this sample might have been fired by secondary glazing with quartz powder over the black-base glaze. Since Jian glazes were known as traditional Chinese iron-based high-temperature glazes, the microstructure-forming mechanism of porcelain glazes might cover three cases according to the reported studies [7,11,27]: (1) homogeneous amorphous glaze without the crystallization or phase separation; (2) local phase separation adjacent to the glaze surface followed by the crystallization of iron oxides; and (3) anorthite crystallization accompanied by inter-crystal phase separation and the subsequent crystallization of iron oxides.

Figure 5.

Raman spectra collected at different regions on glaze surfaces of the three samples: (a) JZ-07 tea-dust-glazed porcelain; (b) JZ-16 grey-glazed porcelain; and (c) JZ-14 pearl-glazed porcelain.

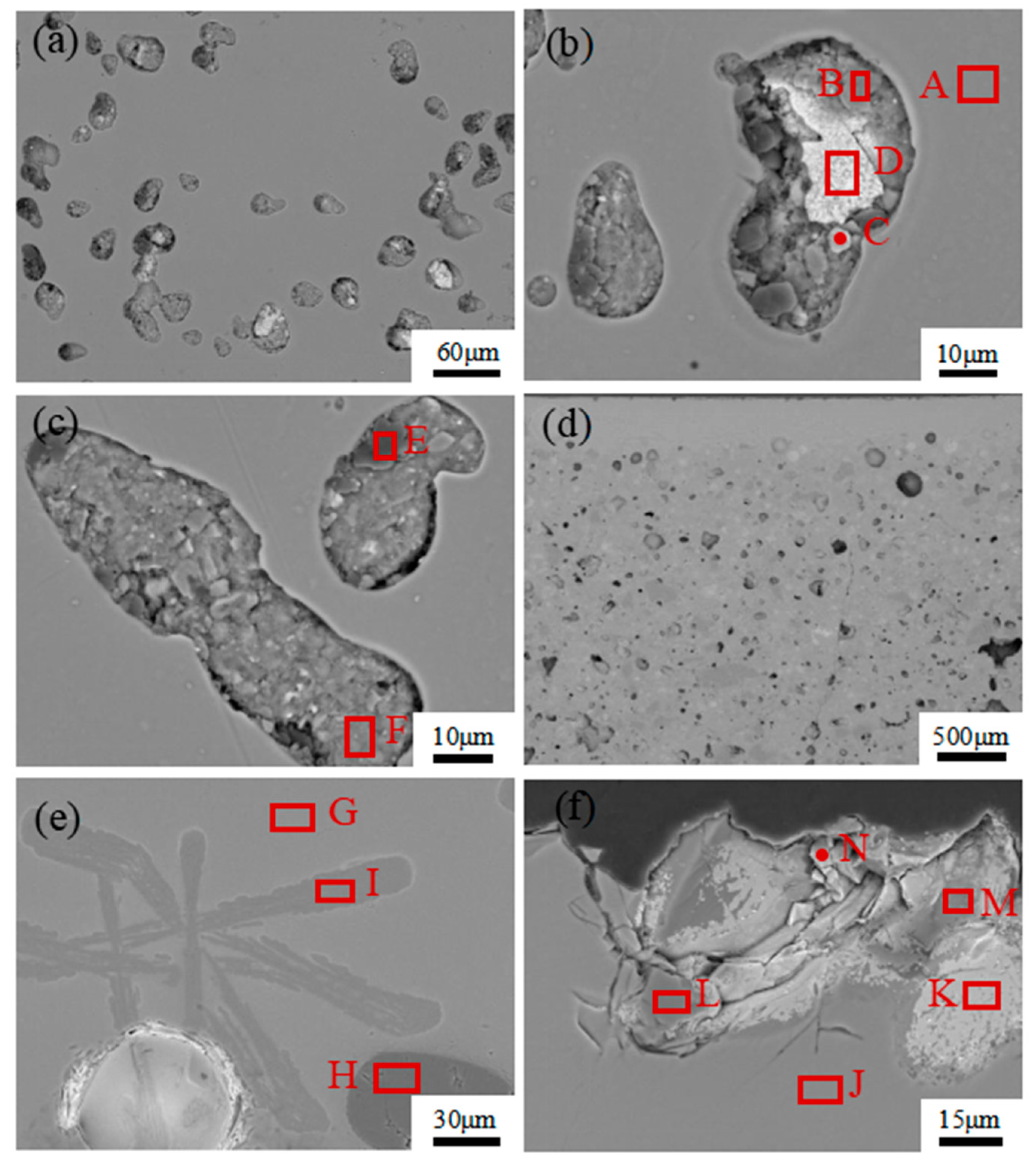

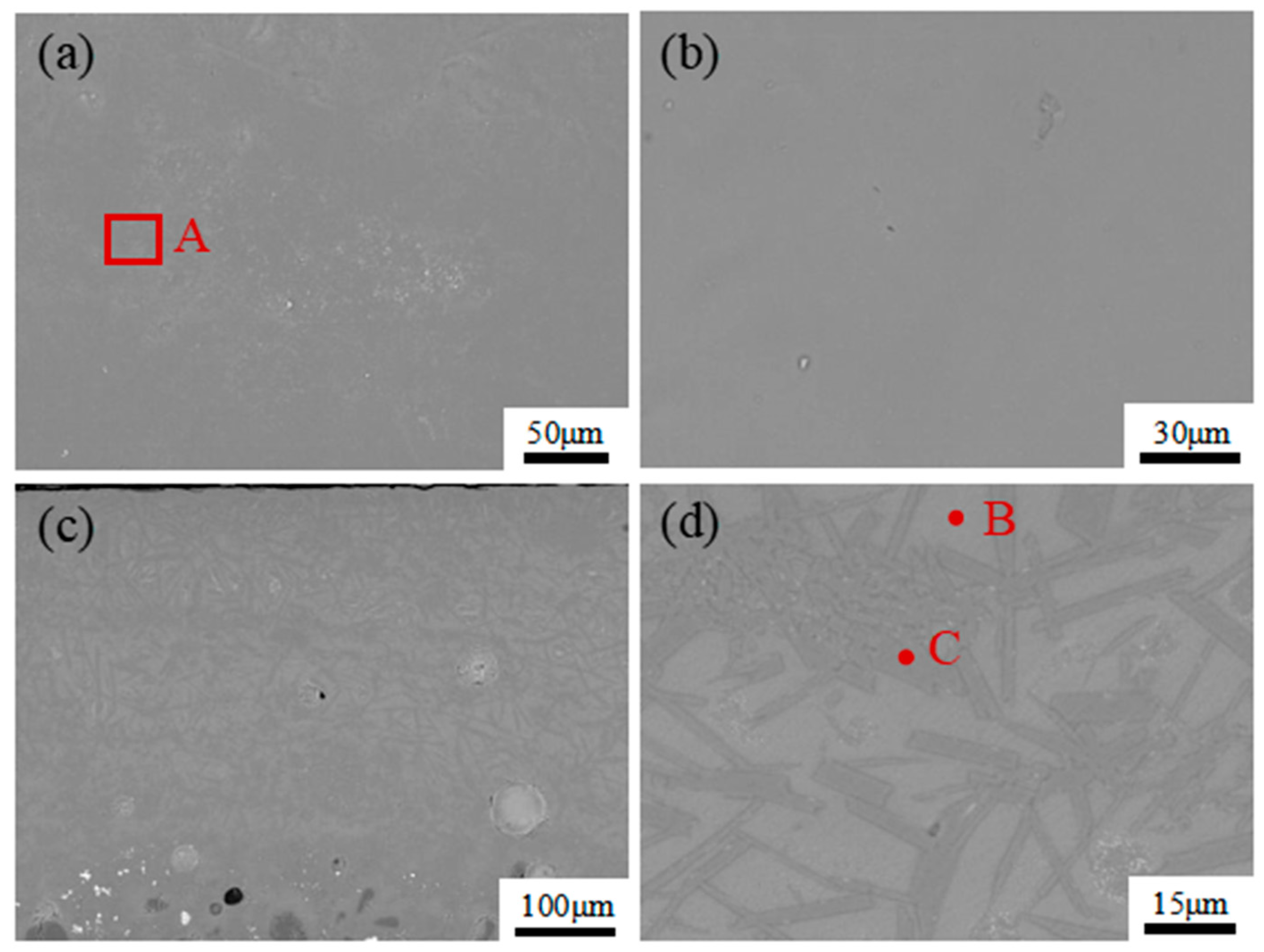

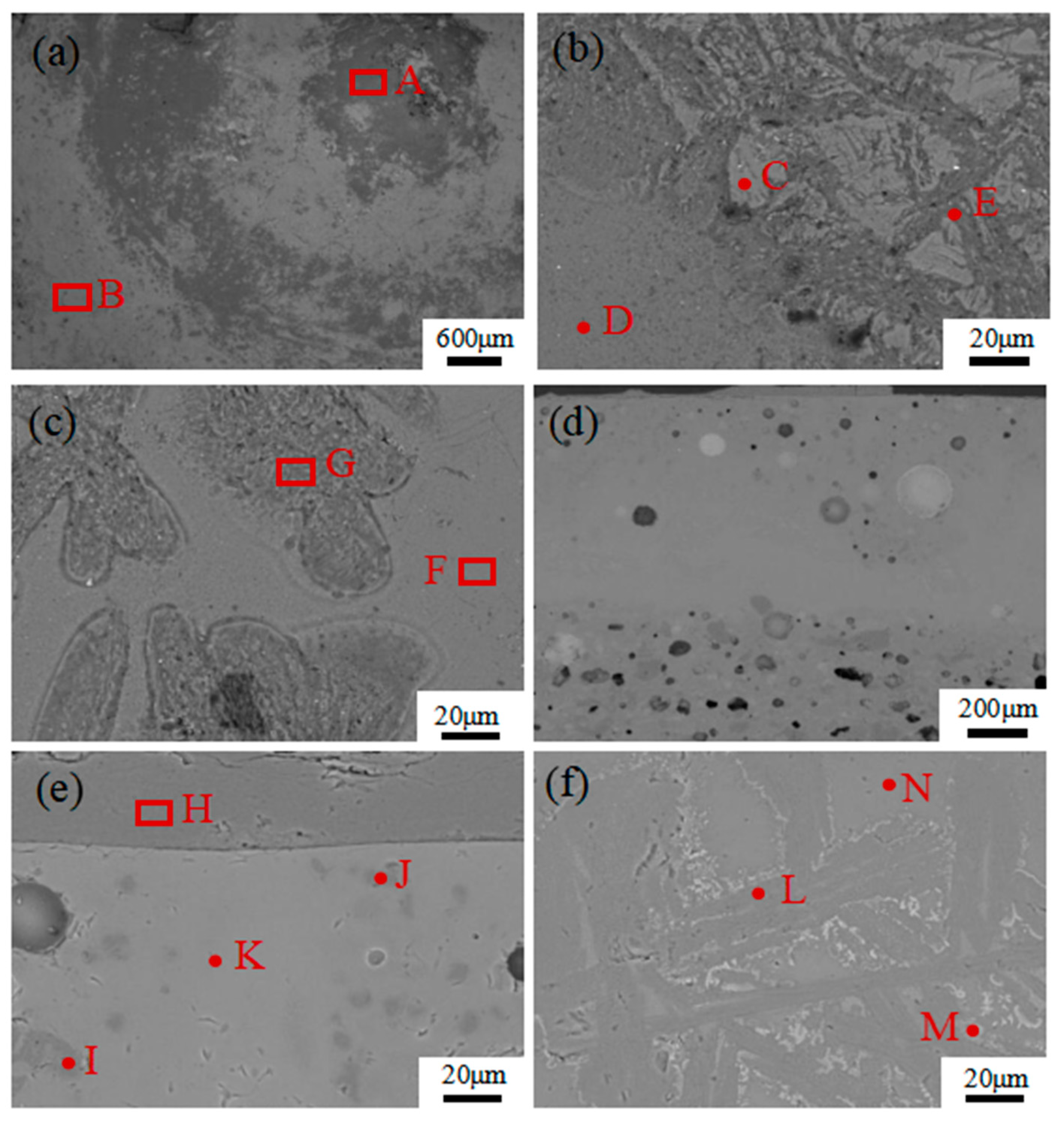

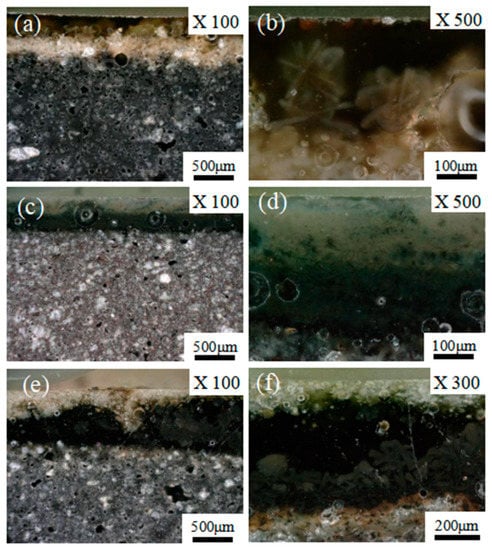

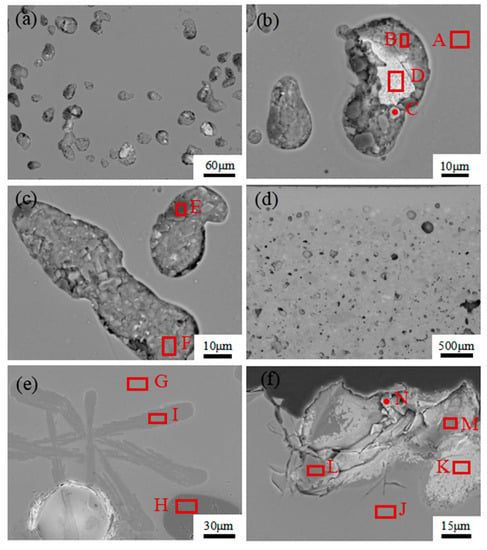

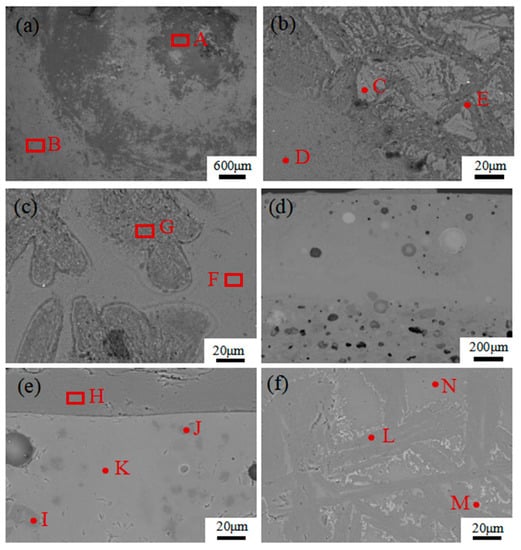

3.5. Microstructure Analysis by SEM

With the aim of achieving a better and deeper understanding of the porcelain glazes and body characteristics, SEM results performed on surface and cross-sections of three types of samples are presented in Figure 6, Figure 7 and Figure 8. In addition, as a supplement to detailed chemical component analysis, quantitative elemental mapping results by EDS are displayed in Table 2.

Figure 6.

SEM images of tea-dust-glazed porcelain (JZ-07) with different magnification: (a–c) surface morphology; and (d–f) the polished cross-section morphology.

Figure 7.

SEM images of grey-glazed porcelain (JZ-16) with different magnification: (a,b) surface morphology; and (c,d) the polished cross-section morphology.

Figure 8.

SEM images of pearl-glazed porcelain (JZ-14) with different magnification: (a–c) surface morphology; and (d–f) the polished cross-section morphology.

Table 2.

EDS results for different regions collected at the glaze surface and cross-sections of the tea-dust-glazed porcelain, grey-glazed porcelain and pearl-glazed porcelain, respectively (wt.%).

As presented in Figure 6, the tea-dust glaze showed a unique and fascinating morphology, irregular pits were randomly distributed all over the surface, completely or partially filled up by the different substances. The yellowish-green glaze was mainly composed of Al2O3 (8.47 wt.%), SiO2 (33.54 wt.%), Fe2O3 (4.40 wt.%), K2O (3.56 wt.%) and CaO (2.28 wt.%). This was similar to the chemical composition of Jian hare’s fur and oil spot black glaze. Typically, inside the tea-dust pits, some Al-enriched crystals could be observed, which exhibited nearly two times (16.99 wt.%) than that of the homogeneous base glaze. Ti concentrated much more on the smaller circular crystals (27.51 wt.%), which could be the rutile mineral (TiO2). Several large tabular crystals possessed a very high level of Fe concentration (52.49 wt.%), indicated that those were the iron oxides (ε-Fe2O3). Besides, the cross-sectional structure (Figure 6f) showed that there were plenty of residual quartz particles existed in spots. Some flower-shaped crystal clusters found at the glaze/body interface contained relatively higher concentrations in Ca, Al and Si, which could be the anorthite. It was generally acknowledged that the tea-dust-glazed porcelain was fired between 1250 °C and 1280 °C with a weaker oxidizing or reducing atmosphere [28], and these crystals jointly produced the appearance of tea dust.

The grey-glazed porcelain displayed a relatively uniform structure without numerous visible crystals precipitated on surface, and this type of glaze showed a sharp decrease in Fe content. The cross-sections revealed that there were plenty of columnar crystals distributed in thickness with high Ca (11.27 wt.%) and Al (16.28 wt.%) concentration, which could be the anorthite. Gray glaze with opalescent texture might result from the widespread crystals and residual quartz particles. Combined with the glaze morphology exhibited in Figure 7, it can be deduced that this grey-glazed porcelain was not fully fired in the dragon kiln with relatively lower temperature when compared to Jian hare’s fur glazed porcelain and oil spot glazed porcelain.

SEM results showed that whites patterns were above the glaze (Figure 8d,e), and only consisted of SiO2, which confirmed that pear glazed porcelain was fired by a secondary glazing process with quartz powder over the base glaze with a maximum thickness of around 50 μm. In the non-stippling regions, some iron oxides precipitated over the glaze surface. It can be inferred that such a high firing-temperature in the dragon kiln not only resulted in silicon oxide vitrified, but also precipitated the iron oxide crystals. In addition, some large-scale Ca-enriched columnar crystals surrounded by small Fe-enriched particles were recognized at the glaze/body interface.

It is worth mentioning that these unique porcelain glazes with different decorated patterns are inevitably derived from local iron-enrichment raw materials and the firing schedules. In the dragon kiln, with the combined contributions of melting, bubbling, diffusion of the cover and ground glazes, as well as the development of phase separation during the firing process, the ideal crystalline markings of iron oxide precipitated during firing come into being [29,30]. Via controlling the process parameters, firing atmosphere (oxidizing or reducing) and temperature (1230–1300 °C, heating and cooling rate, soaking time), the colored streaked or mottled glaze patterns can be obtained [31]. In addition, craftsmen can also obtain predetermined porcelains by changing process procedures or glaze formula (for example, adding a certain type of mineral component).

Research has shown that there were significant differences in the morphology and chemical composition of porcelains fired in different kilns. For the tea-dust-glazed porcelain excavated from the Beijing Longquanwu Kiln and Jiangxi Jingdezhen kiln, their glaze appearance is usually opaque and milky, there is more augite, anorthite, residual quartz and magnetite inside the glaze, indicating that those tea-dust-glazed samples were fired at lower temperatures than that of traditional sauce and black-glazed porcelain [32,33,34]. However, for the tea-dust-glazed porcelain excavated from the Fujian Jian Kiln, the glazes exhibit a translucent appearance, their glazes tend to have more ε-Fe2O3 crystals in combination with some rutile and few residual quartz, suggesting that these tea-dust Jian wares could be overfired. The tea-dust porcelain glaze appeared yellowish-brown in an oxidizing atmosphere but yellowish-green in a reduced atmosphere [35]. For Jian glazes, the decorated patterns turned out variations in shape, scale, distribution and color, which were closely associated with the variety, amount, integrity and degree of order of crystal precipitation on the surface, determined by the firing techniques, viscosity-temperature characteristics of the glaze, and the process of bubble formation and elimination [36].

4. Conclusions

In conclusion, this work contributed to the research of the glaze surfaces and cross-section structure, morphology, phase and chemical composition of three rare types of Jian wares (tea-dust-glazed porcelain, grey-glazed porcelain and pearl-glazed porcelain) via optical or spectroscopic OCT, OM, RS, XRF and SEM-EDS methods. Based on the experiments, the main conclusions were drawn as follows:

(1) Tea-dust-glazed porcelain possessed a higher Fe2O3 concentration in its glaze (8.08 wt.%) and body (11.52 wt.%) than that of the traditional plain black glaze, and this type of glaze exhibited relatively higher contents in fluxing agents such as CaO. It was characterized by a yellowish-green translucent glaze with irregular pits randomly distributed all over the glaze surface, and Fe2O3 functioned as the main crystalline agent and colorant. TiO2 and ε-Fe2O3 crystals, together with residual quartz particles, which produced the appearance of tea dust.

(2) Grey-glazed porcelain consisted of the lowest Al2O3 and highest SiO2 among the glazes, typically with much more alkali oxide (K2O) as flux. It was fired at a relatively lower temperature in the dragon kiln, and its glaze contained plenty of anorthite crystals and residual quartz particles.

(3) Typically for the pearl-glazed porcelain, surface white patterns above the base glaze with a maximum thickness of around 50 μm only consisted of SiO2, which was indicated that this porcelain was fired through a secondary glazing process by artificial stippling quartz powder. In the non-stippling regions, some iron oxides precipitated over the glaze surface. High firing-temperature not only caused the silica vitrification, but also precipitated the iron oxide crystals.

Author Contributions

Conceptualization, S.T. and Q.L.; data curation, S.T.; formal analysis, S.T., Y.Z., S.L., Y.Y., J.D. and Q.L.; writing-original draft preparation, S.T.; writing—review and editing, S.L. and Q.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by the National Key R&D Program of China (Funder: Qinghui Li; grant number: 2019YFC1520203).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The authors are grateful for the technical assistance provided by Shiqian Tao.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Chen, X.; Chen, S.; Huang, R. A study on Song dynasty Jian bowl. China Ceram. 1983, 2, 61–69. (In Chinese) [Google Scholar]

- Ling, Z. A preliminary study on ancient black glazed porcelain in China. J. Chin. Ceram. Soc. 1979, 7, 190–200, 283–284. (In Chinese) [Google Scholar]

- Wu, M. Black-Glazed Jian Ware and Tea Drinking in the Song Dynasty; Orientations: Hong Kong, China, 1998; pp. 22–31. [Google Scholar]

- Li, M.; Li, W.; Lu, X.; Xu, C. Controllable preparation and decorative effect of iron-based crystalline glazes. J. Chin. Ceram. Soc. 2020, 48, 1134–1144. (In Chinese) [Google Scholar]

- Tao, S.; Liu, S.; Yuan, Y.; Dong, J.; Li, Q. A microstructural and compositional study of ε-Fe2O3 crystals in the hare’s fur Jian Ware. Crystals 2022, 12, 367. [Google Scholar] [CrossRef]

- Chen, X.; Li, W.; Xu, C.; Lu, X. Angle dependence of Jian bowl color and its coloring mechanism. J. Eur. Ceram. Soc. 2021, 42, 693–706. [Google Scholar] [CrossRef]

- Li, X.; Lu, J.; Yu, X.; Zhou, J.; Li, L. Imitation of ancient black-glazed Jian bowls (Yohen Tenmoku): Fabrication and characterization. Ceram. Int. 2016, 42, 15269–15273. [Google Scholar] [CrossRef]

- Guan, M.; Kang, B.; Wei, X.; Li, G.; Jia, C.; Li, H.; Ding, Y.; Lei, Y. The microstructure of multicolor hare’s fur glaze: The correlation between mor-phological and compositional characteristics and glaze color. Herit. Sci. 2021, 9, 21. [Google Scholar] [CrossRef]

- Chen, N. Taking the Hare’s fur glazed bowls as an example, discussing the firing process of Jian wares. Orient. Collect. 2020, 6, 48–50. (In Chinese) [Google Scholar]

- Shi, P.; Wang, F.; Zhu, J.; Zhang, B.; Zhao, T.; Wang, Y.; Wang, J. Effect of phase separation on the Jian ware blue colored glaze with iron oxide. Ceram. Int. 2018, 44, 16407–16413. [Google Scholar] [CrossRef]

- Li, W.; Luo, H.; Li, J.; Li, J.; Guo, J. Studies on the microstructure of the black-glazed bowl sherds excavated from the Jian kiln site of ancient China. Ceram. Int. 2008, 34, 1473–1480. [Google Scholar] [CrossRef]

- Dejoie, C.; Sciau, P.; Li, W.; Noé, L.; Mehta, A.; Chen, K.; Luo, H.; Kunz, M.; Tamura, N.; Liu, Z. Learning from the past: Rare ε-Fe2O3 in the ancient black-glazed Jian (Tenmoku) wares. Sci. Rep. 2014, 4, 4941. [Google Scholar] [CrossRef]

- Ouyang, Z. Discussion on the problems related to the decoration of high-foot cup with egg white glaze pearl grains in the Yuan dynasty. China’s Ceram. 2022, 58, 81–87. [Google Scholar]

- Barshchevskii, B.U.; Loginov, V.M.; Neklyudova, T.L. Decorating porcelain ware with precious and semiprecious stones and colored glass. Glas. Ceram. 1995, 52, 127–128. [Google Scholar] [CrossRef]

- Chen, X.; Huang, R.; Zhou, X. Discussion on the peculiarity of oil spot national treasure Tenmoku wares Jian of spot through the research results of the rare sherds. J. Jingdezhen Ceram. Inst. 1995, 16, 26–34. (In Chinese) [Google Scholar]

- Li, W.; Zhang, W.; Lu, X. Chemical compositions and microstructures of hare’s fur black-glazed porcelains from Jian kiln, Jizhou kiln and Yaozhou kiln sites. J. Build. Mater. 2011, 14, 329–334. (In Chinese) [Google Scholar]

- Hoo, Q.; Liang, Y.; Yan, X.; Wang, X.; Cao, T.; Cao, X. Millimeter-sized flower-like clusters composed of mullite and ε-Fe2O3 on the Hare’s Fur Jian Ware. J. Eur. Ceram. Soc. 2020, 40, 4340–4347. [Google Scholar] [CrossRef]

- Liu, S.; Li, Q.H.; Gan, F.; Zhang, P.; Lankton, J.W. Silk Road glass in Xinjiang, China: Chemical compositional analysis and interpretation using a high-resolution portable XRF spectrometer. J. Archaeol. Sci. 2012, 39, 2128–2142. [Google Scholar] [CrossRef]

- Ma, Q.; Pollard, A.M.; Jiang, J.; Weng, Y. Evaluation of Quantitative XRF Analysis Applied to Determine Cobalt Sources in Chinese Blue-and-White Porcelain. Archaeometry 2020, 63, 194–203. [Google Scholar] [CrossRef]

- Qi, Y.; Qiu, M.-Z.; Jing, H.-Z.; Wang, Z.-Q.; Yu, C.-L.; Zhu, J.-F.; Wang, F.; Wang, T. End-to-end ancient ceramic classification toolkit based on deep learning: A case study of black glazed wares of Jian kilns (Song Dynasty, Fujian province). Ceram. Int. 2022, 48, 34516–34532. [Google Scholar] [CrossRef]

- Dong, J.; Li, Q.; Hu, Y. Multi-technique analysis of an ancient stratified glass eye bead by OCT, μ-XRF, and μ-Raman spectroscopy. Chin. Opt. Lett. 2020, 18, 090001. [Google Scholar] [CrossRef]

- Zhong, D.; Guo, M.; Hu, Y.; Song, L.; Dong, J.; Li, Q. Nondestructive analysis of iron rich porcelains excavated from Qingliangsi Site in Baofeng Country, Henan Province. Spectrosc. Spectr. Anal. 2019, 1, 172–179. (In Chinese) [Google Scholar]

- Yan, X.; Dong, J.; Guo, M. Preliminary research in section structure characteristics of ancient glaze based on OCT technology. Chin. J. Lasers 2014, 41, 0908001. [Google Scholar] [CrossRef]

- Zhang, F. Science of Chinese Ancient Ceramics; Shanghai People’s Fine Arts Publishing House: Shanghai, China, 2000; p. 87. [Google Scholar]

- Wu, B.; Zhao, W.; Ren, X.; Liu, X.; Li, B.; Feng, S.; Feng, X.; Zhao, H. Firing process and colouring mechanism of black glaze and brown glaze porce-lains from the Yuan and Ming dynasties from the Qingliang Temple kiln in Baofeng, Henan, China. Ceram. Int. 2021, 47, 32817–32827. [Google Scholar] [CrossRef]

- Zhang, C. The structural analysis and coordination discussion on iron-ion tinting principle in iron oxide Containing glass. Glass Enamel 2004, 32, 38–46. [Google Scholar]

- Wen, R.; Wang, D.; Wang, L.; Dang, Y. The colouring mechanism of the Brown glaze porcelain of the Yaozhou Kiln in the Northern Song Dynasty. Ceram. Int. 2019, 45, 10589–10595. [Google Scholar] [CrossRef]

- Xu, L.; Miu, S.; Yu, P.; Wei, H.; Li, X. Development of high-temperature reducing tea dust glaze. China Ceram. Ind. 2015, 22, 1–5. [Google Scholar]

- Xu, C.; Li, W.; Lu, X.; Zhang, W.; Luo, H.; Guo, J. Unveiling the science behind the tea bowls from the Jizhou kiln. Part I. Chemical compositions and the two-layer glazing technique. Ceram. Int. 2018, 44, 8540–8549. [Google Scholar] [CrossRef]

- Xu, C.; Li, W.; Lu, X.; Zhang, W.; Luo, H.; Guo, J. Unveiling the science behind the tea bowls from the Jizhou kiln. Part II. Microstructures and the coloring mechanism. Ceram. Int. 2018, 44, 19461–19473. [Google Scholar] [CrossRef]

- Franci, G.; Akkas, G.T.; Yildirim, S. Characterization of a Jian-like sherd with the optical microscope, confocal Raman, wavelength-dispersive X-ray fluorescence, and portable XRF spectrometers. J. Raman Spectrosc. 2020, 51, 1343–1352. [Google Scholar] [CrossRef]

- Chen, R.; Yang, J. A discussion of tea dust glaze porcelain. Palace Mus. J. 2004, 01.012, 112–117, 160. [Google Scholar]

- Chen, Y.; Zhang, X.; Huang, X.; Liu, L.; Qi, H. Study on microstructure and technology of black porcelain of Beijing Longquanwu kiln in Liao and Jin Dynasties. China Ceram. 1999, 35, 38–42. [Google Scholar]

- Sun, G.; Wu, G. Effect of firing temperature on crystallization and color of tea dust glaze. J. Ceram. 2014, 35, 411–414. [Google Scholar]

- Qiu, B.; Gu, X.; Dong, W.; Luo, T.; He, M.; Wu, P. Effect of chemical composition on microstructure and appearance of tea-dust type glaze. China Ceram. 2019, 55, 61–67. [Google Scholar]

- Liu, Z.W.; Zhang, Z.G.; Li, H.; Wu, W.; Hua, J.J.; Cheng, G.F.; Lin, C.C. Microstructure Characteristics of the Black-Glazed Shreds Excavated from the Qingliangsi Kiln. Key Eng. Mater. 2011, 492, 112–117. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).