Simulation and Experimental Study of Hot Deformation Behavior in Near β Phase Region for TC21 Alloy with a Forged Structure

Abstract

:1. Introduction

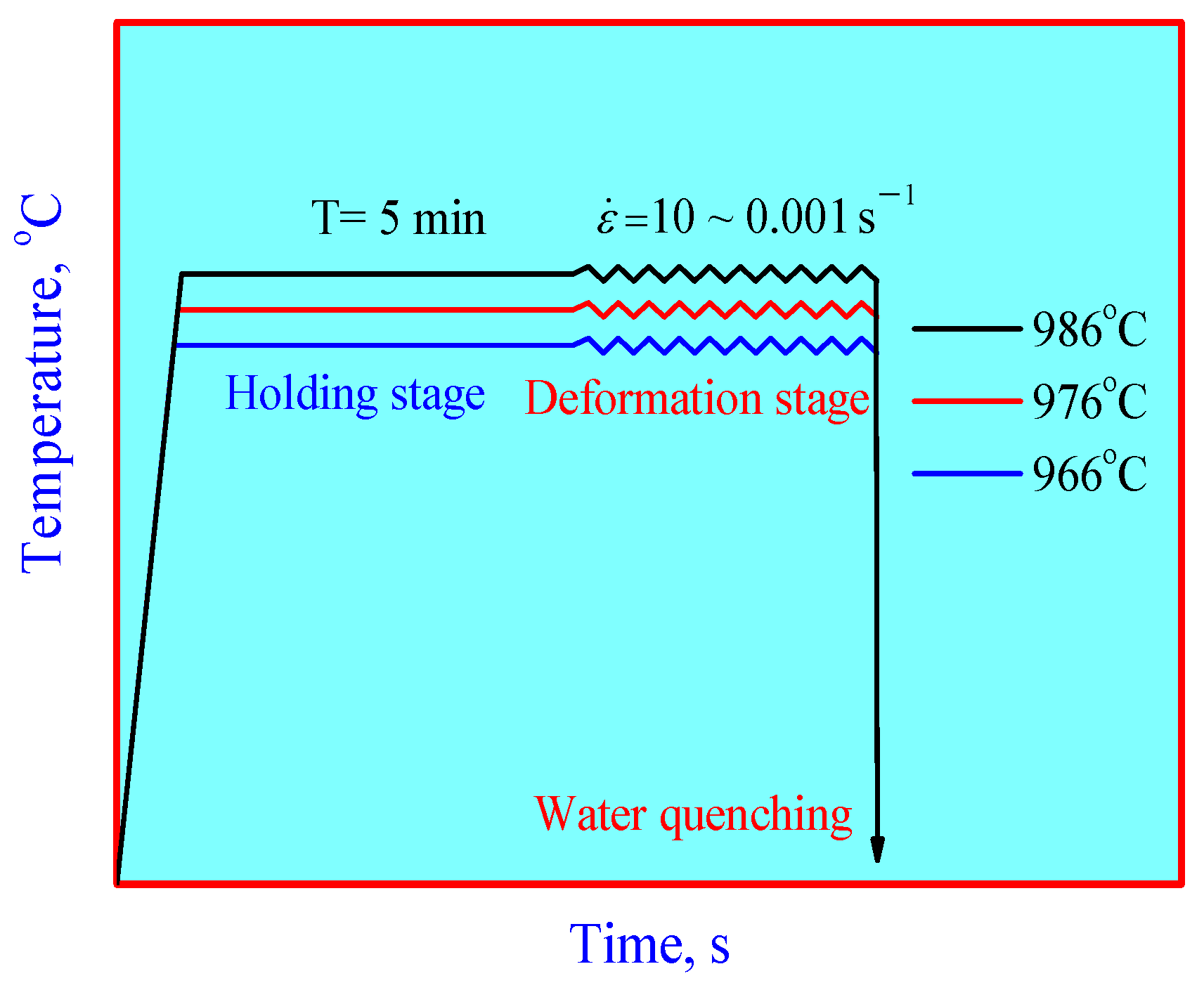

2. Materials and Experimental Procedures

3. Results and Discussion

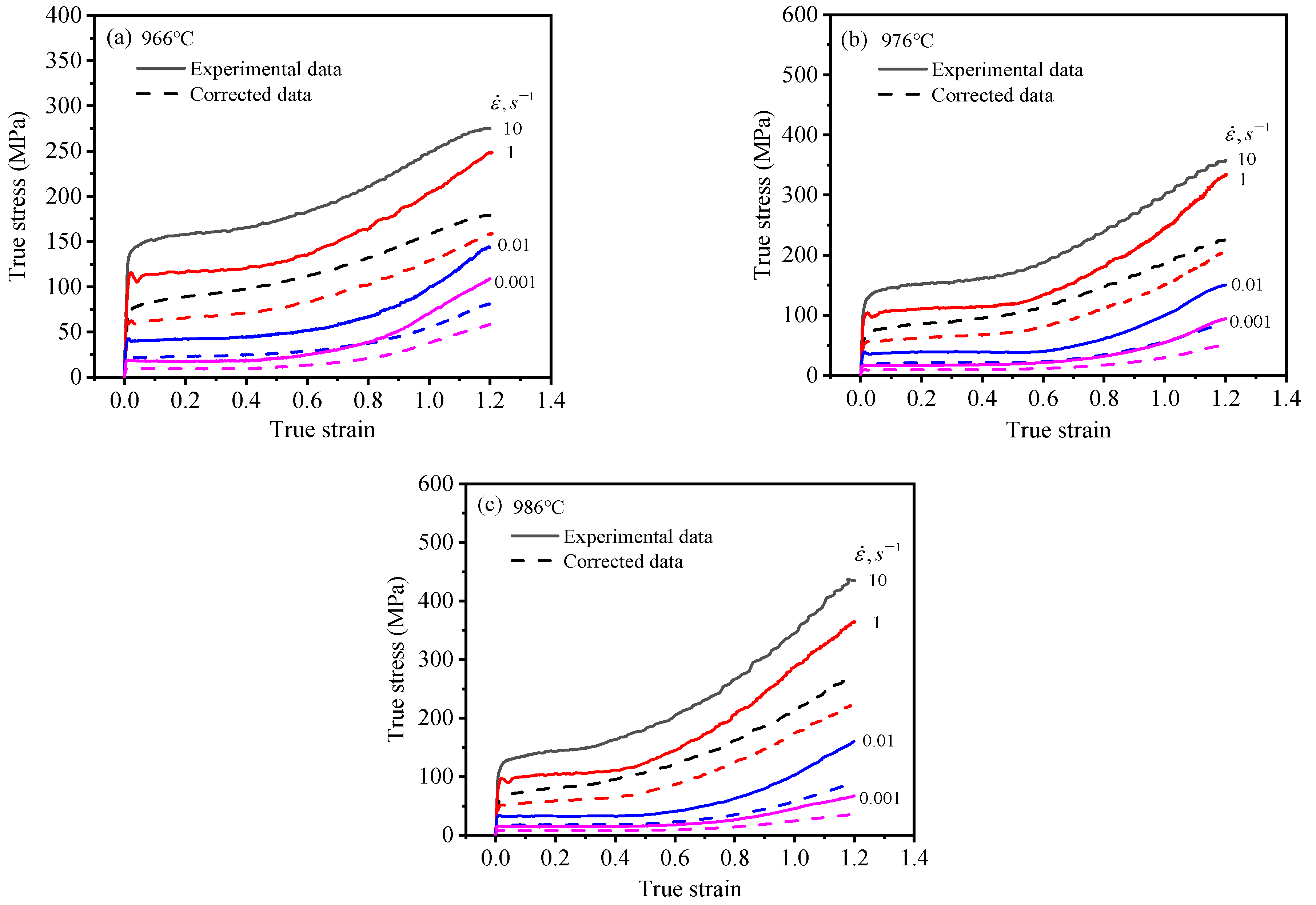

3.1. Flow Curves

3.1.1. Adiabatic Correction

3.1.2. Friction Correction

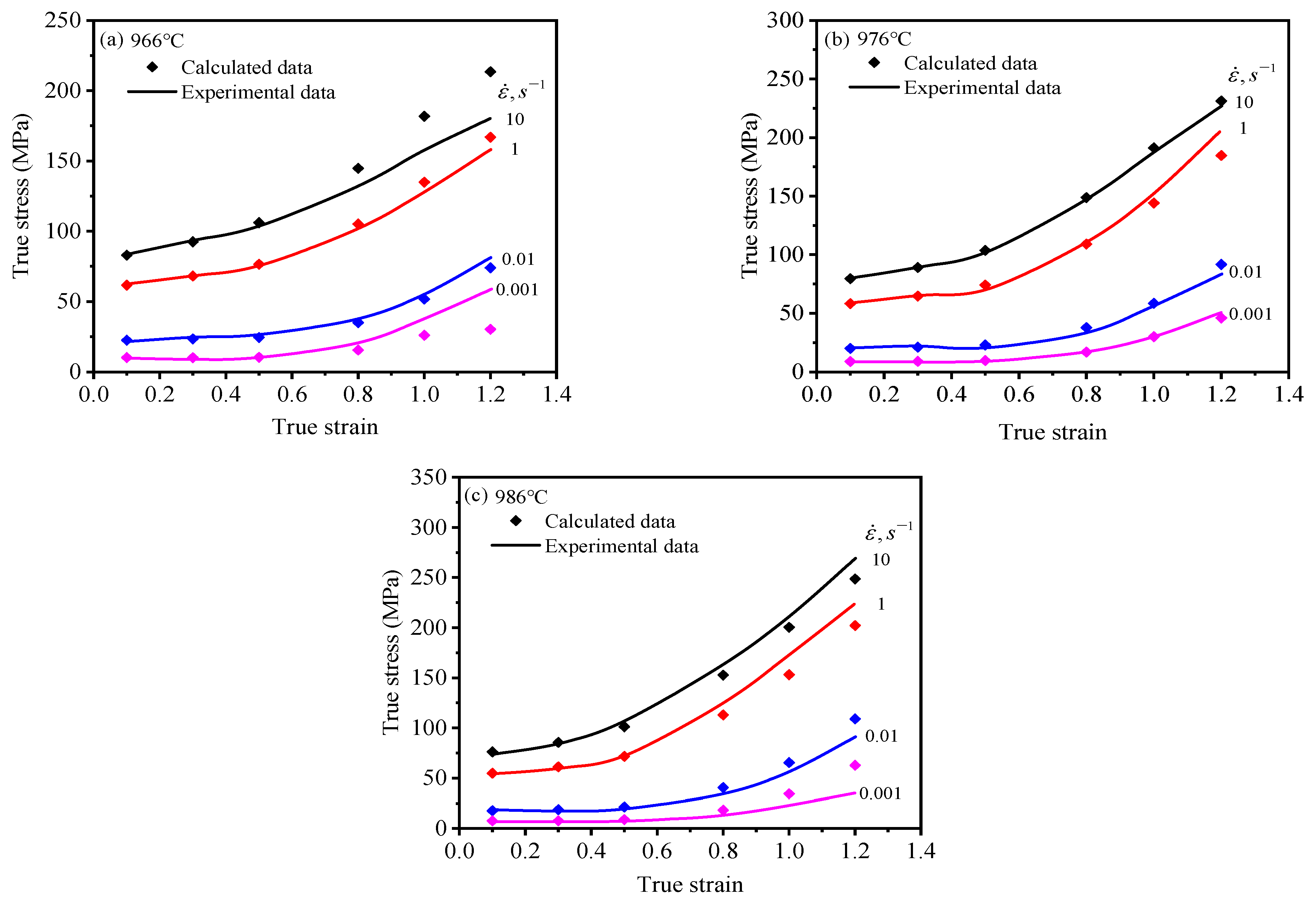

3.1.3. True Stress–Strain Curves

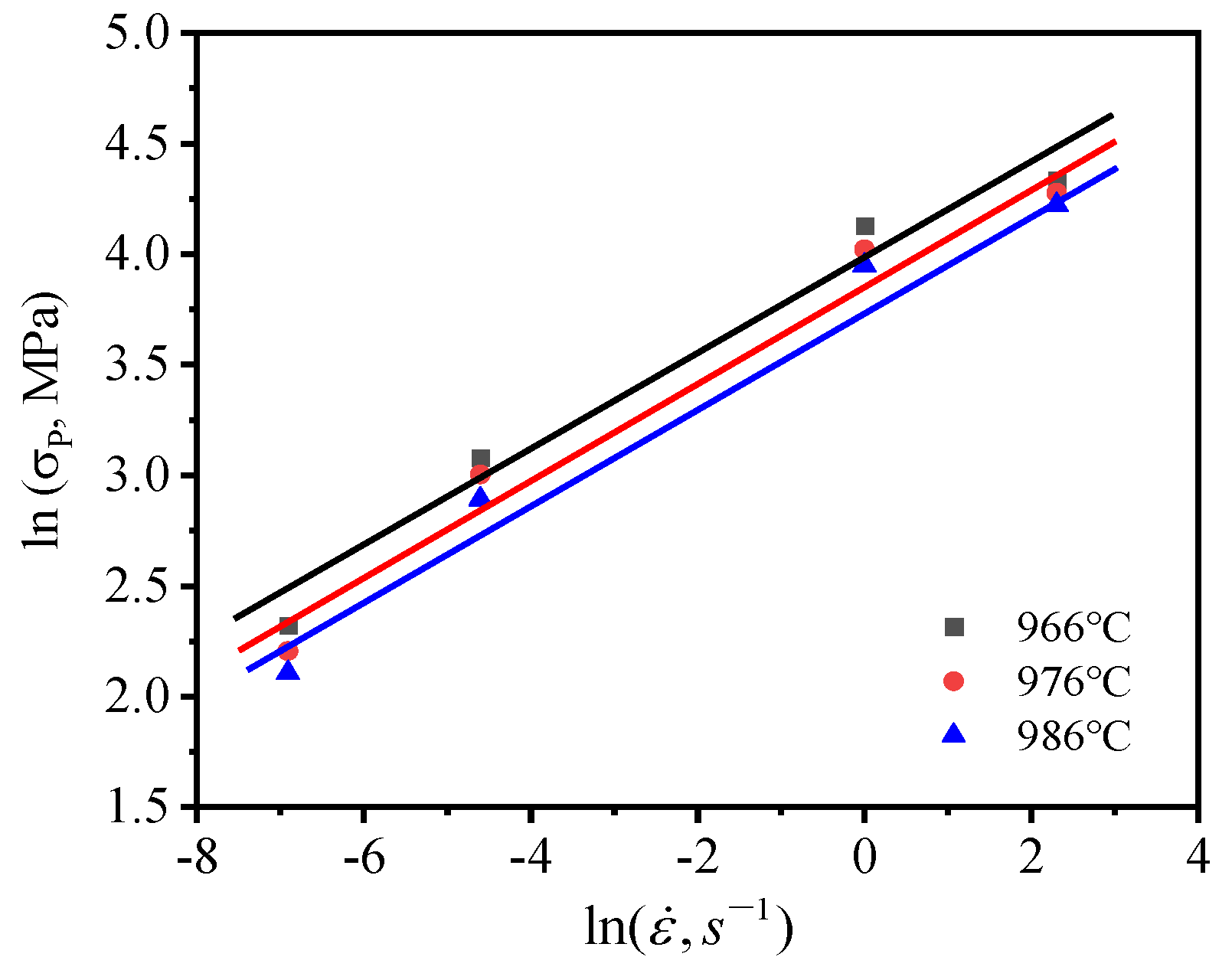

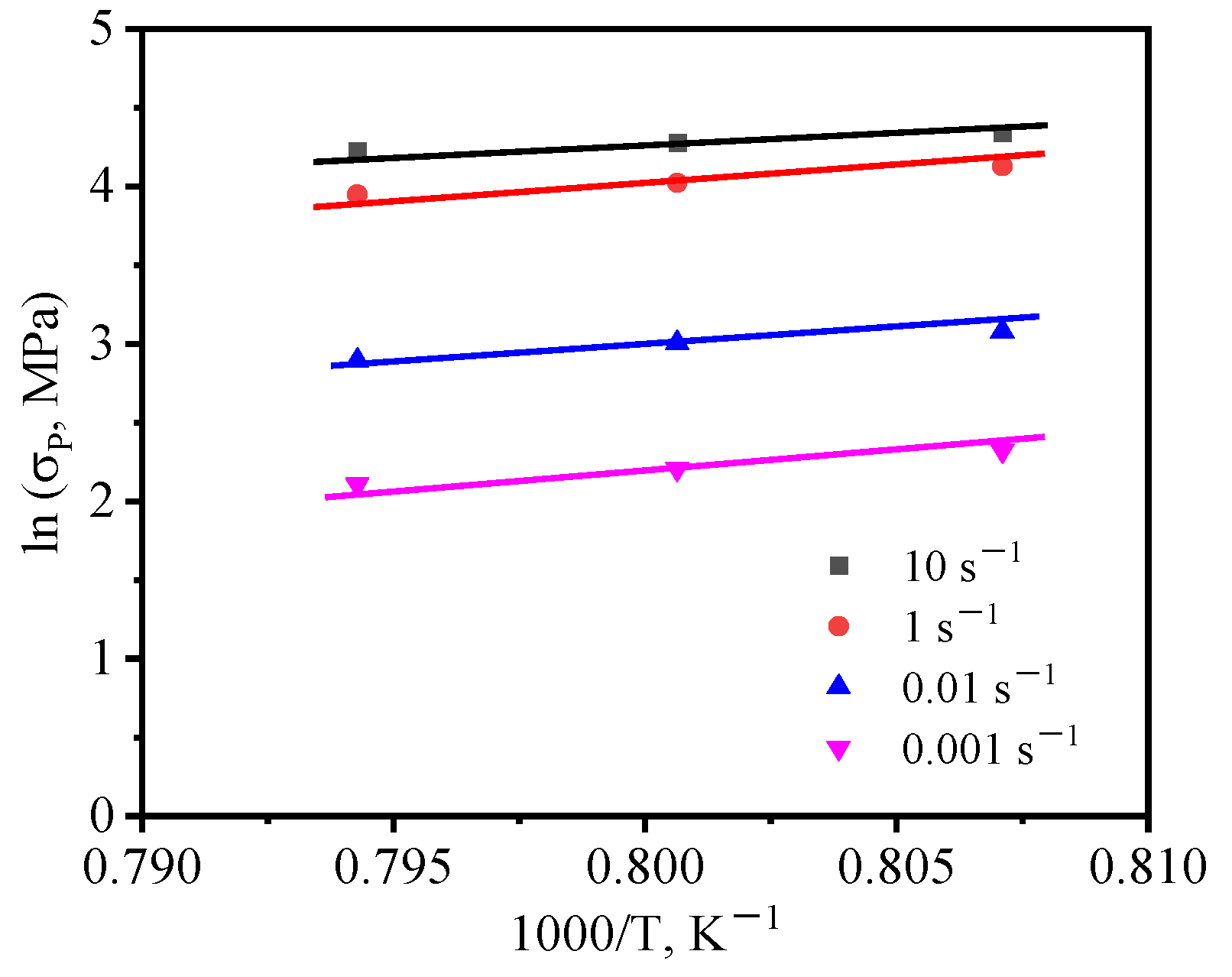

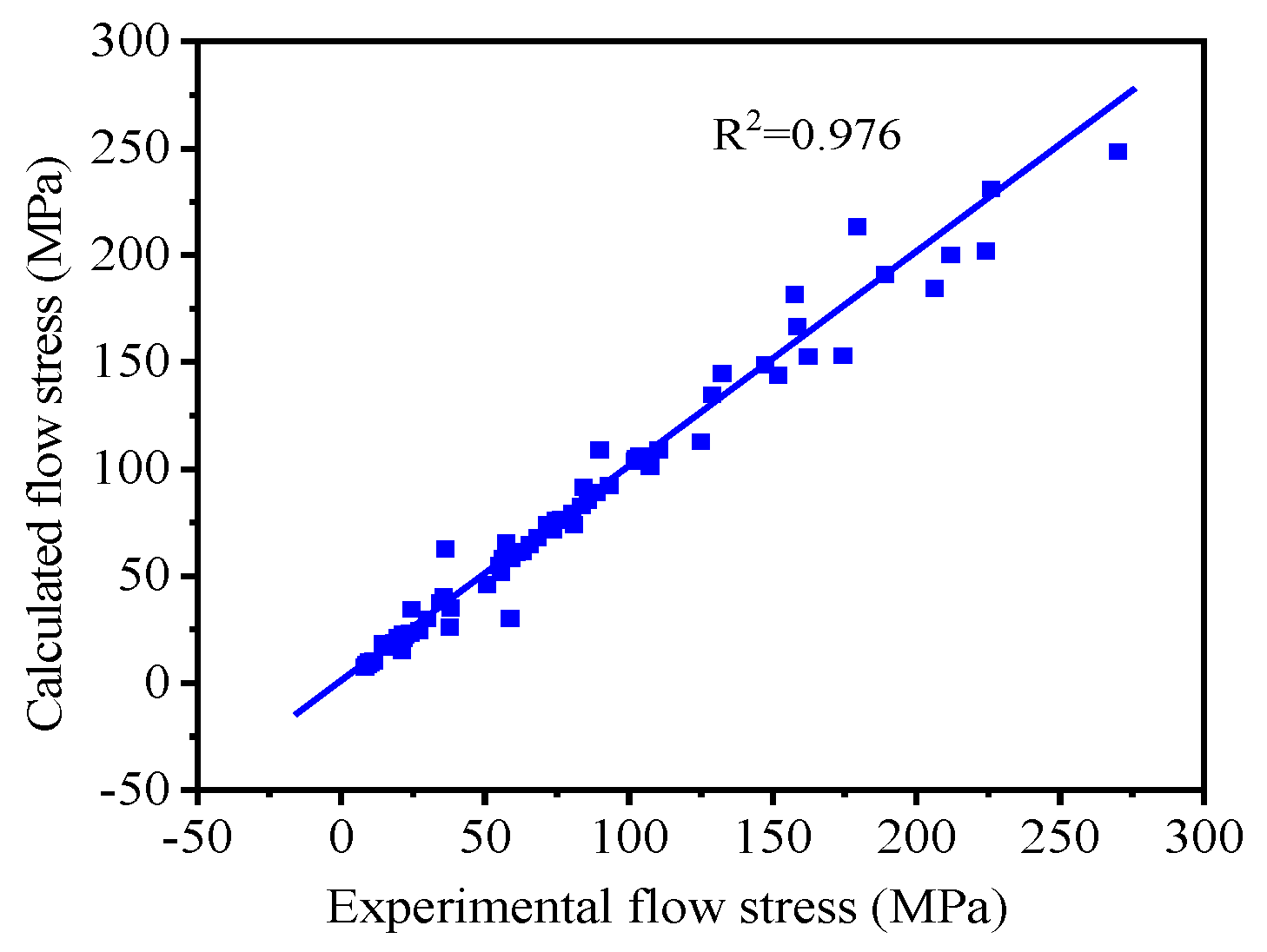

3.2. Constitutive Parameters

3.3. Processing Maps

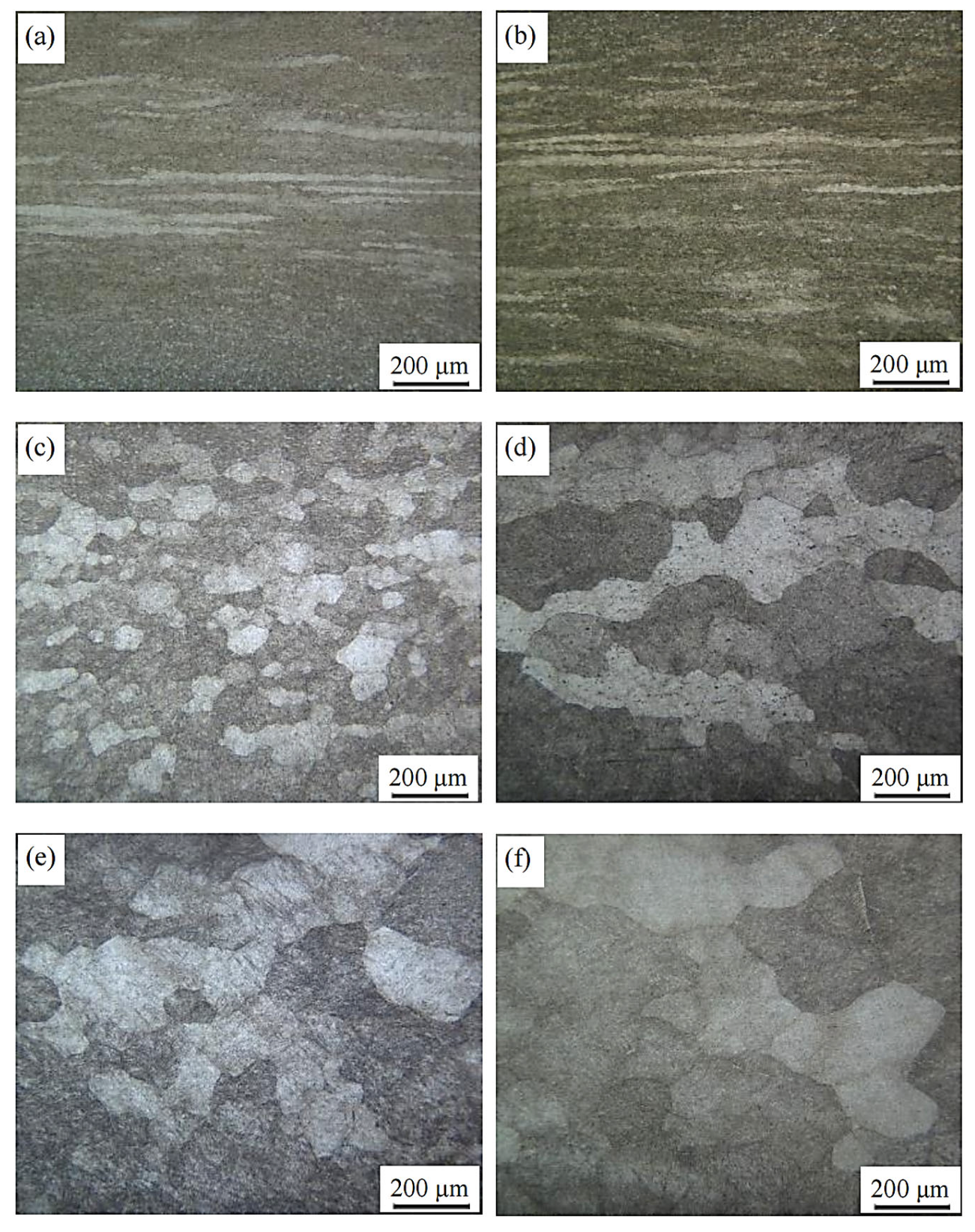

3.4. Microstructure after Hot Deformation

3.5. Finite Element Simulation of the Samples Deformed at Different Parameters

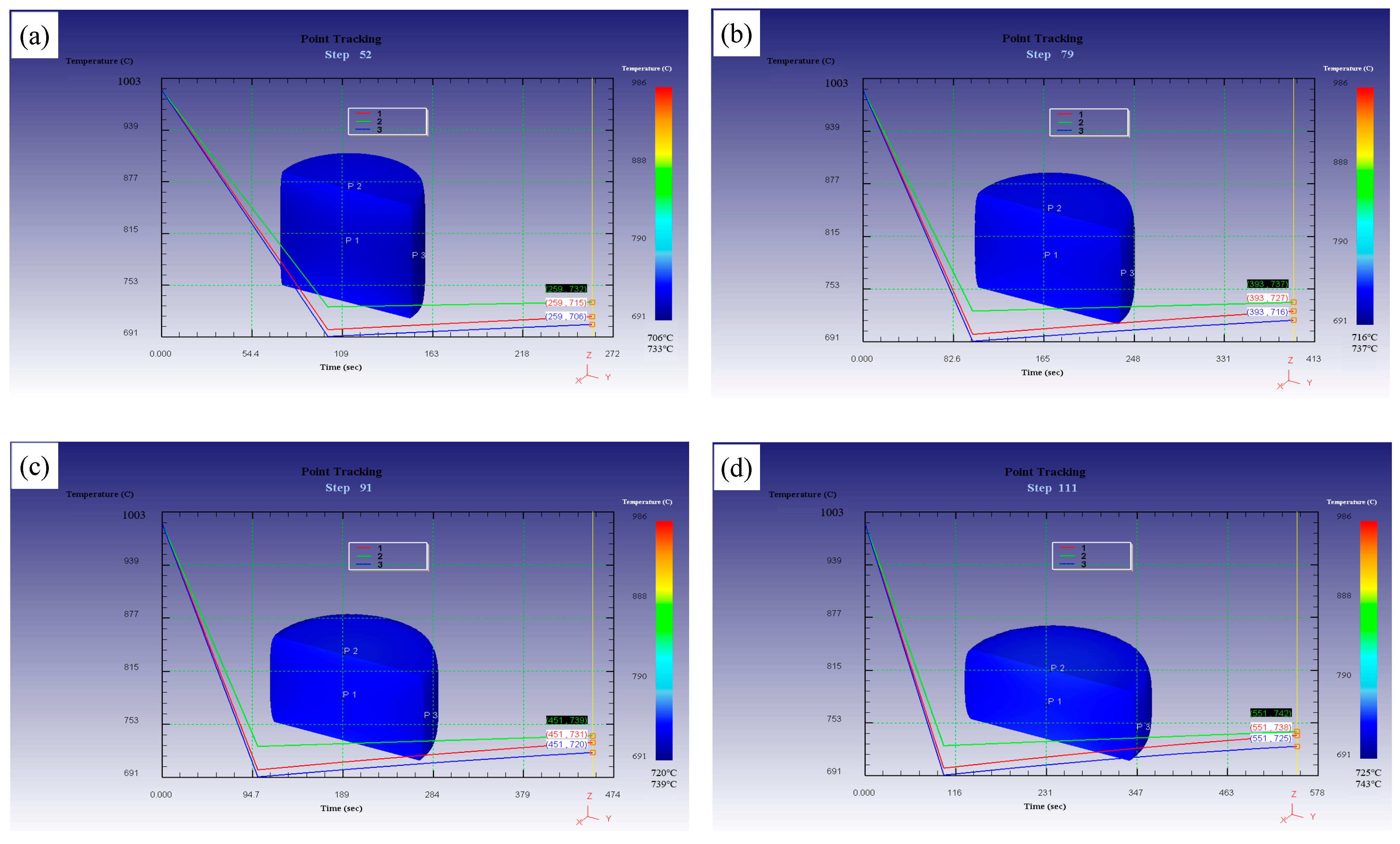

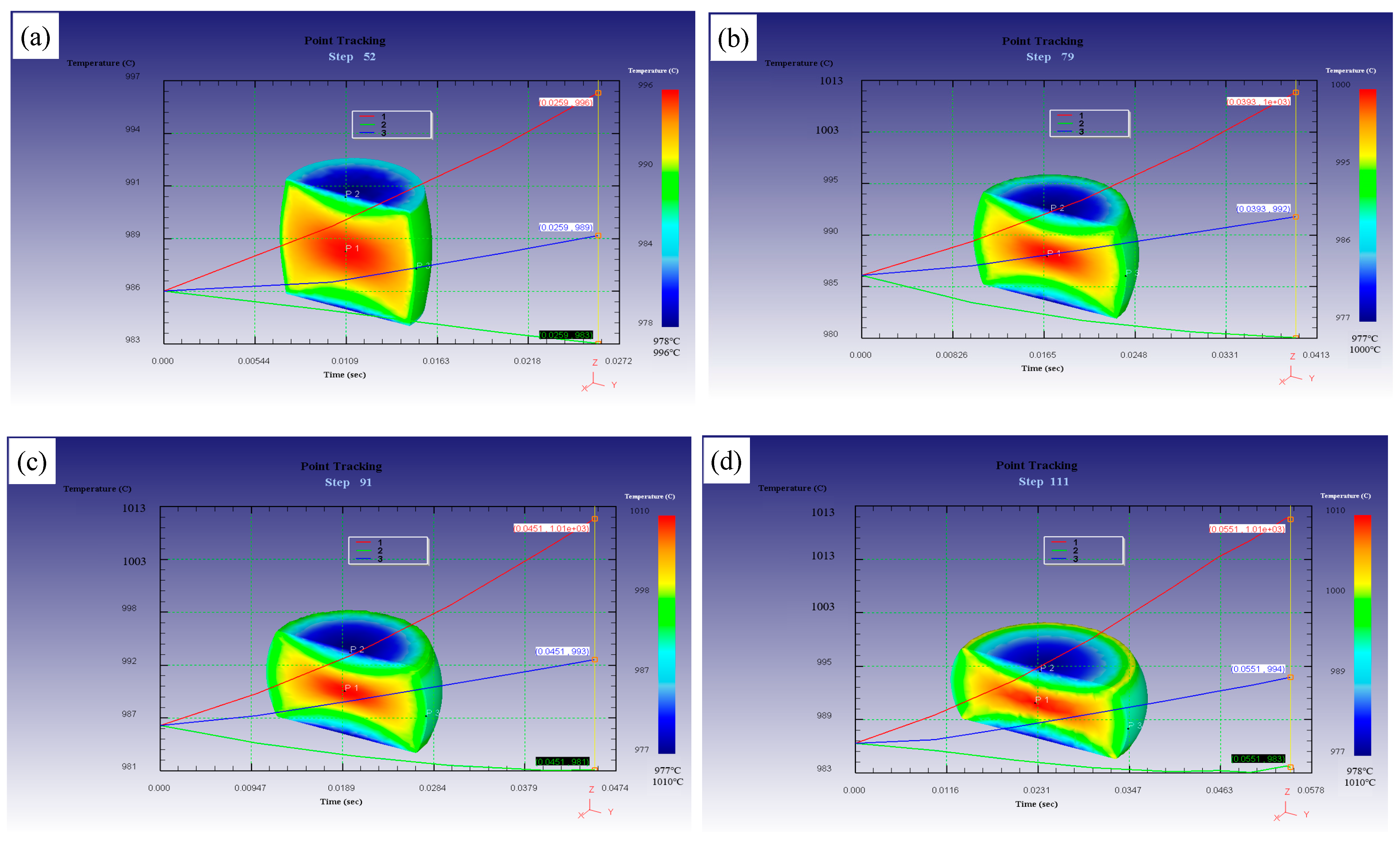

3.5.1. Temperature Field Simulation

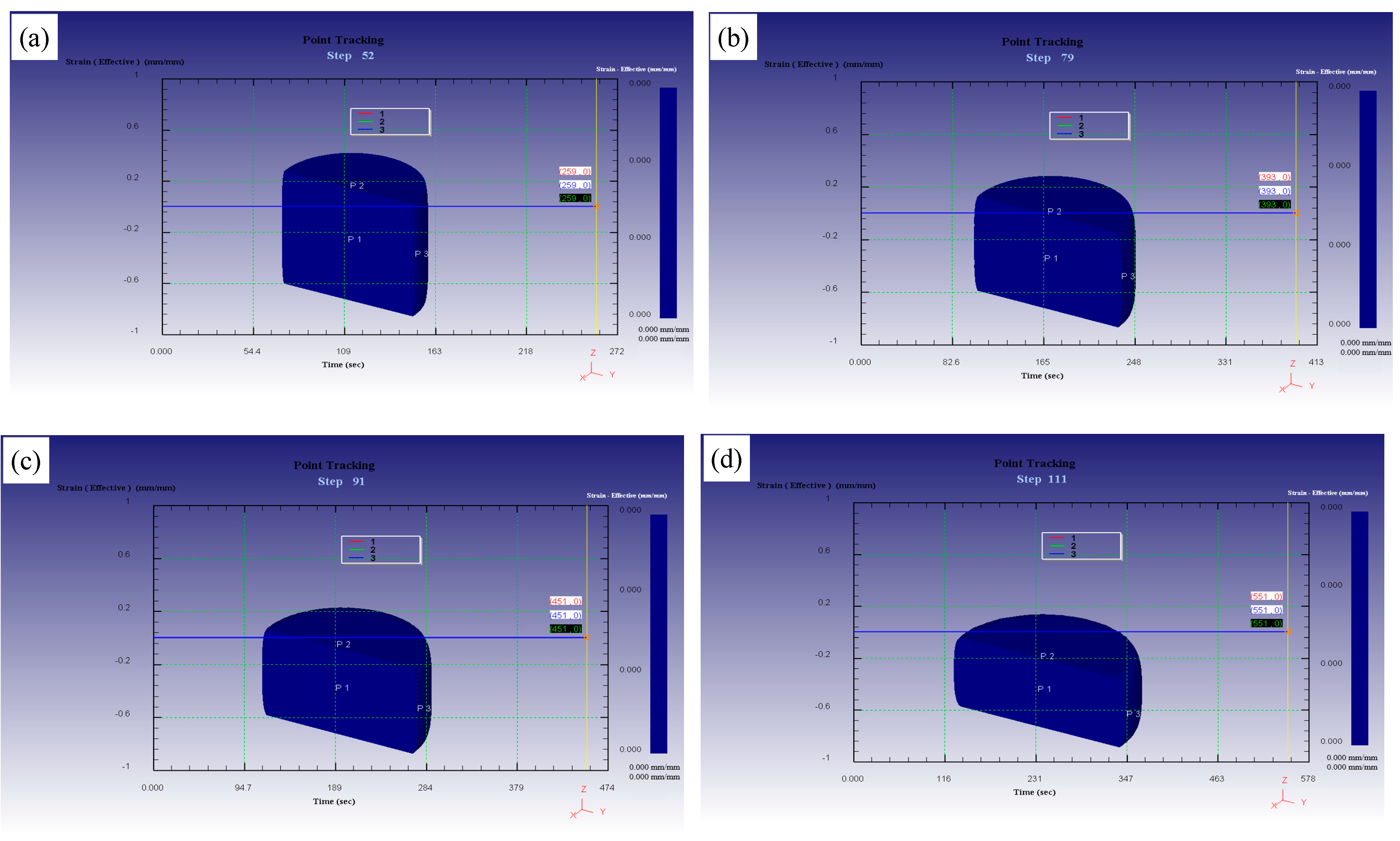

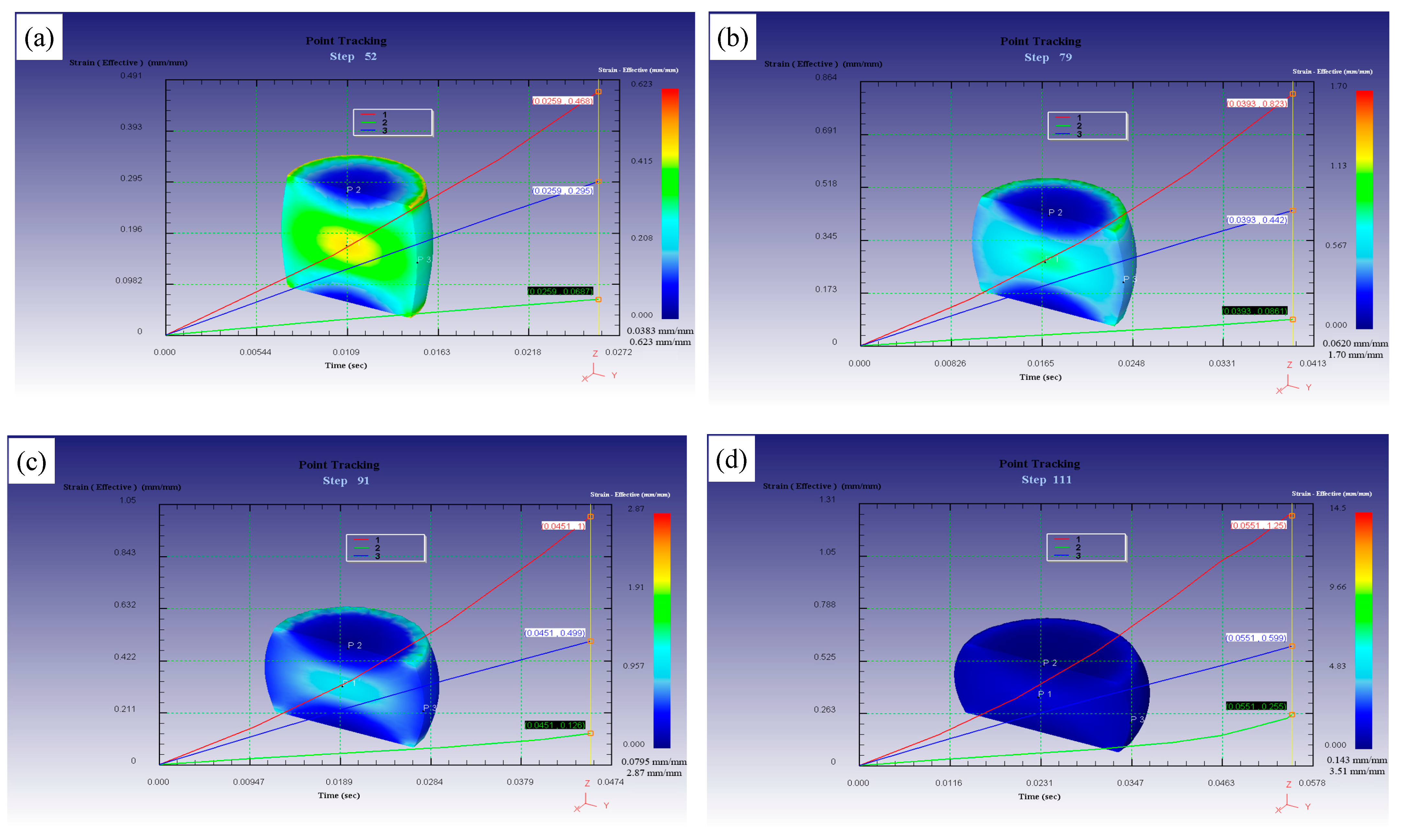

3.5.2. Effective Strain Field Simulation

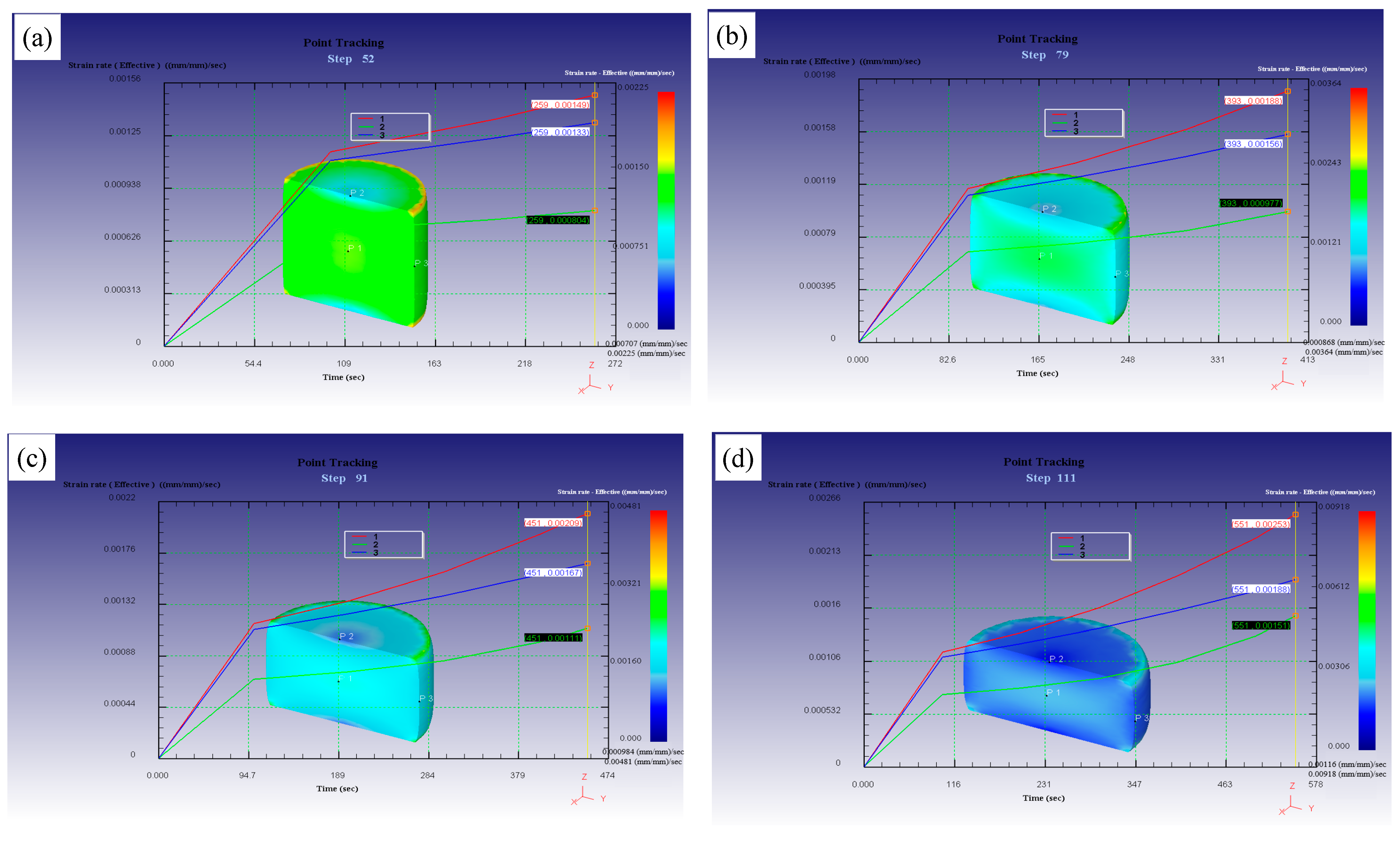

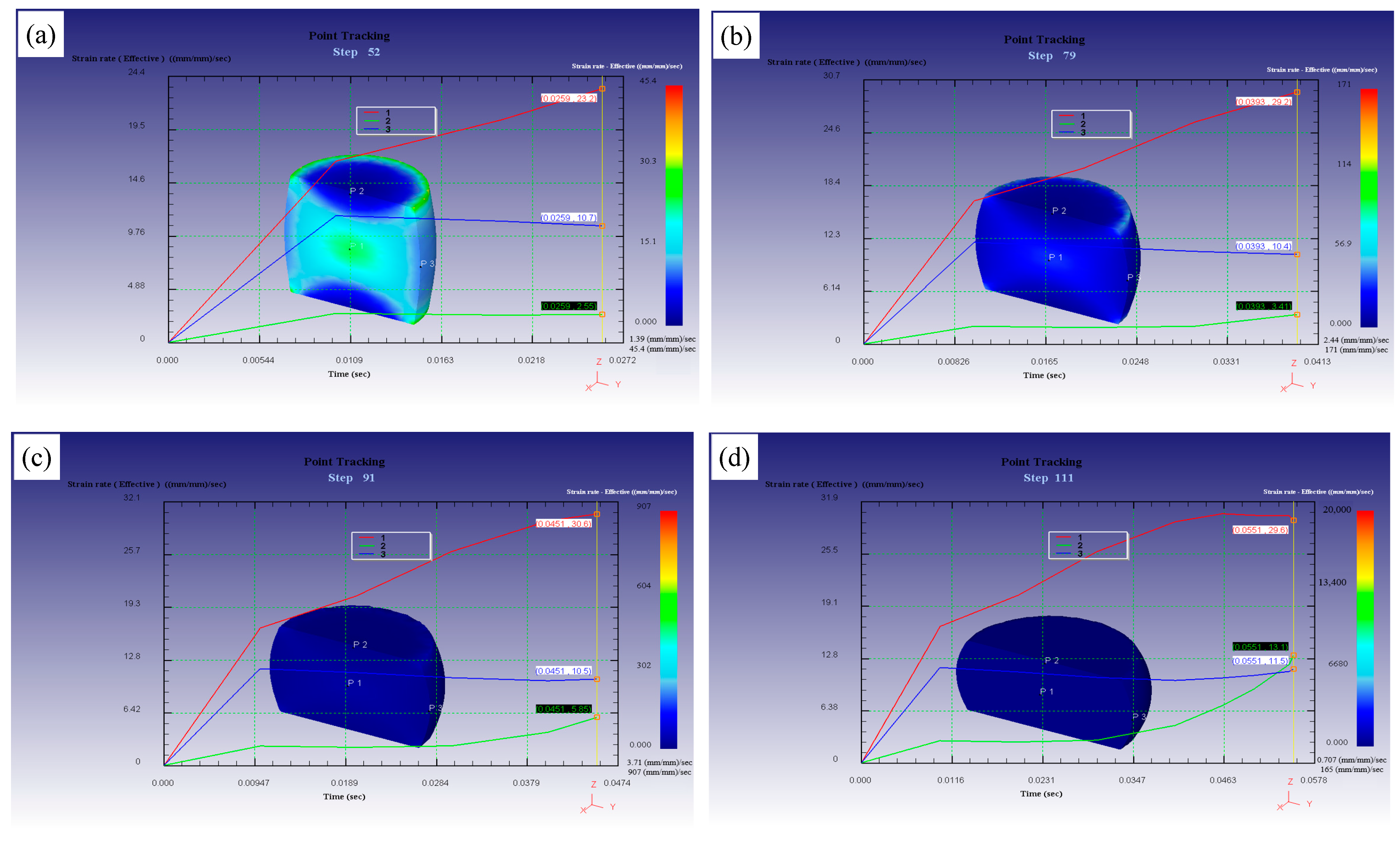

3.5.3. Effective Strain Rate Field Simulation

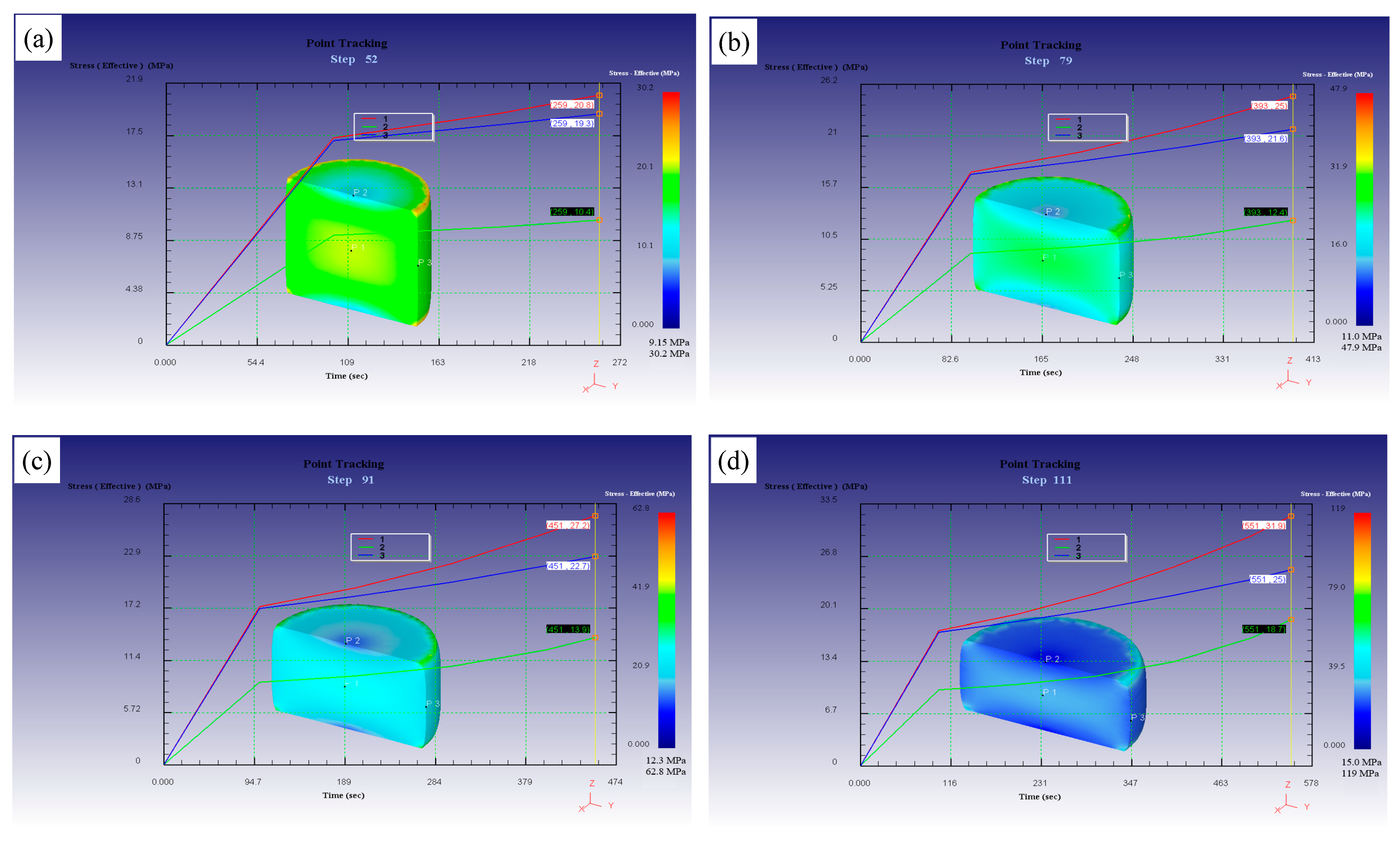

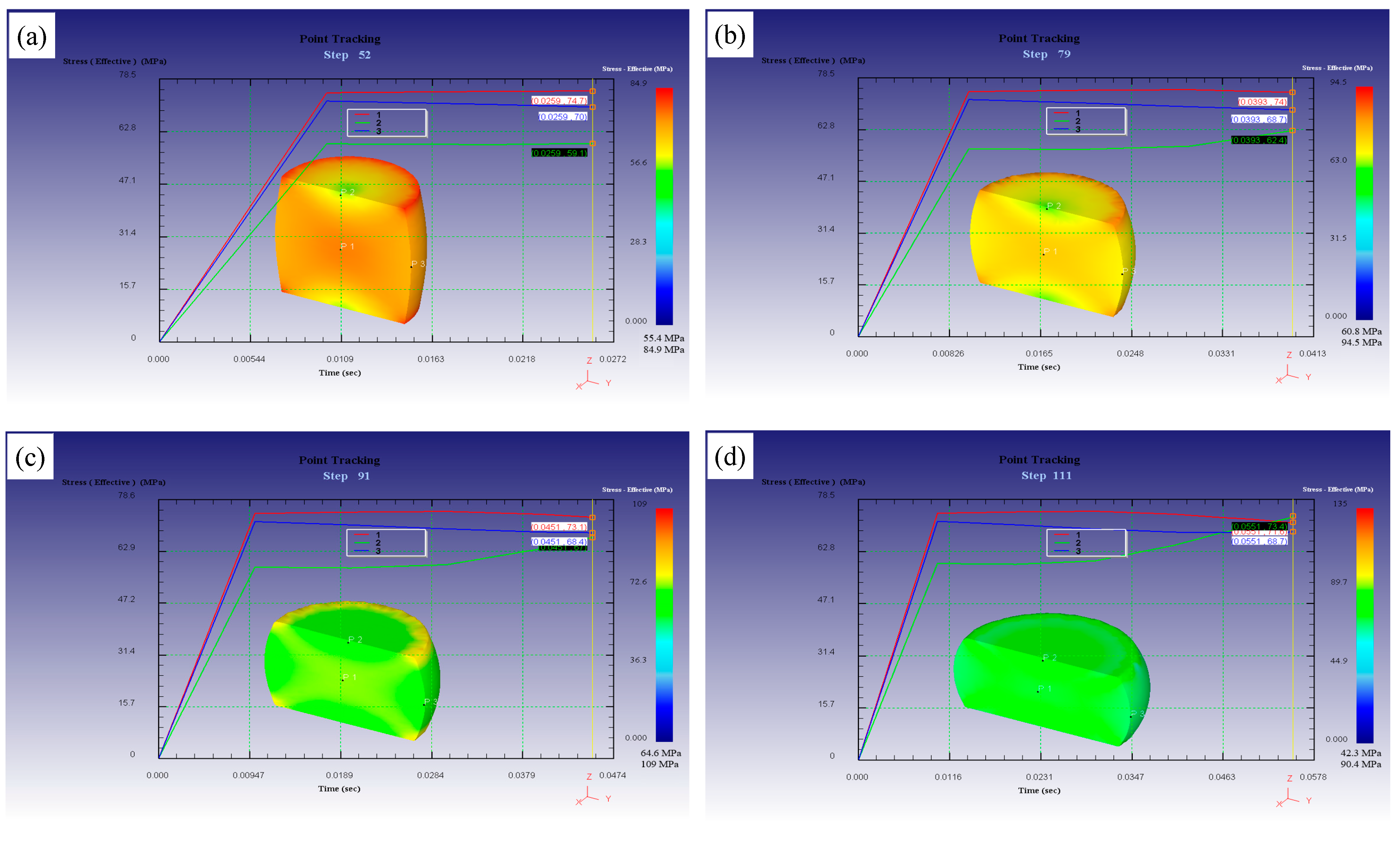

3.5.4. Effective Stress Field Simulation

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Shao, H.; Shan, D.; Zhao, Y.Q.; Ge, P.; Zeng, W.D. Accordance between fracture toughness and strength difference in TC21 alloy with equiaxed microstructure. Mater. Sci. Eng. A 2016, 664, 10–16. [Google Scholar] [CrossRef]

- Tan, C.S.; Sun, Q.Y.; Zhang, G.J.; Zhao, Y.Q. Remarkable increase in high-cycle fatigue resistance in a titanium alloy with a fully lamellar microstructure. Int. J. Fatigue 2020, 138, 105724. [Google Scholar] [CrossRef]

- Elshaer, R.N.; Ibrahim, K.M. Effect of cold deformation and heat treatment on microstructure and mechanical properties of TC21 Ti alloy. Trans. Nonferr. Metal. Soc. China 2020, 30, 1290–1299. [Google Scholar] [CrossRef]

- Wang, Y.S.; Yang, G.; Zhang, S.N.; Xiu, S.C. Effect of crystal orientation on micro-stress distribution in a damage-tolerant titanium alloy TC21. J. Alloys Compd. 2022, 924, 166637. [Google Scholar] [CrossRef]

- Zhu, Y.C.; Zeng, W.D.; Feng, F.; Sun, Y.; Han, Y.F.; Zhou, Y.G. Characterization of hot deformation behavior of as-cast TC21 alloy using processing map. Mater. Sci. Eng. A 2011, 528, 1757–1763. [Google Scholar] [CrossRef]

- Wang, K.; Wu, M.Y.; Yan, Z.B.; Li, D.R.; Xin, R.L.; Liu, Q. Dynamic restoration and deformation heterogeneity during hot deformation of a duplex-structure TC21 alloy. Mater. Sci. Eng. A 2018, 712, 440–452. [Google Scholar] [CrossRef]

- Wang, K.; Wu, M.Y.; Ren, Z.; Zhang, Y.; Xin, R.L.; Liu, Q. Static globularization and grain morphology evolution of α and β phases during annealing of hot-rolled TC21 alloy. Trans. Nonferr. Met. Soc. China 2021, 31, 2664–2676. [Google Scholar] [CrossRef]

- Zhang, J.Q.; Xu, X.Y.; Xue, J.Y.; Liu, S.N.; Deng, Q.H.; Li, F.; Ding, J.; Wang, H.; Chang, H. Hot deformation characteristics and mechanism understanding of Ti-6Al-2Sn-4Zr- 6Mo titanium alloy. J. Mater. Res. Technol. 2022, 20, 2591–2610. [Google Scholar] [CrossRef]

- Qiu, Q.; Wang, K.L.; Li, X.; Wang, J.; Gao, X.; Zhang, K.M. Hot deformation behavior and processing parameters optimization of SP700 titanium alloy. J. Mater. Res. Technol. 2021, 15, 3078–3087. [Google Scholar] [CrossRef]

- Gao, P.F.; Zhan, M.; Fan, X.G.; Lei, Z.N.; Cai, Y. Hot deformation behavior and microstructure evolution of TA15 titanium alloy with nonuniform microstructure. Mater. Sci. Eng. A 2017, 689, 243–251. [Google Scholar] [CrossRef]

- Li, C.M.; Huang, L.; Li, C.L.; Hui, S.X.; Yu, Y.; Zhao, M.J.; Guo, S.Q.; Li, J.J. Research progress on hot deformation behavior of high-strength β titanium alloy: Flow behavior and constitutive model. Rare Met. 2022, 41, 1434–1455. [Google Scholar] [CrossRef]

- Wang, J.; Wang, K.L.; Lu, S.Q.; Li, X.; OuYang, D.L.; Qiu, Q. Softening mechanism and process parameters optimization of Ti-4.2Al-0.005B titanium alloy during hot deformation. J. Mater. Res. Technol. 2022, 17, 1842–1851. [Google Scholar] [CrossRef]

- Li, J.L.; Wang, B.Y.; Huang, H.; Fang, S.; Chen, P.; Shen, J.X. Unified modelling of the flow behavior and softening mechanism of a TC6 titanium alloy during hot deformation. J. Alloys Compd. 2018, 748, 1031–1043. [Google Scholar] [CrossRef]

- Zhao, Y.L.; Li, B.L.; Zhu, Z.S.; Nie, Z.R. The high temperature deformation behavior and microstructure of TC21 alloy. Mater. Sci. Eng. A 2010, 527, 5360–5367. [Google Scholar] [CrossRef]

- Zhu, Y.C.; Zeng, W.D.; Liu, J.L.; Zhao, Y.Q.; Zhou, Y.G.; Yu, H.Q. Effect of processing parameters on the hot deformation behavior of as-cast TC21 alloy. Mater. Des. 2012, 33, 264–272. [Google Scholar] [CrossRef]

- Wang, Y.S.; Xiu, S.C.; Zhang, S.N.; Jiang, C.Y. Effect of grinding parameters on microstructure evolution of TC21 alloy with bimodal starting microstructure. J. Alloys Compd. 2020, 831, 154882. [Google Scholar] [CrossRef]

- Zheng, X.Y.; Wang, K.; Zhang, C.; Xin, R.L.; Liu, Q. Evolution mechanism of lamellar α and interlayered β during hot compression of TC21 alloy with a widmanstätten structure. Chin. J. Aeronaut. 2022, 35, 475–483. [Google Scholar] [CrossRef]

- Shi, Z.F.; Guo, H.Z.; Liu, R.; Wang, X.C.; Yao, Z.K. Microstructure and mechanical properties of TC21 alloy by near-isothermal forging. Trans. Nonferr. Met. Soc. China 2015, 25, 72–79. [Google Scholar] [CrossRef]

- Li, H.H.; Wang, K.; Xin, L.P.; Xin, R.L.; Liu, Q. Effect of hot rolling and annealing on phase component, recrystallization, and mechanical properties of TC21 alloy. J. Mater. Eng. Perform. 2022, 31, 2496–2508. [Google Scholar] [CrossRef]

- Goetz, R.L.; Semiatin, S.L. The adiabatic correction factor for deformation heating during the uniaxial compression test. J. Mater. Eng. Perform. 2001, 10, 710–717. [Google Scholar] [CrossRef]

- Mataya, M.C.; Sackschewsky, V.E. Effect of internal heating during hot compression on the stress-strain behavior of alloy 304L. Metall. Mater. Trans. A 1994, 25, 2737. [Google Scholar] [CrossRef]

- Devadas, C.; Baragar, D.; Ruddle, G. The thermal and metallurgical state of steel strip during hot rolling: Part II. Factors influencing rolling loads. Metall. Trans. A 1991, 22, 321. [Google Scholar] [CrossRef]

- Lu, H.T.; Li, D.Z.; Li, S.Y.; Chen, Y.A. Hot deformation behavior of Fe-27.34Mn-8.63Al-1.03C lightweight steel. Int. J. Miner. Metall. Mater. 2023, 30, 734–743. [Google Scholar] [CrossRef]

- Mollaei, N.; Fatemi, S.M.; Aboutalebi, M.R.; Razavi, S.H.; Bednarczyk, W. Dynamic recrystallization and deformation behavior of an extruded Zn-0.2Mg biodegradable alloy. J. Mater. Res. Technol. 2022, 19, 4969–4985. [Google Scholar] [CrossRef]

- Tan, Y.B.; Liu, W.C.; Yuan, H.; Liu, R.P.; Zhang, X.Y. On the phenomenon of stress drop during hot deformation of ZrTiAlV alloy. Metall. Mater. Trans. A 2013, 44, 5284–5288. [Google Scholar] [CrossRef]

- Philippart, I.; Rack, H.J. High temperature dynamic yielding in metastable Ti-6.8Mo- 4.5Fe-1.5Al alloy. Mater. Sci. Eng. A 1998, 243, 196–200. [Google Scholar] [CrossRef]

- Wang, L.; Li, W.; Luan, S.Y.; Jin, P.P.; Wang, J.H.; Ren, Q.L.; Zhu, L. Study on hot deformation behavior of as-cast Ti-5Al-5Mo-5V-1Cr-1Fe titanium alloy in (α+β) phase region. Mater. Today Commun. 2023, 35, 105797. [Google Scholar] [CrossRef]

- Tan, Y.B.; Ji, L.Y.; Duan, J.L.; Liu, W.C.; Zhang, J.W.; Liu, R.P. A Study on the Hot Deformation Behavior of 47Zr-45Ti-5Al-3V Alloy with Initial Lamellar α Structure. Metall. Mater. Trans. A 2016, 47, 5974–5984. [Google Scholar] [CrossRef]

- Niu, Y.X.; Hou, J.; Ning, F.K.; Chen, X.R.; Jia, Y.H.; Le, Q.C. Hot deformation behavior and processing man of Mg-2Zn-1Al-0.2RE alloy. J. Rare Earth. 2020, 38, 665–675. [Google Scholar] [CrossRef]

- Liu, J.J.; Wang, K.L.; Lu, S.Q.; Gao, X.Y.; Li, X.; Zhou, F. Hot deformation behavior and processing map of Zr-4 alloy. J. Nucl. Mater. 2020, 531, 151993. [Google Scholar] [CrossRef]

- Tan, Y.B.; Yang, L.H.; Duan, J.L.; Liu, W.C.; Zhang, J.W.; Liu, R.P. Effect of initial grain size on the hot deformation behavior of 47Zr-45Ti-5Al-3V alloy. J. Nucl. Mater. 2014, 454, 413–420. [Google Scholar] [CrossRef]

- Tan, Y.B.; Ma, Y.H.; Zhao, F. Hot deformation behavior and constitutive modeling of fine grained Inconel 718 superalloy. J. Alloys Compd. 2018, 741, 85–96. [Google Scholar] [CrossRef]

- Li, C.M.; Huang, L.; Zhao, M.J.; Guo, S.Q.; Li, J.J. Hot deformation behavior and mechanism of a new metastable β titanium alloy Ti-6Cr-5Mo-5V-4Al in single phase region. Mater. Sci. Eng. A 2021, 814, 141231. [Google Scholar] [CrossRef]

- Luo, J.; Ye, P.; Li, M.Q.; Liu, L.Y. Effect of the alpha grain size on the deformation behavior during isothermal compression of Ti-6Al-4V alloy. Mater. Des. 2015, 88, 32–40. [Google Scholar] [CrossRef]

- Ebrahimpourghandi, B.; Mahmudi, R. Hot deformation constitutive analysis and processing maps of the as-cast and wrought Mg-2.5Gd-0.5Zr alloy. J. Alloys Compd. 2023, 942, 169132. [Google Scholar] [CrossRef]

- Liu, P.; Zhang, R.; Yuan, Y.; Cui, C.Y.; Zhou, Y.Z.; Sun, X.F. Hot deformation behavior and workability of a Ni-Co based superalloy. J. Alloys Compd. 2020, 831, 154618. [Google Scholar] [CrossRef]

- Jiang, H.T.; Tian, S.W.; Guo, W.Q.; Zhang, G.H.; Zeng, S.W. Hot deformation behavior and deformation mechanism of two TiAl-Mo alloys during hot compression. Mater. Sci. Eng. A 2018, 719, 104–111. [Google Scholar] [CrossRef]

- Liu, F.; Ma, J.M.; Peng, L.J.; Huang, G.J.; Zhang, W.J.; Xie, H.F.; Mi, X.J. Hot deformation behavior and microstructure evolution of Cu-Ni-Co-Si alloys. Materials 2020, 13, 2042. [Google Scholar] [CrossRef]

- Tan, Y.B.; Duan, J.L.; Yang, L.H.; Liu, W.C.; Zhang, J.W.; Liu, R.P. Hot deformation behavior of Ti-20Zr-6.5Al-4V alloy in the α+β and single β phase field. Mater. Sci. Eng. A 2014, 609, 226–234. [Google Scholar] [CrossRef]

- Wu, H.; Liu, M.X.; Wang, Y.; Huang, Z.Q.; Tan, G.; Yang, L. Experimental study and numerical simulation of dynamic recrystallization for a FGH96 superalloy during isothermal compression. J. Mater. Res. Technol. 2020, 9, 5090–5104. [Google Scholar] [CrossRef]

- Singh, G.; Souza, P.M. Hot deformation behavior of a novel alpha + beta titanium alloy TIMETAL®407. J. Alloys Compd. 2023, 935, 167970. [Google Scholar] [CrossRef]

| Element | Al | Mo | Nb | Sn | Zr | Cr | Si | Fe | C | O | N | Ti |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Content (wt%) | 6.28 | 3.06 | 1.89 | 2.04 | 2.18 | 1.61 | 0.066 | 0.022 | 0.009 | 0.122 | 0.005 | Balance |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ji, X.; Tian, Q.; Tan, Y.; Huang, C.; Wan, M.; Li, R. Simulation and Experimental Study of Hot Deformation Behavior in Near β Phase Region for TC21 Alloy with a Forged Structure. Crystals 2023, 13, 1524. https://doi.org/10.3390/cryst13101524

Ji X, Tian Q, Tan Y, Huang C, Wan M, Li R. Simulation and Experimental Study of Hot Deformation Behavior in Near β Phase Region for TC21 Alloy with a Forged Structure. Crystals. 2023; 13(10):1524. https://doi.org/10.3390/cryst13101524

Chicago/Turabian StyleJi, Xuanming, Qimei Tian, Yuanbiao Tan, Chaowen Huang, Mingpan Wan, and Rudong Li. 2023. "Simulation and Experimental Study of Hot Deformation Behavior in Near β Phase Region for TC21 Alloy with a Forged Structure" Crystals 13, no. 10: 1524. https://doi.org/10.3390/cryst13101524

APA StyleJi, X., Tian, Q., Tan, Y., Huang, C., Wan, M., & Li, R. (2023). Simulation and Experimental Study of Hot Deformation Behavior in Near β Phase Region for TC21 Alloy with a Forged Structure. Crystals, 13(10), 1524. https://doi.org/10.3390/cryst13101524