Effect of Design Parameters on the Flexural Strength of Reinforced Concrete Sandwich Beams

Abstract

:1. Introduction

2. Experimental Procedure

2.1. Materials and Methods

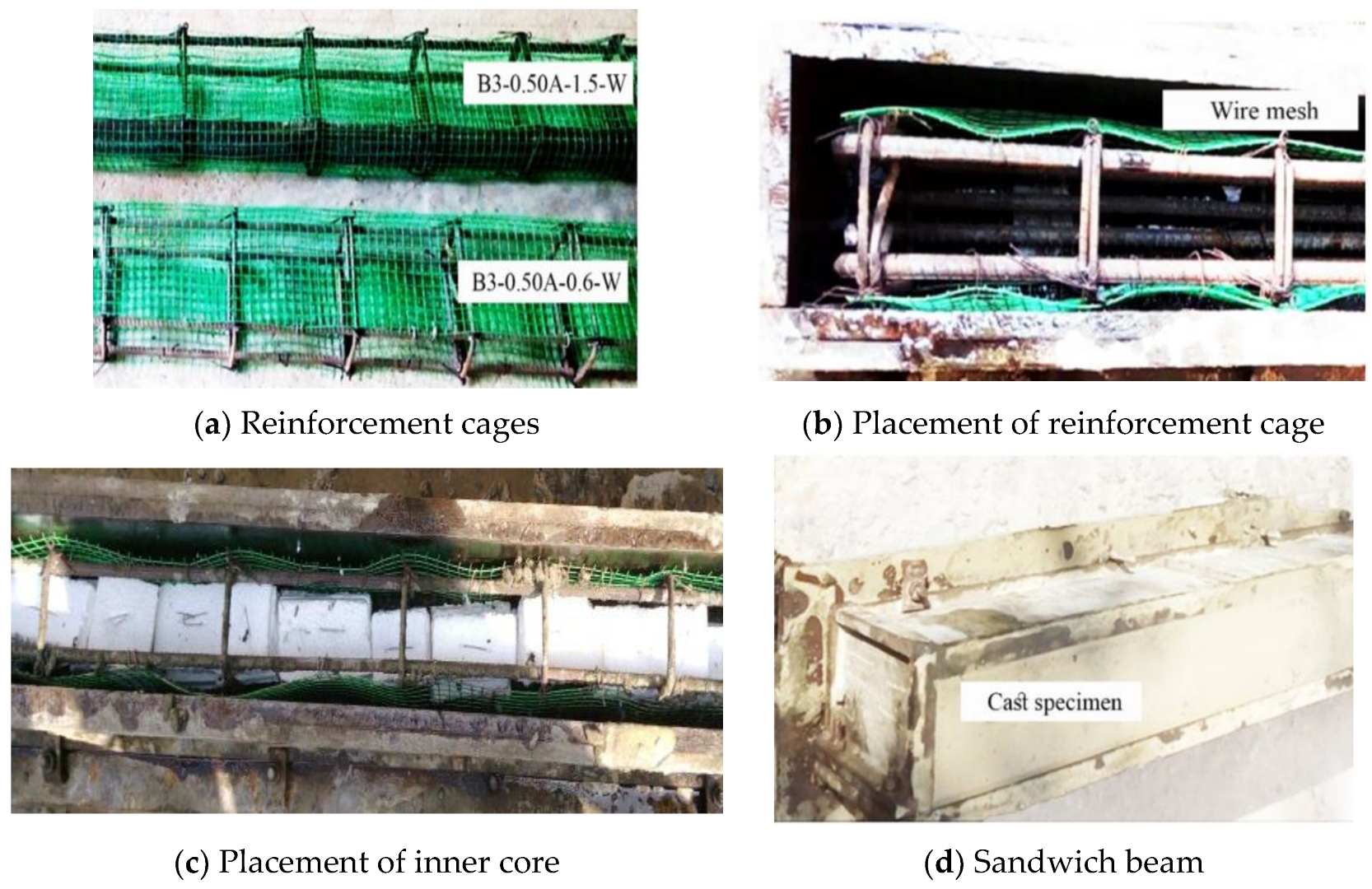

2.2. Fabrication of Sandwich Beams

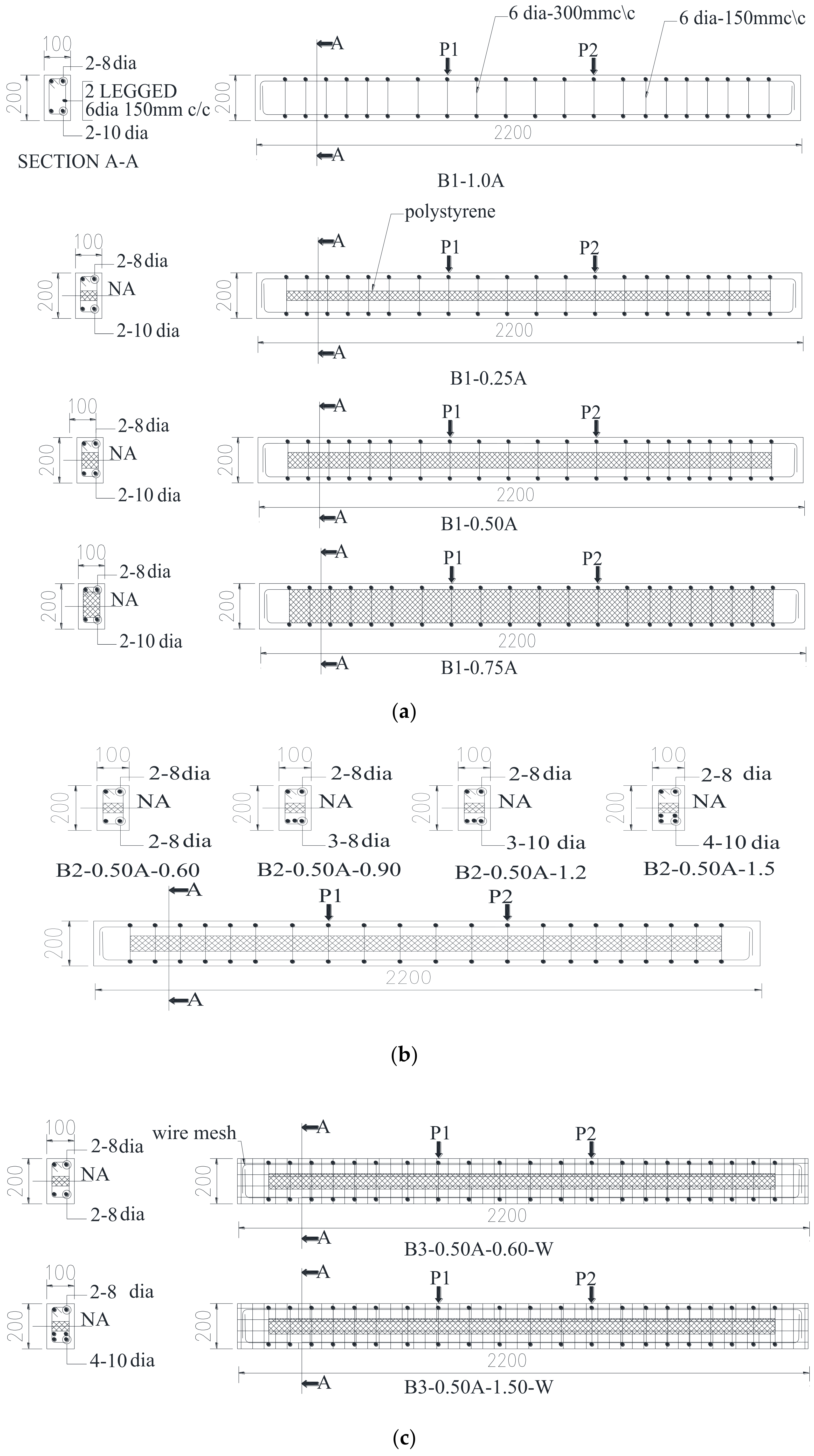

2.3. Details of the Test Specimens

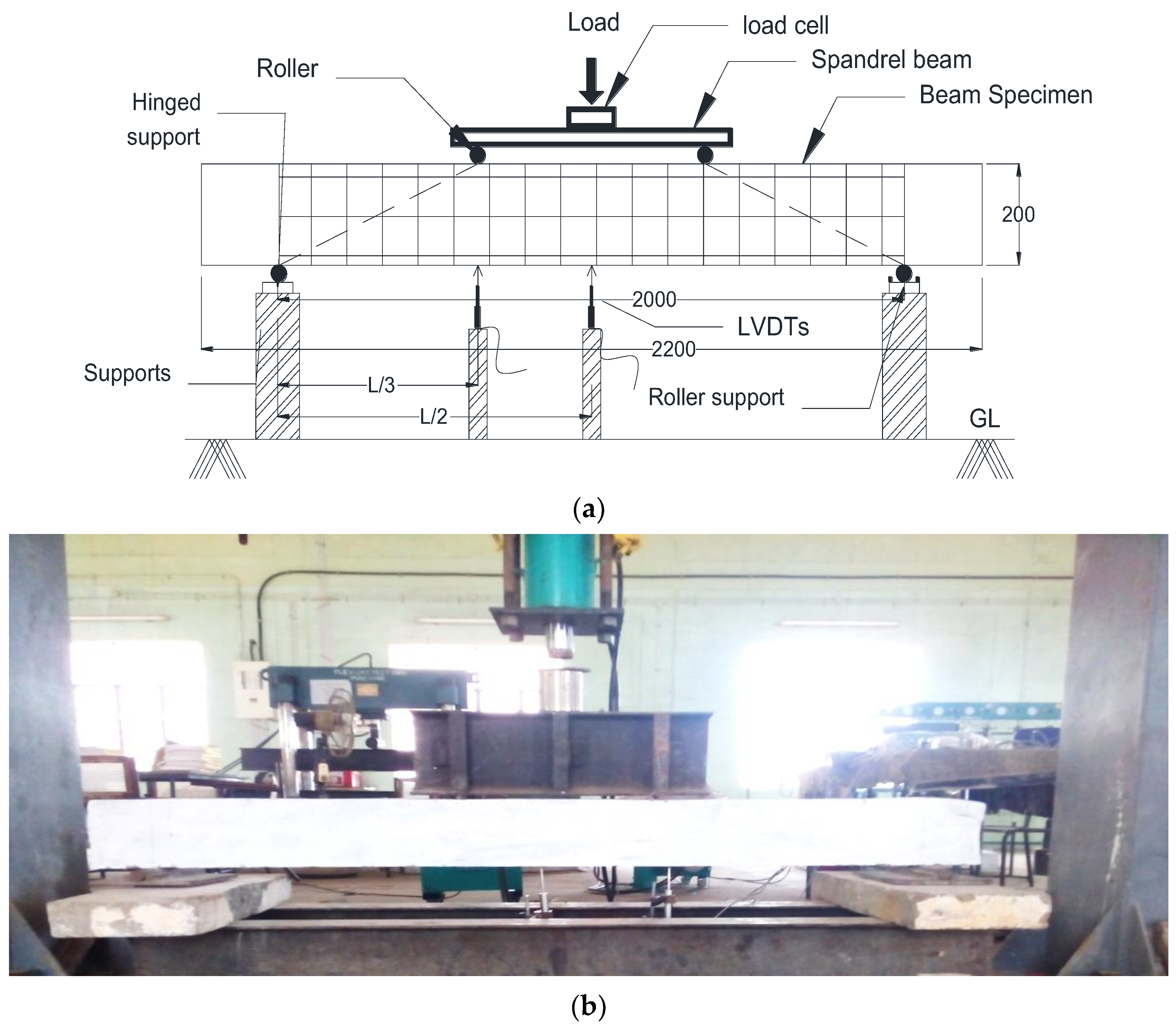

2.4. Test Setup

3. Results and Discussions

3.1. Test on Self-Compacting Concrete

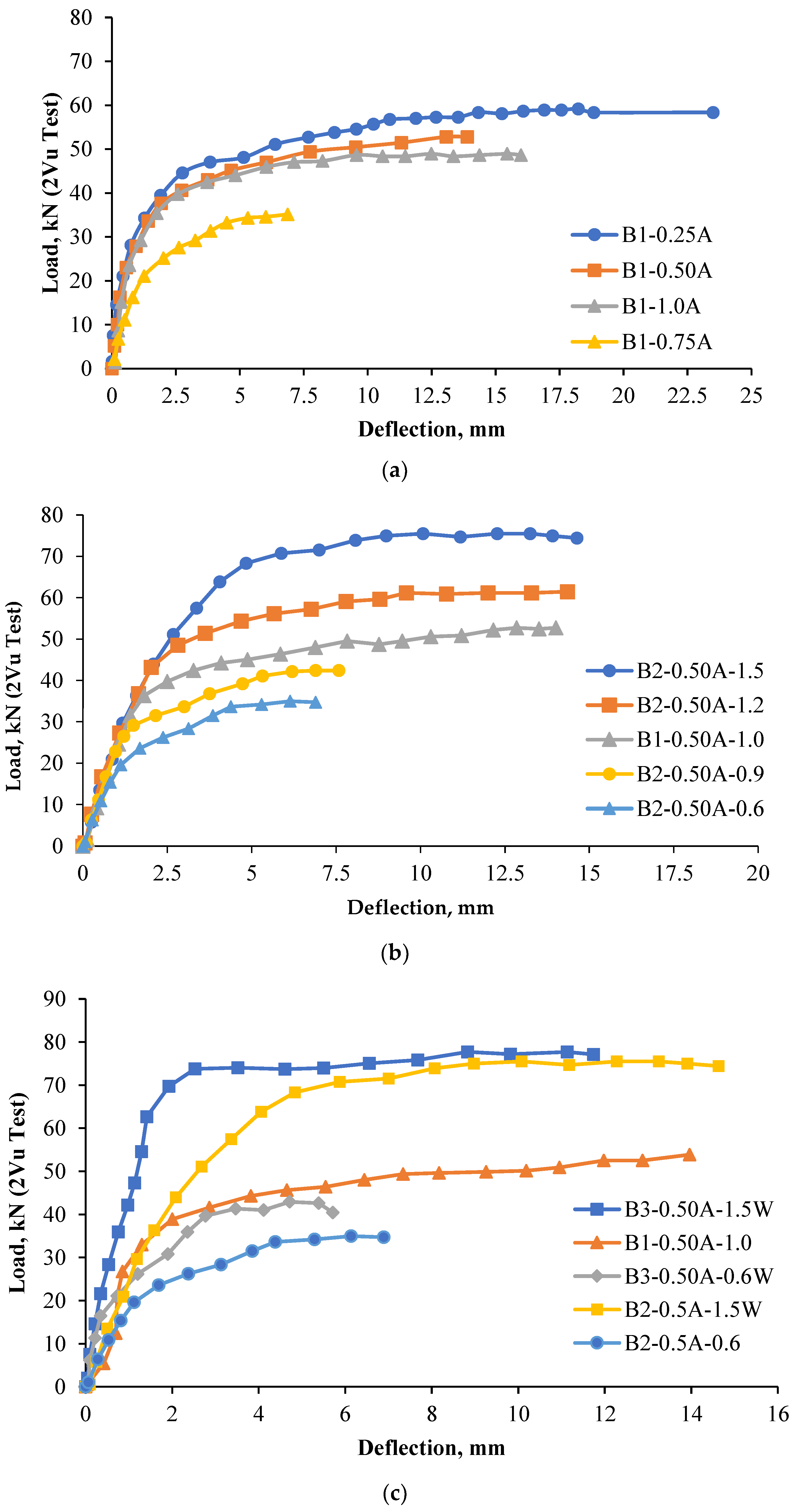

3.2. Load–Deflection Response

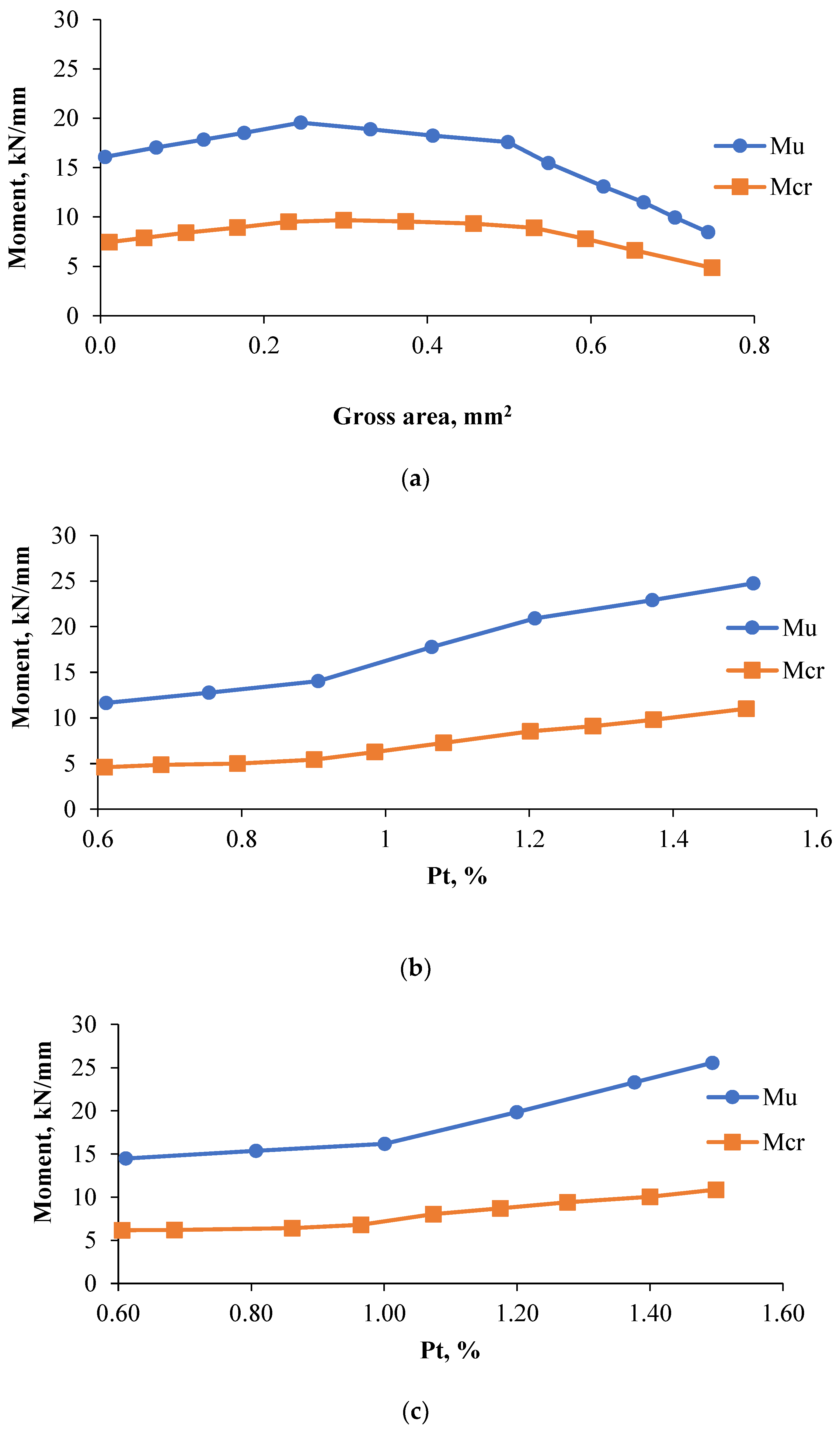

3.3. Moment Resistance

3.4. Reserve Strength Index

3.5. Energy Absorption

3.6. Deflection

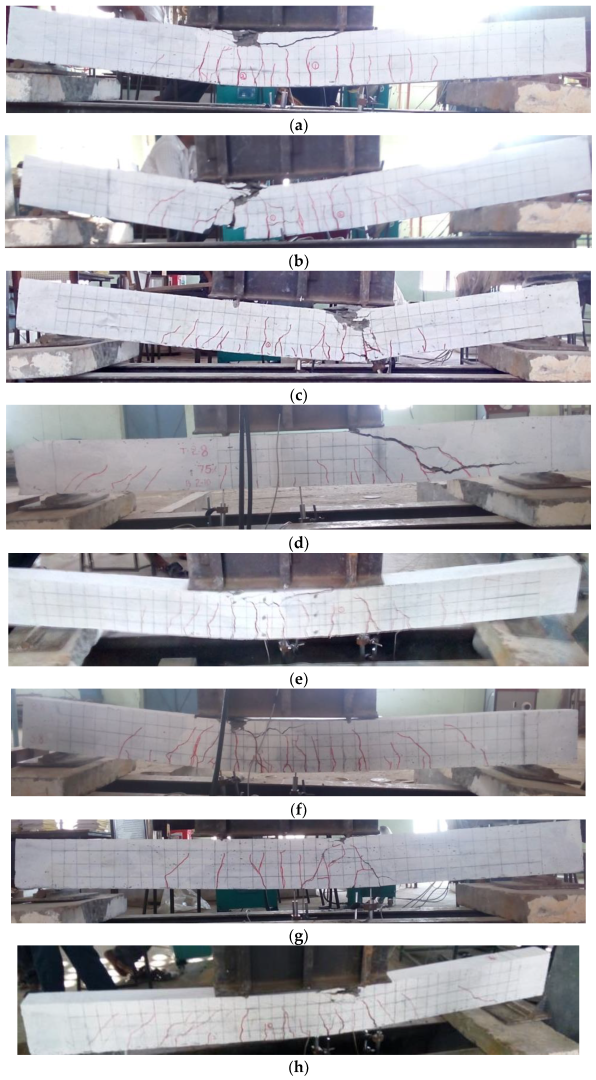

4. Failure Modes and Failure Mechanism

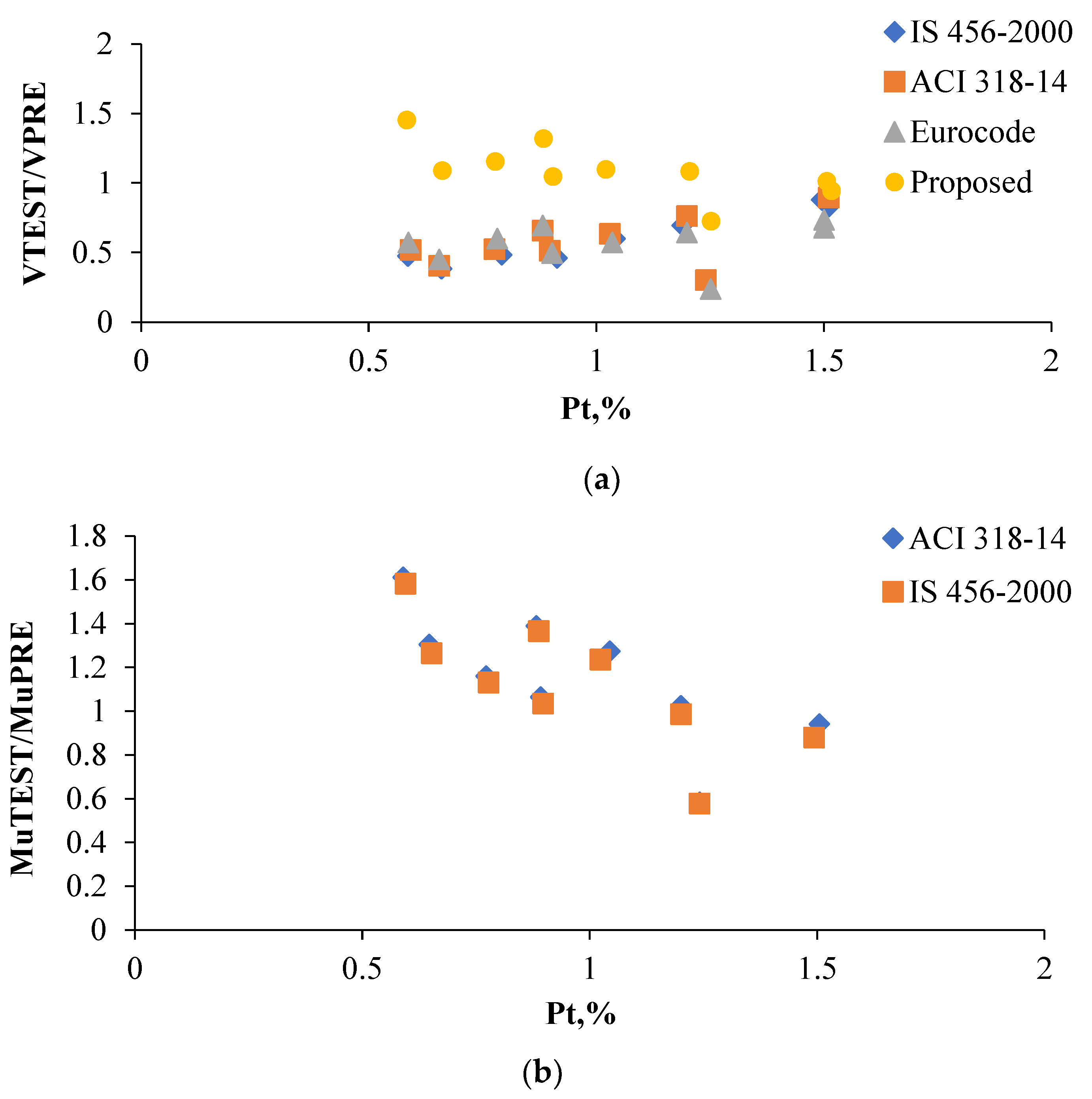

5. Prediction in Accordance with the Existing Expressions

6. Modified Shear Strength Expressions

| Sl. No | Models | Codes of Practice | Expressions | Equation No |

|---|---|---|---|---|

| 1. | Shear strength expressions | IS 456-2000 | = Vc + Vs ; ; ; Vs = 𝑓𝑦𝐴𝑠𝑣D/Sv | (6) |

| 2. | ACI 318-08 | (7) | ||

| 3. | Eurocode 2 | (8) | ||

| 4. | Moment of resistance | IS 456-2000 | (9) | |

| 5. | ACI 318-08 | (10) |

7. Reliability of the Modified Shear Strength Expression

8. Conclusions

- −

- The moment of resistance of sandwich beams increased up to 20% and 8% as the longitudinal inner core area reduced by 25% and 50%, respectively.

- −

- The experimental results proved that the performance of the sandwich beam was better than the normal beam in regard to the mechanical strength-to-weight ratio and serviceability aspect. For achieving high bending strength and stiffness, the optimum limit for adopting the inner core area was 50% and the minimum tension reinforcement was 0.9%.

- −

- The moment-to-weight ratio of sandwich beams was in between 17 and 113% higher than that of the solid beam.

- −

- As the area of the inner core increased for a given reinforcement configuration and geometry, the failure mode of sandwich beams changed from flexure to shear.

- −

- The load-carrying capacity of sandwich beams increased with the quantity of flexural reinforcements. In addition, the welded wire meshes improved the flexural and shear performances of sandwich beams.

- −

- The conventional expressions for the moment of resistance were valid for predicting the moment capacity of sandwich beams, whereas the shear strength expressions available in the current design standards overestimated the shear strength of such sandwich beams. Therefore, design modifications were proposed for the better prediction of shear strength. The proposed shear strength design formula could closely predict the experimental shear strength of sandwich beams and, therefore, can be used by future researchers and by practicing engineers.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mugahed Amran, Y.H. Determination of Structural Behavior of Precast Foamed Concrete Sandwich Panel. Ph.D. Thesis, Universiti Putra Malaysia (UPM), Seri Kembangan, Malaysia, 2016. [Google Scholar]

- Mugahed Amran, Y.H.; El-Zeadani, M.; Huei Lee, Y.; Yong Lee, Y.; Murali, G.; Feduik, R. Design innovation, efficiency and applications of structural insulated panels: A review. Structures 2020, 27, 1358–1379. [Google Scholar] [CrossRef]

- Zhou, Y.; Gao, H.; Hu, Z.; Qiu, Y.; Guo, M.; Huang, X.; Hu, B. Ductile, durable, and reliable alternative to FRP bars for reinforcing seawater sea-sand recycled concrete beams: Steel/FRP composite bars. Constr. Build. Mater. 2021, 269, 121264. [Google Scholar] [CrossRef]

- Liang, Z.; Hu, Z.; Zhou, Y.; Wu, Y.; Zhou, X.; Hu, B.; Guo, M. Improving recycled aggregate concrete by compression casting and nano-silica. Nanotechnol. Rev. 2022, 11, 1273–1290. [Google Scholar] [CrossRef]

- Zhou, Y.; Weng, Y.; Li, L.; Hu, B.; Huang, X.; Zhu, Z. Recycled GFRP Aggregate Concrete Considering Aggregate Grading: Compressive Behavior and Stress–Strain Modeling. Polymers 2022, 14, 581. [Google Scholar] [CrossRef]

- Arularasi, V.; Pachiappan, T.; Avudaiappan, S.; Raman, S.N.; Guindos, P.; Amran, M.; Fediuk, R.; Vatin, N.I. Effects of Admixtures on Energy Consumption in the Process of Ready-Mixed Concrete Mixing. Materials 2022, 15, 4143. [Google Scholar] [CrossRef] [PubMed]

- Makul, N.; Fediuk, R.; Amran, M.; Zeyad, A.M.; Murali, G.; Vatin, N.; Klyuev, S.; Ozbakkaloglu, T.; Vasilev, Y. Use of recycled concrete aggregates in production of green cement-based concrete composites: A review. Crystals 2021, 11, 232. [Google Scholar] [CrossRef]

- Mugahed Amran, Y.H.; Abang Ali, A.A.; Rashid, R.S.M.; Hejazi, F.; Safiee, N.A. Structural behavior of axially loaded precast foamed concrete sandwich panels. Constr. Build. Mater. 2016, 107, 307–320. [Google Scholar] [CrossRef]

- Amran, Y.H.M.; Rashid, R.S.M.; Hejazi, F.; Safiee, N.A.; Ali, A.A.A. Response of precast foamed concrete sandwich panels to flexural loading. J. Build. Eng. 2016, 7, 143–158. [Google Scholar] [CrossRef]

- Akmaluddin, A.; Murtiadi, S.; Anshari, B. Flexural stiffness of normal and sandwich reinforced concrete beam exposed to fire under fixed loading. Int. Rev. Civ. Eng. 2020, 11, 36–44. [Google Scholar] [CrossRef]

- Birman, V.; Kardomateas, G.A. Review of current trends in research and applications of sandwich structures. Compos. Part B Eng. 2018, 142, 221–240. [Google Scholar] [CrossRef]

- Sapuan, S.M.; Aulia, H.S.; Ilyas, R.A.; Atiqah, A.; Dele-Afolabi, T.T.; Nurazzi, M.N.; Supian, A.B.M.; Atikah, M.S.N. Mechanical properties of longitudinal basalt/woven-glass-fiber-reinforced unsaturated polyester-resin hybrid composites. Polymers 2020, 12, 2211. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Rafidah, M.; Ishak, M.R.; Sapuan, S.M.; Yidris, N.; Ilyas, R.A.; Razman, M.R. Integration of TRIZ, morphological chart and ANP method for development of FRP composite portable fire extinguisher. Polym. Compos. 2020, 41, 2917–2932. [Google Scholar] [CrossRef]

- Ashraf, W.; Ishak, M.R.; Zuhri, M.Y.M.; Yidris, N.; Ya’Acob, A.M. Experimental Investigation on the Mechanical Properties of a Sandwich Structure Made of Flax/Glass Hybrid Composite Facesheet and Honeycomb Core. Int. J. Polym. Sci. 2021, 2021, 8855952. [Google Scholar] [CrossRef]

- Gara, F.; Ragni, L.; Roia, D.; Dezi, L. Experimental behaviour and numerical analysis of floor sandwich panels. Eng. Struct. 2012, 36, 258–269. [Google Scholar] [CrossRef]

- Daniel Ronald Joseph, J.; Prabakar, J.; Alagusundaramoorthy, P. Flexural behavior of precast concrete sandwich panels under different loading conditions such as punching and bending. Alex. Eng. J. 2018, 57, 309–320. [Google Scholar] [CrossRef]

- Poluraju, P.; Appa Rao, G. Performance of squat 3D sandwich walls with longitudinal reinforcement and boundary elements under lateral cyclic loading. J. Sandw. Struct. Mater. 2018, 20, 946–973. [Google Scholar] [CrossRef]

- Raj J, L.; Rao G, A. Load configuration, geometry and web reinforcement effects on failure modes of sandwich deep beams. J. Sandw. Struct. Mater. 2018, 20, 811–830. [Google Scholar] [CrossRef]

- Mugahed Amran, Y.H.; Rashid, R.S.M.; Hejazi, F.; Abang Ali, A.A.; Safiee, N.A.; Bida, S.M. Structural Performance of Precast Foamed Concrete Sandwich Panel Subjected to Axial Load. KSCE J. Civ. Eng. 2018, 22, 1179–1192. [Google Scholar] [CrossRef]

- Amran, Y.M.; Rashid, R.S.; Hejazi, F.; Safiee, N.A.; Ali, A.A. Structural behavior of laterally loaded precast foamed concrete sandwich panel. Int. J. Civ. Environ. Struct. Constr. Arch. Eng. 2016, 10, 255–263. [Google Scholar]

- Amran, Y.M.; Rashid, R.S.; Hejazi, F.; Safiee, N.A.; Ali, A.A. Structural behavior of precast foamed concrete sandwich panel subjected to vertical in-plane shear loading. J. Civ. Environ. Struct. Constr. Arch. 2016, 10, 699–708. [Google Scholar]

- Basunbul, I.A.; Saleem, M.; Al-Sulaimani, G.J. Flexural behavior of ferrocement sandwich panels. Cem. Concr. Compos. 1991, 13, 21–28. [Google Scholar] [CrossRef]

- Petras, A.; Sutcliffe, M.P.F. Indentation failure analysis of sandwich beams. Compos. Struct. 2000, 50, 311–318. [Google Scholar] [CrossRef]

- Avilés, F.; Carlsson, L.A. Experimental study of debonded sandwich panels under compressive loading. J. Sandw. Struct. Mater. 2006, 8, 7–31. [Google Scholar] [CrossRef]

- Shipsha, A.; Hallstrom, S.; Zenkert, D. Failure mechanisms and modelling of impact damage in sandwich beams—A 2D approach: Part II—Analysis and modelling. J. Sandw. Struct. Mater. 2003, 5, 33–51. [Google Scholar] [CrossRef]

- Shipsha, A. Failure of Sandwich Structures With Sub-Interface Damage. KTH Stock. 2001, 17, 33. [Google Scholar]

- Rao, G.A.; Raj, J.L. Failure analysis of 3D sandwich beams under transverse shear. J. Struct. Eng. 2017, 44, 76–87. [Google Scholar]

- Benayoune, A.; Samad, A.A.A.; Trikha, D.N.; Ali, A.A.A.; Ellinna, S.H.M. Flexural behaviour of pre-cast concrete sandwich composite panel—Experimental and theoretical investigations. Constr. Build. Mater. 2008, 22, 580–592. [Google Scholar] [CrossRef]

- Bush, T.D.; Stine, G.L. Flexural Behavior of Composite Precast Concrete Sandwich Panels With Continuous Truss Connectors. PCI J. 1994, 39, 112–121. [Google Scholar] [CrossRef]

- Benayoune, A.; Samad, A.A.A.; Trikha, D.N.; Abang Ali, A.A.; Ashrabov, A.A. Structural behaviour of eccentrically loaded precast sandwich panels. Constr. Build. Mater. 2006, 20, 713–724. [Google Scholar] [CrossRef]

- Rezaifar, O.; Kabir, M.Z.; Taribakhsh, M.; Tehranian, A. Dynamic behaviour of 3D-panel single-storey system using shaking table testing. Eng. Struct. 2008, 30, 318–337. [Google Scholar] [CrossRef]

- Cuypers, H.; Wastiels, J. Analysis and verification of the performance of sandwich panels with textile reinforced concrete faces. J. Sandw. Struct. Mater. 2011, 13, 589–603. [Google Scholar] [CrossRef]

- Amran, M.; Abdelgader, H.S.; Onaizi, A.M.; Fediuk, R.; Ozbakkaloglu, T.; Rashid, R.S.; Murali, G. 3D-printable alkali-activated concretes for building applications: A critical review. Constr. Build. Mater. 2022, 319, 126126. [Google Scholar] [CrossRef]

- Lesovik, V.; Fediuk, R.; Amran, M.; Alaskhanov, A.; Volodchenko, A.; Murali, G.; Uvarov, V.; Elistratkin, M. 3D-Printed Mortars with Combined Steel and Polypropylene Fibers. Fibers 2021, 9, 79. [Google Scholar] [CrossRef]

- Klyuev, S.; Klyuev, A.; Fediuk, R.; Ageeva, M.; Fomina, E.; Amran, M.; Murali, G. Fresh and mechanical properties of low-cement mortars for 3D printing. Constr. Build. Mater. 2022, 338, 127644. [Google Scholar] [CrossRef]

- Siddika, A.; Shojib, M.H.H.; Hossain, M.M.; Hossain, M.I.; Mamun, M.A.A.; Alyousef, R.; Amran, Y.H.M. Flexural performance of wire mesh and geotextile-strengthened reinforced concrete beam. SN Appl. Sci. 2019, 1, 1324. [Google Scholar] [CrossRef] [Green Version]

- El-Zeadani, M.R.; Raizal Saifulnaz, M.R.; Mugahed Amran, Y.H.; Hejazi, F.; Jaafar, M.S.; Alyousef, R.; Alabduljabbar, H. Analytical mechanics solution for measuring the deflection of strengthened RC beams using FRP plates. Case Stud. Constr. Mater. 2019, 11, e00272. [Google Scholar] [CrossRef]

- El-Zeadani, M.; Raizal Saifulnaz, M.R.; Hejazi, F.; Mugahed Amran, Y.H.; Jaafar, M.S.; Alyousef, R.; Alrshoudi, F. Mechanics-based approach for predicting the short-term deflection of CFRP plated RC beams. Compos. Struct. 2019, 225, 111169. [Google Scholar] [CrossRef]

- Al-Nini, A.; Nikbakht, E.; Syamsir, A.; Shafiq, N.; Mohammed, B.S.; Al-Fakih, A.; Al-Nini, W.; Amran, Y.H.M. Flexural behavior of double-skin steel tube beams filled with fiber-reinforced cementitious composite and strengthened with CFRP sheets. Materials 2020, 13, 3064. [Google Scholar] [CrossRef] [PubMed]

- Rahim, N.I.; Mohammed, B.S.; Al-Fakih, A.; Wahab, M.M.A.; Liew, M.S.; Anwar, A.; Mugahed Amran, Y.H. Strengthening the structural behavior of web openings in RC deep beam using CFRP. Materials 2020, 13, 2804. [Google Scholar] [CrossRef]

- Bakar, M.B.C.; Muhammad Rashid, R.S.; Amran, M.; Saleh Jaafar, M.; Vatin, N.I.; Fediuk, R. Flexural Strength of Concrete Beam Reinforced with CFRP Bars: A Review. Materials 2022, 15, 1144. [Google Scholar] [CrossRef]

- El-Zeadani, M.; Rashid, R.S.M.; Amran, M.Y.H.; Swi, M.I. Effect of the plate bondstress-slip property on the flexural strength of FRP Plated RC beams using a displacement-based approach. SN Appl. Sci. 2020, 2, 1925. [Google Scholar] [CrossRef]

- Murali, G.; Amran, M.; Fediuk, R.; Vatin, N.; Raman, S.N.; Maithreyi, G.; Sumathi, A. Structural behavior of fibrous-ferrocement panel subjected to flexural and impact loads. Materials 2020, 13, 5648. [Google Scholar] [CrossRef] [PubMed]

- Raj, J.L.; Rao, G.A. Shear strength of rc deep beam panels—A review. Int. J. Res. Eng. Technol. 2014, 3, 89–103. [Google Scholar] [CrossRef]

- Praneeth, A.; Pramod Kumar, K.V.S.; Pramod, R.; Veeresh Kumar, G.B. Investigation of Mechanical properties of Glass Fibre Reinforced Honeycomb Panels. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Bengaluru, India, 16–18 August 2018. [Google Scholar] [CrossRef] [Green Version]

- Saheed, S.; Aziz, F.N.A.A.; Amran, M.; Vatin, N.; Fediuk, R.; Ozbakkaloglu, T.; Murali, G.; Mosaberpanah, M.A. Structural performance of shear loaded precast EPS-foam concrete half-shaped slabs. Sustainability 2020, 12, 9679. [Google Scholar] [CrossRef]

- Saheed, S.; Amran, Y.H.M.; El-Zeadani, M.; Aziz, F.N.A.; Fediuk, R.; Alyousef, R.; Alabduljabbar, H. Structural behavior of out-of-plane loaded precast lightweight EPS-foam concrete C-shaped slabs. J. Build. Eng. 2021, 33, 101597. [Google Scholar] [CrossRef]

- El-Zeadani, M.; Raizal Saifulnaz, M.R.; Amran, M. Full-range bondstress-slip model for externally bonded FRP plates including a frictional component. Compos. Struct. 2021, 262, 113372. [Google Scholar] [CrossRef]

- Hassan, A.A.A.; Hossain, K.M.A.; Lachemi, M. Structural assessment of corroded self-consolidating concrete beams. Eng. Struct. 2010, 32, 874–885. [Google Scholar] [CrossRef]

- Choulli, Y.; Marí, A.R.; Cladera, A. Shear behaviour of full-scale prestressed i-beams made with self compacting concrete. Mater. Struct. Constr. 2008, 41, 131–141. [Google Scholar] [CrossRef]

- Hassan, A.A.A.; Hossain, K.M.A.; Lachemi, M. Behavior of full-scale self-consolidating concrete beams in shear. Cem. Concr. Compos. 2008, 30, 588–596. [Google Scholar] [CrossRef]

- Xu, G.; Li, A. Experimental and numerical studies on the lateral performance of concrete sandwich walls. Struct. Des. Tall Spec. Build. 2020, 29, e1715. [Google Scholar] [CrossRef]

- Bureau of Indian Standard(BIS) IS: 8112-1989; Specification for 43 Grade Ordinary Portland Cement. Bureau of Indian Standards: New Delhi, India, 2013.

- BIS:383; Specification for Coarse and Fine Aggregates from Natural Sources for Concrete. Bureau of Indian Standards: New Delhi, India, 1970.

- ASTM C1609/C1609M-19a; Standard Test Method for Flexural Performance of Fiber-Reinforced Concrete (Using Beam with Third-Point Loading). ASTM International: West Conshohocken, PA, USA, 2019.

- Ferdous, W.; Manalo, A.; Aravinthan, T.; Fam, A. Flexural and shear behaviour of layered sandwich beams. Constr. Build. Mater. 2018, 173, 429–442. [Google Scholar] [CrossRef]

- Hu, B.; Wu, Y.F. Quantification of shear cracking in reinforced concrete beams. Eng. Struct. 2017, 147, 666–678. [Google Scholar] [CrossRef]

- Caliskan, U.; Apalak, M.K. Bending impact behaviour of sandwich beams with expanded polystyrene foam core: Analysis. J. Sandw. Struct. Mater. 2019, 21, 230–259. [Google Scholar] [CrossRef]

- Guo, L.; Mao, R.; Li, S.; Liu, Z.; Lu, G.; Wang, Z. The load-carrying capacity of sandwich beams in different collapse mechanisms. J. Sandw. Struct. Mater. 2021, 23, 2988–3016. [Google Scholar] [CrossRef]

- Zhang, W.; Qin, Q.; Li, J.; Su, B.; Zhang, J. A comparison of structural collapse of fully clamped and simply supported hybrid composite sandwich beams with geometrically asymmetric face sheets. Compos. Part B Eng. 2020, 201, 108398. [Google Scholar] [CrossRef]

- Tarlochan, F. Sandwich structures for energy absorption applications: A review. Materials 2021, 14, 4731. [Google Scholar] [CrossRef]

- Theotokoglou, E.E.; Hortis, D.; Carlsson, L.A.; Mahfuz, H. Numerical study of fractured sandwich composites under flexural loading. J. Sandw. Struct. Mater. 2008, 10, 75–94. [Google Scholar] [CrossRef]

- Kumar, A.S.; Joy, A. Experimental Study on Partial Replacement of Concrete Below Neutral Axis of Beam. Int. J. Eng. Res. Technol. 2015, 3, 1–5. [Google Scholar]

- Theotokoglou, E.E. Prediction of crack propagation in sandwich beams under flexural loading. In Proceedings of the ECCM 2012-Composites at Venice, Proceedings of the 15th European Conference on Composite Materials, Venice, Italy, 24–28 June 2012. [Google Scholar]

- Cook, J.; Gordon, J.E. A mechanism for the control of crack propagation in all-brittle systems. Proc. R. Soc. London. Ser. A. Math. Phys. Sci. 1964, 282, 508–520. [Google Scholar] [CrossRef]

- Daniel, I.M. Influence of core properties on the failure of composite sandwich beams. J. Mech. Mater. Struct. 2009, 4, 1271–1286. [Google Scholar] [CrossRef] [Green Version]

- Bureau of Indian Standards IS 456:2000; Indian Standard Plain and Reinforced Concrete—Code of Practice. Bureau of Indian Standards: New Delhi, India, 2000.

- ACI 318-14; Building code requirements for reinforced concrete (ACI 318-14). ACI: Farmington Hills, MI, USA, 2014.

- BS EN 1992-1-1; Eurocode 2: Design of concrete structures—Part 1-1: General rules and rules for buildings. British Standard Institution: London, UK, 2004.

| Group No | Beam Designation | L, mm | B, mm | D, mm | Hanging Bars | Ast | fck, MPa | Size of Polystyrene, mm2 | |

|---|---|---|---|---|---|---|---|---|---|

| I | B1-1.0A | 2200 | 100 | 200 | 2# 8ᴓ | 2# 10ᴓ | 3.5 | 33.40 | -- |

| B1-0.25A | 2200 | 100 | 200 | 2# 8ᴓ | 2# 10ᴓ | 3.5 | 33.28 | 50 × 50 | |

| B1-0.50A | 2200 | 100 | 200 | 2# 8ᴓ | 2# 10ᴓ | 3.5 | 31.90 | 50 × 100 | |

| B1-0.75A | 2200 | 100 | 200 | 2# 8ᴓ | 2# 10ᴓ | 3.5 | 32.66 | 50 × 150 | |

| II | B2-0.50A-0.6 | 2200 | 100 | 200 | 2# 8ᴓ | 2# 8ᴓ | 3.5 | 34.64 | 50 × 100 |

| B2-0.50A-0.9 | 2200 | 100 | 200 | 2# 8ᴓ | 3# 8ᴓ | 3.5 | 32.86 | 50 × 100 | |

| B2-0.50A-1.2 | 2200 | 100 | 200 | 2# 8ᴓ | 3# 10ᴓ | 3.5 | 33.62 | 50 × 100 | |

| B2-0.50A-1.5 | 2200 | 100 | 200 | 2# 8ᴓ | 4# 10ᴓ | 3.5 | 34.01 | 50 × 100 | |

| III | B3-0.50A-0.6-W | 2200 | 100 | 200 | 2# 8ᴓ | 2# 10ᴓ | 3.5 | 33.41 | 50 × 100 |

| B3-0.50A-1.5-W | 2200 | 100 | 200 | 2# 8ᴓ | 4# 10ᴓ | 3.5 | 31.06 | 50 × 100 |

| Methods | Standard Values | SCC by Using Conplast for a Particular Water–Cement Ratio (w/c) | SCC by Using Cerahyperplast for a Particular Water–Cement Ratio (w/c) | ||||

|---|---|---|---|---|---|---|---|

| w/c 0.33 | w/c 0.42 | w/c 0.46 | w/c 0.33 | w/c 0.42 | w/c 0.46 | ||

| Slump Flow | 650–800 mm | 680 mm | 695 mm | 699 mm | 740 mm | 745 mm | 750 mm |

| T50 Slump Flow | 2–5 s | 5 s | 4 s | 4 s | 5 s | 4 s | 3 s |

| J-Ring | 0–10 mm | 10 mm | 9 mm | 8 mm | 9 mm | 8 mm | 8 mm |

| V-funnel test | 8–12 s | 11 s | 10 s | 8 s | 9 s | 8 s | 8 s |

| U-box | H2-H1 = 30 mm (max) | 29 mm | 27 mm | 27 mm | 28 mm | 26 mm | 25 mm |

| L-box | H2/H1 = 0.8 to1.0 | 0.8 | 0.8 | 1.0 | 0.9 | 0.8 | 1.0 |

| Compressive strength in MPa | 33.92 | 31.44 | 30.23 | 30.36 | 28.44 | 26.50 | |

| Group Name | Designation | Failure Mode | Mcr, kN-m | My, kN-m | Mu, kN-m | R a | Eabs, kN mm | |||

|---|---|---|---|---|---|---|---|---|---|---|

| I | B1-1.0A | F | 22.4 | 48.1 | 6.72 | 11.262 | 14.43 | 53.43 | 17.55 | 765.58 |

| B1-0.25A | F | 18.5 | 58.1 | 5.55 | 10.236 | 17.43 | 68.16 | 21.58 | 1098.5 | |

| B1-0.50A | F | 27.7 | 52.3 | 8.31 | 12.897 | 15.69 | 47.04 | 15.40 | 687.26 | |

| B1-0.75A | S | 14.7 | 24.3 | 4.41 | 6.225 | 7.29 | 39.51 | 7.643 | 206.25 | |

| II | B2-0.50A-0.6 | F | 13.9 | 34.5 | 4.17 | 7.068 | 10.35 | 59.71 | 7.63 | 190.96 |

| B2-0.50A-0.9 | F | 16.3 | 42.3 | 4.89 | 9.258 | 12.69 | 61.47 | 8.74 | 300.2 | |

| B2-0.50A-1.2 | F | 25.6 | 63.1 | 7.68 | 15.192 | 18.93 | 59.43 | 16.10 | 859.83 | |

| B2-0.50A-1.5 | F | 33.4 | 75.0 | 10.02 | 19.488 | 22.5 | 55.47 | 6.23 | 1033.9 | |

| III | B3-0.50A-0.6-W | F | 18.0 | 42.9 | 5.4 | 10.566 | 12.87 | 58.04 | 6.10 | 204.62 |

| B3-0.50A-1.5-W | F | 32.7 | 77.0 | 9.81 | 20.067 | 23.1 | 57.53 | 13.04 | 899.08 | |

| Area under load–deflection curve = a R =; Eabs | ||||||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chakrawarthi, V.; Raj Jesuarulraj, L.; Avudaiappan, S.; Rajendren, D.; Amran, M.; Guindos, P.; Roy, K.; Fediuk, R.; Vatin, N.I. Effect of Design Parameters on the Flexural Strength of Reinforced Concrete Sandwich Beams. Crystals 2022, 12, 1021. https://doi.org/10.3390/cryst12081021

Chakrawarthi V, Raj Jesuarulraj L, Avudaiappan S, Rajendren D, Amran M, Guindos P, Roy K, Fediuk R, Vatin NI. Effect of Design Parameters on the Flexural Strength of Reinforced Concrete Sandwich Beams. Crystals. 2022; 12(8):1021. https://doi.org/10.3390/cryst12081021

Chicago/Turabian StyleChakrawarthi, Vijayaprabha, Leon Raj Jesuarulraj, Siva Avudaiappan, Divya Rajendren, Mugahed Amran, Pablo Guindos, Krishanu Roy, Roman Fediuk, and Nikolai Ivanovich Vatin. 2022. "Effect of Design Parameters on the Flexural Strength of Reinforced Concrete Sandwich Beams" Crystals 12, no. 8: 1021. https://doi.org/10.3390/cryst12081021

APA StyleChakrawarthi, V., Raj Jesuarulraj, L., Avudaiappan, S., Rajendren, D., Amran, M., Guindos, P., Roy, K., Fediuk, R., & Vatin, N. I. (2022). Effect of Design Parameters on the Flexural Strength of Reinforced Concrete Sandwich Beams. Crystals, 12(8), 1021. https://doi.org/10.3390/cryst12081021