1. Introduction

Nickel-based single-crystal superalloys are widely used as turbine-bladematerials in advanced aero engines because of their excellent comprehensive properties [

1,

2,

3,

4]. Beijing Institute of Aeronautical Materials has developed a third-generation single-crystal superalloy, DD9, for applications of advanced aero-engine blades [

5,

6,

7]. The tensile and stress-rupture properties of DD9 alloy are equivalent to those of other third-generation single-crystal superalloys, such as CMSX-10, René N6, and TMS-75 [

6].

To meet the demands of advanced aero engines, theaero engines’ thrust–weight ratios increase; thus, the geometries of the turbine blade become more complex, such as the dual-wall cooling structure. Meanwhile, there are more refractory elements added to the third-generation single-crystal superalloys. As a result, during the directional solidification process of the single-crystal blades, grain defects are easy to form, for example, low-angle boundaries (LABs). However, it is almost impossible for single-crystal superalloy castings to keep their exact [

1] orientation during the single-crystal growth process. Turbine blades of advanced aero engines usually operate at high service stresses and temperatures. LAB defects may influence the mechanical properties of single-crystal superalloys, which may harm the single-crystal turbine blade’s quality.

It has been reported that the effect of LABs on the tensile properties of single-crystal superalloy relates to the LABs’ misorientation angle, and some levels of LABs can be accepted [

8,

9,

10,

11,

12,

13,

14]. Tamaki has found that there is no significant decrease in ultimate tensile strength of YH61 alloy with the increase in the misorientation angle of LABs below 800 °C, while the ultimate tensile strength clearly decreases with the increase in themisorientation angle of LABs above 800 °C [

8]. Patel reported that the tensile property of CMSX-10K alloy at 900 °C decreases significantly when the misorientation angle of LABs is higher than 10° [

9]. Zhao and Shi have studied the effect of LABs on the tensile properties of DD6 alloy; it was found that the tensile strength of DD6 alloy decreases with the increase in themisorientation angle of LABs, and the ultimate tensile strength of DD6 alloy clearly decreases when the misorientation angle of LABs is higher than 9° [

10,

11,

12]. Li found that the LABs begin to influence the tensile properties of SRR99 alloy at room temperature when the misorientation angle of the LAB reaches 10°, while the LABs with misorientation angles of 16° and 18° have a great effect on the tensile properties and the fracture shows obvious interdendritic characteristics [

13]. Qin reported that the LABs with misorientation angles of 0°~18° have little effect on the tensile strength of DD5 alloy at 870 °C, while elongation decreases quickly when the misorientation angle is above 11.4° [

14].

The effects of LABs on the tensile properties of single-crystal superalloys are of great importance, which is one of the critical bases for establishing acceptance criteria for single-crystal turbine blades. The main purpose of our paper is to report on the microstructure of LABs of DD9 alloy and its effects on the tensile properties and fracture behavior of the alloy at 1100 °C.

2. Materials and Methods

Commercially pure raw materials were used to prepare DD9 master alloy heat in a vacuum-induction furnace [

6]. The DD9 alloy’s chemical compositions are (weight percent) 3.5% Cr, 7% Co, 2% Mo, 6.5% W, 5.6% Al, 7.5% Ta, 4.5% Re, 0.1% Hf, 0.5% Nb, 0.008% C, 0.001% Y, Ni balance. We used double seed crystals techniques to obtain bicrystal slabs with tilt low-angle boundaries in a directional-solidification vacuum furnace [

11,

15]. The orientations of DD9 alloy slabs with LABs were determined byX-ray technology, and the slabs with [

1] orientation deviating from the longitudinal direction within 10° were chosen.

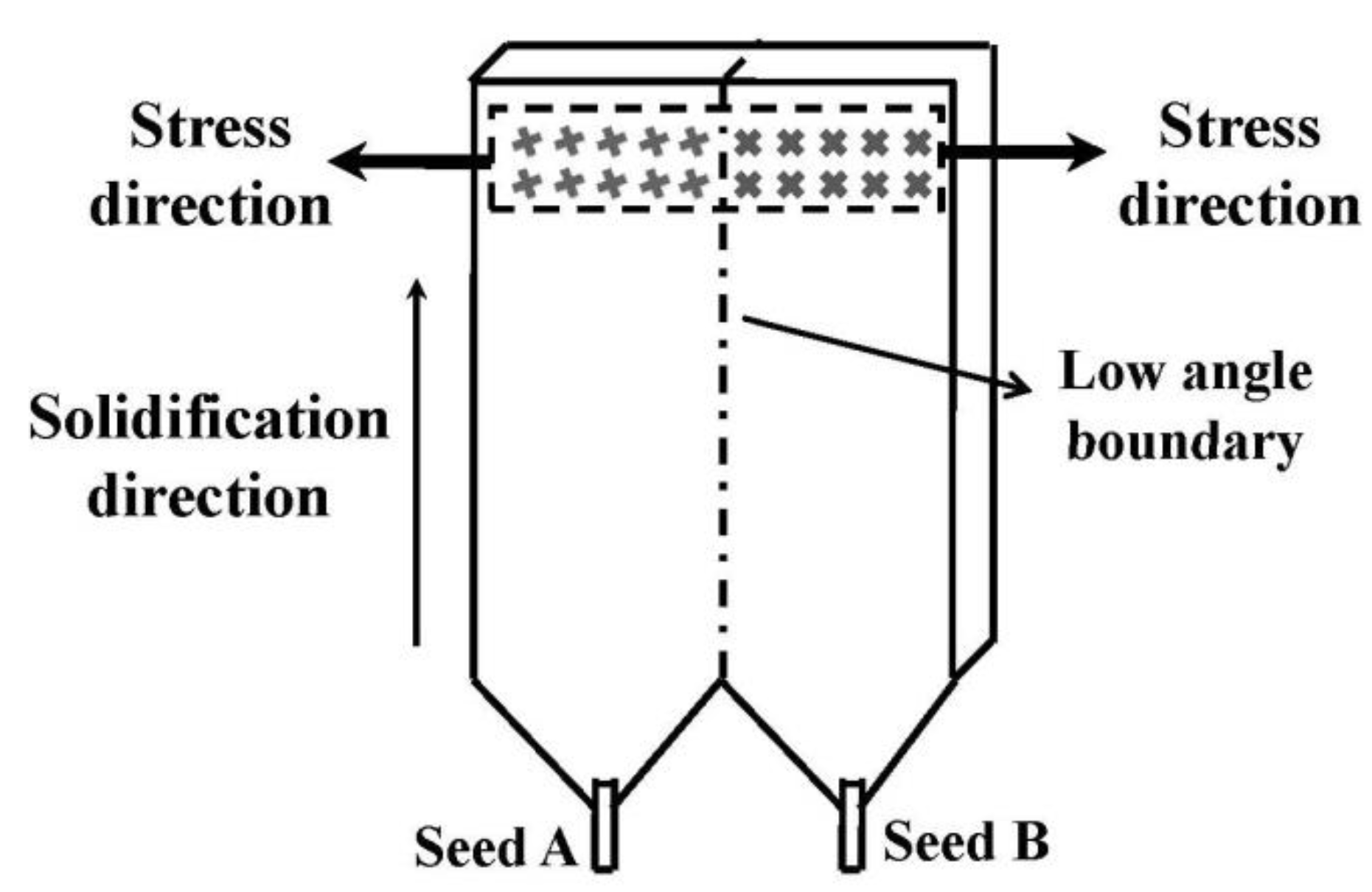

Figure 1 shows the schematic of the bicrystal slab and the transverse specimen with LABs. A total of 5bicrystalslabs with dimensions of 15 mm × 80 mm × 120 mm were prepared and the LABs’ misorientation angles of themare 3.7°, 4.8°, 6.0°, 8.9°, and 11.4°, respectively. When the misorientation angle of the LAB is 0°, the transverse specimens were taken from a single-crystal slab.

The specimens were all then heat-treated with a three-step process, which includes the solution heat treatment (preheat treatment +1340 °C/6 h/AC), primary-aging heat treatment (1120 °C/4 h/AC) and secondary-aging heat treatment (870 °C/32 h/AC). After the heat treatment, the specimens were machined into test specimens with a 25 mm gauge distance and a 5 mm gauge diameter according to the requirements of the testing standard (HB 5195). The tensile test was conducted at atemperature of 1100 °C, and two specimens were used for each kind of LAB.

The microstructures of the LABs and fracture surfaces of tensile-ruptured specimens were observed with Leica DM4000M optical microscopy (OM), Zeiss Supra 55 field-emission scanning electron microscopy (SEM) and JEOL JEM-2100F transmission electron microscopy (TEM). After rupture, the specimens were cut along the stress direction, and the microstructures of the sections were also studied. Samples for OM and SEM observations were firstly polished and then etched with a chemical etchant (80 mL HCl + 100 mL H2O + 5 mL H2SO4 + 25 g CuSO4) for 5~10 s. Samples for TEM analysis were cut about 5 mm away from the fracture surface with 0.4 mm thickness. They were mechanically ground to 50 μm and the nelectropolished at −30 °C in a solution of 90% ethyl alcohol + 10% perchloric acid, and they were observed with TEM operating at 200 kV.

3. Results

3.1. Microstructures of LABs

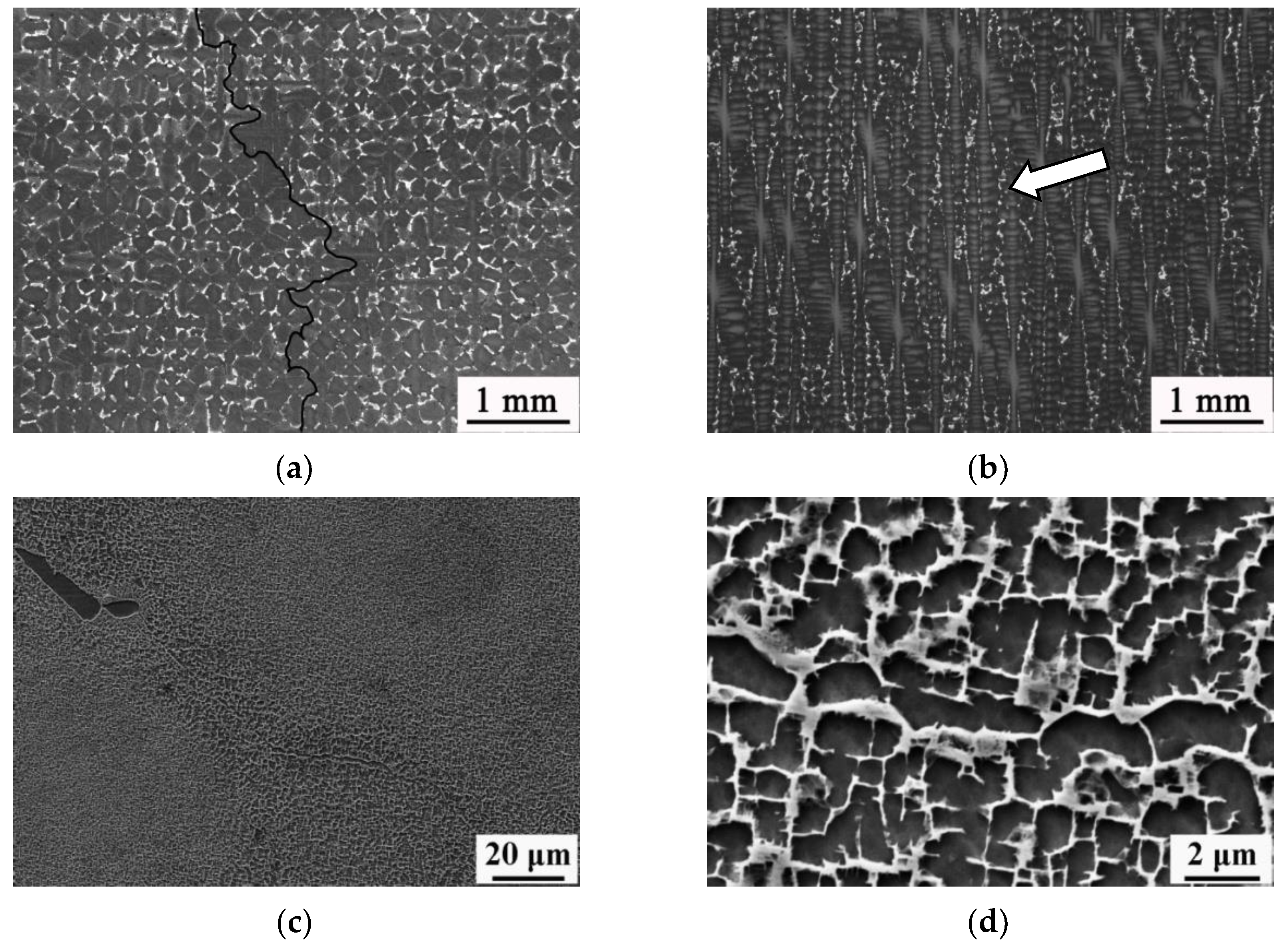

Figure 2 illustratesthe microstructures of LABs of 3.7° in the as-cast DD9 alloy. It can be seen that the LABs are curved in the transverse morphologies, as indicated by a black line in

Figure 2a, while the LABs are in a parallel relationship with the primary dendrite arms and they are almost straight along the longitudinal direction, as indicated by an arrow in

Figure 2b. From

Figure 2c,d, it is also found that the LABs connect with eutectic γ-γ′ and are composed of strip-like and bulk γ′ phases with γ matrix adjacent to them.

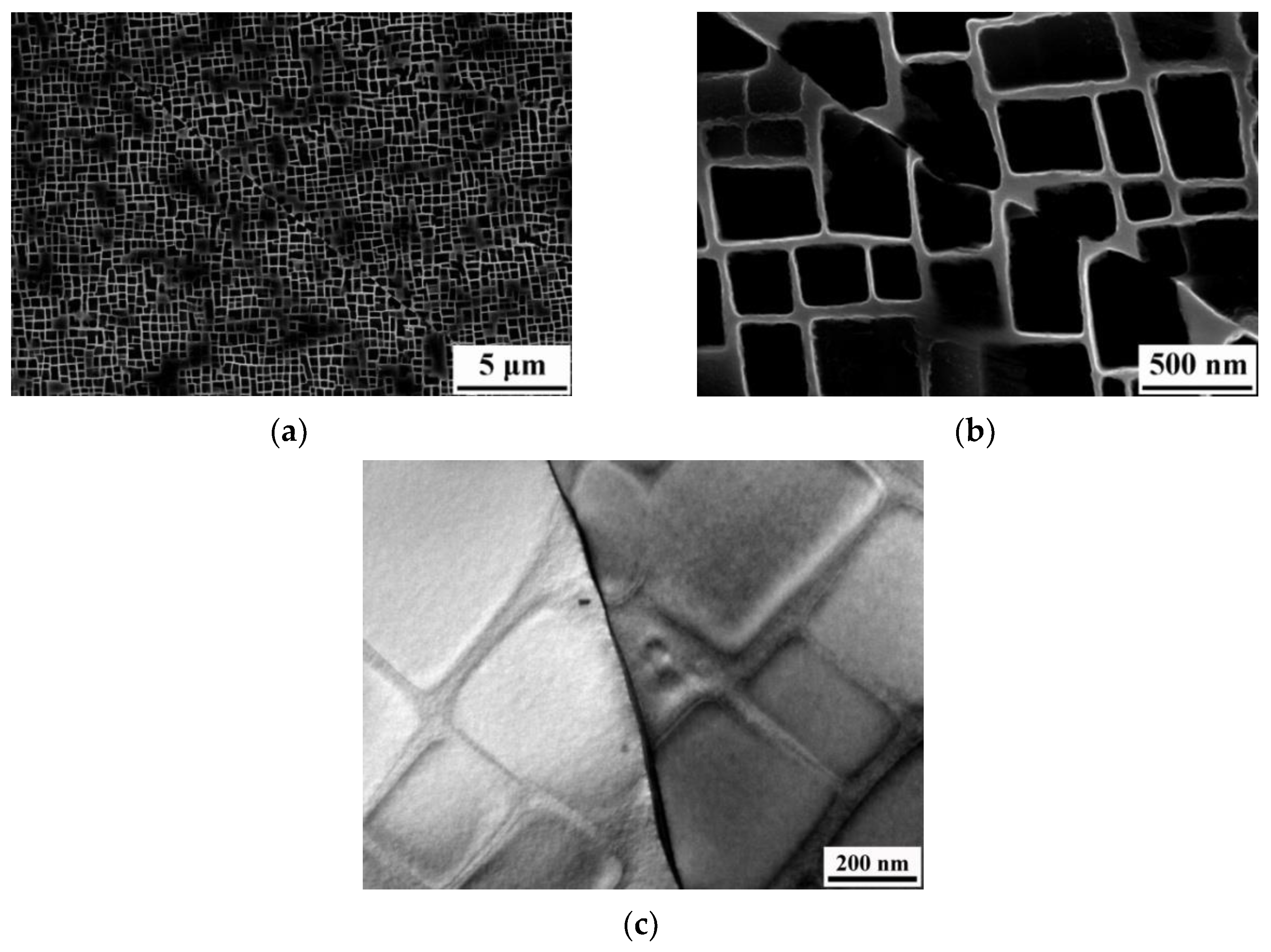

Figure 3 shows the microstructures of LABs of 3.7° in DD9 alloy after the heat treatment. Compared to the as-cast LABs, the heat-treated LABs become straighter, and there are no γ′ phases at the LABs. This indicates that the massive γ′ phases and eutectic γ-γ′ at the grain boundaries are all dissolved during the process of heat treatment. Meanwhile, it can be seen that orientations of the γ′ phases on both sides of the LABs are different, and the cuboidal forms of the γ′ phases are well-developed.

3.2. Tensile Properties

Table 1 shows the tensile properties of DD9 alloy with LABsat 1100 °C.

Figure 4 illustrates the relationships between the yield strength (YS), ultimate tensile strength (UTS) and elongation of DD9 alloy, and the misorientation angles of the LABs at 1100 °C. It can be seen that at 1100 °C, the YS and UTS of DD9 alloy with LABs decrease a little as the misorientation angle of the LABs increases from 0° to 11.4°. When the misorientation angle of the LABs reaches 11.4°, the YS of the DD9 alloy is equivalent tothat withLABs of 0°, while the UTS of the DD9 alloy decreases only 16 MPa compared to that with LABs of 0°.However, the elongationsof DD9 alloy with LABs decrease almost monotonically as the misorientation angle of the LABs increases. The elongation of the DD9 alloy with LABs of 11.4° decreases by 94.6% compared to that with LABs of 0°.

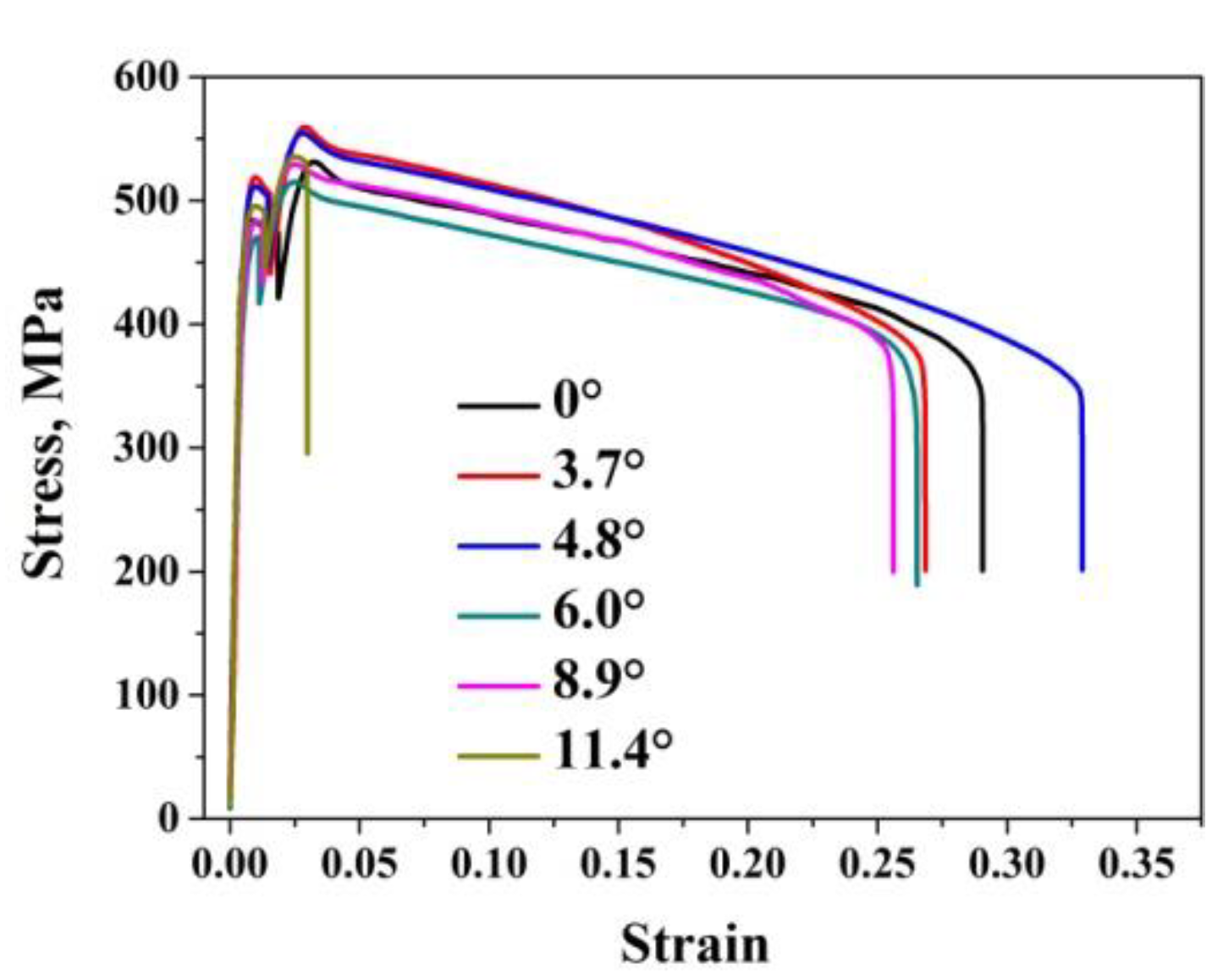

Figure 5 illustrates the tensile stress–strain curves of DD9 alloy with LABs at 1100 °C. As shown in

Figure 5,the flow stress of DD9 alloy with LABs of 0°~11.4° all show a double-stage feature. During the second stage of the curve, the stress first increases steeply to the peak point and then gradually drops until rupture. It can be seen that in

Figure 4 and

Figure 5, the LABs mainly affect the tensile elongation of DD9 alloy, and the the elongations drop obviously when the misorientation angle of the LABs is greater than 8.9°.

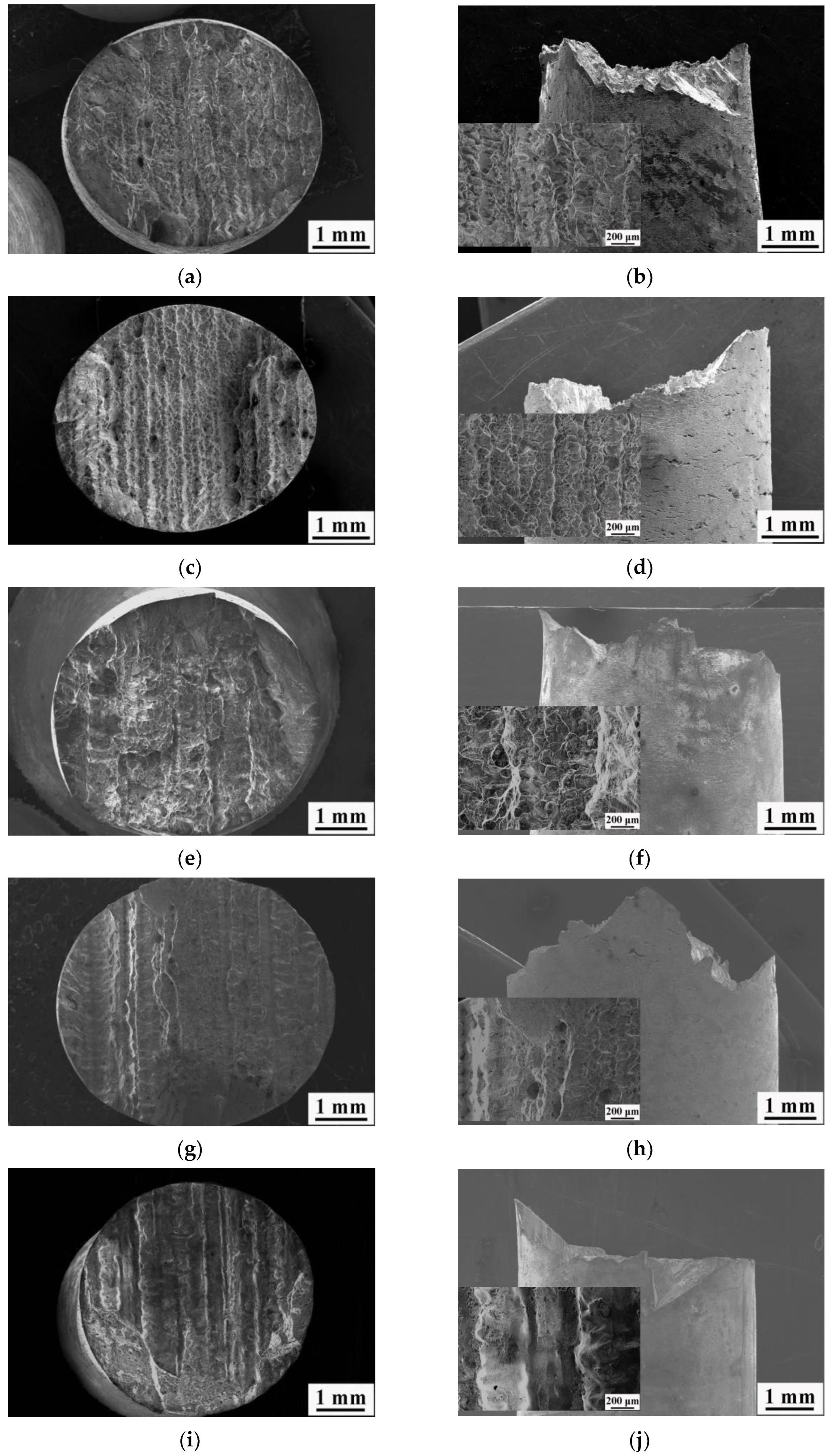

3.3. Fracture Surface

Figure 6 shows the tensile fracture surfaces and longitudinal morphologies of DD9 alloy with LABs at 1100 °C. The higher magenification of the fracture surfaces are also given in

Figure 6. As can be seen, all the tensile fracture surfaces of DD9 alloy with LABs are almost circular, and no obvious neck-downare observed near the fracture surfaces of the specimens with LABs of 3.7°~11.4°, which is similiar in the other single-crystal superalloy with LABs [

11,

12]. The fracture surfaces of DD9 alloy of LABs of 3.7°~11.4° all display dendrites morphology and this feature can be seen throughout almost the whole fracture surfaces, which indicates that the intergranular fracture occurs. Meanwhile, dimple characteristics can be foundon the fracture surface of DD9 alloy with LABs, as seen in

Figure 6b,d,f,h,j. There are small pores in the center of the dimples, which usually originate from pores growing and coalescencing at high temperatures [

16]. However, it can be seen that fewerdimples are formed as the misorientation angles of the LABs increase from 3.7° to 11.4°. This may imply that as the misorientation angles of the LABs become larger, the plastic deformation before fracture of the alloys with LABsbecomes smaller, and thus the elongation of the alloy is lower.

3.4. Microstructures after Tensile Rupture

Figure 7 illustrates the morphologies of the longitudinal section and microstructures near the fracture surface of tensile-ruptured DD9 alloy with LABs at 1100 °C. It can be seen that the numberof microcracks on the sections of tensile-ruptured specimens decreases as the misorientation angles of the LABs increase from 3.7° to 11.4°. There is almost no microcrack on the section of the DD9 alloy with LABs of 11.4°. Because the intergranular fracture occurs for all the specimens with LABs in our study, therefore no LABs are found on the section of ruptured alloy. As for the γ′ phases’ morphologies near the fracture surfaces, the γ′ phases’ cuboidal forms are still well-maintained comparedto the heat-treated state in

Figure 3. Moreover, there are slip bands near the fracture surfaces, which are indicated by arrows in

Figure 7b,d,f.

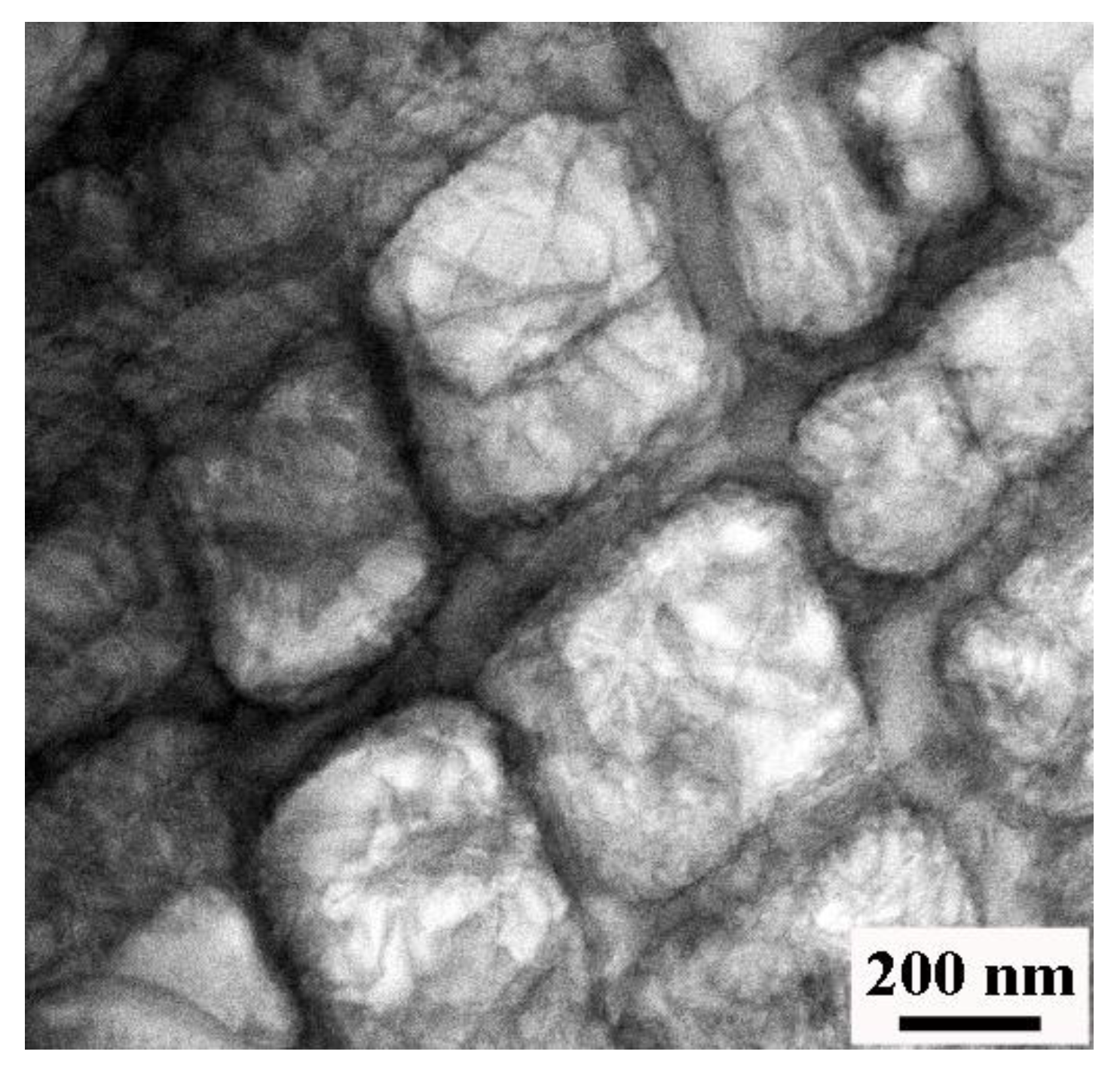

Figure 8 shows the dislocation configurations near fracture surfaces of tensile-ruptured DD9 alloy with LABs of 3.7° at 1100 °C. It is shown that the γ′ phases’ morphologies are similar to those of the heat-treated state in

Figure 3c. However, it is obvious that a lotof dislocations appear, and the dislocation tangle and dislocation networks are formed, which have also been found in the tensile-ruptured transverse DD9 alloy (corresponding to the misorientation angle of the LABs is 0°) [

17]. These dislocation configurations are the result of multiple slips at high temperatures, of which higher temperatures benefit the activation of multiple slip systems, then the dislocations interact with each other from different slip systems and the dislocation tangles and networks appear. This phenomenon is also common in other single-crystal superalloys [

18,

19].

4. Discussion

The DD9 alloy with LABs is actually a transverse specimen, of which the stress axis is perpendicular to the solidification direction. The dendritic-growth feature of directional solidification of single-crystal superalloys determines that there are microstructure differences andcomposition segregation between the dendritic cores and interdendritic regions. Thus, the interdendritic regions’strength is lower than the dendrite cores’ strength at high temperatures [

17]. However, the yield strength and ultimate tensile strength of DD9 alloy with LABs of 0° to 11.4° exceed 440 MPa and 510 MPa at 1100 °C, respectively, which can satisfy the technical requirements of DD9 alloy with [

1] orientation. These demonstrate that the DD9 alloy with LABs possess excellent tensile-strength properties. As for the tensile-plasticity properties, the elongations of DD9 alloy with LABs of 0° to 8.9° are all greater than 20% at 1100 °C, while the elongation clearly drops only when the misorientation angle of the LABs increases to 11.4°. This shows that the LABs have little effect on the tensile strength of DD9 alloy at 1100 °C, but have an obvious effect on the tensile plasticity.

It has been reported that microcracks are easy to nucleate and propagate at grain boundaries at high temperatures [

10]. As in our study, the yield strength and ultimate tensile strength of DD9 alloy with LABs of 11.4° are almost equivalent to those of DD9 alloy with LABs of 0°. This implys that the strength of LABs of DD9 alloy with relatively small misorientation angles are comparable to that of the single grains next to the grain boundaries during the tensile-deformation process. However, the abilities of LABs to withstand plastic deformation are sensitive to the misorientation angles. When the misorientation angle of LABs is higher than 8.9°, the plastic deformation before fracture is limited and fewer dimples are formed, as shown in

Figure 6; thus, the elongation of DD9 alloy with LABs of 11.4° is less than 2% and almost no microcracksare found on the section of the ruptured specimen. The change law of the tensile plastic is similar to the results of othersingle-crystal superalloys [

9,

11,

12,

13,

14].

5. Conclusions

The microstructure of low-angle boundaries of a third-generationsingle-crystal superalloy, DD9, and its effect on the tensile properties and fracture behavior of the alloy at the temperature of 1100 °C were investigated. The mainconclusions are summarized as follows:

- (1)

The as-cast LABs of DD9 alloy are composed of strip-like and bulk γ′ phases with γ matrix. After heat treatment, no γ′ phases are found at the LABs.

- (2)

The LABs have little effect on the tensile strength of DD9 alloy at 1100 °C, but have an obvious effect on the tensile plasticity. The elongation of DD9 alloy with LABs declines rapidly when the misorientation angle of the LABs exceeds 8.9° at 1100 °C.

- (3)

The fracture surfaces of tensile-ruptured DD9 alloy with LABs of 3.7°~11.4° exhibit intergranular fracture features at 1100 °C.

Author Contributions

Experiment conduction, writing—original draft preparation, W.Y.; data and image processing—X.W., J.Z. and Z.S.; writing—review and editing, J.L. and S.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by National Science and Technology Major Project (2017-VI-0001-0070).

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Gell, M.; Duhl, D.N.; Giamei, A.F. The development of single crystal superalloy turbine blades. In Superalloys 1980: Proceedings of the 4th Intenational Symposium of Superalloys; Wiley Online Library: Hoboken, NJ, USA, 1980; pp. 205–214. [Google Scholar]

- Li, J.R.; Zhong, Z.G.; Tang, D.Z.; Liu, S.Z.; Wei, P.; Wei, P.Y.; Wu, Z.T.; Huang, D.; Han, M. A low cost second generation single crystal superalloy DD6. In Proceedings of the Superalloys 2000: Proceedings of the 9th Intenational Symposium of Superalloys, Warrendale, PA, USA, 17–21 September 2000; Wiley Online Library: Hoboken, NJ, USA, 2000; pp. 777–783. [Google Scholar]

- Park, K.; Withey, P. Compositions of gamma and gamma prime phases in an as-cast nickel-based single crystal superalloy turbine blade. Crystals 2022, 12, 299. [Google Scholar] [CrossRef]

- Epishin, A.; Fedelich, B.; Finn, M.; Künecke, G.; Rehmer, B.; Nolze, G.; Leistner, C.; Petrushin, N.; Svetlov, I. Investigation of elastic properties of the single-crystal nickel-base superalloy CMSX-4 in the temperature interval between room temperature and 1300 °C. Crystals 2021, 11, 152. [Google Scholar] [CrossRef]

- Li, J.R.; Liu, S.Z.; Shi, Z.X.; Luo, Y.S.; Wang, X.G. Third generation single crystal superalloy DD9. J. Iron. Steel. Res. 2011, 23, 337–340. [Google Scholar]

- Li, J.R.; Liu, S.Z.; Wang, X.G.; Shi, Z.X.; Zhao, J.Q. Development of a low-cost third generation single crystal superalloy DD9. In Superalloys 2016: Proceedings of the 13th Intenational Symposium of Superalloys; Wiley Online Library: Hoboken, NJ, USA, 2016; pp. 57–63. [Google Scholar]

- Yang, W.P.; Li, J.R.; Liu, S.Z.; Shi, Z.X.; Zhao, J.Q.; Wang, X.G. Orientation dependence of transverse tensile properties of nickel-based third generation single crystal superalloy DD9 from 760 to 1100 °C. Trans. Nonferrous Met. Soc. China 2019, 29, 558–568. [Google Scholar] [CrossRef]

- Tamaki, H.; Yoshinari, A.; Okayama, A.; Nakamura, S. Development of a low angle grain boundary resistant single crystal superalloy YH61. In Proceedings of the Superalloys 2000: Proceedings of the 9th Intenational Symposium of Superalloys, Warrendale, PA, USA, 17–21 September 2000; Wiley Online Library: Hoboken, NJ, USA, 2000; pp. 757–766. [Google Scholar]

- Patel, Y.; Browning, P.F.; Fitzpatrick, M.D.; Schmiedechnekt, D.; Price, A.; Simpson, T.; Erickson, G.; Harris, K. The effect of primary axis and low angle boundary misorientation on CMSX-10K mechanical properties. In International Gas Turbine & Aeroengine Congress & Exhibition; American Society of Mechanical Engineers: Munich, Germany, 2000; pp. 1–7. [Google Scholar]

- Zhao, J.Q.; Li, J.R.; Liu, S.Z.; Yuan, H.L. Effects of low angle grain boundaries on tensile properties ofsingle crystal superalloy DD6. J. Mater. Eng. 2008, 8, 73–76. [Google Scholar]

- Zhao, J.Q.; Li, J.R.; Liu, S.Z.; Yuan, H.L.; Han, M. Effect of low angle grain boundaries on tensile properties of single crystal superalloy DD6 at 980 °C. Rare Metal Mat. Eng. 2007, 36, 2232–2235. [Google Scholar]

- Shi, Z.X.; Li, J.R.; Liu, S.Z.; Zhao, J.Q. Tensile properties of twist low angle boundary ofDD6 single crystal superalloy. J. Aeron. Mater. 2009, 29, 88–92. [Google Scholar]

- Li, X.Y.; Li, P.; Zhou, Y.Z.; Jin, T.; Zhang, Z.F. Effect of misorientation on the tensile properties of SRR99 superalloy bicrystals. Acta Metall Sin 2013, 49, 351–357. [Google Scholar] [CrossRef]

- Qin, J.C.; Cui, R.J.; Huang, Z.H.; Zhao, J.Q.; Zhang, Y.P.; Zong, C.; Chen, S.P. Effect of low angle grain boundaries on mechanical properties of DD5 single crystal Ni-base superalloy. J. Aeron. Mater. 2017, 37, 24–29. [Google Scholar]

- Yang, W.P.; Li, J.R.; Liu, S.Z.; Zhao, J.Q.; Shi, Z.X.; Wang, X.G. Microstructures of low angle boundaries of a third generation single crystal superalloy DD9. Mater. Sci. Forum. 2017, 898, 413–421. [Google Scholar] [CrossRef]

- Shi, Z.X.; Liu, S.Z.; Han, M.; Li, J.R. Stress rupture properties and fracture behavior of DD6 single crystalsuperalloy. Mater. Sci. Forum. 2016, 849, 468–474. [Google Scholar] [CrossRef]

- Yang, W.P.; Li, J.R.; Liu, S.Z.; Shi, Z.X.; Zhao, J.Q.; Wang, X.G. Transverse tensile properties of a nickel-based third generation single crystal superalloy. Rare Metal Mat. Eng. 2018, 47, 2964–2969. [Google Scholar]

- Feller-Kniepmeier, M.; Link, T.; Poschmann, I.; Scheunemann-Frerker, G.; Schulze, C. Temperature dependence of deformationmechanisms in a single crystal nickel-basealloy with high volume fraction ofγ′ phase. Acta Mater. 1996, 44, 2397–2407. [Google Scholar] [CrossRef]

- Liu, J.L.; Yu, J.J.; Jin, T.; Sun, X.F.; Guan, H.R.; Hu, Z.Q. Influence of temperature on tensile behavior and deformation mechanism ofRe-containing single crystal superalloy. rans. Nonferrous Met. Soc. China 2011, 21, 1518–1523. [Google Scholar] [CrossRef]

| Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).