Artificial Neural Network Modeling to Predict the Effect of Milling Time and TiC Content on the Crystallite Size and Lattice Strain of Al7075-TiC Composites Fabricated by Powder Metallurgy

Abstract

:1. Introduction

2. Materials and Methods

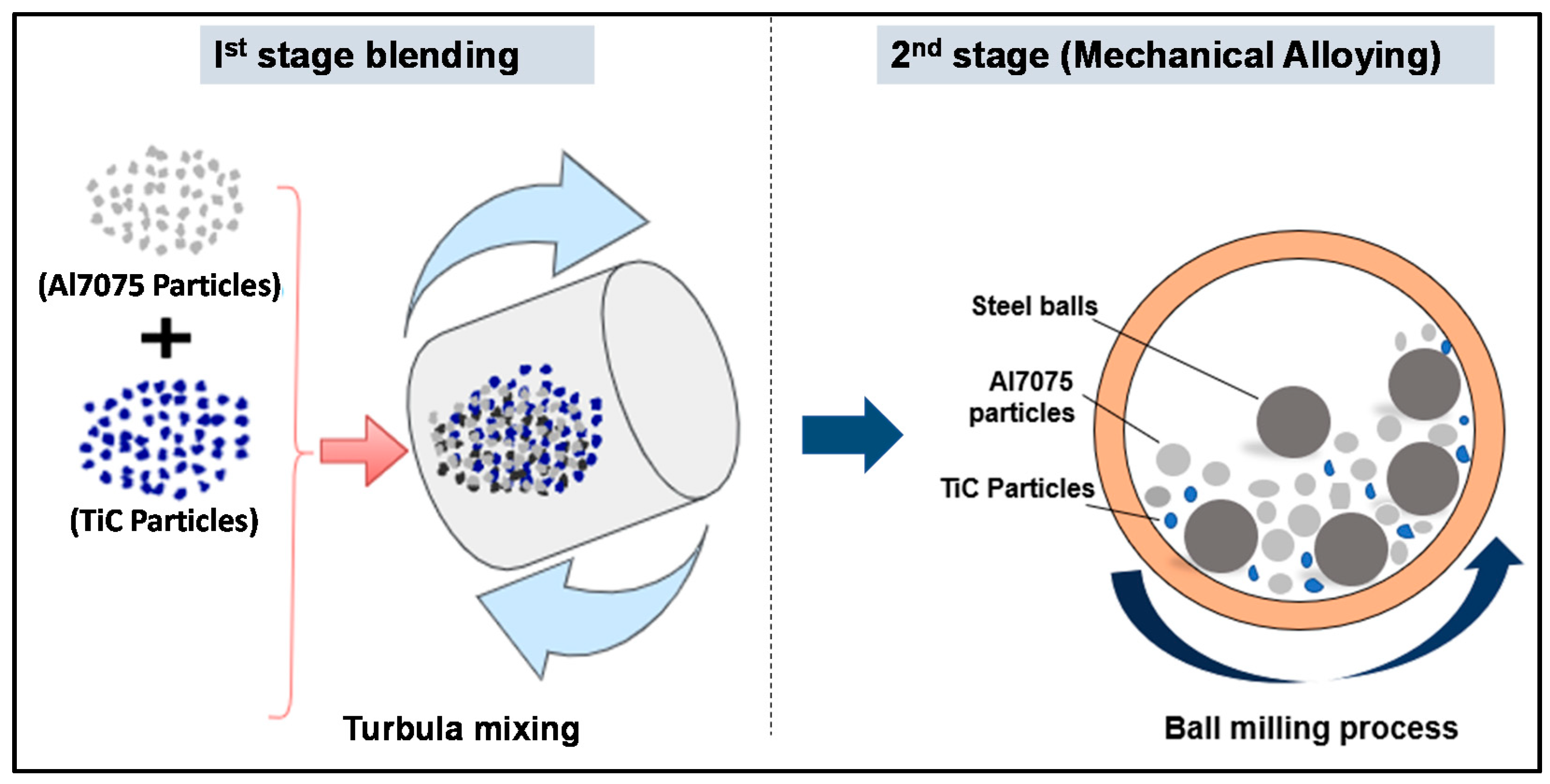

- Synthesis of composite powders by dual blending scheme.

- Determination of crystallite size, lattice strain, and their predictions using ANN.

- Microstructural characterizations and analysis of blended composite powders.

- Fabrication of bulk composites and investigations on microhardness behavior.

2.1. Starting Materials

2.2. Blending of Matrix and Reinforcement Powders

2.3. Microhardness Measurement and Microstructural Characterization

2.4. Crystal Structure Analysis

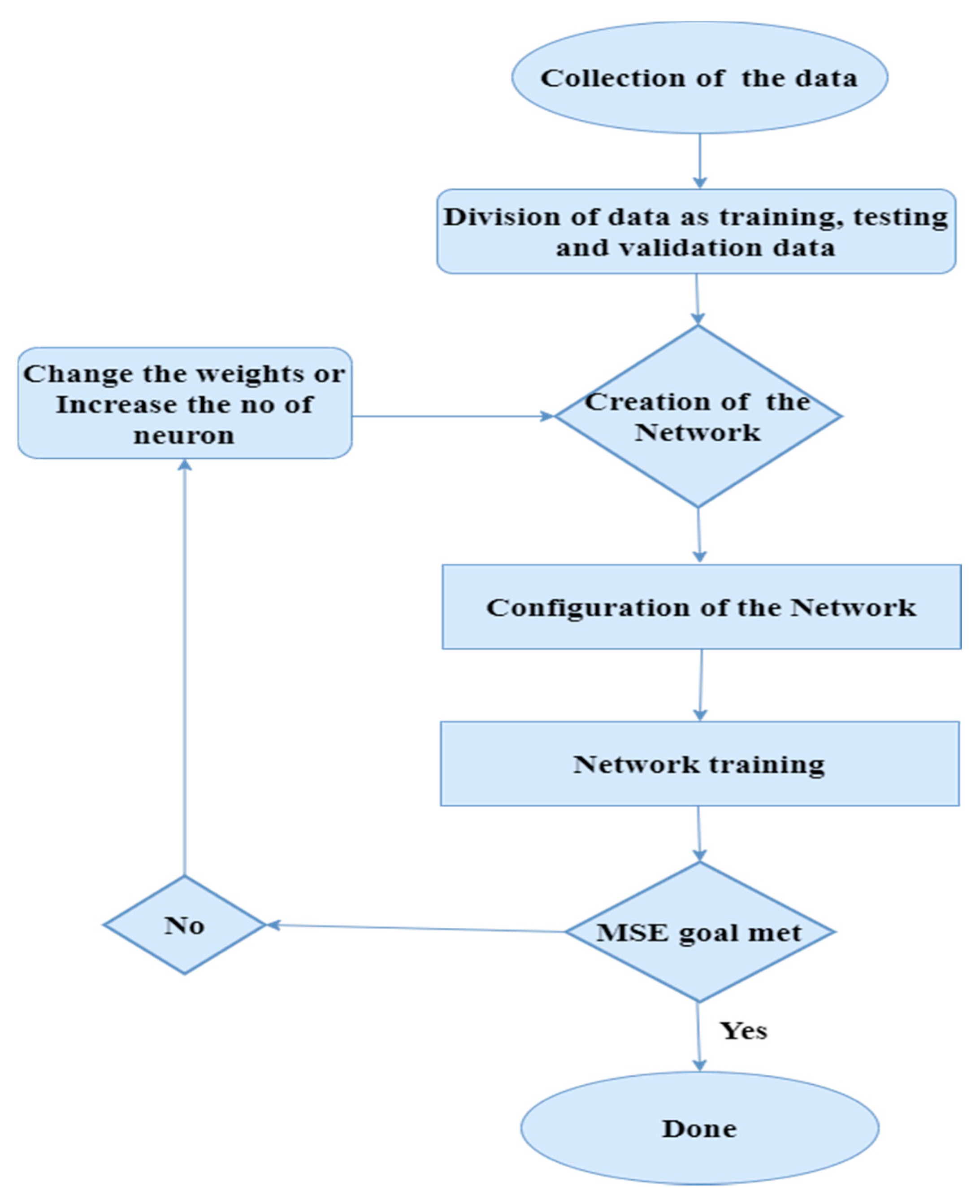

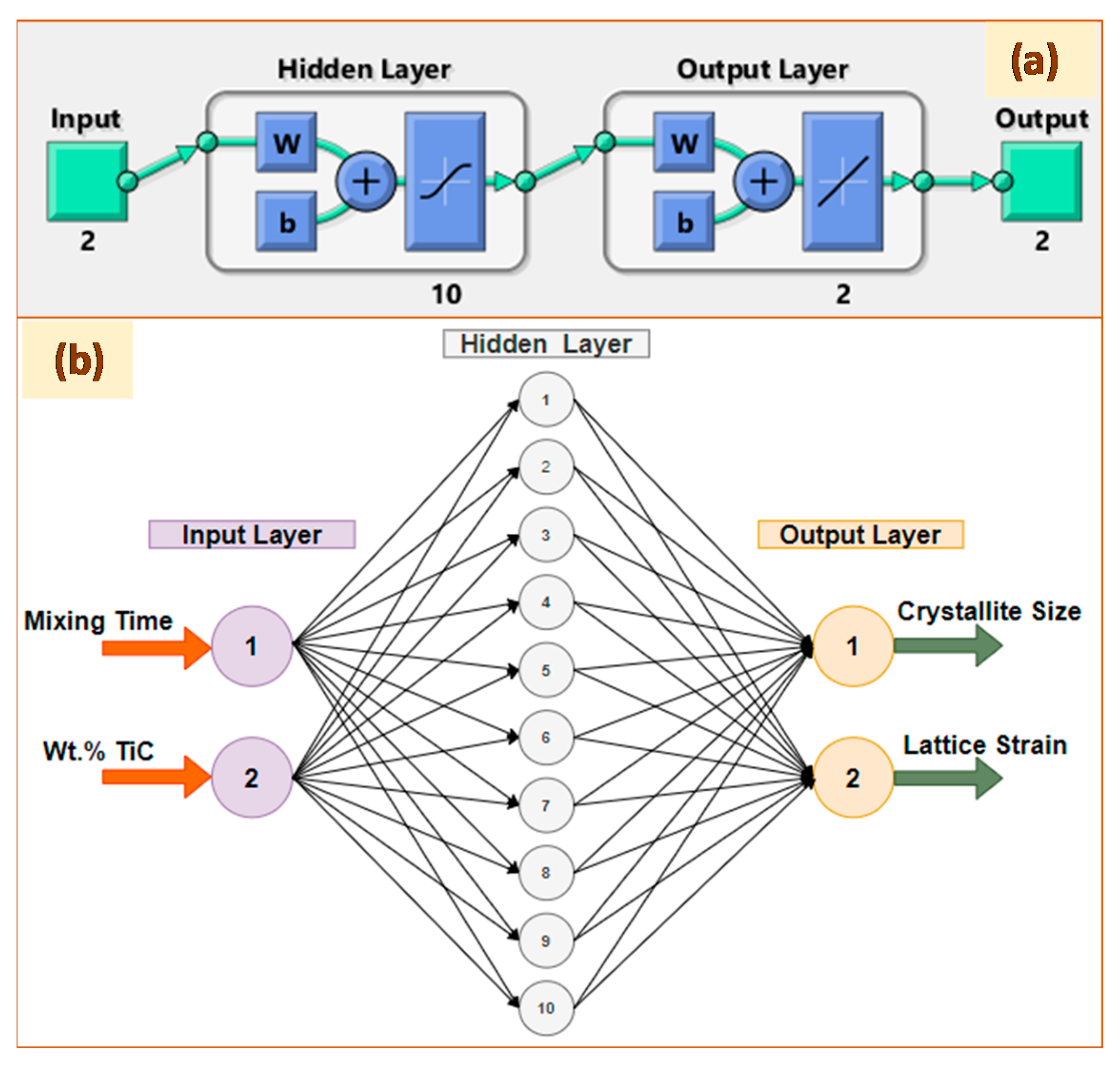

2.5. Architecture of the Neural Network

3. Results and Discussion

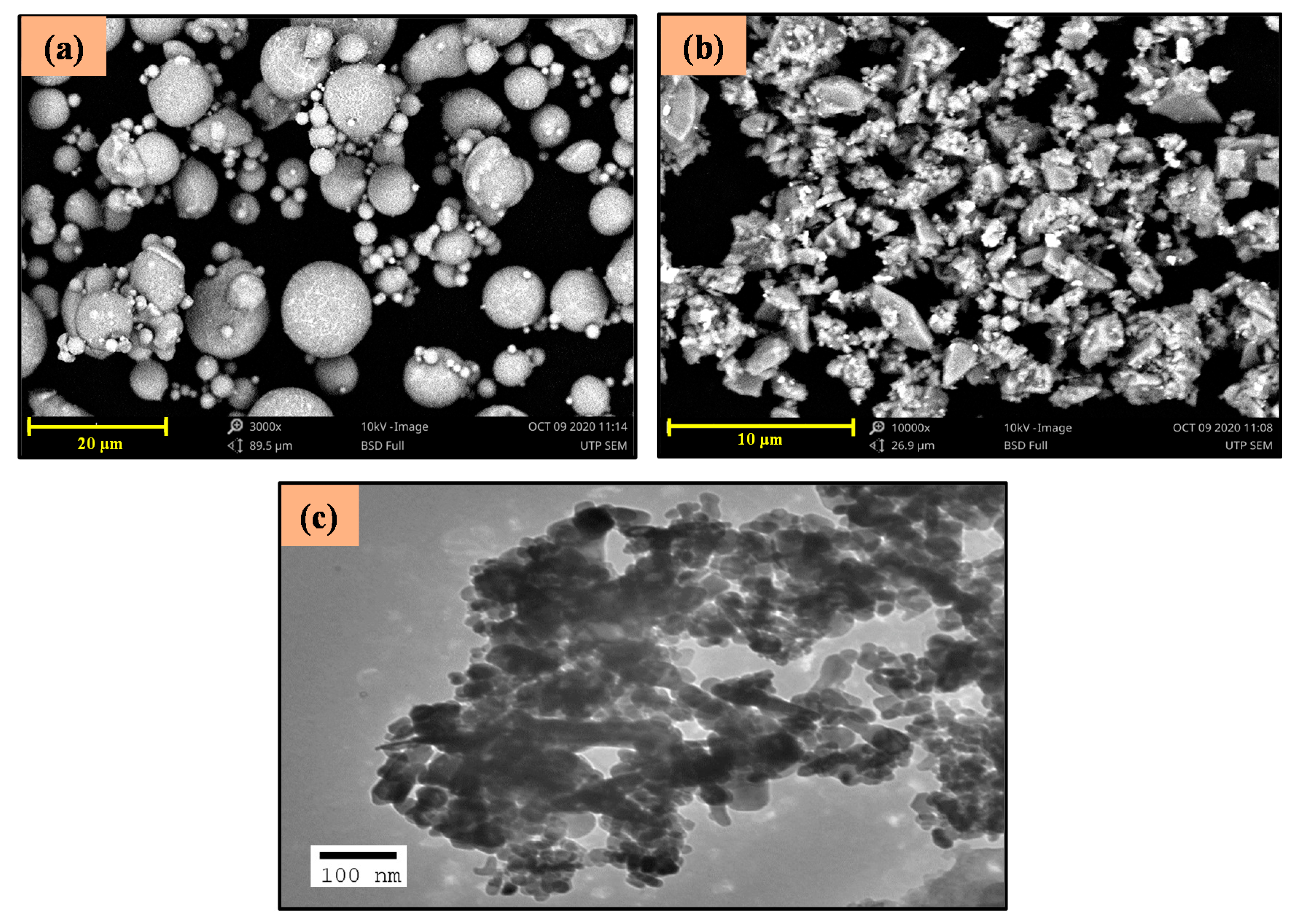

3.1. Morphology of Received Powders

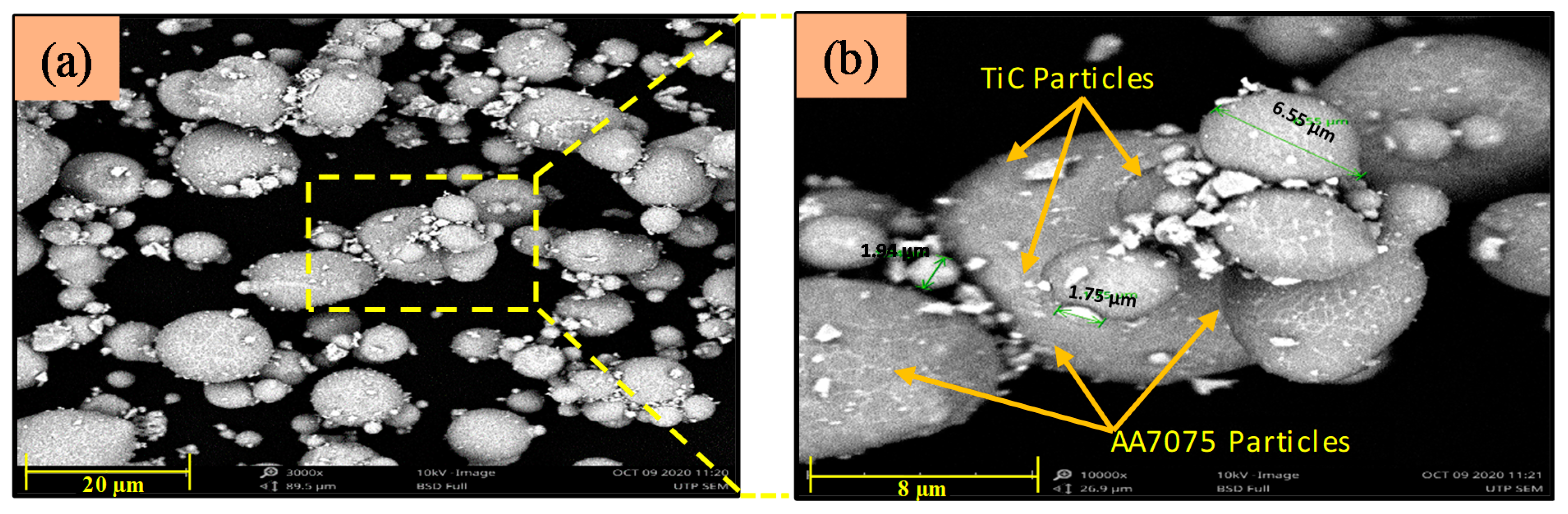

3.2. SEM Characterization of Composites

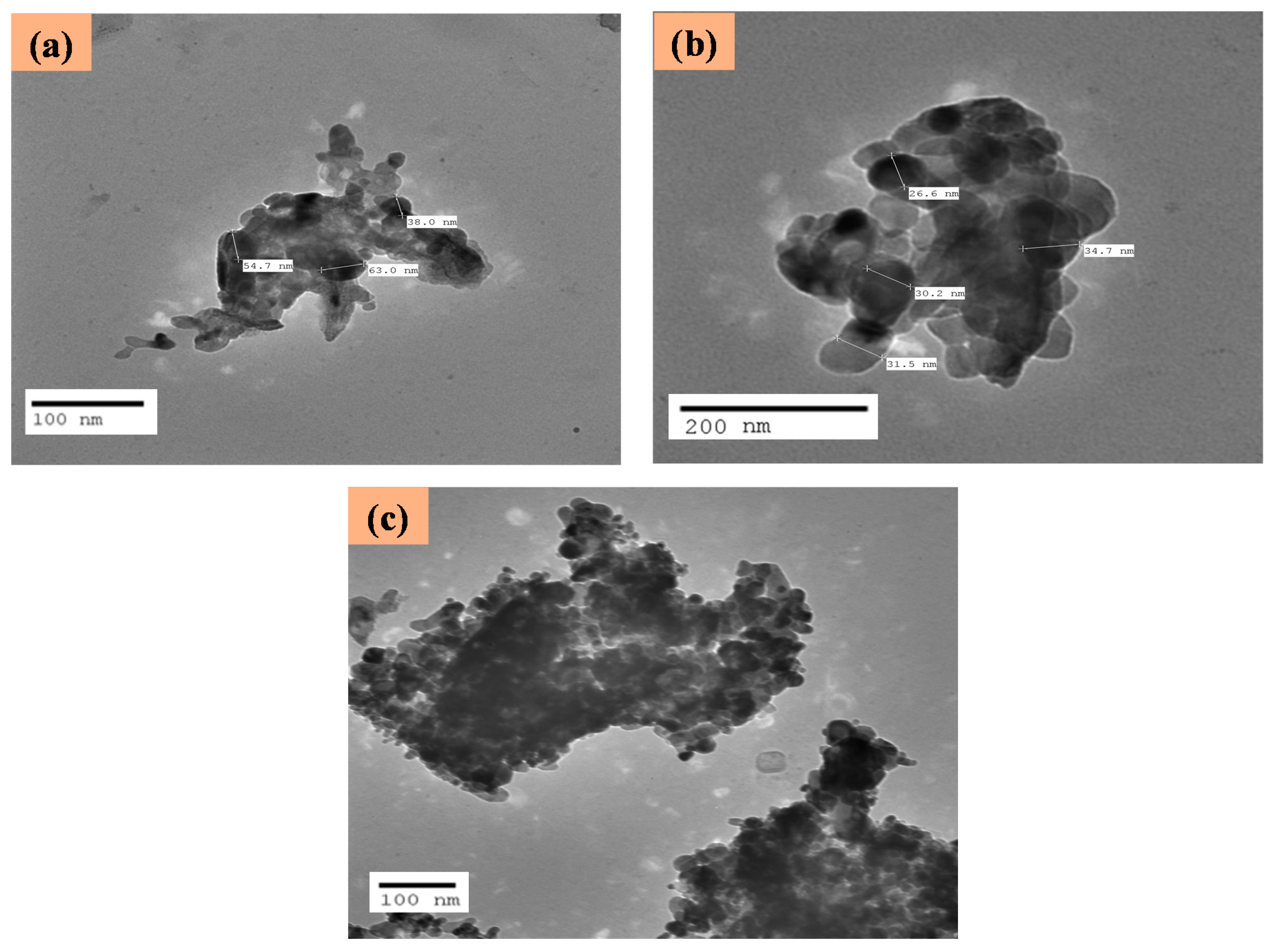

3.3. TEM Morphology of Composite Powder

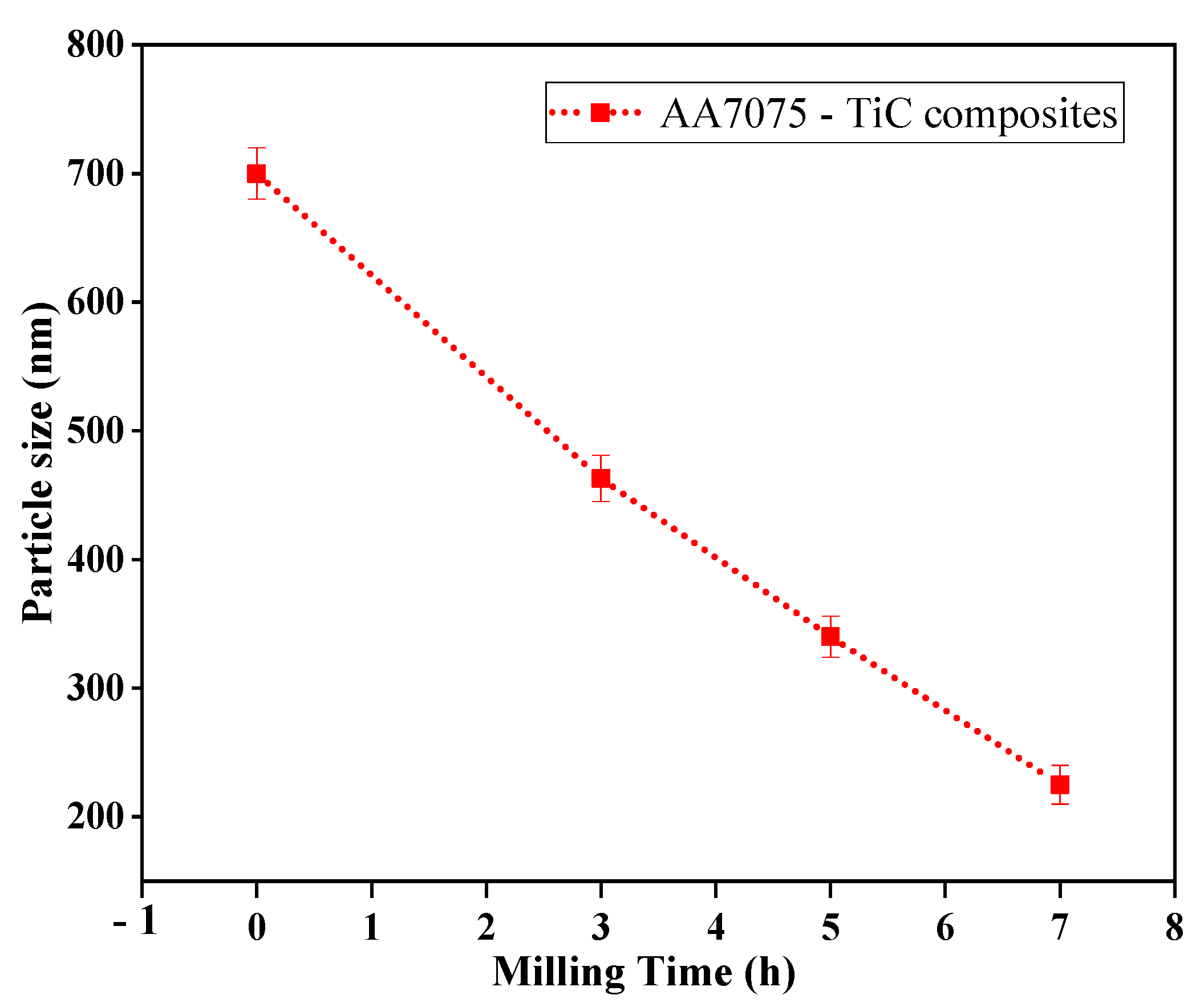

3.4. Particle Size of Composites as a Function of Milling Time

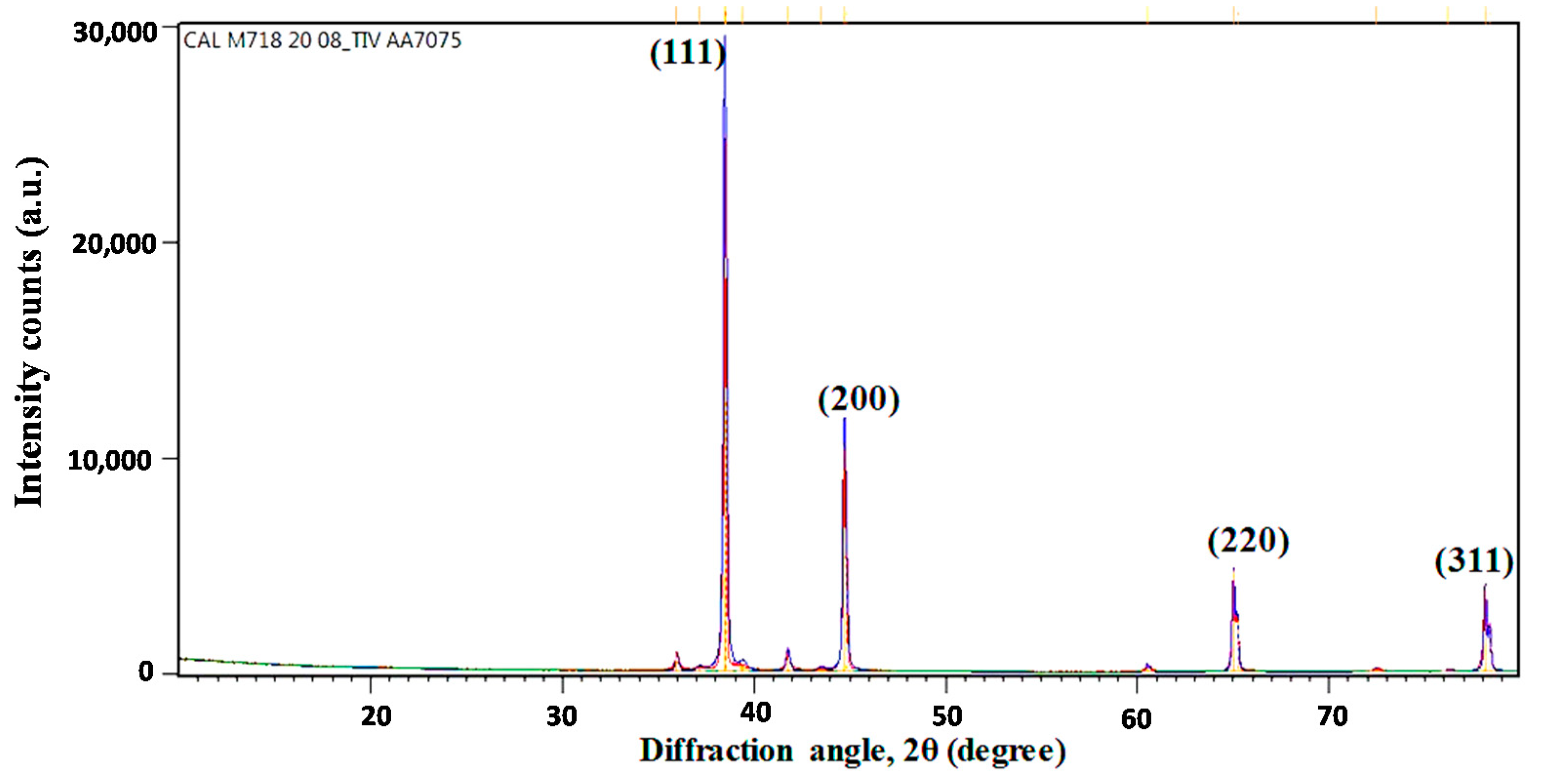

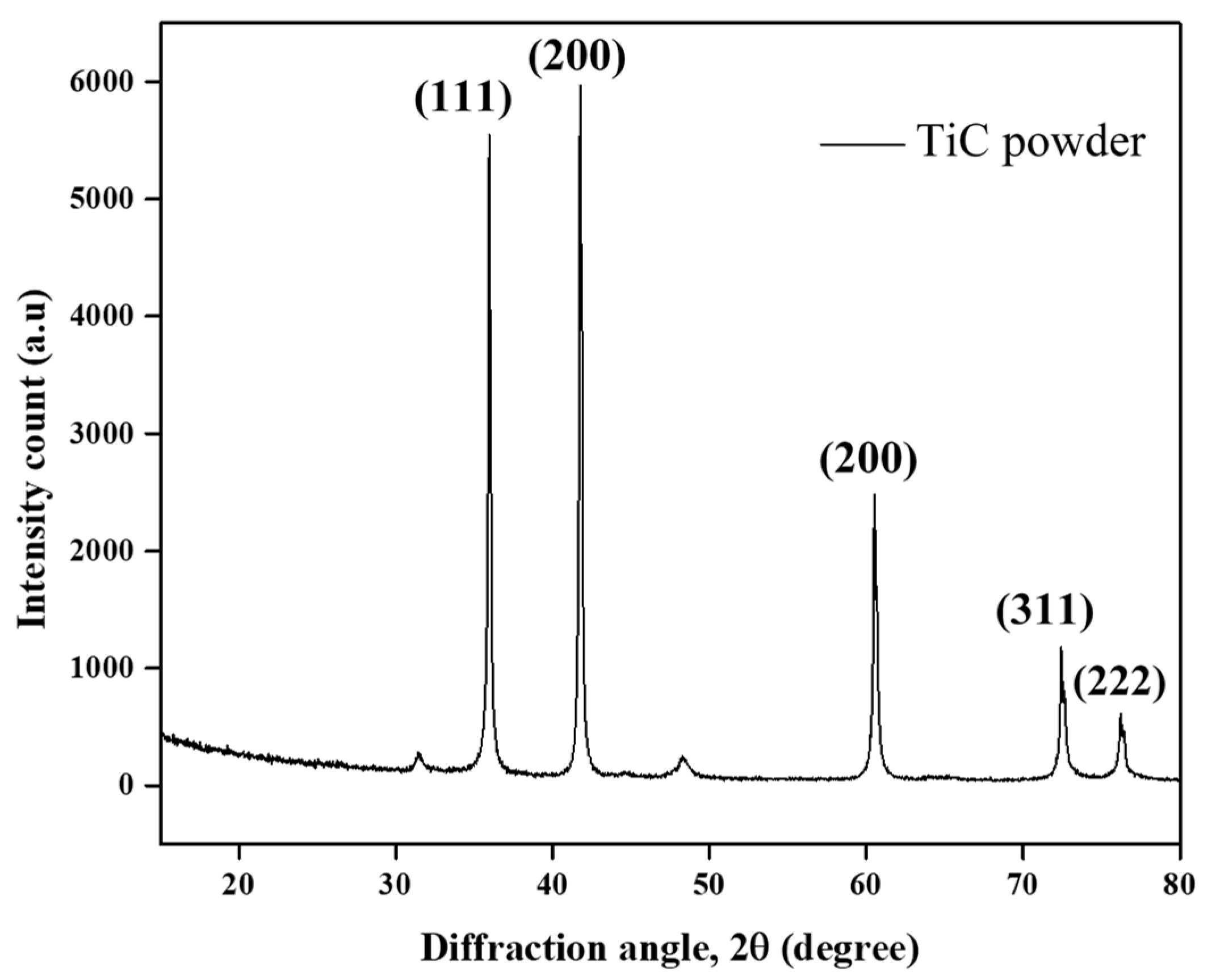

3.5. X-ray Diffraction (XRD) of the Received Powders

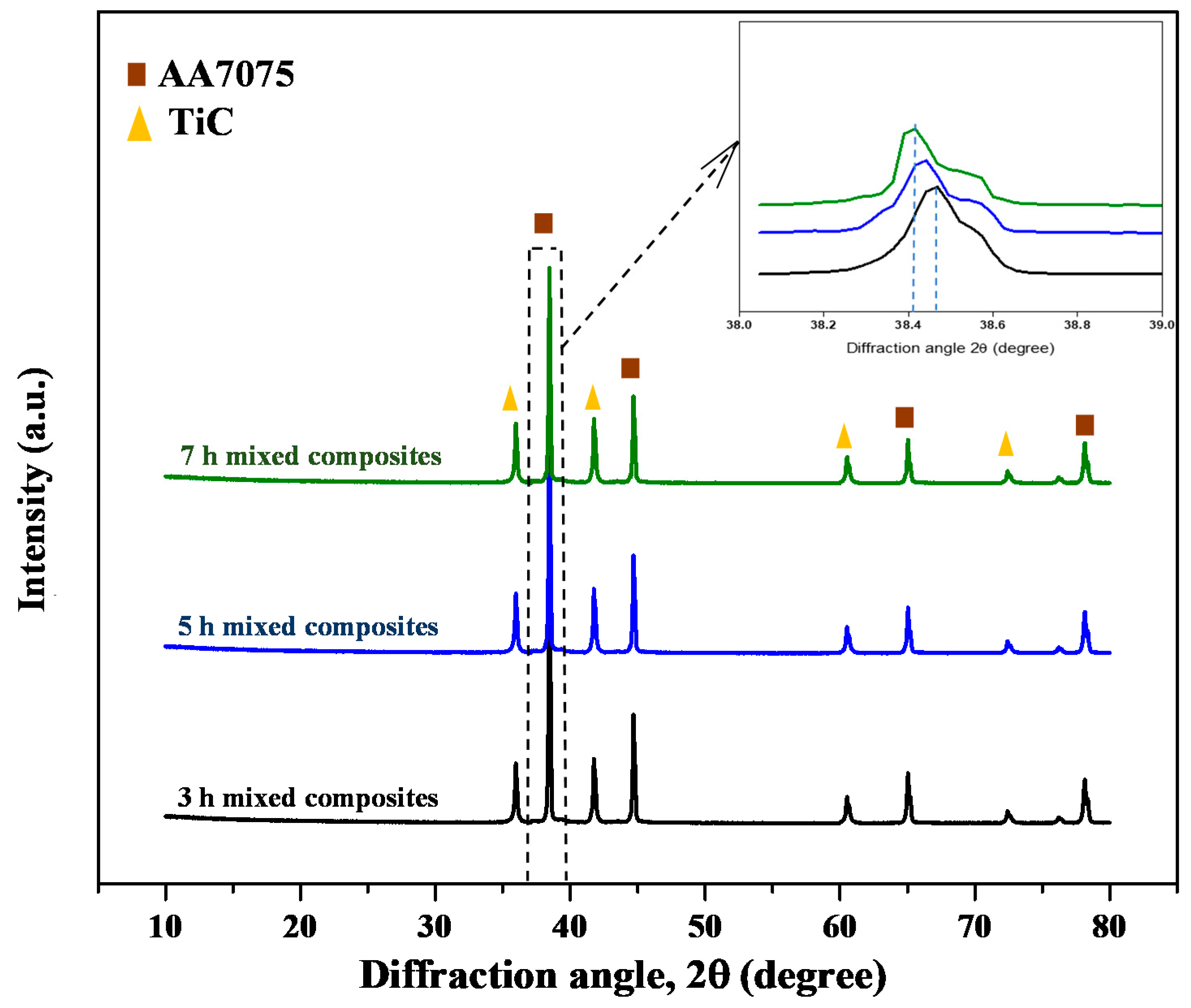

3.6. X-ray Diffraction (XRD) of the Composite Powders

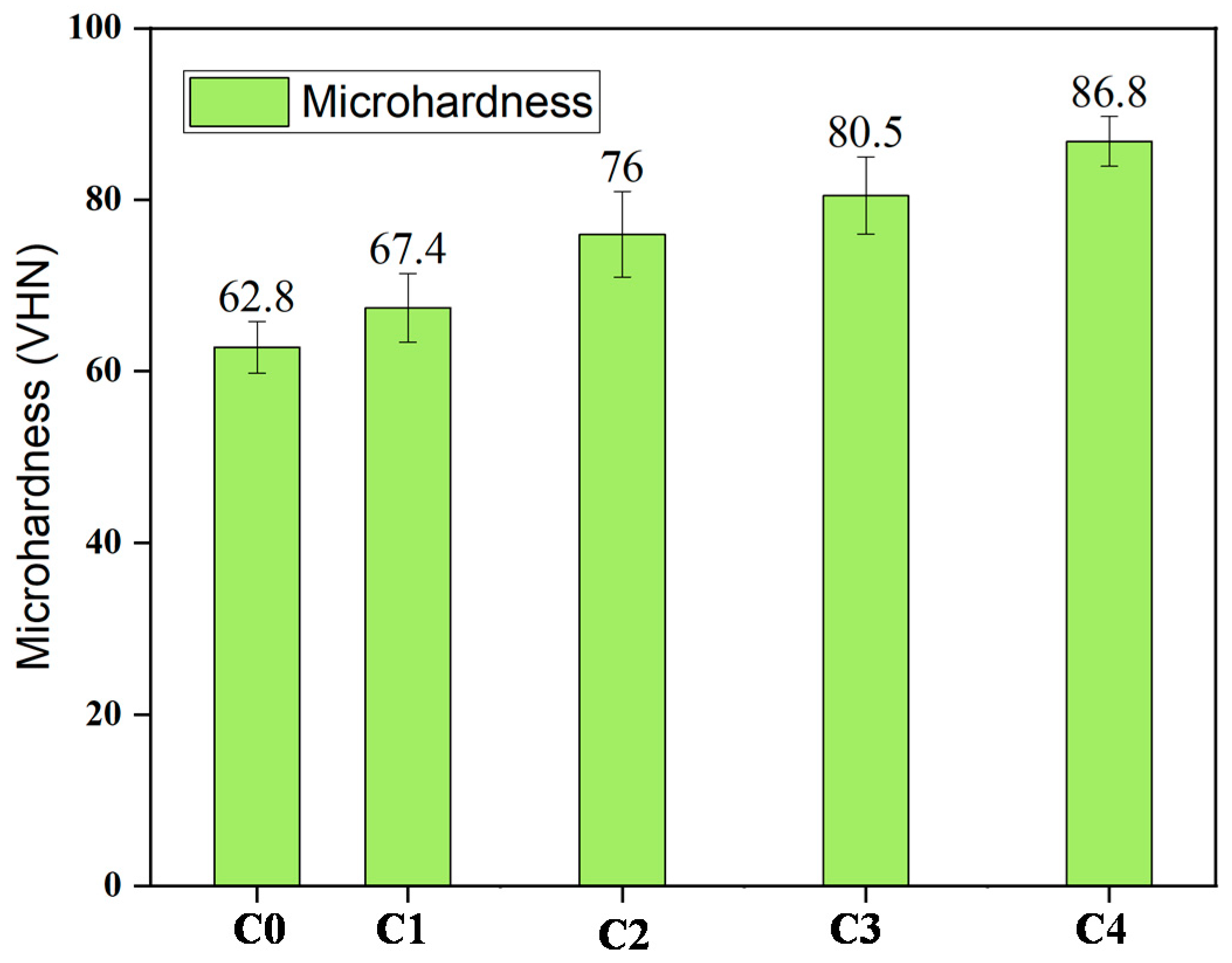

3.7. Effect of Milling Time on the Microhardness Behavior

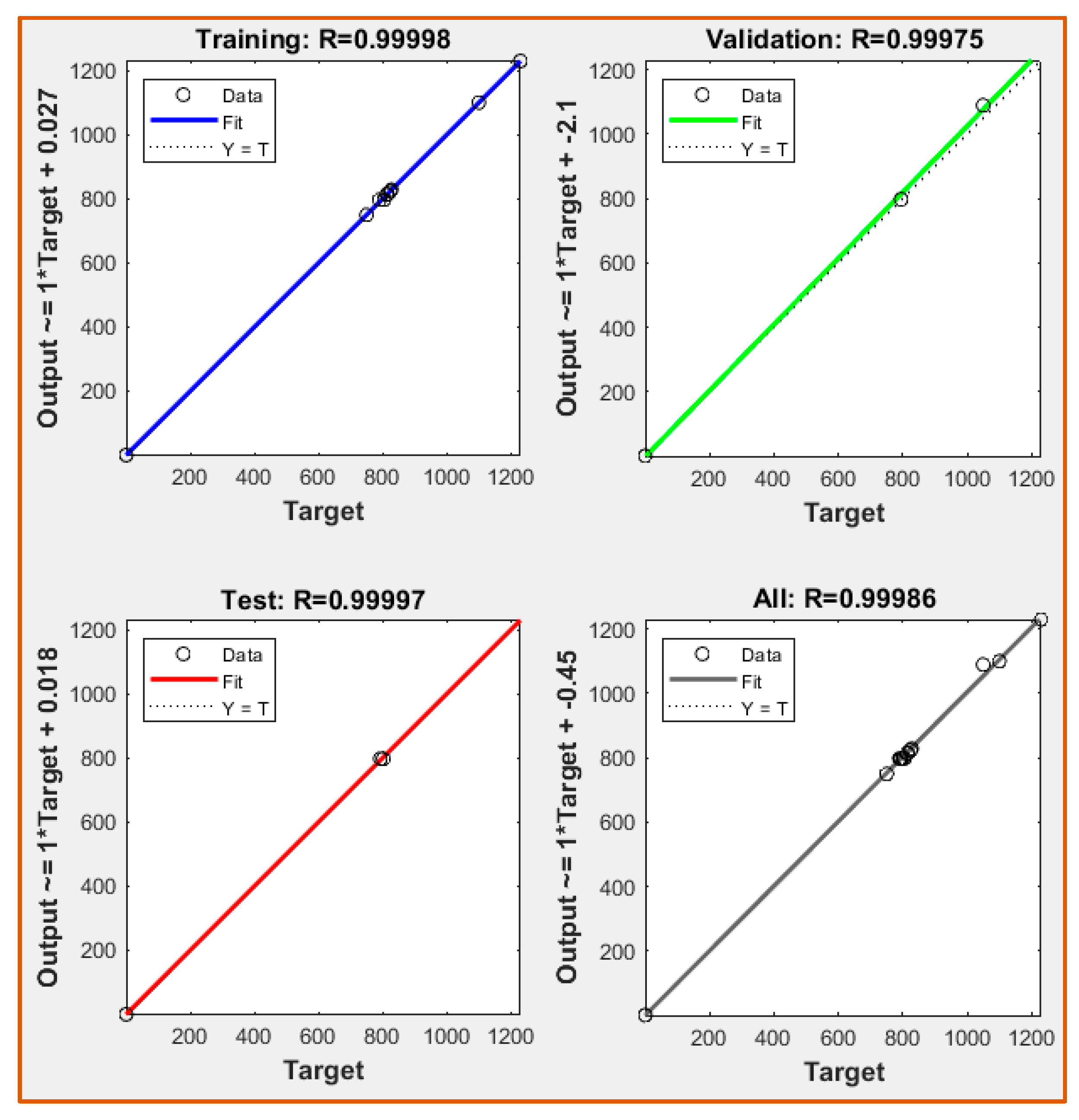

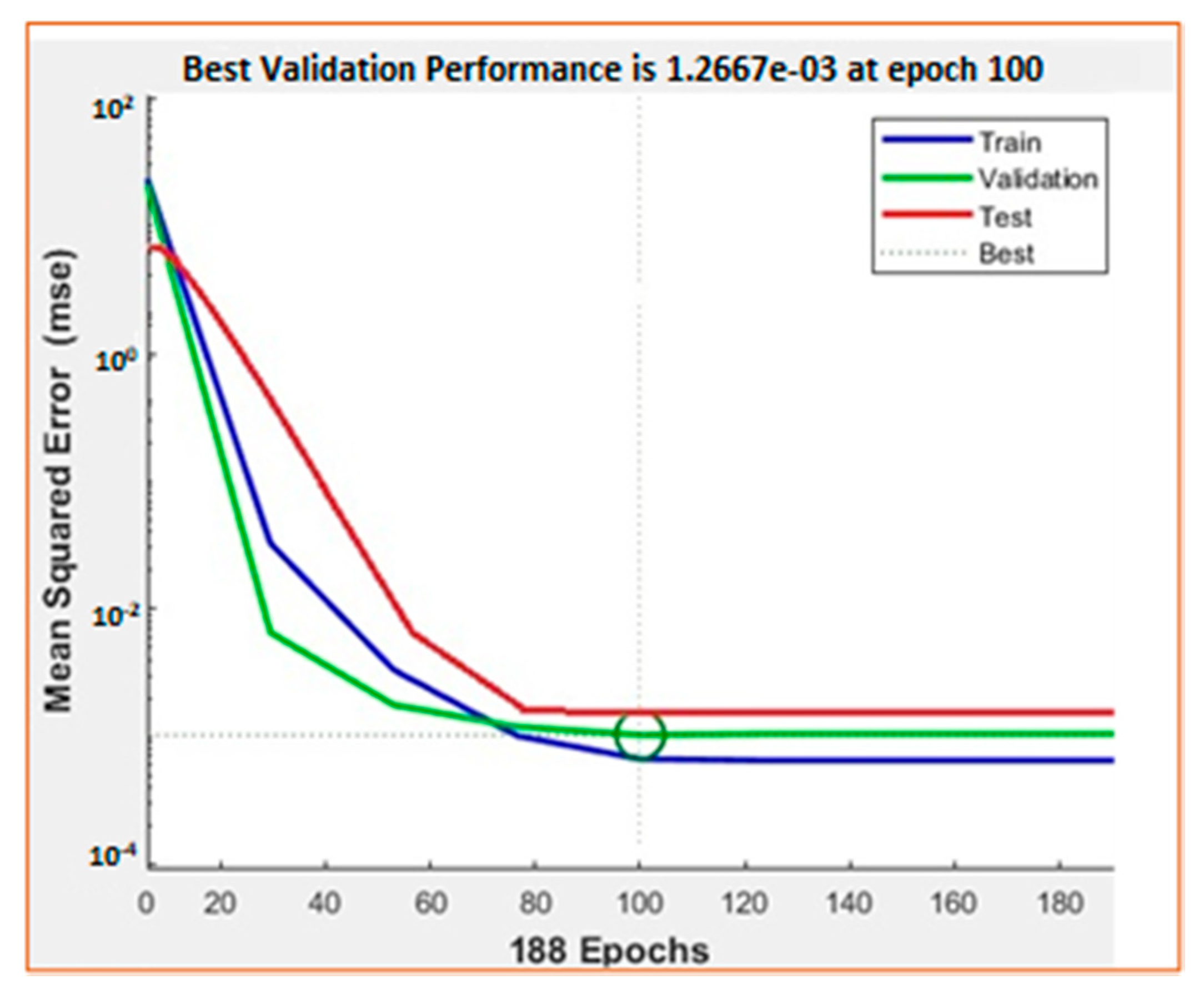

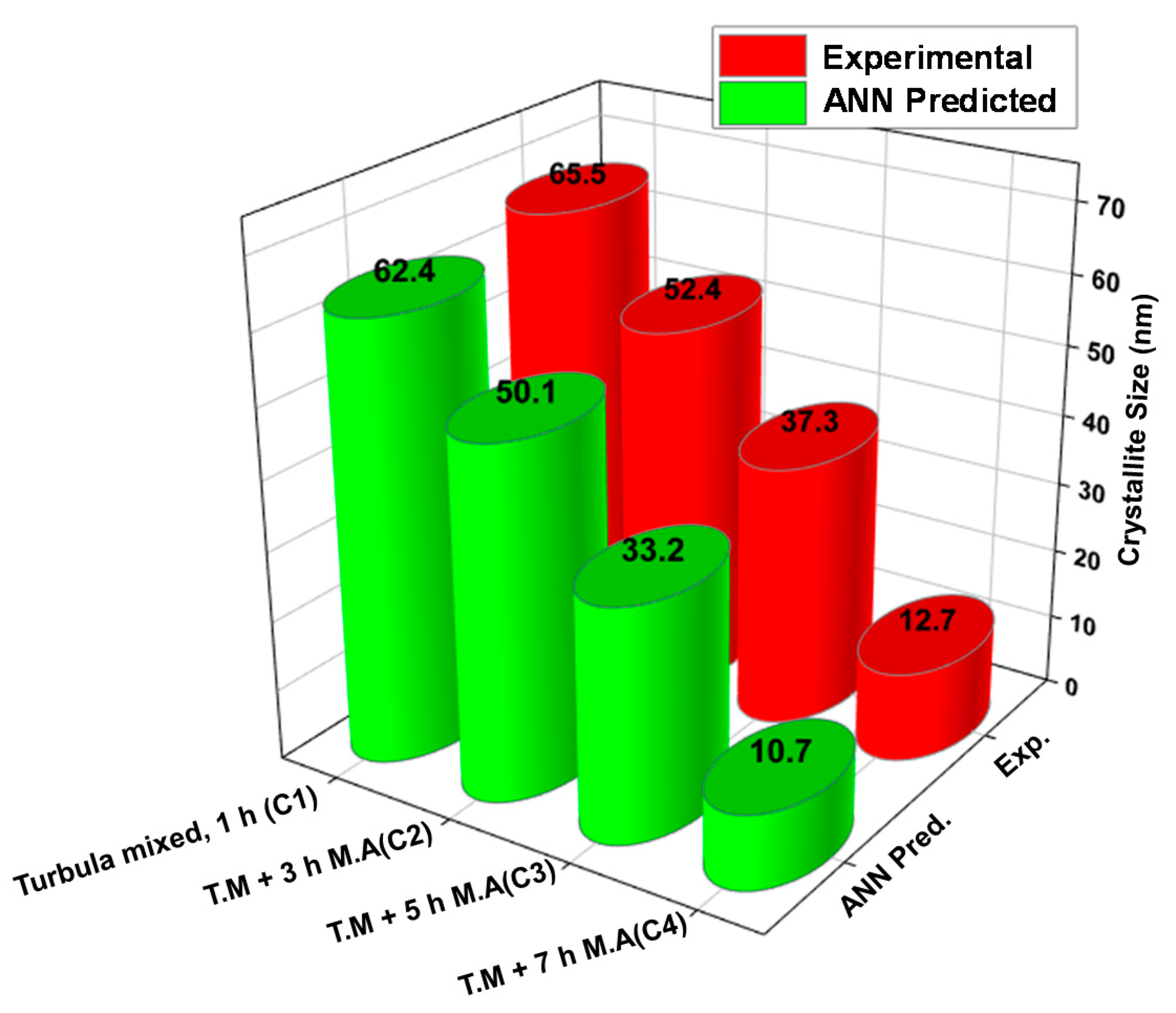

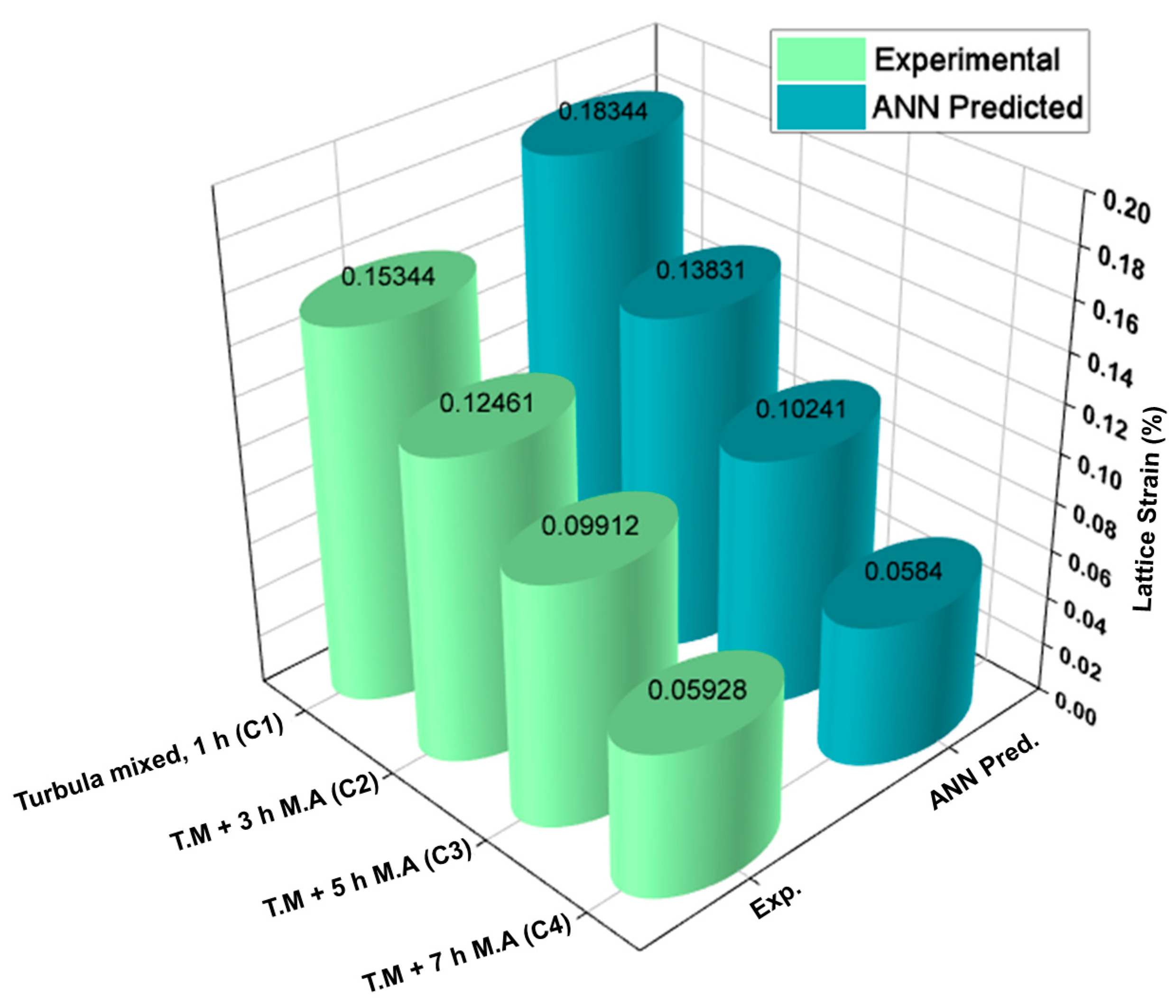

3.8. ANN Modeling Results

4. Conclusions and Future Scope

- The two-stage blending of composite powders resulted in good incorporation and uniform dispersion of TiC particle reinforcement in the Al7075 powder matrix. The SEM and TEM micrographs of the synthesized composite powders confirm the homogeneous distribution of reinforcement into the matrix.

- Al7075-TiC composite powder XRD patterns have been verified since there were no intermetallic compounds, even after 7 h of ball milling. With this milling period (i.e., 7 h), the decrement in AL7075 peaks indicates its dissolution in reinforcement TiC, thus causing lattice distortion that results in peaks expanding and shifting.

- With an increase in milling time, a decrease in average crystallite size is achieved, and the minimum crystallite size of 12.7 nm is attained for all composites at 7 h of milling time. Lattice strain increased significantly with milling time; the maximum value achieved at 7 h was 0.1534 %.

- Rising milling time gradually (from 3 h to 7 h) activated the deformation hardening mechanism and consequently resulted in an improvement in the microhardness values of the synthesized composites. The results of microhardness measurements revealed that the highest increment in the microhardness of synthesized composites was observed as 38.4 % at 7 h of milling for sample C4. The microhardness of the composite samples was higher as compared to the unreinforced Al7075 matrix. Thus, increasing ball milling is beneficial for the homogeneous dispersion of TiC particles within the Al7075 matrix.

- A backpropagation-based ANN model was developed to predict the crystallite size and lattice strain of the synthesized composites. The ANN model results are in good agreement with the experimental results. Moreover, the developed ANN model can be used as a tool in predicting composite lattice parameters and other related properties. Thus, the ANN is an effective method for estimating the lattice parameters of Al7075–TiC composites produced by the mechanical alloying method.

- The limitation of the present work is the small range of milling time and limited characteristics (crystallite size, lattice strain, and microhardness behavior) studies. However, the effect of different process variables viz., sintering temperature, compaction pressure, and dwell time on the physical, mechanical, and tribological characteristics of powder metallurgy processed Al7075/TiC composites can be investigated and predicted by some other machine learning techniques. It is also recommended to extend the present study by increasing the milling time with same experimental boundary conditions.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Almotairy, S.M.; Alharthi, N.H.; Alharbi, H.F.; Abdo, H.S. Superior Mechanical Performance of Inductively Sintered Al/SiC Nanocomposites Processed by Novel Milling Route. Sci. Rep. 2020, 10, 10368. [Google Scholar] [CrossRef] [PubMed]

- Alam, M.A.; Ya, H.H.; Sapuan, S.M.; Mamat, O.; Parveez, B.; Yusuf, M.; Masood, F.; Ilyas, R.A. Recent Advancements in Advanced Composites for Aerospace Applications: A Review BT—Advanced Composites in Aerospace Engineering Applications; Mazlan, N., Sapuan, S.M., Ilyas, R.A., Eds.; Springer International Publishing: Cham, Switzerland, 2022; pp. 319–339. ISBN 978-3-030-88192-4. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Ilyas, R.A.; Sapuan, S.M.; Harussani, M.M.; Hariz, H.M.; Aiman, J.M.; Baitaba, D.M.; Sanjay, M.R.; Ishak, M.R.; Norkhairunnisa, M.; et al. Advanced Composite in Aerospace Applications: Opportunities, Challenges, and Future Perspective BT—Advanced Composites in Aerospace Engineering Applications; Mazlan, N., Sapuan, S.M., Ilyas, R.A., Eds.; Springer International Publishing: Cham, Switzerland, 2022; pp. 471–498. ISBN 978-3-030-88192-4. [Google Scholar] [CrossRef]

- Alam, M.A.; Asoushe, M.H.; Pourhakkak, P.; Gritsch, L.; Alipour, A.; Mohammadi, S. Preparation of bioactive polymer-based composite by different techniques and application in tissue engineering: A review. J. Compos. Compd. 2021, 3, 194–205. [Google Scholar] [CrossRef]

- Alam, M.A.; Ya, H.H.; Ahmad, A.; Yusuf, M.; Azeem, M.; Masood, F. Influence of aluminum addition on the mechanical properties of brass/Al composites fabricated by stir casting. Mater. Today Proc. 2022, 48, 811–814. [Google Scholar] [CrossRef]

- Azimi, A.; Shokuhfar, A.; Nejadseyfi, O. Mechanically alloyed Al7075—TiC nanocomposite: Powder processing, consolidation and mechanical strength. Mater. Des. 2015, 66, 137–141. [Google Scholar] [CrossRef]

- Arsun, O.; Akgul, Y.; Simsir, H. Investigation of the properties of Al7075-HTC composites produced by powder metallurgy. J. Compos. Mater. 2021, 55, 2339–2348. [Google Scholar] [CrossRef]

- Ezatpour, H.R.; Torabi Parizi, M.; Sajjadi, S.A.; Ebrahimi, G.R.; Chaichi, A. Microstructure, mechanical analysis and optimal selection of 7075 aluminum alloy based composite reinforced with alumina nanoparticles. Mater. Chem. Phys. 2016, 178, 119–127. [Google Scholar] [CrossRef]

- Al-Salihi, H.A.; Mahmood, A.A.; Alalkawi, H.J. Mechanical and wear behavior of AA7075 aluminum matrix composites reinforced by Al2O3 nanoparticles. Nanocomposites 2019, 5, 67–73. [Google Scholar] [CrossRef] [Green Version]

- Alam, M.A.; Sapuan, S.M.; Ya, H.H.; Hussain, P.B.; Azeem, M.; Ilyas, R.A. Application of biocomposites in automotive components: A review. In Biocomposite and Synthetic Composites for Automotive Applications; Elsevier: Amsterdam, The Netherlands, 2021; pp. 1–17. [Google Scholar] [CrossRef]

- Feijoo, I.; Cabeza, M.; Merino, P.; Pena, G.; Pérez, M.C.; Cruz, S.; Rey, P. Estimation of crystallite size and lattice strain in nano-sized TiC particle-reinforced 6005A aluminium alloy from X-ray diffraction line broadening. Powder Technol. 2019, 343, 19–28. [Google Scholar] [CrossRef]

- Hadian, M.; Shahrajabian, H.; Ra, M. Mechanical properties and microstructure of Al/(TiC + TiB2) composite fabricated by spark plasma sintering. Ceram. Int. 2019, 45, 12088–12092. [Google Scholar] [CrossRef]

- Ramkumar, K.R.; Sivasankaran, S.; Al-mufadi, F.A.; If, T.D.; Siddharth, S. ScienceDirect Investigations on microstructure, mechanical, and tribological behaviour of AA 7075—x wt. % TiC composites for aerospace applications. Arch. Civ. Mech. Eng. 2019, 19, 428–438. [Google Scholar] [CrossRef]

- Baek, M.S.; Euh, K.; Lee, K.A. Microstructure, tensile and fatigue properties of high strength Al 7075 alloy manufactured via twin-roll strip casting. J. Mater. Res. Technol. 2020, 9, 9941–9950. [Google Scholar] [CrossRef]

- Azeem, M.; Ya, H.H.; Alam, M.A.; Kumar, M.; Stabla, P.; Smolnicki, M.; Gemi, L.; Khan, R.; Ahmed, T.; Ma, Q.; et al. Application of Filament Winding Technology in Composite Pressure Vessels and Challenges: A Review. J. Energy Storage 2022, 49, 103468. [Google Scholar] [CrossRef]

- Jeyasimman, D.; Sivasankaran, S.; Sivaprasad, K.; Narayanasamy, R.; Kambali, R.S. An investigation of the synthesis, consolidation and mechanical behaviour of Al 6061 nanocomposites reinforced by TiC via mechanical alloying. Mater. Des. 2014, 57, 394–404. [Google Scholar] [CrossRef]

- Moorthy, C.V.K.N.S.N.; Kumar, G.N.; Srinivas, V.; Kumar, M.A.; Reddy, K.R.R.M.; Vasundhara, D.N.; Sabri, M.F.M.; Said, S.M. Metallography, Microstructure, and Wear Analysis of AA 6063/TiC Composites for Augmented Dry Sliding Property at Room Temperature. Metallogr. Microstruct. Anal. 2020, 9, 140–151. [Google Scholar] [CrossRef]

- Mohapatra, S.; Chaubey, A.K.; Mishra, D.K.; Singh, S.K. Fabrication of Al—TiC composites by hot consolidation technique: Its microstructure and mechanical properties. Integr. Med. Res. 2015, 5, 117–122. [Google Scholar] [CrossRef] [Green Version]

- Popov, V.A.; Burghammer, M.; Rosenthal, M.; Kotov, A. In situ synthesis of TiC nano-reinforcements in aluminum matrix composites during mechanical alloying. Compos. Part B Eng. 2018, 145, 57–61. [Google Scholar] [CrossRef]

- Hernández-Martinez, S.E.; Cruz-Rivera, J.J.; Garay-Reyes, C.G.; Martínez-Sánchez, R.; Estrada-Guel, I.; Hernández-Rivera, J.L. Comparative study of synthesis of AA 7075-ZrO2 metal matrix composite by different mills. J. Alloys Compd. 2015, 643, S107–S113. [Google Scholar] [CrossRef]

- Estrada-Guel, I.; Carreño-Gallardo, C.; Mendoza-Ruiz, D.C.; Miki-Yoshida, M.; Rocha-Rangel, E.; Martínez-Sánchez, R. Graphite nanoparticle dispersion in 7075 aluminum alloy by means of mechanical alloying. J. Alloys Compd. 2009, 483, 173–177. [Google Scholar] [CrossRef]

- Cabeza, M.; Feijoo, I.; Merino, P.; Pena, G.; Pérez, M.C.; Cruz, S.; Rey, P. Effect of high energy ball milling on the morphology, microstructure and properties of nano-sized TiC particle-reinforced 6005A aluminium alloy matrix composite. Powder Technol. 2017, 321, 31–43. [Google Scholar] [CrossRef]

- Alam, M.; Ya, H.; Azeem, M.; Yusuf, M.; Sapuan, S.; Masood, F. Investigating the effect of mixing time on the crystallite size and lattice strain of the AA7075/TiC composites. Mater. Werkst. 2021, 52, 1112–1120. [Google Scholar] [CrossRef]

- Ghasali, E.; Fazili, A.; Alizadeh, M.; Shirvanimoghaddam, K. Evaluation of Microstructure and Mechanical Properties of Al-TiC Metal Matrix Composite Prepared by Conventional, Microwave and Spark. Materials 2017, 10, 1255. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Fouly, A.; Almotairy, S.M.; Aijaz, M.O.; Alharbi, H.F.; Abdo, H.S. Balanced mechanical and tribological performance of high-frequency-sintered al-sic achieved via innovative milling route—Experimental and theoretical study. Crystals 2021, 11, 700. [Google Scholar] [CrossRef]

- Hamed, A.T.; Mosa, E.S.; Mahdy, A.; El-Batanony, I.G.; Elkady, O.A. Preparation and evaluation of cu-zn-gnss nanocomposite manufactured by powder metallurgy. Crystals 2021, 11, 1449. [Google Scholar] [CrossRef]

- Esmati, M.; Sharifi, H.; Raesi, M.; Atrian, A.; Rajaee, A. Investigation into thermal expansion coefficient, thermal conductivity and thermal stability of Al-graphite composite prepared by powder metallurgy. J. Alloys Compd. 2019, 773, 503–510. [Google Scholar] [CrossRef]

- Akinwamide, S.O.; Lesufi, M.; Akinribide, O.J.; Mpolo, P.; Olubambi, P.A. Evaluation of microstructural and nanomechanical performance of spark plasma sintered TiFe-SiC reinforced aluminium matrix composites. J. Mater. Res. Technol. 2020, 9, 12137–12148. [Google Scholar] [CrossRef]

- Singh, L.K.; Bhadauria, A.; Laha, T. Al-MWCNT nanocomposite synthesized via spark plasma sintering: Effect of powder milling and reinforcement addition on sintering kinetics and mechanical properties. J. Mater. Res. Technol. 2019, 8, 503–512. [Google Scholar] [CrossRef]

- Kushwaha, A.K.; John, M.; Misra, M.; Menezes, P.L. Nanocrystalline Materials: Synthesis, Characterization, Properties, and Applications. Crystals 2021, 11, 1317. [Google Scholar] [CrossRef]

- Bera, S.; Chowdhury, S.G.; Estrin, Y.; Manna, I. Mechanical properties of Al7075 alloy with nano-ceramic oxide dispersion synthesized by mechanical milling and consolidated by equal channel angular pressing. J. Alloys Compd. 2013, 548, 257–265. [Google Scholar] [CrossRef]

- Ahamed, H.; Senthilkumar, V. Role of nano-size reinforcement and milling on the synthesis of nano-crystalline aluminium alloy composites by mechanical alloying. J. Alloys Compd. 2010, 505, 772–782. [Google Scholar] [CrossRef]

- Obadele, B.A.; Masuku, Z.H.; Olubambi, P.A. Turbula mixing characteristics of carbide powders and its influence on laser processing of stainless steel composite coatings. Powder Technol. 2012, 230, 169–182. [Google Scholar] [CrossRef]

- Sulima, I.; Hyjek, P.; Podsiadło, M. Fabrication of the zirconium diboride-reinforced composites by a combination of planetary ball milling, turbula mixing and spark plasma sintering. Materials 2021, 14, 4056. [Google Scholar] [CrossRef]

- Kulecki, P.; Lichańska, E. The Effect of Powder Ball Milling on the Microstructure and Mechanical Properties of Sintered Fe-Cr-Mo-Mn-(Cu) Steel. Powder Metall. Prog. 2017, 17, 82–92. [Google Scholar] [CrossRef] [Green Version]

- Abd Elhamid, M.; Emara, M.M.; Salem, H.G. Influence of mixing technique on the mechanical properties and structural evolution of Al-NiAl Composites. J. Mater. Eng. Perform. 2014, 23, 3425–3435. [Google Scholar] [CrossRef]

- Hafeez, A.; Ammar Taqvi, S.A.; Fazal, T.; Javed, F.; Khan, Z.; Amjad, U.S.; Bokhari, A.; Shehzad, N.; Rashid, N.; Rehman, S.; et al. Optimization on cleaner intensification of ozone production using Artificial Neural Network and Response Surface Methodology: Parametric and comparative study. J. Clean. Prod. 2020, 252, 119833. [Google Scholar] [CrossRef]

- Roohi, R.; Jafari, M.; Jahantab, E.; Aman, M.S.; Moameri, M.; Zare, S. Application of artificial neural network model for the identification the effect of municipal waste compost and biochar on phytoremediation of contaminated soils. J. Geochem. Explor. 2020, 208, 106399. [Google Scholar] [CrossRef]

- Varol, T.; Canakci, A.; Ozsahin, S. Artificial neural network modeling to effect of reinforcement properties on the physical and mechanical properties of Al2024–B4C composites produced by powder metallurgy. Compos. Part B Eng. 2013, 54, 224–233. [Google Scholar] [CrossRef]

- Amirjan, M.; Khorsand, H.; Siadati, M.H.; Eslami Farsani, R. Artificial Neural Network prediction of Cu-Al2O3 composite properties prepared by powder metallurgy method. J. Mater. Res. Technol. 2013, 2, 351–355. [Google Scholar] [CrossRef] [Green Version]

- Dewangan, S.K.; Samal, S.; Kumar, V. Microstructure exploration and an artificial neural network approach for hardness prediction in AlCrFeMnNiWx High-Entropy Alloys. J. Alloys Compd. 2020, 823, 153766. [Google Scholar] [CrossRef]

- Durmuş, H.K.; Özkaya, E.; Meri, C. The use of neural networks for the prediction of wear loss and surface roughness of AA 6351 aluminium alloy. Mater. Des. 2006, 27, 156–159. [Google Scholar] [CrossRef]

- Arif, S.; Alam, M.T.; Ansari, A.H.; Shaikh, M.B.N.; Siddiqui, M.A. Analysis of tribological behaviour of zirconia reinforced Al-SiC hybrid composites using statistical and artificial neural network technique. Mater. Res. Express 2018, 5, 056506. [Google Scholar] [CrossRef]

- Nwobi-Okoye, C.C.; Ochieze, B.Q. Age hardening process modeling and optimization of aluminum alloy A356/Cow horn particulate composite for brake drum application using RSM, ANN and simulated annealing. Def. Technol. 2018, 14, 336–345. [Google Scholar] [CrossRef]

- Varol, T.; Canakci, A.; Ozsahin, S. Prediction of effect of reinforcement content, flake size and flake time on the density and hardness of flake AA2024-SiC nanocomposites using neural networks. J. Alloys Compd. 2018, 739, 1005–1014. [Google Scholar] [CrossRef]

- Alam, M.A.; Ya, H.H.; Azeem, M.; Hussain, P.B.; Sapuan, S.M.; Khan, R.; Arif, S.; Ansari, A.H. Modelling and optimisation of hardness behaviour of sintered Al/SiC composites using RSM and ANN: A comparative study. J. Mater. Res. Technol. 2020, 9, 14036–14050. [Google Scholar] [CrossRef]

- Ahmed, I.; Ahmad, A.; Rahaman, S.A.; Abdul-rani, A.; Azad, M. Modelling and optimization of microhardness of electroless Ni–P–TiO2 composite coating based on machine learning approaches and RSM. J. Mater. Res. Technol. 2021, 12, 1010–1025. [Google Scholar] [CrossRef]

- Erturun, V.; Çetin, S.; Sahin, O. Investigation of Microstructure of Aluminum Based Composite Material Obtained by Mechanical Alloying. Met. Mater. Int. 2020, 27, 1662–1670. [Google Scholar] [CrossRef]

- Jiang, J.; Shen, Y.; Feng, X. Microstructures evolution, formation mechanisms and properties of Sicp/ Al composite coatings on Ti-6Al-4v substrate via mechanical alloying method. Surf. Interfaces 2020, 19, 100487. [Google Scholar] [CrossRef]

- Zawrah, M.F.; Abdel-Kader, H.; Elbaly, N.E. Fabrication of Al2O3-20 vol. % Al nanocomposite powders using high energy milling and their sinterability. Mater. Res. Bull. 2012, 47, 655–661. [Google Scholar] [CrossRef]

- Surya, M.S.; Prasanthi, G.; Kumar, A.K.; Sridhar, V.K.; Gugulothu, S.K. Optimization of Tribological Properties of Powder Metallurgy-Processed Aluminum7075/SiC Composites Using ANOVA and Artificial Neural Networks. J. Bio- Tribo-Corros. 2021, 7, 161. [Google Scholar] [CrossRef]

- Zhang, Y.F.; Lu, L.; Yap, S.M. Prediction of the amount of PCA for mechanical milling. J. Mater. Process. Technol. 1999, 89–90, 260–265. [Google Scholar] [CrossRef]

- Cullity, B.D. Answers to Problems: Elements of X-ray Diffraction; Addison-Wesley Publishing Company: Boston, MA, USA, 1978; ISBN 0201089173. [Google Scholar]

- Sivasankaran, S.; Sivaprasad, K.; Narayanasamy, R.; Satyanarayana, P.V. X-ray peak broadening analysis of AA 6061100-x-x wt.% Al2O3 nanocomposite prepared by mechanical alloying. Mater. Charact. 2011, 62, 661–672. [Google Scholar] [CrossRef]

- Rajesh Kumar, B.; Hymavathi, B. X-ray peak profile analysis of solid-state sintered alumina doped zinc oxide ceramics by Williamson–Hall and size-strain plot methods. J. Asian Ceram. Soc. 2017, 5, 94–103. [Google Scholar] [CrossRef] [Green Version]

- Zawrah, M.F.; Zayed, H.A.; Essawy, R.A.; Nassar, A.H.; Taha, M.A. Preparation by mechanical alloying, characterization and sintering of Cu-20wt.% Al2O3 nanocomposites. Mater. Des. 2013, 46, 485–490. [Google Scholar] [CrossRef]

- Dashtbayazi, M.R.; Shokuhfar, A.; Simchi, A. Artificial neural network modeling of mechanical alloying process for synthesizing of metal matrix nanocomposite powders. Mater. Sci. Eng. A 2007, 466, 274–283. [Google Scholar] [CrossRef]

- Sethi, J.; Das, S.; Das, K. Evaluating the influence of milling time,and sintering temperature and time on the microstructural changes and mechanical properties of Al-Y2W3O12-AlN hybrid composites. Powder Technol. 2021, 377, 244–256. [Google Scholar] [CrossRef]

- Sohi, M.H.; Hojjatzadeh, S.M.H.; Moosavifar, S.S.; Heshmati-Manesh, S. Liquid phase surface melting of AA8011 aluminum alloy by addition of Al/Al2O3 nano-composite powders synthesized by high-energy milling. Appl. Surf. Sci. 2014, 313, 76–84. [Google Scholar] [CrossRef]

- Jeyasimman, D.; Sivaprasad, K.; Sivasankaran, S.; Ponalagusamy, R.; Narayanasamy, R.; Iyer, V. Microstructural observation, consolidation and mechanical behaviour of AA 6061 nanocomposites reinforced by γ-Al2O3 nanoparticles. Adv. Powder Technol. 2015, 26, 139–148. [Google Scholar] [CrossRef]

- Nath, A.K.; Jiten, C.; Singh, K.C. Influence of ball milling parameters on the particle size of barium titanate nanocrystalline powders. Phys. B Condens. Matter 2010, 405, 430–434. [Google Scholar] [CrossRef]

- Michael Rajan, H.B.; Ramabalan, S.; Dinaharan, I.; Vijay, S.J. Synthesis and characterization of in situ formed titanium diboride particulate reinforced AA7075 aluminum alloy cast composites. Mater. Des. 2013, 44, 438–445. [Google Scholar] [CrossRef]

- Arif, S.; Alam, T.; Ansari, A.H.; Bilal, M.; Shaikh, N. Morphological characterization, statistical modelling and tribological behaviour of aluminum hybrid nanocomposites reinforced with micro-nano-silicon carbide. J. Asian Ceram. Soc. 2019, 7, 434–448. [Google Scholar] [CrossRef]

- Yusuf, M.; Farooqi, A.S.; Keong, L.K.; Hellgardt, K.; Abdullah, B. Contemporary trends in composite Ni-based catalysts for CO2 reforming of methane. Chem. Eng. Sci. 2021, 229, 116072. [Google Scholar] [CrossRef]

- Jain, R.; Dewangan, S.K.; Kumar, V.; Samal, S. Artificial neural network approach for microhardness prediction of eight component FeCoNiCrMnVAlNb eutectic high entropy alloys. Mater. Sci. Eng. A 2020, 797, 140059. [Google Scholar] [CrossRef]

| S.No. | Materials | Preparation Technique | Major Outcomes | References | |

|---|---|---|---|---|---|

| Matrix | Reinforcements with CONTENTS | ||||

| 1 | Al7075 | TiC (5%) | Mechanical alloying (MA) followed by hot pressing (10 h, 30 h, and 50 h). | Significant improvement in crystallite size, accumulations in lattice strains, and high mechanical properties. | [6] |

| 2 | Al7075 | ZrO2 (2%, and 5%) | Mechanical alloying by three different mills (planetary, horizontal attritor, and shaker), 15 h. | Considerable improvement in crystallite size and enhancement in lattice strain. | [20] |

| 3 | Al7075 | GNP (0, 1, and 2%) | Mechanical alloying in high energy SPEX mill (for 2.5, 5, and 10 h) followed by consolidation. | Improvement in particle size and mechanical properties (hardness and strength). | [21] |

| 4 | AA6061 | TiC (1, 1.5, 2 wt.%) | Mechanical alloying with a milling time of 30 h. | The structural and mechanical properties improved. | [16] |

| 5 | AA6005 A | TiC (1.5, 3, and 6 vol. %) | High energy ball milling for different milling times, in the range from 1 to 10 h. | The effect of the milling process is greater than that of the reinforcement. | [22] |

| 6 | Al7075 | TiC (5 %) | Turbula mixing | Reduction in crystallite size | [23] |

| 7 | Al7075 | TiC (4 wt.%) | (Turbula mixing + high energy planetary ball mill) for 3, 5, and 7 h MA. | Significant improvement in crystallite size and accumulation in lattice strain achieved. Microhardness improved. | Present study |

| Elements | Si | Cr | Mn | Fe | Cu | Mg | Ai | Zn | Al |

|---|---|---|---|---|---|---|---|---|---|

| wt.% | 0.087 | 0.185 | 0.08 | 0.092 | 1.56 | 2.31 | 0.05 | 5.72 | Bal. |

| Network Parameters | Values/Types |

|---|---|

| Configuration of networks | 2-10-2 |

| Neurons number in the layers | Input: 2, hidden: 10, output: 2 |

| Hidden and output layer activation functions | Logsig (sigmoid) |

| Learning rules for training parameters | Backpropagation |

| Number of Epochs | 1000 |

| Error Prediction | Crystallite Size | Lattice Strain |

|---|---|---|

| RMSE | 3.34 | 3.45 |

| MAPE | 2.84 | 1.45 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alam, M.A.; Ya, H.H.; Azeem, M.; Yusuf, M.; Soomro, I.A.; Masood, F.; Shozib, I.A.; Sapuan, S.M.; Akhter, J. Artificial Neural Network Modeling to Predict the Effect of Milling Time and TiC Content on the Crystallite Size and Lattice Strain of Al7075-TiC Composites Fabricated by Powder Metallurgy. Crystals 2022, 12, 372. https://doi.org/10.3390/cryst12030372

Alam MA, Ya HH, Azeem M, Yusuf M, Soomro IA, Masood F, Shozib IA, Sapuan SM, Akhter J. Artificial Neural Network Modeling to Predict the Effect of Milling Time and TiC Content on the Crystallite Size and Lattice Strain of Al7075-TiC Composites Fabricated by Powder Metallurgy. Crystals. 2022; 12(3):372. https://doi.org/10.3390/cryst12030372

Chicago/Turabian StyleAlam, Mohammad Azad, Hamdan H. Ya, Mohammad Azeem, Mohammad Yusuf, Imtiaz Ali Soomro, Faisal Masood, Imtiaz Ahmed Shozib, Salit M. Sapuan, and Javed Akhter. 2022. "Artificial Neural Network Modeling to Predict the Effect of Milling Time and TiC Content on the Crystallite Size and Lattice Strain of Al7075-TiC Composites Fabricated by Powder Metallurgy" Crystals 12, no. 3: 372. https://doi.org/10.3390/cryst12030372

APA StyleAlam, M. A., Ya, H. H., Azeem, M., Yusuf, M., Soomro, I. A., Masood, F., Shozib, I. A., Sapuan, S. M., & Akhter, J. (2022). Artificial Neural Network Modeling to Predict the Effect of Milling Time and TiC Content on the Crystallite Size and Lattice Strain of Al7075-TiC Composites Fabricated by Powder Metallurgy. Crystals, 12(3), 372. https://doi.org/10.3390/cryst12030372