An Investigation of the Pressure-Induced Structural Phase Transition of Nanocrystalline α-CuMoO4

Abstract

:1. Introduction

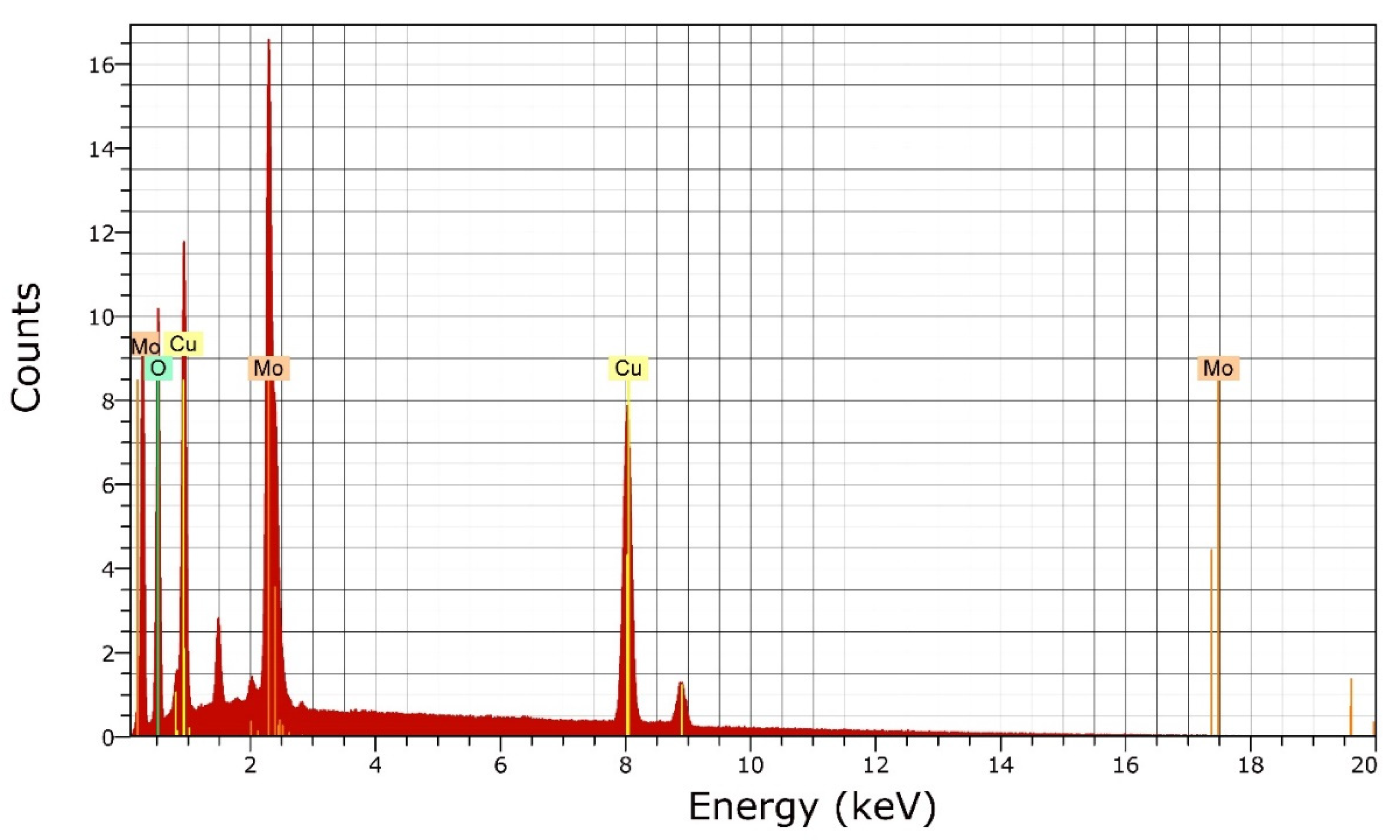

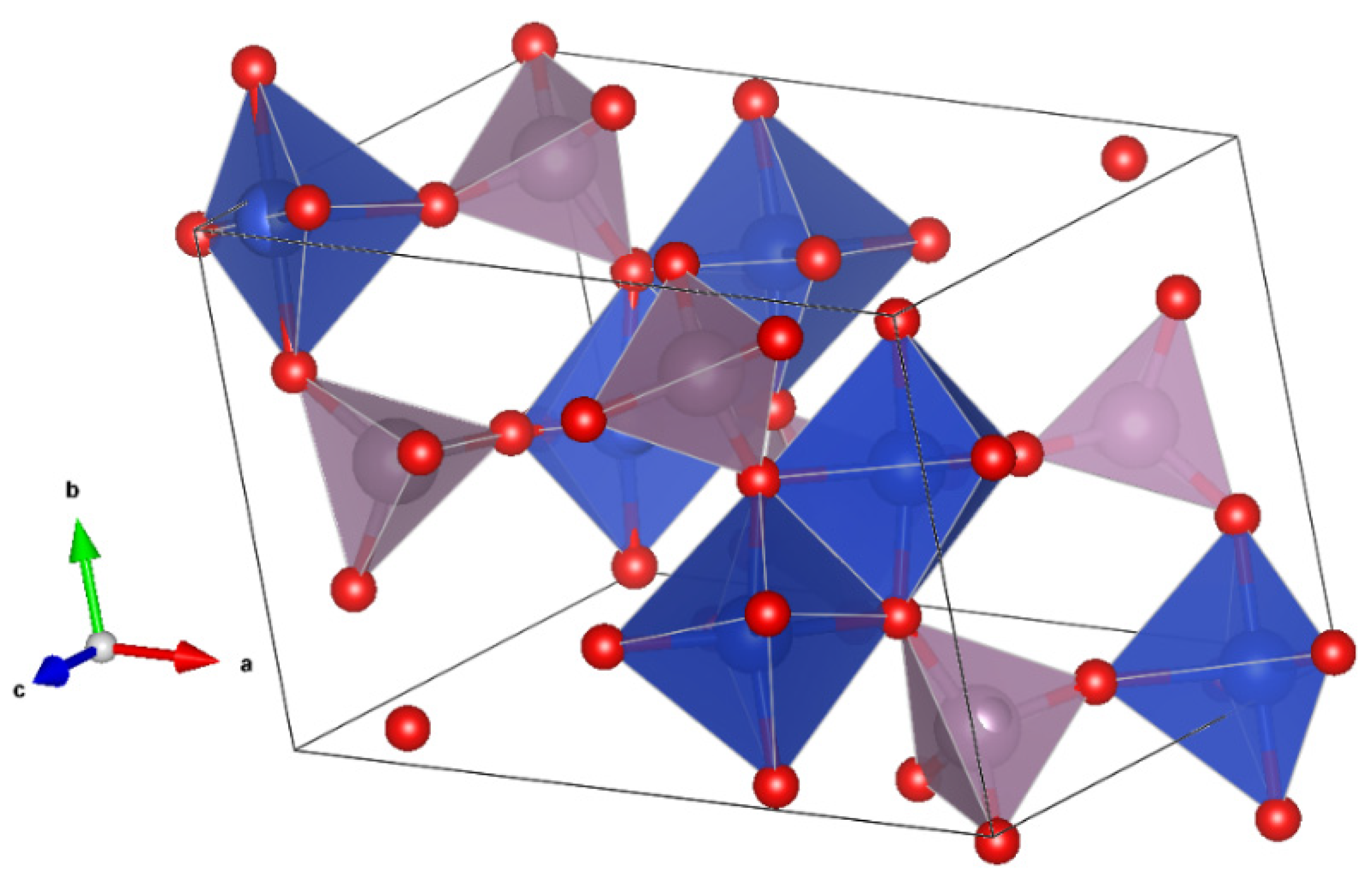

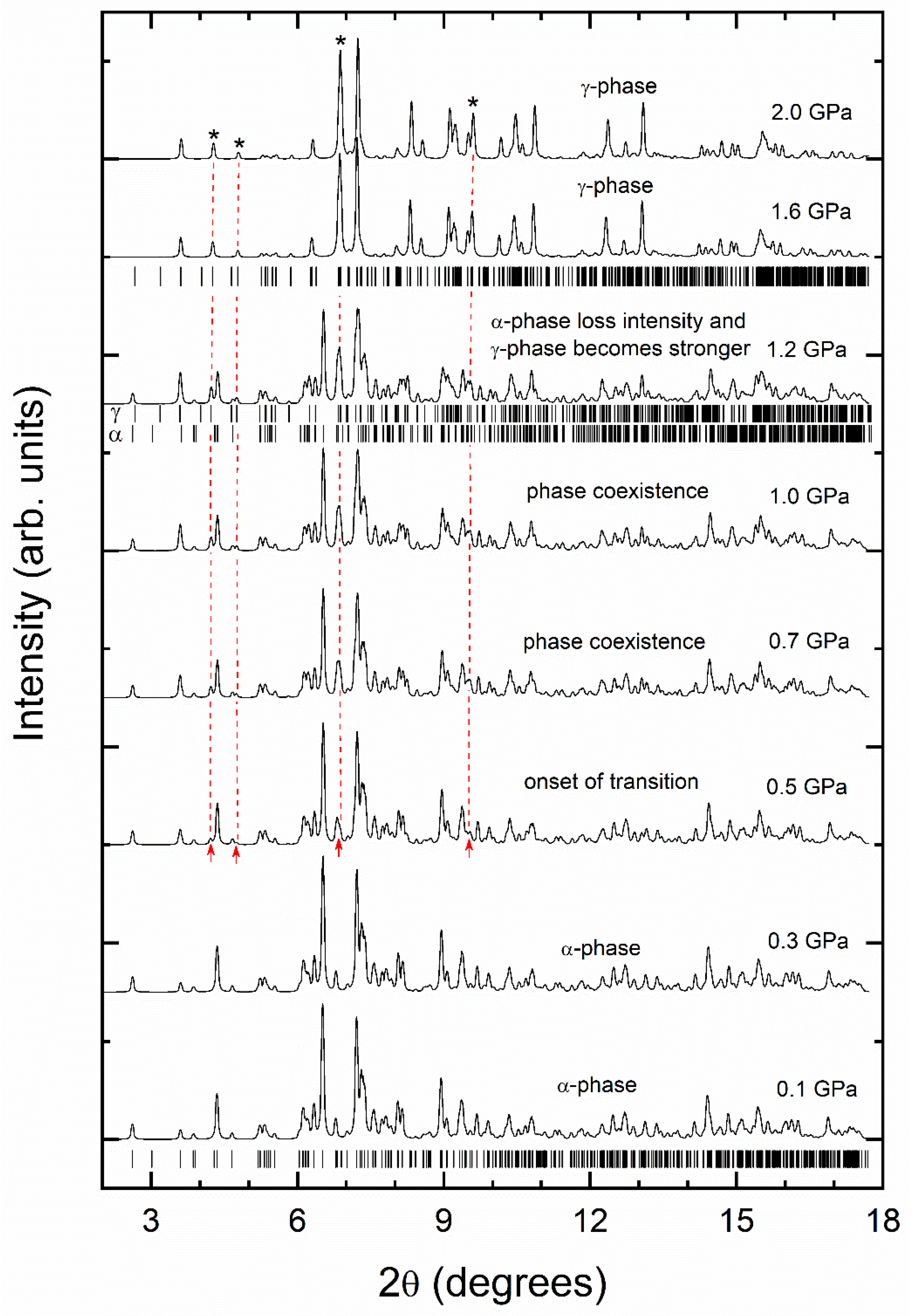

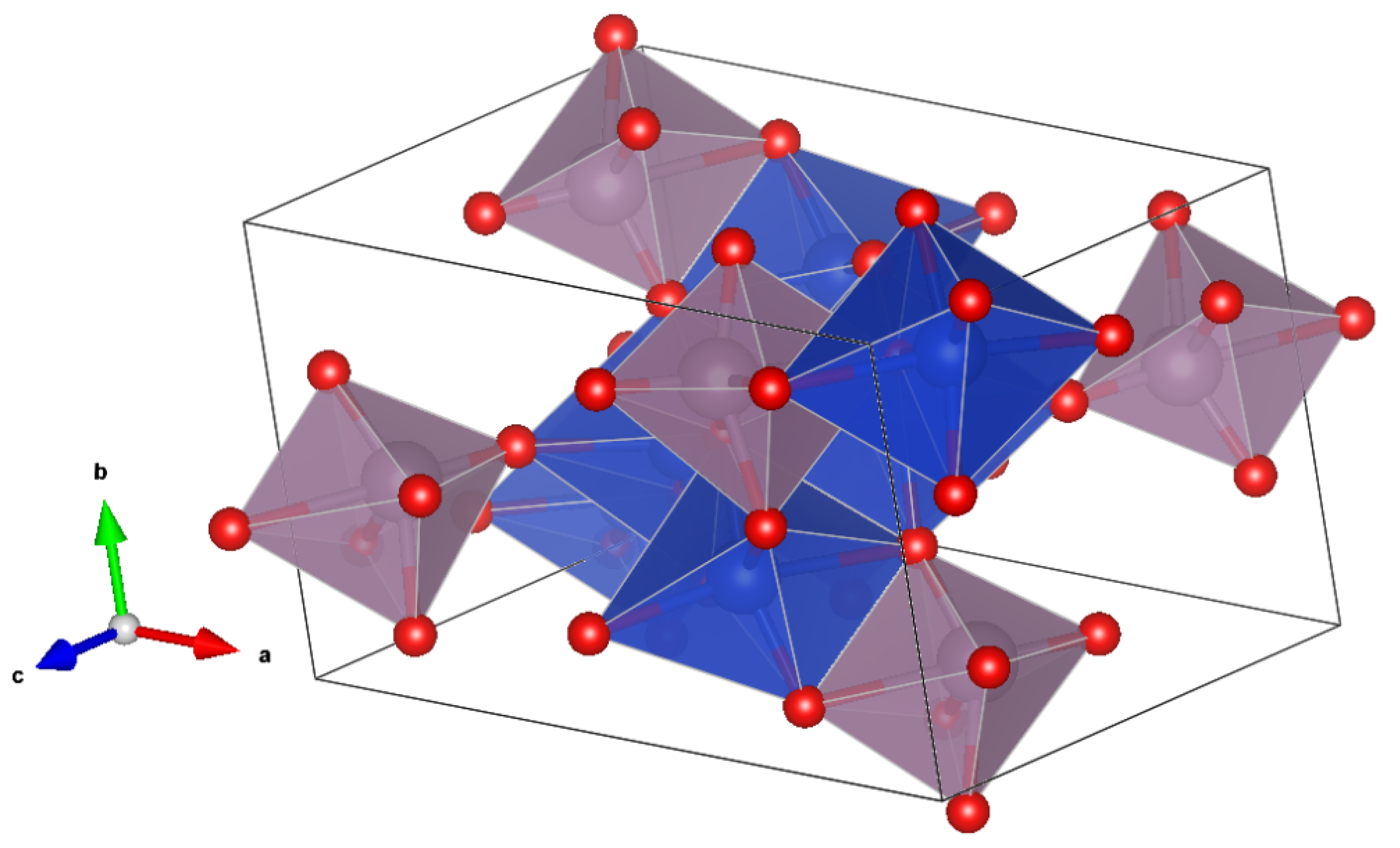

2. Experiment

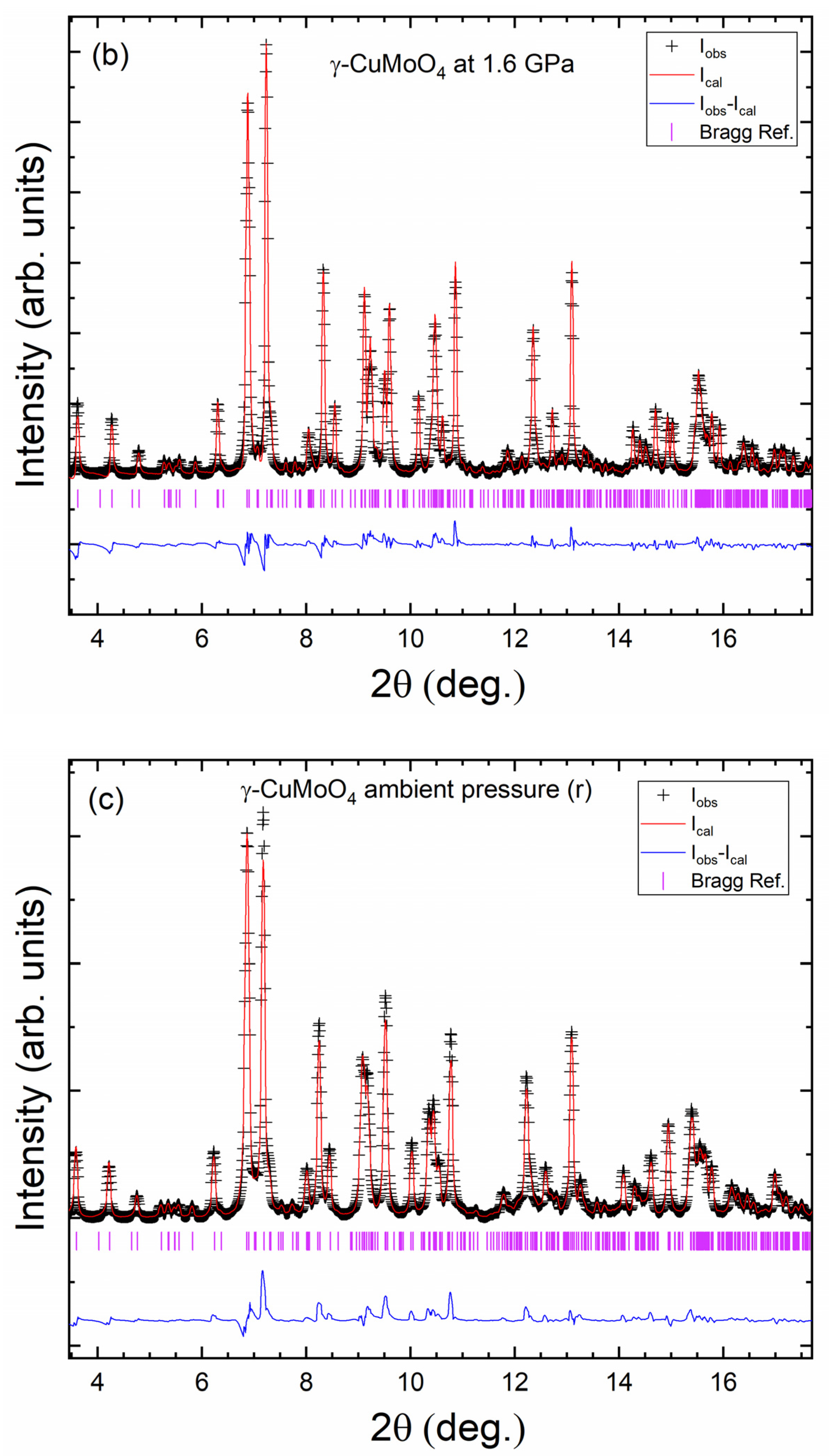

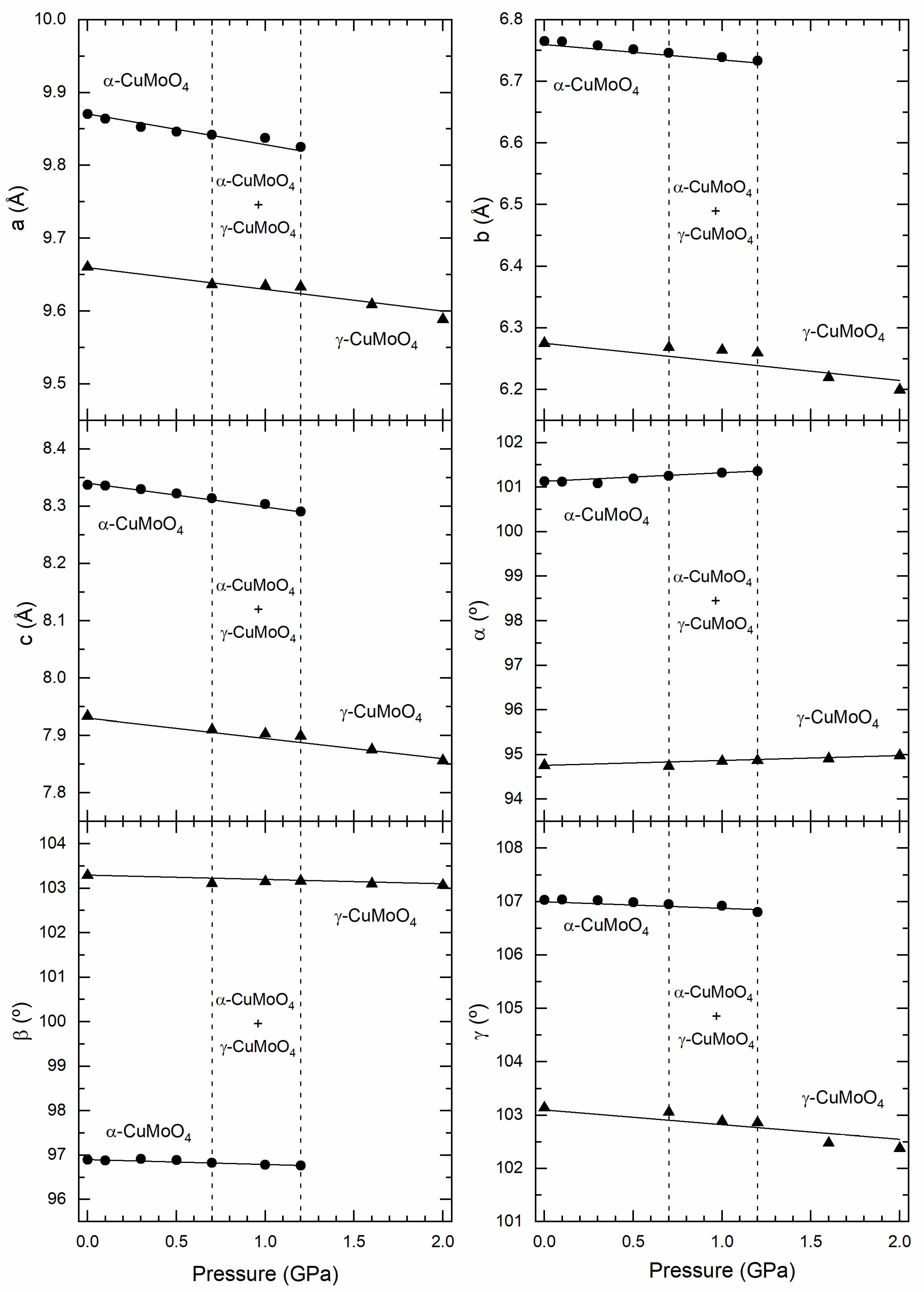

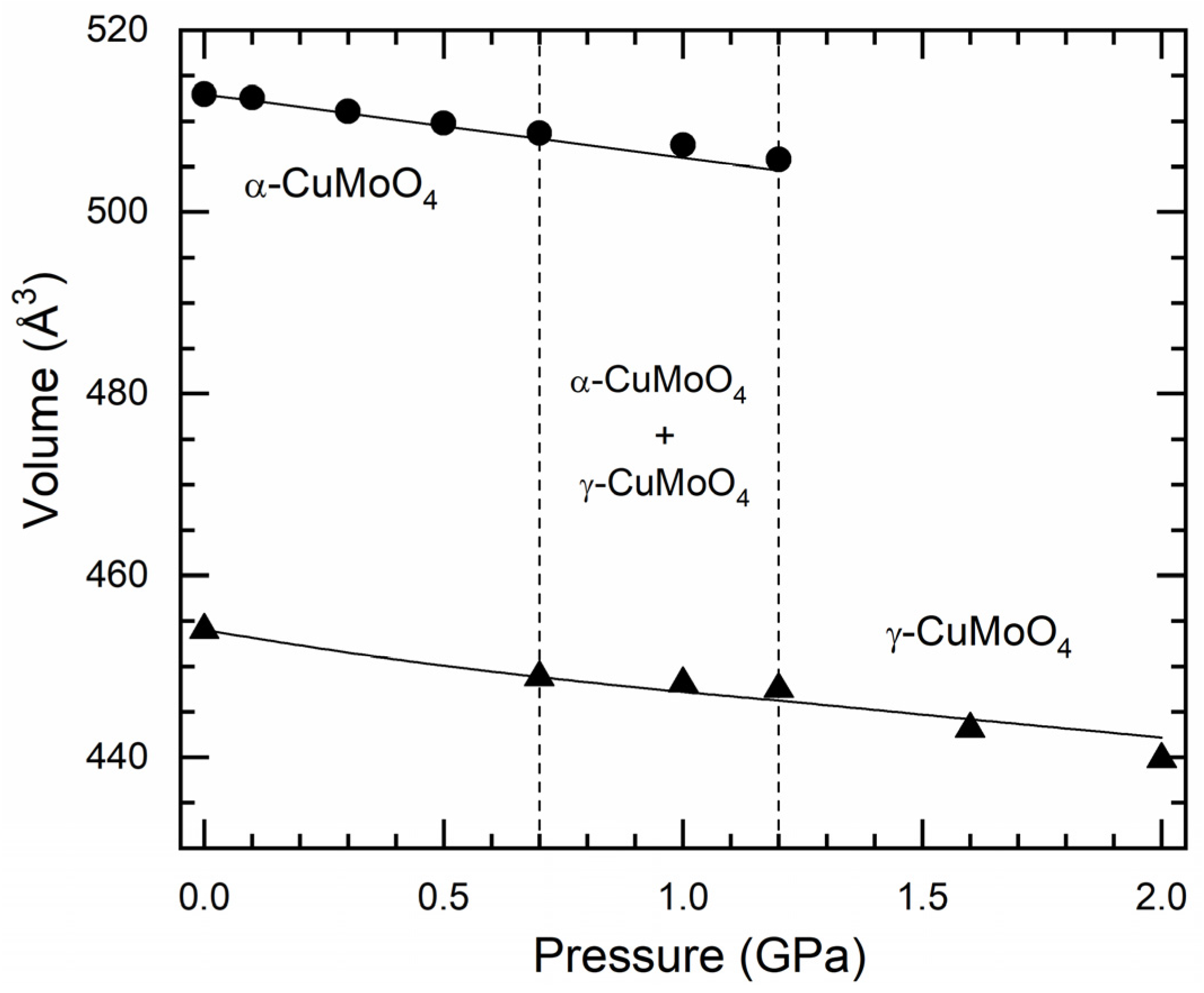

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kharisov, B.I.; Dias, H.V.R.; Kharissova, O.V.; Jiménez-Pérez, V.M.; Pérez, B.O.; Flores, B.M. Iron-containing nanomaterials: Synthesis, properties, and environmental applications. RSC Adv. 2012, 2, 9325–9358. [Google Scholar] [CrossRef]

- Tan, X.; Liu, Y.-G.; Gu, Y.-L.; Xu, Y.; Zeng, G.-M.; Hu, X.-J.; Liu, S.-B.; Wang, X.; Liu, S.-M.; Li, J. Biochar-based nano-composites for the decontamination of wastewater: A review. Bioresour. Technol. 2016, 212, 318–333. [Google Scholar] [CrossRef] [PubMed]

- Ullattil, S.G.; Narendranath, S.B.; Pillai, S.C.; Periyat, P. Black TiO2 Nanomaterials: A Review of Recent Advances. Chem. Eng. J. 2018, 343, 708–736. [Google Scholar] [CrossRef]

- Pourmortazavi, S.M.; Hajimirsadeghi, S.S.; Rahimi, N.M.; Zahedi, M.M. Facile and Effective Synthesis of Praseodymium Tungstate Nanoparticles through an Optimized Procedure and Investigation of Photocatalytic Activity. Mater. Sci. Semicond. Process. 2013, 16, 131–137. [Google Scholar] [CrossRef]

- Sundaram, R.; Nagaraja, K.S. Solid state electrical conductivity and humidity sensing studies on metal molybdate–molybdenum trioxide composites (M = Ni2+, Cu2+ and Pb2+). Sens. Actuators B 2004, 101, 353–360. [Google Scholar] [CrossRef]

- Brito, J.L.; Barbosa, A.L.; Albornoz, A.; Severino, F.; Laine, J. Nickel molybdate as precursor of HDS catalysts: Effect of phase composition. Catal. Lett. 1994, 26, 329–337. [Google Scholar] [CrossRef]

- Liu, J.P.; Huang, X.T.; Li, Y.Y.; Li, Z.K. A general route to thickness-tunable multilayered sheets of sheelite-type metal molybdate and their self-assembled films. J. Mater. Chem. 2007, 17, 2754–2758. [Google Scholar] [CrossRef]

- Naja, M.; Abbasi, A.; Masteri-Farahani, M.; Rodrigues, V.H. Synthesis, characterization and crystal structure of a copper molybdate coordination polymer as an epoxidation catalyst. Inorg. Chim. Acta 2015, 433, 21–25. [Google Scholar]

- Abrahams, S.C.; Bernstein, J.L.; Jamieson, P.B.; Crystal Structure of the Transition Metal Molybdates and Tungstates. IV. Paramagnetic CuMoO4. J. Chem. Phys. 1968, 48, 2619–2629. [Google Scholar] [CrossRef]

- Kohlmuller, R.; Faurie, J.P. Etude des systemes MoO3–Ag2MoO4 et MoO3–MO (M−Cu, Zn, Cd). Bull. Soc. Chim. Fr. 1968, 11, 4379–4382. [Google Scholar]

- Ehrenberg, H.; Weitzel, H.; Paulus, H.; Wiesmann, M.; Wltschek, G.; Geselle, M.; Fuess, H. Crystal structure and magnetic properties of CuMoO4 at low temperature (γ-phase). J. Phys. Chem. Sol. 1997, 58, 153–160. [Google Scholar] [CrossRef]

- Sleight, A.W. High Pressure CuMoO4. Mater. Res. Bull. 1973, 8, 863–866. [Google Scholar] [CrossRef]

- Tali, R.; Tabachenko, V.V.; Kovba, L.M.; DemÕyanets, L.N. Kristallicheskaya struktura CuMoO4. Zhurnal Neorg. Khimii 1991, 36, 1642–1644. [Google Scholar]

- Baek, J.; Sefat, A.S.; Mandrus, D.; Halasyamani, P.S. A New Magnetically Ordered Polymorph of CuMoO4: Synthesis and Characterization of ε-CuMoO4. Chem. Mater. 2008, 20, 3785–3787. [Google Scholar] [CrossRef]

- Wiesmann, M.; Ehrenberg, H.; Miehe, G.; Peun, T.; Weitzel, H.; Fuess, H. P-T Phase Diagram of CuMoO4. J. Solid State Chem. 1997, 132, 88–97. [Google Scholar] [CrossRef]

- Rodrıguez, F.; Hernandez, D.; Garcia-Jaca, J.; Ehrenberg, H.; Weitzel, H. Optical study of the piezochromic transition in CuMoO4 by pressure spectroscopy. Phys. Rev. B 2000, 61, 16497–16501. [Google Scholar] [CrossRef]

- Hassani, H.O.; Akouibaa, M.; Rakass, S.; Abboudi, M.; Bali, B.E.; Lachkar, M.; Wadaani, F. A simple and cost-effective new synthesis method of copper molybdate CuMoO4 nanoparticles and their catalytic performance. J. Sci. Adv. Mater. Dev. 2021, 6, 501–507. [Google Scholar] [CrossRef]

- Rahmani, A.; Farsi, H. Nanostructured copper molybdates as promising bifunctional electrocatalysts for overall water splitting and CO2 reduction. RSC Adv. 2020, 10, 39037. [Google Scholar] [CrossRef]

- Mohamed, B.; El Ouatib, R.; Guillemet, S.; Er-Rakho, L.; Durand, B. Characterization and photoluminescence properties of ultrafine copper molybdate (α-CuMoO4) powders prepared via a combustion-like process. Int. J. Miner. Metall. Mater. 2016, 23, 1340–1345. [Google Scholar]

- Popescu, C.; Sans, J.A.; Errandonea, D.; Segura, A.; Villanueva, R.; Sapiña, F. Compressibility and Structural Stability of Nanocrystalline TiO2 Anatase Synthesized from Freeze-Dried Precursors. Inorg. Chem. 2014, 53, 11598–11603. [Google Scholar] [CrossRef]

- Wang, J.; Yang, J.; Hu, T.; Chen, X.; Lang, J.; Wu, X.; Zhang, J.; Zhao, H.; Yang, J.; Cui, Q. Structural Phase Transition and Compressibility of CaF2 Nanocrystals under High Pressure. Crystals 2018, 8, 199. [Google Scholar] [CrossRef] [Green Version]

- Srihari, V.; Verma, A.K.; Pandey, K.K.; Vishwanadh, B.; Panchal, V.; Garg, N.; Errandonea, D. Making Yb2Hf2O7 Defect Fluorite Uncompressible by Particle Size Reduction. J. Phys. Chem. C 2021, 125, 27354–27362. [Google Scholar] [CrossRef]

- Yuan, H.; Rodriguez-Hernandez, P.; Muñoz, A.; Errandonea, D. Putting the squeeze on lead chromate nanorods. J. Phys. Chem. Lett. 2019, 10, 4744–4751. [Google Scholar] [CrossRef] [PubMed]

- Patterson, A.L. The Scherrer Formula for X-Ray Particle Size Determination. Phys. Rev. 1939, 56, 978–982. [Google Scholar] [CrossRef]

- Lutterotti, L.; Matthies, S.; Wenk, H.R. MAUD: A friendly Java program for material analysis using diffraction. IUCr Newsl. CPD 1999, 21, 14–15. [Google Scholar]

- Fauth, F.; Peral, I.; Popescu, C.; Knapp, M. The new Material Science Powder Diffraction beamline at ALBA Synchrotron. Powder Diffr. 2013, 28, S360–S370. [Google Scholar] [CrossRef]

- Prescher, C.; Prakapenka, V.B. DIOPTAS: A program for reduction of two-dimensional X-ray diffraction data and data exploration. High Press. Res. 2015, 35, 223–230. [Google Scholar] [CrossRef]

- Klotz, S.; Chervin, J.C.; Munsch, P.; Le Marchand, G. Hydrostatic limits of 11 pressure transmitting media. J. Phys. D Appl. Phys. 2009, 42, 075413. [Google Scholar] [CrossRef]

- Errandonea, D. Exploring the properties of MTO4 compounds using high-pressure powder x-ray diffraction. Cryst. Res. Technol. 2015, 50, 729–736. [Google Scholar] [CrossRef]

- Mao, H.K.; Xu, J.; Bell, P.M. Calibration of the ruby pressure gauge to 800 kbar under quasi-hydrostatic conditions. J. Geophys. Res. 1986, 91, 4673–4676. [Google Scholar] [CrossRef]

- Chervin, J.C.; Canny, B.; Mancinelli, M. Ruby-spheres as pressure gauge for optically transparent high-pressure cells. High Press. Res. 2001, 21, 305–314. [Google Scholar] [CrossRef]

- Dai, L.; Liu, K.; Li, H.; Wu, L.; Hu, H.; Zhang, Y.; Yang, L.; Pu, C.; Liu, P. Pressure-induced irreversible metallization with phase transitions of Sb2S3. Phys. Rev. B 2018, 97, 024103. [Google Scholar]

- Yang, L.; Jiang, J.; Dai, L.; Hu, H.; Hong, M.; Zhang, X.; Li, H.; Liu, P. High-pressure structural phase transition and metallization in Ga2S3 under non-hydrostatic and hydrostatic conditions up to 36.4 GPa. J. Mater. Chem. C 2021, 9, 2912–2918. [Google Scholar]

- Chijioke, A.D.; Nellis, W.J.; Soldatov, A.; Silvera, I.F. The ruby pressure standard to 150 GPa. J. Appl. Phys. 2005, 98, 114905. [Google Scholar] [CrossRef] [Green Version]

- Brian, H.T. EXPGUI, a graphical user interface for GSAS. J. Appl. Crystallogr. 2001, 34, 210–213. [Google Scholar]

- Rietveld, H.M. A profile refinement method for nuclear and magnetic structures. J. Appl. Crystallogr. 1969, 2, 65–71. [Google Scholar] [CrossRef]

- Tolbert, S.H.; Alivisatos, A.P. High-pressure structural transformations in semiconductor nanocrystals. Annu. Rev. Phys. Chem. 1995, 46, 595–625. [Google Scholar] [CrossRef]

- Razek, S.A.; Popeil, M.R.; Wangoh, L.; Rana, J.; Suwandaratne, N.; Andrews, J.L.; Watson, D.F.; Banerjee, S.; Piper, L.F.J. Designing catalysts for water splitting based on electronic structure considerations. Electron. Struct. 2020, 2, 023001. [Google Scholar] [CrossRef]

- Curetti, N.; Sochalski-Kolbus, L.M.; AngeL, R.J.; Benna, P.; Nestola, F.; Bruno, E. High-pressure structural evolution and equation of state of albite. Am. Mineral. 2011, 96, 383–392. [Google Scholar] [CrossRef]

- Cliffe, M.J.; Goodwin, A.L. PASCal: A principal axis strain calculator for thermal expansion and compressibility determination. J. Appl. Crystallogr. 2012, 45, 1321–1329. [Google Scholar] [CrossRef] [Green Version]

- Gonzalez-Plattas, J.; Alvaro, M.; Nestola, F.; Angel, R. EosFit7-GUI: A new graphical user interface for equation of state calculations, analyses and teaching. J. Appl. Crystallogr. 2016, 49, 1377–1382. [Google Scholar] [CrossRef]

- Errandonea, D.; Manjon, F.J. Pressure effects on the structural and electronic properties of ABX4 scintillating crystals. Prog. Mater. Sci. 2008, 53, 711–773. [Google Scholar] [CrossRef]

- Anzellini, S.; Errandonea, D.; MacLeod, S.G.; Botella, P.; Daisenberger, D.; De’Ath, J.M.; Gonzalez-Platas, J.; Ibáñez, J.; McMahon, M.I.; Munro, K.A.; et al. Phase diagram of calcium at high pressure and high temperature. Phys. Rev. Mater. 2018, 2, 083608. [Google Scholar] [CrossRef]

- Ruiz-Fuertes, J.; Errandonea, D.; Lacomba-Perales, R.; Segura, A.; González, J.; Rodríguez, F.; Manjón, F.J.; Ray, S.; Rodríguez-Hernández, P.; Muñoz, A.; et al. High-pressure structural phase transitions in CuWO4. Phys. Rev. B 2010, 81, 224115. [Google Scholar] [CrossRef] [Green Version]

- Díaz-Anichtchenko, D.; Turnbull, R.; Bandiello, E.; Anzellini, S.; Achary, S.N.; Errandonea, D. Pressure-induced chemical decomposition of copper orthovanadate (α-Cu3V2O8). J. Mater. Chem. C 2021, 9, 13402–13409. [Google Scholar] [CrossRef]

- Turnbull, R.; Gonzáles-Platas, J.; Rodríguezc, F.; Liang, A.; Popescu, C.; Santamaría-Pérez, Z.D.; Rodríguez-Hernandez, P.; Muñoz, A.; Errandonea, D. Pressure-induced phase transition and band-gap collapse in semiconducting β-Cu2V2O7. Inorg. Chem. 2022, 61, 3697–3707. [Google Scholar] [CrossRef]

- Errandonea, D.; Gracia, L.; Lacomba-Perales, R.; Polian, A.; Chervin, J.C. Compression of scheelite-type SrMoO4 under quasi-hydrostatic conditions: Redefining the high-pressure structural sequence. J. Appl. Phys. 2013, 113, 123510. [Google Scholar] [CrossRef] [Green Version]

- Errandonea, D.; Ruiz-Fuertes, J. A Brief Review of the Effects of Pressure on Wolframite-Type Oxides. Crystals 2018, 8, 71. [Google Scholar] [CrossRef] [Green Version]

| Atoms | Sites | x | y | z |

|---|---|---|---|---|

| Cu1 | 2i | 0.4054 (3) | 0.7466 (3) | 0.1983 (3) |

| Cu2 | 2i | 0.9922 (3) | 0.0472 (3) | 0.2024 (3) |

| Cu3 | 2i | 0.2365 (3) | 0.4626 (3) | 0.3853 (3) |

| Mo1 | 2i | 0.3450 (2) | 0.1970 (2) | 0.0850 (2) |

| Mo2 | 2i | 0.1064 (2) | 0.4960 (2) | 0.7776 (2) |

| Mo3 | 2i | 0.2500 (2) | 0.9927 (2) | 0.4648 (2) |

| O1 | 2i | 0.1425 (12) | 0.9355 (12) | 0.6056 (12) |

| O2 | 2i | 0.2751 (12) | 0.7459 (12) | 0.3590 (12) |

| O3 | 2i | 0.1839 (12) | 0.1582 (12) | 0.3414 (12) |

| O4 | 2i | 0.1644 (12) | 0.0642 (12) | 0.9873 (12) |

| O5 | 2i | 0.1846 (12) | 0.5020 (12) | 0.5974 (12) |

| O6 | 2i | 0.3669 (12) | 0.4518 (12) | 0.2238 (12) |

| O7 | 2i | 0.2405 (12) | 0.5940 (12) | 0.9484 (12) |

| O8 | 2i | 0.4122 (12) | 0.1567(12) | 0.5772 (12) |

| O9 | 2i | 0.0039 (12) | 0.2291 (12) | 0.7692 (12) |

| O10 | 2i | 0.0107 (12) | 0.3455 (12) | 0.2115 (12) |

| O11 | 2i | 0.4463 (12) | 0.2493 (12) | 0.9330 (12) |

| O12 | 2i | 0.4104 (12) | 0.0335 (12) | 0.1952 (12) |

| Atoms | Sites | x | y | z |

|---|---|---|---|---|

| Cu1 | 2i | 0.4339 (3) | 0.7158 (3) | 0.2360 (3) |

| Cu2 | 2i | 0.0069 (3) | 0.0931 (3) | 0.1939 (3) |

| Cu3 | 2i | 0.3355 (3) | 0.4240 (3) | 0.5260 (3) |

| Mo1 | 2i | 0.3481 (2) | 0.2165 (2) | 0.1269 (2) |

| Mo2 | 2i | 0.1092 (2) | 0.4145 (2) | 0.8800 (2) |

| Mo3 | 2i | 0.2269 (12) | 0.9336 (2) | 0.4583 (2) |

| O1 | 2i | 0.1193 (12) | 0.8973 (12) | 0.6000 (12) |

| O2 | 2i | 0.2951 (12) | 0.6970 (12) | 0.4544 (12) |

| O3 | 2i | 0.1998 (12) | 0.2082 (12) | 0.3424 (12) |

| O4 | 2i | 0.1546 (12) | 0.1263 (12) | 0.9699 (12) |

| O5 | 2i | 0.1927 (12) | 0.4514 (12) | 0.7175 (12) |

| O6 | 2i | 0.4765 (12) | 0.4375 (12) | 0.3011 (12) |

| O7 | 2i | 0.2720 (12) | 0.5024 (12) | 0.0747 (12) |

| O8 | 2i | 0.3863 (12) | 0.1490 (12) | 0.5890 (12) |

| O9 | 2i | 0.9406 (12) | 0.1831 (12) | 0.7561 (12) |

| O10 | 2i | 0.9744 (12) | 0.3626 (12) | 0.1078 (12) |

| O11 | 2i | 0.4474 (12) | 0.2102 (12) | 0.9788 (12) |

| O12 | 2i | 0.3568 (12) | 0.9728 (12) | 0.2219 (12) |

| Eigenvalues | Eigenvectors |

|---|---|

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Panchal, V.; Popescu, C.; Errandonea, D. An Investigation of the Pressure-Induced Structural Phase Transition of Nanocrystalline α-CuMoO4. Crystals 2022, 12, 365. https://doi.org/10.3390/cryst12030365

Panchal V, Popescu C, Errandonea D. An Investigation of the Pressure-Induced Structural Phase Transition of Nanocrystalline α-CuMoO4. Crystals. 2022; 12(3):365. https://doi.org/10.3390/cryst12030365

Chicago/Turabian StylePanchal, Vinod, Catalin Popescu, and Daniel Errandonea. 2022. "An Investigation of the Pressure-Induced Structural Phase Transition of Nanocrystalline α-CuMoO4" Crystals 12, no. 3: 365. https://doi.org/10.3390/cryst12030365

APA StylePanchal, V., Popescu, C., & Errandonea, D. (2022). An Investigation of the Pressure-Induced Structural Phase Transition of Nanocrystalline α-CuMoO4. Crystals, 12(3), 365. https://doi.org/10.3390/cryst12030365